Experimental Verification of Use of Vacuum Insulating Material in Electric Vehicle Headliner to Reduce Thermal Load

Abstract

1. Introduction

2. Vacuum Insulator for Electric Vehicle Headliner

3. Experimental Verification

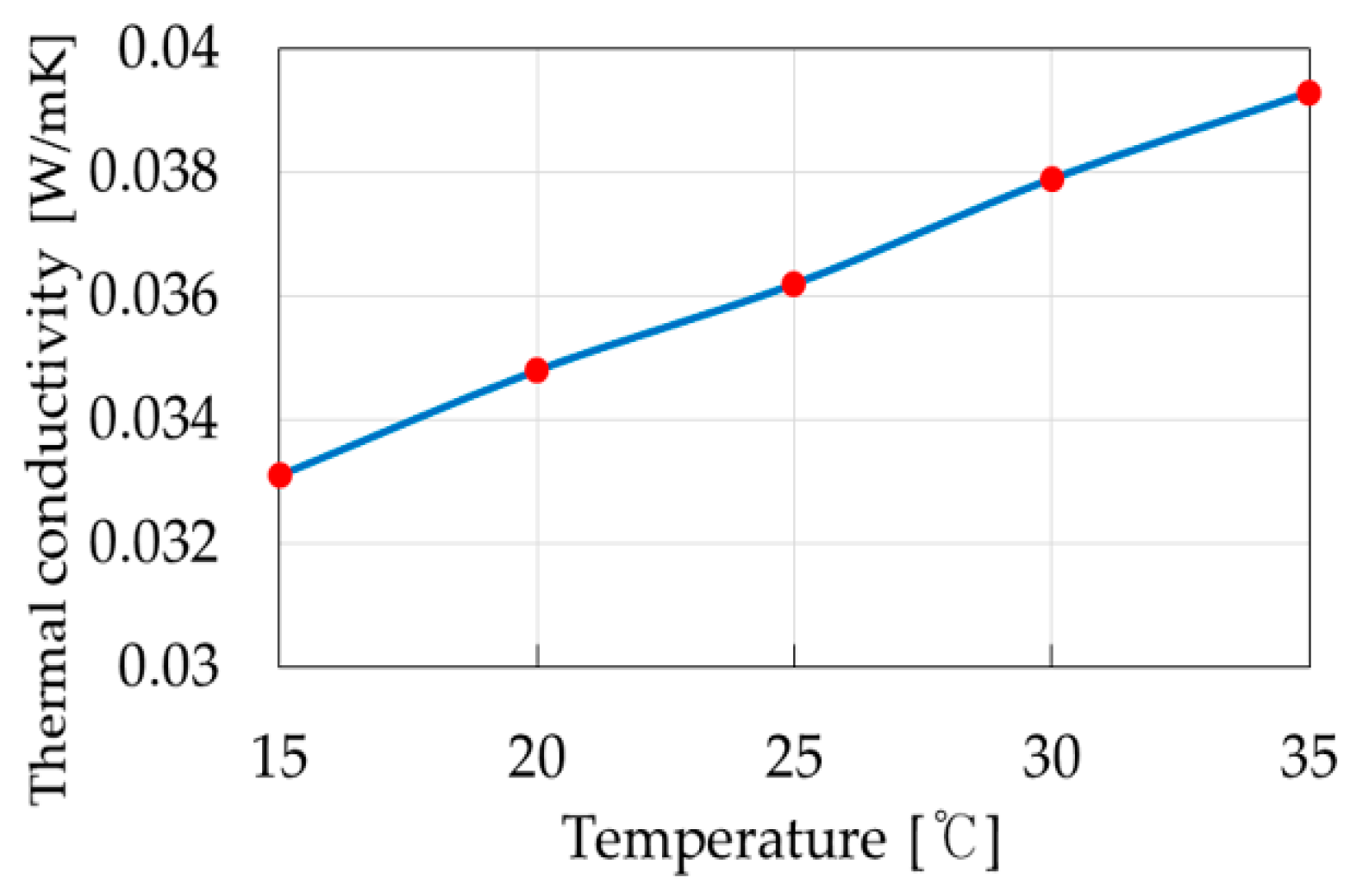

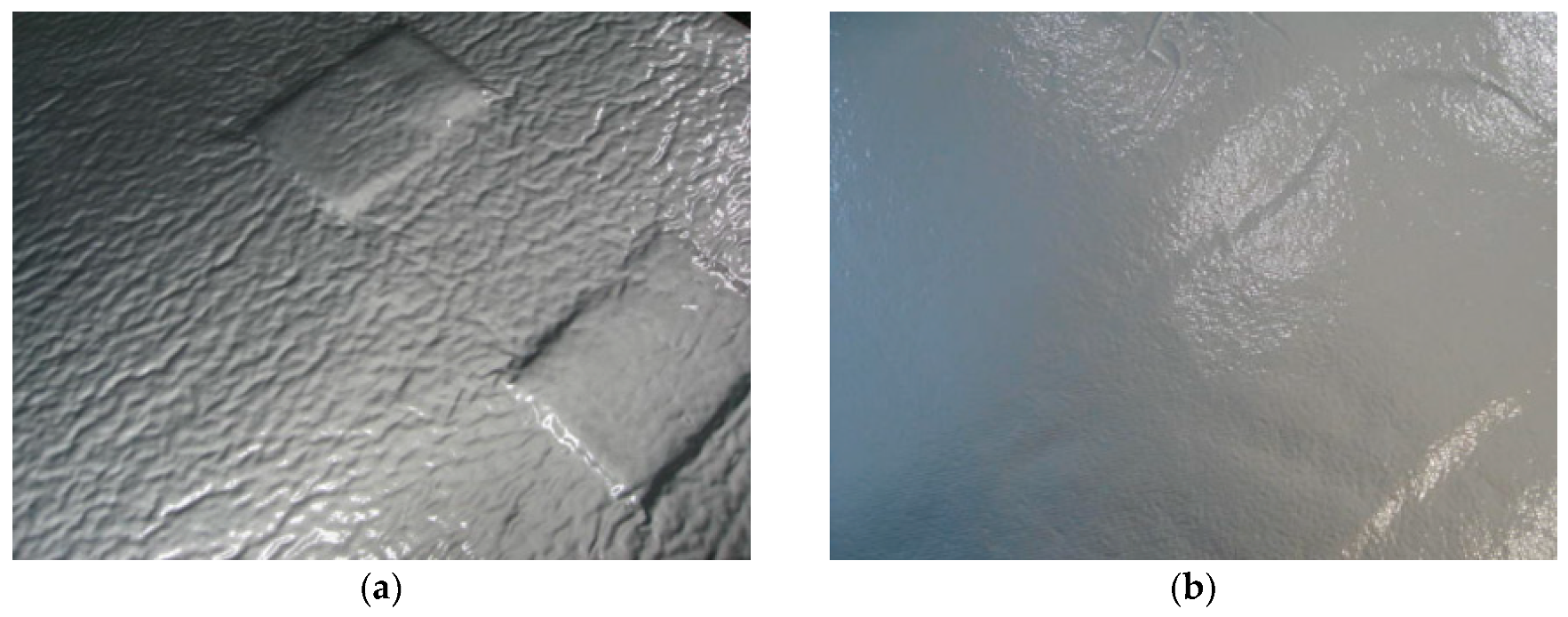

3.1. Material Evaluation

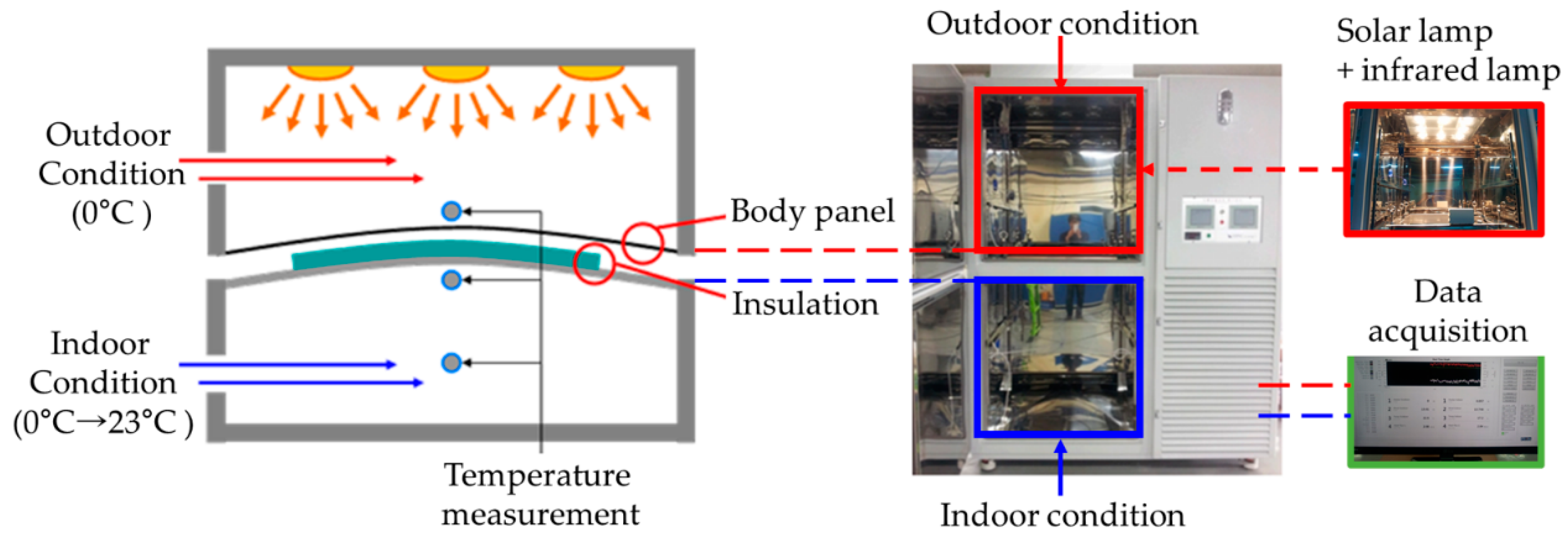

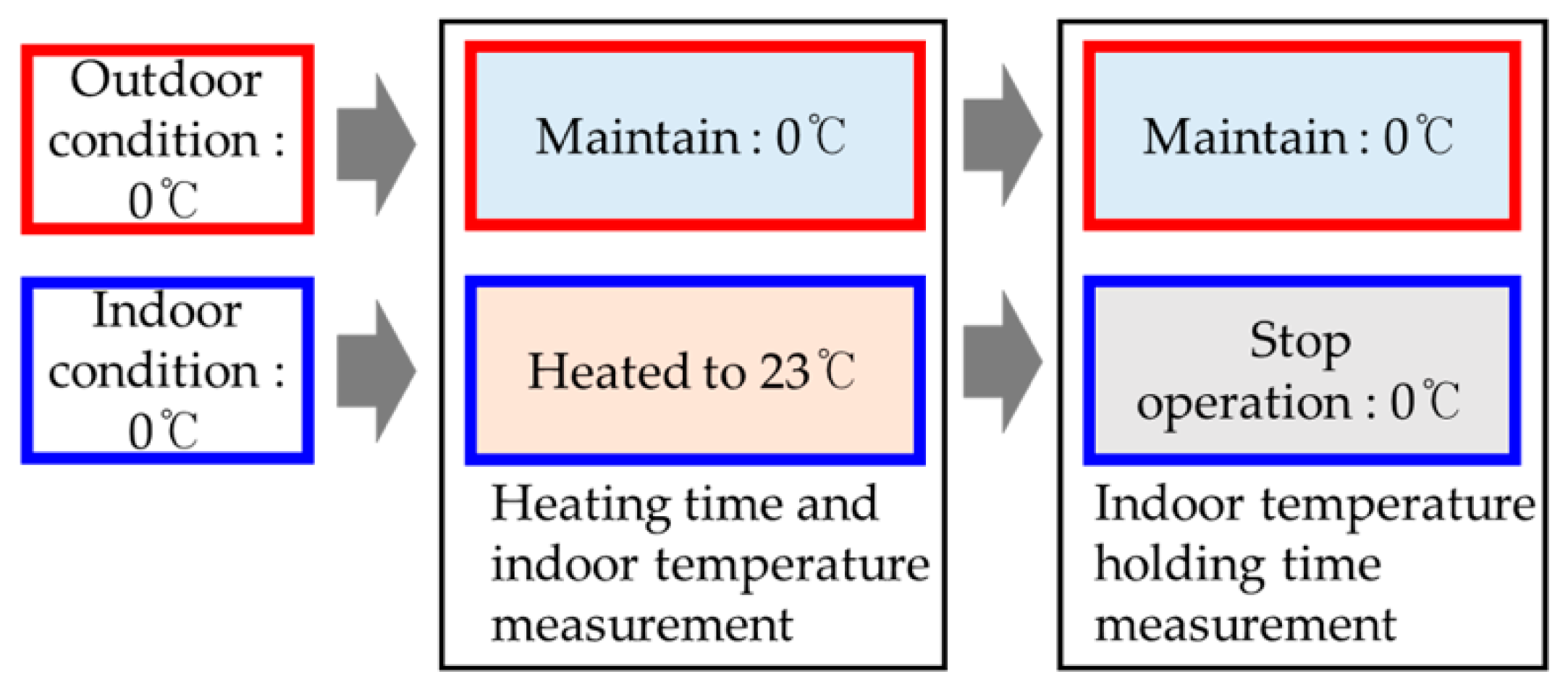

3.2. Parts Evaluation

3.3. Actual Vehicle Evaluation

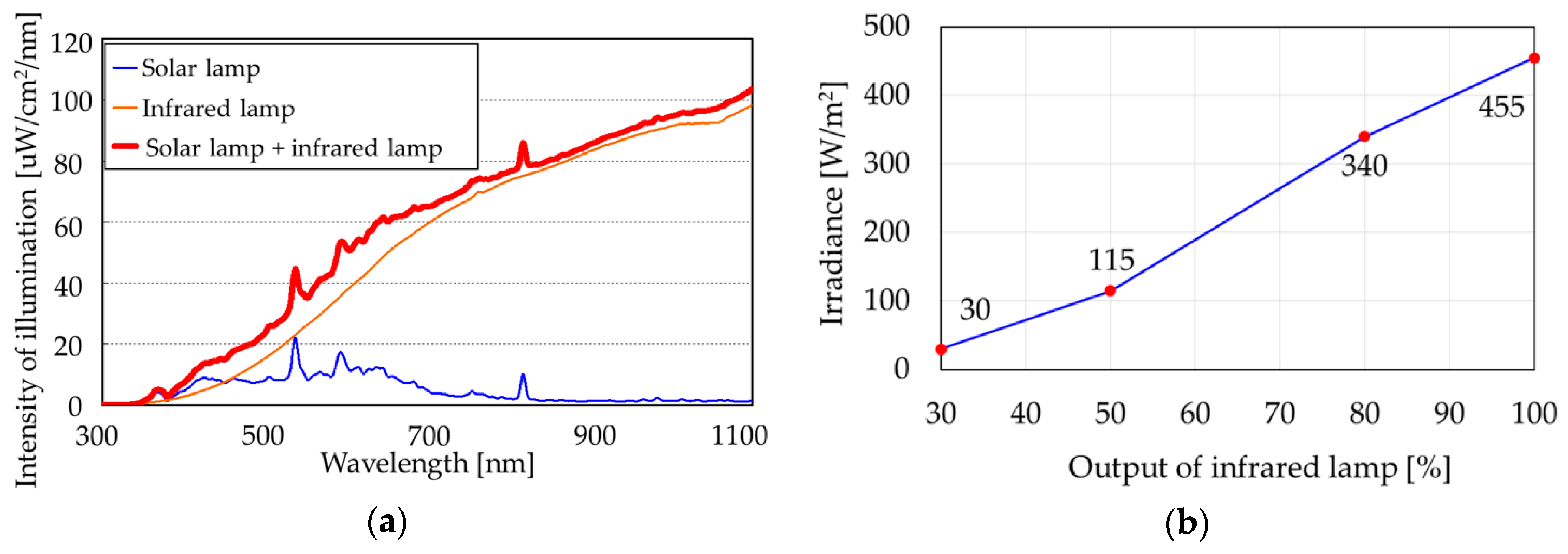

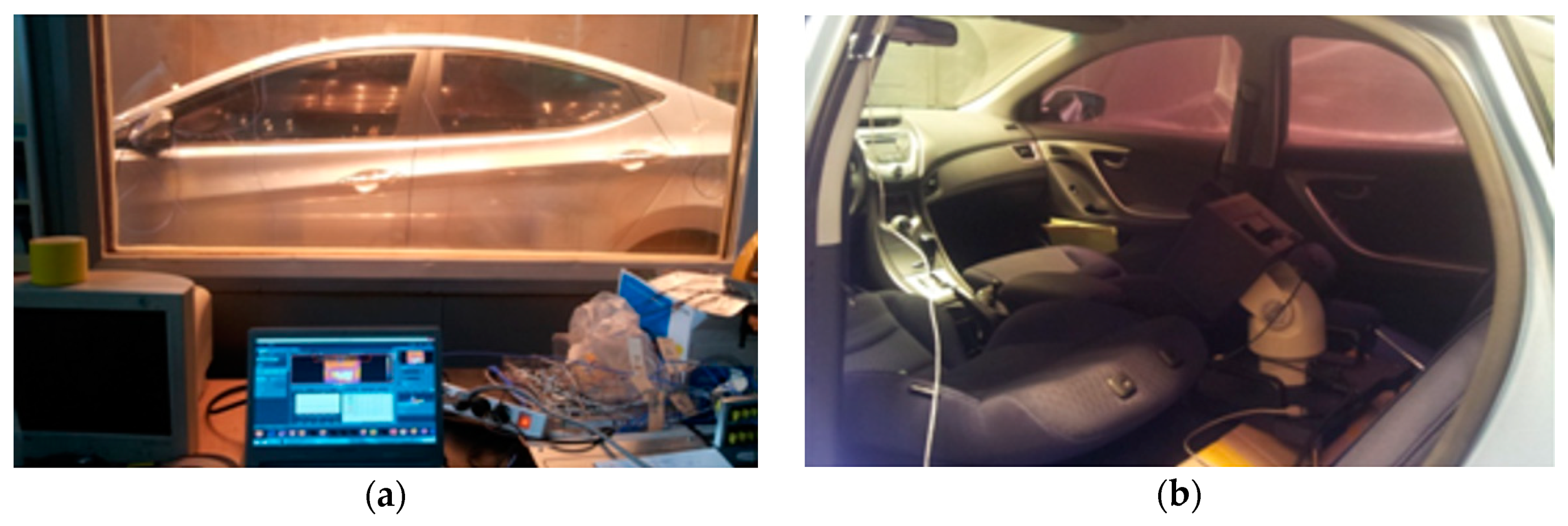

- IR is possible and testing is carried out in a chamber that can enter the vehicle.

- The IR irradiation conditions are based on the surface temperature of 100 °C on the vehicle roof panel.

- In summer, indoor temperature rise can occur due to sunlight.

- In order to check the indoor temperature increase due to sunlight in the summer, the outdoor temperature is maintained at 35 °C and the vehicle roof panel temperature is maintained at 100 °C.

- In summer, cooling starts after checking the room temperature rise due to outside parking.

- The winter season outdoor temperature is assumed as 0 °C in the absence of sunlight.

- The indoor air-conditioning is temperature 23 °C and the blower shift position is set to 5; the same blowing condition is applied for both cooling and heating.

- Measurement and analysis of real-time indoor temperature.

- Remote up/down and left/right movement of the thermal imaging camera.

- Insulation cover that can be applied to prevent the thermal damage of the imaging camera.

- In summer, the elevated indoor temperature is 2.8 °C lower under outdoor parking conditions.

- The indoor temperature is 3.9 °C lower than the conventional model for cooling outdoor vehicles in summer.

- The indoor temperature increases by 7.7 °C relative to the case of the conventional model when heating the vehicle outdoor in winter.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Loiselle-Lapointe, A.; Whittal, I.; Christenson, M. Electric Vehicles: Impacts of Mileage Accumulation and Fast Charging. World Electr. Veh. J. 2016, 8, 249–262. [Google Scholar] [CrossRef]

- Botsford, C.W.; Edwards, A. An Integrated Global Philosophy of EV Charging. World Electr. Veh. J. 2016, 8, 495–500. [Google Scholar] [CrossRef]

- Trentadue, G.; Lucas, A.; Otura, M.; Pliakostathis, K.; Zanni, M.; Scholz, H. Evaluation of Fast Charging Efficiency under Extreme Temperatures. Energies 2018, 11, 1937. [Google Scholar] [CrossRef]

- Dost, P.K.; Spichartz, P.; Sourkounis, C. Charging Behavior of Users Utilizing Battery Electric Vehicles and Extended Range Electric Vehicles Within the Scope of a Field Test. IEEE Trans. Ind. Appl. 2018, 54, 580–590. [Google Scholar] [CrossRef]

- Zhang, G.; Qin, F.; Zou, H.; Tian, C. Experimental Study on a Dual-parallel-evaporator Heat Pump System for Thermal Management of Electric Vehicles. Energy Procedia 2017, 105, 2390–2395. [Google Scholar] [CrossRef]

- Zhang, G.; Zou, H.; Qin, F.; Xue, Q.; Tian, C. Investigation on an Improved Heat Pump AC System with the View of Return Air Utilization and Anti-fogging for Electric Vehicles. Appl. Therm. Eng. 2017, 115, 726–735. [Google Scholar] [CrossRef]

- Kato, T.; Suzuki, R.; Miyao, R.; Kato, H.; Narita, T. A Fundamental Consideration of Active Noise Control System by Small Actuator for Ultra-Compact EV. Actuators 2018, 7, 49. [Google Scholar] [CrossRef]

- Musat, R.; Helerea, E. Characteristics of the PTC Heater Used in Automotive HVAC Systems. IFIP Adv. Inf. Commun. Technol. 2010, 314, 461–468. [Google Scholar]

- Shin, Y.H.; Ahn, S.K.; Kim, S.C. Performance Characteristics of PTC Elements for an Electric Vehicle Heating System. Energies 2016, 9, 813. [Google Scholar] [CrossRef]

- Cho, S.; Jung, K.; Choi, J. Design Optimization of Interior Permanent Magnet Synchronous Motor for Electric Compressors of Air-Conditioning Systems Mounted on EVs and HEVs. IEEE Trans. Magn. 2018, 54, 1–5. [Google Scholar] [CrossRef]

- Aziz, M.; Oda, T.; Ito, M. Battery-assisted charging system for simultaneous charging of electric vehicles. Energy 2016, 100, 82–90. [Google Scholar] [CrossRef]

- Quddus, M.A.; Shahvari, O.; Marufuzzaman, M.; Usher, J.M.; Jaradat, R. A collaborative energy sharing optimization model among electric vehicle charging stations, commercial buildings, and power grid. Appl. Energy 2018, 229, 841–857. [Google Scholar] [CrossRef]

- Collin, R.; Miao, Y.; Yokochi, A.; Enjeti, P.; von Jouanne, A. Advanced Electric Vehicle Fast-Charging Technologies. Energies 2019, 12, 1839. [Google Scholar] [CrossRef]

- Jung, H.; Silva, R.; Han, M. Scaling Trends of Electric Vehicle Performance: Driving Range, Fuel Economy, Peak Power Output, and Temperature Effect. World Electr. Veh. J. 2018, 9, 46. [Google Scholar] [CrossRef]

- Li, C.; Brewer, E.; Pham, L.; Jung, H. Reducing Mobile Air Conditioner (MAC) Power Consumption Using Active Cabin-Air-Recirculation in A Plug-In Hybrid Electric Vehicle (PHEV). World Electr. Veh. J. 2018, 9, 51. [Google Scholar] [CrossRef]

- Wei, C.; Hofman, T.; Ilhan Caarls, E.; van Iperen, R. Integrated Energy and Thermal Management for Electrified Powertrains. Energies 2019, 12, 2058. [Google Scholar] [CrossRef]

- Kwon, C.; Lee, C.W.; Foster, L.; Kwon, J.; Shin, Y. Development of an energy-saving occupied-zone HVAC system (OZ HVAC). In Proceedings of the SAE 2012 World Congress & Exhibition, Detroit, MI, USA, 24–26 April 2012. [Google Scholar]

- Tabei, K.; Watanabe, M.; Doi, N.; Imai, K.; Young, S. Development of a S-FLOW System and Control (S-FLOW: Energy Saving Air Flow Control System. In Proceedings of the SAE 2013 World Congress & Exhibition, Detroit, MI, USA, 16–18 April 2013. [Google Scholar]

- Wang, M.; Wolfe, E.; Ghosh, D.; Bozeman, J.; Chen, K.H.; Han, T.; Zhang, H.; Arens, E. Localized cooling for human comfort. SAE Int. J. Passeng. Cars Mech. Syst. 2014, 7, 755–768. [Google Scholar] [CrossRef][Green Version]

- Dolgopolsky, I.; Duley, J.A. Polyurethane Foam as an Integral “Core” Component of Automotive Headliner. J. Ind. Text. 2000, 30, 26–41. [Google Scholar]

- Parikh, D.V.; Chen, Y.; Sun, L. Reducing Automotive Interior Noise with Natural Fiber Nonwoven Floor Covering Systems. Text. Res. J. 2006, 76, 813–820. [Google Scholar] [CrossRef]

- Da Silva, C.; Calçada, M.; Massarelli, L. Vehicle Interior Noise Reduction Using Innovative Roof Trim Structure; SAE Technical Paper 2014-36-0767; SAE International: Warrendale, PA, USA, 2014. [Google Scholar] [CrossRef]

- Kwon, J.-S.; Jang, C.H.; Jung, H.; Song, T.-H. Effective thermal conductivity of various filling materials for vacuum insulation panels. Int. J. Heat Mass Transf. 2009, 52, 5525–5532. [Google Scholar] [CrossRef]

- Peng, C.; Yang, J. Structure, Mechanism, and Application of Vacuum Insulation Panels in Chinese Buildings. Adv. Mater. Sci. Eng. 2016, 2016. [Google Scholar] [CrossRef]

- Kim, J.H.; Kim, S.M.; Kim, J.T. Simulation performance of building wall with vacuum insulation panel. Procedia Eng. 2016, 180, 1247–1255. [Google Scholar] [CrossRef]

- Biswas, K.; Desjarlais, A.; Smith, D.; Letts, J.; Yao, J.; Jiang, T. Development and thermal performance verification of composite insulation boards containing foam-encapsulated vacuum insulation panels. Appl. Energy 2018, 228, 1159–1172. [Google Scholar] [CrossRef]

- Simmler, H.; Brunner, S.; Heinemann, U.; Schwab, H.; Kumaran, K.; Mukhopadhyaya, P.; Quenard, D.; Sallee, H.; Noller, K.; Kucukpinar-Niarchos, E.; et al. Vacuum Insulation Panels: Study on VIP-components and Panels for Service Life Prediction of VIP in Building Applications (Subtask A). IEA/EBC Annex 39 2005, 39, 1–159. [Google Scholar]

- Binz, A.; Moosmann, A.; Steinke, G.; Schonhardt, U.; Fregnan, F.; Simmler, H.; Brunner, S.; Ghazi Wakili, K.; Bundi, R.; Heinemann, U. Vacuum Insulation in the Building Sector-Systems and Applications (Subtask B). IEA/EBC Annex 39 2005, 39, 1–134. [Google Scholar]

- ISO 8302 Standard: 1991(R2013). Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Prosperities—Guarded Hot Plate Apparatus; International Organization for Standardization: Geneva, Switzerland, 1991. [Google Scholar]

- Manini, P. Recent Developments in the Open Cell Foam-Filled Vacuum Insulated Panels for Appliances Applications. J. Cell. Plast. 1999, 35, 403–420. [Google Scholar] [CrossRef]

- Brunner, S.; Simmler, H. In Situ Performance of Vacuum Insulation Panels in a Flat Roof Construction. Vacuum 2007, 82, 700–707. [Google Scholar] [CrossRef]

- Chuntonov, K.; Ivanov, A.O.; Verbitsky, B.; Setina, J. Getters for vacuum insulated glazing. Vacuum 2018, 155, 300–306. [Google Scholar] [CrossRef]

- Memon, S.; Farukh, F.; Kandan, K. Effect of Cavity Vacuum Pressure Diminution on Thermal Performance of Triple Vacuum Glazing. Appl. Sci. 2018, 8, 1705. [Google Scholar] [CrossRef]

| Items | Conventional | Improved | Unit |

|---|---|---|---|

| Surface roughness | 100 | 5 | µm |

| Thermal conductivity | 0.0364 | 0.0028 | W/mK |

| Items | Conventional | Improved | Unit | Remark |

|---|---|---|---|---|

| Heating time up to indoor temperature 23 °C | 52 | 45 | Minute | Blower output: 100 W |

| Inner headliner temperature | 18.20 | 19.84 | °C | Infrared lamp output: 100% |

| Indoor temperature holding time | 150 | 170 | Second | - |

| Insulation effect at indoor temperature holding time | - | 13.33 | % | - |

| Items | Requirements | Value | Unit |

|---|---|---|---|

| Surface density | Below 840 | 829.5 | g/m2 |

| Flexural strength | Above 2.40 | 2.46 | kgf/cm |

| Heat-resistant cycle | No deformation | Clear | - |

| Items | Conventional | Improved | Unit | Remark |

|---|---|---|---|---|

| Headliner portion (Sp1) | 65.5 | 57.9 | °C | Reduced by 7.6 °C |

| Non-headliner portion (Sp2) | 66.7 | 62.6 | °C | Reduced by 4.1 °C |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baek, S.-W.; Lee, S.W.; Kim, C.-S. Experimental Verification of Use of Vacuum Insulating Material in Electric Vehicle Headliner to Reduce Thermal Load. Appl. Sci. 2019, 9, 4207. https://doi.org/10.3390/app9204207

Baek S-W, Lee SW, Kim C-S. Experimental Verification of Use of Vacuum Insulating Material in Electric Vehicle Headliner to Reduce Thermal Load. Applied Sciences. 2019; 9(20):4207. https://doi.org/10.3390/app9204207

Chicago/Turabian StyleBaek, Soo-Whang, Sang Wook Lee, and Chul-Soo Kim. 2019. "Experimental Verification of Use of Vacuum Insulating Material in Electric Vehicle Headliner to Reduce Thermal Load" Applied Sciences 9, no. 20: 4207. https://doi.org/10.3390/app9204207

APA StyleBaek, S.-W., Lee, S. W., & Kim, C.-S. (2019). Experimental Verification of Use of Vacuum Insulating Material in Electric Vehicle Headliner to Reduce Thermal Load. Applied Sciences, 9(20), 4207. https://doi.org/10.3390/app9204207