Effects of Magnetic Fields on Quench Characteristics of Superconducting Tape for Superconducting Fault Current Limiter

Abstract

:1. Introduction

2. SFCLs in a Power System

2.1. The Advantage of the R-SFCL to DC Distribution System

2.2. The Requirements to the R-SFCL

3. Experimental Step

3.1. Schematic of the Testing Samples

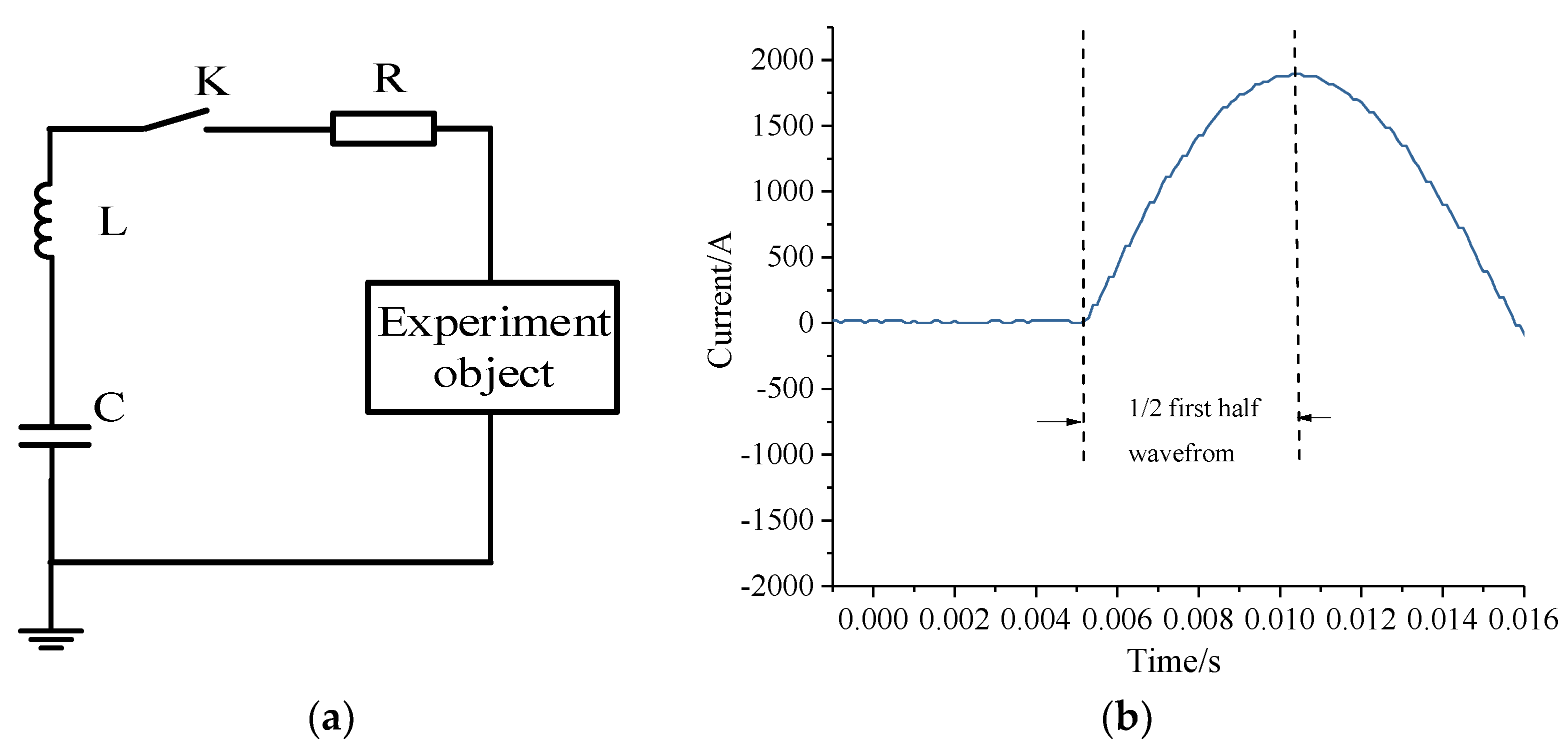

3.2. Testing Circuit

3.3. Testing Conditions

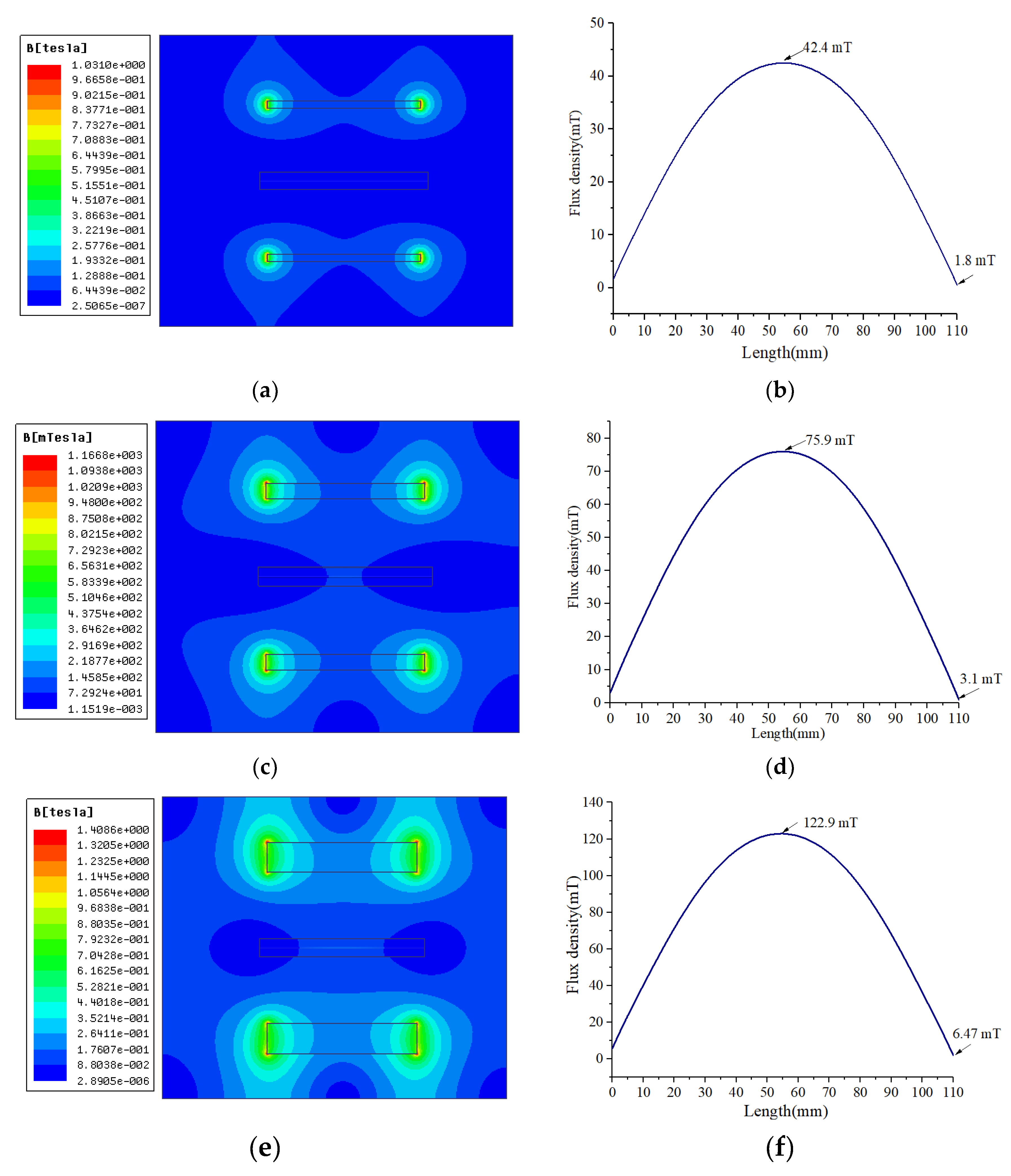

4. Simulation of Magnetic Fields

5. Effects of Magnetic Fields on Quenching Characteristics of Superconducting Tapes

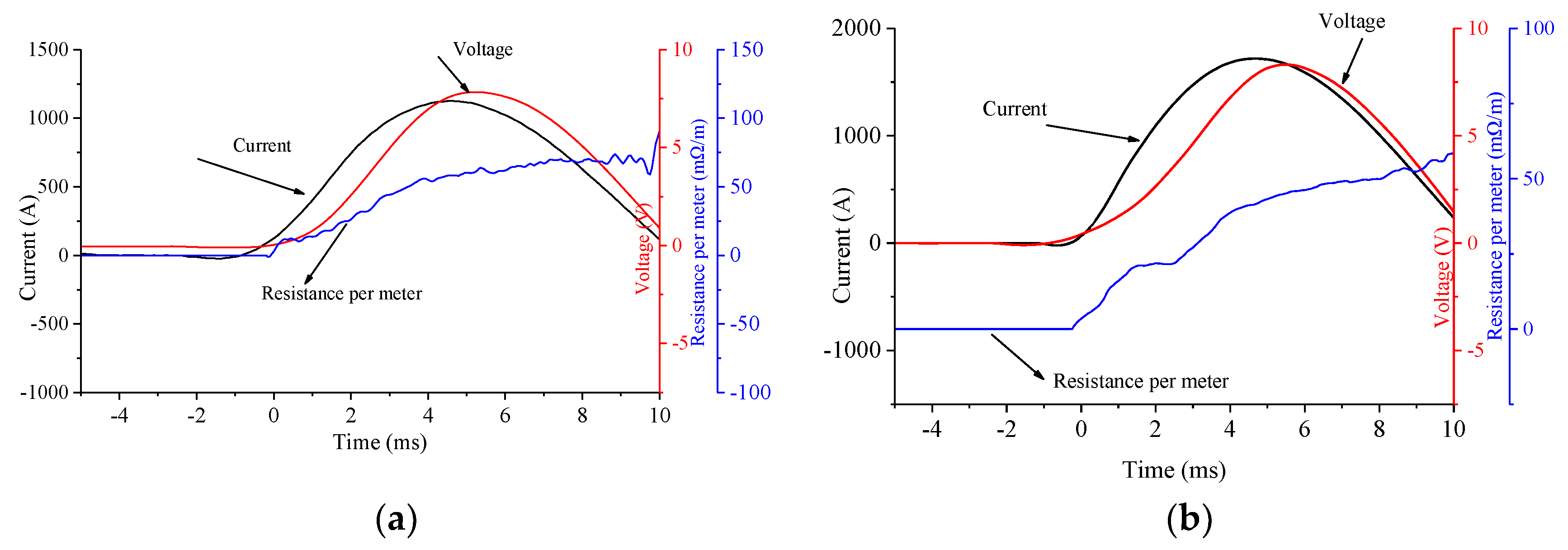

5.1. Waveforms of Experimental Results

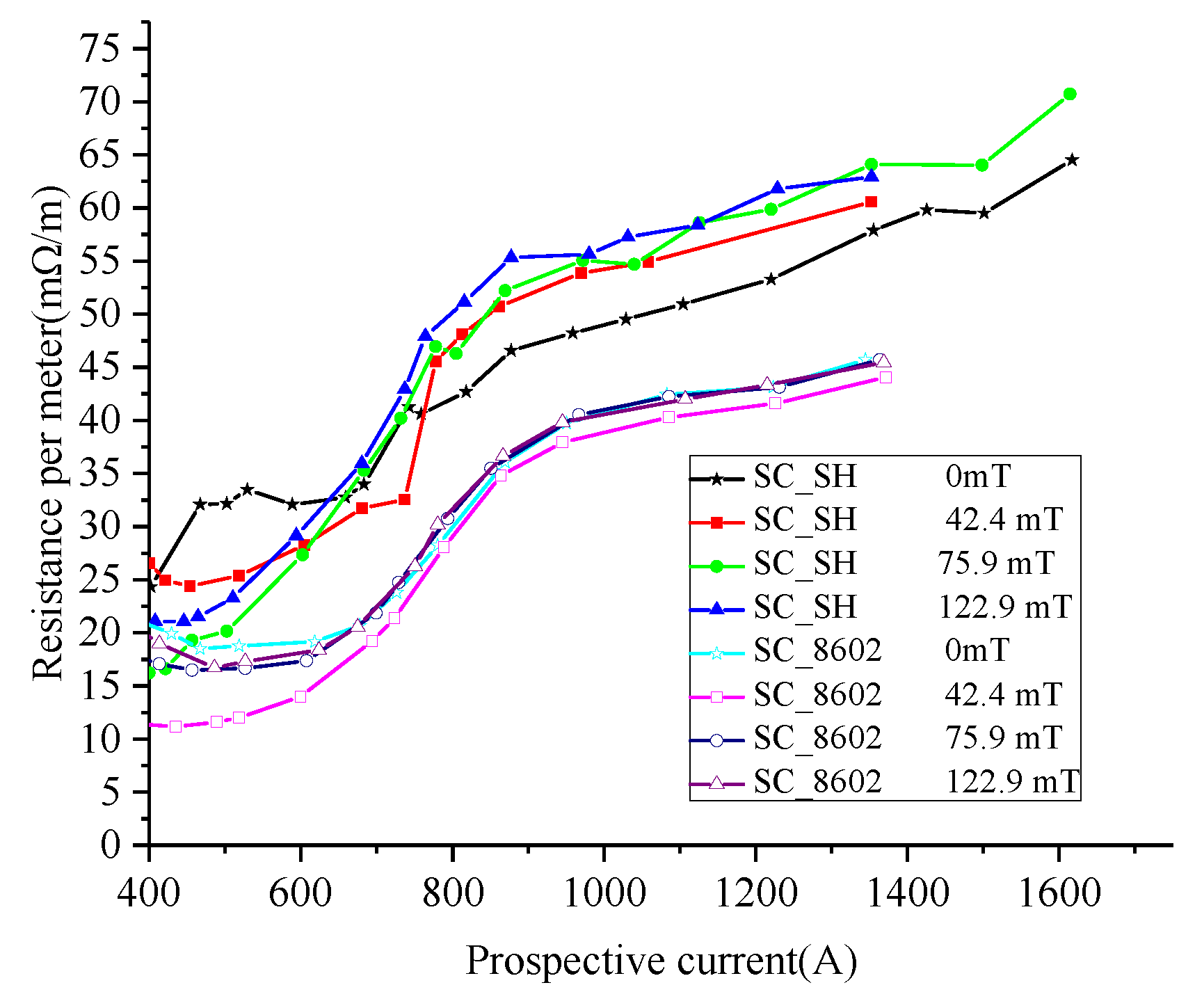

5.2. Effects of Magnetic Fields on the Quenched Characteristics of Superconducting Tapes

6. Conclusions

- (1)

- The magnetic fields influenced both the amplitude and the rising rate of the quenched resistance of the SC_SH tape.

- (2)

- When the prospective current was 1200 A, the quenched resistance of SC_SH superconducting types increased with an increase of the magnet fields. However, the magnetic fields had little effect on the quenched resistance of the SC_8602 superconducting types.

- (3)

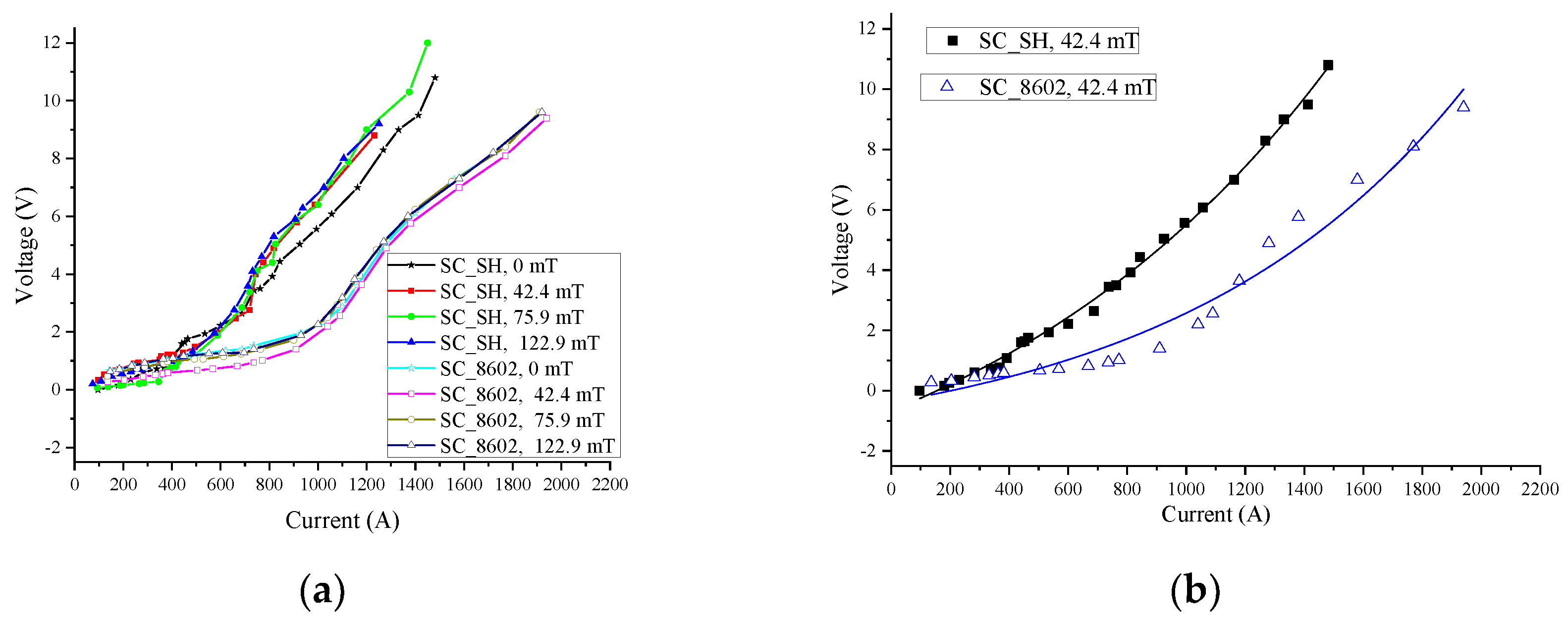

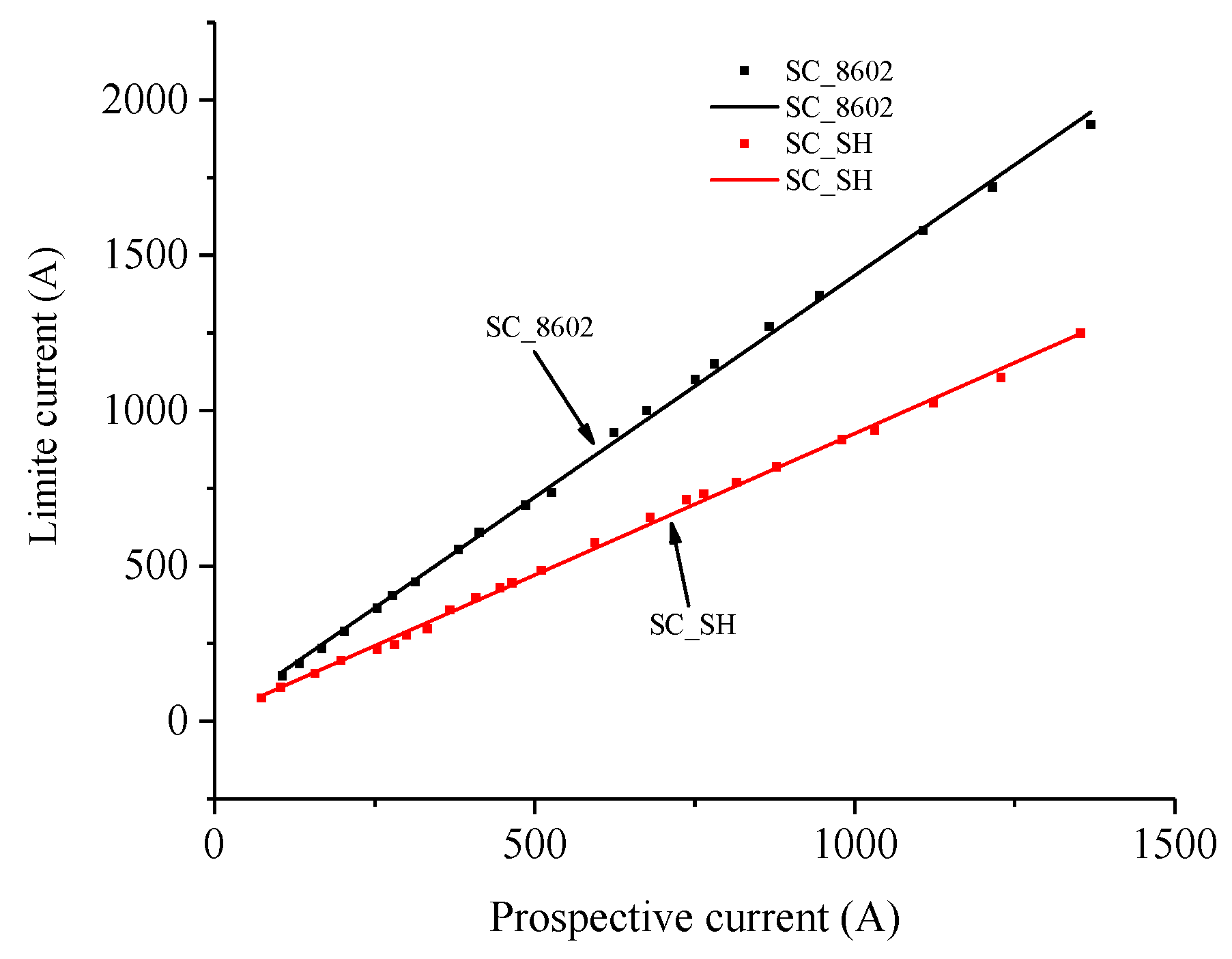

- The effects of the transport current on the voltage of the two kinds of tapes increased with exponential growth. The voltage between the SC_SH was higher than the SC_8602 under the same transport current.

- (4)

- Under the same magnetic fields, both the rising rate and the amplitude of quenched resistance of SC_SH were higher than that of SC_8602 when the prospective current exceeded 800 A. Thus, SC_SH can limit the current quicker and to a lower level than SC_8602.

- (5)

- The SC_SH tapes were more sensitive to the magnetic field. The magnetic field can prevent a local hot spot in the YBCO tapes, which may cause burnout. Furthermore, the R-SFCL with SC_SH tapes could achieve a more uniform quench distribution with magnetic fields.

Author Contributions

Funding

Conflicts of Interest

References

- Liang, C.; Li, C.; Zhang, P.; Song, M.; Ma, T.; Zhou, T.; Ge, Z. Winding Technology and Experimental Study on 500 kV Superconductive Fault Current Limiter. IEEE Trans. Appl. Supercond. 2018, 28, 5601105. [Google Scholar] [CrossRef]

- Yang, J.; Fletcher, J.E.; O’Reilly, J. Short-circuit and ground fault analyses and location in VSC-based dc network cable. IEEE Trans. Ind. Electron. 2012, 59, 3827–3837. [Google Scholar] [CrossRef]

- Lee, J.G.; Khan, U.A.; Lee, H.Y.; Lee, B.W. Impact of SFCL on the four types of HVDC circuit breakers by simulation. IEEE Trans. Appl. Supercond. 2016, 26, 5602606. [Google Scholar] [CrossRef]

- Xiang, B.; Liu, Z.; Wang, C.; Nan, Z.; Geng, Y.; Wang, J.; Yanabu, S. DC Interrupting with Self-excited Oscillation Based on Superconducting Current-Limiting Technology. IEEE Trans. Power Deliv. 2018, 33, 529–536. [Google Scholar] [CrossRef]

- Xiang, B.; Liu, Z.; Geng, Y.; Yanabu, S. DC Circuit Breaker Using Superconductor for Current Limiting. IEEE Trans. Appl. Supercond. 2015, 25, 5600207. [Google Scholar]

- Xiang, B.; Yang, K.; Tan, Y.; Liu, Z.; Geng, Y.; Wang, J.; Yanabu, S. DC-Current-Limiting Characteristics of YBCO Tapes for DC Currents of 50 A to 10 Ka. IEEE Trans. Appl. Supercond. 2017, 27, 5600605. [Google Scholar] [CrossRef]

- Yazawa, T.; Koyanagi, K.; Takahashi, M.; Ono, M.; Toba, K.; Takigami, H.; Urata, M.; Iijima, Y.; Saito, T.; Amemiya, N.; et al. Supercon-ducting fault current limiter using high-resistive YBCO tapes. Physica 2008, 468, 2046–2049. [Google Scholar] [CrossRef]

- Hernandez-Llambes, J.C.; Hazelton, D. Advantages of secondgeneration high temperature superconductors for pulsed power applications. In Proceedings of the Pulsed Power Conference, Washington, DC, USA, 28 June–2 July 2019; pp. 221–226. [Google Scholar]

- Jiang, Z.; Wang, Y.; Zhang, H.; Kan, C.; Fu, Y. Coil design of 200 MVA/200 kV DC superconducting fault current limiter by employing iron yoke. IEEE Trans. Appl. Supercond. 2017, 27, 5600905. [Google Scholar]

- Dias, D.H.N.; Sotelo, G.G.; Dias, F.J.M.; Rocha, L.M.M.; Matins, F.G.R.; Sass, F.; Polasek, A. Characterization of a second generation HTS coil for electrical power devices. IEEE Trans. Appl. Supercond. 2014, 25, 4601304. [Google Scholar] [CrossRef]

- Kopylov, S.I.; Balashov, N.N.; Zheltov, V.V.; Krivetsky, I.V.; Sytnikov, V.E. The effect of sectioning on the characteristics of resistive superconducting fault current limiter. IEEE Trans. Appl. Supercond. 2015, 25, 5602604. [Google Scholar] [CrossRef]

- Qiu, Q.; Xiao, L.; Zhang, Z.; Jing, L.; Liu, S.; Zhang, G. Investigation of flux-coupling type superconducting fault current limiter with multiple parallel branches. IEEE Trans. Appl. Supercond. 2016, 26, 5601305. [Google Scholar] [CrossRef]

- Tekletsadik, K.; Saravolac, M.P.; Rowley, A. Development of a 7.5 MVA superconducting fault curren limiter. IEEE Trans. Appl. Supercond. 1999, 9, 672–675. [Google Scholar] [CrossRef]

- Ito, D.; Yang, C.; Miura, O. kA class resistive fault current limiting device development using QMG HTS bulk superconductor. IEEE Trans. Appl. Supercond. 1999, 9, 1312–1315. [Google Scholar] [CrossRef]

- Elschner, S.; Breuer, F.; Walter, H.; Bock, J. Magnetic Field “Assisted Quench Propagation as a New Concept for Resistive Current Limiting Devices”. J. Phys. Conf. Ser. 2006, 43, 917–920. [Google Scholar] [CrossRef]

- Kato, H.; Miura, O.; Ito, D. Quench behaviors of QMG current limiting elements under the influence of magnetic field. IEEE Trans. Appl. Supercond. 2000, 10, 869–872. [Google Scholar] [CrossRef]

- Park, K.B.; Kang, J.S.; Lee, B.W.; Oh, I.S.; Choi, H.S.; Kim, H.R.; Hyun, O.B. Quench Behavior of YBaCuO Films for Fault Current Limiters Under Magnetic Field. IEEE Trans. Appl. Supercond. 2003, 13, 2092–2095. [Google Scholar] [CrossRef]

- Lee, B.W.; Park, K.B.; Kang, J.S.; Oh, I.S. Quench characteristics of YBCO thin films using magnetic field source for superconducting fault limiter. J. Korea Inst. Appl. Supercond. Cryog. 2004, 6, 11–14. [Google Scholar]

- Matsumura, T.; Shimizu, H.; Yokomizu, Y. Design guideline of flux-lock type HTS fault current limiter for power system application. IEEE Trans. Appl. Supercond. 2001, 11, 1956–1959. [Google Scholar] [CrossRef]

- Matsumura, T.; Uchii, T.; Yokomizu, Y. Development of flux-lock-type current limiter with high-Tc superconducting element. IEEE Trans. Appl. Supercond. 1997, 7, 1001–1004. [Google Scholar] [CrossRef]

- Lim, S.H.; Choi, H.-S.; Han, B.-S. The fault current limiting characteristics of a flux-lock type high-Tc superconducting fault current limiter using series resonance. Cryogenics 2004, 44, 249–254. [Google Scholar] [CrossRef]

- Lim, S.H.; Choi, H.S.; Chung, D.C.; Ko, S.; Han, B.S. Impedance Variation of a Flux-Lock Type SFCL Dependent on Winding Direction Between Coil 1 and Coil 2. IEEE Trans. Appl. Supercond. 2005, 15, 2039–2042. [Google Scholar] [CrossRef]

- Lim, S.H.; Kang, H.G.; Choi, H.S.; Lee, S.R.; Han, B.S. Current Limiting Characteristics of Flux-Lock Type High-TC Superconducting Fault Current Limiter with Control Circuit for Magnetic Field. IEEE Trans. Appl. Supercond. 2003, 13, 2056–2059. [Google Scholar]

- Li, B.; He, J. Studies on the Application of R-SFCL in the VSC-Based DC Distribution System. IEEE Trans. Appl. Supercond. 2016, 26, 1–5. [Google Scholar] [CrossRef]

| Sample | SC_SH | SC_8602 |

|---|---|---|

| Length/cm | 11 | 11 |

| Width/mm | 12 | 12 |

| Critical Current Ic/A (77K, self-magnetic field) | 230 | 225 |

| Room resistance per meter/Ω/m | 0.125 | 0.117 |

| Magnet Field (mT) | Rising Rate of Quenched Resistance (mΩ/A) | ||||

|---|---|---|---|---|---|

| SC_SH | SC_8602 | ||||

| 400–900 (A) | >900 (A) | 400–620 (A) | 620–900 (A) | >900 (A) | |

| 0 | 0.0289 | 0.0208 | 0.0068 | 0.0571 | 0.0127 |

| 42.4 | 0.0292 | 0.0183 | 0.0077 | 0.0583 | 0.0125 |

| 75.9 | 0.0450 | 0.0244 | 0.0071 | 0.0574 | 0.0118 |

| 122.9 | 0.0336 | 0.0165 | 0.0125 | 0.0613 | 0.0175 |

| Magnet Field (mT) | The Value of Quenched Resistance (mΩ/m) | |

|---|---|---|

| SC_SH | SC_8602 | |

| 1200(A) | 1200(A) | |

| 0 | 53.28 | 43.14 |

| 42.4 | 56.92 | 41.60 |

| 75.9 | 59.87 | 43.14 |

| 122.9 | 61.81 | 43.34 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiang, B.; Gao, L.; Junaid, M.; Liu, Z.; Geng, Y.; Wang, J.; Yanabu, S. Effects of Magnetic Fields on Quench Characteristics of Superconducting Tape for Superconducting Fault Current Limiter. Appl. Sci. 2019, 9, 1466. https://doi.org/10.3390/app9071466

Xiang B, Gao L, Junaid M, Liu Z, Geng Y, Wang J, Yanabu S. Effects of Magnetic Fields on Quench Characteristics of Superconducting Tape for Superconducting Fault Current Limiter. Applied Sciences. 2019; 9(7):1466. https://doi.org/10.3390/app9071466

Chicago/Turabian StyleXiang, Bin, Lei Gao, Muhammad Junaid, Zhiyuan Liu, Yingsan Geng, Jianhua Wang, and Satoru Yanabu. 2019. "Effects of Magnetic Fields on Quench Characteristics of Superconducting Tape for Superconducting Fault Current Limiter" Applied Sciences 9, no. 7: 1466. https://doi.org/10.3390/app9071466