Waterjet Erosion Model for Rock-Like Material Considering Properties of Abrasive and Target Materials

Abstract

:Featured Application

Abstract

1. Introduction

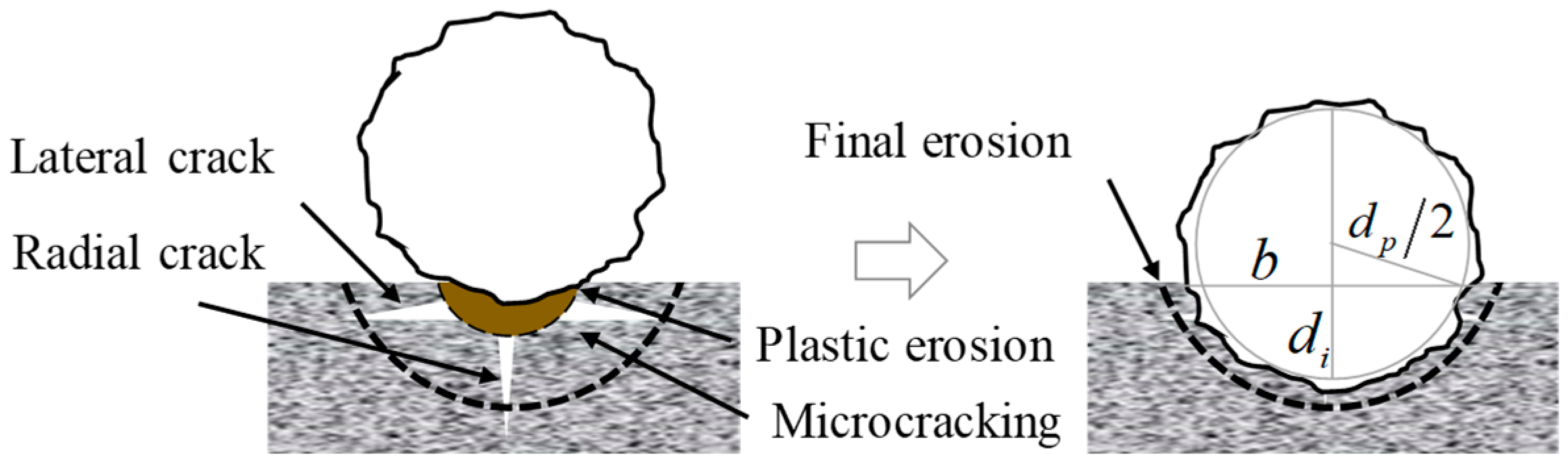

2. Waterjet Erosion Model of an Abrasive Particle

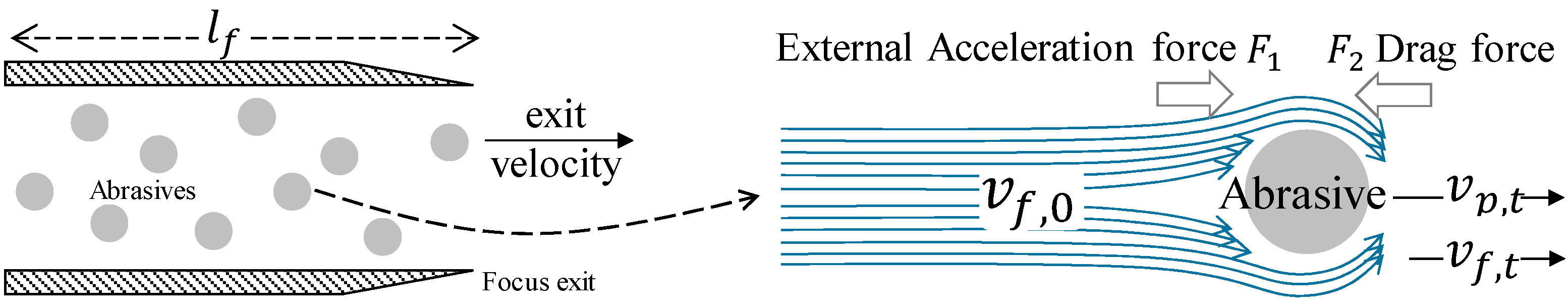

2.1. Acceleration of an Abrasive Particle

2.2. Abrasive Particle Energy and Erosion Model

3. Model Verification

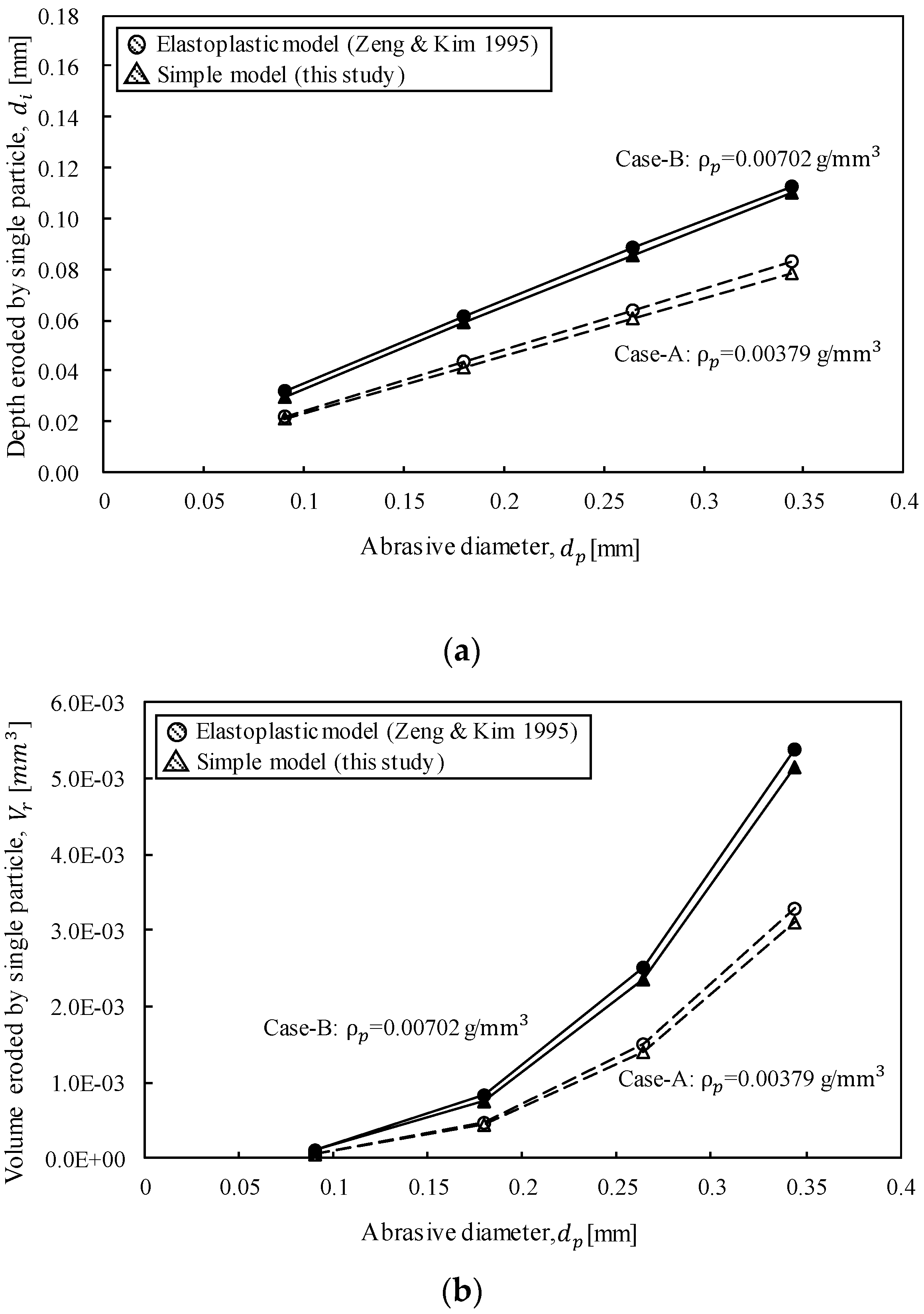

3.1. Theoretical Comparison of Erosion by Single Abrasive Particle

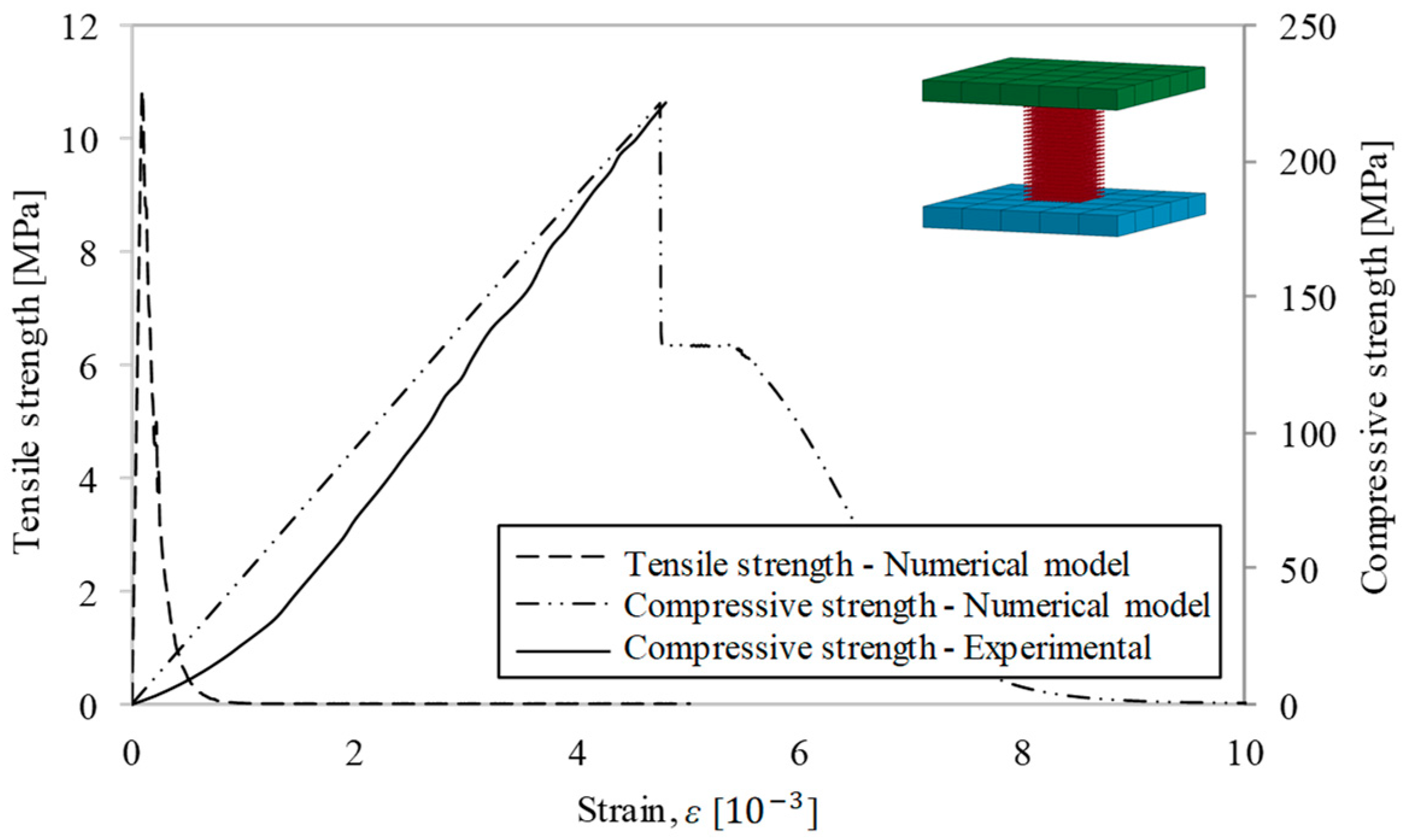

3.2. Numerical Analysis for Single Abrasive Erosion

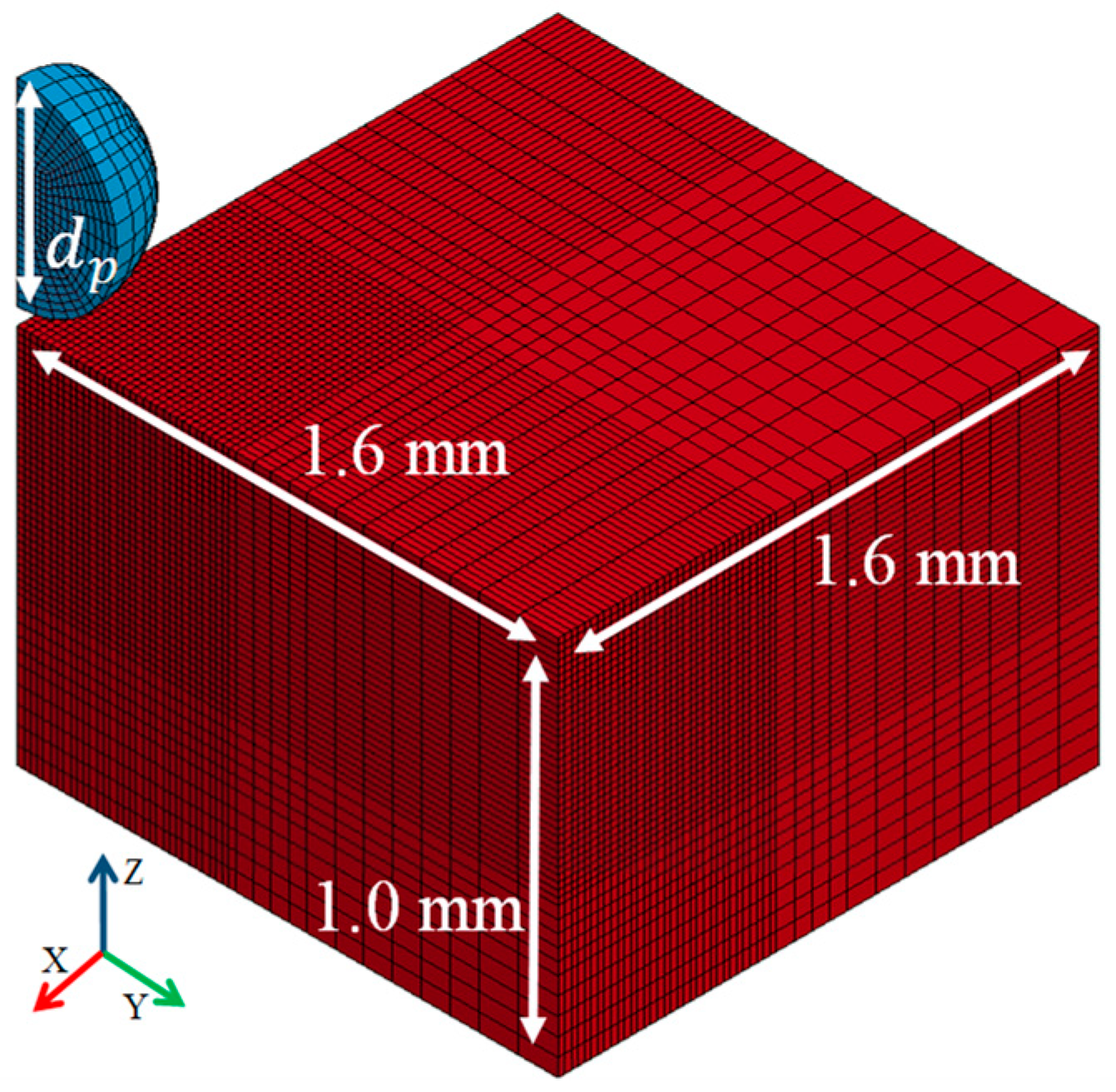

3.2.1. Numerical Model Details

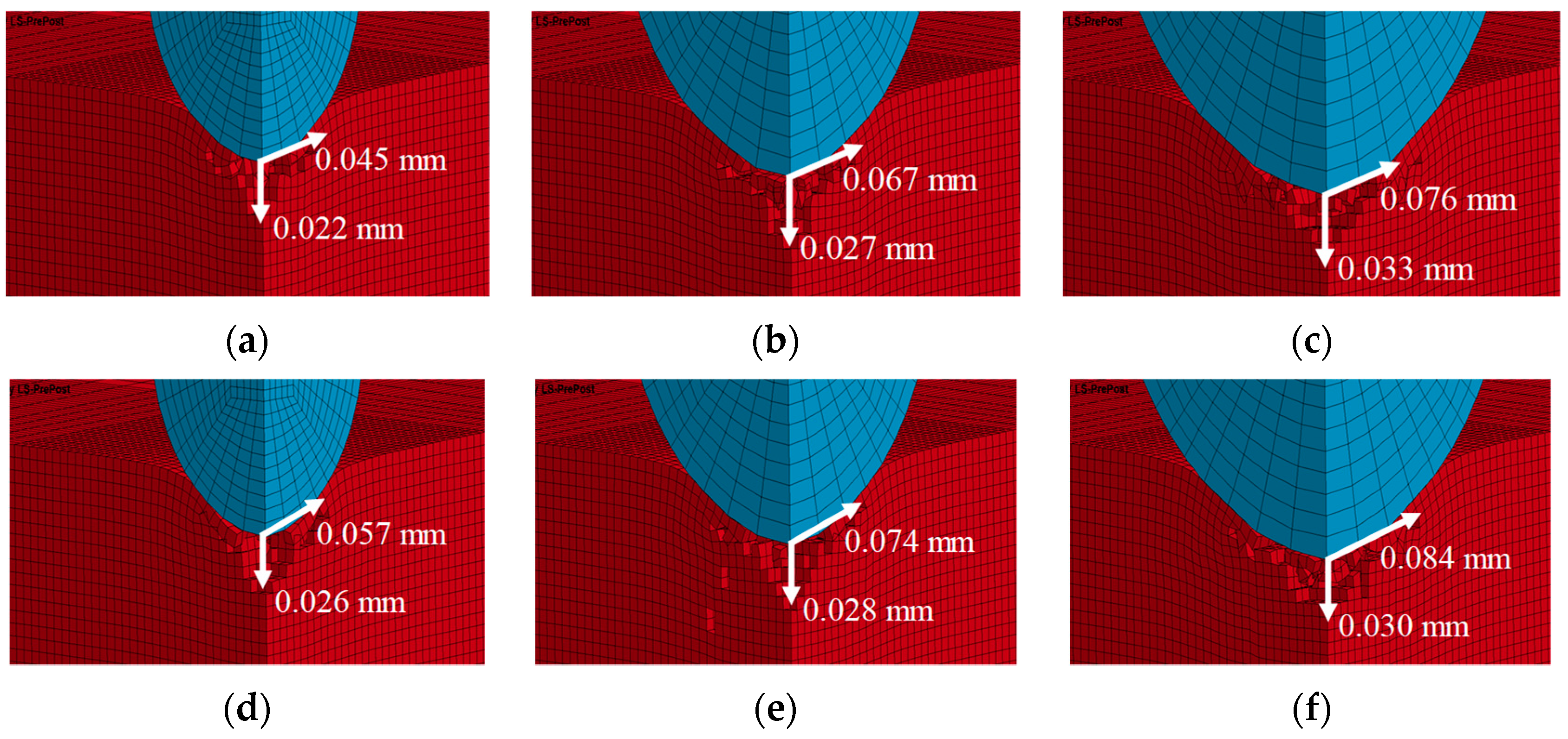

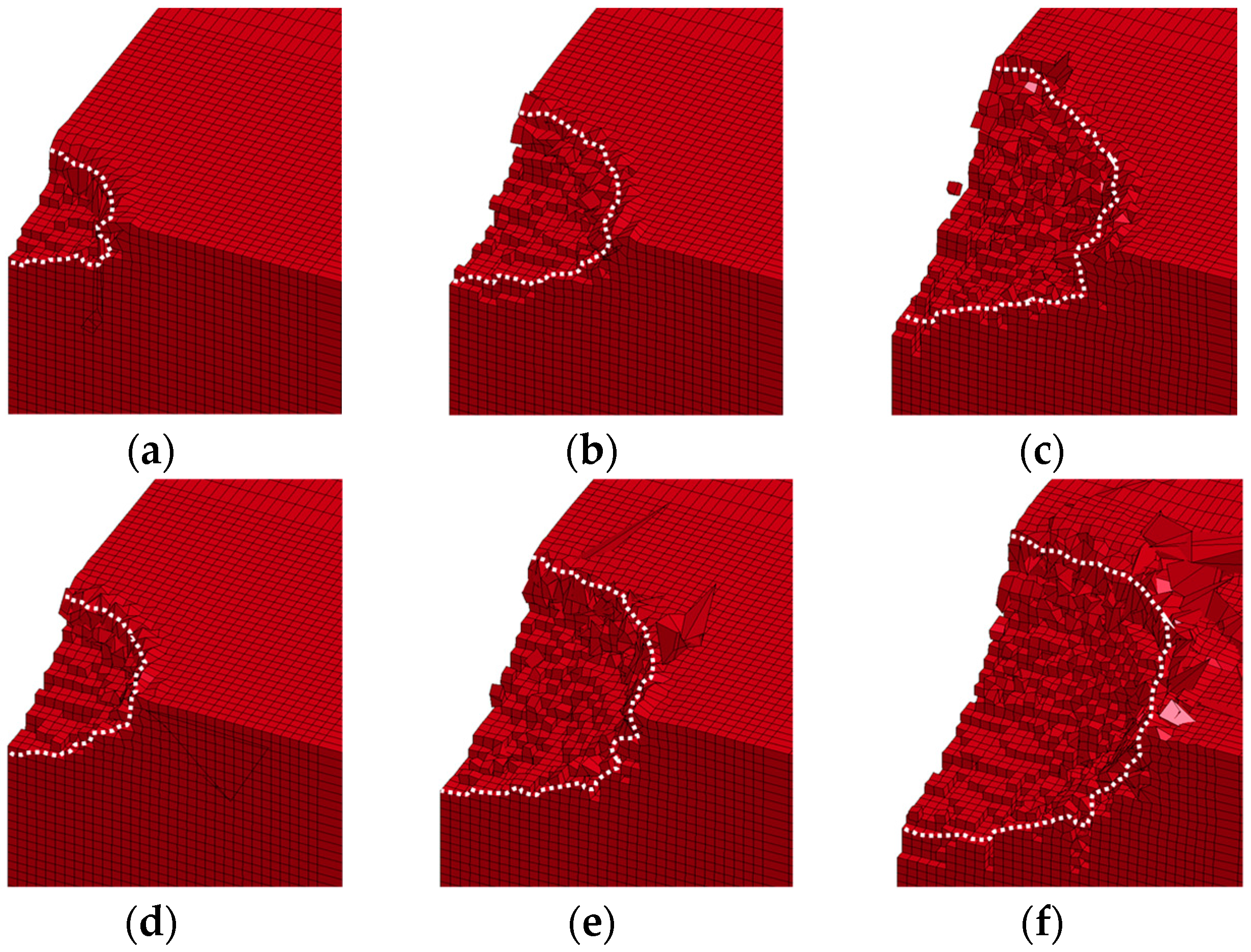

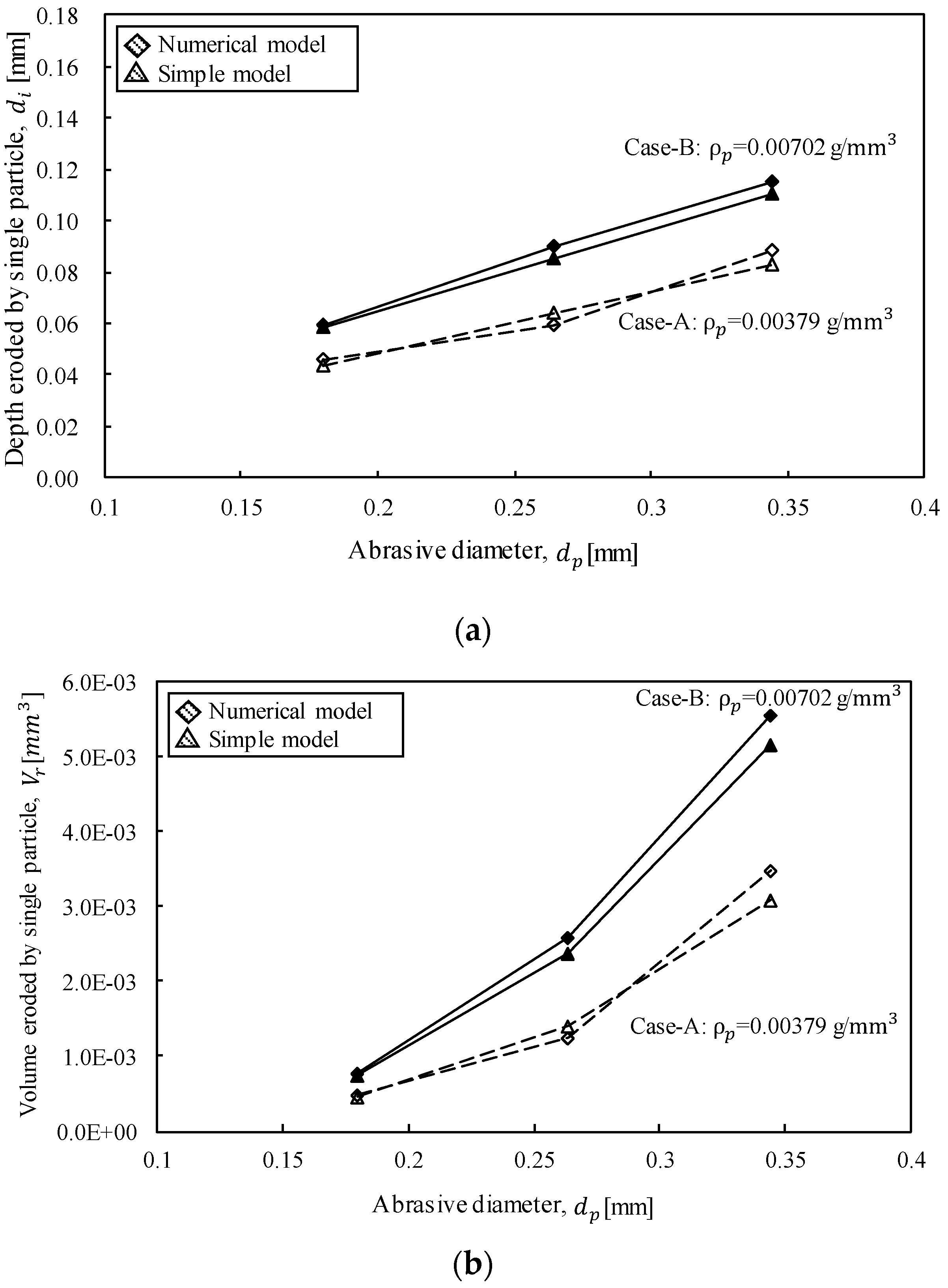

3.2.2. Numerical Analyses and Verification Results

4. Parametric Study of Single-Particle Acceleration and Erosion

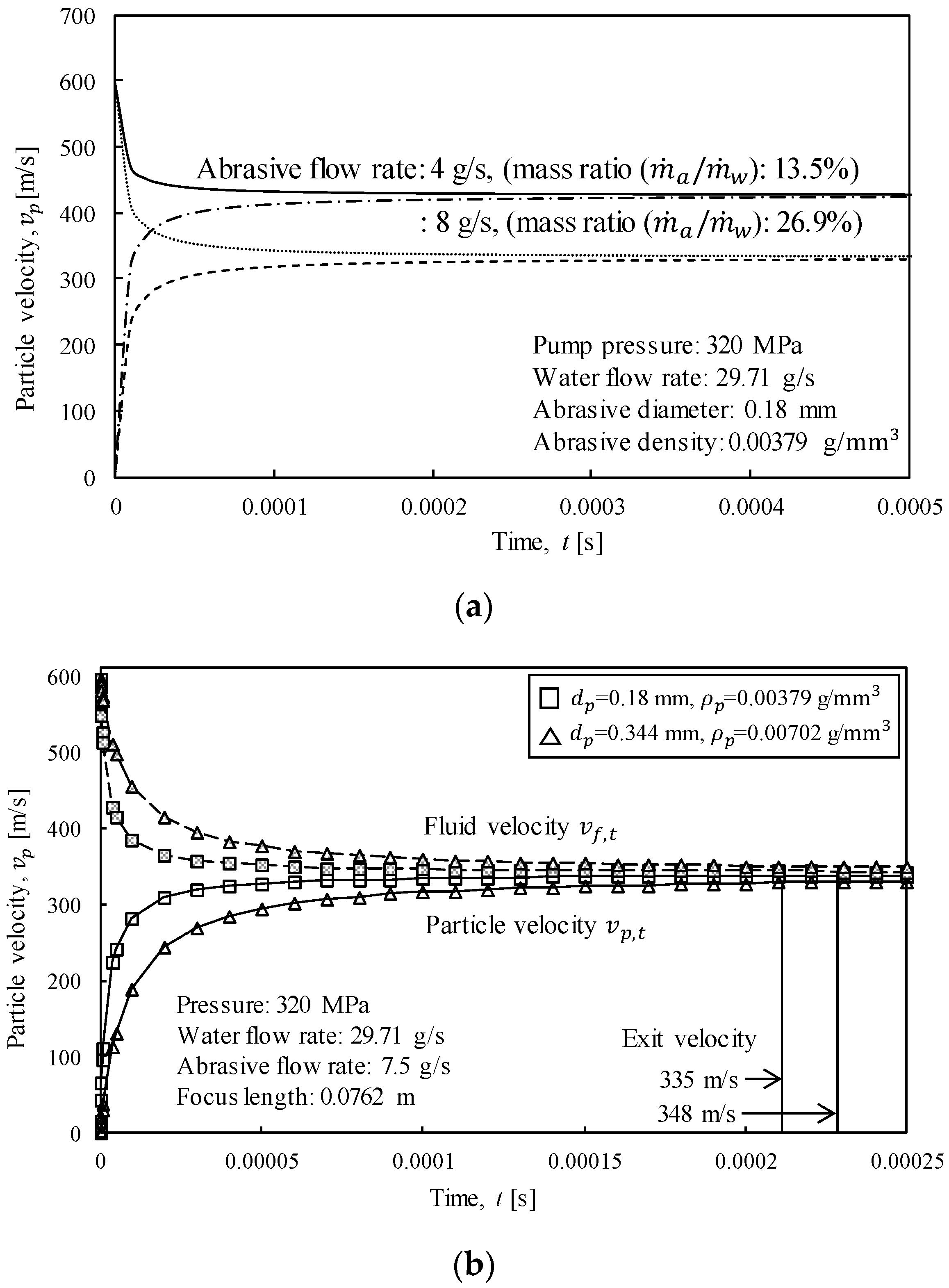

4.1. Abrasive Particle Acceleration Parameters

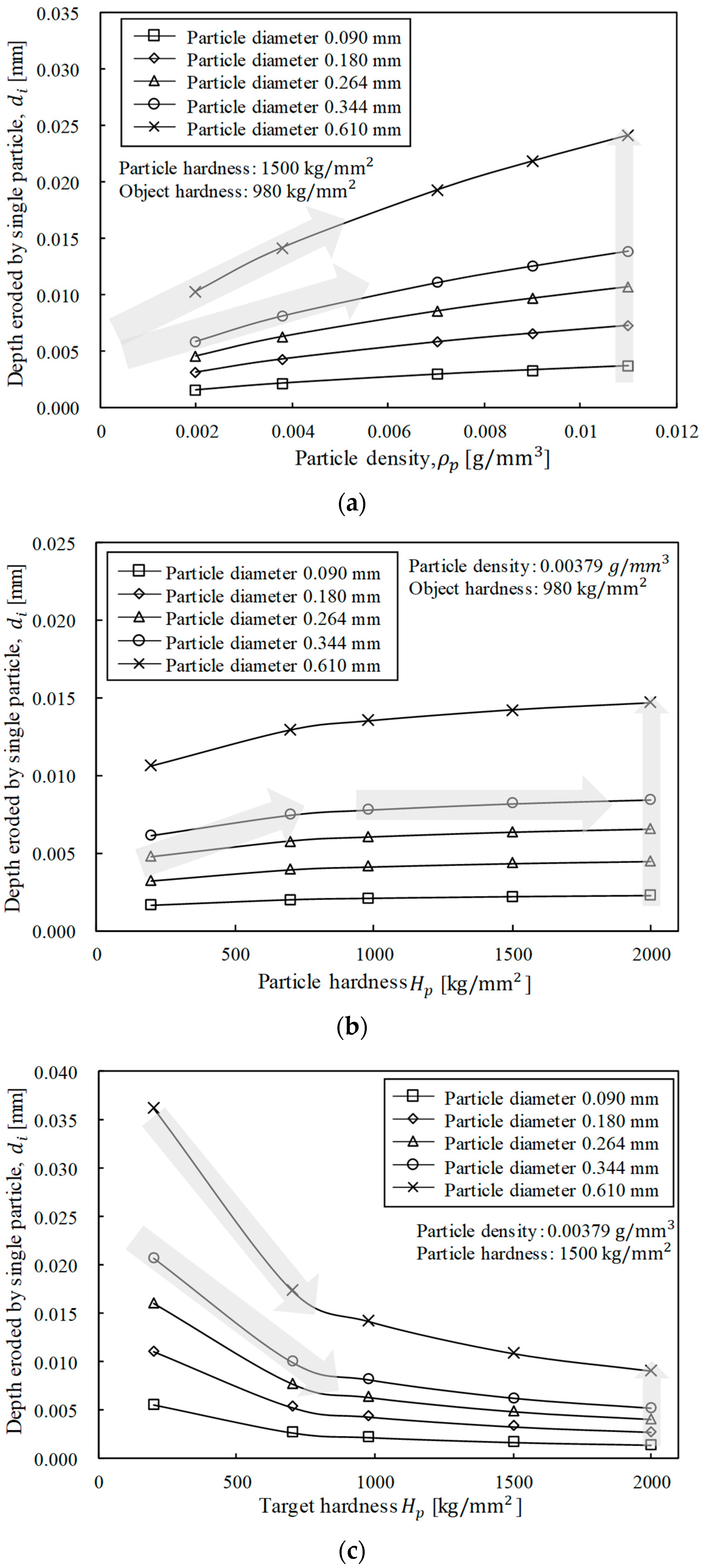

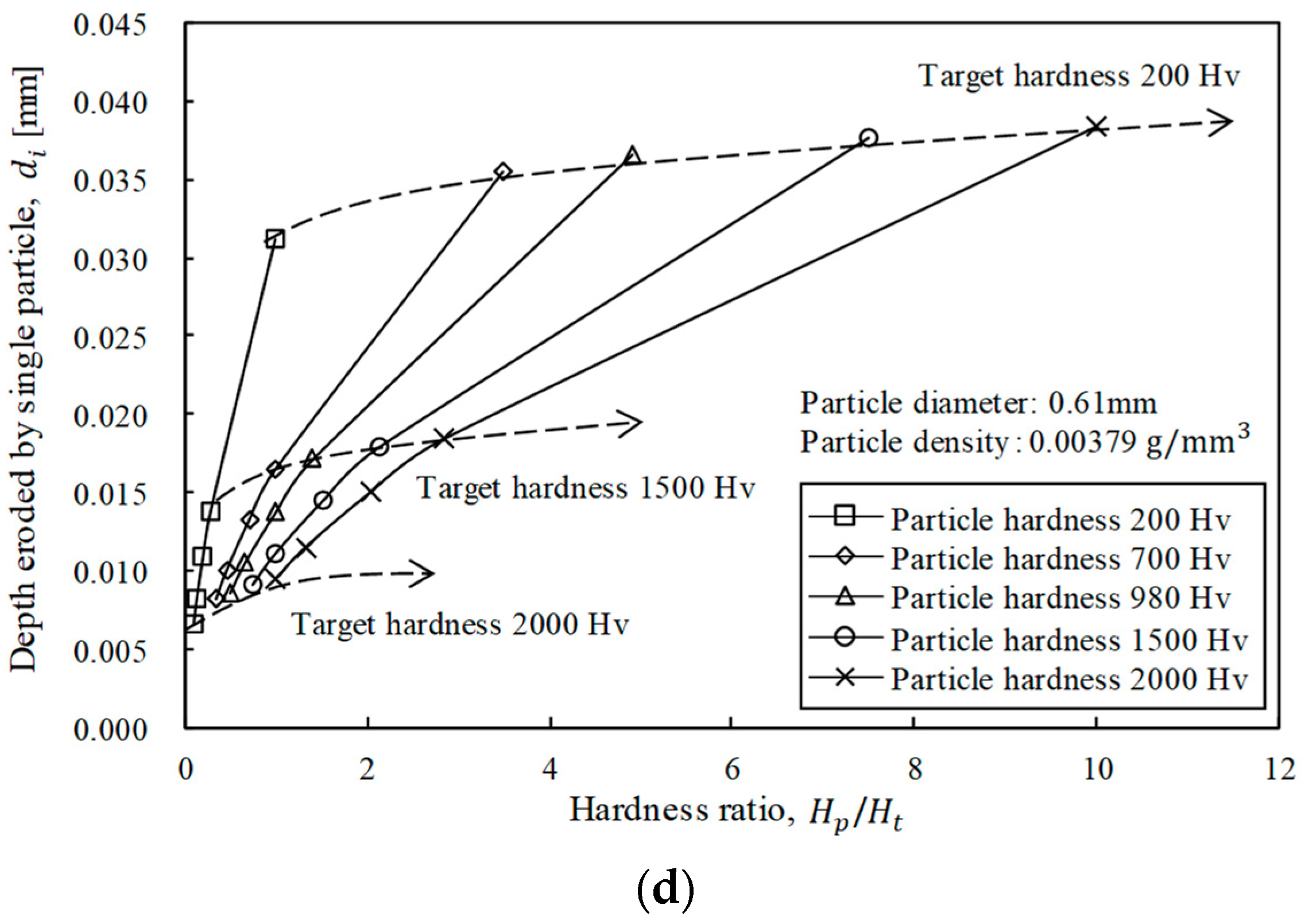

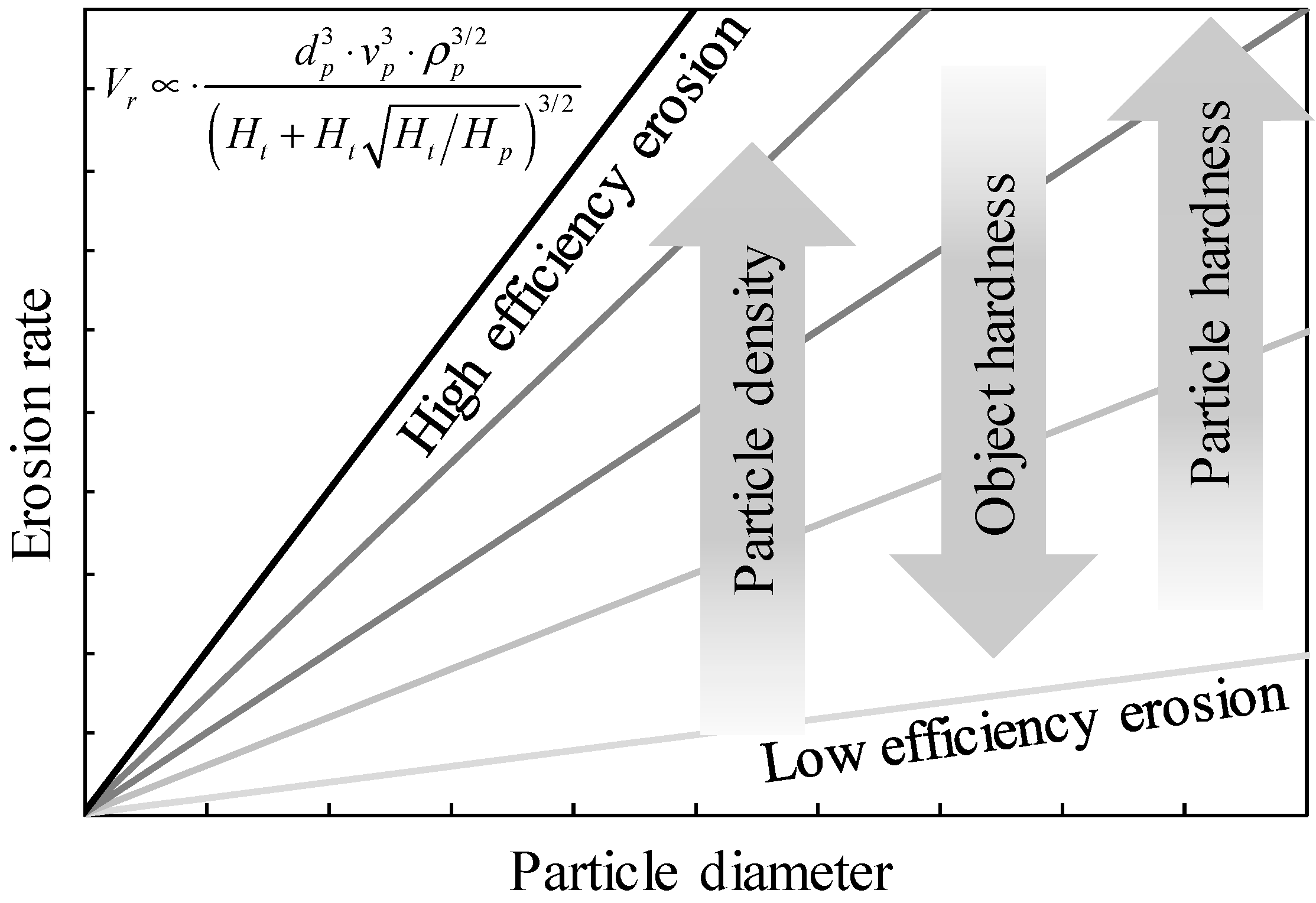

4.2. Single-Particle Erosion Parameters

5. Conclusions

- The abrasive acceleration characteristics were theoretically derived depending on the density and diameter of the abrasive particle, the density of the fluid, and the fluid flow state. Therefore, the particle velocity, exit velocity, and distance traveled by the particle could be calculated;

- A simplified erosion model was developed considering the hardness as a resistance force for energy transfer from the particle to the target. The erosion depth and volume could be calculated depending on the diameter, density, and hardness of the abrasive particle and target;

- For the erosion of rock-like materials, simultaneously occurring plastic failure and microcracking were simulated numerically. A CSCM was used for modeling the brittle material, and this numerical model was used to validate the theoretical erosion model developed in this study;

- Parametric studies were conducted to evaluate the acceleration and erosion characteristics using a wide range of abrasive particle properties (diameters, densities, and hardness values) and target hardness values. General acceleration and erosion characteristics could be identified.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Projection area drag force exerted (mm2) | |

| a | Flaw distribution parameter |

| b | Radius of indentation circle (mm) |

| Drag coefficient | |

| Mixing efficiency coefficient | |

| Diameter of abrasive particle (mm) | |

| Depth of erosion by single particle (mm) | |

| Constant term concerning the erosion energy | |

| Effective kinetic erosion energy (J) | |

| Erosion energy of single particle (J) | |

| External acceleration force (N) | |

| Drag force (N) | |

| Proportional factor for stress-wave energy | |

| g | Gravitational acceleration (m/) |

| Potential head in the pipe tip section (mm) | |

| Potential head in the pump section (mm) | |

| Hardness of particle, Knoop (kg/) | |

| Hardness of target, Knoop (kg/) | |

| K | Resistance constant |

| Threshold velocity of impact (m/s) | |

| Constant for kinetic structure of reaction | |

| Distance traveled by the particle (mm) | |

| m | Reaction order |

| Abrasive flow rate (g/s) | |

| Single-particle mass (g) | |

| Fluid (water) flow rate (g/s) | |

| Pressure of fluid (water) in the pipe tip section (Pa) | |

| Pressure of fluid (water) in the pump section (Pa) | |

| Displacement rate of target | |

| Fluid velocity at time t (m/s) | |

| Fluid velocity in the pipe tip section (initial fluid velocity) (m/s) | |

| Fluid velocity in the pump section (m/s) | |

| Volume of particle () | |

| Particle velocity at time t (m/s) | |

| Volume removed by single particle () | |

| Terminal velocity (m/s) | |

| W | Total stress-wave energy |

| γ | Fracture energy per unit area (J/) |

| ε | Energy required to remove unit material volume (/J) |

| ρf | Fluid density (g/) |

| Particle density (g/) |

References

- Summers, D.A. Waterjetting Technology; CRC Press: London, UK, 2003. [Google Scholar]

- Hashish, M.A. Modeling study of metal cutting with abrasive waterjets. J. Engmater. Technol. 1984, 106, 88–100. [Google Scholar] [CrossRef]

- Hashish, M. The potential of an ultrahigh-pressure abrasive water jet rock drill. In Proceedings of the Fifth American Water Jet Conference, Toronto, ON, Canada, 29–31 August 1989; Vijay, M.M., Savanick, G.A., Eds.; pp. 321–332. [Google Scholar]

- Chen, C.; Pan, D.; Yang, L.; Zhang, H.; Li, B.; Jin, C.; Li, X.; Cheng, Y.; Zhong, X. Investigation into the water jet erosion efficiency of hydrate-bearing sediments based on the arbitrary Lagrangian-Eulerian method. Appl. Sci. 2019, 9, 182. [Google Scholar] [CrossRef]

- Song, K.-I.; Oh, T.-M.; Cho, G.-C. Precutting of tunnel perimeter for reducing blasting-induced vibration and damaged zone—Numerical analysis. KSCE J. Civ. Eng. 2014, 18, 1165–1175. [Google Scholar] [CrossRef]

- Xiao, S.; Ge, Z.; Lu, Y.; Zhou, Z.; Li, Q.; Wang, L. Investigation on coal fragmentation by high-velocity water jet in drilling: size distributions and fractal characteristics. Appl. Sci. 2018, 8, 1988. [Google Scholar] [CrossRef]

- Kim, J.-G.; Song, J.-J.; Han, S.S.; Lee, C.-I. Slotting of concrete and rock using an abrasive suspension waterjet system. KSCE J. Civ. Eng. 2012, 16, 571–578. [Google Scholar] [CrossRef]

- Huang, M.; Kang, Y.; Long, X.; Wang, X.; Hu, Y.; Li, D.; Zhang, M. Effects of a nano-silica additive on the rock erosion characteristics of a SC-CO2 jet under various operating conditions. Appl. Sci. 2017, 7, 153. [Google Scholar] [CrossRef]

- Momber, A.W.; Kovacevic, R. Principles of Abrasive Water Jet Machining; Springer: London, UK, 1997. [Google Scholar]

- Cha, Y.; Tae-Zin, A.; Cho, G.-C. The state of abrasive waterjet technologies for construction in Korea. In Proceedings of the 6th International Young Geotechnical Engineers Conference, Seoul, Korea, 17 September 2017; pp. 86–87. [Google Scholar]

- Kalla, D.; Zhang, B.; Asmatulu, R.; Dhanasekaran, P. Current research trends in abrasive waterjet machining of fiber reinforced composites. Mater. Sci. Forum 2012, 713, 37–42. [Google Scholar] [CrossRef]

- Krajcarz, D. Comparison metal water jet cutting with laser and plasma cutting. Procedia Eng. 2014, 69, 838–843. [Google Scholar] [CrossRef]

- Finnie, I. Erosion of surfaces by solid particles. Wear 1960, 3, 87–103. [Google Scholar] [CrossRef]

- Momber, A. Stress–strain relation for water-driven particle erosion of quasi-brittle materials. Appl. Fractmec. 2001, 35, 19–37. [Google Scholar] [CrossRef]

- Jankovic, P.; Igic, T.; Nikodijevic, D. Process parameters effect on material removal mechanism and cut quality of abrasive water jet machining. Theor. Appl. Mech. 2013, 40, 277–291. [Google Scholar] [CrossRef] [Green Version]

- Buijs, M. Erosion of glass as modeled by indentation theory. J. Am. Ceram. Soc. 1994, 77, 1676–1678. [Google Scholar] [CrossRef]

- Hashish, M. Optimization factors in abrasive waterjet machining. J. Eng. Ind. 1991, 113, 29–37. [Google Scholar] [CrossRef]

- Cha, Y.; Oh, T.-M.; An, T.-Z.; Cho, G.-C. The kinetic energy of abrasive particles considering specific gravity in waterjet rock cutting. In Proceedings of the World Tunnel Congress 2018, Dubai, UAE, 21–26 Aprill 2018. DXB1026. [Google Scholar]

- Hashish, M. An improved model of erosion by solid particle impact. In Proceedings of the 7th International Conference, Erosion by Liquid and Solid Impact; Field, J.E., Dear, J.P., Eds.; Cavendish Lab.: Cambridge, UK, 1987; pp. 66.1–66.9. [Google Scholar]

- Zeng, J.; Kim, T.J. Development of an abrasive waterjet kerf cutting model for brittle materials. In Jet Cutting Technology; Springer: Berlin, Germany, 1992; pp. 483–501. [Google Scholar]

- Zeng, J.; Kim, T.J. An erosion model of polycrystalline ceramics in abrasive waterjet cutting. Wear 1996, 193, 207–217. [Google Scholar] [CrossRef]

- Capello, E.; Groppetti, R. On a simplified model for hydro abrasive jet machining prediction, control and optimization. In Proceedings of the 7th American Water Jet Conference, Seattle, WA, USA, 28–31 August 1993; pp. 157–174. [Google Scholar]

- El-Domiaty, A.; Abdel-Rahman, A.A. Fracture mechanics-based model of abrasive waterjet cutting for brittle materials. Int. J. Adv. Manuf. Technol. 1997, 13, 172–181. [Google Scholar] [CrossRef]

- Chung, Y.; Geskin, E.; Singh, P.J. Prediction of the geometry of the kerf created in the course of abrasive waterjet machining of ductile materials. In Jet Cutting Technology; Springer: Berlin, Germany, 1992; pp. 525–541. [Google Scholar]

- Matsui, S.; Matsumura, H.; Ikemoto, Y.; Kumon, Y.; Shimizu, H. Prediction equations for depth of cut made by abrasive water jet. In Proceedings of the 6th American Water Jet Conference, Houston, TX, USA, 24–27 August 1991; pp. 24–27. [Google Scholar]

- Momber, A. A generalized abrasive water jet cutting model. In Proceedings of the 8th American Water Jet Conference, Houston, TX, USA, 26–29 August 1995; pp. 359–376. [Google Scholar]

- Momber, A.W. A probabilistic model for the erosion of cement-based composites due to very high-speed hydro-abrasive flow. Wear 2016, 368, 39–44. [Google Scholar] [CrossRef]

- Bitter, J.G.A. A study of erosion phenomena part I. Wear 1963, 6, 5–21. [Google Scholar] [CrossRef]

- Bitter, J.G.A. A study of erosion phenomena: Part II. Wear 1963, 6, 169–190. [Google Scholar] [CrossRef]

- Hutchings, I. Energy absorbed by elastic waves during plastic impact. J. Phys. D Appl. Phys. 1979, 12, 1819. [Google Scholar] [CrossRef]

- Kovacevic, R.; Momber, A.; Mohen, R. Energy dissipation control in hydro-abrasive machining using quantitative acoustic emission. Int. J. Adv. Manuf. Technol. 2002, 20, 397–406. [Google Scholar] [CrossRef]

- Paul, S.; Hoogstrate, A.; Van Luttervelt, C.; Kals, H. Analytical modelling of the total depth of cut in the abrasive water jet machining of polycrystalline brittle material. J. Mater. Process Technol. 1998, 73, 206–212. [Google Scholar] [CrossRef]

- Abdel-Rahman, A.A. A Closed-form Expression for an abrasive waterjet cutting model for ceramic materials. Int. J. Math. Mod. Meth. Appl. Sci. 2011, 5, 722–729. [Google Scholar]

- Momber, A. The kinetic energy of wear particles generated by abrasive–water-jet erosion. J. Mater. Process Technol. 1998, 83, 121–126. [Google Scholar] [CrossRef]

- Momber, A.W.K.; Kovacevic, R. Energy dissipative processes in high speed water solid particle erosion. Proc. ASME Heat Transf. Fluids Eng. Div. 1995, 321, 555–564. [Google Scholar]

- Mott, R.L.; Noor, F.M.; Aziz, A.A. Applied Fluid Mechanics; Prentice Hall: Upper Saddle River, NJ, USA, 2006. [Google Scholar]

- Oh, T.-M.; Cho, G.-C. Rock cutting depth model based on kinetic energy of abrasive waterjet. Rock Mech. Rock Eng. 2015, 49, 1059–1072. [Google Scholar] [CrossRef]

- Roth, P.; Looser, H.; Heiniger, K.; Bühler, S. Determination of abrasive particle velocity using laser-induced fluorescence and particle tracking methods in abrasive water jets. In Proceedings of the 2005 WJTA Conference and Exposition, Houston, TX, USA, 21–23 August 2005; pp. 21–23. [Google Scholar]

- Vahedi Tafreshi, H.; Pourdeyhimi, B. The effects of nozzle geometry on waterjet breakup at high Reynolds numbers. Exp. Fluids 2003, 35, 364–371. [Google Scholar] [CrossRef]

- Zhu, H.T.; Huang, C.Z.; Wang, J.; Zhao, G.Q.; Li, Q.L. Modeling material removal in fracture erosion for brittle materials by abrasive waterjet. Adv. Mater. Res. 2009, 76–78, 357–362. [Google Scholar] [CrossRef]

- Zhu, H. Study on Erosion Mechanisms and Polishing Technology of Hard-Brittle Materials Machined with Precision Abrasive Waterjet; Shandong University: Jinan, China, 2007. [Google Scholar]

- Fowler, G.; Pashby, I.R.; Shipway, P.H. The effect of particle hardness and shape when abrasive water jet milling titanium alloy Ti6Al4V. Wear 2009, 266, 613–620. [Google Scholar] [CrossRef]

- Wang, J. Predictive depth of jet penetration models for abrasive waterjet cutting of alumina ceramics. Int. J. Mech. Sci. 2007, 49, 306–316. [Google Scholar] [CrossRef]

- Meng, J.; Wei, Q.; Ma, Y. Numerical simulation study on erosion mechanism of pre-mixed abrasive water jet. Adv. Mech. Eng. 2017, 9, 1–10. [Google Scholar] [CrossRef]

- Agus, M.; Bortolussi, A.; Ciccu, R.; Kim, W.; Vargiu, A. Abrasive performance in rock cutting with AWJ and ASJ. In Proceedings of the 8th American Water Jet Conference, Houston, TX, USA, 26–29 August 1995; p. 29. [Google Scholar]

- Hallquist, J.O. LS-DYNA keyword user’s manual. Livermore Softw. Technol. Corp. 2007, 970, 299–800. [Google Scholar]

- Zhang, F.-G.; Li, E.-Z. A computational model for concrete subjected to large strains, high strain rates, and high pressures. Explos. Shock Waves 2002, 22, 198–202. [Google Scholar]

- Lu, Z.; Wan, L.; Zeng, Q.; Zhang, X.; Gao, K. Numerical simulation of fragment separation during rock cutting using a 3d dynamic finite element analysis code. Adv. Mater. Sci. Eng. 2017, 2017, 1–17. [Google Scholar] [CrossRef]

- Tao, M.; Li, X.; Wu, C. Characteristics of the unloading process of rocks under high initial stress. Comput. Geotech. 2012, 45, 83–92. [Google Scholar] [CrossRef]

- Khoe, Y.S.; Weerheijm, J. Limitations of smeared crack models for dynamic analysis of concrete. In Proceedings of the 12th International LS-DYNA Users Conference, Detroit, MI, USA, 3–5 June 2012; pp. 1–14. [Google Scholar]

- Parfilko, Y. Study of Damage Progression in CSCM Concretes under Repeated Impacts; Rochester Institute of Technology: Rochester, NY, USA, 2017. [Google Scholar]

- Jiang, H.; Liu, Z.; Gao, K. Numerical simulation on rock fragmentation by discontinuous water-jet using coupled SPH/FEA method. Powder Technol. 2017, 312, 248–259. [Google Scholar] [CrossRef]

- Tazibt, A.; Parsy, F.; Abriak, N. Theoretical analysis of the particle acceleration process in abrasive water jet cutting. Comput. Matersci. 1996, 5, 243–254. [Google Scholar] [CrossRef]

- Long, X.; Ruan, X.; Liu, Q.; Chen, Z.; Xue, S.; Wu, Z. Numerical investigation on the internal flow and the particle movement in the abrasive waterjet nozzle. Powder. Technol. 2017, 314, 635–640. [Google Scholar] [CrossRef]

- Swanson, R.K.; Kilman, M.; Cerwin, S.; Tarver, W.; Wellman, R. Study of particle velocities in water driven abrasive jet cutting. In Proceedings of the 4th US Water Jet Conference, Berkeley, CA, USA, 26–28 August 1987; pp. 103–107. [Google Scholar]

| Abrasive Waterjet Models | Equations | References |

|---|---|---|

| Volume displacement models | = | [9,19] |

| Energy conservation models | = | [20,21,22,23] |

| Regression models | = | [16,24,25] |

| Reaction kinetic models | = | [26,27] |

| Water pressure (MPa) | 320 | |||||||

| Water flow rate (g/s) | 29.71 (orifice diameter 0.254 mm) | |||||||

| Abrasive flow rate (g/s) | 7.5 | |||||||

| Vickers hardness of abrasive (kg/mm2) | 1500 | |||||||

| Vickers hardness of target) kg/mm2) | 980 | |||||||

| Abrasive density (g/mm3) | Density I: 0.00379; | Density II: 0.00702 | ||||||

| Abrasive diameter (mm) | 0.09 | 0.18 | 0.264 | 0.344 | 0.09 | 0.18 | 0.264 | 0.344 |

| Abrasive exit velocity (m/s) | 352 | 348 | 346 | 344 | 349 | 344 | 342 | 335 |

| Theoretical study cases (this, previous) | O | O | O | O | O | O | O | O |

| Numerical study cases | X | O | O | O | X | O | O | O |

| Case codes | A-0 | A-1 | A-2 | A-3 | B-0 | B-1 | B-2 | B-3 |

| Density (kg/m3) | Compressive Strength (MPa) | Shear Strength (MPa) | Tensile Strength (MPa) | Young’s Modulus (GPa) | Vickers Hardness (kg/mm3) |

|---|---|---|---|---|---|

| 2650 | 236 | 23 | 11 | 56.5 | 980 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cha, Y.; Oh, T.-M.; Cho, G.-C. Waterjet Erosion Model for Rock-Like Material Considering Properties of Abrasive and Target Materials. Appl. Sci. 2019, 9, 4234. https://doi.org/10.3390/app9204234

Cha Y, Oh T-M, Cho G-C. Waterjet Erosion Model for Rock-Like Material Considering Properties of Abrasive and Target Materials. Applied Sciences. 2019; 9(20):4234. https://doi.org/10.3390/app9204234

Chicago/Turabian StyleCha, Yohan, Tae-Min Oh, and Gye-Chun Cho. 2019. "Waterjet Erosion Model for Rock-Like Material Considering Properties of Abrasive and Target Materials" Applied Sciences 9, no. 20: 4234. https://doi.org/10.3390/app9204234

APA StyleCha, Y., Oh, T.-M., & Cho, G.-C. (2019). Waterjet Erosion Model for Rock-Like Material Considering Properties of Abrasive and Target Materials. Applied Sciences, 9(20), 4234. https://doi.org/10.3390/app9204234