1. Introduction

Abandoned coal mines are widely distributed in China [

1]. Several residual coal pillars are arranged and left permanently in abandoned coal mines to support the weight of overburdened strata [

2]. Dynamic failure of residual coal pillars in abandoned coal mines is usually powerful, destructive, and dangerous [

3]. The long-term stability of residual coal pillars in abandoned coal mines urgently needs to be investigated.

Experiments have been performed to study the mechanical behaviors and failure characteristics of pure coal specimens. The experimental results obtained from the uniaxial loading tests, triaxial loading tests, and cyclic loading tests provide a deeper understanding about the failure evolution of pure coal pillars [

4]. However, the associated mechanical parameters obtained from these experiments either underestimated or overestimated the instability tendency of residual coal pillars [

5]. Due to the influence of the surrounding rock strata above or below the coal pillar, the existing research does not accurately reflect the failure mechanism of residual coal pillars in abandoned coal mines [

6].

In fact, residual coal pillars, together with roof strata and floor strata, play a combined bearing role in underground engineering [

7,

8]. A distinctive roof-pillar-floor system is usually formed in abandoned coal mines [

9]. The failure of a roof-pillar-floor system can easily induce the occurrence of dynamic disasters, such as a rock burst, coal bump, roof collapse, floor heave, and coal-gas compound outburst [

10]. Therefore, the long-term stability of a roof-pillar-floor system is very significant for mining design, construction, and operation, and is also helpful for the investigation of the mechanisms of dynamic disasters.

Extensive tests and simulations have been performed to investigate the failure characteristics of combined coal and rock specimens. The instability mechanism of a roof-pillar-floor system could be well revealed. With a set of uniaxial and triaxial compression tests, Chen et al. [

10] applied the acoustic emission monitoring method and X-ray computed tomography (CT) technology to observe the internal damage characteristics of a combined rock and coal specimen. Du et al. [

11] analyzed the seepage characteristics of a gas-bearing coal-rock body subjected to different loadings. Liu et al. [

12] simulated the hydraulic fracture propagation of a combined coal and artificial roof/floor. Yin et al. [

13] numerically carried out lateral pressure unloading numerical tests of composite coal–rock models with PFC

2D to study energy evolution and burst behavior. Both the experimental and numerical results showed that the failure characteristics of a combined coal and rock body were significantly different from those of a pure coal or rock specimen, which illustrates that residual coal pillars and the surrounding rock strata need to be studied as a whole.

In view of this theoretical analysis, Chen et al. [

10] proposed a new nonlinear constitutive model with the concept of natural volumetric strain to describe the deformation of a combined rock and coal body. Zhao et al. [

14] established an equivalent homogeneous model of a coal–rock body based on the strain energy equivalency principle. The proposed compression–shear model could be used to reflect the strength behavior of a coal-rock body containing the structural plane. Liu et al. [

15] developed a damage constitutive model of coal with a cascade system of a damaged body and Newton body to investigate the stress-strain curves of coal in the combined coal-rock specimen. The accuracy of these constitutive models was also verified by the results of laboratory tests or numerical simulations. The failure mechanism of the roof-pillar-floor system was explored to some extent.

The influencing factors associated with the mechanical properties of a combined coal and rock specimen were further investigated by many scholars. Huang et al. [

5] found that the strength and deformation of a combined coal and rock body were strongly dependent on the loading rate. Liu et al. [

12] believed that the peak strain of a composite rock-coal-rock sample decreased with an increase of the rock strength. Zhao et al. [

16] explored the effect of the interface angle on the failure characteristics of combined coal and rock specimens. The coupled effects of the height ratio and loading rate on the failure modes of composite samples were also examined by using granular dynamic models [

17]. The factors in these researches were diverse, and contained not only the internal material parameters of a combined coal and rock body, but also involved the external loading parameters of a combined coal and rock body. The instability characteristics and mechanisms of a combined coal and rock body in specific geological conditions were well reflected by these valuable researches.

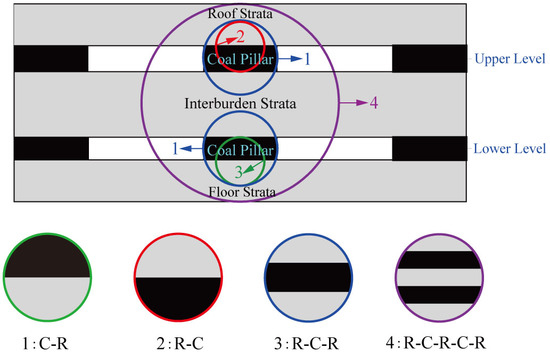

In the existing researches, the combined rock-coal specimen represents the roof-pillar system. The combined coal-rock specimen represents the pillar-floor system. Additionally, the rock-coal-rock specimen is a reflection of the overall roof-pillar-floor system. The failure characteristics of the rock-coal specimen, coal-rock specimen, and the rock-coal-rock specimen offer a deeper insight into the occurrence mechanisms of dynamic disasters in single seam mining. However, it is difficult to use the obtained results to directly guide the safety of ultra-close multiple seam mining.

Generally, ultra-close multiple seam mining is widely conducted in China [

18] and other famous coal-mining countries [

19,

20]. Various multi-seam mining configurations are defined based on the mining methods at the upper and lower levels. Multi-seam pillar mining is one of the main configurations in practice [

21]. In this situation, the overlapped residual coal pillars are designed at different mining levels [

22]. The roof strata, upper pillar, interburden strata, lower pillar, and the floor strata, shown in

Figure 1, form a whole bearing system in the underground space. That is, different kinds of sandwiched coal-rock systems exist in ultra-close multiple seam mining. It includes not only the C-R, R-C, and R-C-R sandwiched system, but also the R-C-R-C-R sandwiched system. The safety of ultra-close multiple seam mining is closely associated with the stability of the sandwiched coal-rock system.

With the coupled effects of environmental weathering, mining-induced stress, and other unfavorable factors, catastrophic collapse of sandwiched coal-rock systems in ultra-close multiple seam mining may be induced [

23]. A famous collapsing case, which occurred in the Shigetai coal mine of China, was described by Zhu et al [

24]. The roof strata-upper pillar-interburden-lower pillar-floor strata system simultaneously collapsed, which induced an abnormal response of strata behaviors. Therefore, further observations about the sandwiched coal-rock system are necessary to provide thorough insights into the progressive failure characteristics and mechanisms. They are significant for revealing the occurrence mechanism of dynamic disasters in ultra-close multiple seam mining.

In this study, the description of the sandwiched coal-rock system is first presented. Four groups of uniaxial compression tests are designed and conducted for different kinds of sandwiched coal-rock specimens (C-R, R-C, R-C-R, and R-C-R-C-R). The mechanical behaviors, electrical resistivity responses, acoustic emission features, and local strain evolutions are observed simultaneously during the loading process to reveal the progressive failure characteristics of the sandwiched coal-rock system. Furthermore, the progressive failure mechanism of the sandwiched coal-rock system is investigated.

4. Experimental Results

In this section, the experimental results for different kinds of sandwiched coal-rock specimens are presented. The mechanical behaviors, AE features, electrical resistivity responses, and local strain evolution are analyzed in detail to reveal the progressive failure characteristics.

4.1. Mechanical Behaviors

During the whole loading process, the stress-time relations for different kinds of sandwiched coal-rock specimens are shown by the dark curves in

Figure 6. According to the bearing characteristics, the overall tendency of the mechanical behaviors was basically similar. It can be divided into four stages. Stage I was the nonlinear growth stage of the bearing capacity. Stage II was the linear growth stage of the bearing capacity. Stage III was the yielding growth stage of the bearing capacity. Stage IV was the weakening stage of the bearing capacity. A thorough description of the mechanical behaviors is presented as follows (see

Figure 6):

(1) The axial stress of C-R, R-C, R-C-R, and R-C-R-C-R grew during stage I in an up-concaved form (see

Figure 6a–d). Original pores and cracks inside the testing specimen, especially in the coal elements, were enclosed gradually with the rising stress. The compaction deformation was dominant at stage I. As a result, the nonlinear growth of the bearing capacity was presented for different kinds of sandwiched coal-rock specimens.

(2) As presented in

Figure 6, the bearing stress of the sandwiched coal-rock specimen increased linearly during stage II. The sandwiched coal-rock specimens mainly experienced elastic deformation. The duration of stage II was approximately 460 s, 440 s, 300 s, and 360 s for C-R, R-C, R-C-R, and R-C-R-C-R, respectively.

(3) For different kinds of sandwiched coal-rock specimens, the bearing capacity began to depart from the linear growth. As shown in

Figure 6, weakening growth of the bearing stress was monitored for different kinds of sandwiched coal-rock specimens. It indicated the arrival of the yielding growth stage. Plastic deformation was dominant at stage III. It was noted that a little stress fluctuation was observed for C-R and R-C-R-C-R (see

Figure 6a,d). However, the overall yielding growth of the bearing load was not influenced. Stage III proceeded until the appearance of peak stress. It was the arrival of the limit bearing capacity for sandwiched coal-rock specimens. As shown in

Figure 6a,b, the peak stress was 26.24 MPa and 27.88 MPa, respectively. Apparently, the limit bearing capacity for C-R and R-C was almost equivalent in value. The limit bearing stress of R-C-R, shown in

Figure 6c, was approximately 17.15 MPa. It was 12.98 MPa for R-C-R-C-R, as shown in

Figure 6d.

(4) After the peak stress, the bearing load of the sandwiched coal-rock specimens tended to decrease as a whole. At the initial period of stage IV, the weakening rate of the bearing capacity was relatively small. Subsequently, a large drop of the bearing stress occurred within a short time. It indicated that the sandwiched coal-rock specimens experienced intense damage. The continuity and integrity were seriously destructed. It was worth noting that stage IV for C-R, R-C-R, and R-C-R-C-R was relatively longer than that of R-C. The bearing stress of R-C specimen declined within a very short time during stage IV, which could be explained by the earlier instability of the coal element at the lower position. The bearing capacity of R-C was lost sharply as soon as the coal element failed.

4.2. Electrical Resistivity Responses

Real-time electrical resistance for different kinds of sandwiched coal-rock specimens was monitored throughout the unaxial compressive experiments. Then, the electrical resistivity was calculated based on Equation (1). The green curves in

Figure 6 represent the response of the electrical resistivity for C-R, R-C, R-C-R, and R-C-R-C-R, respectively.

Before loading, the initial electrical resistivity for C-R, R-C, R-C-R, and R-C-R-C-R was 1.67 MΩ·m, 1.67 MΩ·m, 1.42 MΩ·m, and 1.55 MΩ·m, respectively. With the development of compaction deformation, the electrical resistivity of the sandwiched coal-rock specimens decreased gradually although a slight fluctuation was observed during stage I (see

Figure 6). The enclosure of natural micro-pores and cracks could explain this phenomenon, which resulted in the generation of new electrical channels [

10]. Under the coupled effects of the original and newborn electrical channels, the overall conductive capability of the sandwiched coal-rock specimens was improved.

At stage II, the declining tendency of the electrical resistivity continued to be monitored for different kinds of sandwiched coal-rock specimens. However, the declining rate weakened gradually. It indicated that the conductive channels in the defective areas were damaged locally during the elastic deformation process.

The electrical resistivity of the sandwiched coal-rock specimens was maintained at a relatively small value during stage III. An overall decreasing tendency was shown along with the yielding growth of the bearing capacity. A remarkable increase of the electrical resistivity appeared at the end of stage III when the peak bearing stress was captured. This was attributed to the generation of macro-cracks, which further induce serious damage to the electrical conductive channels.

When the axial stress evolved into stage IV, the electrical resistivity of the sandwiched coal-rock specimens seemed to be chaotic due to the uncertainty of crack propagation and the diversity of the failure mode. As presented in

Figure 6a, sudden drops and growth of the electrical resistivity were captured at stage IV for C-R. A general increasing tendency of the electrical resistivity is shown in

Figure 6b,c for R-C and R-C-R. As shown in

Figure 6d, the electrical resistivity for R-C-R-C-R declined initially with some fluctuations, while it tended to grow at the end of stage IV.

4.3. AE Characteristics

AE features are not only described by the evolution of AE energy quantitatively [

30], but are also revealed by the distribution of AE events qualitatively [

31]. The red and blue curves in

Figure 6 represent the AE energy and accumulative AE energy of the sandwiched coal-rock specimens at different loading times. The AE events distributions are also shown in

Figure 7,

Figure 8,

Figure 9 and

Figure 10 for different kinds of sandwiched coal-rock specimens during the loading process. The letters shown in

Figure 7,

Figure 8,

Figure 9 and

Figure 10 correspond to the purple markers and time slices sown in

Figure 6.

4.3.1. Evolution of AE Energy

The overall evolution of the AE energy and accumulated AE energy for different kinds of sandwiched coal-rock specimens is presented in

Figure 6. Detailed descriptions of the AE energy and accumulated AE energy at different load times are as follows.

During stage I, the AE energy of the sandwiched coal-rock specimens was maintained at relatively small values with little fluctuation (see

Figure 6). It was primarily released due to the closure effect of the initial pores and cracks. With the increase of loading time, the AE energy was accumulated slightly at a very slow rate.

The output of AE energy at stage II was mainly attributed to the generation and expanding of micro-cracks in the sandwiched coal-rock specimens. It was activated gradually along with the linear growth of the bearing capacity. Correspondingly, the accumulated AE energy also presented a gentle smooth rising tendency.

The AE behavior of sandwiched coal-rock specimens became more intense at stage III. Massive AE energies were released at this stage. It resulted in the fast growth of accumulated AE energy. The exacerbation of internal damage and the acceleration of the micro-cracks’ expansion provides an explanation for this phenomenon. It is worth noting that the sudden growth of AE energy was observed along with stress drops in

Figure 6a,d. As soon as the appearance of the maximum bearing stress, peak AE energy was recorded. As presented in

Figure 6, the maximum values of AE energy for C-R, R-C, R-C-R, and R-C-R-C-R were approximately 35.45 × 10

4 mV·mS, 41.68 × 10

4 mV·mS, 25.31 × 10

4 mV·mS, and 36.74 × 10

4 mV·mS, respectively. The fastest growth rate of accumulated AE energy at this point was also captured for different kinds of sandwiched coal-rock specimens.

Due to the exacerbation of internal damage and the generation of macro-cracks, the release of AE energy for the sandwiched coal-rock specimens was still active during stage IV. However, it tended to be chaotic as a whole. As shown

Figure 6, the increasing tendency of accumulated AE energy was continuously monitored during stage IV.

4.3.2. Distribution of AE Events

AE energy reflects the global acoustic information about different kinds of sandwiched coal-rock specimens. However, it cannot be applied to describe the local acoustic characteristics of coal elements and rock elements. To provide deeper insight into the progressive failure characteristics of sandwiched coal-rock specimens, the three-dimensional (3D) distribution of AE events was also investigated in detail. This reflects the spatial evolution of micro-cracks and internal damages inside the coal elements and rock elements at different heights [

10].

Figure 7 shows the 3D distribution of accumulated AE events inside the C-R specimen during the loading process. Under the compaction effects at stage I (see

Figure 7a,c), earlier AE events appeared randomly on both the coal element (50–100 mm) and rock element (0–50 mm). The number of AE events inside the C-R specimen increased slightly during the elastic deformation process at stage II, which were mainly caused by the initiation and propagation of micro-cracks at the height of 50–100 mm. As shown

Figure 7d–g, AE events were mostly inside the coal element. The distribution space of AE events in this area also expanded progressively from the top section to the bottom section. Furthermore, the number and density of AE events inside the coal element (50–100 mm) were apparently more than those in the rock element (0–50 mm). That is, the coal element in the C-R specimen primarily experienced the micro-damage at stage II due to its lower strength. In terms of the rock element in the C-R specimen, little internal damage appeared and AE events were random at this stage. It is worth noting that several AE events were spread across the interface of the coal element and rock element at the later period of stage II (see

Figure 7g). However, most of them were located at the left-top corner of the rock element. This indicates that local damage of the rock element was induced by the damage to the coal element. At stage III, the number of AE events in

Figure 7h,i grew significantly inside the C-R specimen. Corresponding to the intensive release of accumulated energy in

Figure 6a, the AE events were almost distributed throughout the coal element. This indicates that the internal damage inside the coal element was exacerbated during stage III. Furthermore, the AE events scattered at the top corner of the rock element also increased in number. Both the distribution area and density were enlarged. When it turned into stage IV, the number of AE events inside the C-R sandwiched coal-rock specimen continued to grow (see

Figure 7i,j). This was attributed to the connection of macro-cracks, the formation of the sliding plane, and the dislocation of material particles. AE events inside the coal element were greater than those in the rock element. The distribution space of AE events in the rock element was still centralized near the top corner, which demonstrated the induced damage was not spread across the entire rock element at stage IV.

The 3D distribution of the accumulated AE events inside the R-C specimen at different loading times is presented in

Figure 8. As a whole, AE events in

Figure 8a–d started to generate both on the coal element (0–50 mm) and the rock element (50–100 mm) at stage I. This was attributed to the closure of natural pores and cracks inside the specimen. With the increase of the loading time, a more rapid increase of AE events was monitored inside the coal element. The distribution space of AE events also expanded progressively inside the coal element. As shown in

Figure 8e–h, primary AE events were located at the height of 0–50 mm (coal element) during the elastic deformation stage. The total number of AE events inside the rock element also increased. However, the growth rate was obviously less than that in the coal element. At stage III, a drastic increase of AE events was observed inside the coal element, which quickly distributed throughout the whole coal element (see

Figure 8h,i). This is evidence of the exacerbated damage inside the coal element. Moreover, the micro-damage at this stage propagated across the interface between the rock element and the coal element. Many AE events were also found at the bottom corner of the rock element. After the peak stress in

Figure 8j, the AE events maintained the increasing tendency inside the R-C specimen. The growth rate was fast at the height of 0–50 mm, while it was relatively weak at the height of 50–100 mm. It should be noted that dense AE events at stage IV were still scattered inside the coal element. Only rare AE events were distributed at the local areas of the rock element.

For the R-C-R specimen, the 3D distribution of AE events during the compressive process is displayed in

Figure 9. The AE events first appeared at the height of 33.33–66.67mm. As shown in

Figure 9a–c, they were almost located inside the coal element during stage I. No AE events were captured inside the upper and lower rock elements. At stage II, the number of AE events was mainly accumulated inside the coal element, as shown in

Figure 9d–h. The distribution space also propagated gradually at the height of 33.33–66.67 mm. At this stage, a few AE events also appeared near the top and bottom coal-rock interfaces. This demonstrates that the micro-damage that stemmed from the coal element had interconnected and spread into the rock element. Afterwards, AE events increased continuously at a height of 33.33–66.67 mm, as shown in

Figure 9i,j. The coal element experienced the most damage at the yielding stage. The distribution density of AE events inside the rock elements also gathered slightly at stage III. Ultimately, a weak increasing tendency of AE events inside the R-C-R specimen was presented at stage IV. This can be seen in

Figure 9k–n. Massive AE events were concentrated on the coal element. However, the damage was rarely scattered inside the rock element without the formation of a distinct nucleation belt.

The distribution of AE events in the R-C-R-C-R specimen during the loading process is revealed in

Figure 10. Apparently, the AE events first originated at a height of 20–40 mm at stage I (see

Figure 10a,b). Then, sporadic AE events were captured at a height of 60–80 mm. At stage II, the AE events, as shown in

Figure 10c,d, were dominantly gathered and generated inside the coal elements. A small amount of AE events also appeared randomly at a height of 40–60 mm, which indicates that the released damage energy spread to the rock element. Subsequently, the number of AE events at stage III not only gathered inside the coal elements, but also in the rock elements (see

Figure 10e,f). The growth rate in the coal elements was continuously greater than that in the rock elements. Consequently, the distribution area and density of AE events in the coal elements further thrived at stage IV. The concentration of AE events in the interburden rock element is shown in

Figure 10g–j. This provides evidence that damage occurred to the rock element at a height of 40–60 mm.

4.4. Local Strain Development

The local stain development for different kinds of sandwiched coal-rock specimens is presented in

Figure 11a–d. To gain a deeper understanding of the local strain, the time-stress curves of sandwiched specimens are also shown by the black curves. A positive value of local strain means the lateral strain measured by the longitudinal gauge, while a negative value of local strain means the axial strain measured by the horizontal gauge.

The local strain of the coal element (50–100 mm) and rock element (0–50 mm) in the C-R specimen at different loading times is shown in

Figure 11a. The axial strain of the coal element and rock element increased at stage I and II. As a whole, the growing rate of the coal element was more rapid than that of the rock element. It is obvious that the axial strain value of the rock element was smaller than that of the coal element. The lateral strain of the coal element was basically close to that of the rock element during the initial loading process. A significant difference between the lateral strains of the coal element and rock element gradually appeared at the later period of stage II. The lateral strain of the coal element was almost twice that of rock element at the end of stage II. When the axial stress yielded at stage III, the growth rate of the local strain was enhanced for the coal element. When the peak stress of the C-R specimen was observed, the axial strain of the coal element and rock element was −11.94 × 10

−3 and −3.34 × 10

−3, respectively. The lateral strain of the coal element and rock element was +6.78 × 10

−3 and +2.98 × 10

−3, respectively. At the beginning of stage IV, the axial strain of the coal element accelerated. Then, it tended to decrease from 800 s. The lateral strain of the coal element increased apparently throughout stage IV. For the rock element, both the axial strain and lateral strain started to decrease after the peak stress. The declining rate was almost opposite to the growth rate at stage II and stage III. It suggested that the rock element caused a partial recovery of strain at stage IV, which was induced by the collapse of the coal element.

A similar evolution tendency of the local strain was presented for the R-C sandwiched specimen, which is shown in

Figure 11b. The axial strain of the coal element (0–50 mm) was always larger than that of the rock element (50–100 mm) from stage I to stage III. Continuous growth of the axial strain was observed on the coal element after peak stress. With the sudden decrease of the bearing stress, a sharp decrease of the axial strain also appeared on the coal element. When the axial stress evolved into stage IV, the axial strain of the rock element tended to decrease slightly. Moreover, the lateral strains of the coal element and rock element were nearly synchronous at stage I and the initial period of stage II. After, the coal element generated a larger lateral strain than the rock element. The growth of the lateral strain continued throughout stage III and stage IV for the coal element. A turning point of the lateral strain was captured on the rock element as soon as the appearance of the peak stress. Then, a recovery of the lateral strain appeared on the rock element.

For the R-C-R specimen, the axial strain of the coal element (33.33–66.67 mm) was obviously larger than that of the rock element (0–33.33 mm and 66.67–100 mm) from stage I to stage III (see

Figure 11c). The lateral strain of the coal element and rock elements was nearly coincident at stage I. The difference was gradually highlighted when the axial stress turned into stage II. The lateral strain of the coal element was significantly more than that of the rock elements at stage II and stage III. It should be noted that the local strain of the upper and lower rock elements was not consistent after stage II. It was attributed to the heterogeneity of the rock elements. The original defects in the different rock elements were not exactly same. At stage IV, the earlier decreasing of the local strain appeared slightly in the rock elements, which indicates the recovery of the local strain. At this moment, the local strain on the coal element was still increasing. When the loading time was about 725 s, there was a sudden decrease in the local strain for the coal elements. It predicted the rupture of the coal element. Ultimately, a little fluctuation of the local strain was apparent in the coal element.

Figure 11d shows the local strain of the coal elements and rock elements at different heights in the R-C-R-C-R specimen. With the increase of the loading time, the local strains of the coal elements and rock elements presented a gradual increasing tendency from stage I to stage III. As shown in

Figure 11d, the axial strain and lateral strain of the rock elements (0–20 mm, 40–60 mm, and 80–100 mm) were almost the same from stage I to stage III. Additionally, little differences were also observed for the coal element at the height of 20–40 mm and 60–80 mm. As a whole, the growth rate of the local strain on the coal elements was faster than that of the rock elements. Consequently, the local strains generated on the coal elements were also larger than those of the rock elements. After the peak stress of the R-C-R-C-R specimen, the rebounding of local strains was observed on the rock elements at the height of 0–20 mm and 80–100 mm. However, the rock element (40–60 mm) was an exception. The lateral strain was still increasing at stage IV. Although several chaotic jumps and drops were found, the overall growth of the axial strain was also presented for the rock element (40–60 mm) at stage IV. Coal elements at the height of 20–40 mm and 60–80 mm experienced further damage at stage IV. The growth of the lateral strain was maintained at stage IV. The axial strain of the coal elements was not stable as a whole. Initially, it increased gradually. With the sudden decrease of the bearing stress, a decrease of the axial strain for the coal elements (20–40 mm and 60–80 mm) successively appeared at 1100 s and 1250 s.

Based on the mechanical behaviors, electrical resistivity responses, AE characteristics, and local strain evolution, the failure characteristics for different kinds of sandwiched coal-rock specimens can be summarized as follows: (1) Four stages were observed during the progressive failure process of sandwiched coal-rock specimens, i.e., stage I: Nonlinear growth stage of the bearing capacity; stage II: Linear growth stage of the bearing capacity; stage III: Yielding growth stage of the bearing capacity; and stage IV: Weakening stage of the bearing capacity. (2) The response of the electrical resistivity and the evolution of AE energy were in good agreement with the mechanical behaviors at different stages, which could be used to reveal the global failure characteristics of sandwiched coal-rock specimens. The distribution of AE events and the development of local strain provide further insight into the local failure characteristics of coal or rock elements in the sandwiched specimens. (3) AE events generated earlier in coal elements, which expanded along with the increase of the loading time. Until the failure of sandwiched coal-rock specimens, almost all areas of coal elements were distributed with AE events. AE events also propagated across the coal-rock interfaces, thus local damage of rock elements was induced. For the C-R, R-C and R-C-R specimens, the AE events were distributed in the local areas of rock elements. For the R-C-R-C-R specimen, the upper and lower rock elements experienced local damage. However, the AE events were scattered throughout the whole interburden rock elements. (4) Local strain of coal elements and rock elements in the sandwiched specimen were not always coordinated during the whole failure process. Unbalanced deformation characteristics were apparently revealed. Compared with the rock element, the growth rate of the axial strain and lateral strain in the coal elements was much faster before the peak stress, which accelerated intense deformation of the coal elements. During the weakening stage of the bearing stress, the local strain of coal elements was continuously stable, while a certain recovery of the local strain was observed on the rock elements.

6. Conclusions

In this paper, the sandwiched coal-rock specimen was proposed to investigate the stability of overlapped residual coal pillars and the surrounding rock strata in ultra-close multiple seam mining. A series of uniaxial compression tests were designed and conducted for different kinds of sandwiched coal-rock specimens. The progressive failure characteristics and mechanisms of sandwiched coal-rock specimens were investigated. The following conclusions can be drawn:

(1) The roof strata, upper pillar, interburden strata, lower pillar, and floor strata form a whole bearing system in ultra-close multiple seam mining. The sandwiched coal-rock specimen was firstly proposed to study the stability of overlapped coal pillars and the surrounding rock strata.

(2) The mechanical behavior of the sandwiched coal-rock specimen is mainly divided into four stages during the progressive failure process: Nonlinear growth stage of the bearing capacity, linear growth stage of the bearing capacity, yielding growth stage of the bearing capacity, and weakening stage of the bearing capacity. The response of the electrical resistivity and the evolution of AE energy were in good agreement with the mechanical behaviors at different stages, which can be used to reveal the global failure characteristics of sandwiched coal-rock specimens.

(3) The distribution of AE events and the development of local strain can provide further insight into the local failure characteristics of coal elements or rock elements in sandwiched system. AE events are more likely to generate in coal elements, which can propagate across the coal-rock interfaces and induce the damage of rock elements in a certain area. Similarly, the unbalanced deformation characteristics of coal elements and rock elements were apparently revealed during the progressive failure process of sandwiched coal-rock specimens. The growth rate of local strain on coal elements was much faster than that on rock elements in the initial loading process. A certain recovery of the local strain was observed on the rock elements after the peak stress.

(4) The progressive failure of sandwiched coal-rock specimen was closely associated with the interactions between the coal elements and rock elements. Initial failure usually appeared in the coal elements. In this process, the recovery of the elastic deformation and the output of the strain energy were observed in the rock elements, which can accelerate the rupture of coal elements. In turn, the dynamic fracture energy generated in the rupture process of coal elements can propagate into the rock elements and induce damage of rock elements in a certain area. Consequently, sudden collapse of the sandwiched coal-rock specimen occurred.

(5) The experimental results are helpful for maintaining the long-term stability of sandwiched coal-rock systems in ultra-close multiple seam mining. Overlapped coal pillars should firstly be designed with proper sizes. The backfilling method should be implemented to share the overburdening weight and generate a lateral constraint for the residual coal pillars. Once coal pillars begin to rupture, the pre-cracking technique should be applied to mitigate the propagation of stored strain energy in the surrounding rock strata. Moreover, the interburden rock strata can receive the dynamic fracture energy from the upper coal pillars and lower coal pillars. The stability of interburden rock strata should be given more attention in ultra -close multiple seam mining.