Nonlinear Modeling and Flight Validation of a Small-Scale Compound Helicopter

Abstract

:1. Introduction

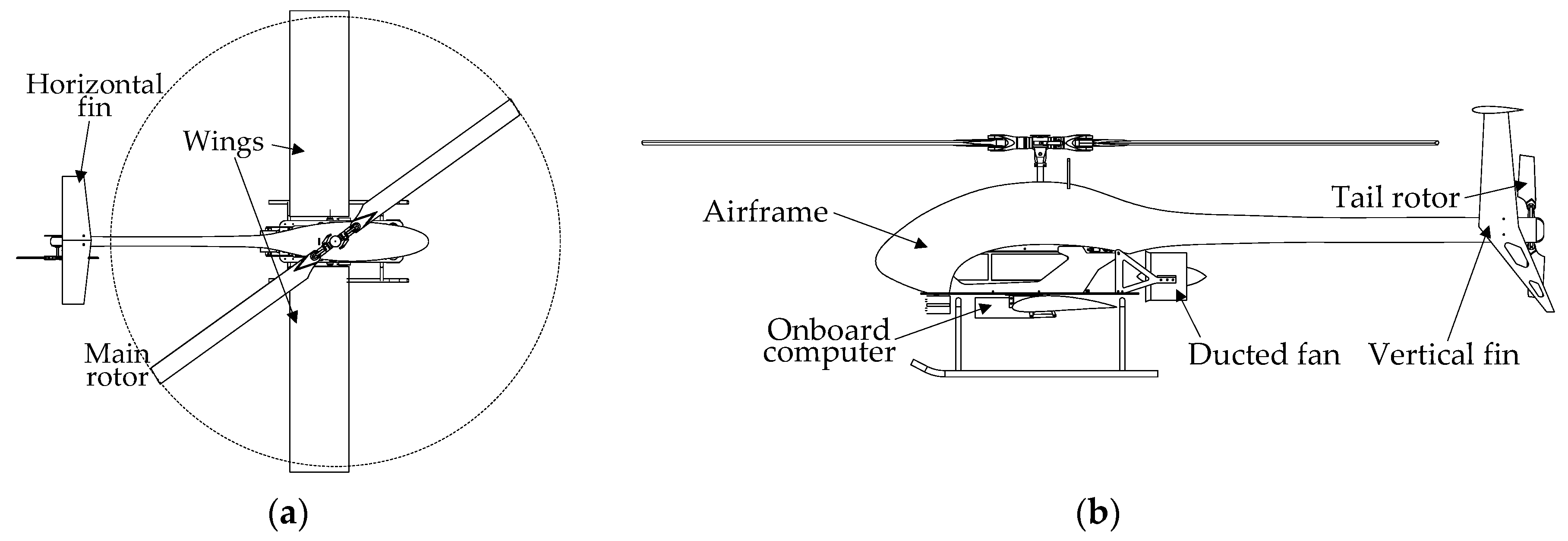

2. Small-Scale Compound Helicopter (SCH) Illustration

- Configuration D: general helicopter + ducted fan.

- Configuration WD: general helicopter + ducted fan + wings.

- Configuration WDH: general helicopter + ducted fan + wings (work also as ailerons) + elevator (on the horizontal stabilizer).

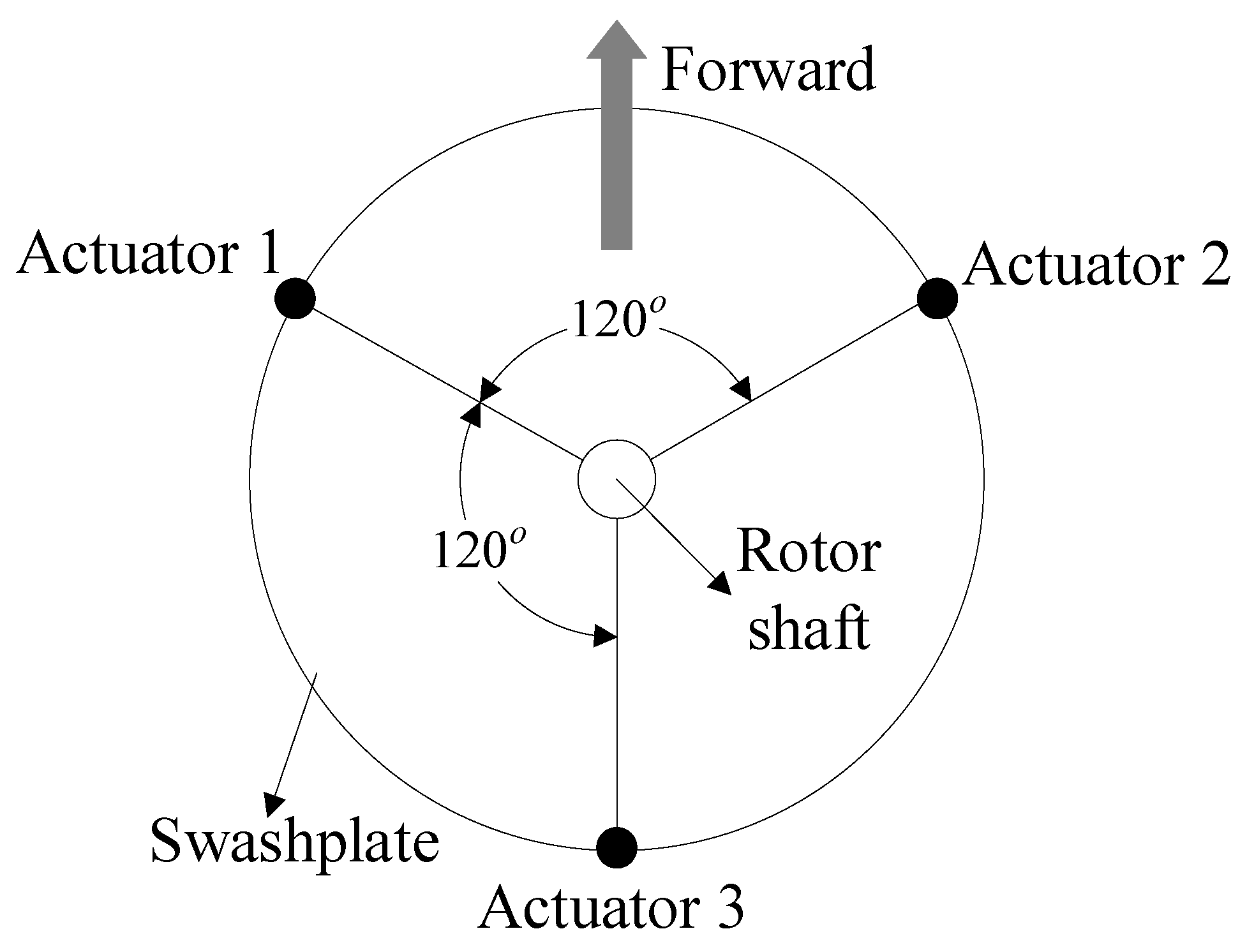

2.1. General Helicopter Components

2.2. Compound Components

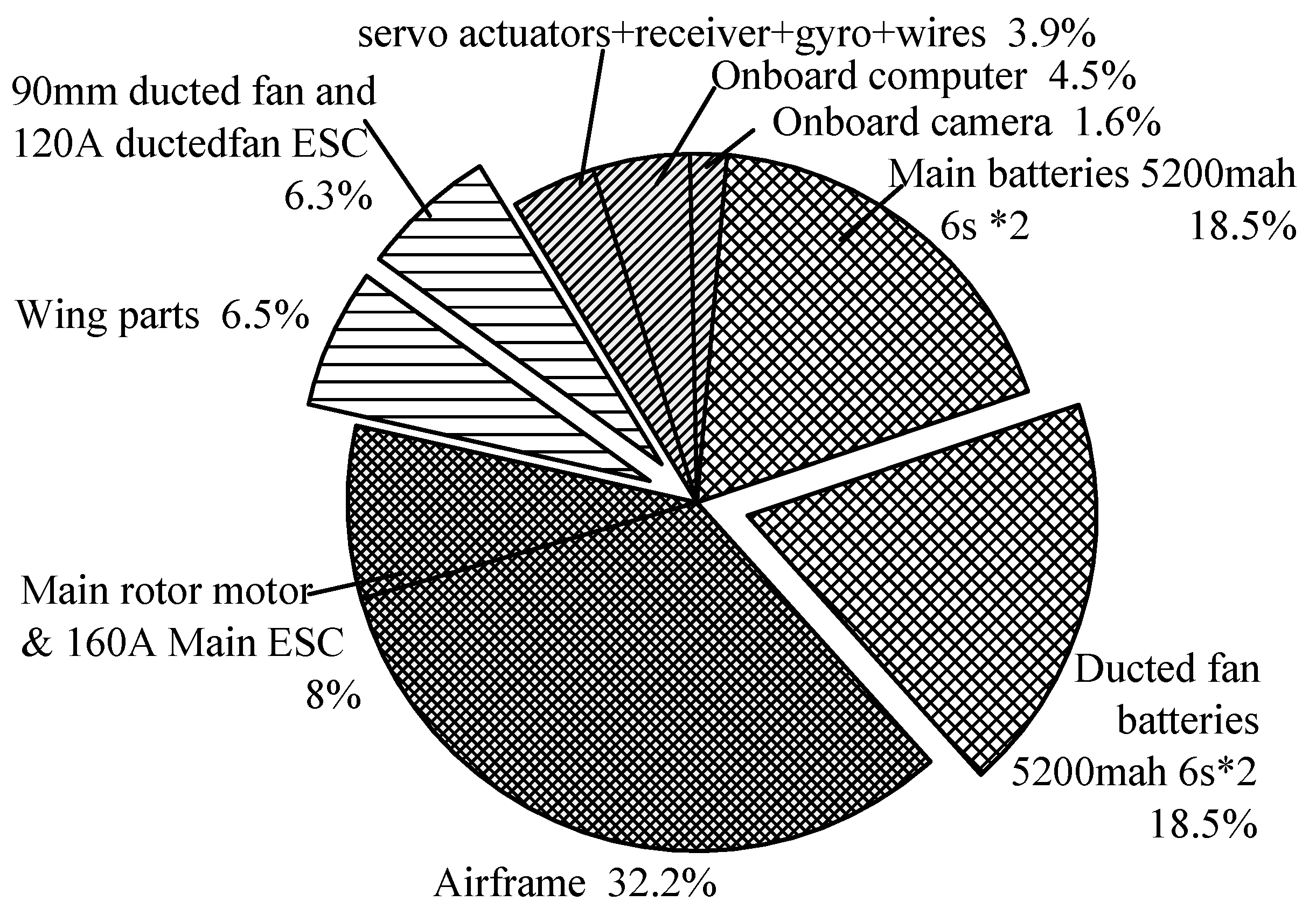

2.3. Overall Parameters

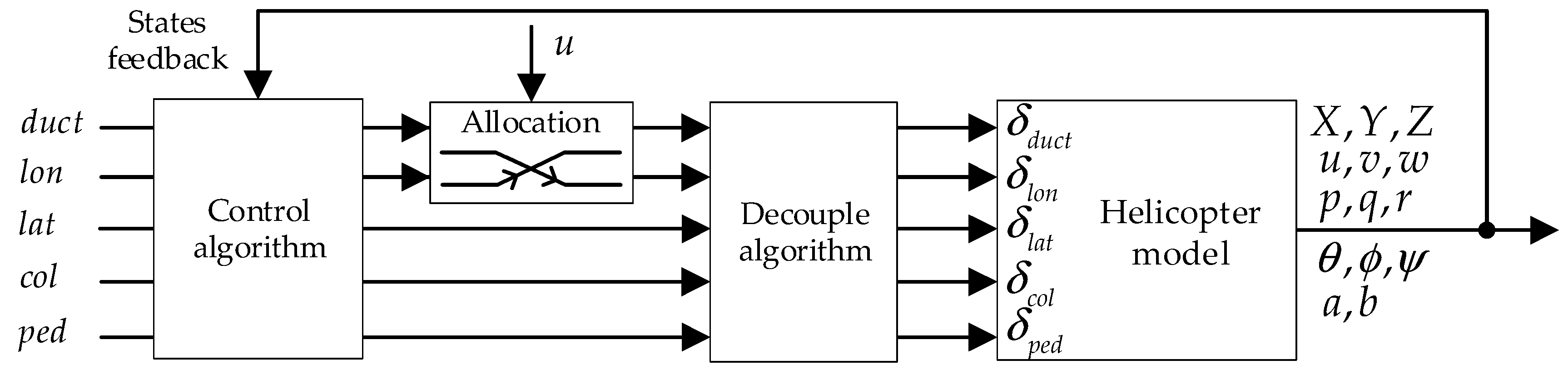

3. SCH Nonlinear Mathematical Model (NMM)

3.1. Modeling According to First Physical Principles

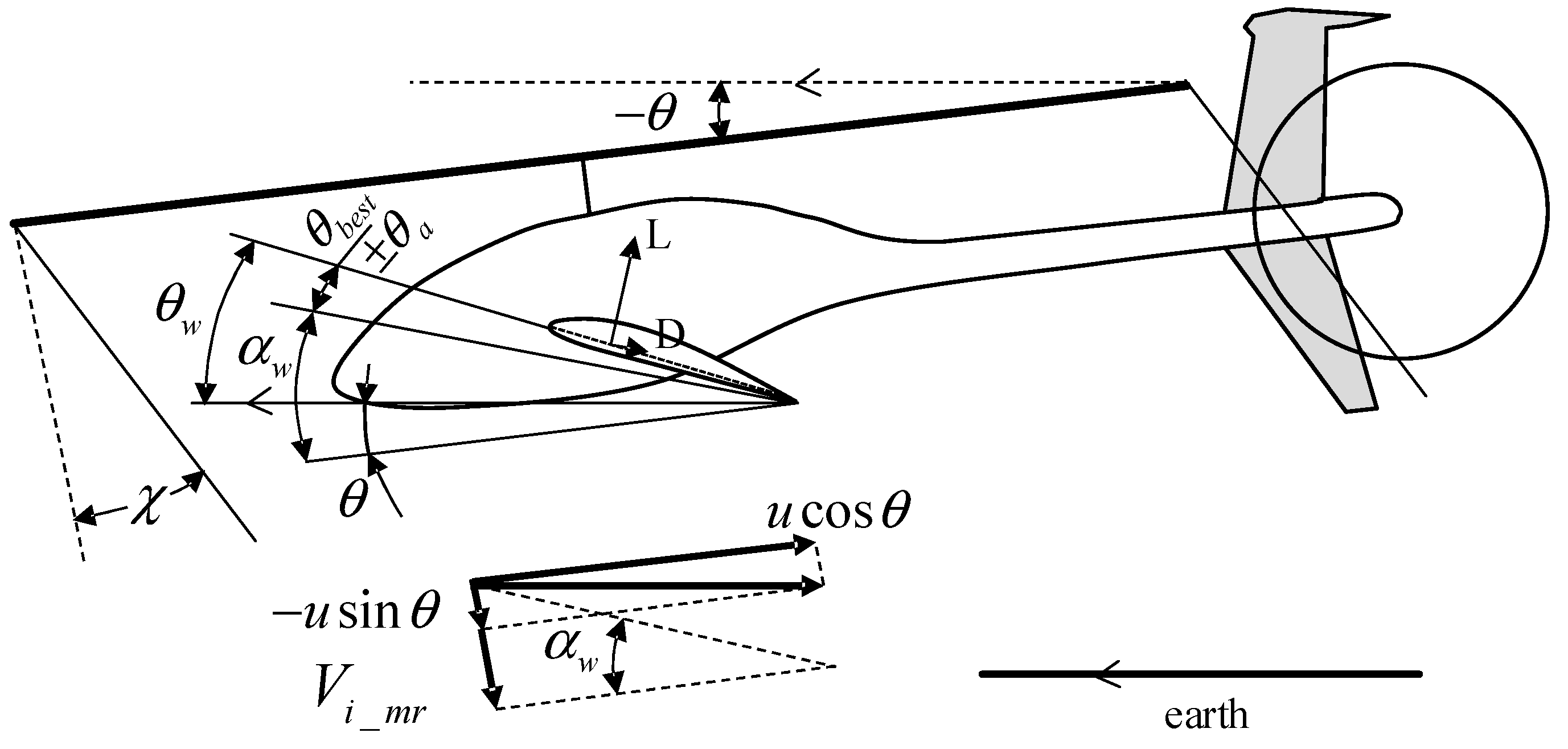

3.1.1. Main Rotor Model

3.1.2. Airframe Model

3.1.3. Tail Model

3.1.4. Vertical Fin Model

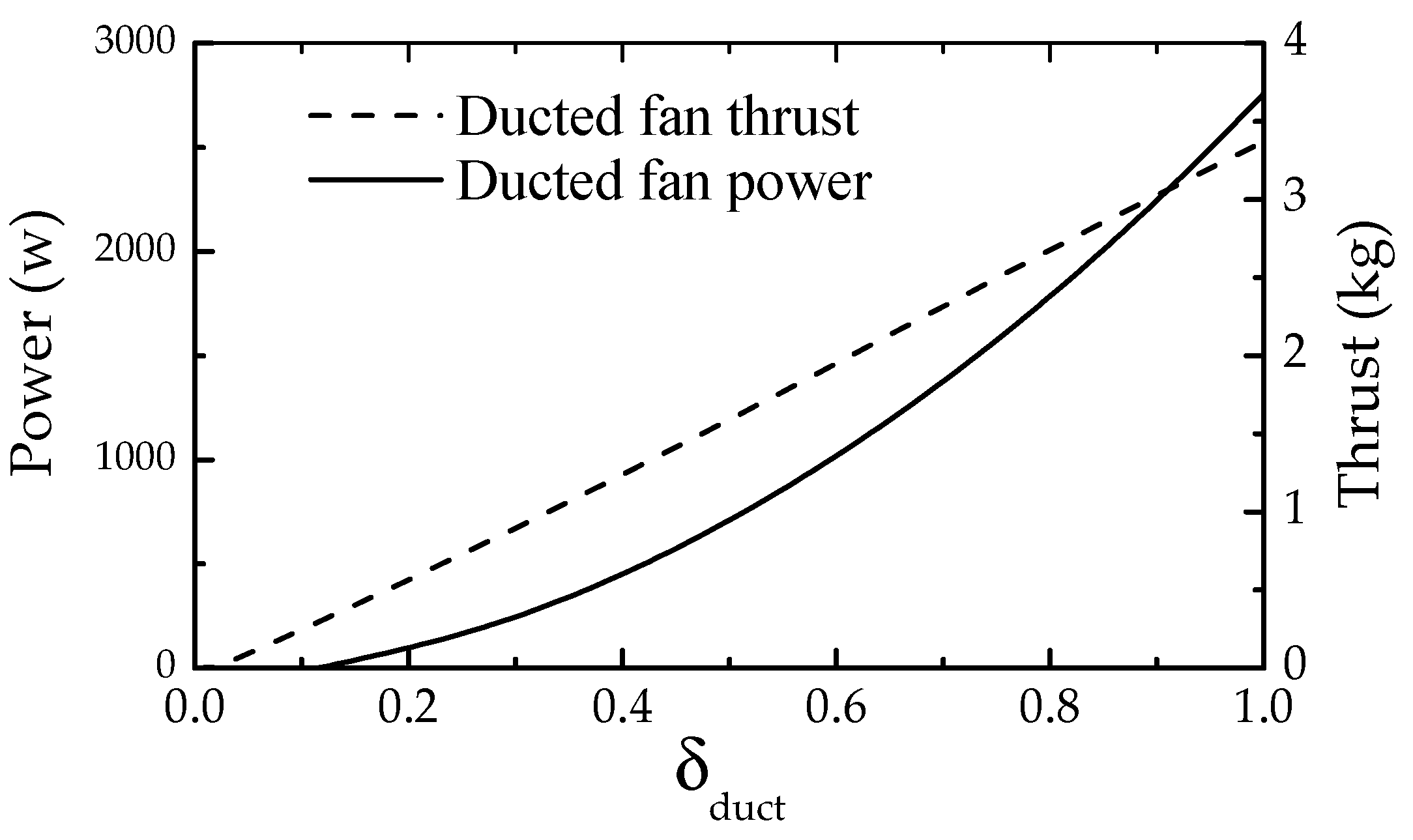

3.1.5. Ducted Fan Model

3.1.6. Wing Model

3.1.7. Horizontal Stabilizer Model

3.1.8. Full Dynamics Model

3.2. Nonlinear Model Modification

3.2.1. Hover Modification

3.2.2. Forward Flight Modification

4. Flight Experiments

5. Results and Discussion

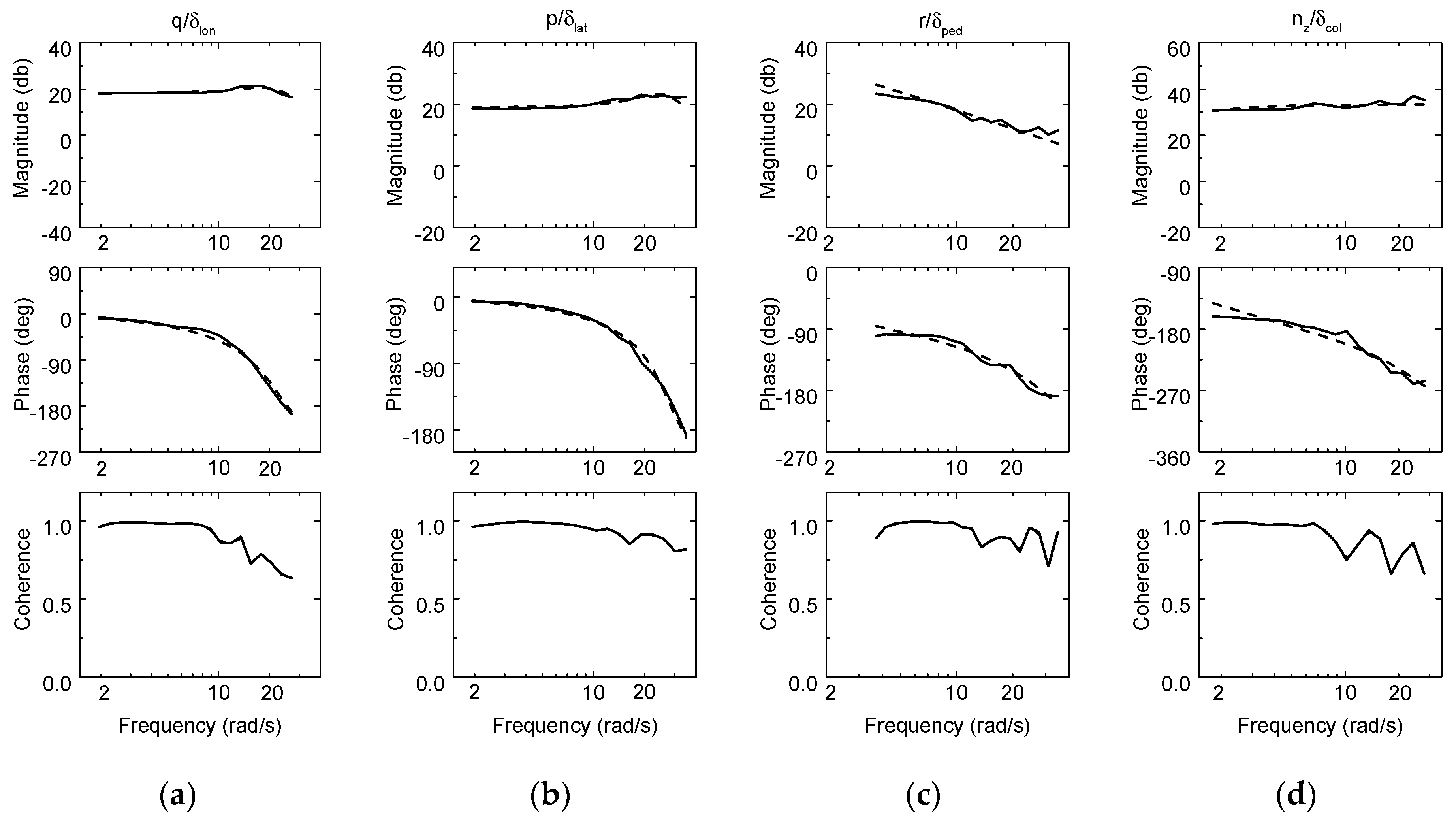

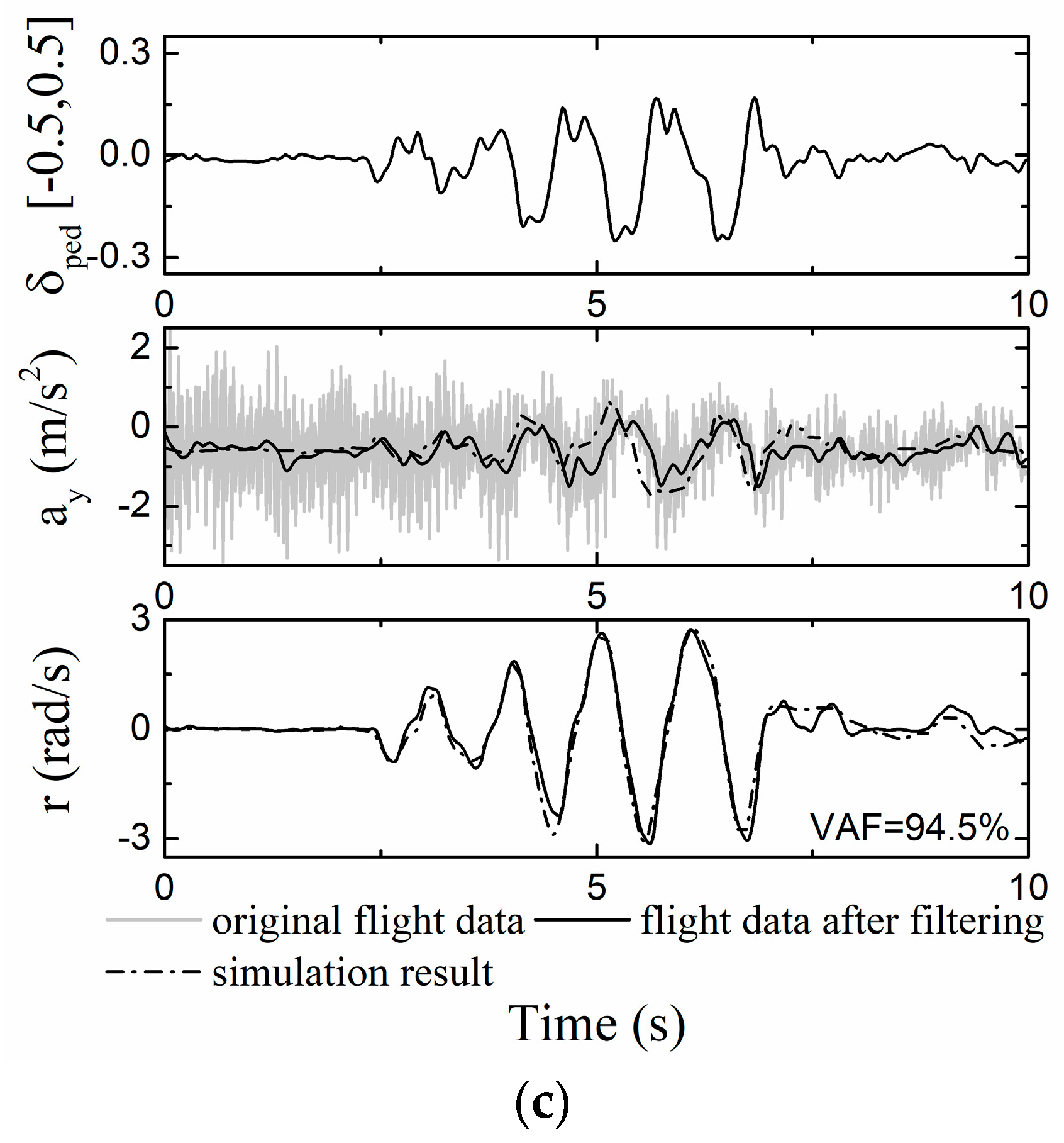

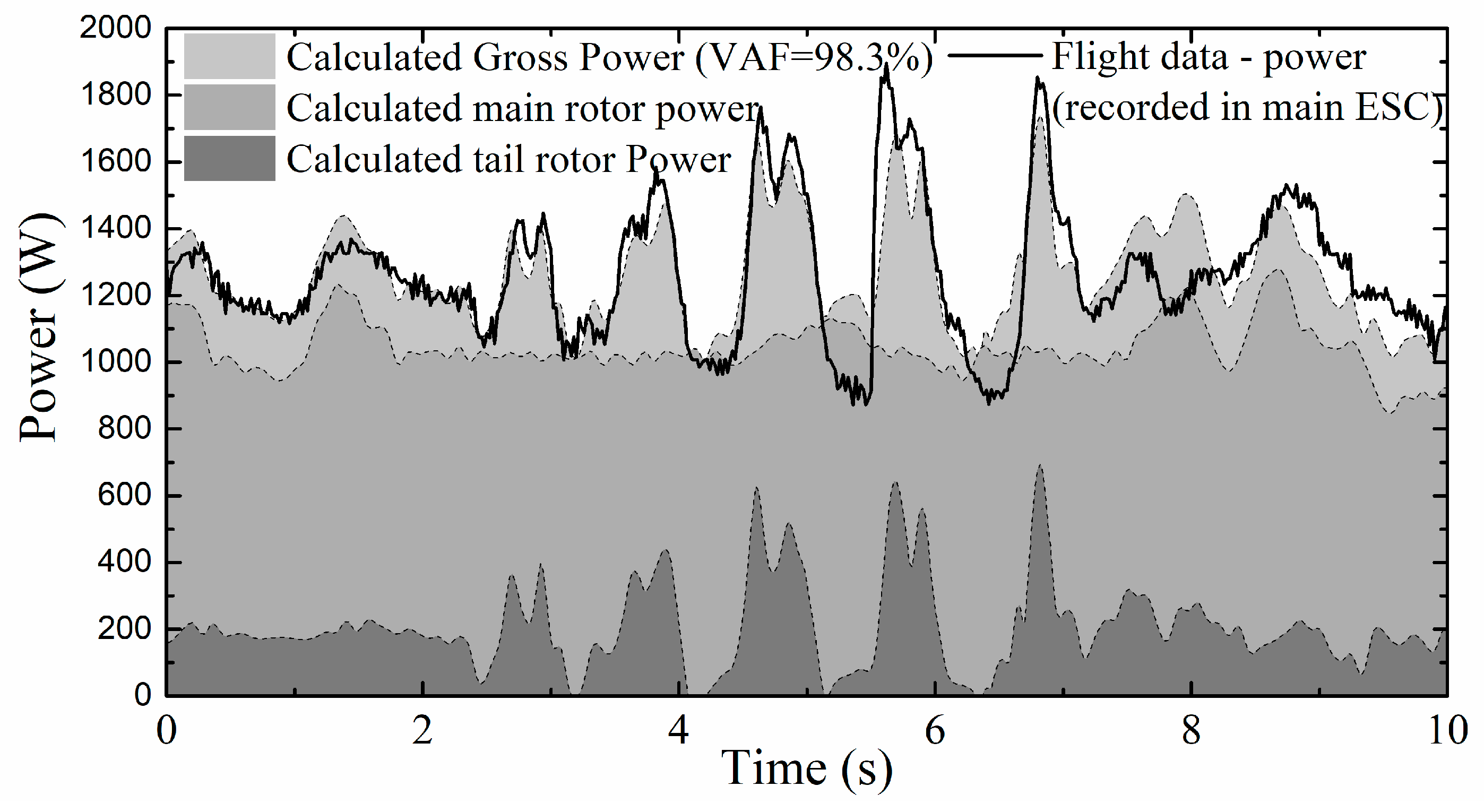

5.1. Hovering Validation

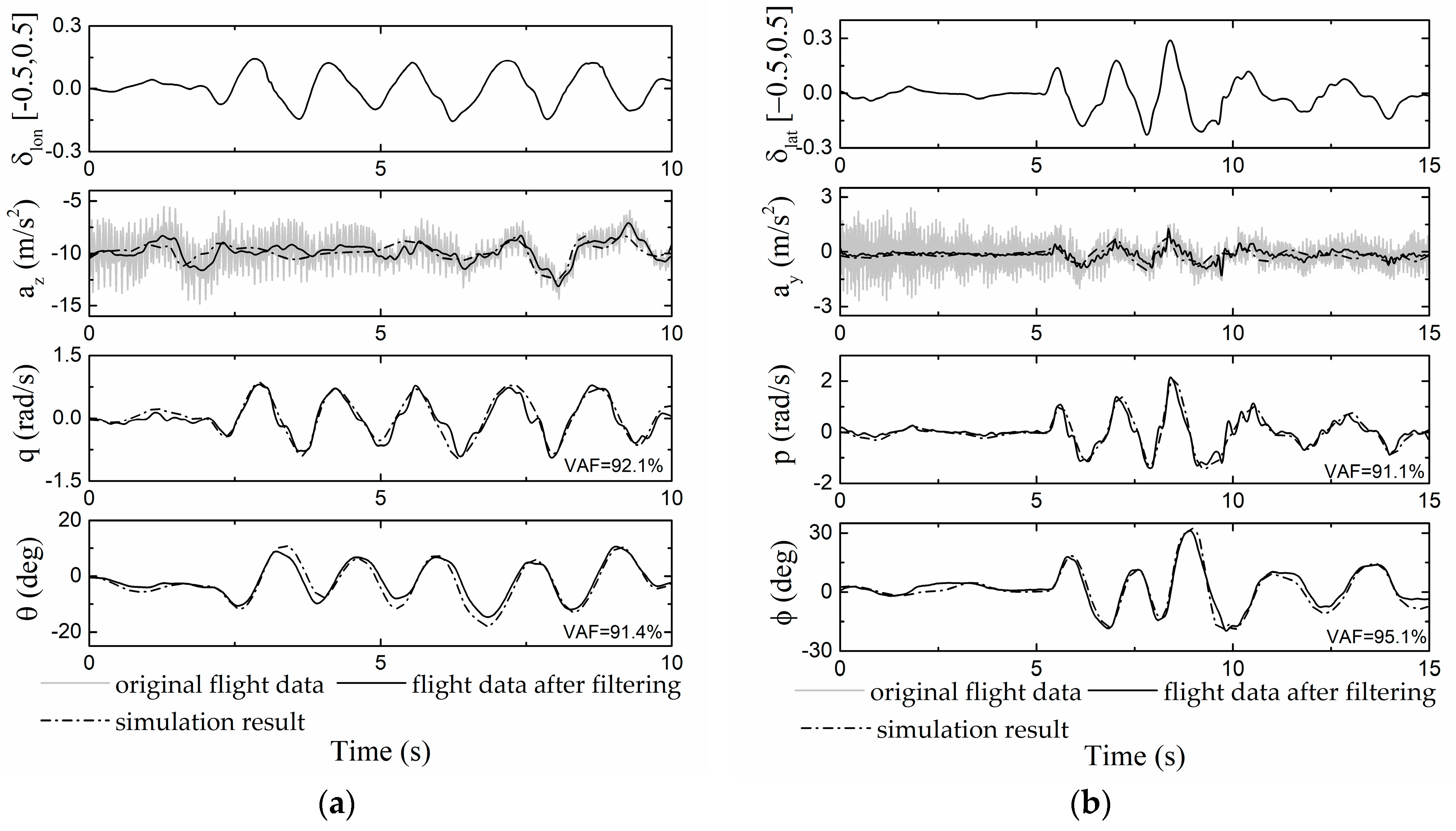

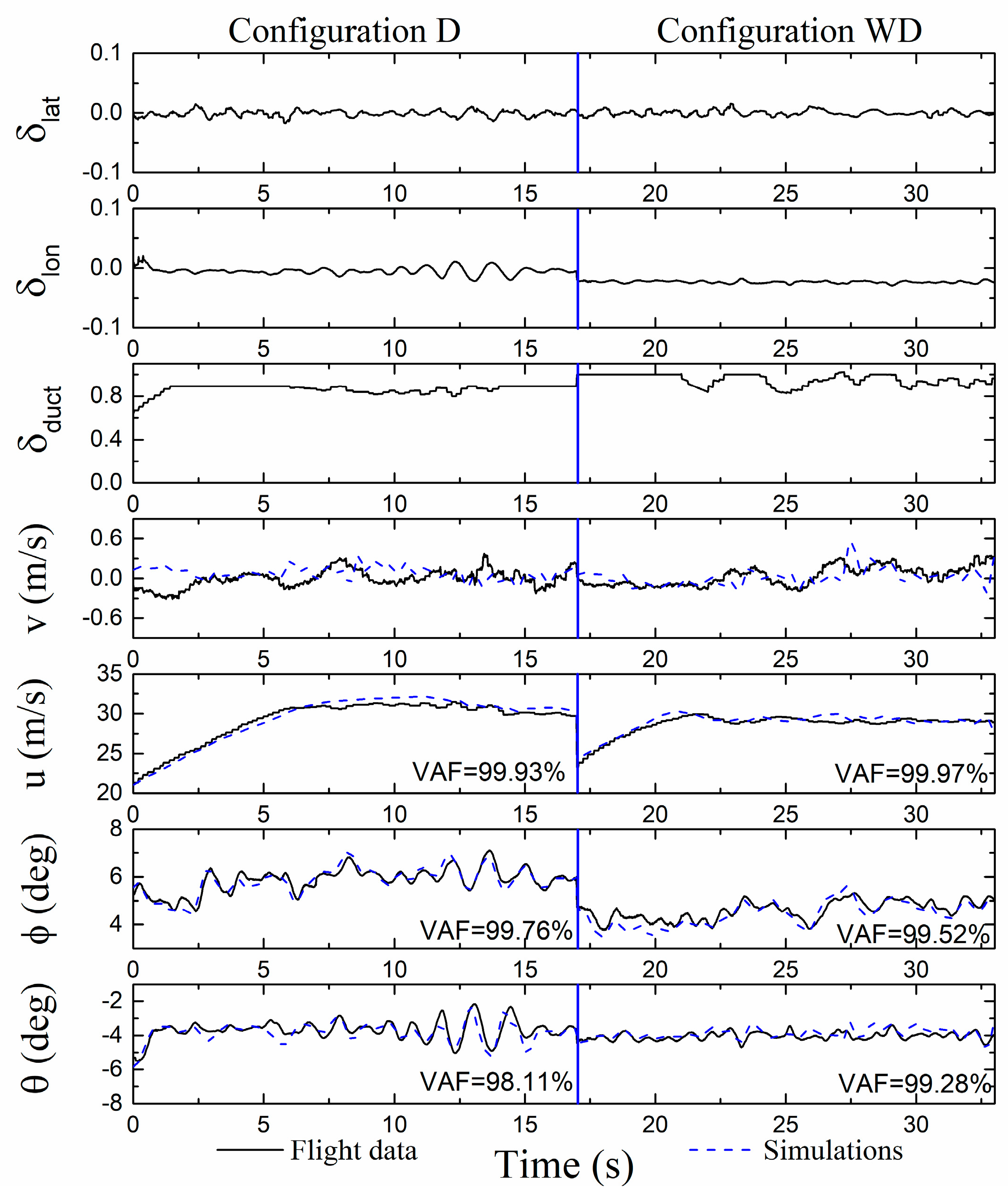

5.2. Forward Flight Validation

5.3. Configuration WDH Simulation

6. Conclusions

- (1)

- Compared with the hover data, the nonlinear dynamics model has high accuracy in simulating the sweep responses, especially in the calculations of pitch and roll angles. The power of main rotor occupied 85% of the gross power. Tail rotor made the gross power vary from 1 kW to 1.7 kW in yaw maneuver.

- (2)

- In forward flight comparisons, the predictions of the nonlinear model are in good agreement with the trim results from the real flights, especially in Configuration D and in Configuration WD below 27 m/s. The interference between the wing and main rotor should be treated more carefully under a large negative pitch angle in speed above 27 m/s. The nonlinear model with modification is successful in predicting the time-domain responses in forward speed around 30 m/s.

- (3)

- In the coordinated turn simulation, the elevator and aileron work efficiently. The control fluctuations decrease greatly in 2 s. The control performance in Configuration WDH has smaller oscillation and overshot than the control in the real flights. The main rotor creates stable damping in roll movement during the turn simulation.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| IDM | Identification model by CIFER |

| NMM | Nonlinear mathematical model |

| SCH | Small-scale compound helicopter |

| Configuration D | The configuration of general helicopter + ducted fan |

| Configuration WD | The configuration of general helicopter + ducted fan + wings |

| Configuration WDH | The configuration of general helicopter + ducted fan + wings + elevator |

References

- Romero, P.; Sartorius, S. Feasibility Study of a Novel Asymmetric Rotorcraft Configuration: Single-Rotor Advancing Blade Concept. In Proceedings of the 2013 International Powered Lift Conference, Los Angeles, CA, USA, 12–14 August 2013; p. 4295. [Google Scholar] [CrossRef]

- Orchard, M.; Newman, S. The Fundamental Configuration and Design of the Compound Helicopter. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2003, 217, 297–315. [Google Scholar] [CrossRef]

- Ferguson, K.; Thomson, D. Flight Dynamics Investigation of Compound Helicopter Configurations. J. Aircr. 2014, 52, 156–167. [Google Scholar] [CrossRef]

- Ferguson, K.; Thomson, D. Maneuverability Assessment of a Compound Helicopter Configuration. J. Am. Helicopter Soc. 2016, 61, 1–15. [Google Scholar] [CrossRef]

- Yeo, H.; Johnson, W. Optimum Design of a Compound Helicopter. J. Aircr. 2009, 46, 1210–1221. [Google Scholar] [CrossRef]

- Yeo, H.; Johnson, W. Aeromechanics Analysis of a Heavy Lift Slowed-Rotor Compound Helicopter. J. Aircr. 2007, 44, 501–508. [Google Scholar] [CrossRef]

- Silva, C.; Yeo, H.; Johnson, W. Design of a Slowed-Rotor Compound Helicopter for Future Joint Service Missions. In Proceedings of the American Helicopter Society Aeromechanics Specialist’s Conference, San Francisco, CA, USA, 20–22 January 2010. [Google Scholar]

- Sartorius, S. Optimization and Design Space Visualization Applied to Early Conceptual Design of Compound Helicopters. In Proceedings of the 52nd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Denver, CO, USA, 4–7 April 2011. [Google Scholar] [CrossRef]

- Vu, N.A.; Lee, Y.J.; Lee, J.W.; Kim, S.; Chung, I.J. Configuration Design and Optimization Study of a Compound Gyroplane. Aircr. Eng. Aerosp. Technol. 2011, 83, 420–428. [Google Scholar] [CrossRef]

- Ormiston, R.A. Revitalizing Advanced Rotorcraft Research and the Compound Helicopter: 35th AHS Alexander A. Nikolsky Honorary Lecture. J. Am. Helicopter Soc. 2016, 61, 1–23. [Google Scholar] [CrossRef]

- Mettler, B.; Tischler, M.B.; Kanade, T. System Identification Modeling of a Small-Scale Unmanned Rotorcraft for Flight Control Design. J. Am. Helicopter Soc. 2002, 47, 50–63. [Google Scholar] [CrossRef]

- Mettler, B. Identification Modeling and Characteristics of Miniature Rotorcraft; Kluwer Academic Publishers: Boston, MA, USA, 2002; pp. 53–120. [Google Scholar]

- Tischler, M.B.; Remple, R.K. Aircraft and Rotorcraft System Identification: Engineering Methods with Flight Test Examples, 2nd ed.; AIAA Education Series; AIAA: Reston, VA, USA, 2012; Chapters 12–13; ISBN 1600868207. [Google Scholar]

- Bhandari, S.; Colgren, R. High-order dynamics models of a small UAV helicopter using analytical and parameter identification techniques. J. Am. Helicopter Soc. 2015, 60, 1–10. [Google Scholar] [CrossRef]

- Cai, G.; Chen, B.M.; Lee, T.H.; Kai, Y.L. Comprehensive nonlinear modeling of an unmanned-aerial-vehicle helicopter. In Proceedings of the AIAA Guidance, Navigation and Control Conference and Exhibit, Honolulu, HI, USA, 18–21 August 2008. [Google Scholar] [CrossRef]

- Khaligh, S.P.; Fahimi, F.; Robert Koch, C. A System Identification Strategy for Nonlinear Model of Small-Scale Unmanned Helicopters. J. Am. Helicopter Soc. 2016, 61, 1–13. [Google Scholar] [CrossRef]

- Yang, F.; Chen, Z.; Wei, C. Nonlinear system modeling and identification of small helicopter based on genetic algorithm. Int. J. Intell. Comput. Cybern. 2013, 6, 45–61. [Google Scholar] [CrossRef]

- Tang, S.; Zheng, Z.; Qian, S.; Zhao, X. Nonlinear system identification of a small-scale unmanned helicopter. Control Eng. Pract. 2014, 25, 1–15. [Google Scholar] [CrossRef]

- Gavrilets, V.; Martinos, I.; Mettler, B.; Feron, E. Control Logic for Automated Aerobatic Flight of a Miniature Helicopter. In Proceedings of the AIAA Guidance, Navigation, and Control Conference and Exhibit, Monterey, CA, USA, 5–8 August 2002. [Google Scholar] [CrossRef]

- Cai, G.; Chen, B.M.; Tong, H.L. Unmanned Rotorcraft Systems; Springer: London, UK, 2011; pp. 39–99. [Google Scholar]

- Leishman, J.G. Principles of Helicopter Aerodynamics, 2nd ed.; Cambridge University Press: New York, NY, USA, 2006; pp. 90–120. ISBN 0-521-85860-7. [Google Scholar]

- Johnson, W. Helicopter Theory; Dover Publication: New York, NY, USA, 1994; pp. 179–184. [Google Scholar]

- Padfield, G.D. Helicopter Flight Dynamics; Blackwell Publishing: Oxford, UK, 2008; pp. 87–184. ISBN 978-14051-1817-0. [Google Scholar]

- Fang, Z.P.; Chen, W.C.; Zhang, S.G. Aircraft Flight Dynamics; Beihang University Press: Beijing, China, 2005; pp. 214–217. ISBN 9787810776707. (In Chinese) [Google Scholar]

- Wu, M.; Chen, M. System identifications of three-axis gyro model and base model of a RC helicopter without stabilizer bar. In Proceedings of the 2017 European Rotorcraft Forum, Milano, Italy, 12–15 September 2017. [Google Scholar]

- Wu, M.; Chen, M.; Wang, F. System Identification of Flight Dynamics Models of a Small-scale Unmanned Helicopter in Hover Condition. J. Beijing Univ. Aeronaut. Astronaut. 2018. (In Chinese) [Google Scholar] [CrossRef]

| Parameter | Value | Meaning |

|---|---|---|

| 0.0715 | Main rotor blade moment of inertia related to the hub | |

| 0.767 | Main rotor disc radius | |

| 0.137 | Tail rotor disc radius | |

| 0.065 | Main rotor blade chord length | |

| 0.031 | Tail rotor blade chord length | |

| 1.332 | Airframe length | |

| 0.963 | Tail rotor hub location behind the CG | |

| 0.025 | Tail rotor hub location above the CG | |

| 0.214 | Main rotor hub location above the CG | |

| 9.8015 | Acceleration due to gravity | |

| 1.225 | Air density | |

| 1700 | Main rotor rotation speed | |

| 360.2 | Tail rotor rotation speed |

| Parameter | Value |

|---|---|

| 22.67 | |

| 16.06 | |

| 14.64 | |

| 64.70 |

| Parameter | Value | Meaning |

|---|---|---|

| 0.75 m | Half wingspan | |

| 0.204 m | Wing chord | |

| 0.015 m | Wing hub location behind the CG | |

| 0.08 m | Wing hub location below the CG | |

| 0.3 m | Horizontal stabilizer span | |

| 0.03 m | Elevator chord | |

| 0.025 m2 | Horizontal stabilizer area | |

| 0.967 m | Horizontal stabilizer location behind the CG | |

| 0.276 m | Horizontal stabilizer location above the CG | |

| 0.01 m | Ducted fan shaft location below the CG | |

| 3.4 kg | 90 mm Ducted fan maximum thrust |

| Hover | 30 m/s Configuration D | 30 m/s Configuration WD | |||||

|---|---|---|---|---|---|---|---|

| Parameter | Value | Parameter | Value | Parameter | Value | Parameter | Value |

| 0.05560 | −0.03270 | 0.0510 | −0.328 | ||||

| −0.06020 | −0.4568 | 331.2 | −3.09 | ||||

| −0.1420 | 0.5046 | 0.2680 | 3.53 | ||||

| −1.714 | −0.05330 | −0.297 | |||||

| 448.4 | −45.87 | −0.115 | |||||

| 740.9 | 75.28 | ||||||

| −1.084 | |||||||

| Cost value | 39.9078 | Cost value | 47.7424 | Cost value | 58.1301 | ||

| Parameter | Previous | Updated | Parameter | Previous | Updated |

|---|---|---|---|---|---|

| 6.28 | 5.75 | (hover) | 0 | −0.041 | |

| 0.3011 | 0.2932 | (hover) | 0 | 0.0485 | |

| 157.54 | 160.57 | (30 m/s D) | 0 | 0.0102 | |

| 0.412 | 0.396 | (30 m/s WD) | 0 | 0.0291 | |

| 0.676 | 0.653 | 1 | 0.8762 |

| Mode | IDM | NMM |

|---|---|---|

| Pitch | [0.4261, 21.6214] | [0.4812, 20.2831] |

| Roll | [0.3288, 26.9422] | [0.3695, 27.8265] |

| Yaw | [0.5045, 19.8832] | [0.5100, 23.1020] |

| Heave | (−1.7136) | (−1.7101) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, M.; Chen, M. Nonlinear Modeling and Flight Validation of a Small-Scale Compound Helicopter. Appl. Sci. 2019, 9, 1087. https://doi.org/10.3390/app9061087

Wu M, Chen M. Nonlinear Modeling and Flight Validation of a Small-Scale Compound Helicopter. Applied Sciences. 2019; 9(6):1087. https://doi.org/10.3390/app9061087

Chicago/Turabian StyleWu, Meiliwen, and Ming Chen. 2019. "Nonlinear Modeling and Flight Validation of a Small-Scale Compound Helicopter" Applied Sciences 9, no. 6: 1087. https://doi.org/10.3390/app9061087

APA StyleWu, M., & Chen, M. (2019). Nonlinear Modeling and Flight Validation of a Small-Scale Compound Helicopter. Applied Sciences, 9(6), 1087. https://doi.org/10.3390/app9061087