Influence of Fuel Injection, Turbocharging and EGR Systems Control on Combustion Parameters in an Automotive Diesel Engine

Abstract

:Featured Application

Abstract

1. Introduction

1.1. Analysis of Indicated Pressure Diagrams in Recent Literature

1.2. Effects of Rail Pressure Control

2. Methodologies

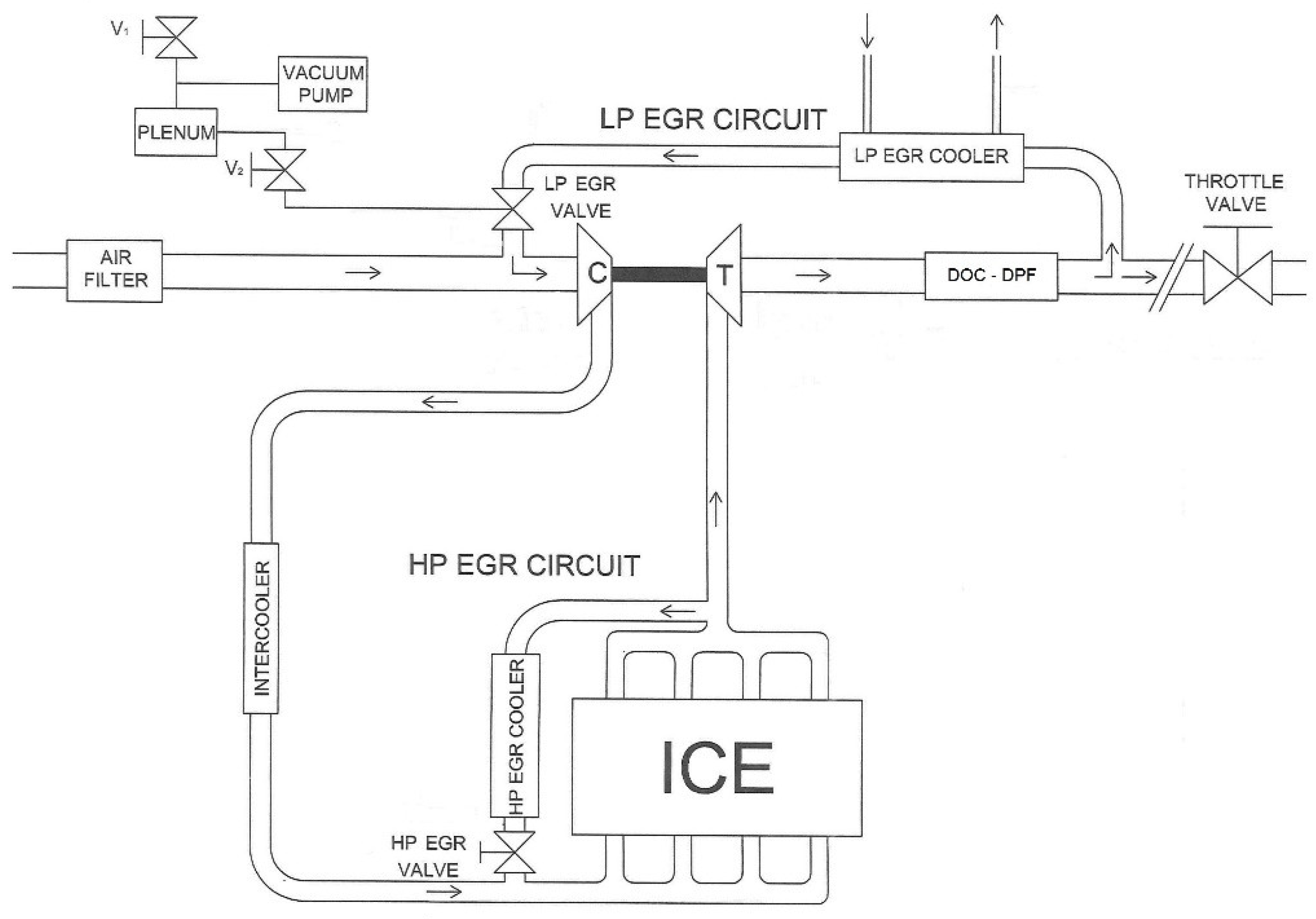

2.1. Engine Test Facility

2.2. Engine Management System and Control Variables

2.3. Measurement of in-Cylinder Pressure Diagrams and Calculation of Rate of Heat Release

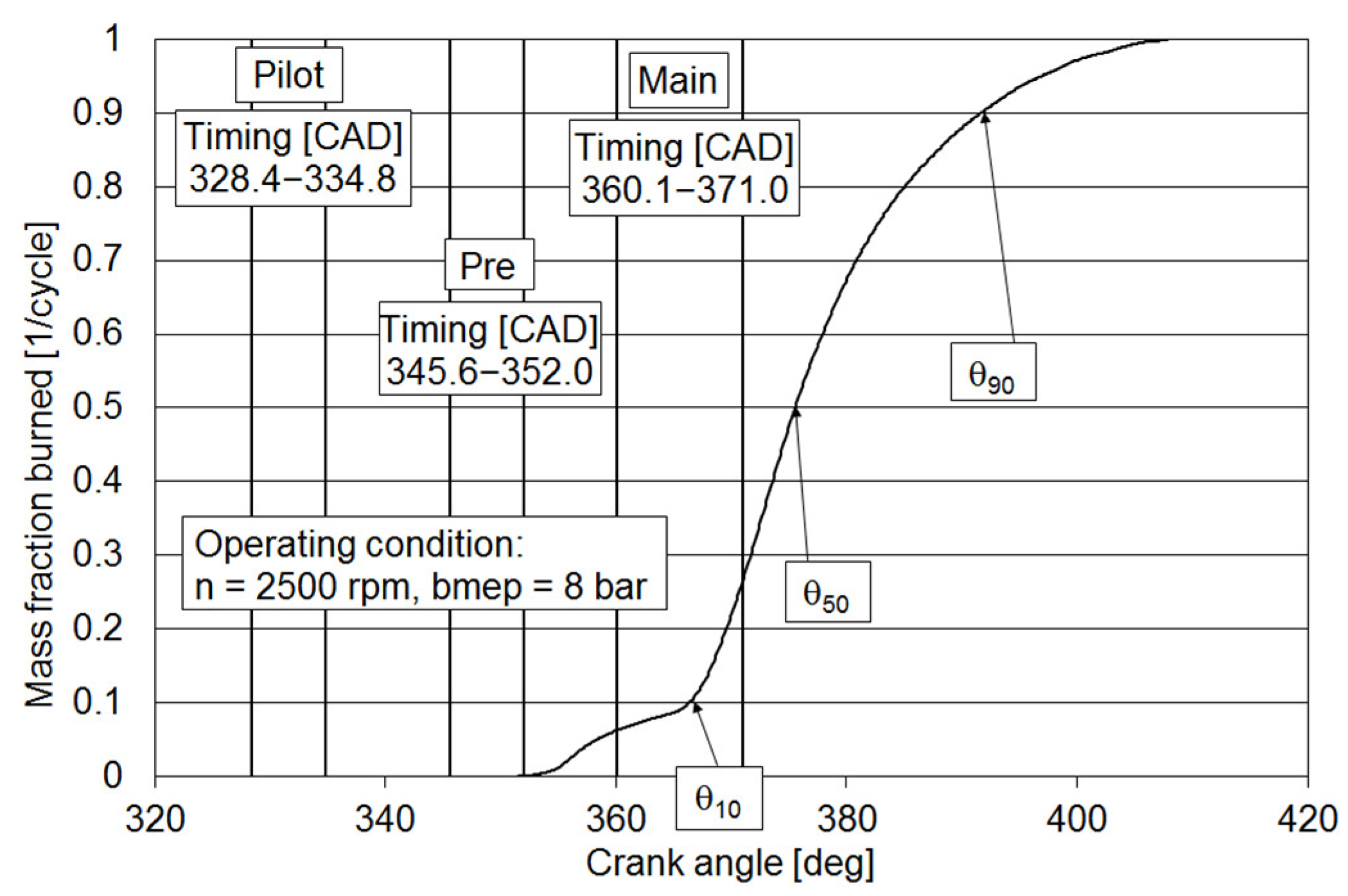

2.4. Evaluation of Combustion Parameters

2.5. Investigation Programme

3. Results and Discussion

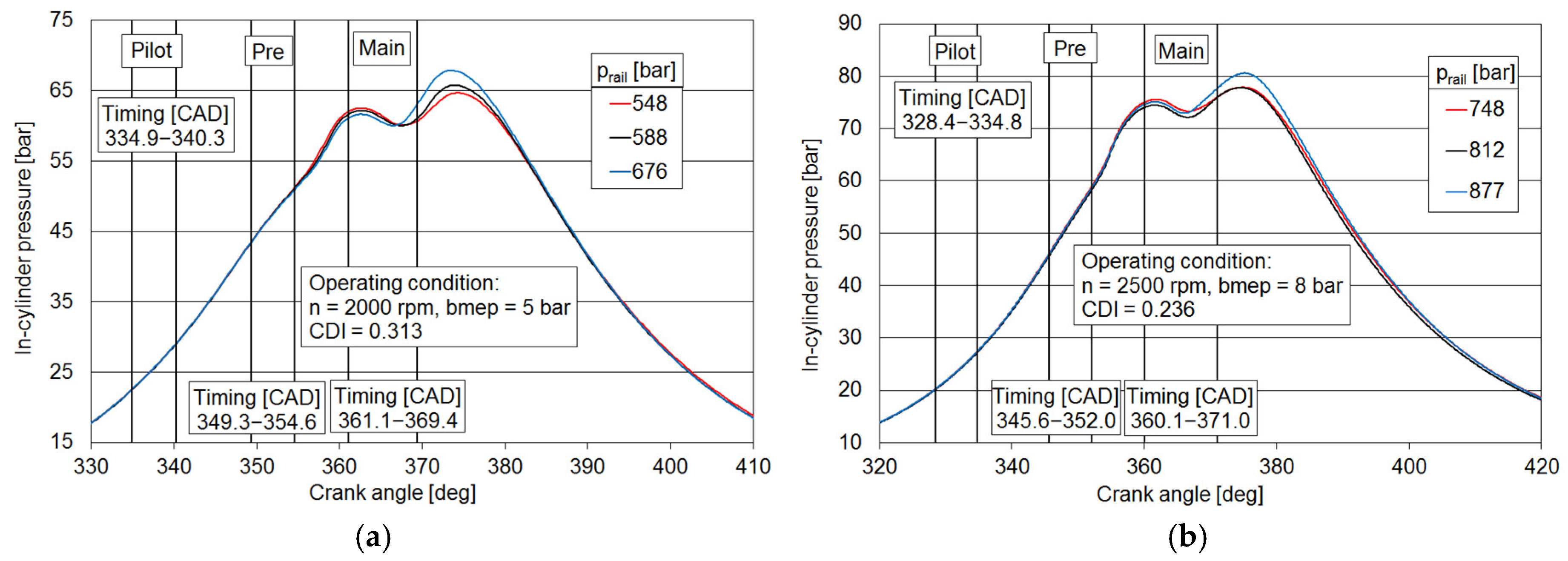

3.1. Trends in Pressure Diagrams and Heat Release Curves

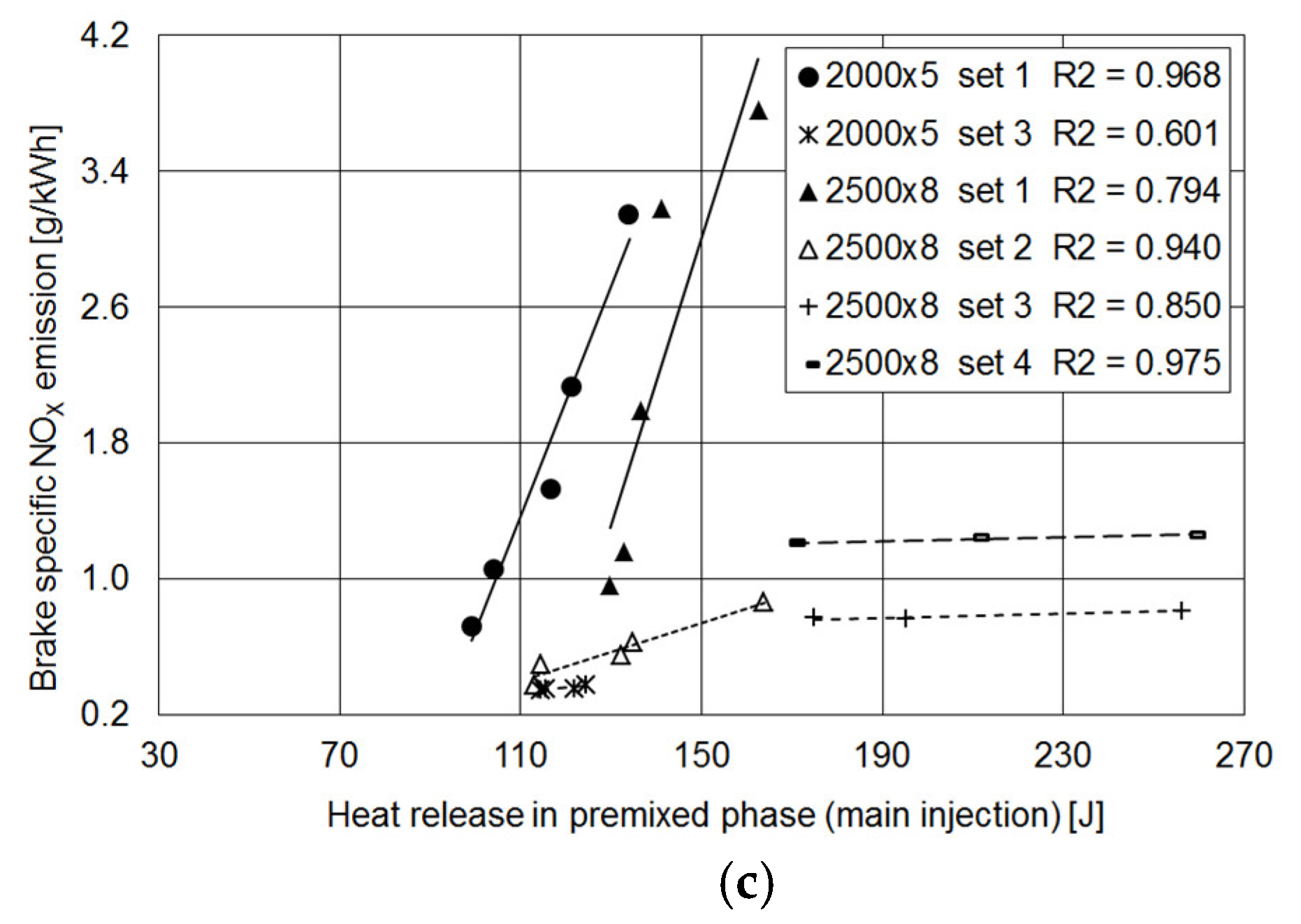

3.2. Links with Heat Released in the Premixed Phase of Main Combustion

3.3. Links with Maximum of Heat Release

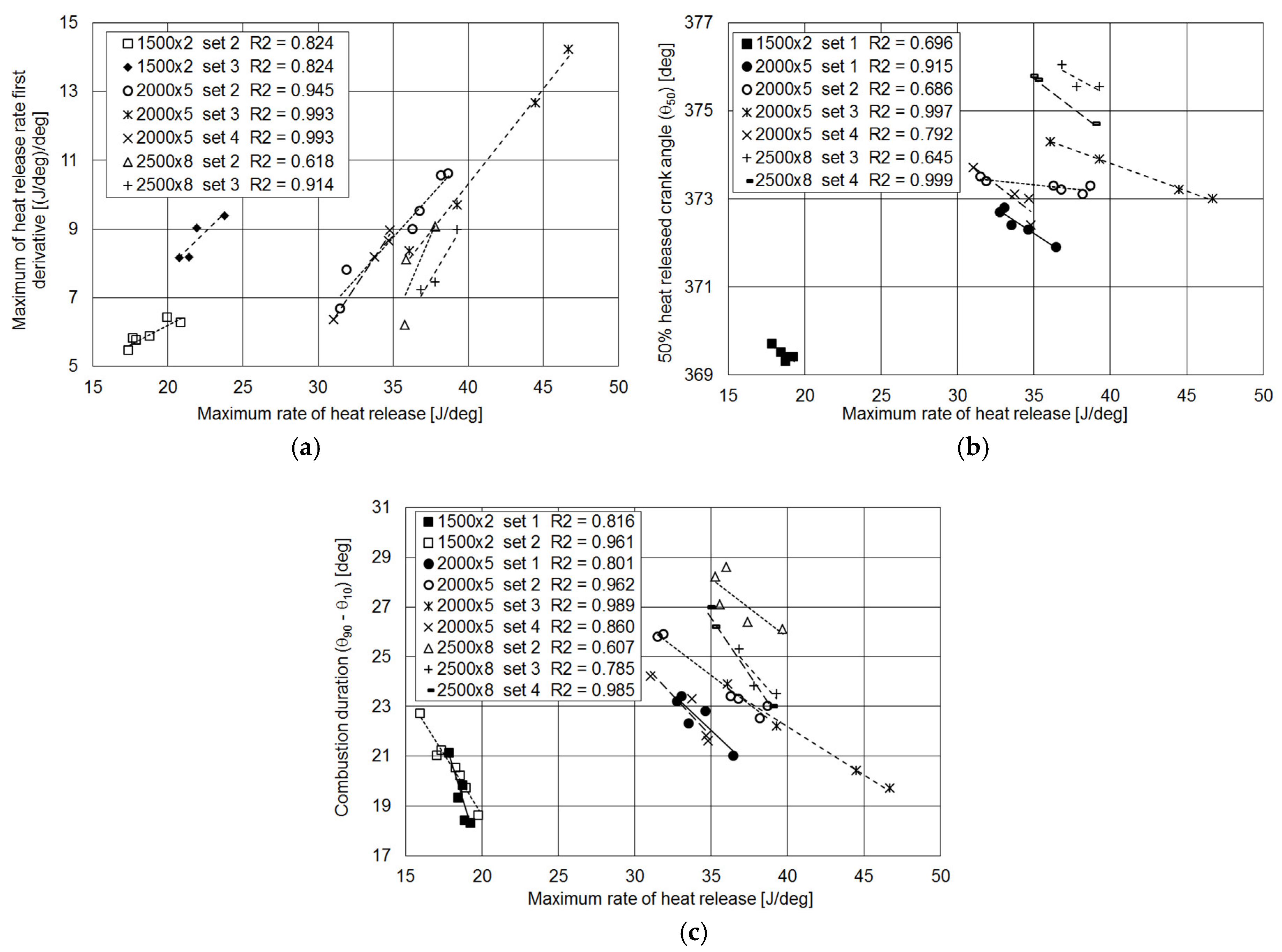

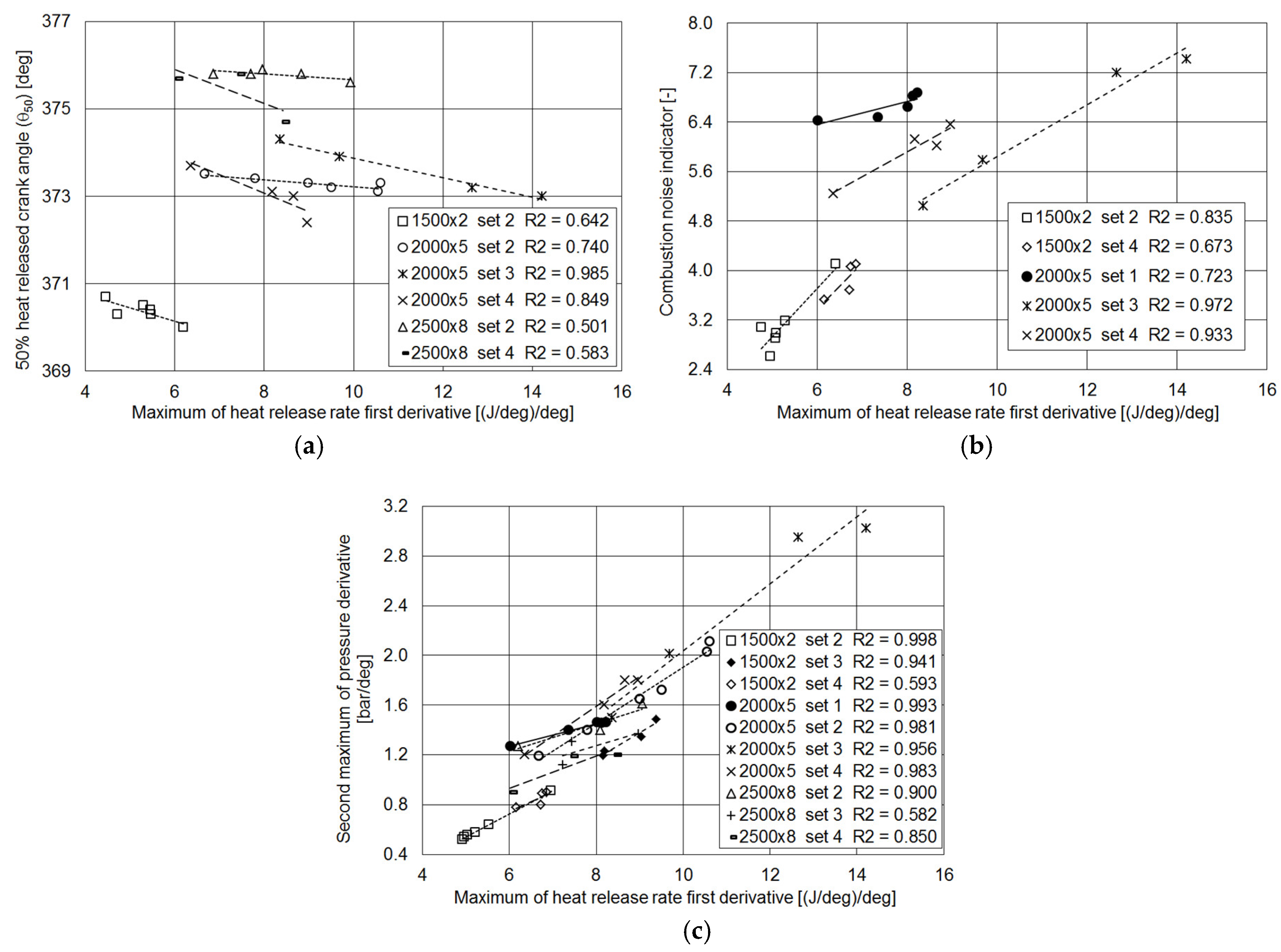

3.4. Links with Maximum of Heat Release Rate First Derivative

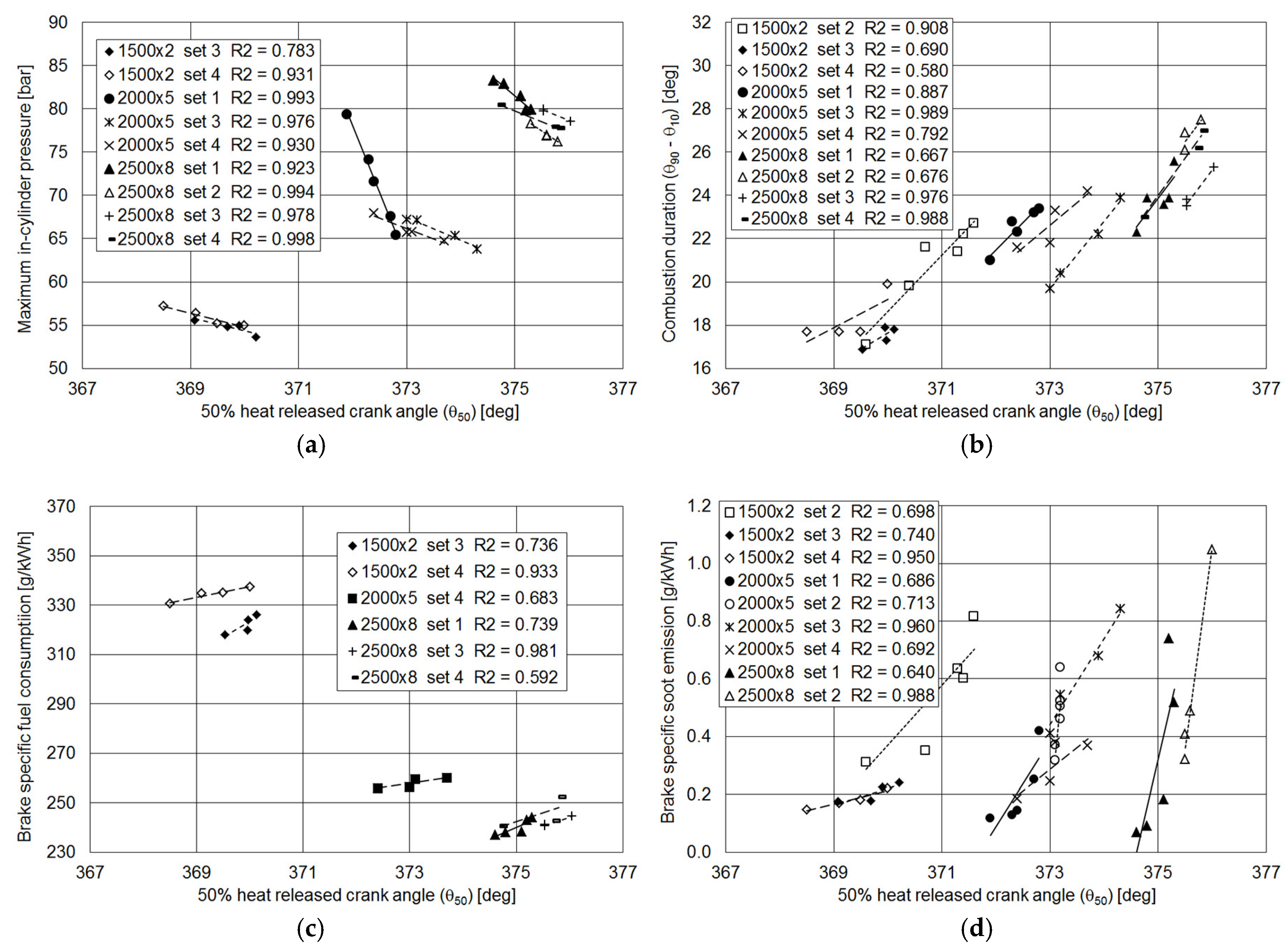

3.5. Influence of 50% Heat Released Crank Angle

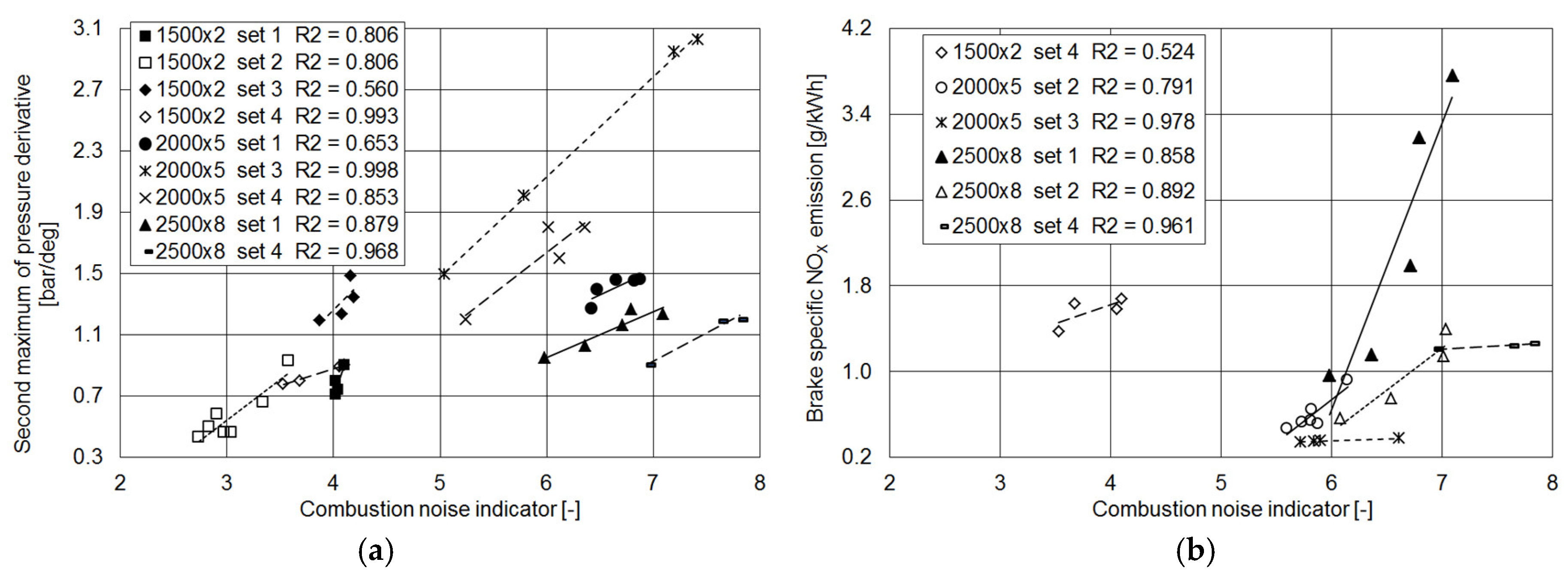

3.6. Links with Combustion Noise Indicator

4. Conclusions

- Generally, controlling CDI and prail led to inverse effects, as increasing the amount of recirculated gases corresponded to the decrease of rail pressure in terms of observed variations of engine average quantities and combustion parameters.

- Test Sets 1 and 2 were mainly influenced by EGR rate/Charge Dilution Index control, with significant differences when adding recirculated gases from low-pressure circuit (Set 2) to conventional high-pressure EGR (Set 1). This was related to the effects of LP contribution, lowering charge temperature at the engine intake and allowing a better mixing between air and recirculated gases.

- Test Sets 3 and 4 showed the influence of rail pressure control, as the reduction of average fuel droplets dimensions and better spray development enhanced mixture formation and the development of combustion, especially in the premixed phase, reducing ignition delay and increasing maximum levels of pressure, heat release and its first derivative.

- The expected effects of rail pressure control on fuel consumption, NOX and soot emissions and combustion noise were observed, as well as the relationship between these quantities and combustion parameters such as θ50 and HRpremix. This outcome validated the calculation procedure of the selected combustion parameters, which could be affected by the standard injection strategy based on three events and the main injection timing, resulting in a trend of rate of heat release where premixed and diffusive phases were not clearly separated.

- Combustion noise indicator proved to be a suitable quantity to describe noise issues, as it was affected by control variables (CDI and prail) according to findings discussed in the literature. A further simplification may be applied to this topic, as the linear relationship between In and (dp/dθ)MAX 2 (i.e., the maximum of in-cylinder pressure derivative occurring during the combustion related to the main injection) suggests to consider only the second quantity. This means to neglect the effects of (dp/dθ)MAX 1 (i.e., the maximum of in-cylinder pressure derivative occurring during the combustion related to the pilot injections), which was marginally affected by control variables.

Funding

Conflicts of Interest

Nomenclature

| Notations | |

| bmep | brake mean effective pressure |

| bsfc | brake specific fuel consumption |

| bsNOX | brake specific NOX emission |

| bsS | brake specific soot emission |

| f | mass flow fraction |

| k | ratio of specific heats |

| imep | indicated mean effective pressure |

| isfc | indicated specific fuel consumption |

| n | rotational speed |

| p | pressure |

| t | temperature [°C] |

| A | opening degree |

| AFR | air-fuel ratio |

| BDC | bottom dead centre |

| CAD | crank angle degree |

| CDI | Charge Dilution Index |

| DC | duty-cycle |

| DI | direct injection |

| ECU | electronic control unit |

| EGR | exhaust gas recirculation |

| FSN | Filter Smoke Number |

| HP | high-pressure |

| HR | heat release |

| I | combustion indicator |

| LP | low-pressure |

| M | mass flow rate |

| PM | Particulate Matter |

| Q | injected quantity, heat |

| RoHR | rate of heat release |

| S | soot, nozzle ring push rod displacement |

| SOI | start of injection |

| TDC | top dead centre |

| TV | exhaust throttle valve |

| V | instantaneous cylinder volume |

| VNT | variable nozzle turbine |

| X | volumetric concentration |

| θ | crank angle |

| Δ | variation |

| Subscripts | |

| a | air, ambient |

| f | fuel |

| i | intake |

| idle | engine idling condition |

| e | exhaust |

| main | referred to the main injection |

| n | noise |

| pilot | referred to pilot injection |

| pre | referred to pre injection |

| premix | premixed combustion mode |

| rail | common rail |

| CO2 | carbon dioxide |

| EGR | exhaust gas recirculation |

| HP | high-pressure |

| LP | low-pressure |

| MAX | maximum |

| MIN | minimum |

| O2 | oxygen |

| VNT | variable nozzle turbine |

References

- Zamboni, G. A study on combustion parameters in an automotive turbocharged diesel engine. Energies 2018, 11, 2531. [Google Scholar] [CrossRef]

- Li, G.; Zhang, C.; Li, Y. Effects of diesel injection parameters on the rapid combustion and emissions of an HD common-rail diesel engine fueled with diesel-methanol dual-fuel. Appl. Therm. Eng. 2016, 108, 1214–1225. [Google Scholar] [CrossRef]

- Barnstedt, K.; Ratzberger, R.; Grabner, P.; Eichlseder, H. Thermodynamic investigation of different natural gas combustion processes on the basis of a heavy-duty engine. Int. J. Engine Res. 2016, 17, 28–34. [Google Scholar] [CrossRef]

- Pielecha, I.; Wisłocki, K.; Cies’lik, W.; Bueschke, W.; Skowron, M.; Fiedkiewicz, Ł. Application of IMEP and MBF50 indexes for controlling combustion in dual-fuel reciprocating engine. Appl. Therm. Eng. 2018, 132, 188–195. [Google Scholar] [CrossRef]

- Ge, J.C.; Yoon, S.K.; Kim, M.S.; Choi, N.J. Application of Canola Oil Biodiesel/Diesel Blends in a Common Rail Diesel Engine. Appl. Sci. 2017, 7, 34. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, P.; Liu, Y. Investigation on combustion and emission performance of a common rail diesel engine fueled with diesel-ethylene glycol dual fuel. Appl. Therm. Eng. 2018, 142, 43–55. [Google Scholar] [CrossRef]

- Nazemi, M.; Shahbakhti, M. Modeling and analysis of fuel injection parameters for combustion and performance of an RCCI engine. Appl. Energy 2016, 165, 135–150. [Google Scholar] [CrossRef]

- Shibata, G.; Ogawa, H.; Amanuma, Y.; Okamoto, Y. Optimization of multiple heat releases in pre-mixed diesel engine combustion for high thermal efficiency and low combustion noise by a genetic-based algorithm method. Int. J. Engine Res. 2018, 1–15. [Google Scholar] [CrossRef]

- Mao, B.; Yao, M.; Zheng, Z.; Li, Y.; Liu, H.; Yan, B. Effects of Dual Loop EGR on Performance and Emissions of a Diesel Engine. SAE Int. 2015. [Google Scholar] [CrossRef]

- Kim, J.; Bae, C. Emission reduction through internal and low-pressure loop exhaust gas recirculation configuration with negative valve overlap and late intake valve closing strategy in a compression ignition engine. Int. J. Engine Res. 2017, 18, 973–990. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Dhar, A.; Gupta, J.G.; Kim, W.I.; Lee, C.S.; Park, S. Effect of fuel injection pressure and injection timing on spray characteristics and particulate size-number distribution in a biodiesel fuelled common rail direct injection diesel engine. Appl. Energy 2014, 130, 212–221. [Google Scholar] [CrossRef]

- Du, W.; Zhang, Q.; Zhang, Z.; Lou, J.; Bao, W. Effects of injection pressure on ignition and combustion characteristics of impinging diesel spray. Appl. Energy 2018, 226, 1163–1168. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Gupta, J.G.; Maurya, R.K.; Kim, W.I.; Lee, S.; Lee, C.S.; Park, S. Spray evolution, engine performance, emissions and combustion characterization of Karanja biodiesel fuelled common rail turbocharged direct injection transportation engine. Int. J. Engine Res. 2016, 17, 1092–1107. [Google Scholar] [CrossRef]

- Syed Aalam, C.; Saravanan, C.G.; Prem Anand, B. Impact of high fuel injection pressure on the characteristics of CRDI diesel engine powered by mahua methyl ester blend. Appl. Therm. Eng. 2016, 106, 702–711. [Google Scholar] [CrossRef]

- Ashok, B.; Nanthagopal, K.; Chaturvedi, B.; Sharma, S.; Thundil Karuppa Raj, R. A comparative assessment on Common Rail Direct Injection (CRDI) engine characteristics using low viscous biofuel blends. Appl. Therm. Eng. 2018, 145, 494–506. [Google Scholar] [CrossRef]

- Xu, L.; Baib, X.; Jiac, M.; Qiana, Y.; Qiaoa, X.; Lu, X. Experimental and modeling study of liquid fuel injection and combustion in diesel engines with a common rail injection system. Appl. Energy 2018, 230, 287–304. [Google Scholar] [CrossRef]

- Imperato, M.; Kaario, O.; Sarjovaara, T.; Larmi, M. Influence of the in-cylinder gas density and fuel injection pressure on the combustion characteristics in a large-bore diesel engine. Int. J. Engine Res. 2016, 17, 525–533. [Google Scholar] [CrossRef]

- Li, M.; Zhang, Q.; Li, G.; Shao, S. Experimental investigation on performance and heat release analysis of a pilot ignited direct injection natural gas engine. Energy 2015, 90, 1251–1260. [Google Scholar] [CrossRef]

- Jeon, J.; Park, S. Effect of injection pressure on soot formation/oxidation characteristics using a two-color photometric method in a compression-ignition engine fueled with biodiesel blend (B20). Appl. Therm. Eng. 2018, 131, 284–294. [Google Scholar] [CrossRef]

- Zamboni, G.; Moggia, S.; Capobianco, M. Hybrid EGR and turbocharging systems control for low NOX and fuel consumption in an automotive diesel engine. Appl. Energy 2016, 165, 839–848. [Google Scholar] [CrossRef]

- Zamboni, G.; Moggia, S.; Capobianco, M. Effects of a dual-loop EGR system and VNT control on the operating parameters of an automotive diesel engine. Energies 2017, 10, 47. [Google Scholar] [CrossRef]

- Asad, U.; Zheng, M. Exhaust gas recirculation for advanced diesel combustion cycles. Appl. Energy 2014, 123, 242–252. [Google Scholar] [CrossRef]

- Park, Y.; Bae, C. Experimental study on the effects of high/low pressure EGR proportion in a passenger car diesel engine. Appl. Energy 2014, 133, 308–316. [Google Scholar] [CrossRef]

- Asad, U.; Tjong, J.; Zheng, M. Exhaust gas recirculation—Zero dimensional modelling and characterization for transient diesel combustion control. Energy Convers. Manag. 2014, 86, 309–324. [Google Scholar] [CrossRef]

- Hsu, B.D. Practical Diesel-Engine Combustion Analysis; SAE International: Warrendale, PA, USA, 2002; ISBN 0-7680-0914-6. [Google Scholar]

- Heywood, J.B. Internal Combustion Engine Fundamentals; Mc Graw-Hill: New York, NY, USA, 1988; ISBN 0-07-028637-X. [Google Scholar]

- Hohenberg, J.F. Advanced approaches for heat transfer calculations. SAE Int. 1979. [Google Scholar] [CrossRef]

- Benson, R.S.; Whitehouse, N.D. Internal Combustion Engines; Pergamon Press: London, UK, 1979; ISBN 978-0080227177. [Google Scholar]

- Badami, M.; Mallamo, F.; Millo, F.; Rossi, E.E. Influence of multiple injection strategies on emissions, combustion noise and bsfc of a DI Common Rail Diesel engine. SAE Int. 2002. [Google Scholar] [CrossRef]

- Torregrosa, A.J.; Broatch, A.; Martin, J.; Monelletta, L. Combustion noise level assessment in direct injection Diesel engines by means of in-cylinder pressure components. Meas. Sci. Technol. 2007, 18, 2131–2142. [Google Scholar] [CrossRef]

- Badami, M.; Mallamo, F.; Millo, F.; Rossi, E.E. Experimental investigation on the effect of multiple injection strategies on emissions, noise and brake specific fuel consumption of an automotive direct injection common-rail diesel engine. Int. J. Engine Res. 2003, 4, 299–314. [Google Scholar] [CrossRef]

- Asad, U.; Zheng, M. Real-time heat release analysis for model-based control of diesel combustion. SAE Int. 2008. [Google Scholar] [CrossRef]

- Liu, J.; Zhu, G.; Fu, J.; Xu, Z.; Yao, J.; Zhan, Z. Quantitative study on in-cylinder combustion and heat release characteristic parameters of gasoline engine based on single variable sweeping tests. Appl. Therm. Eng. 2017, 117, 487–500. [Google Scholar] [CrossRef]

- Chung, J.; Oh, S.; Min, K.; Sunwoo, M. Real-time combustion parameter estimation algorithm for light-duty diesel engines using in-cylinder pressure measurement. Appl. Therm. Eng. 2013, 60, 33–43. [Google Scholar] [CrossRef]

- Thangaraja, J.; Kannan, C. Effect of exhaust gas recirculation on advanced diesel combustion and alternate fuels—A review. Appl. Energy 2016, 180, 169–184. [Google Scholar] [CrossRef]

- Kook, S.; Bae, C.; Miles, P.C.; Choi, D.; Pickett, L.M. The Influence of Charge Dilution and Injection Timing on Low-Temperature Diesel Combustion and Emissions. SAE Int. 2005. [Google Scholar] [CrossRef]

- Eastwood, P. Particulate Emissions from Vehicles; John Wiley & Sons Ltd.: Chichester, UK, 2008; ISBN 978-0-470-72455-2. [Google Scholar]

- Mei, D.; Yue, S.; Zhao, X.; Hielscher, K.; Baar, R. Effects of centre of heat release on combustion and emissions in a PCCI diesel engine fuelled by DMC-diesel blend. Appl. Therm. Eng. 2017, 114, 969–976. [Google Scholar] [CrossRef]

- He, T.; Chen, Z.; Zhu, L.; Zhang, Q. The influence of alcohol additives and EGR on the combustion and emission characteristics of diesel engine under high-load condition. Appl. Therm. Eng. 2018, 140, 363–372. [Google Scholar] [CrossRef]

- Selim, M.Y.E. Effect of exhaust gas recirculation on some combustion characteristics of dual fuel engine. Energy Convers. Manag. 2003, 44, 707–721. [Google Scholar] [CrossRef]

- Bunce, M.; Snyder, D.; Adi, G.; Hall, C.; Koehler, J.; Davila, B.; Kumar, S.; Garimella, P.; Stanton, D.; Shaver, G.; et al. Optimization of soy-biodiesel combustion in a modern diesel engine. Fuel 2011, 90, 2560–2570. [Google Scholar] [CrossRef]

- Torregrosa, A.J.; Broatch, A.; Plá, B.; Mónico, L.F. Impact of Fischer-Tropsch and biodiesel fuels on trade-offs between pollutant emissions and combustion noise in diesel engines. Biomass Bioenergy 2013, 52, 22–33. [Google Scholar] [CrossRef]

- Jung, I.; Jin, J.; Lee, D.; Lee, S.; Yang, S.; Min, K. Closed-Loop control method for monitoring and improving the diesel combustion noise. SAE Int. 2016. [Google Scholar] [CrossRef]

| Characteristics | Description/Value |

|---|---|

| Engine type | Four-stroke, Diesel |

| Cylinders | 4 in-line |

| Bore [mm] × stroke [mm] | 69.9 × 82 |

| Total displacement [cm3] | 1248 |

| Compression ratio | 16.8:1 |

| Valves for cylinder | 4 |

| Intake Valve Opening | 12 CAD BTDC |

| Intake Valve Closure | 12 CAD ABDC |

| Exhaust Valve Opening | 24 CAD BBDC |

| Exhaust Valve Closure | 12 CAD ATDC |

| Maximum Power [kW] | 70 at 4000 rpm |

| Maximum Torque [Nm] | 200 at 1500–3000 rpm |

| Fuel injection system | Direct injection, Multijet II common rail with solenoid injectors, maximum pressure 1650 bar |

| Turbocharging system | Single stage, variable nozzle turbine, intercooler |

| HP EGR system | Standard HP circuit, cooled |

| LP EGR system | Prototype LP loop, cooled |

| Tests | Description |

|---|---|

| Set 1 | HP EGR trade-off |

| Set 2 | HP EGR + LP EGR + VNT control |

| Set 3 | Selected modes from set 2 + prail control |

| Set 4 | Standard level of HP EGR + prail control |

| Operating Condition ID = n × bmep [rpm × bar] | Relative Air-Fuel Ratio | fEGR [%] | CDI [-] | pi [bar] | Mi [kg/h] | ti [°C] |

|---|---|---|---|---|---|---|

| No.1 = 1500 × 2 | 3.3 | 0 | 0 | 1.134 | 59.1 | 27.9 |

| 3.2 | 15.8 | 0.191 | 1.118 | 65.9 | 31.5 | |

| 3.0 | 18.8 | 0.236 | 1.105 | 64.2 | 34.2 | |

| 2.9 1 | 22.1 | 0.291 | 1.092 | 62.1 | 37.5 | |

| 2.7 | 25.7 | 0.354 | 1.079 | 61.0 | 41.1 | |

| SOIpilot = 20.1 CAD BTDC, SOIpre = 8.0 CAD BTDC, SOImain = 1.3 CAD ATDC, Qpilot = Qpre = 1 mm3/stroke, prail = 370 bar, AVNT = 1.4% | ||||||

| No.2 = 2000 × 5 | 2.5 | 0 | 0 | 1.513 | 106.5 | 25.2 |

| 2.2 | 13.4 | 0.160 | 1.433 | 105.0 | 31.4 | |

| 2.0 | 17.8 | 0.224 | 1.390 | 101.1 | 36.6 | |

| 1.8 1 | 22.8 | 0.306 | 1.341 | 95.7 | 43.6 | |

| 1.6 | 27.6 | 0.396 | 1.299 | 92.2 | 51.6 | |

| SOIpilot = 25.1 CAD BTDC, SOIpre = 10.7 CAD BTDC, SOImain = 1.1 CAD ATDC, Qpilot = Qpre = 1 mm3/stroke, prail = 588 bar, AVNT = 7.6% | ||||||

| Operating Condition ID = n × bmep [rpm × bar] | Relative Air-Fuel Ratio | fEGR [%] | CDI [-] | Mi [kg/h] | ti [°C] | AVNT [%] |

|---|---|---|---|---|---|---|

| No.3 = 2500 × 8 | 2.1 | 0.0 | 0 | 146.2 | 27.2 | 29.2 |

| 2.0 | 4.7 | 0.051 | 148.5 | 31.3 | 26.9 | |

| 1.8 | 12.3 | 0.146 | 145.3 | 39.0 | 23.7 | |

| 1.6 1 | 18.1 | 0.231 | 137.3 | 50.3 | 18.8 | |

| 1.5 | 19.9 | 0.260 | 135.9 | 55.2 | 17.1 | |

| SOIpilot = 31.6 CAD BTDC, SOIpre = 14.4 CAD BTDC, SOImain = 0.1 CAD ATDC, Qpilot = Qpre = 1 mm3/stroke, prail = 812 bar, pi = 1.52 bar | ||||||

| Operating Condition ID = n × bmep [rpm × bar] | Control Variables (Fixed in Each Test) | Tests | Control Variables (LP EGR and VNT Control) |

|---|---|---|---|

| No.1 = 1500 × 2 | Relative air-fuel ratio Exhaust throttle valve position | Rel.AFR = 3.01-TV pos. 1 Rel.AFR = 2.90 1-TV pos. 1 1,2,3 Rel.AFR = 2.77-TV pos. 1,2 Rel.AFR = 2.62-TV pos. 1,2 | LP EGR valve opening VNT opening degree |

| AVNT = 1.4%-9.5%-16.5% SOIpilot = 20.1 CAD BTDC, SOIpre = 8.0 CAD BTDC, SOImain = 1.3 CAD ATDC, Qpilot = Qpre = 1 mm3/stroke, prail = 370 bar | |||

| No.2 = 2000 × 5 | Relative air-fuel ratio Exhaust throttle valve position | Rel.AFR = 1.94-TV pos. 1 Rel.AFR = 1.80 1-TV pos. 1 1,2,3 Rel.AFR = 1.67-TV pos. 1,2 | LP EGR valve opening VNT opening degree |

| AVNT = 7.6%-14.0%-17.0% SOIpilot = 25.1 CAD BTDC, SOIpre = 10.7 CAD BTDC, SOImain = 1.1 CAD ATDC, Qpilot = Qpre = 1 mm3/stroke, prail = 588 bar | |||

| No.3 = 2500 × 8 | Relative air-fuel ratio Exhaust throttle valve position Intake pressure | Rel.AFR = 1.60-Intake press. = 1.48 bar-TV pos. 1 Rel.AFR = 1.60 1-Intake press. = 1.52 1,1.57 bar-TV pos. 0,1 1 Rel.AFR = 1.47-Intake press. = 1.52 bar-TV pos. 1 | LP EGR valve opening |

| SOIpilot = 31.6 CAD BTDC, SOIpre = 14.4 CAD BTDC, SOImain = 0.1 CAD ATDC, Qpilot = Qpre = 1 mm3/stroke, prail = 812 bar | |||

| Operating Condition ID = n × bmep [rpm × bar] | Selected Values for Control Variables | Rail Pressure [bar] |

|---|---|---|

| No.1 = 1500 × 2 | Rel. AFR = 2.62 TV position = 2 DCVNT = 80 and 86% (AVNT = 16.5 and 9.5%) | 345 (−6.75%) 370 (standard level) 395 (+6.75%) 420 +13.5% |

| No.2 = 2000 × 5 | Rel. AFR = 1.80 DCVNT = 82% (AVNT = 17%) Exhaust throttle valve position = 1 and 3 | 544 (−7.5%) 588 (standard level) 632 (+7.5%) 676 (+15.0%) |

| No.3 = 2500 × 8 | Rel. AFR = 1.60 TV position = 0 Intake pressure = 1.520 and 1.570 bar | 747 (−8.0%) 812 (standard level) 877 (+8.0%) |

| Operating Condition ID = n × bmep [rpm × bar] | Relative Air-Fuel Ratio | fEGR [%] | CDI [-] | Mi [kg/h] | ti [°C] | pi [bar] | prail [bar] |

|---|---|---|---|---|---|---|---|

| No.1 = 1500 × 2 | 2.9 | 22.5 | 0.297 | 64.0 | 40.6 | 1.100 | 345 |

| 370 | |||||||

| 395 | |||||||

| 420 | |||||||

| SOIpilot = 20.1 CAD BTDC, SOIpre = 8.0 CAD BTDC, SOImain = 1.3 CAD ATDC, Qpilot = Qpre = 1 mm3/stroke, AVNT = 1.4% | |||||||

| No.2 = 2000 × 5 | 1.8 | 23.2 | 0.313 | 95.9 | 46.4 | 1.306 | 544 |

| 588 | |||||||

| 632 | |||||||

| 676 | |||||||

| SOIpilot = 25.1 CAD BTDC, SOIpre = 10.7 CAD BTDC, SOImain = 1.1 CAD ATDC, Qpilot = Qpre = 1 mm3/stroke, AVNT = 7.6% | |||||||

| Operating Condition ID = n × bmep [rpm × bar] | Relative Air-Fuel Ratio | fEGR [%] | CDI [-] | Mi [kg/h] | ti [°C] | AVNT [%] | prail [bar] |

|---|---|---|---|---|---|---|---|

| No.3 = 2500 × 8 | 1.6 | 18.4 | 0.236 | 134.7 | 55.8 | 19.7 | 747 |

| 812 | |||||||

| 877 | |||||||

| SOIpilot = 31.6 CAD BTDC, SOIpre = 14.4 CAD BTDC, SOImain = 0.1 CAD ATDC, Qpilot = Qpre = 1 mm3/stroke, pi = 1.52 bar | |||||||

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zamboni, G. Influence of Fuel Injection, Turbocharging and EGR Systems Control on Combustion Parameters in an Automotive Diesel Engine. Appl. Sci. 2019, 9, 484. https://doi.org/10.3390/app9030484

Zamboni G. Influence of Fuel Injection, Turbocharging and EGR Systems Control on Combustion Parameters in an Automotive Diesel Engine. Applied Sciences. 2019; 9(3):484. https://doi.org/10.3390/app9030484

Chicago/Turabian StyleZamboni, Giorgio. 2019. "Influence of Fuel Injection, Turbocharging and EGR Systems Control on Combustion Parameters in an Automotive Diesel Engine" Applied Sciences 9, no. 3: 484. https://doi.org/10.3390/app9030484

APA StyleZamboni, G. (2019). Influence of Fuel Injection, Turbocharging and EGR Systems Control on Combustion Parameters in an Automotive Diesel Engine. Applied Sciences, 9(3), 484. https://doi.org/10.3390/app9030484