Cutting Performance and Wear/Damage Characteristics of PCBN Tool in Hard Milling

Abstract

:1. Introduction

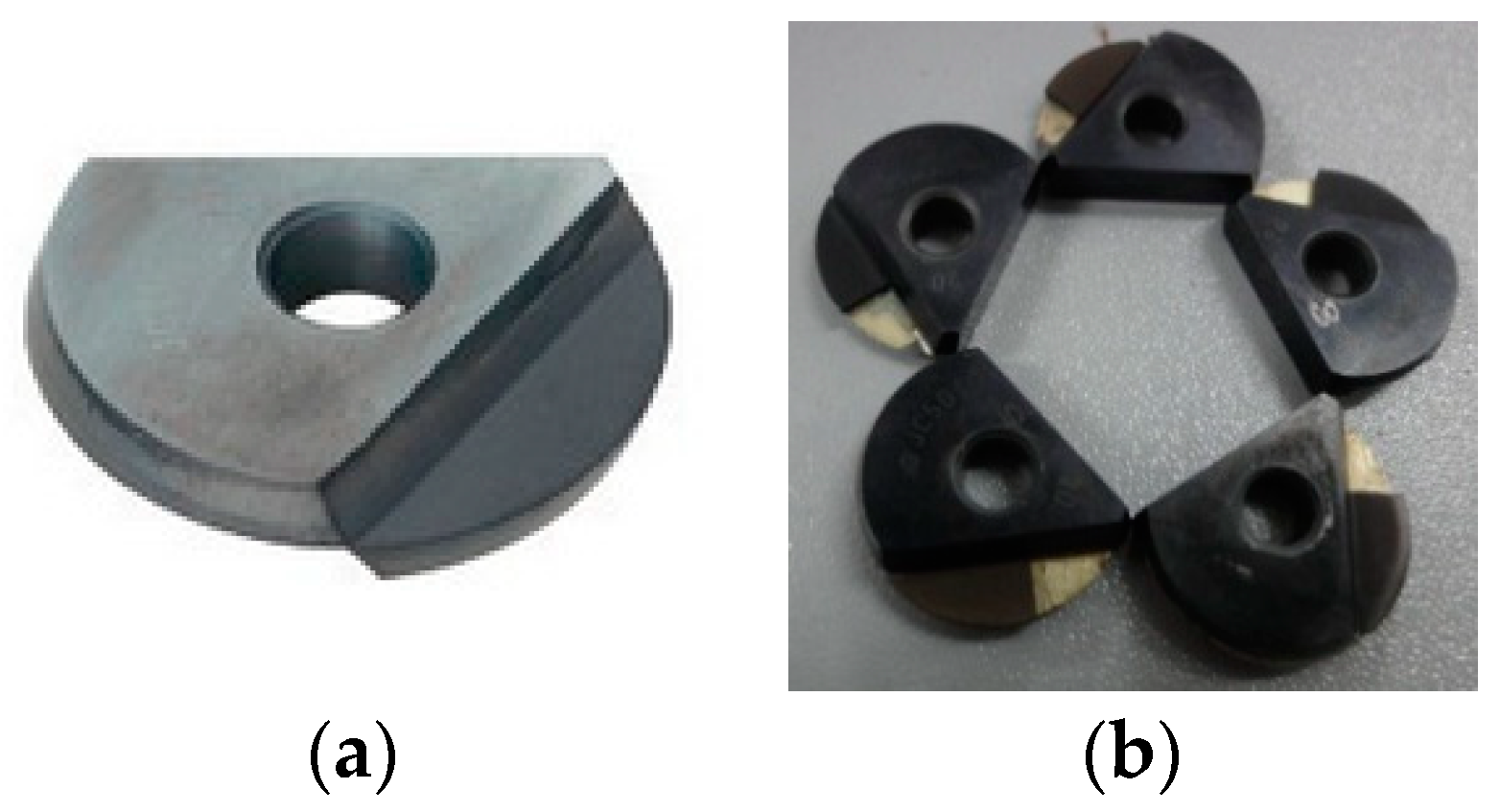

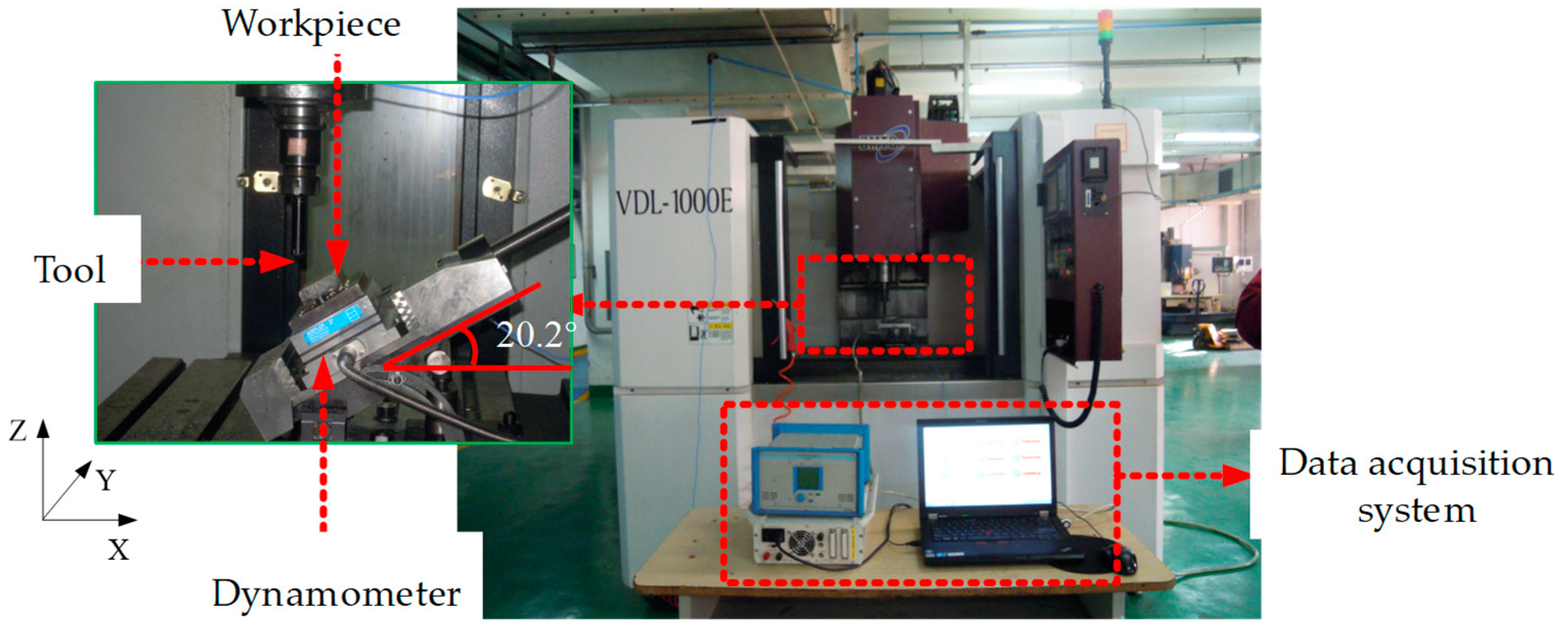

2. Experimental Set-Up

2.1. Experimental Conditions

2.2. Experimental Scheme

3. Experimental Analysis

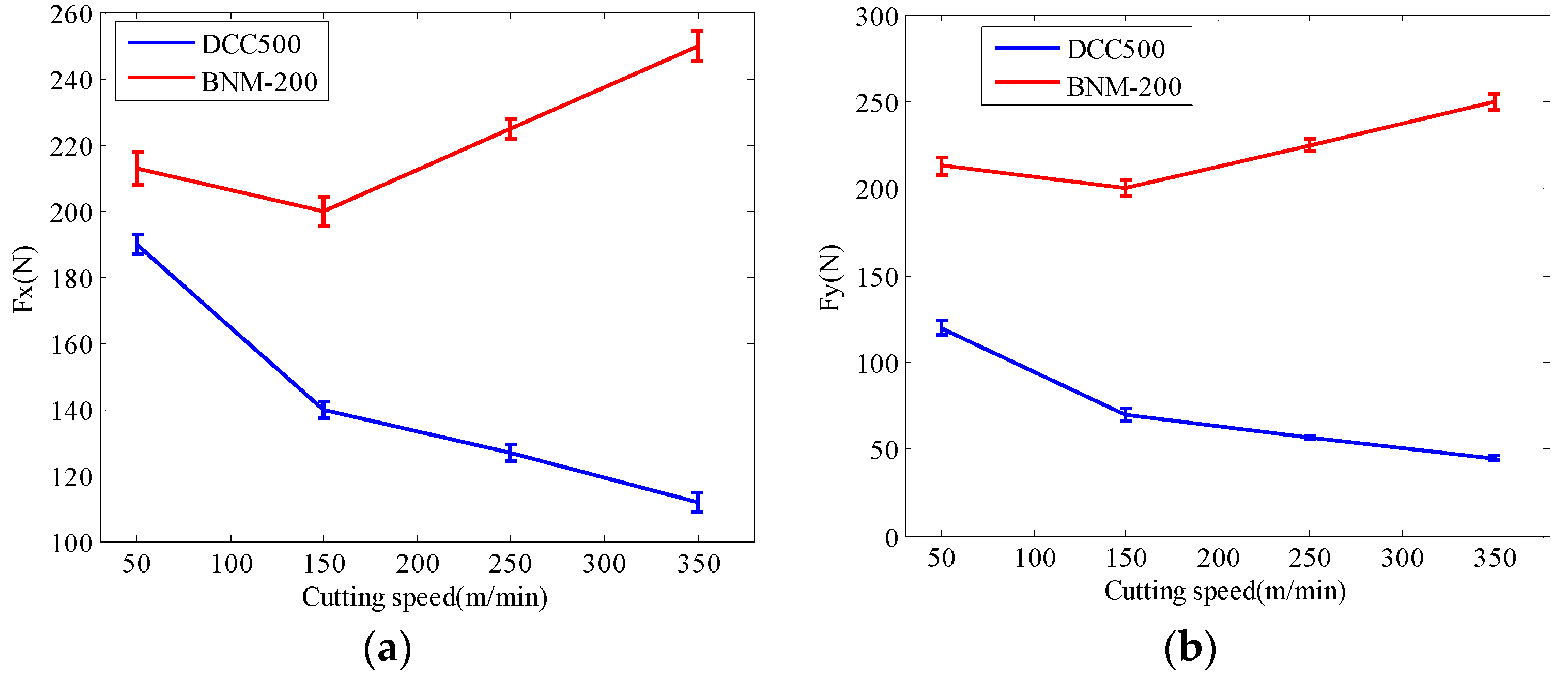

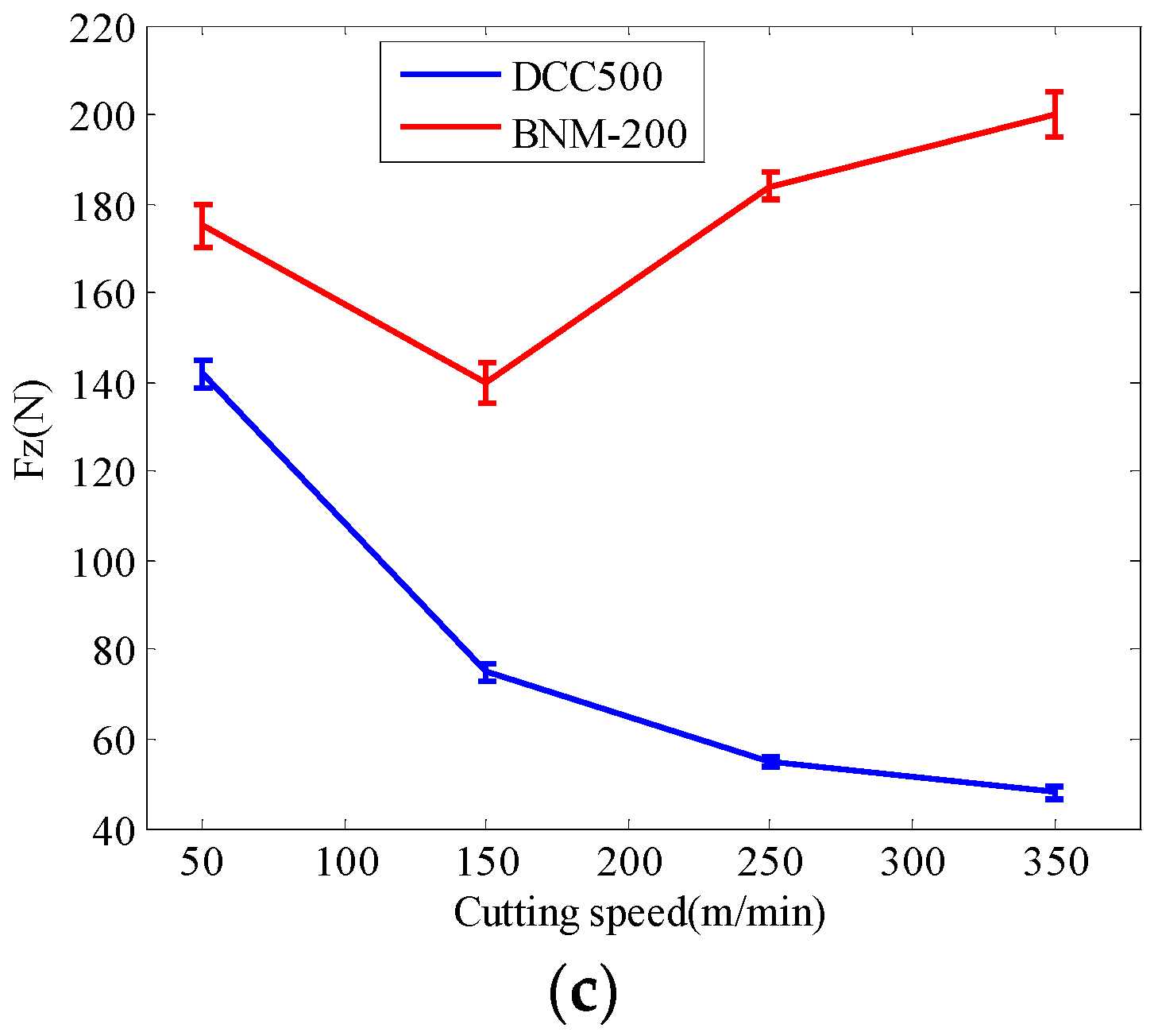

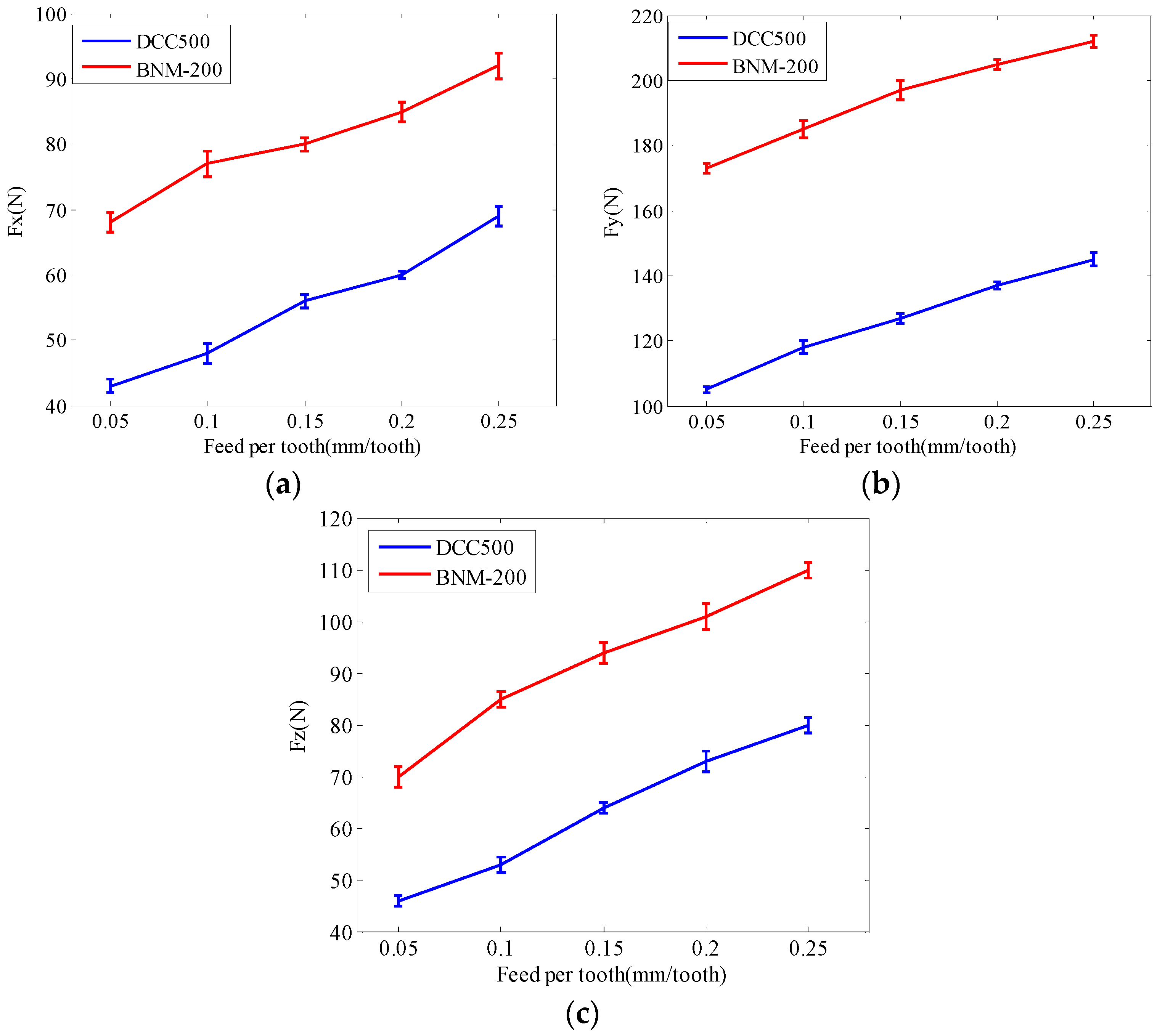

3.1. Milling Force

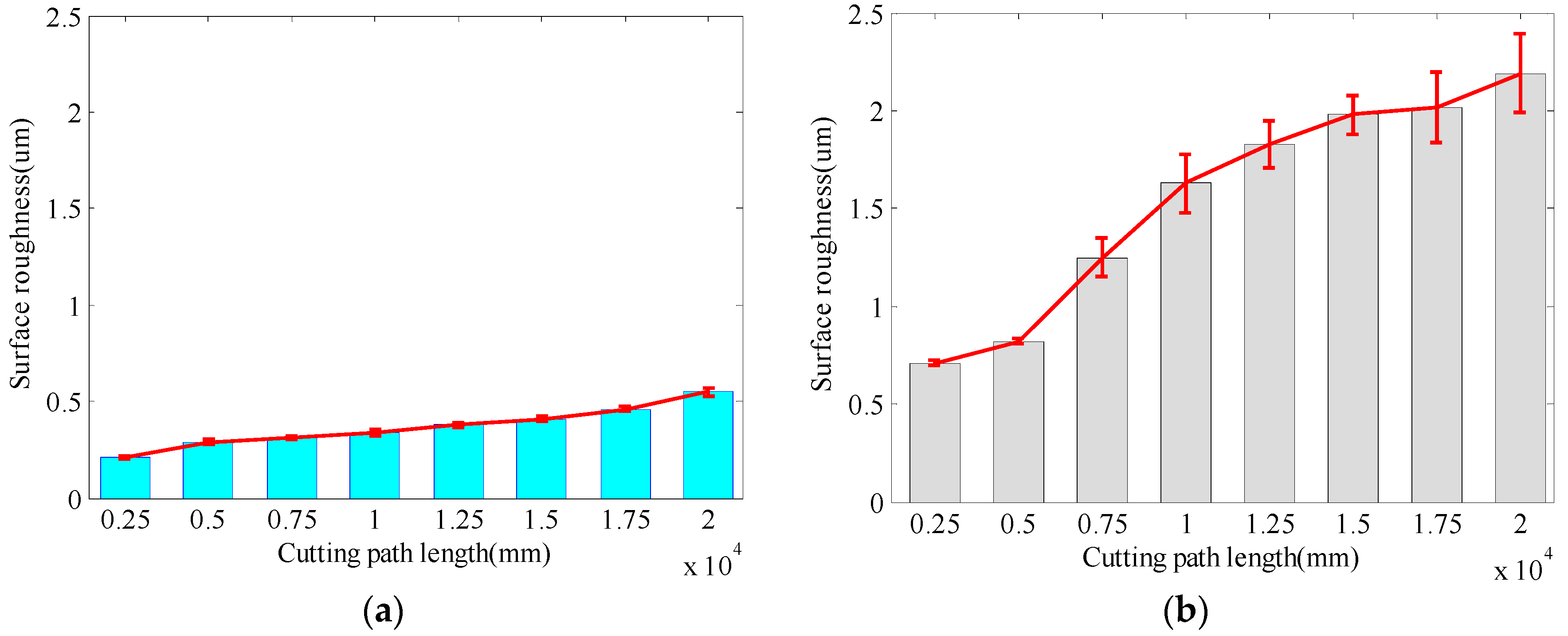

3.2. Surface Quality

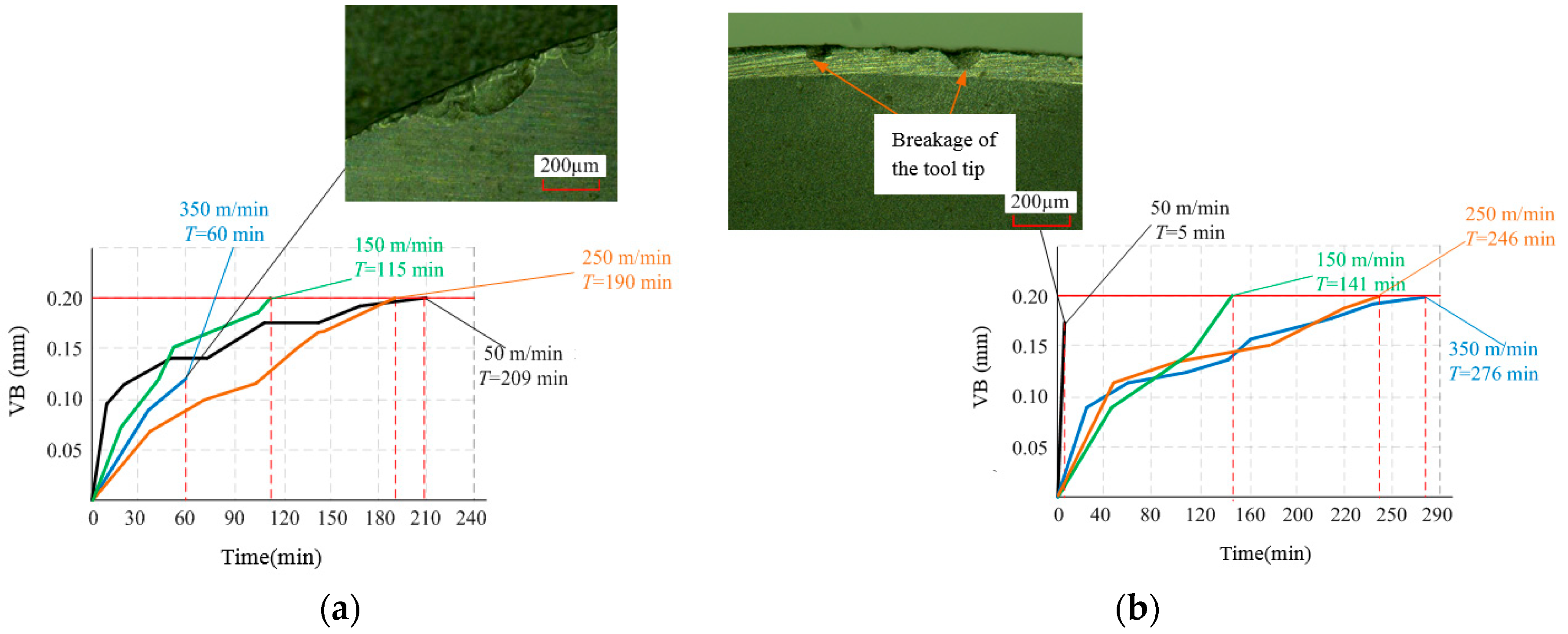

3.3. Tool Life

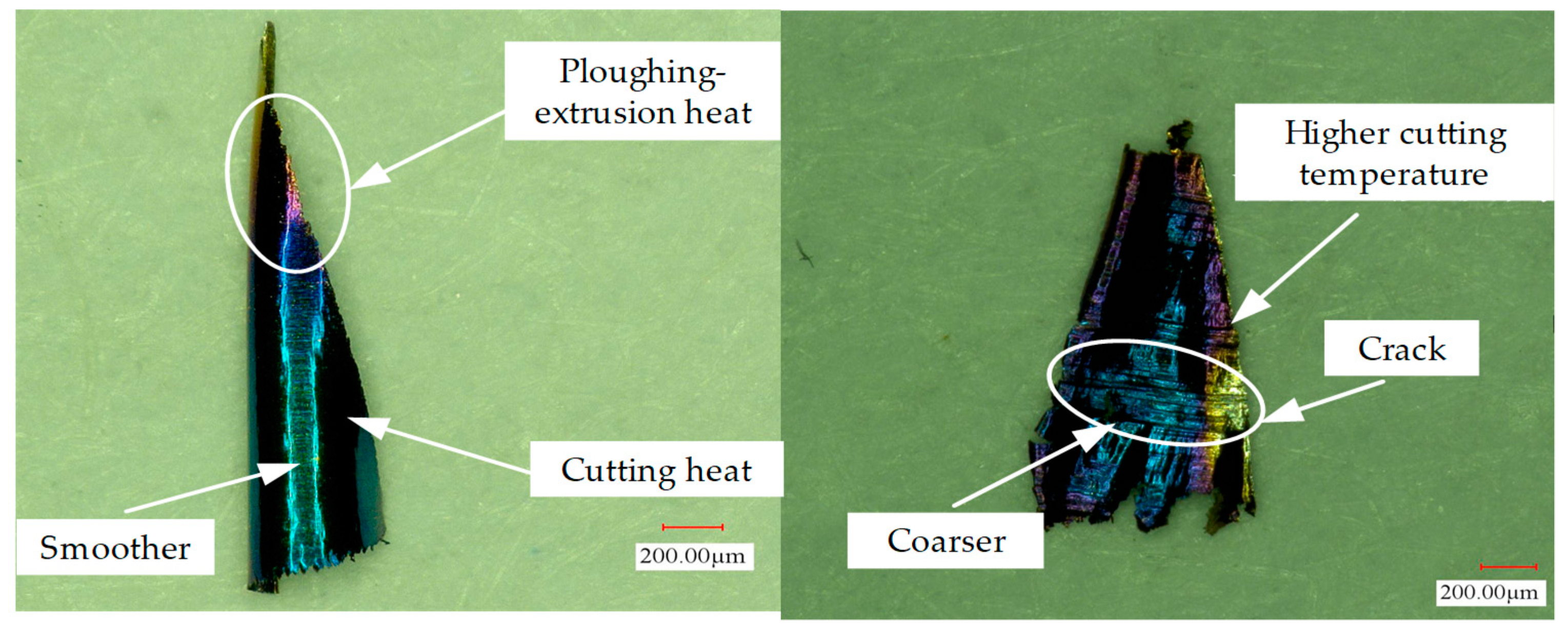

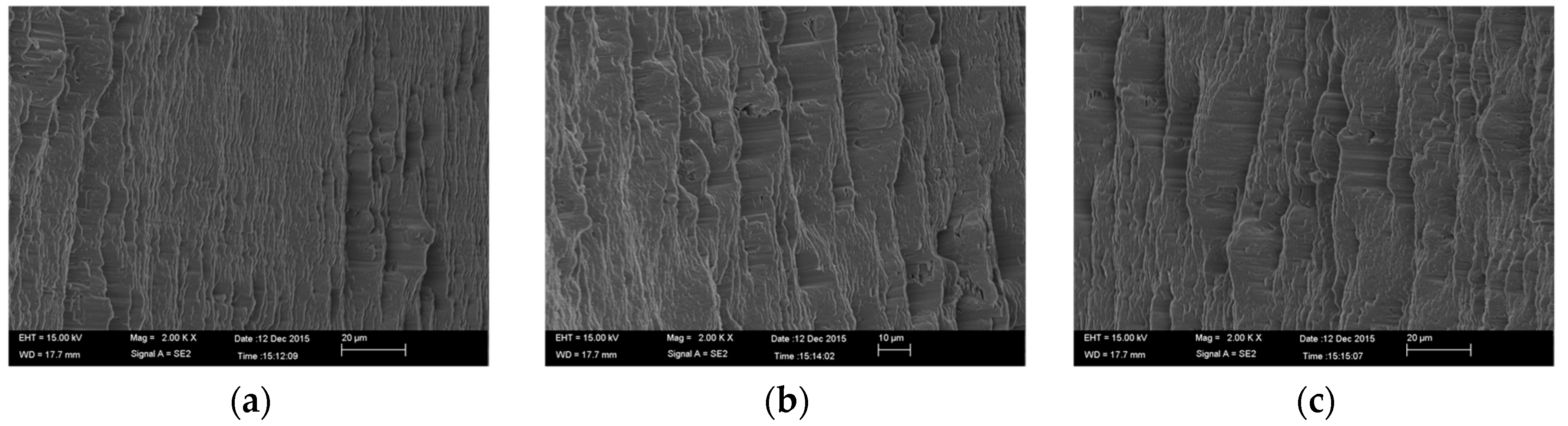

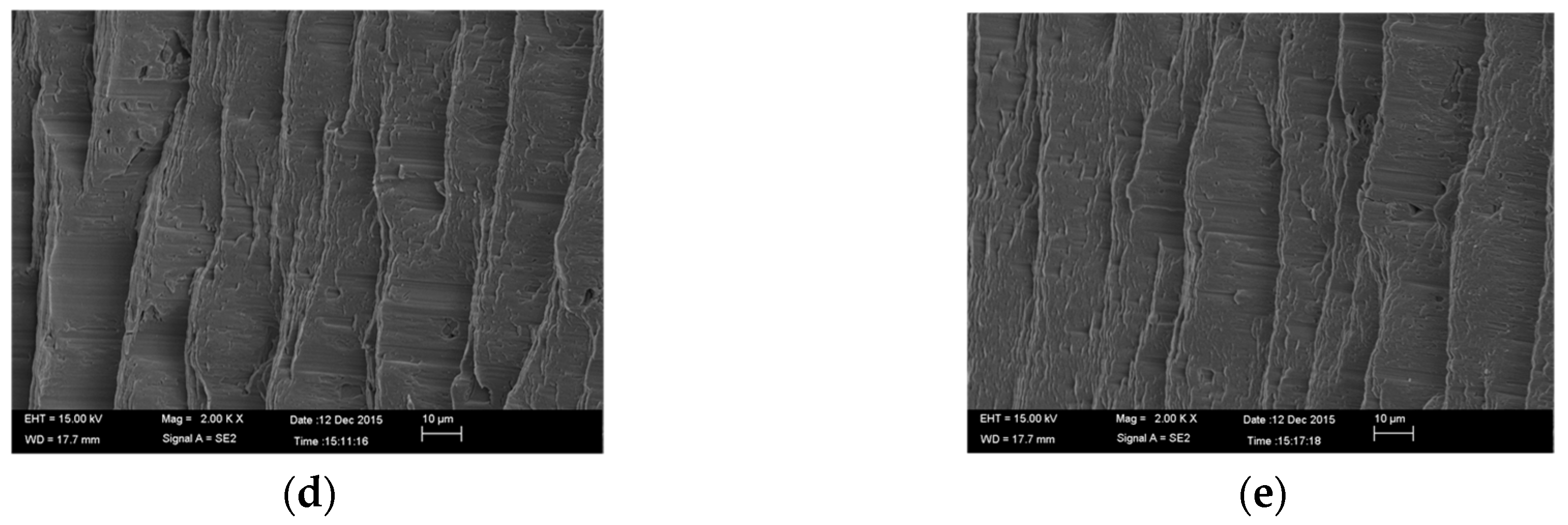

3.4. Chip Formation

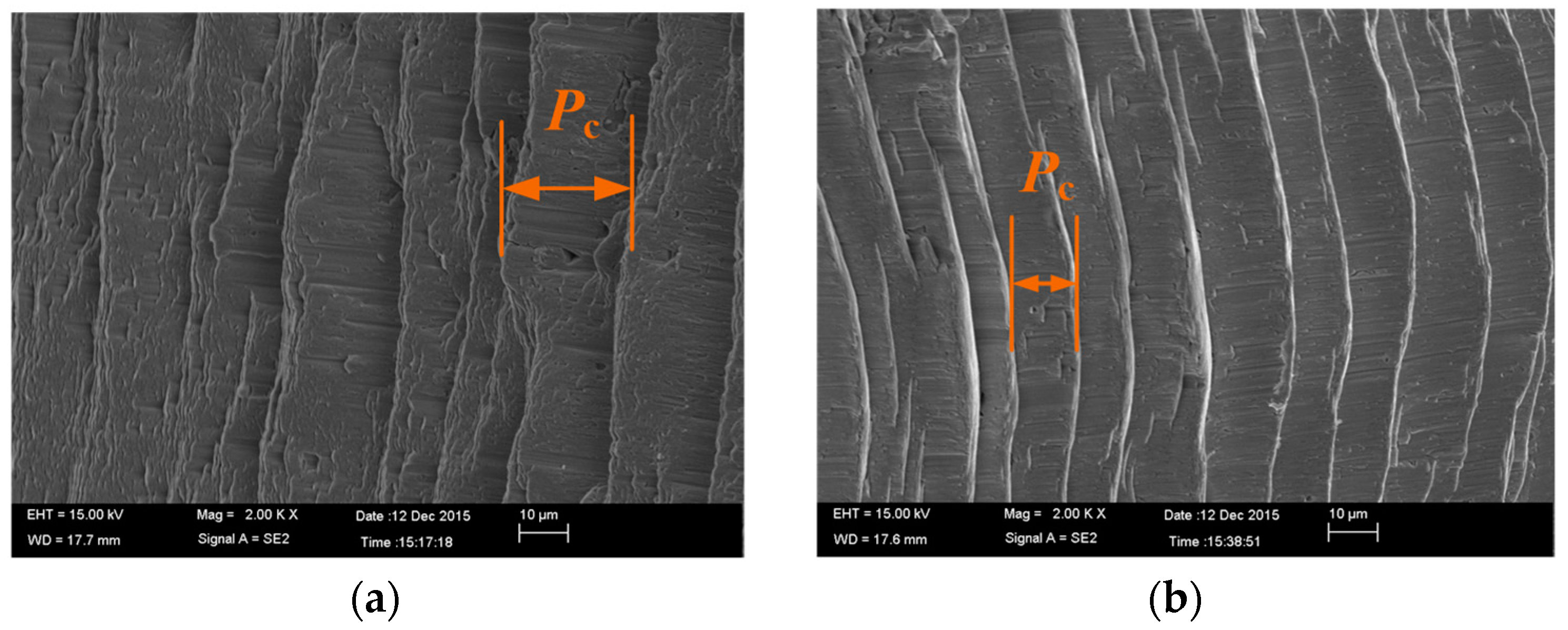

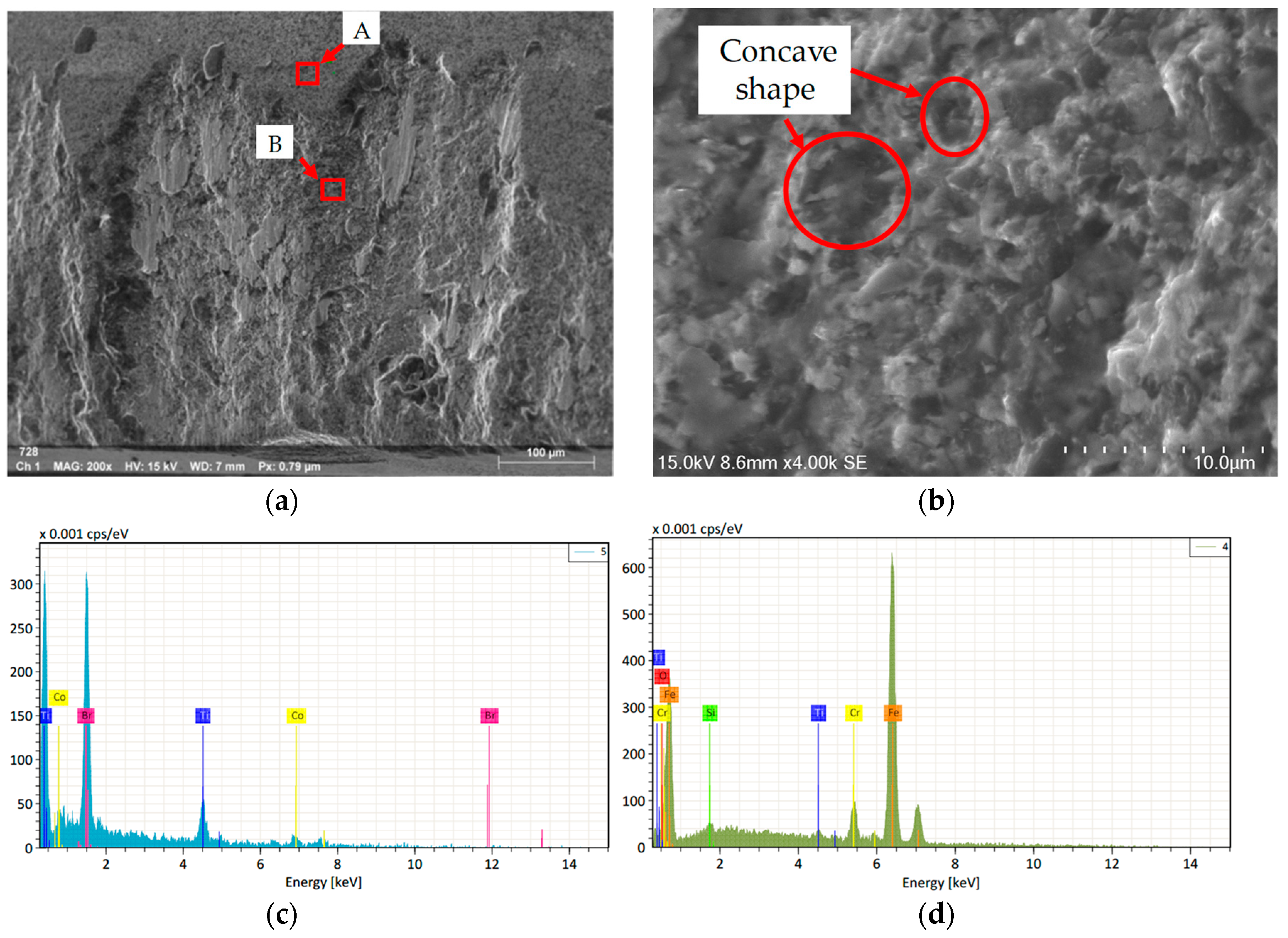

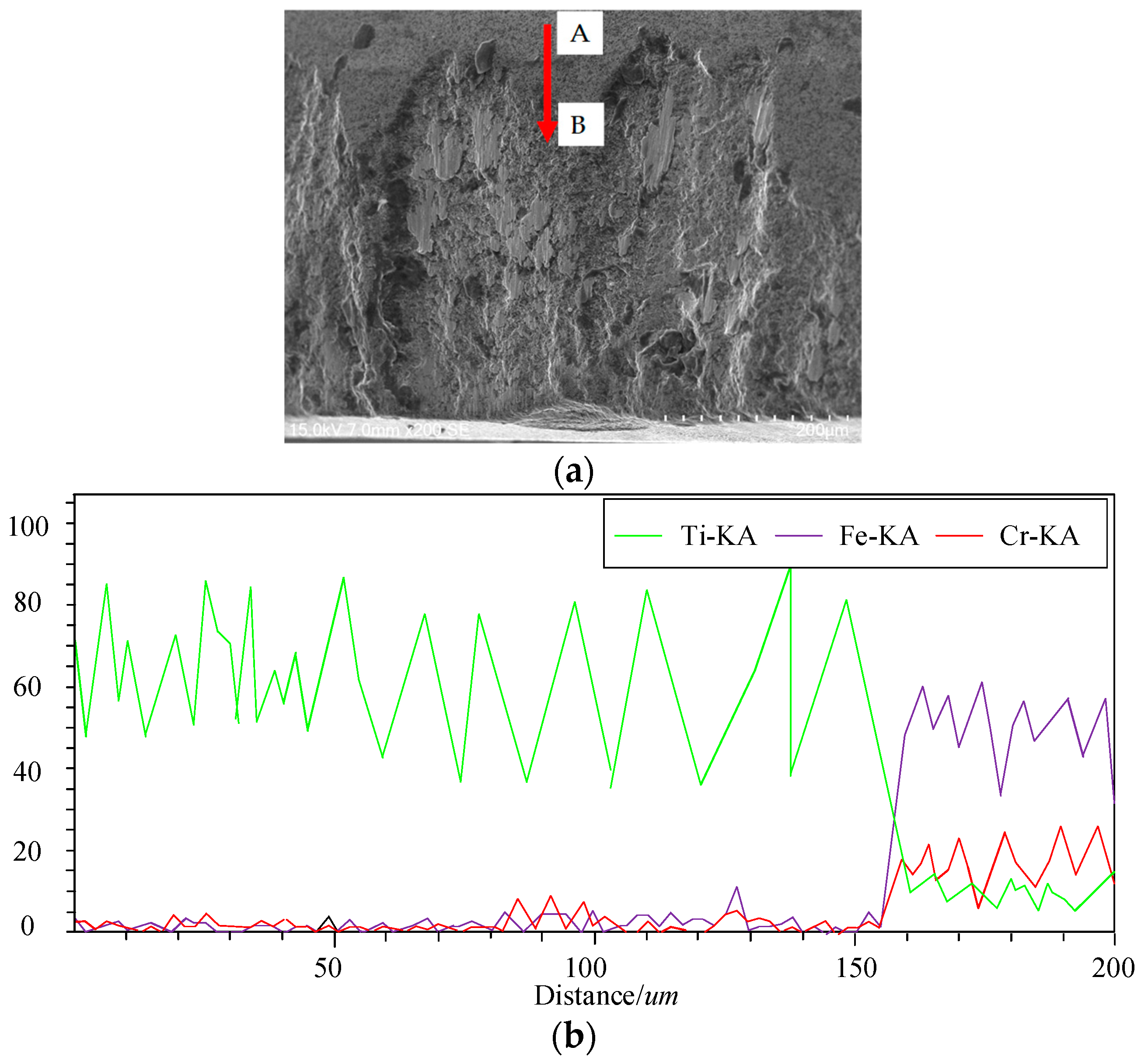

3.5. Flank Wear

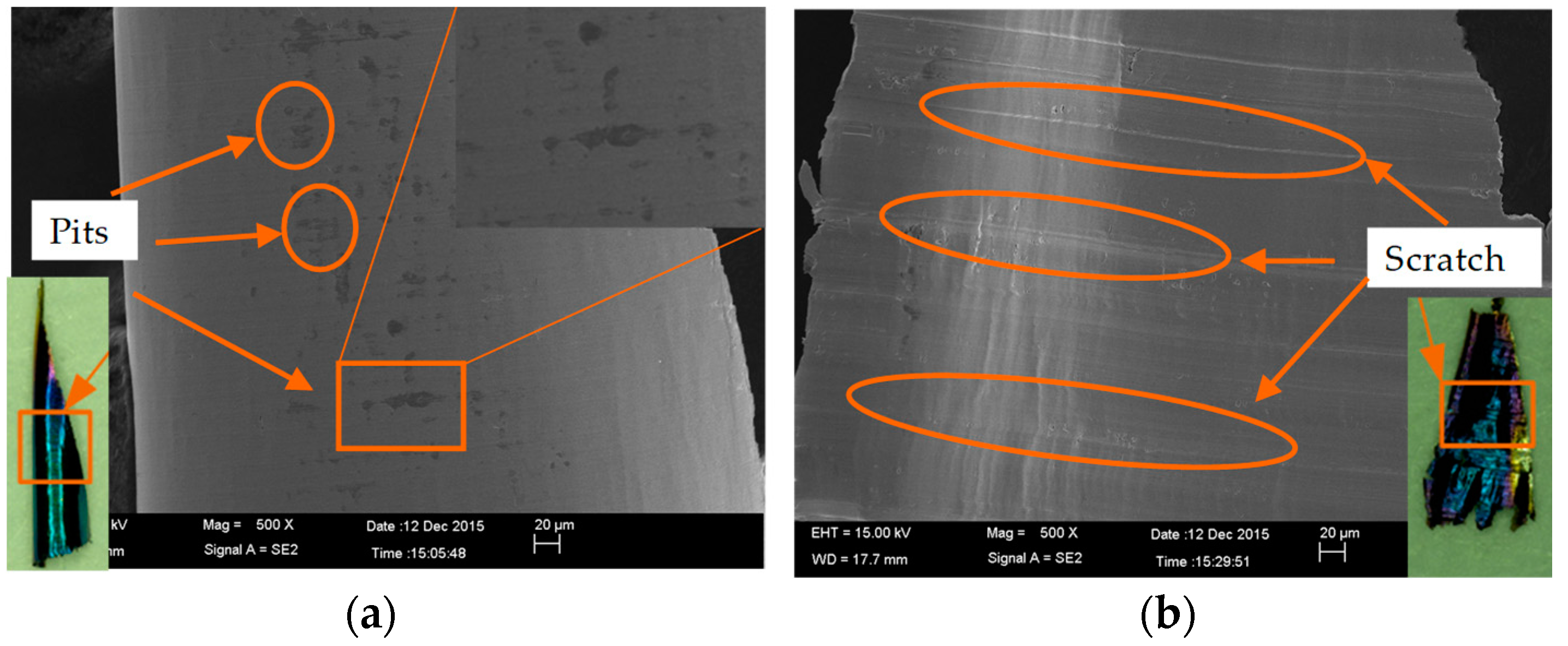

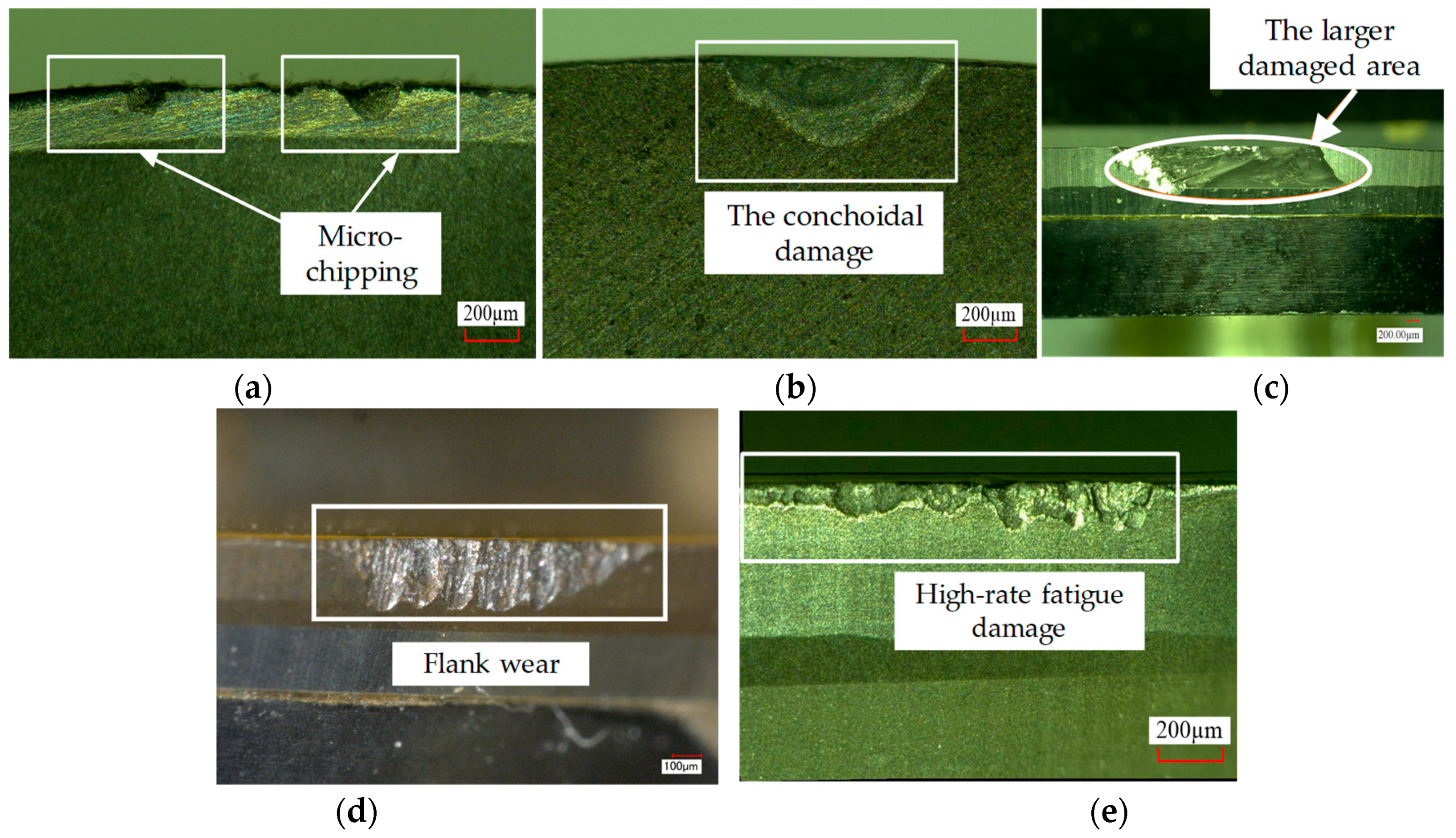

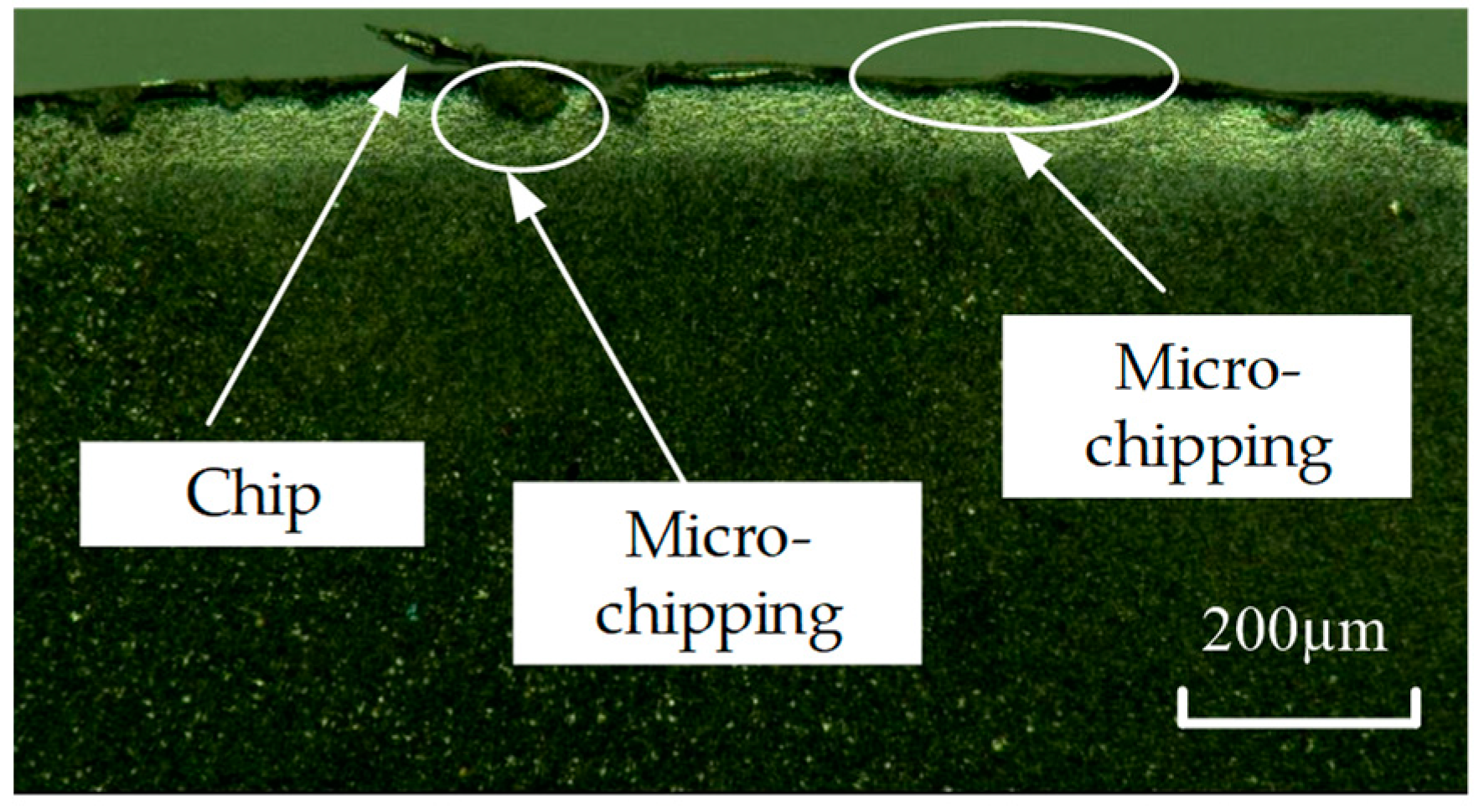

3.6. Tool Damage

4. Conclusions and Outlook

- Based on the evaluation indexes of cutting force, surface quality, chip morphology, and cutting temperature, it was concluded that the cutting performance of the PCBN tool was better than that of the coated cemented carbide tool.

- A combination of oxidation wear, adhesive wear, and diffusion wear was believed to control the flank wear of the PCBN cutting tool.

- The main failure modes of the PCBN tool in the machining of hardened steel at low speed were tool micro-chipping, and low-rate impact damage of the rake face and the flank face. The main failure modes of the PCBN tool in the machining of hardened steel at high speed were flank wear and high-rate fatigue damage.

- The PCBN tool’s life is affected by the cutting speed. When the cutting speed was greater than 150 m/min, the PCBN tool’s life was better than that of the carbide tool. Meanwhile, PCBN tools should be avoided at low cutting speeds.

- The sawtooth pitch of chip increased with the increase in cutting speed. The reason was that the increase in cutting speed made the shear slip more easily during chip formation, which led to the increase in sawtooth degree.

- When the PCBN tool was used to machine hardened steel, the cutting temperature was higher at the smaller chip thickness. The reason was that the action mechanism between the cutter and the workpiece was mainly ploughing and extrusion in the place where the chip thickness was small. Because the size of chip section was small, the excessive heat generated by ploughing and extrusion could not be discharged in time and, thus, the chip color was deepened.

Author Contributions

Funding

Conflicts of Interest

References

- Huang, Y.; Chou, Y.K.; Liang, S.Y. CBN tool wear in hard turning: a survey on research progresses. Int. J. Adv. Manuf. Technol. 2007, 35, 443–453. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Skury, A.L.; de Azevedo, M.G.; Bobrovnitchii, G.S. Cubic boron nitride competing with diamond as a superhard engineering material—An overview. J. Mater. Res. Technol. 2013, 2, 68–74. [Google Scholar] [CrossRef]

- Xi, Y.; Zhan, H.; Rashid, R.R.; Wang, G.; Sun, S.; Dargusch, M. Numerical modeling of laser assisted machining of a beta titanium alloy. Comp. Mater. Sci. 2014, 92, 149–156. [Google Scholar] [CrossRef]

- Taylan, F.; Çolak, O.; Kayacan, M.C. Investigation of TiN coated CBN and CBN cutting tool performance in hard milling application. Strojniski Vestnik J. Mech. Eng. 2011, 57, 417–424. [Google Scholar] [CrossRef]

- Kurt, A.; Şeker, U. The effect of chamfer angle of polycrystalline cubic boron nitride cutting tool on the cutting forces and the tool stresses in finishing hard turning of AISI 52100 steel. Mater. Des. 2005, 26, 351–356. [Google Scholar] [CrossRef]

- Li, S.; Chen, T.; Qiu, C.; Wang, D.; Liu, X. Experimental investigation of high-speed hard turning by PCBN tooling with strengthened edge. Int. J. Adv. Manuf. Technol. 2017, 92, 3785–3793. [Google Scholar] [CrossRef]

- Zhou, J.M.; Walter, H.; Andersson, M.; Stahl, J.E. Effect of chamfer angle on wear of PCBN cutting tool. Int. J. Mach. Tools Manuf. 2003, 43, 301–305. [Google Scholar] [CrossRef]

- Özel, T.; Karpat, Y.; Srivastava, A. Hard turning with variable micro-geometry PcBN tools. CIRP Ann. Manuf. Technol. 2008, 57, 73–76. [Google Scholar] [CrossRef] [Green Version]

- Poulachon, G.; Bandyopadhyay, B.P.; Jawahir, I.S.; Pheulpin, S.; Seguin, E. The influence of the microstructure of hardened tool steel workpiece on the wear of PCBN cutting tools. Int. J. Mach. Tools Manuf. 2003, 43, 139–144. [Google Scholar] [CrossRef]

- Khanna, N.; Rashid RA, R.; Palanisamy, S. Experimental evaluation of the effect of workpiece heat treatments and cutting parameters on the machinability of Ti-10V-2Fe-3Al β titanium alloy using Taguchi’s design of experiments. Int. J. Mach. Mach. Mater. 2017, 19, 374–393. [Google Scholar]

- Zareena, A.R.; Rahman, M.; Wong, Y.S. Binderless CBN tools, a breakthrough for machining titanium alloys. J. Manuf. Sci. Eng. 2005, 127, 277–279. [Google Scholar] [CrossRef]

- Li, L.; Wu, M.; Liu, X.; Cheng, Y.; Yu, Y. Experimental study of the wear behavior of PCBN inserts during cutting of GH4169 superalloys under high-pressure cooling. Int. J. Adv. Manuf. Technol. 2018, 95, 1941–1951. [Google Scholar] [CrossRef]

- Pavel, R.; Marinescu, I.; Deis, M.; Pillar, J. Effect of tool wear on surface finish for a case of continuous and interrupted hard turning. J. Mater. Process. Technol. 2005, 170, 341–349. [Google Scholar] [CrossRef]

- Ko, T.J.; Kim, H.S. Surface integrity and machineability in intermittent hard turning. Int. J. Adv. Manuf. Technol. 2001, 18, 168–175. [Google Scholar] [CrossRef]

- Oliveira, A.J.; Diniz, A.E.; Ursolino, D.J. Hard turning in continuous and interrupted cut with PCBN and whisker-reinforced cutting tools. J. Mater. Process. Technol. 2009, 209, 5262–5270. [Google Scholar] [CrossRef]

- Tang, L.; Sun, Y.; Li, B.; Shen, J.; Meng, G. Wear performance and mechanisms of PCBN tool in dry hard turning of AISI D2 hardened steel. Tribol. Int. 2018, 132, 228–236. [Google Scholar] [CrossRef]

- Chen, L.; Stahl, J.E.; Zhao, W.; Zhou, J. Assessment on abrasiveness of high chromium cast iron material on the wear performance of PCBN cutting tools in dry machining. J. Mater. Process. Technol. 2018, 255, 110–120. [Google Scholar] [CrossRef]

- Gutnichenko, O.; Bushlya, V.; Zhou, J.; Ståhl, J.E. Tool wear and machining dynamics when turning high chromium white cast iron with pcBN tools. Wear 2017, 390, 253–269. [Google Scholar] [CrossRef]

- Gopalsamy, B.M.; Mondal, B.; Ghosh, S.; Arntz, K.; Klocke, F. Experimental investigations while hard machining of DIEVAR tool steel (50 HRC). Int. J. Adv. Manuf. Technol. 2010, 51, 853–869. [Google Scholar] [CrossRef]

- Wojciechowski, S.; Twardowski, P. Tool Life and Process Dynamics in High Speed Ball End Milling of Hardened Steel. Procedia CIRP 2012, 1, 289–294. [Google Scholar] [CrossRef] [Green Version]

- Okada, M.; Hosokawa, A.; Tanaka, R.; Ueda, T. Cutting performance of PVD-coated carbide and CBN tools in hardmilling. Int. J. Mach. Tools Manuf. 2011, 51, 127–132. [Google Scholar] [CrossRef]

- Elbestawi, M.A.; Chen, L.; Becze, C.E.; El-Wardany, T.I. High-Speed Milling of Dies and Molds in Their Hardened State. CIRP Ann. Manuf. Technol. 1997, 46, 57–62. [Google Scholar] [CrossRef]

- Boing, D.; Schroeter, R.B.; de Oliveira, A.J. Three-dimensional wear parameters and wear mechanisms in turning hardened steels with PCBN tools. Wear 2018, 398, 69–78. [Google Scholar] [CrossRef]

- Luo, S.Y.; Liao, Y.S.; Tsai, Y.Y. Wear characteristics in turning high hardness alloy steel by ceramic and CBN tools. J. Mater. Process. Technol. 1999, 88, 114–121. [Google Scholar] [CrossRef]

- Saketi, S.; Sveen, S.; Gunnarsson, S.; M’Saoubi, R.; Olsson, M. Wear of a high cBN content PCBN cutting tool during hard milling of powder metallurgy cold work tool steels. Wear 2015, 332, 752–761. [Google Scholar] [CrossRef]

- Cui, X.; Guo, J.; Zhao, J.; Yan, Y. Analysis of PCBN tool failure mechanisms in face milling of hardened steel using damage equivalent stress. Int. J. Adv. Manuf. Technol. 2015, 80, 1985–1994. [Google Scholar] [CrossRef]

- Rashid, R.R.; Palanisamy, S.; Sun, S.; Dargusch, M. A case-study on the mechanism of flank wear during laser-assisted machining of a titanium alloy. Int. J. Mach. Mach. Mater. 2017, 19, 538–553. [Google Scholar] [CrossRef]

- Venkatesh, V.C.; Zhou, D.Q.; Xue, W.; Quinto, D.T. A study of chip surface characteristics during the machining of steel. CIRP Ann. 1993, 42, 631–636. [Google Scholar] [CrossRef]

- Ning, Y.; Rahman, M.; Wong, Y.S. Investigation of chip formation in high speed end milling. J. Mater. Process. Technol. 2001, 113, 360–367. [Google Scholar] [CrossRef]

- Zhang, S.; Guo, Y.B. An experimental and analytical analysis on chip morphology, phase transformation, oxidation, and their relationships in finish hard milling. Int. J. Mach. Tool. Manuf. 2009, 49, 805–813. [Google Scholar] [CrossRef]

- Xing, G. Metal Cutting Technology; China Agriculture Press: Beijing, China, 1983; pp. 6–7. [Google Scholar]

| Element | C | Cr | Mo | Si | Mn | Ni | V |

|---|---|---|---|---|---|---|---|

| % | 1.55 | 10.50 | 0.40 | ≤0.4 | ≤0.4 | 0 | 0.25 |

| Density (g/cm3) | Thermal Conductivity (W/(m∙K)) | Specific Heat (J/(g∙K)) | Line Expansion Coefficient (K−1) | Elasticity Modulus (GPa) |

|---|---|---|---|---|

| 7.70 | 20.0 | 0.46 | 1.12 × 10−5 | 223 |

| Coating Film | Hardness (HV) | Surface Roughness Rz (μm) | Film Thickness (μm) | Thermal Effusivity J/(s0.5 m2 K) | Oxidizing Temperature (°C) |

|---|---|---|---|---|---|

| TiAlN | 4353 | 0.71 | 2.9 | 3027 | 800 |

| Base Materials | Rockwell Hardness (HRA) | Young’s Modulus × 104 (kg/mm2) | Thermal Conductivity k (W/m∙K) at 20/500/900 °C | Thermal Diffusivity a × 106 (m2/s) at 20/500/900 °C |

|---|---|---|---|---|

| K10 | 91.1 | 6.4 | 91.7/74.4/68.1 | 31.9/18.9/15.0 |

| Test | Cutting Speed (m/min) | Feed per Tooth (mm/tooth) | Axial Depth of Cut (mm) | Radial Depth of Cut (mm) |

|---|---|---|---|---|

| 1 | 50, 150, 250, 350 | 0.05 | 0.05 | 0.3 |

| 2 | 250 | 0.1, 0.15, 0.2, 0.25 | 0.05 | 0.3 |

| 3 | 250 | 0.05 | 0.1, 0.15, 0.20, 0.25 | 0.3 |

| 4 | 300 | 0.15 | 0.3 | 0.3 |

| 5 | 376 | 0.1 | 0.3 | 0.3 |

| 6 | 250, 314, 376, 440, 500 | 0.25 | 0.3 | 0.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, H.; Liu, X.; Chen, Z. Cutting Performance and Wear/Damage Characteristics of PCBN Tool in Hard Milling. Appl. Sci. 2019, 9, 772. https://doi.org/10.3390/app9040772

Gao H, Liu X, Chen Z. Cutting Performance and Wear/Damage Characteristics of PCBN Tool in Hard Milling. Applied Sciences. 2019; 9(4):772. https://doi.org/10.3390/app9040772

Chicago/Turabian StyleGao, Haining, Xianli Liu, and Zhitao Chen. 2019. "Cutting Performance and Wear/Damage Characteristics of PCBN Tool in Hard Milling" Applied Sciences 9, no. 4: 772. https://doi.org/10.3390/app9040772

APA StyleGao, H., Liu, X., & Chen, Z. (2019). Cutting Performance and Wear/Damage Characteristics of PCBN Tool in Hard Milling. Applied Sciences, 9(4), 772. https://doi.org/10.3390/app9040772