Computational strategies such as Computational Fluid Dynamic (CFD) are usually applied to simulate fluids (gas and liquids) to obtain different physical variables such as pressure, velocity, mass rate, turbulence energy, temperature, turbulence intensity, vorticity, and others. Based-on CFD applications work over a computational domain using partial differential equations (PDE) and ordinary differential equations (ODE) to describe the relationship among different physical variables to understand the characteristics of fluid flow. The specific applications of the method can be very diverse, depending on the objectives of the analysis, the required accuracy and other factors, such as computing times (which can be high, namely, from hours to days) [

1]. The main applications of CFD encompass aerodynamic analyses, multi-phase flows, transport, compressible flows, phenomena and chemical processes involving transfer heat phenomenon, dissipative phenomenon, rotary, mixing of different fluids and chemical reactions [

1,

2,

3,

4,

5].

Furthermore, specific CFD software can be difficult to handle and, sometimes, unintuitive for students without previous experience. Carrying out processing tasks using CFD can become a long, hard and intense work when it is performed for specific applications [

1], for example, optimization [

3,

6], model calibration [

7], sensitivity analysis and consequence analysis [

8]).

As it is established in [

9], within the CFD context, the Finite Volume Method (FVM) is a specific numerical iterative technique that involves partial differential equations (mainly representing conservation laws) applied over differential volumes. This discretization process is similar to the Finite Element Method (FEM) [

9]. The meshing procedure is highly important in the FVM method because it strongly affects the accuracy and stability of the flow predictions [

10]. The meshing consists of the generation of a grid over the fluid computational domain. This grid can be generated for the computational model with different typologies (mainly structured, non-structured and hybrid) being a quality mesh essential for a quality simulation [

11]. Through the mesh, the discretization of the volume is obtained and the partial differential equations are discretized into algebraic equations by integrating them over each discrete volume element. As a result, a discrete number of algebraic equations are established over a finite number of volumes from application of the meshing process to the whole study volume. These algebraic equations are solved as an algebraic equation system to calculate and compute the values of the dependent variable of each discrete volume element. An adequate mesh design is critical, since the accuracy of the results of the simulation process highly depends on how well the equation system or the mathematical model captures the flow physics [

1].

1.1. CFD Method in the Learning Context

The CFD method has been used as a teaching resource for university studies, specifically, for undergraduate courses in engineering [

12,

13,

14]. Nevertheless, simulation methods such as CFD and FEM are frequently offered as specific elective course in many academic institutions around the world for the acquisition of competence in simulation [

1]. However, the assimilation of the learning of these types of tools involves long training times and it could be an impediment in the context of basic courses in engineering programs, considering the usual intensity of the scholarship for students and professors [

15]. In this way, specific strategies can be used to integrate CFD in basic courses in engineering, specifically in the fluid-mechanics course [

15].

The calculation of energy losses in pipes is an important skill which students must achieve in the fluid-mechanical course. Pressure drop in a pipe system is caused by fluid rising in elevation, shaft work, friction, and turbulence from sudden changes in direction or cross-sectional area [

16]. Specifically, the calculation and application of pressure loss coefficients for different pipe sizes is important to calculate the energy loss and pressure drop in pipes and specific hydraulic elements installed in the line and, in this way, determine important parameters for engineering tasks, such as determining the correct pump size [

17]. A summary of the published literature about pipes fitting in the learning context is established in [

1]. When the pipe has a complex internal geometry or specific elements are installed in the pipelines (nozzles, valves, elbows, filters, etc.), the energy losses can be obtained experimentally or through simulation tools such as CFD. However, pressure drop in singular elements can be also calculated using empirical tables and/or graphics, available in the literature (e.g., [

11]). Unfortunately, the casuistry of this method based on the literature is reduced for several reasons: Limited number of head loss elements and also limited since ideal conditions are considered as ideal geometries for the elements, single-phase flow, Newtonian fluids, no consideration of the material type of the solids, etc. [

15]. However, fluid-mechanical industry problems are sometimes more complex, including multiple phases, complex boundary conditions and complex geometry of the volume. These problems cannot be addressed using only the classic equations and empirical tables and/or graphics; nevertheless, they can be addressed using computer methods based on CFD. Thus, it is important that students, as future professionals, understand the scope and significance of this issue and the limitations of theoretical methods explained in the classroom [

15].

Students tend to identify pressure drop with the concept of pressure drop “in line” (caused by friction with respect to the pipe). However, pressure drop is a wider concept which includes the local pressure loss caused by specific elements located in the fluid line, such as contractions or expansions, valves, etc. Due to this simplification of a complex reality, students sometimes ignore the fact that pressure drop can be caused by apparently insignificant anomalies in the geometry of the pipeline.

Teaching this concept in a laboratory using experimental equipment is often expensive because some sophisticated stations and instruments are required [

1]. Taking into account the high economic cost of the specific instrumentation, the amount of time spent doing the experimental tasks with the students, and operational limitations (e.g., presence of large groups of students) justifies the creation of virtual laboratory resources to support teaching activities [

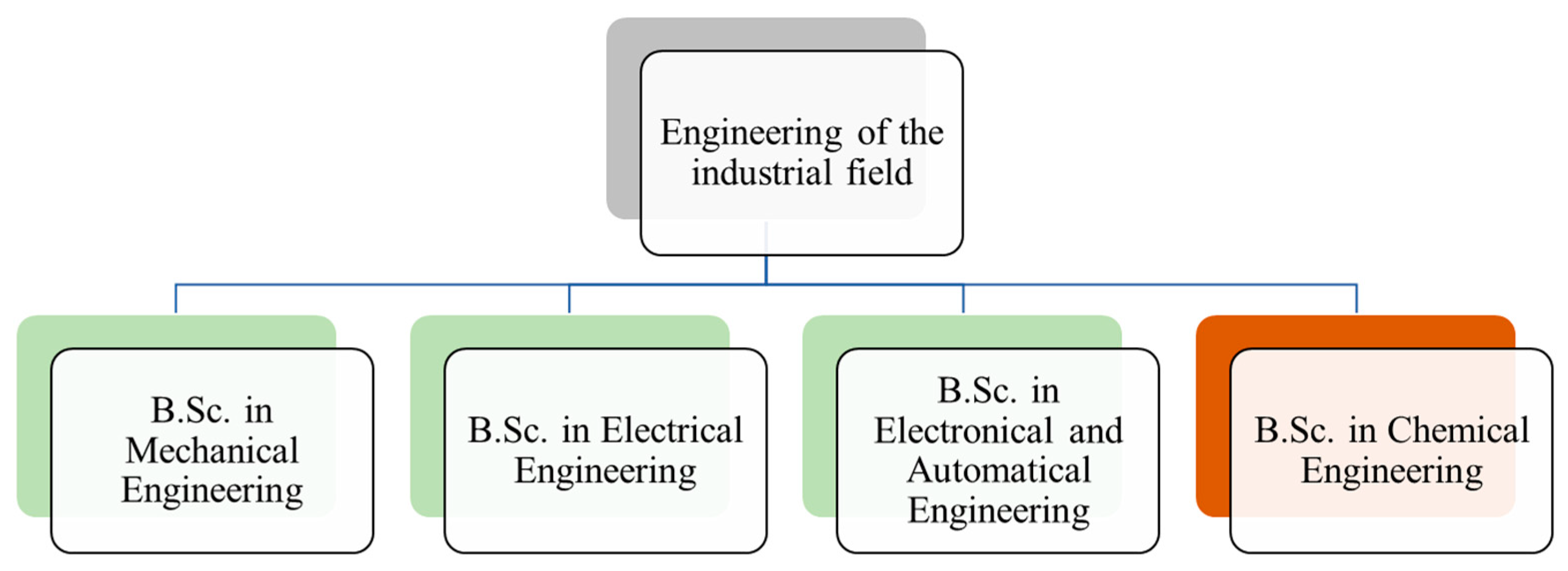

18]. These initiatives share many objectives with respect to simulation activities, insofar as they replace or complement experimental laboratory lessons. Besides, CFD could be an adequate tool to explain concepts that complement the theoretical classes to understand the pressure drop phenomenon, while we are providing the student with very useful software skills which can be important for their future professional career. The fluid-mechanical course is a subject common to all engineering degrees in the industrial teaching program, but, as has been mentioned, learning times for the CFD method of the tool are normally long. Concurrently, machine-learning based methodologies have shown great potential for pattern recognition and predicting results for multiple types of datasets, in spite of the field using supervised algorithms for most of these works. The results of these methods can be incorporated into the decision-making process [

19], even for strategic decision making at higher educational institutions [

20], predicting the performance of the students in blended learning [

21] or prediction of early dropout [

22].

1.2. Research Question

The research question can be divided in two parts: First, we want to know if the specific use of short practical activities using the CFD module of Solidworks

® [

23] is appropriate for the goals raised. Mainly, we want to know whether its use is adequate in terms of usability, satisfaction scalability, learning, thinking over and motivation, which are the most analyzed issues in education [

24,

25,

26]. Please note that we study the activity’s motivation since it is linked with academic performance [

27]).

Secondly, by means of a machine-learning approach, we want to know whether the response to the activity is independent of the bachelor’s degree of origin or, on the contrary, there are questionnaire response patterns. The presence of a pattern that differentiates the activity’s response depending on the bachelor degree will justify future modification to adapt the learning activity.