A Multi–Level Approach for Simulation of Storage and Respiration of Produce

Abstract

Featured Application

Abstract

1. Introduction

2. Digital Characterization of Produce Shape

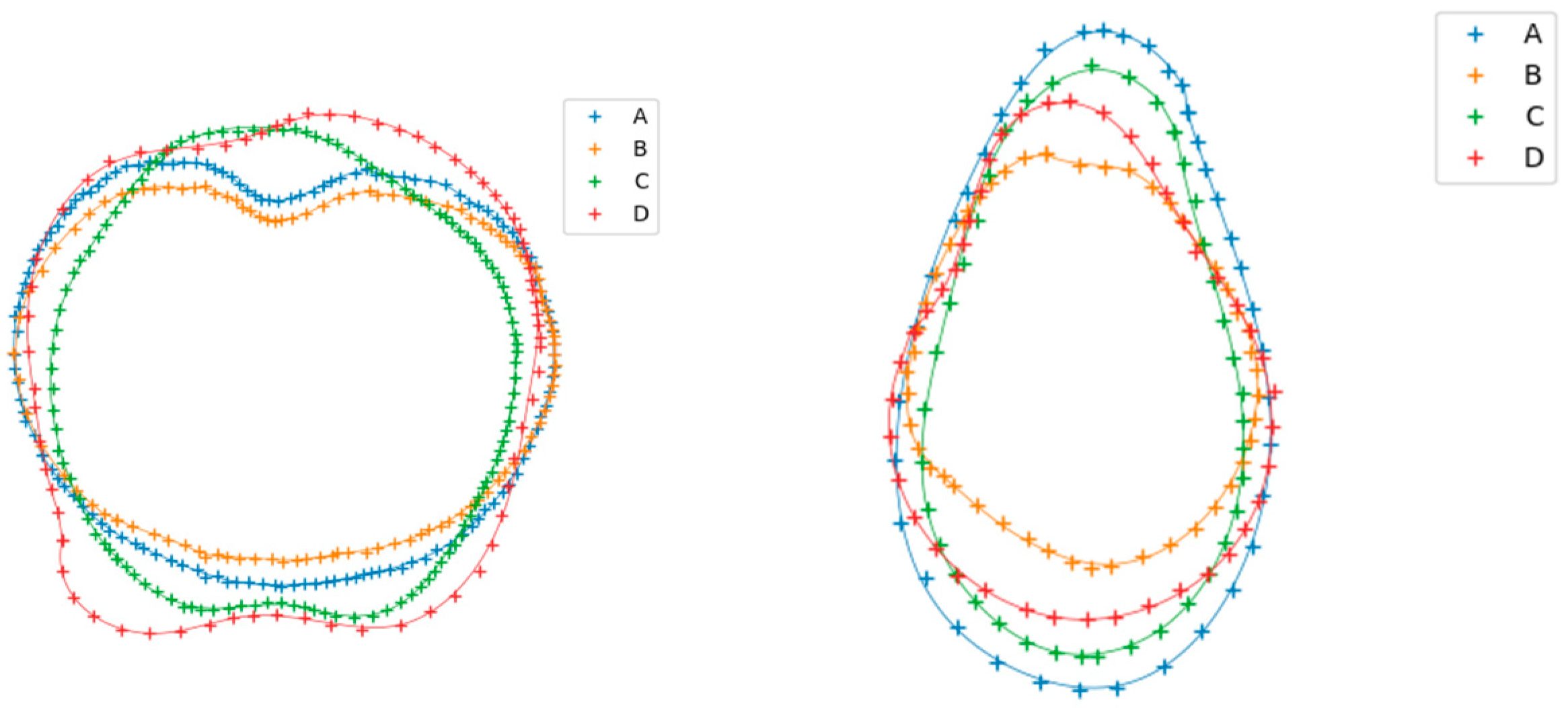

- Photographs of the fruit of interest were acquired for different random shapes. From these photographs, the outer edges were extracted as a series of points using graph digitization (see Figure 1 showing extracted points from tomatoes and avocadoes).

- Each profile was scaled uniformly such that the centerline height of each fruit was a reference length of 1 and then divided along the centerline (the axis connecting the stalk and stamen) to produce two half profiles.

- Each half profile was fitted to an appropriate spline curve using the Scipy function splprep in the python module Scipy.interpolate [28] to obtain a suitable smooth representation of the half profile, as shown in Figure 1. The spline representations were stored to be used to generate 3D geometric models.

- A random permutation of four half-profiles was selected from the set of half profiles produced in the above procedure. This was achieved by shuffling the elements of the array of assigned profile indices in the python script so that a number of unique shapes for tomatoes and avocadoes is created by selecting a different set of half-profiles each time a sample of produce is made. Four half profiles were needed to produce realistic shapes for each commodity considered.

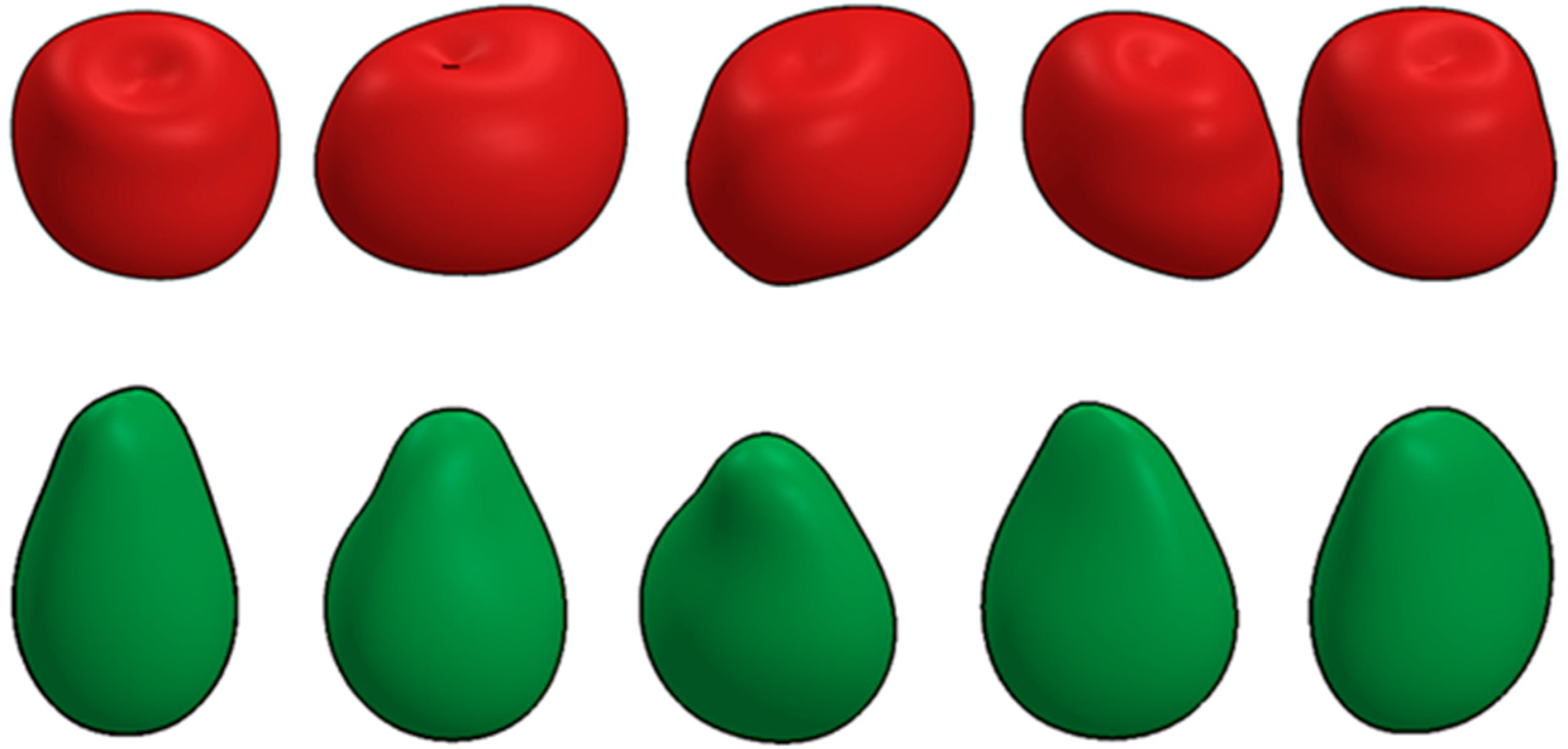

- A macro was used to sketch the selected spline profiles in SolidworksTM [29]; the sketches were spaced evenly around a common axis, which contained the centerline of each sketch.

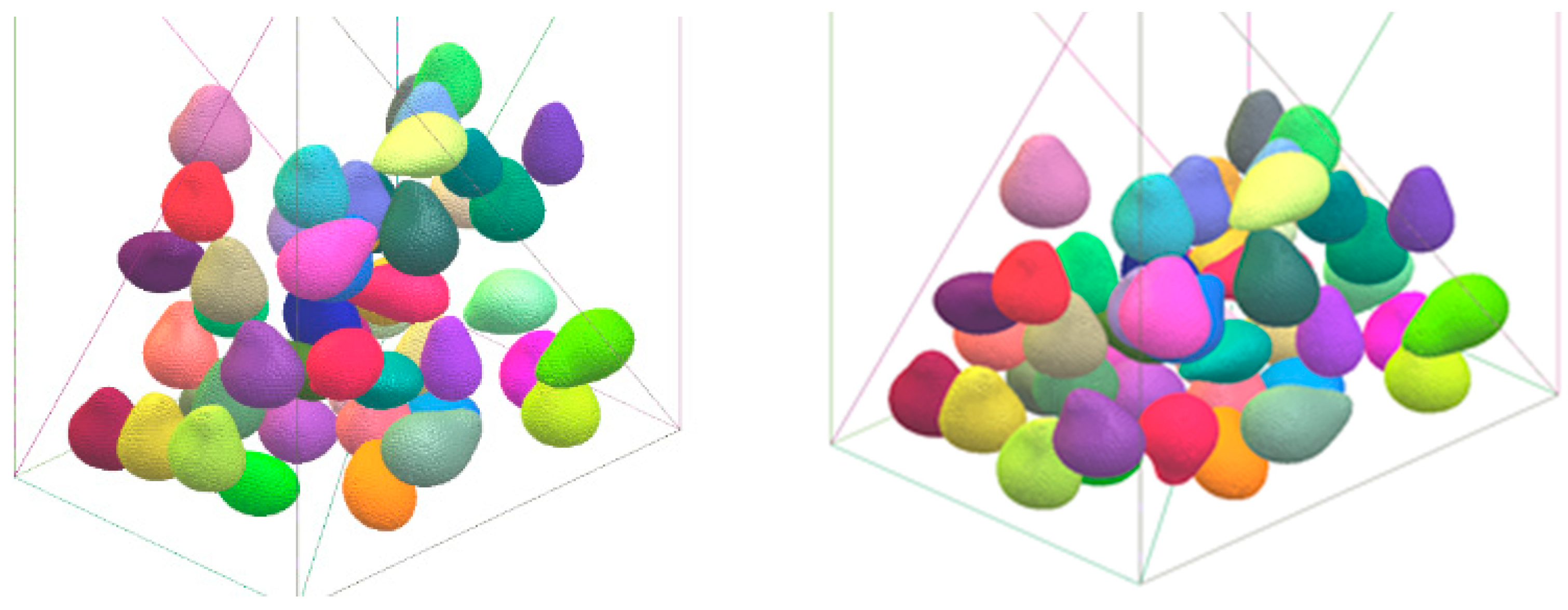

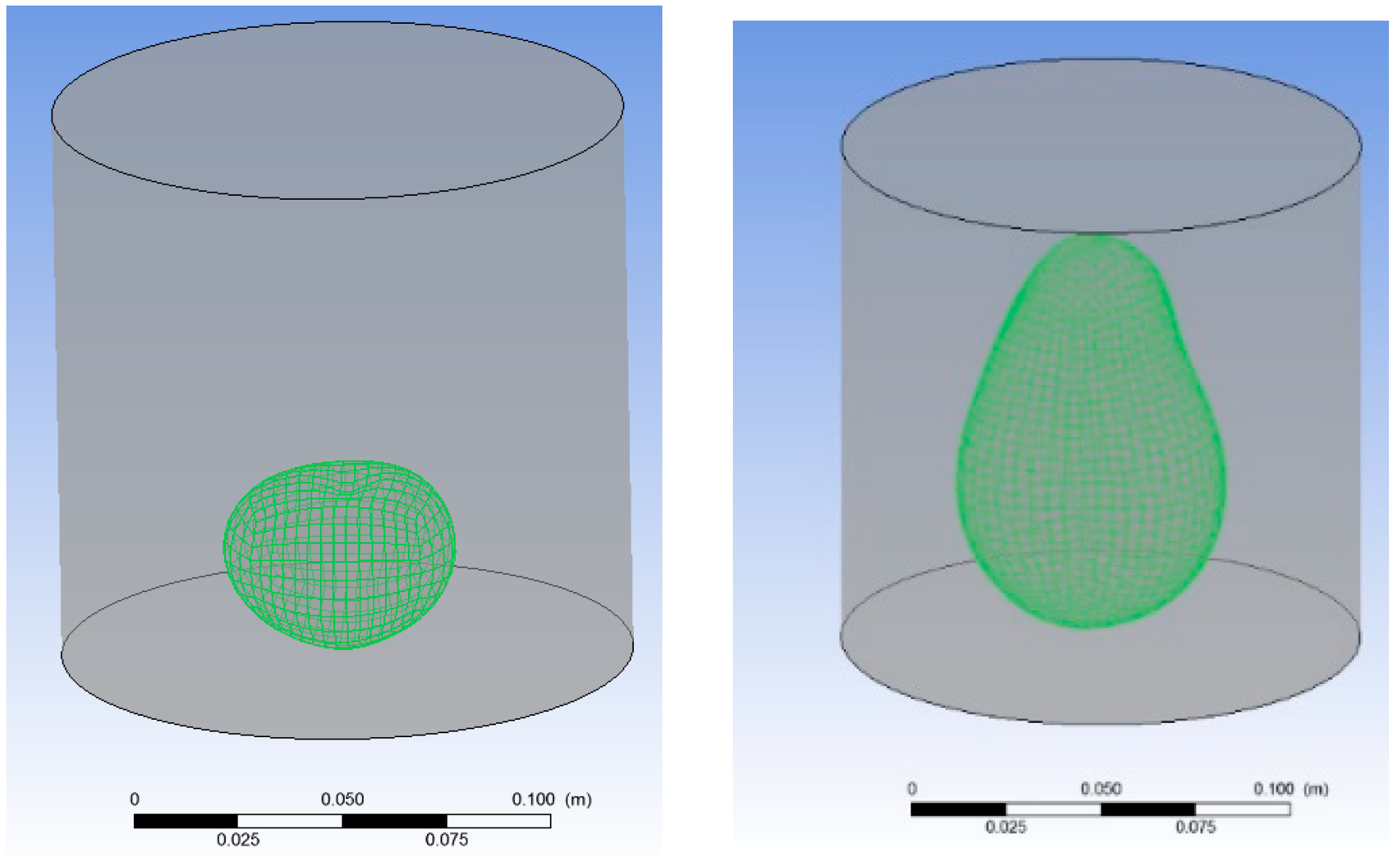

- The profile sketches were revolved about the common axis and blended together using the loft feature. The resulting digital representations of the fruits are smooth so that CFD meshing is carried out with acceptable quality. The smoothness of the surface was achieved while still exhibiting the asymmetry characteristic of real fruits, as shown in Figure 2. Each unique shape of produce was also statistically varied in size, as elaborated later, to produce a larger set of unique shapes and sizes of produce.

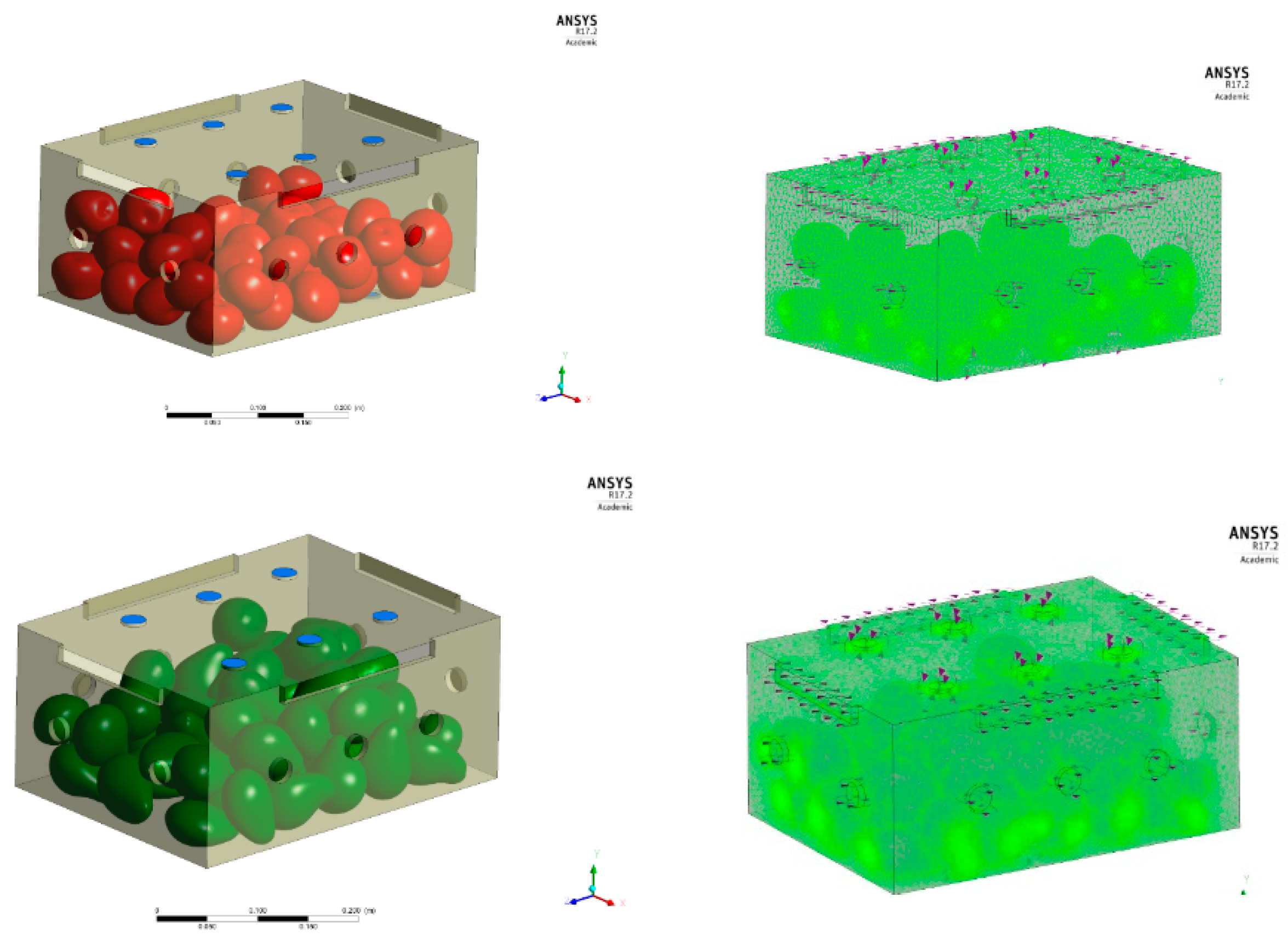

- A surface mesh for each fruit template was generated using the ANSYS meshing tool [30], in preparation for modelling the interaction of the piece of fruit with other fruits.

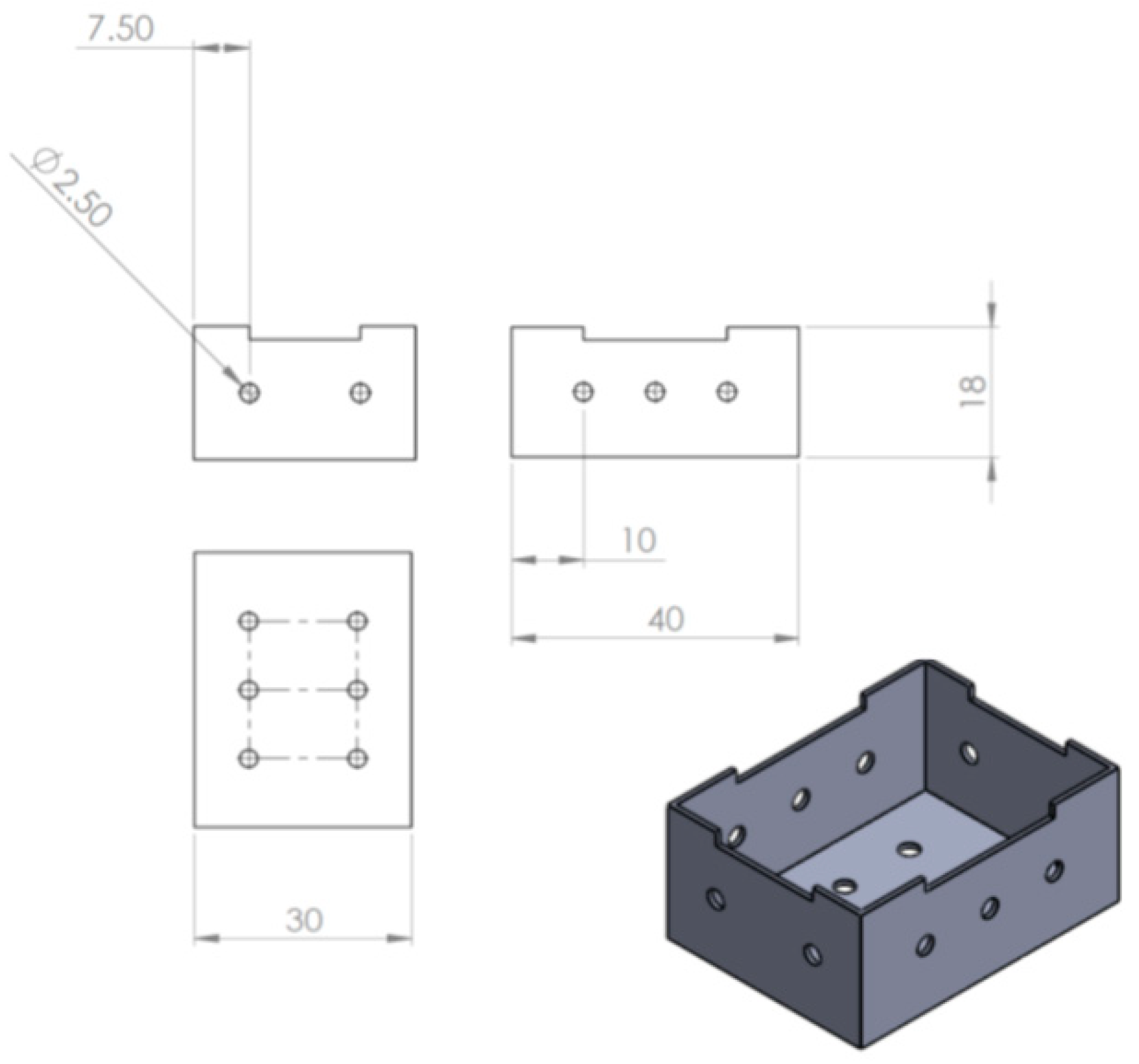

- Fifty digital pieces of fruit are generated by randomly selecting from the set of templates, and pairing them with a suitable size. For simplicity, the shape of each piece of fruit was fixed, and only the scale (in all directions) was adjusted to match the desired size. The size of each piece of fruit was selected from a uniform distribution with upper and lower bounds chosen from a suitable reference. The USDA size standards for tomatoes (Solanum lycopersicum L.) [31] were utilized where the dimension range was 5.4–7 cm. For avocadoes, based on an Ontario grocery store purchase of Hass avocadoes, the larger dimension was 7–12 cm in size and the smaller size was 5–7 cm in size.

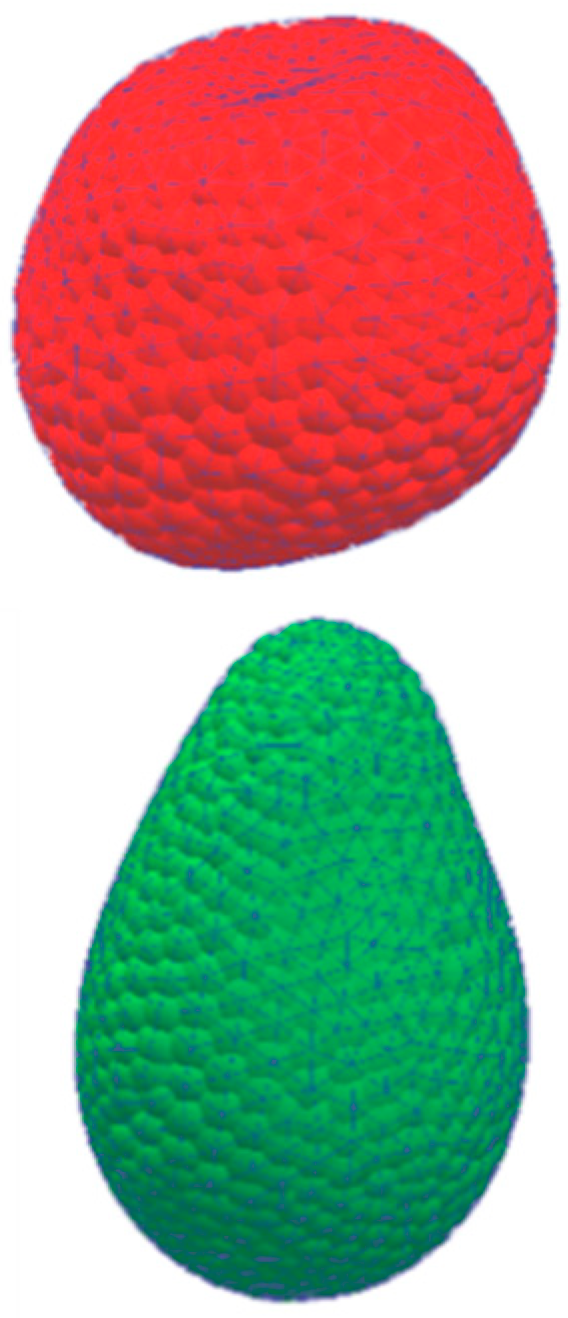

- Using the Discrete Element Method (DEM) open source tool YADE [12], each piece of fruit was modelled as a rigid clump (union) of spheres. The spheres in each clump were placed near the nodes of the surface mesh, such that the surface of the clump yields a visually acceptable approximation of the surface mesh. Refer to Figure 4 for a depiction of the clump-of-spheres approximation of the fruits, and an illustration of the surface mesh used to smooth the shapes.

- The digitally-generated pieces of fruit were placed at random locations within a short rectangular column of the same cross-sectional dimensions as the box, but taller to accommodate the initial locations of the produce. Initial placement of the fruit ensures that they are not overlapping. The shapes are then allowed to fall and interact naturally under the influence of gravity. As such, the digitally-generated pieces were able to change both position and orientation within the rectangular column as the simulated packing algorithm progressed. Interactions between pieces of fruit, and between the fruit and column walls, were governed by the Cundall-Strack contact law [32]. The simulation was halted when the total kinetic energy fell below a specified threshold such that the velocity of each piece of fruit was sufficiently small. Snapshots of a simulation at two different instants in time are shown in Figure 5.

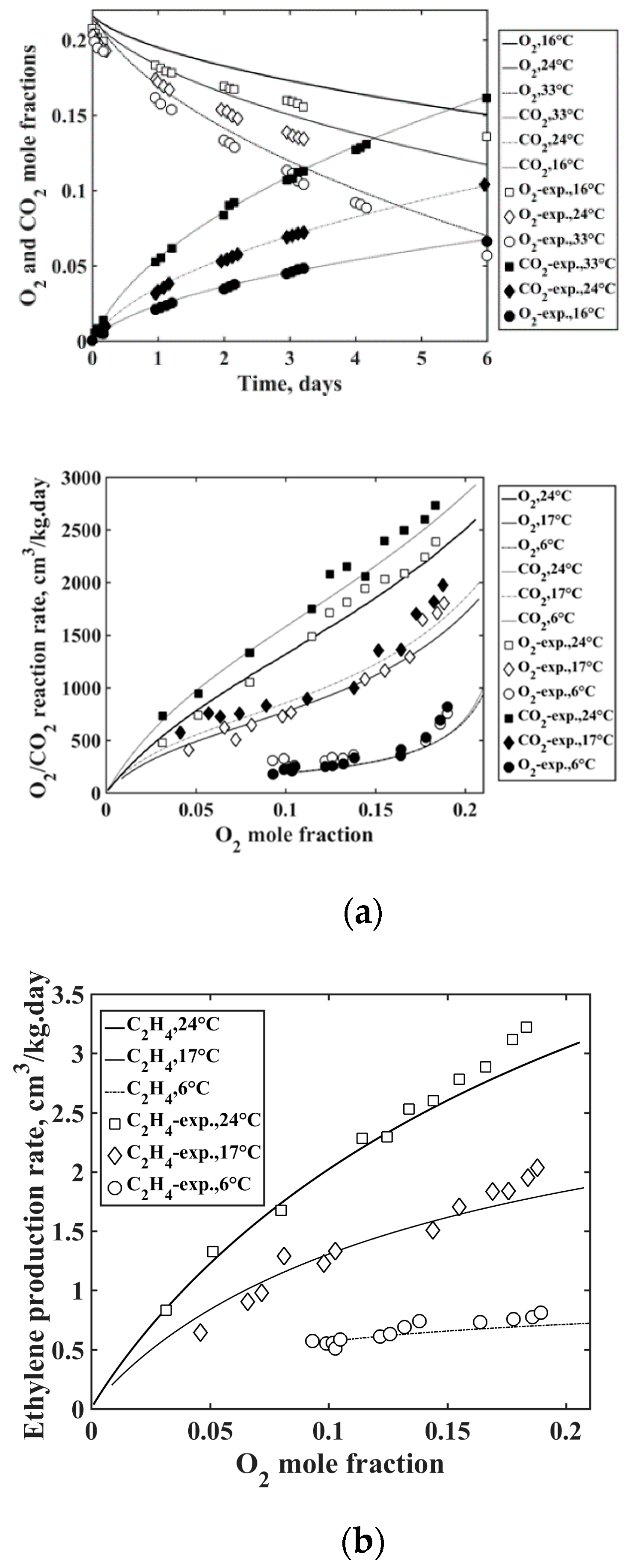

3. The Inner-Produce Gas Respiration Model

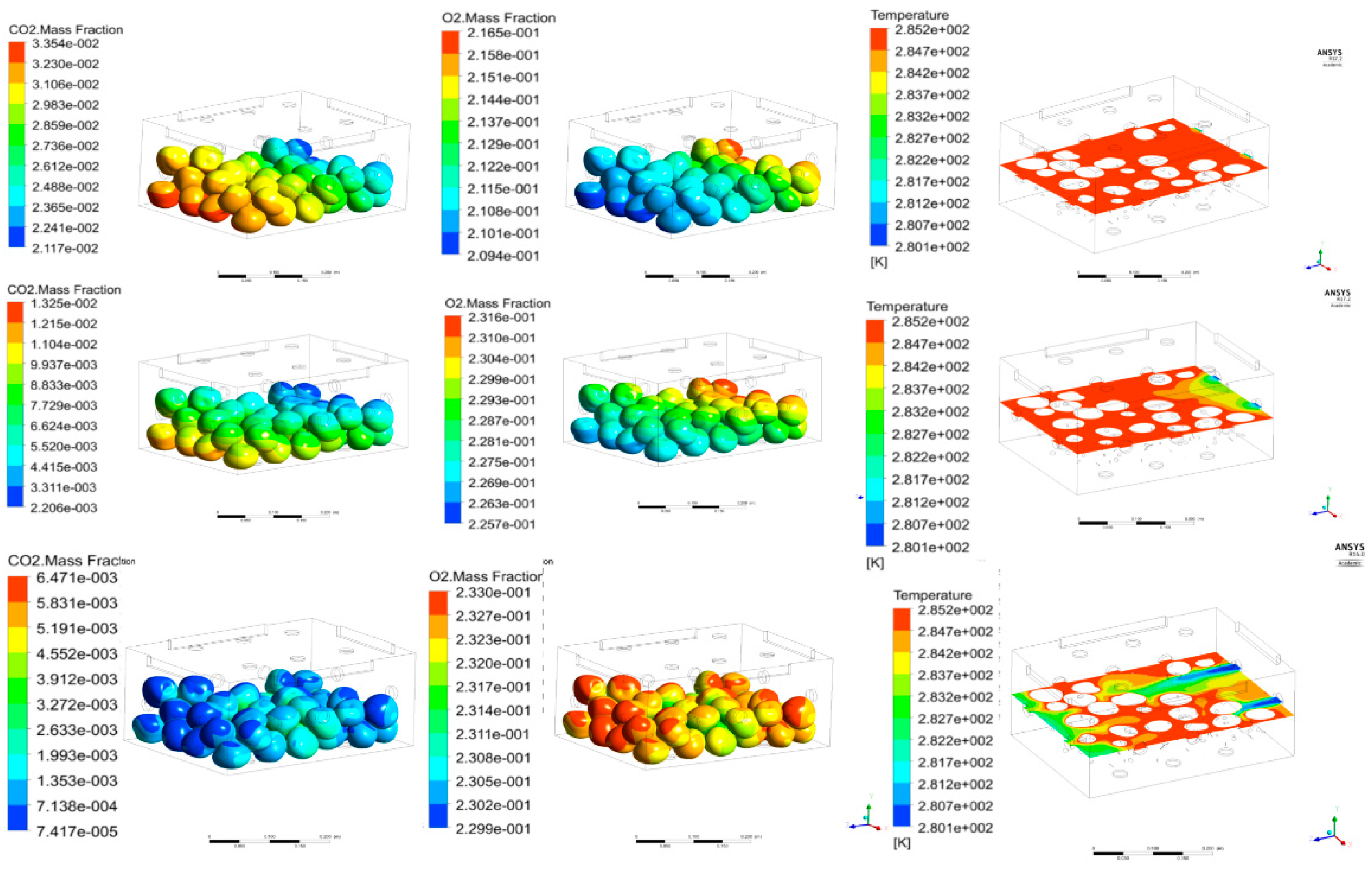

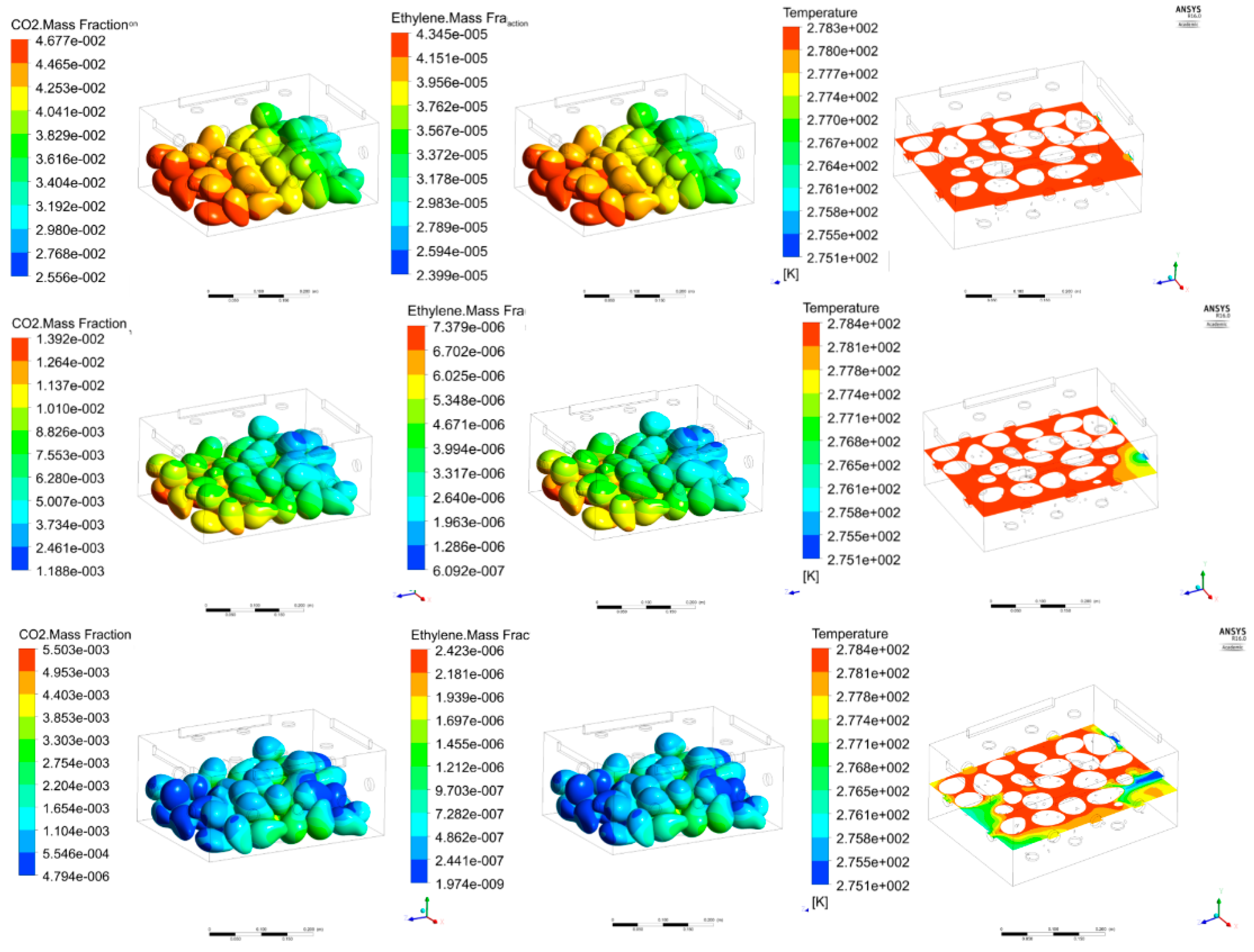

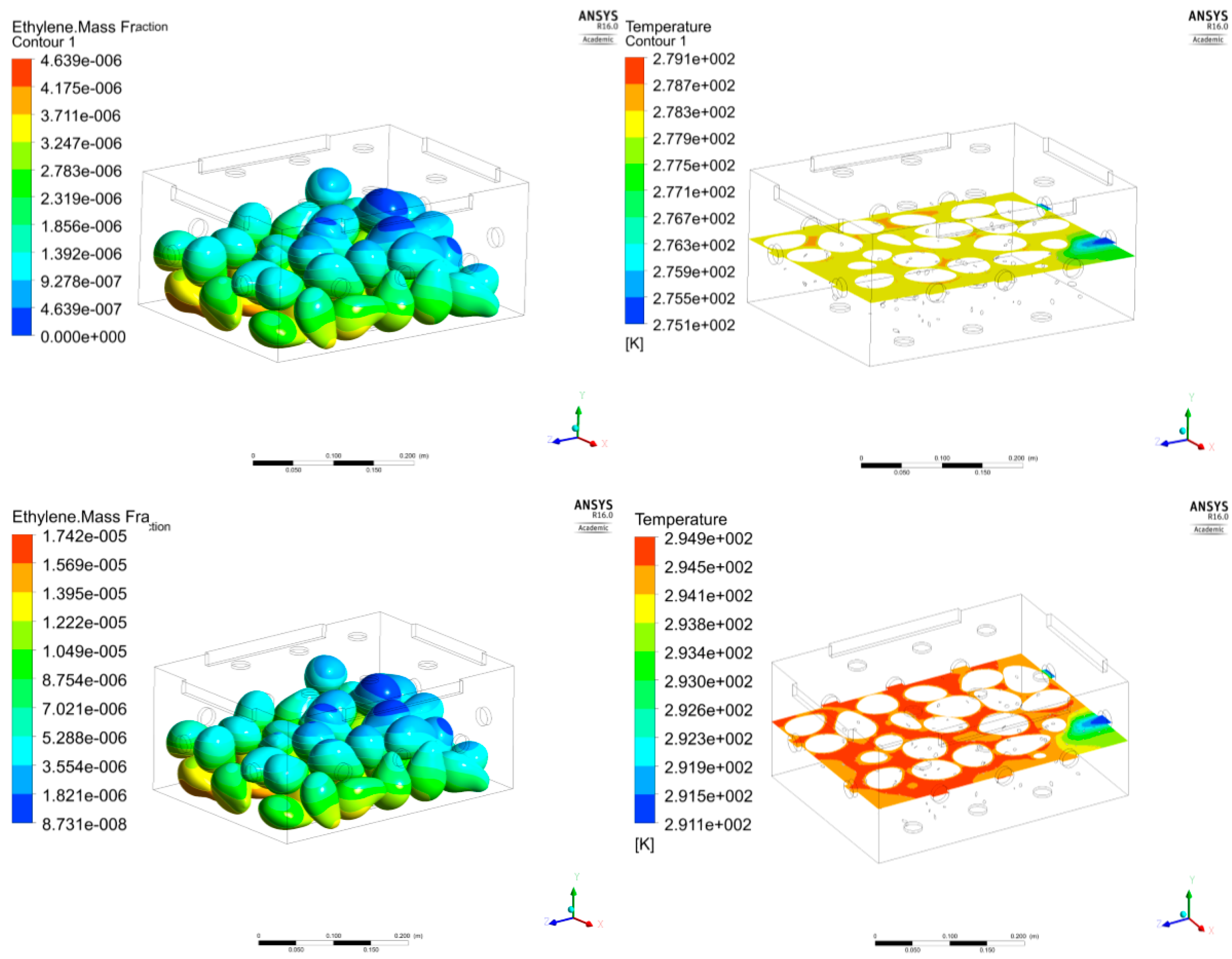

4. CFD Simulation of the REV

4.1. Computational Setup

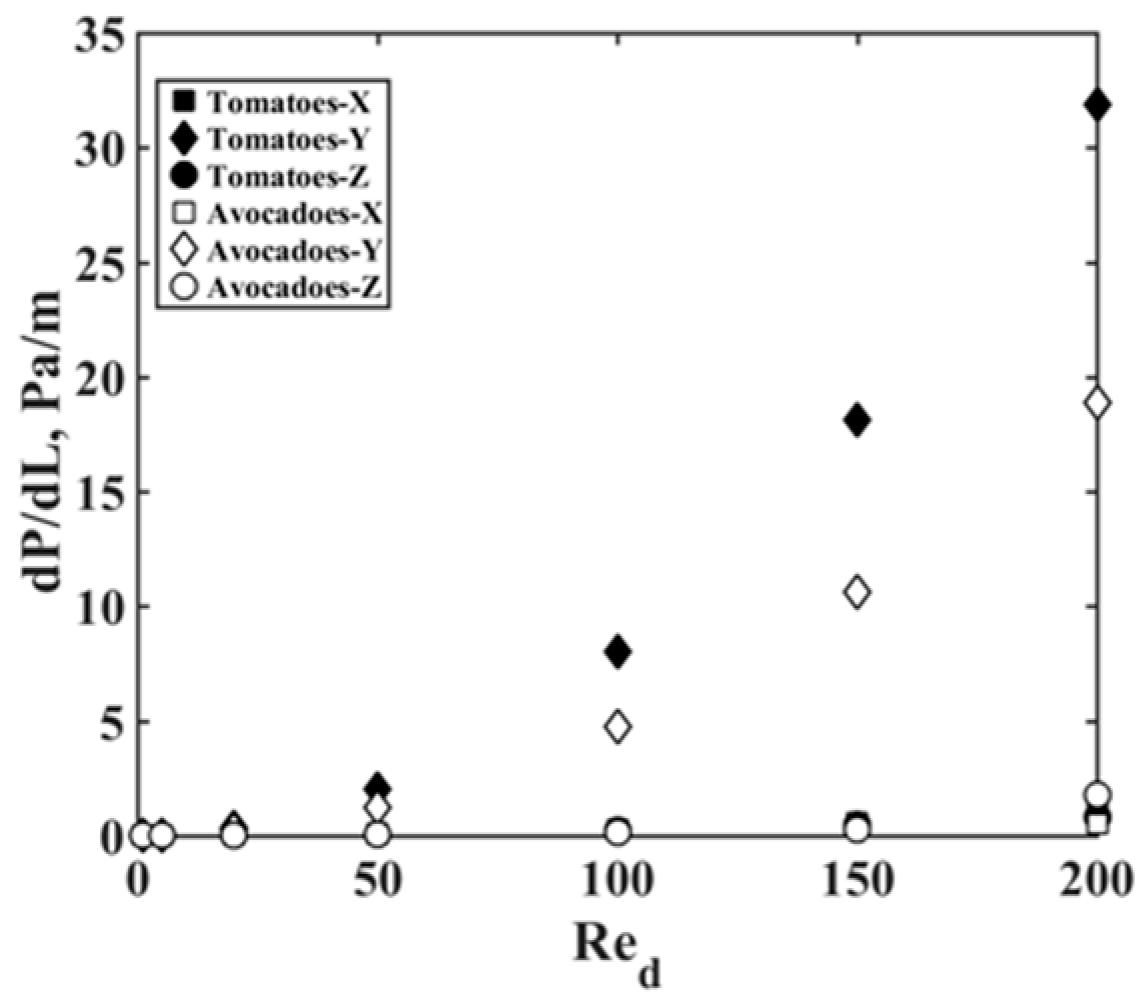

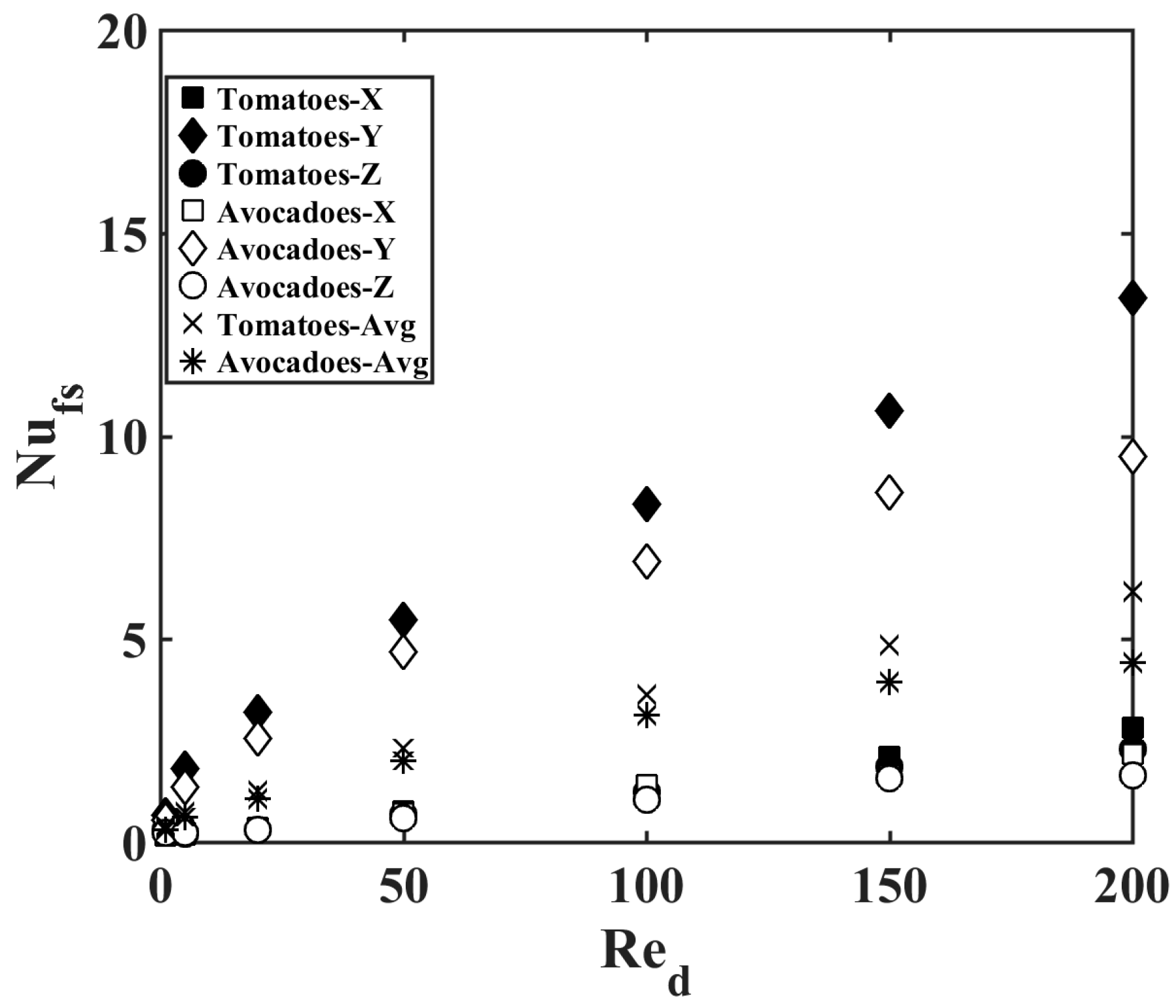

4.2. Results and Discussion

5. The Porous Continuum Model

6. Summary

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Arrhenius pre-exponential factor (takes the same unit for each individual constant it represents e.g., | |

| Interfacial specific surface area of porous media, m-1 | |

| a, b, c and m | Curve fitting constants |

| Forchheimer tensor representing inertia effects of porous media | |

| specific heat at constant pressure, J/kg·K | |

| binary diffusivion coefficient, m2/s | |

| Pore diameter, m (herein as average produce dimension) | |

| Activation energy, kJ/mol. | |

| Energy accompanying respiration (Transpiration), W | |

| Hill coefficient representing degree of cooperativity | |

| interfacial heat transfer coefficient in porous media, W/m2·K | |

| Species counter | |

| j | A counter that signify coordiantes x,y,z |

| thermal conductivity, W/m·K | |

| Darcy permeability tensor of porous media | |

| dissociation constants of the enzyme-substrate complex | |

| constants of uncompetitive inhibition for consumption of O2 and generation of CO2, respectively | |

| Molecular weight of gas component i, kg/kmol | |

| mass flow rate, kg/s | |

| Respiration mass flux of gas i, kg of i/m2s | |

| Nusselt number | |

| pressure, Pa | |

| Prandtl number | |

| Universal gas constant, kJ/mol·K | |

| Respiration rate of gas i, cm3 of i/kg·day | |

| Reynolds number | |

| temperature, K | |

| time, s | |

| fluid velocity [=()], m/s | |

| Fruit volume to surface area ratio, m | |

| mass fraction | |

| Mole fraction | |

| dynamic viscosity, N·s/m2 | |

| density of fluid mixture, kg/m3 | |

| density of individual produce (ratio between its weight and volume), kg/m3 | |

| porosity | |

| 〈 〉 | extrinsic volume-average |

| Intrinsic volume-average of phase x | |

| Subscripts and Superscripts | |

| effective property in porous media | |

| fluid | |

| at fluid/solid interface (microscopic interface) | |

| solid | |

References

- Dyck, N.J.; Straatman, A.G. A new approach to digital generation of spherical void phase porous media microstructures. Int. J. Heat Mass Trans. 2015, 81, 470–477. [Google Scholar] [CrossRef]

- Khan, F.A.; Straatman, A.G. Closure of a macroscopic turbulence and non-equilibrium turbulent heat and mass transfer model for a porous media comprised of randomly packed spheres. Int. J. Heat Mass Trans. 2016, 101, 1003–1015. [Google Scholar] [CrossRef]

- Ambaw, A.; Verboven, P.; Defraeye, T.; Tijskens, E.; Schenk, A.; Opara, U.L.; Nicolai, B.M. Porous medium modeling and parameter sensitivity analysis of 1-MCP distribution in boxes with apple fruit. J. Food Eng. 2013, 119, 13–21. [Google Scholar] [CrossRef]

- Ambaw, A.; Verboven, P.; Delele, M.A.; Defraeye, T.; Tijskens, E.; Schenk, A.; Nicolai, B.M. CFD-based analysis of 1-MCP distribution in commercial cool store rooms: Porous medium model application. Food Bioprocess Technol. 2014, 7, 1903–1916. [Google Scholar] [CrossRef]

- Ferrua, M.J.; Singh, R.P. Modeling the forced-air cooling process of fresh strawberry packages, Part I: Numerical model. Int. J. Refrig. 2009, 32, 335–348. [Google Scholar] [CrossRef]

- Castellanos, D.A.; Mendoza, R.; Gavara, R.; Herrera, A.O. Respiration and Ethylene Generation Modeling of “Hass” Avocado and Feijoa Fruits and Application in Modified Atmosphere Packaging. Int. J. Food Prop. 2017, 20, 1–17. [Google Scholar] [CrossRef]

- Yu, Q.; Thompson, B.E.; Straatman, A.G. A unit cube-based model for heat transfer and fluid flow in porous carbon foam. J. Heat Trans. 2006, 128, 352–360. [Google Scholar] [CrossRef]

- Yang, J.; Wang, Q.; Zeng, M.; Nakayama, A. Computational Study of Forced Convective Heat Transfer in Structured Packed Beds with Spherical or Ellipsoidal Particles. Chem. Eng. Sci. 2010, 65, 726–738. [Google Scholar] [CrossRef]

- Yang, J.; Wang, J.; Bu, S.; Zeng, M.; Wang, Q.; Nakayama, A. Experimental Analysis of Forced Convective Heat Transfer in Novel Structured Packed Beds of Particles. Chem. Eng. Sci. 2012, 71, 126–137. [Google Scholar] [CrossRef]

- Soulaine, C. Direct Numerical Simulation in Fully Saturated Porous Media. Available online: https://web.stanford.edu/~csoulain/PORE_SCALE/Chap2.pdf (accessed on 10 December 2017).

- Buchgraber, M.; Al-Dossary, M.; Ross, C.M.; Kovscek, A.R. Creation of a Dual-Porosity Micromodel for Pore-Level Visualization of Multiphase Flow. J. Pet. Sci. Eng. 2012, 86, 27–38. [Google Scholar] [CrossRef]

- Smilauer, V.; Chareyre, B. Yade dem Formulation. Smilauer, V., Ed.; Yade Documentation. 2010. Available online: www.yade-dem.org (accessed on 3 November 2016).

- Lencki, R.W.; Zhu, M.; Chu, C.L. Comparison of unsteady-and steady-state methods for produce respiration rate determination: 1. Model development and validation. Postharvest Biol. Technol. 2004, 31, 229–238. [Google Scholar] [CrossRef]

- Waghmare, R.B.; Mahajan, P.V.; Annapure, U.S. Modelling the effect of time and temperature on respiration rate of selected fresh-cut produce. Postharvest Biol. Technol. 2013, 80, 25–30. [Google Scholar] [CrossRef]

- Kang, J.S.; Lee, D.S. A kinetic model for transpiration of fresh produce in a controlled atmosphere. J. Food Eng. 1998, 35, 65–74. [Google Scholar] [CrossRef]

- Sousa-Gallagher, M.J.; Mahajan, P.V.; Mezdad, T. Engineering packaging design accounting for transpiration rate: Model development and validation with strawberries. J. Food Eng. 2013, 119, 370–376. [Google Scholar] [CrossRef]

- Reid, M.S.; Rhodes, M.J.C.; Hulme, A.C. Changes in ethylene and CO2 during the ripening of apples. J. Sci. Food Agric. 1973, 24, 971–979. [Google Scholar] [CrossRef]

- Shewfelt, R.L.; Thai, C.N.; Davis, J.W. Prediction of changes in color of tomatoes during ripening at different constant temperatures. J. Food Sci. 1988, 53, 1433–1437. [Google Scholar] [CrossRef]

- Tripathi, K.; Pandey, S.; Malik, M.; Kaul, T. Fruit Ripening of Climacteric and Nonclimacteric Fruit. J. Environ. Appl. Biores. 2016, 4, 27–34. [Google Scholar]

- Klee, H.J.; Clark, D.G. Ethylene signal transduction in fruits and flowers. In Plant Hormones; Springer: Dordrecht, The Netherlands, 2010; pp. 377–398. [Google Scholar]

- Iqbal, T.; Rodrigues, F.A.; Mahajan, P.V.; Kerry, J.P. Mathematical modeling of the influence of temperature and gas composition on the respiration rate of shredded carrots. J. Food Eng. 2009, 91, 325–332. [Google Scholar] [CrossRef]

- Fonseca, S.C.; Oliveira, F.A.; Brecht, J.K. Modelling respiration rate of fresh fruits and vegetables for modified atmosphere packages: A review. J. Food Eng. 2002, 52, 99–119. [Google Scholar] [CrossRef]

- Finnegan, E.; Mahajan, P.V.; O’Connell, M.; Francis, G.A.; O’Beirne, D. Modelling respiration in fresh-cut pineapple and prediction of gas permeability needs for optimal modified atmosphere packaging. Postharvest Biol. Technol. 2013, 79, 47–53. [Google Scholar] [CrossRef]

- Paull, R.E.; Chen, N.J. Heat treatment and fruit ripening. Postharvest Bioll. Technol. 2000, 21, 21–37. [Google Scholar] [CrossRef]

- Defraeye, T.; Cronjé, P.; Verboven, P.; Opara, U.L.; Nicolai, B. Exploring ambient loading of citrus fruit into reefer containers for cooling during marine transport using computational fluid dynamics. Postharvest Biol. Technol. 2015, 108, 91–101. [Google Scholar] [CrossRef]

- Mebatsion, H.K.; Boudon, F.; Godin, C.; Pradal, C.; Génard, M.; Goz-Bac, C.; Bertin, N. A novel profile based model for virtual representation of quasi-symmetric plant organs. Comput. Electron. Agric. 2011, 75, 113–124. [Google Scholar] [CrossRef]

- Rogge, S.; Beyene, S.D.; Herremans, E.; Hertog, M.L.; Defraeye, T.; Verboven, P.; Nicolai, B.M. A geometrical model generator for quasi-axisymmetric biological products. Food Bioprocess Technol. 2014, 7, 1783–1792. [Google Scholar] [CrossRef]

- Jones, E.; Oliphant, T.; Peterson, P. {SciPy}: Open Source Scientific Tools for {Python}. 2014. Available online: www.scipy.org (accessed on 20 November 2016).

- Dassault Systemes. Solidworks Educational Version 2012–2013; Dassault Systemes: Vélizy-Villacoublay, France, 2013. [Google Scholar]

- ANSYS. Workbench Meshing Tool, Volume 16.0; ANSYS: Canonsburg, PA, USA, 2015. [Google Scholar]

- United States Department of Agriculture (USDA). US Standards for Grades of Greenhouse Tomatoes; USDA, Agricultural Marketing Service: Washington, DC, USA, 2007.

- Cundall, P.A.; Strack, O.D. A discrete numerical model for granular assemblies. Geotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Elhalwagy, M.M.; Straatman, A.G. Dynamic coupling of phase-heat and mass transfer in porous media and conjugate fluid/porous domains. Int. J. Heat Mass Trans. 2017, 106, 1270–1286. [Google Scholar] [CrossRef]

- Goyette, B.; Vigneault, C.; Raghavan, V.; Charles, M.T. Hyperbaric treatment on respiration rate and respiratory quotient of tomato. Food Bioprocess Technol. 2012, 5, 3066–3074. [Google Scholar] [CrossRef]

- Liplap, P.; Vigneault, C.; Rennie, T.J.; Boutin, J.; Raghavan, G.V. Method for determining the respiration rate of horticultural produce under hyperbaric treatment. Food Bioprocess Technol. 2014, 7, 2461–2471. [Google Scholar] [CrossRef]

- Bhande, S.D.; Ravindra, M.R.; Goswami, T.K. Respiration rate of banana fruit under aerobic conditions at different storage temperatures. J. Food Eng. 2008, 87, 116–123. [Google Scholar] [CrossRef]

- Ho, Q.T.; Verboven, P.; Fanta, S.W.; Abera, M.K.; Retta, M.A.; Herremans, E.; Nicolaï, B.M. A multiphase pore scale network model of gas exchange in apple fruit. Food Bioprocess Technol. 2014, 7, 482–495. [Google Scholar] [CrossRef]

- Castellanos, D.A.; Cerisuelo, J.P.; Hernandez-Muñoz, P.; Herrera, A.O.; Gavara, R. Modelling the evolution of O2 and CO2 concentrations in MAP of a fresh product: Application to tomato. J. Food Eng. 2016, 168, 84–95. [Google Scholar] [CrossRef]

- Ansys CFX-Solver Theory Guide. ANSYS CFX Release 16.0; Ansys Inc.: Canonsburg, PA, USA, 2015. [Google Scholar]

- Becker, B.R.; Fricke, B.A. Simulation of moisture loss and heat loads in refrigerated storage of fruits and vegetables. New Dev. Refrig. Food Saf. Qual. 1996, 210–221. [Google Scholar]

- A. S. H. R. A. E. Handbook—Refrigeration, Chapter 21; Commodity storage requirements; Knovel: New York, NY, USA, 2010.

- Whitaker, S. Volume averaging of transport equations. Int. Ser. Adv. Fluid Mech. 1997, 13, 1–60. [Google Scholar]

- Whitaker, S. The Forchheimer equation: A theoretical development. Trans. Porous Med. 1996, 25, 27–61. [Google Scholar] [CrossRef]

- DeGroot, C.T.; Straatman, A.G. Numerical results for the effective flow and thermal properties of idealized graphite foam. J. Heat Trans. 2012, 134, 042603. [Google Scholar] [CrossRef]

- DeGroot, C.T.; Straatman, A.G. A Porous media model of Alveolar duct flow in the human lung. J. Porous Med. 2018, 21, 405–422. [Google Scholar] [CrossRef]

| Tomatoes, x-Dir. | Tomatoes, y-Dir. | Tomatoes, z-Dir. | Avocadoes, x-Dir. | Avocadoes, y-Dir. | Avocadoes, z-Dir. | |

|---|---|---|---|---|---|---|

| 7.403 × 10−4 | 1.940 × 10−3 | 7.091 × 10−4 | 9.631 × 10−4 | 3.804 × 10−4 | 1.00 × 10−4 | |

| 2.060 × 10−5 | 7.885 × 10−4 | 1.670 × 10−5 | 8.656 × 10−6 | 4.702 × 10−4 | 4.252 × 10−5 | |

| R2-fit | 9.9998 × 10−1 | 9.9998 × 10−1 | 9.9990 × 10−1 | 9.929 × 10−1 | 9.99994 × 10−1 | 9.666 × 10−1 |

| , m2 | 6.080 × 10−6 | 2.325 × 10−6 | 6.348 × 10−6 | 3.739 × 10−6 | 9.466 × 10−6 | 3.600 × 10−5 |

| , m3 | 0.699 | 16.56 | 0.579 | 0.360 | 31.14 | 5.49 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elhalwagy, M.; Dyck, N.; Straatman, A.G. A Multi–Level Approach for Simulation of Storage and Respiration of Produce. Appl. Sci. 2019, 9, 1052. https://doi.org/10.3390/app9061052

Elhalwagy M, Dyck N, Straatman AG. A Multi–Level Approach for Simulation of Storage and Respiration of Produce. Applied Sciences. 2019; 9(6):1052. https://doi.org/10.3390/app9061052

Chicago/Turabian StyleElhalwagy, Mahmoud, Nolan Dyck, and Anthony G. Straatman. 2019. "A Multi–Level Approach for Simulation of Storage and Respiration of Produce" Applied Sciences 9, no. 6: 1052. https://doi.org/10.3390/app9061052

APA StyleElhalwagy, M., Dyck, N., & Straatman, A. G. (2019). A Multi–Level Approach for Simulation of Storage and Respiration of Produce. Applied Sciences, 9(6), 1052. https://doi.org/10.3390/app9061052