Novel Liquid Transfer Active Balancing System for Hollow Rotors of High-Speed Rotating Machinery

Abstract

:Featured Application

Abstract

1. Introduction

2. Operating Principle of the Active Balancing System

2.1. Balancing System

2.2. Balance Actuator

2.3. Balancing Principle

3. Performance Analysis of Balance Actuator

3.1. Balancing Velocity

3.2. Balancing Accuracy

3.3. Effect on Rotor Dynamics

4. Feature Extraction and Control Methods

4.1. Monitoring and Control Program

4.2. Feature Extraction

4.2.1. Tracking-Filter Method

4.2.2. Cross-Power Spectrum Method

4.2.3. Simulation

4.3. Control Program

5. Balancing Experiments

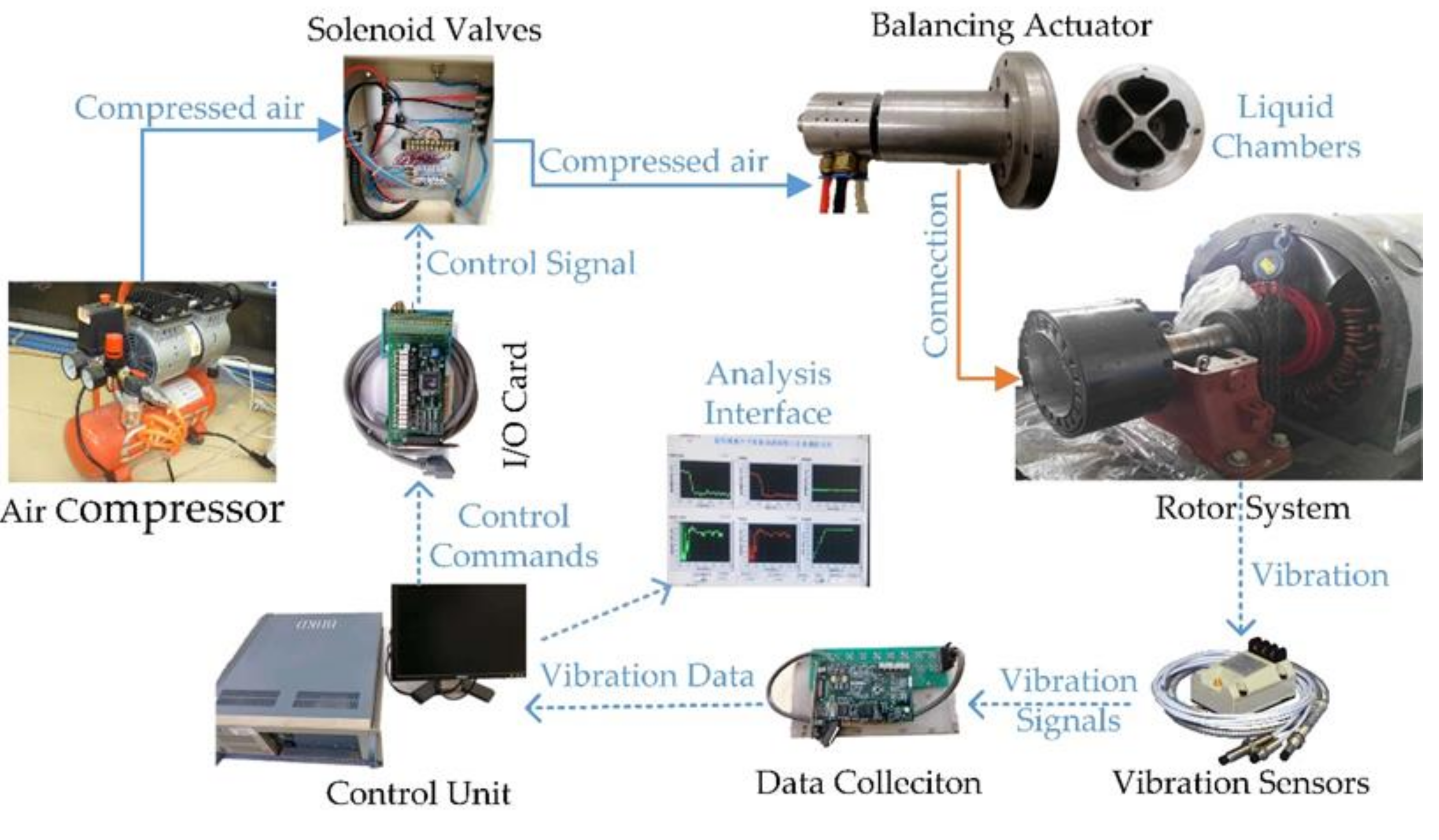

5.1. Introduction of the Experimental Devices

5.2. Balancing Experiments and Results

6. Conclusions

7. Patents

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| x(t) | initial vibration signal | B | depth of liquid chamber |

| f0 | working frequency of the rotor | l | length of connecting tube |

| ω0 | angular speed of the rotor | d | equivalent diameter of connecting tube |

| A0 | amplitude of unbalance vibration | ρ | density of balance liquid |

| φ0 | phase of unbalance vibration | ν | kinematic viscosity of balance liquid |

| Cxy | cross-correlation function | V | volume of liquid chamber |

| Pxy | cross power spectral function | Mmin | minimum amount of mass change |

| u | balancing velocity | dU/dm | linear coefficient of mass change |

| p0 | pressure of compressed air | ΔUmin | minimum amount of balance capacity |

| k | drag coefficient in connecting tube | Uper | permissible residual imbalance |

References

- Zhang, S.; Wang, Y.; Zhang, Z. Online Dynamic Balance Technology for High Speed Spindle Based on Gain Parameter Adaption and Scheduling Control. Appl. Sci. 2018, 8, 917. [Google Scholar] [CrossRef]

- Levecque, N.; Mahfoud, J.; Violette, D.; Ferraris, G.; Dufour, R. Vibration reduction of a single cylinder reciprocating compressor based on multi-stage balancing. Mech. Mach. Theory 2011, 46, 1–9. [Google Scholar] [CrossRef]

- Kang, Y.; Lin, T.W.; Chang, Y.J. Optimal balancing of flexible rotors by minimizing the condition number of influence coefficients. Mech. Mach. Theory 2008, 43, 891–908. [Google Scholar] [CrossRef]

- Deepthikumar, M.B.; Sekhar, A.S.; Srikanthan, M.R. Modal balancing of flexible rotors with bow and distributed unbalance. J. Sound Vib. 2013, 24, 6216–6233. [Google Scholar] [CrossRef]

- Fang, J.C.; Wang, Y.G.; Han, B.C.; Zheng, S.Q. Field Balancing of Magnetically Levitated Rotors without Trial Weights. Sensors 2013, 13, 16000–16022. [Google Scholar] [CrossRef]

- Xu, X.B.; Chen, S. Field Balancing and Harmonic Vibration Suppression in Rigid AMB-Rotor Systems with Rotor Imbalances and Sensor Runout. Sensors 2015, 15, 21876–21897. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zheng, L.; Liu, Z. Balancing of flexible rotors without trial weights based on finite element modal analysis. J. Vib. Control 2013, 19, 461–470. [Google Scholar] [CrossRef]

- Bin, G.F.; Li, X.J.; Shen, Y.P.; Wang, W.M. Development of whole-machine high speed balance approach for turbomachinery shaft system with N+ 1 supports. Measurement 2018, 122, 368–379. [Google Scholar] [CrossRef]

- Rodrigues, D.J.; Champneys, A.R.; Friswell, M.I. Experimental investigation of a single-plane automatic balancing mechanism for a rigid rotor. J. Sound Vib. 2011, 330, 385–403. [Google Scholar] [CrossRef]

- Ishida, Y.; Matsuura, T.; Zhang, X.L. Efficiency Improvement of an Automatic Ball Balancer. ASME J. Vib. Acoust. 2012, 134, 021012. [Google Scholar] [CrossRef]

- Cho, J.; Jeong, H.; Kong, K. Analysis of Dynamic Model of a Top Loading Laundry Machine with a Hydraulic Balancer. Int. J. Precis. Eng. Manuf. 2014, 15, 1615–1623. [Google Scholar] [CrossRef]

- Mayr, J.; Spanlang, F.; Gattringer, H. Mechatronic Design of a Self-Balancing Three-Dimensional Inertia Wheel Pendulum. Mechatronics 2015, 30, 1–10. [Google Scholar] [CrossRef]

- Xu, X.B.; Chen, S.; Zhang, Y. Automatic balancing of AMB systems using plural notch filter and adptive synchronous compensation. J. Sound Vib. 2016, 374, 29–42. [Google Scholar] [CrossRef]

- Hredzak, B.; Guo, G.X. New Electromechanical Balancing Device for Active Imbalance Compensation. J. Sound Vib. 2006, 294, 737–751. [Google Scholar] [CrossRef]

- Dyer, S.W.; Ni, J.; Shi, J.J. Robust optimal influence-coefficient control of multiple-plane active rotor balancing systems. ASME J. Dyn. Syst. Meas. Control 2002, 124, 41–46. [Google Scholar] [CrossRef]

- Fan, H.; Jing, M.; Wang, R.; Liu, H.; Zhi, J. New electromagnetic ring balancer for active imbalance compensation of rotating machinery. J. Sound Vib. 2014, 333, 3837–3858. [Google Scholar] [CrossRef]

- Schmitt Company. SBS Automatic Balancing System. Available online: http://www.schmitteurope.com/Balancers/SBS-automatic.html (accessed on 20 June 2018).

- Zhang, X.N.; Liu, X.; Zhao, H. New Active Online Balancing Method for Grinding Wheel Using Liquid Injection and Free Dripping. ASME J. Vib. Acoust. 2018, 140, 031001. [Google Scholar] [CrossRef]

- Pan, X.; Wu, H.Q.; Gao, J.J.; Wang, W.M. New Liquid Transfer Active Balancing System Using Compressed Air for Grinding Machine. ASME J. Vib. Acoust. 2015, 137, 011002. [Google Scholar] [CrossRef]

- Pan, X.; Wu, H.Q.; Gao, J.J. Rotating Machinery Targeting Self-recovery Regulation System for Imbalance Vibration Fault with Liquid-transfer Active Balancing Device. Chin. J. Mech. Eng. 2015, 51, 146–152. [Google Scholar] [CrossRef]

- Jiang, Z.N.; Hu, M.H.; Feng, K.; He, Y. Weak Fault Feature Extraction Scheme for Intershaft Bearings Based on Linear Prediction and Order Tracking in the Rotation Speed Difference Domain. Appl. Sci. 2017, 7, 937. [Google Scholar] [CrossRef]

- Hao, Y.S.; Song, L.Y.; Ke, Y.L.; Wang, H.Q.; Chen, P. Diagnosis of Compound Fault Using Sparsity Promoted-Based Sparse Component Analysis. Sensors 2017, 17, 1307. [Google Scholar] [CrossRef] [PubMed]

- Qin, Y.; Mao, Y.; Tang, B. Multicomponent decomposition by wavelet modulus maxima and synchronous detection. Mech. Syst. Signal Process. 2017, 91, 57–80. [Google Scholar] [CrossRef]

- Pan, X. Research on Priciple and Methods of Pneumatic Liquid Type and Electromagnetic Ring Type Auto-Balancing Systems for High-End Machine Tools. Ph.D. Thesis, Beijing University of Chemical Technology, Beijing, China, 2015. [Google Scholar]

| Items | Values | Items | Values |

|---|---|---|---|

| Density of balance liquid | 950 kg/m3 | Central angle of each liquid chamber | 90° |

| Volume of each liquid chamber | 16 mL | Length of connecting tube | 116 mm |

| Depth of each liquid chamber | 70 mm | Equivalent diameter of connecting tube | 1.5 mm |

| Working Speed | Required Balance Level | |||

|---|---|---|---|---|

| G0.4 | G1.0 | G2.5 | G6.3 | |

| n(r/min) | Permissible residual imbalance Uper(g.mm) | |||

| 15,000 | 4.20 | 10.50 | 26.26 | 66.18 |

| Standard Deviation (μm) | Phase Error (°) | Amplitude Error (μm) | ||

|---|---|---|---|---|

| Tracking-Filter | Cross-Power | Tracking-Filter | Cross-Power | |

| 0.2 | 0.27 | 0.34 | 0.026 | 0.029 |

| 0.5 | 0.73 | 1.02 | 0.044 | 0.044 |

| 1.0 | 1.48 | 2.03 | 0.110 | 0.146 |

| Item | Maker | Model |

|---|---|---|

| Data acquisition card | NI | PCI-6280 |

| Digital I/O card | ADVANTECH | PCI-6172 |

| Spindle motor | ZYS | 170MD18Z16 |

| Control unit | BHKD | Industrial controlling computer |

| Displacement sensor | Bently | 3300 XL11 mm |

| Speed sensor | Omron | E2E-X2ME1 |

| Electromagnetic valve | SMC | Two-position solenoid valve |

| Air source | Eluan | Air compressor |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, X.; Xie, Z.; Lu, J.; Wu, H.; Gao, J.; Jiang, Z. Novel Liquid Transfer Active Balancing System for Hollow Rotors of High-Speed Rotating Machinery. Appl. Sci. 2019, 9, 833. https://doi.org/10.3390/app9050833

Pan X, Xie Z, Lu J, Wu H, Gao J, Jiang Z. Novel Liquid Transfer Active Balancing System for Hollow Rotors of High-Speed Rotating Machinery. Applied Sciences. 2019; 9(5):833. https://doi.org/10.3390/app9050833

Chicago/Turabian StylePan, Xin, Zhen Xie, Juan Lu, Haiqi Wu, Jinji Gao, and Zhinong Jiang. 2019. "Novel Liquid Transfer Active Balancing System for Hollow Rotors of High-Speed Rotating Machinery" Applied Sciences 9, no. 5: 833. https://doi.org/10.3390/app9050833

APA StylePan, X., Xie, Z., Lu, J., Wu, H., Gao, J., & Jiang, Z. (2019). Novel Liquid Transfer Active Balancing System for Hollow Rotors of High-Speed Rotating Machinery. Applied Sciences, 9(5), 833. https://doi.org/10.3390/app9050833