CO2 Transcritical Refrigeration Cycle with Dedicated Subcooling: Mechanical Compression vs. Absorption Chiller

Abstract

:1. Introduction

2. Material and Methods

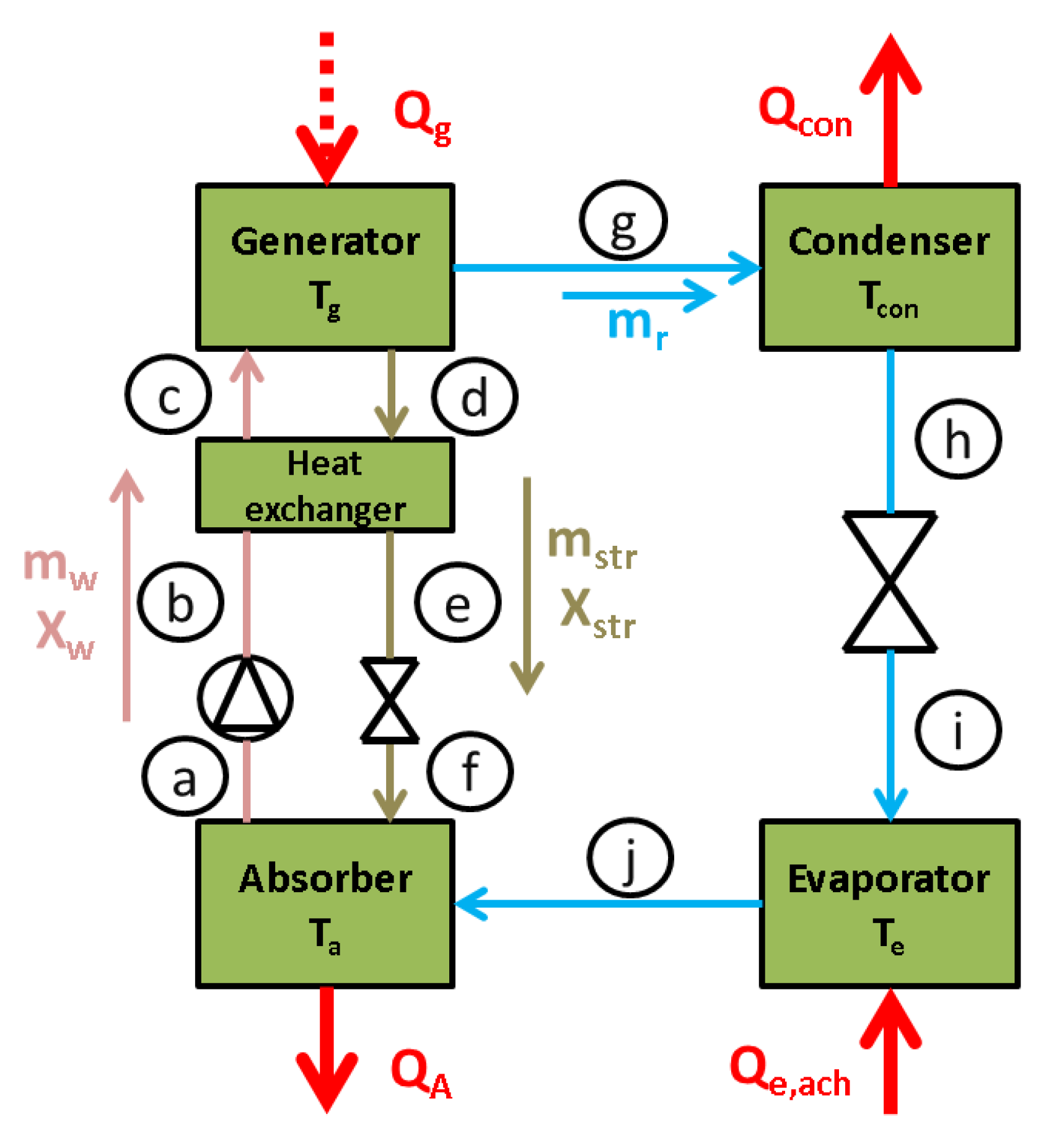

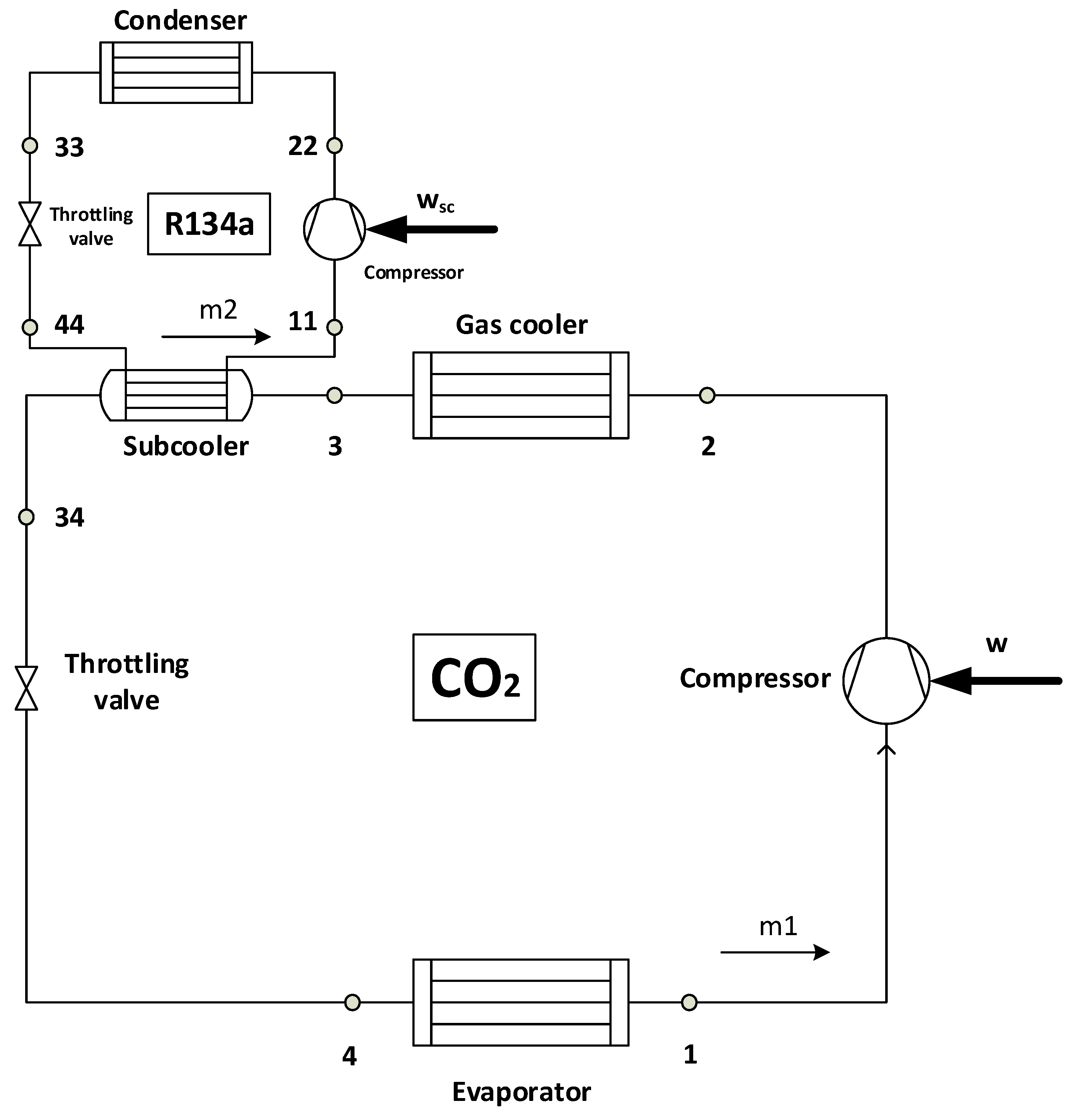

2.1. The Examined Systems

2.2. Mathematical Formulation

2.3. Followed Methodology

- -

- There is no pressure drop in the devices.

- -

- All the systems are in steady-state conditions.

- -

- There is no superheating in the evaporator outlet for the main cycle, as well as for the subcooling cycles.

- -

- The expansion in the throttling valves is adiabatic, which means that the inlet enthalpy is equal to the outlet enthalpy because the process is adiabatic without any work production/consumption (first thermodynamic law). This assumption is applied in the main cycle, as well as in the subcooling cycles.

- -

- The heat exchanger effectiveness in the absorption chiller is 70%.

- -

- The cooling capacity is 100 kW in all the cases.

- -

- The heat rejection temperature is the same in all cases. More specifically this parameter (Tc) regards the gas cooler outlet temperature, the condenser of the M-SC, the condenser of the ACH-SC, and the absorber of the ACH-SC.

- -

- The approach temperature difference in the subcooler is 5 °C. This fact means that the evaporating temperature in the subcooling cycle is 5 °C lower than the temperature level of the CO2 in the outlet of the subcooler.

- -

- The cooling capacity of the subcooling system is depended on the operating conditions and on the subcooling value of every examined scenario.

2.4. Model Validation

3. Results and Discussion

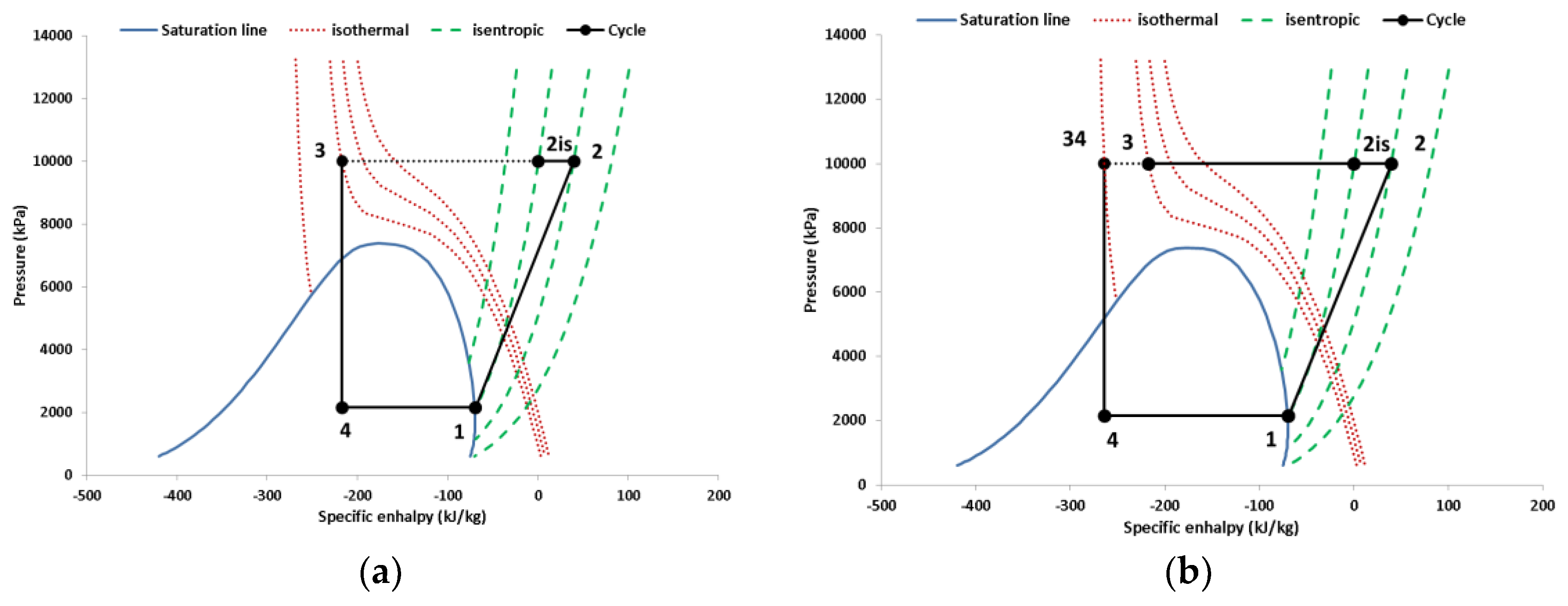

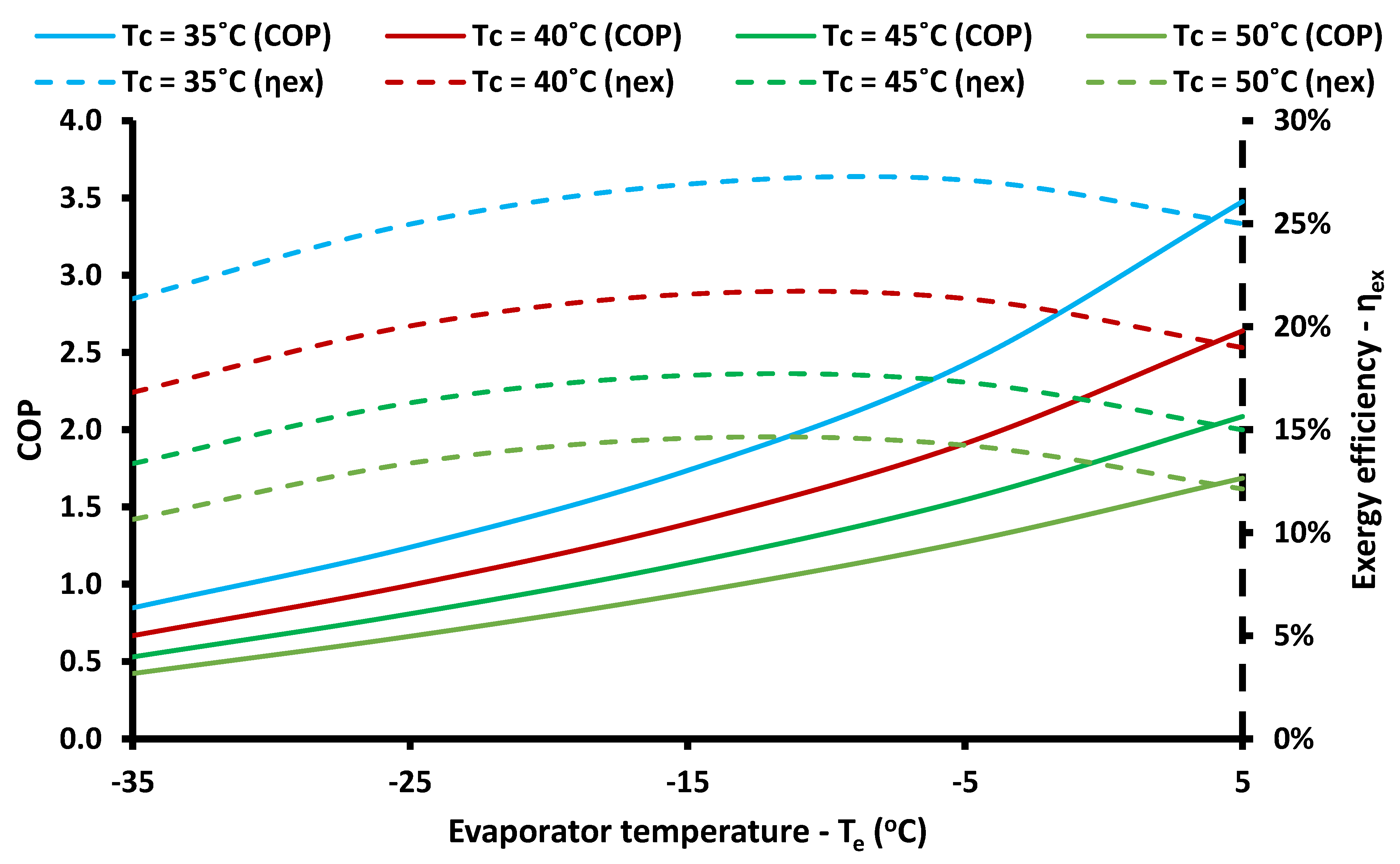

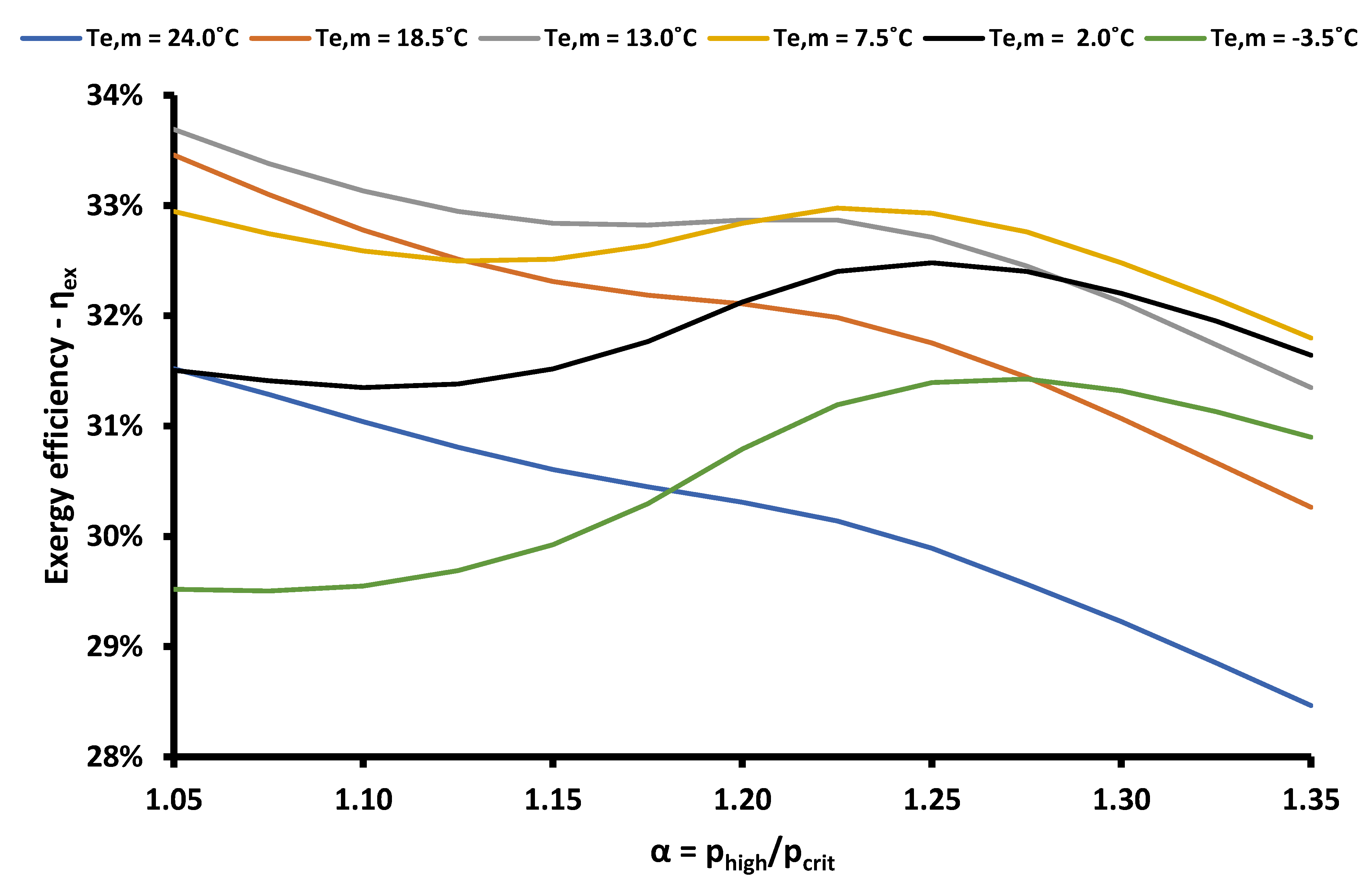

3.1. Reference System Performance

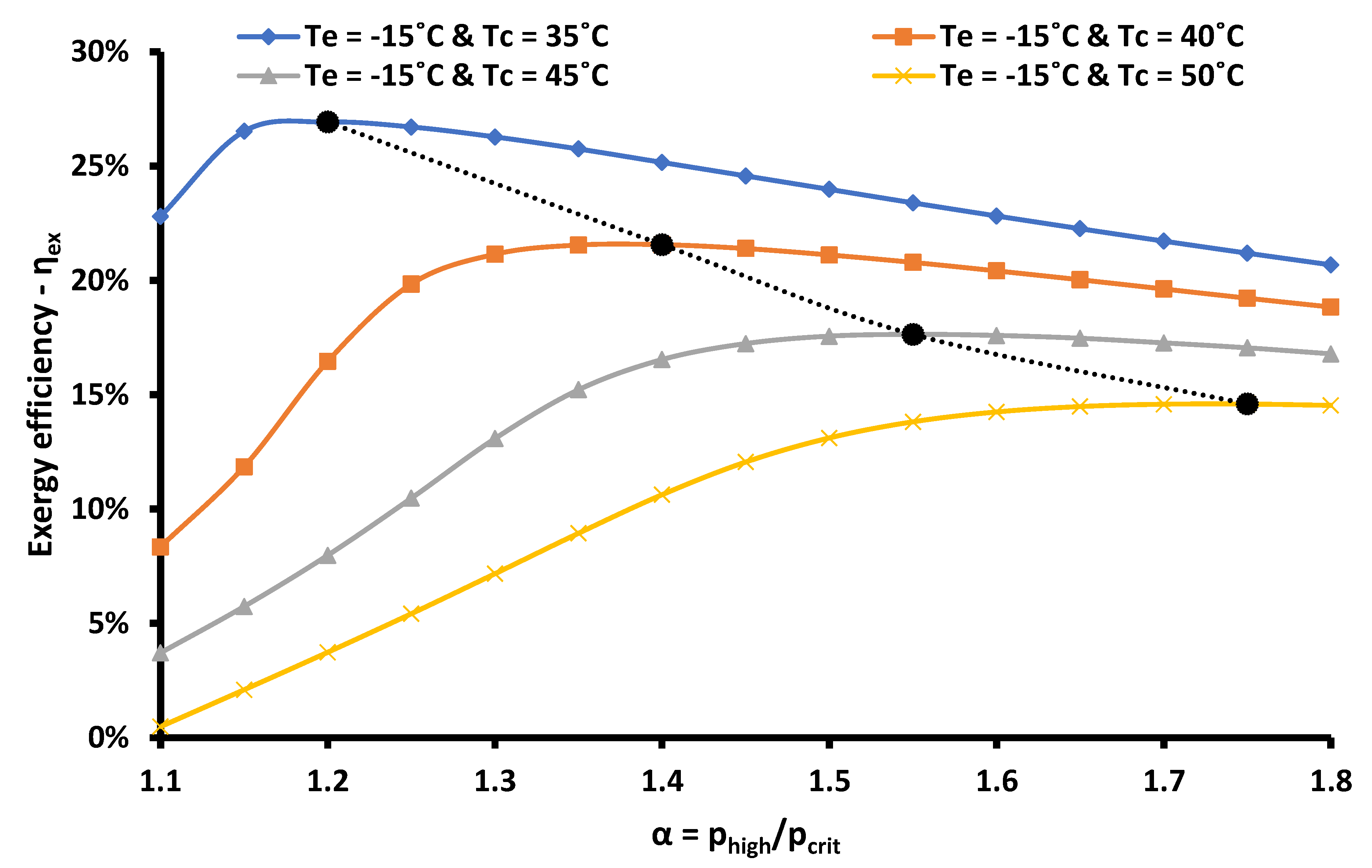

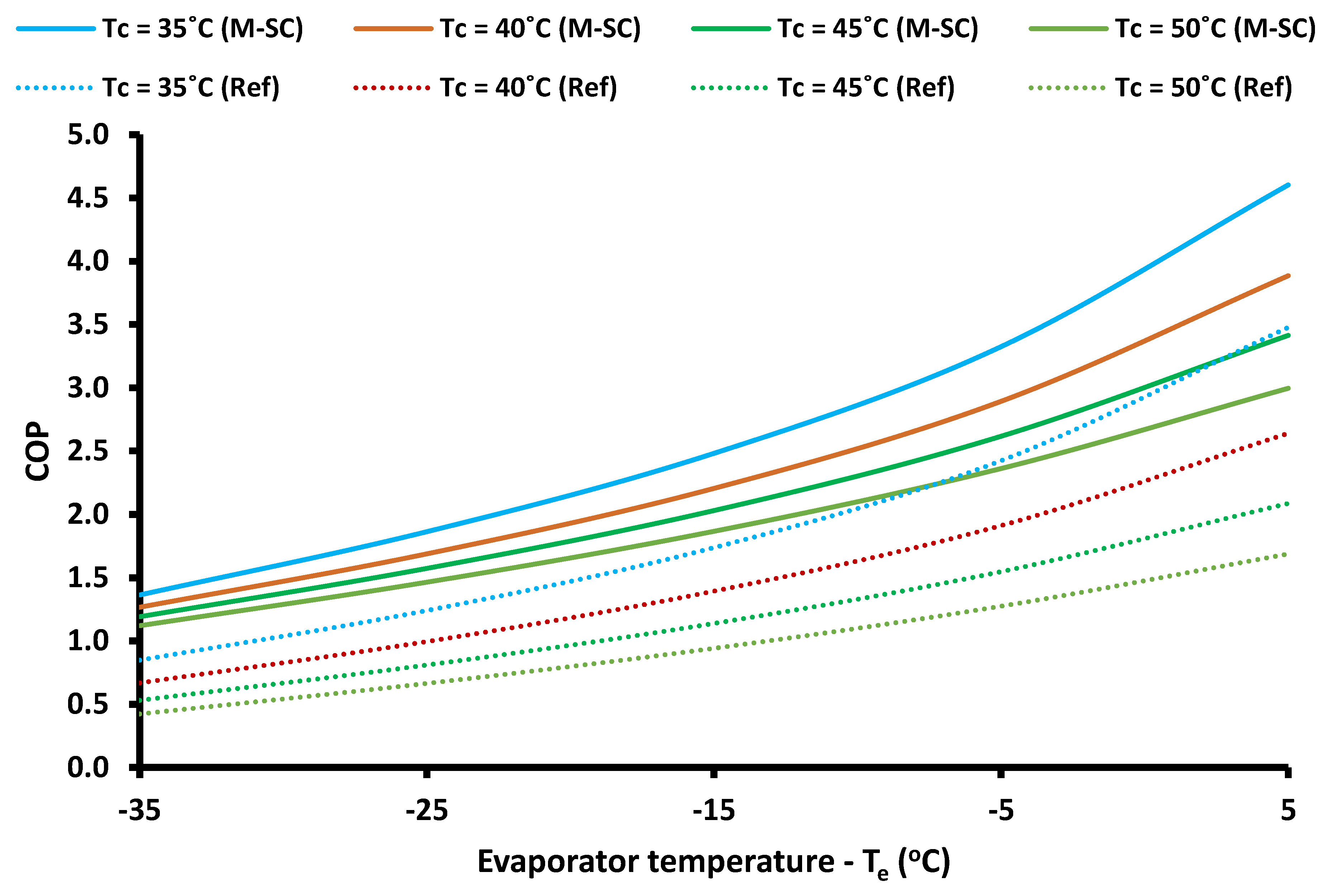

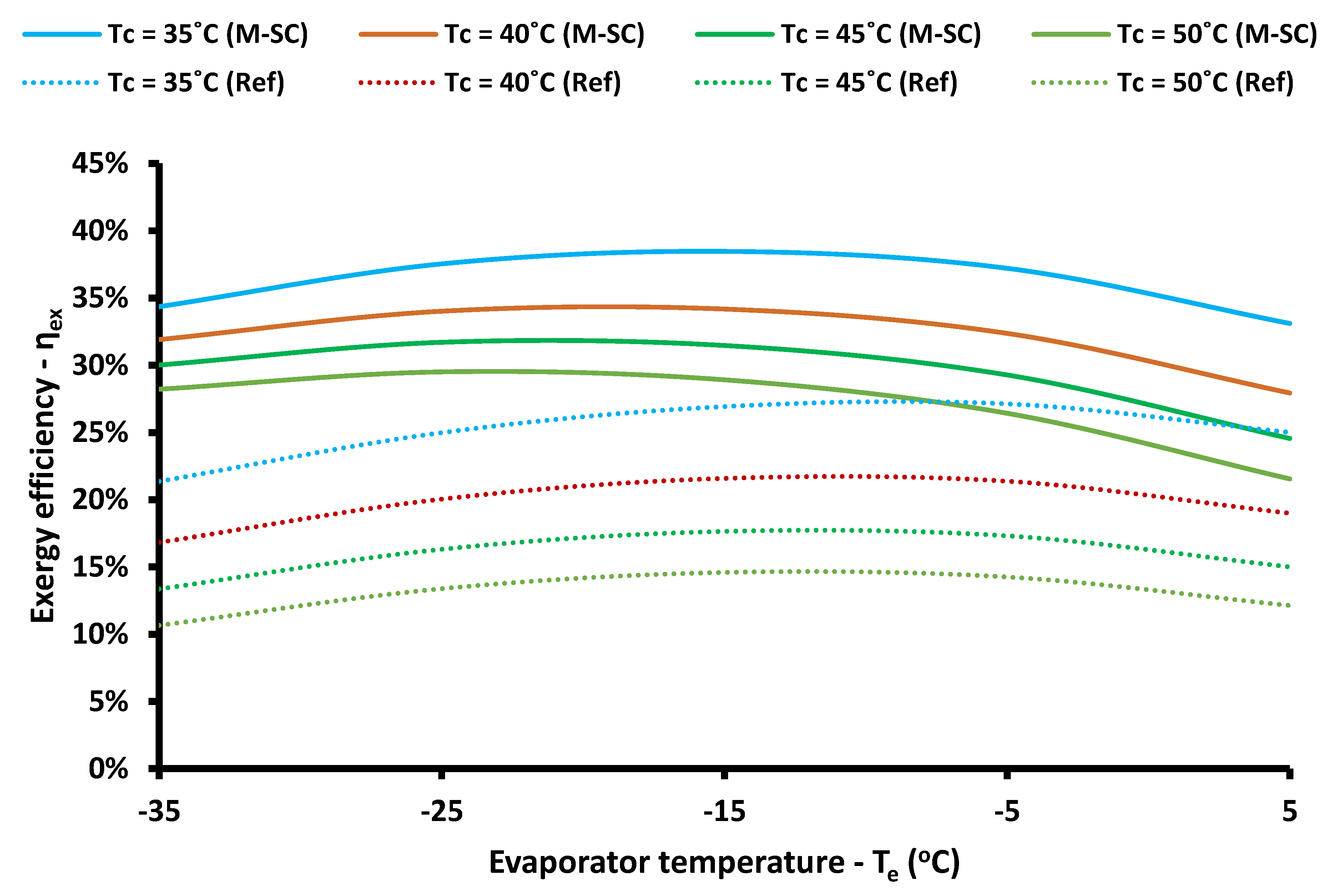

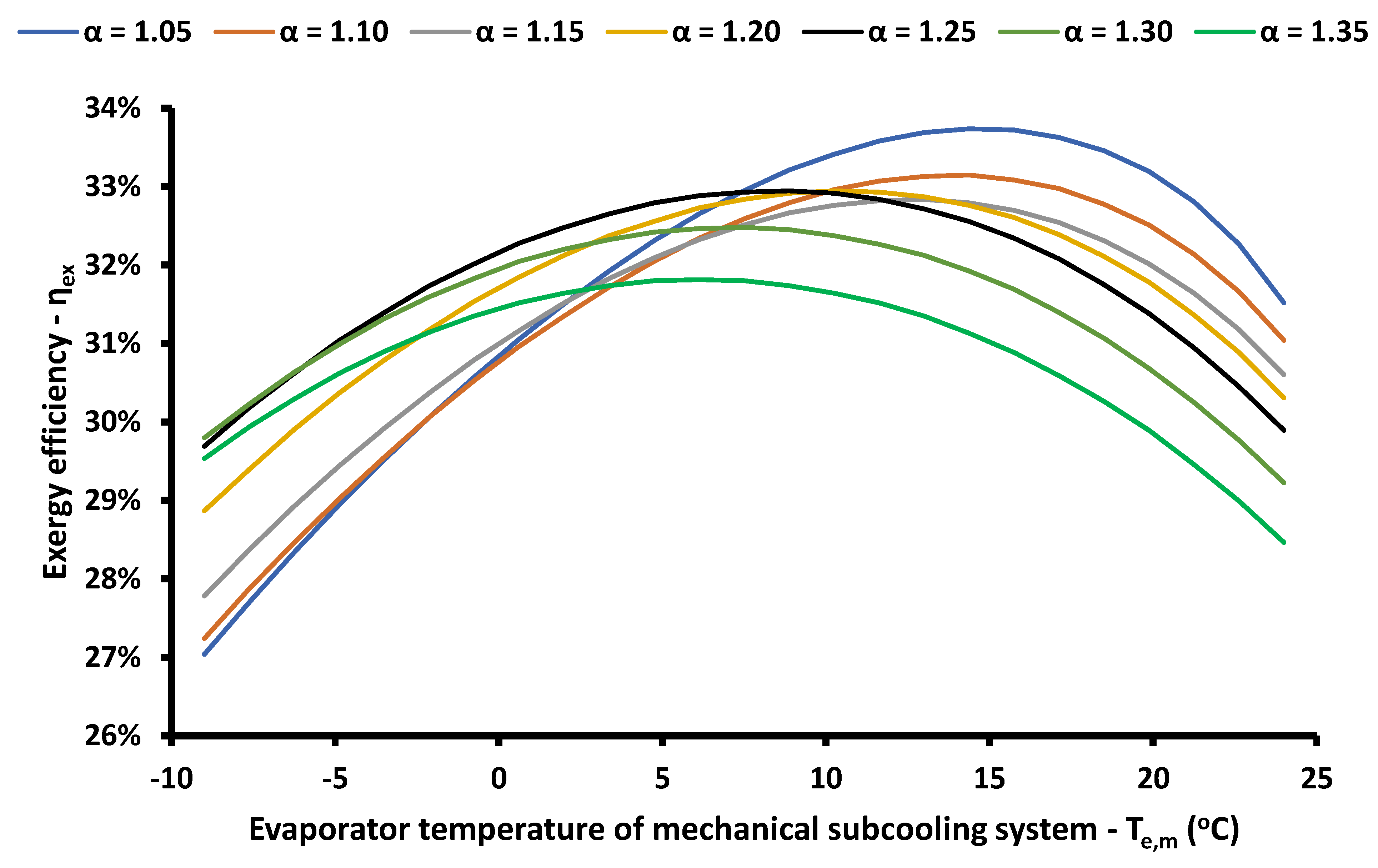

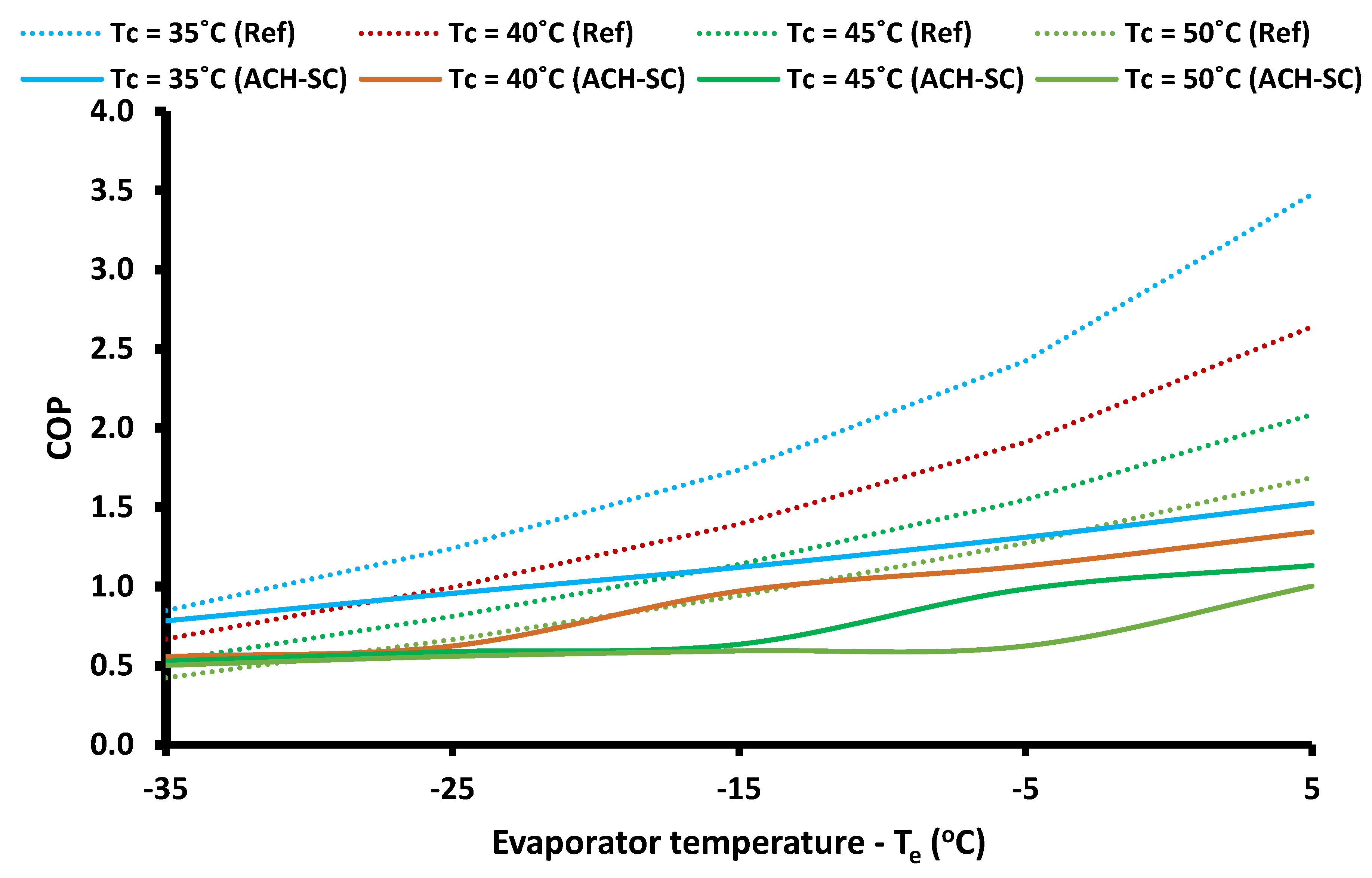

3.2. Mechanical Subcooling System Performance

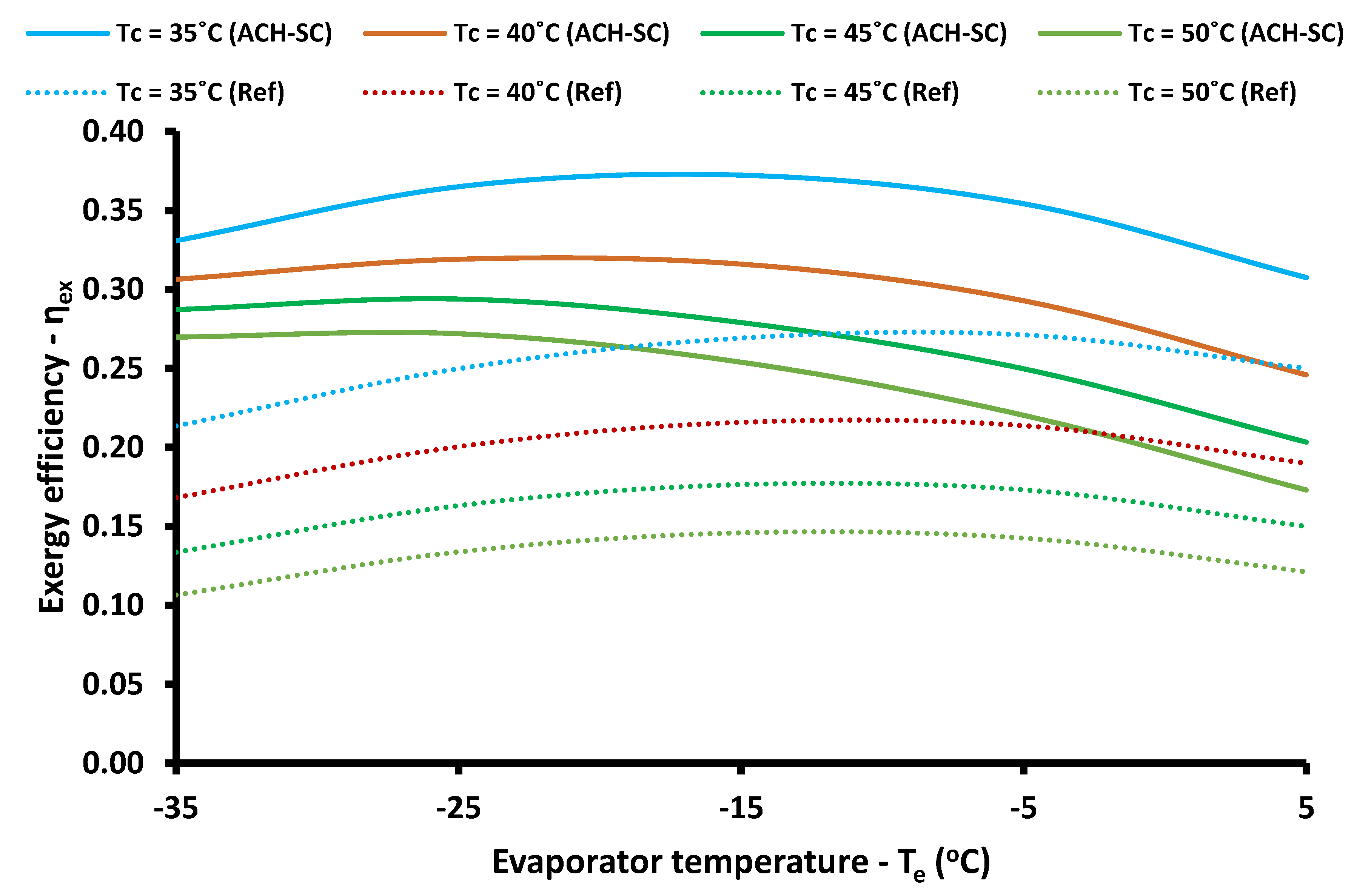

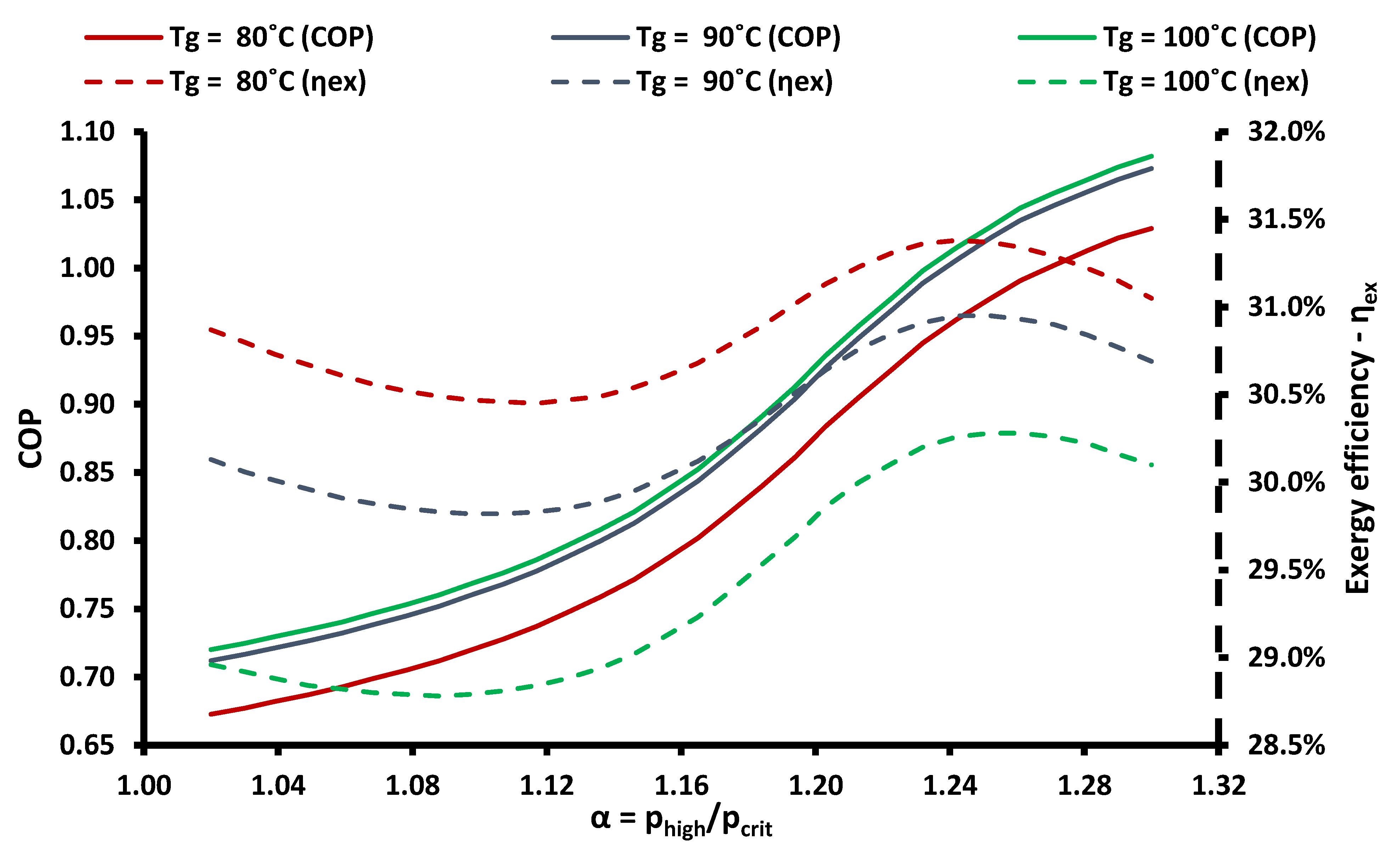

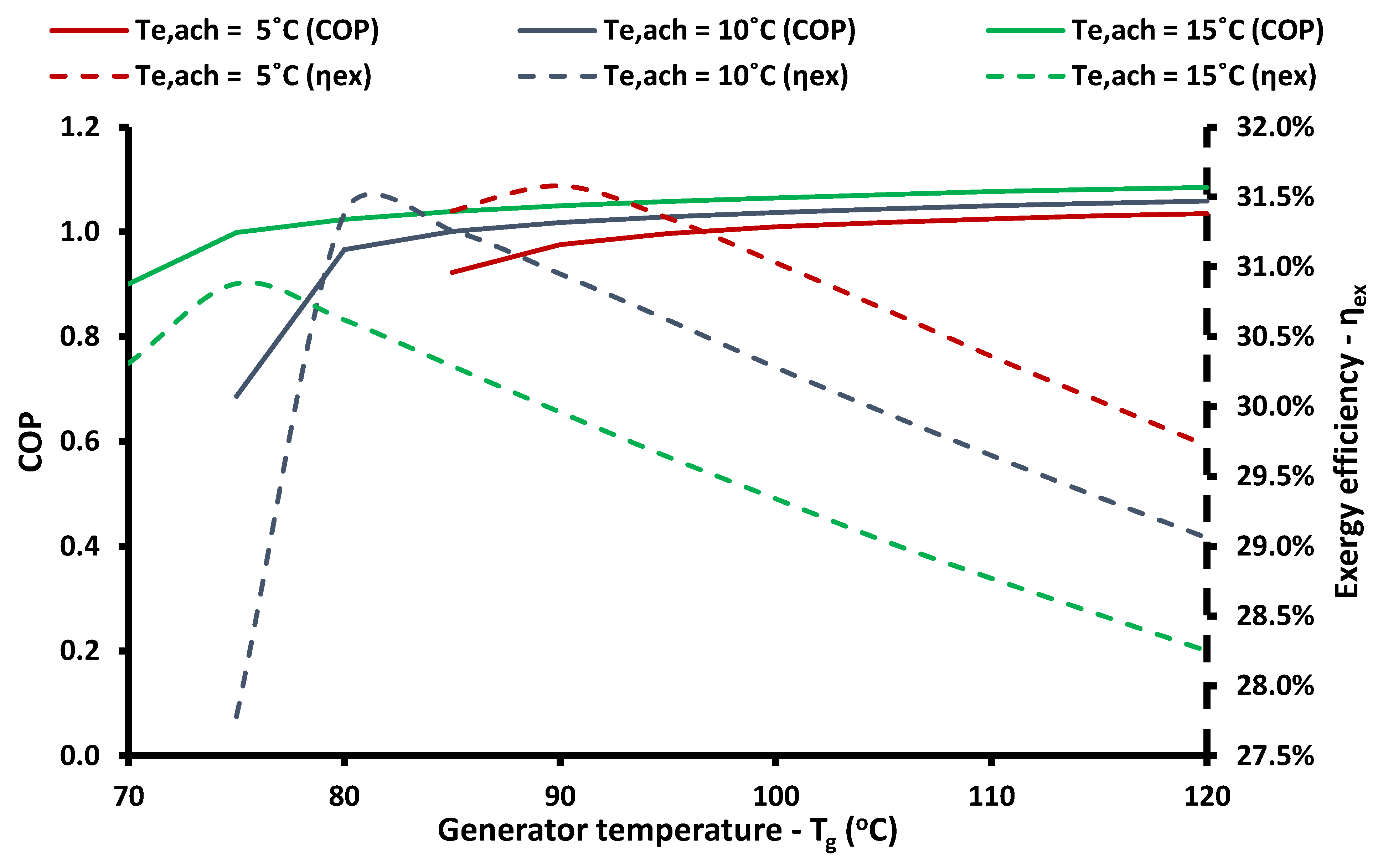

3.3. Absorption Chiller Subcooling System Performance

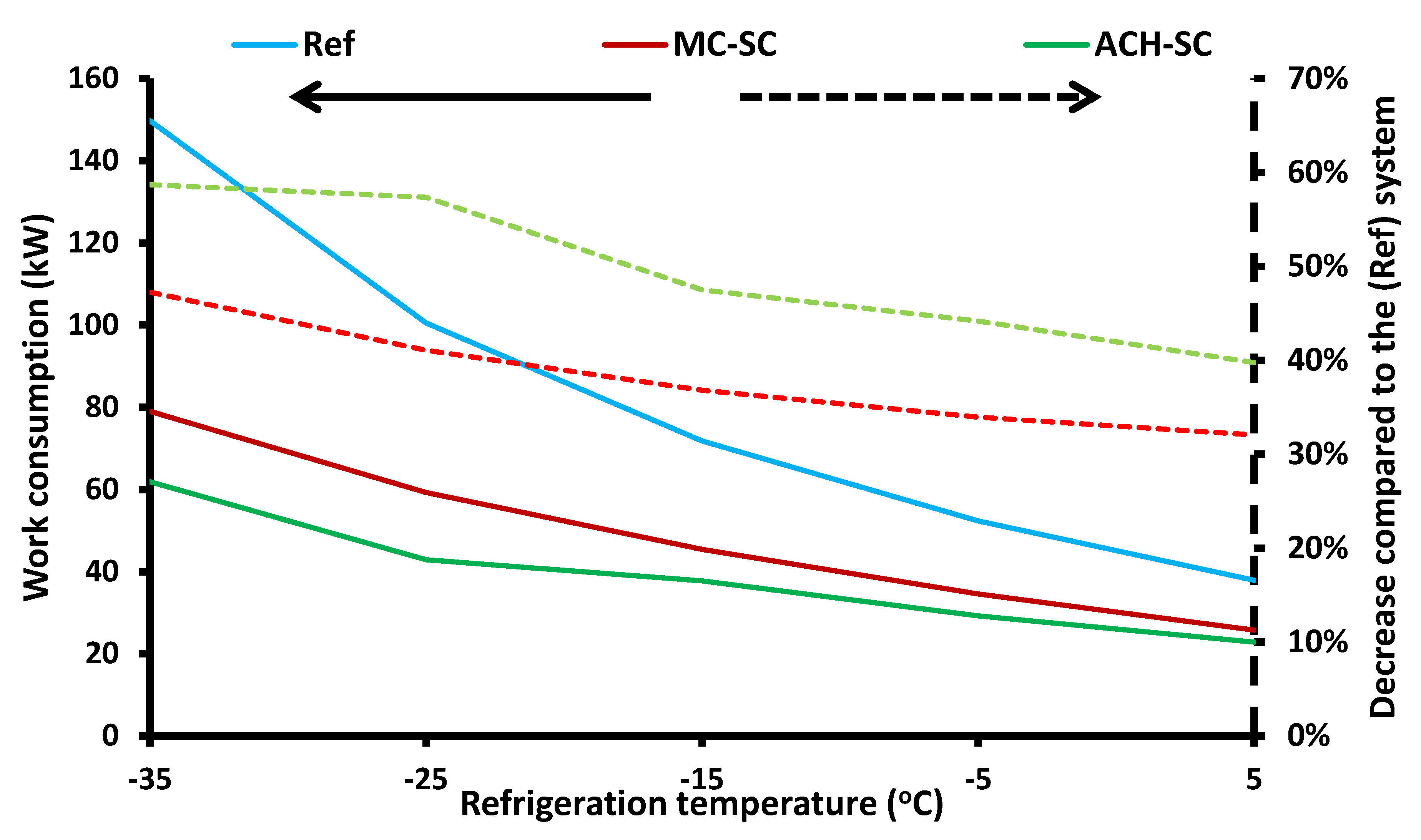

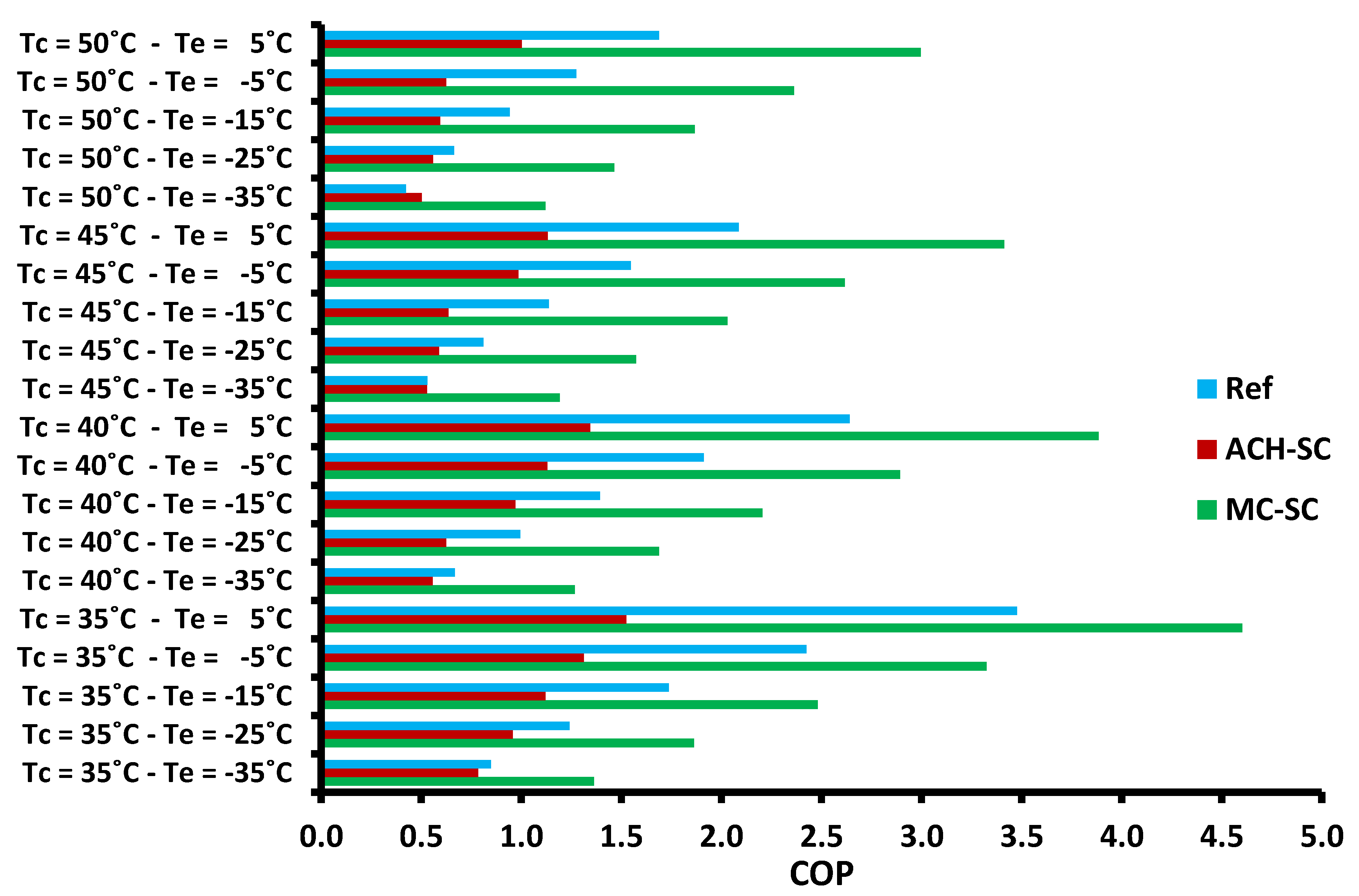

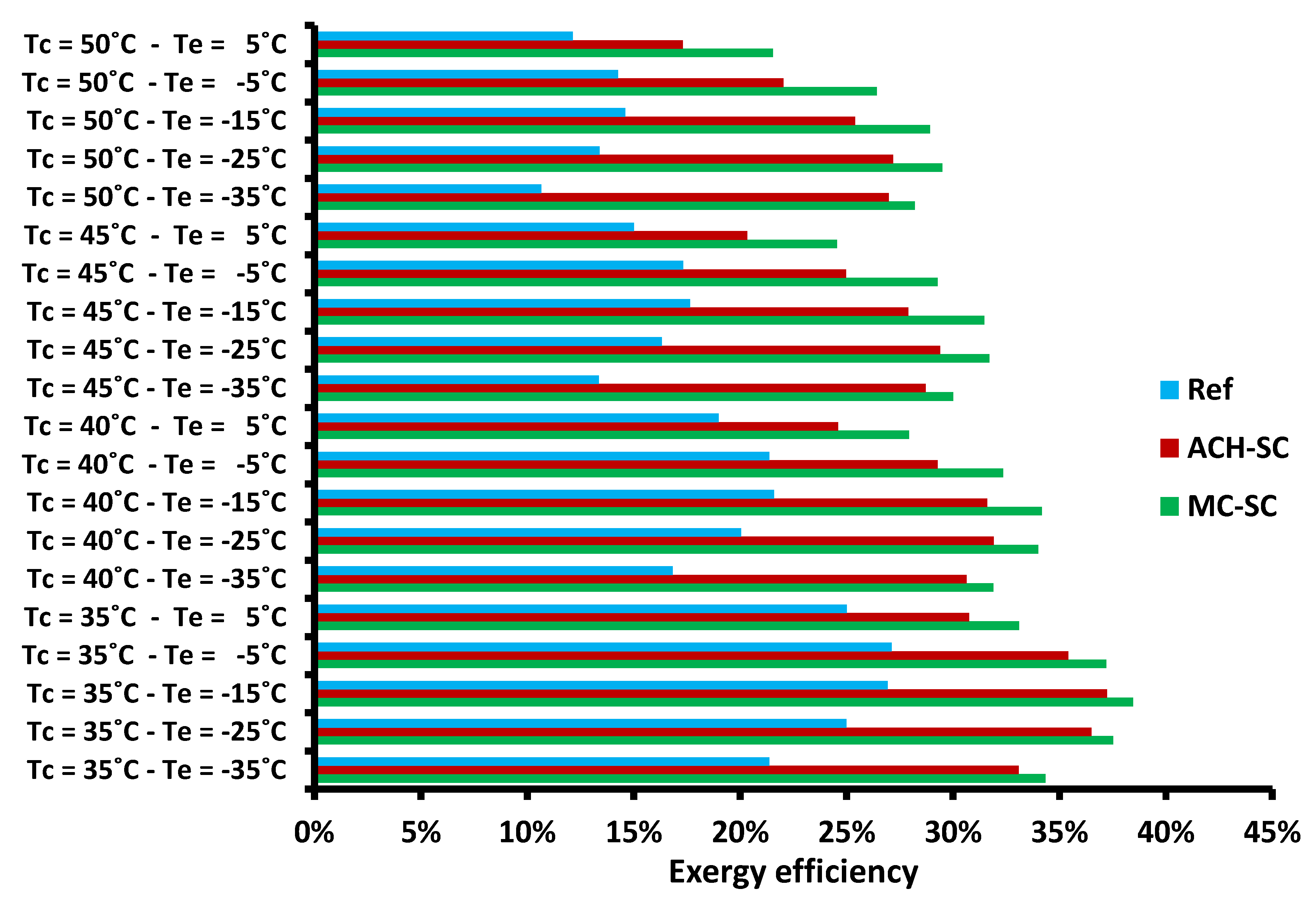

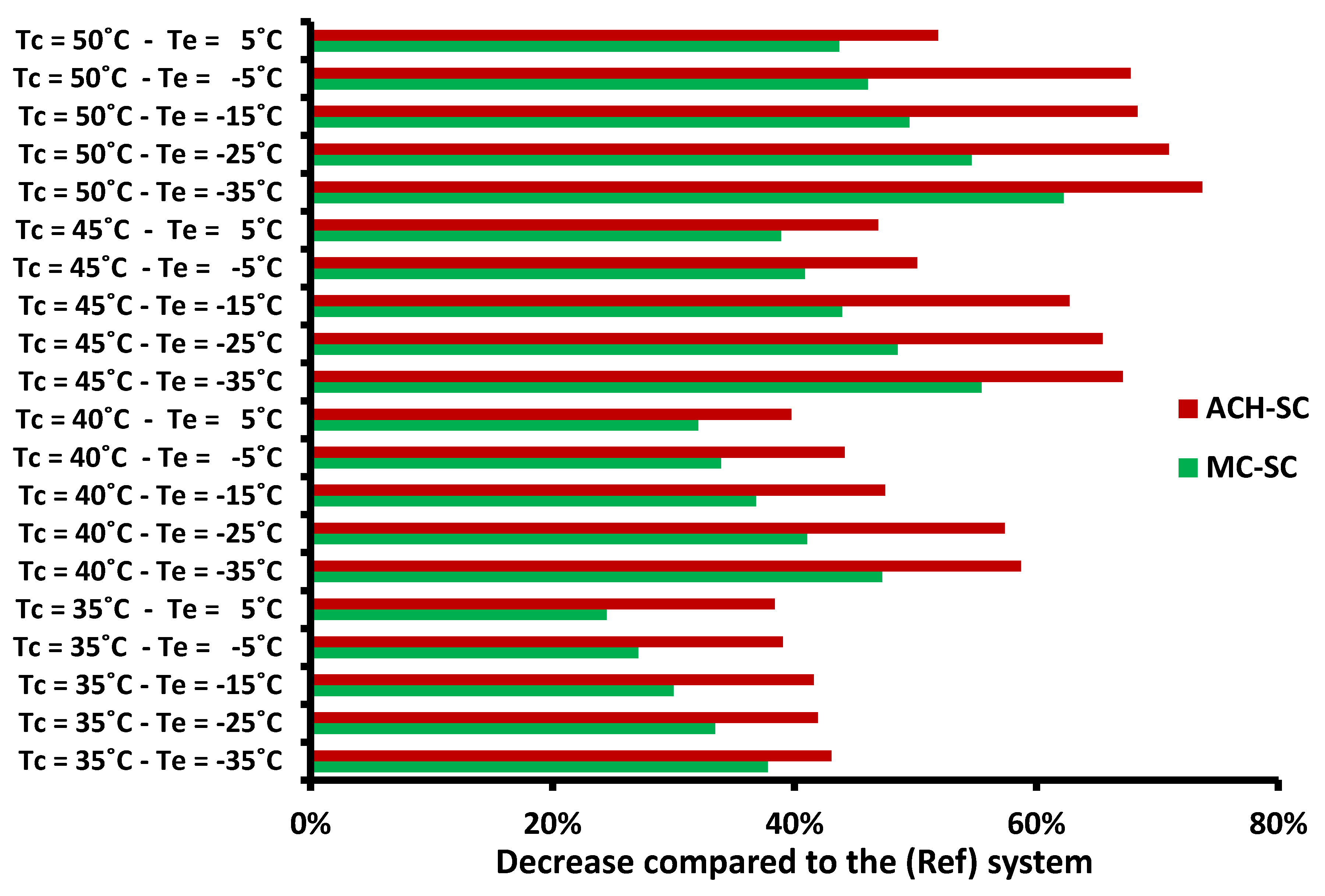

3.4. Comparative Analysis

4. Conclusions

- -

- The use of dedicated subcooling with the mechanical compression (M-SC) system leads to higher COP and to higher exergy efficiency compared to the reference (Ref) system.

- -

- The use of dedicated subcooling with the absorption chiller (ACH-SC) system leads to lower COP and to higher exergy efficiency compared to the reference (Ref) system.

- -

- The mean decrease in the work consumption is found to be 41.39% for the mechanical subcooling system and 53.83% with the absorption chiller subcooling system.

- -

- The heat input in the absorption chiller ranged from 51 up to 137 kW. Generally, it is high for cases with high heat rejection temperature levels.

- -

- The exergy efficiency of the ACH-SC system is a bit lower than the M-SC system, but the electricity savings are higher in the ACH-SC. These facts in combination with the environmental parameters have to be taken into consideration for the future design of the dedicated subcooling systems. Moreover, the availability of any heat source (e.g., solar systems, geothermal energy, or waste heat) is an extra parameter for the final selection.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| COP | Coefficient of performance |

| h | Specific enthalpy, kJ kg−1 K−1 |

| m | Mass flow rate, kg s−1 |

| p | Pressure, bar |

| Q | Heat rate, kW |

| Qe | Refrigeration production, kW |

| Qg | Generator heat input, kW |

| r | Compression pressure ratio |

| T | Temperature, °C |

| Tc | Heat rejection temperature, °C |

| T0 | Reference temperature, K |

| W | Work consumption in the CO2 compressor, kW |

| Wsc | Work consumption in the subcooling compressor, kW |

| X | LiBr concentration in the solution, % |

| Greek Symbols | |

| α | Pressure ratio |

| ΔTsc | Subcooling temperature difference, °C |

| ηex | Exergy efficiency |

| ηhex | Solution heat exchanger effectiveness |

| ηis | Isentropic efficiency of the compressor |

| Subscripts and Superscripts | |

| a | absorber |

| con | condenser |

| crit | critical |

| exp | experimental |

| e,ach | evaporator of the absorption chiller |

| e,m | evaporator of the mechanical subcooling system |

| g | generator |

| high | high |

| is | isentropic |

| low | low |

| r | refrigerant (water) |

| SC | subcooling |

| str | strong solution |

| sim | simulation |

| w | weak solution |

| Abbreviations | |

| ACH-SC | System with absorption chiller subcooling |

| EES | Engineering Equation Solver |

| GWP | Global warming potential |

| M-SC | System with mechanical subcooling |

| Ref | Reference system |

Appendix A. Absorption Chiller Modeling

References

- Wang, J.; Shang, S.; Li, X.; Wang, B.; Wu, W.; Shi, W. Dynamic Performance Analysis for an Absorption Chiller under Different Working Conditions. Appl. Sci. 2017, 7, 797. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Investigation of the Environmentally-Friendly Refrigerant R152a for Air Conditioning Purposes. Appl. Sci. 2019, 9, 119. [Google Scholar] [CrossRef]

- European Commission. Regulation (EU) No 517/2014 of the European Parliament and of the Council of 16th April 2014 on Fluorinated Greenhouse Gases and Repealing Regulation (EC) No 842/2006; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- Ciconkov, R. Refrigerants: There is still no vision for sustainable solutions. Int. J. Refrig. 2018, 86, 441–448. [Google Scholar] [CrossRef]

- Llopis, R.; Sánchez, D.; Cabello, R.; Catalán-Gil, J.; Nebot-Andrés, L. Conversion of a Direct to an Indirect Refrigeration System at Medium Temperature Using R-134a and R-507A: An Energy Impact Analysis. Appl. Sci. 2018, 8, 247. [Google Scholar] [CrossRef]

- Abas, N.; Kalair, A.R.; Khan, N.; Haider, A.; Saleem, Z.; Saleem, M.S. Natural and synthetic refrigerants, global warming: A review. Renew. Sustain. Energy Rev. 2018, 90, 557–569. [Google Scholar] [CrossRef]

- Gullo, P.; Elmegaard, B.; Cortella, G. Energy and environmental performance assessment of R744 booster supermarket refrigeration systems operating in warm climates. Int. J. Refrig. 2016, 64, 61–79. [Google Scholar] [CrossRef] [Green Version]

- Tsamos, K.M.; Ge, Y.T.; Santosa, I.; Tassou, S.A.; Bianchi, G.; Mylona, Z. Energy analysis of alternative CO2 refrigeration system configurations for retail food applications in moderate and warm climates. Energy Convers. Manag. 2017, 150, 822–829. [Google Scholar] [CrossRef]

- Purohit, N.; Gupta, D.K.; Dasgupta, M.S. Energetic and economic analysis of trans-critical CO2 booster system for refrigeration in warm climatic condition. Int. J. Refrig. 2017, 80, 182–196. [Google Scholar] [CrossRef]

- Chen, Y.; Gu, J. The optimum high pressure for CO2 transcritical refrigeration systems with internal heat exchangers. Int. J. Refrig. 2005, 28, 1238–1249. [Google Scholar] [CrossRef]

- Torrella, E.; Sánchez, D.; Llopis, R.; Cabello, R. Energetic evaluation of an internal heat exchanger in a CO2 transcritical refrigeration plant using experimental data. Int. J. Refrig. 2011, 34, 40–49. [Google Scholar] [CrossRef]

- Cavallini, A.; Cecchinato, L.; Corradi, M.; Fornasieri, E.; Zilio, C. Two-stage transcritical carbon dioxide cycle optimisation: A theoretical and experimental analysis. Int. J. Refrig. 2005, 28, 1274–1283. [Google Scholar] [CrossRef]

- Sarkar, J.; Agrawal, N. Performance optimization of transcritical CO2 cycle with parallel compression economization. Int. J. Therm. Sci. 2010, 49, 838–843. [Google Scholar] [CrossRef]

- Gullo, P.; Elmegaard, B.; Cortella, G. Energetic, Exergetic and Exergoeconomic Analysis of CO2 Refrigeration Systems Operating in Hot Climates. In Proceedings of the ECOS 2015: 28th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Pau, France, 29 June–3 July 2015. [Google Scholar]

- Chesi, A.; Esposito, F.; Ferrara, G.; Ferrari, L. Experimental analysis of R744 parallel compression cycle. Appl. Energy 2014, 135, 274–285. [Google Scholar] [CrossRef]

- Nakagawa, M.; Marasigan, A.R.; Matsukawa, T.; Kurashina, A. Experimental investigation on the effect of mixing length on the performance of two-phase ejector for CO2 refrigeration cycle with and without heat exchanger. Int. J. Refrig. 2011, 34, 1604–1613. [Google Scholar] [CrossRef]

- Chen, G.; Volovyk, O.; Zhu, D.; Ierin, V.; Shestopalov, K. Theoretical analysis and optimization of a hybrid CO2 transcritical mechanical compression—Ejector cooling cycle. Int. J. Refrig. 2017, 74, 86–94. [Google Scholar] [CrossRef]

- Yang, J.L.; Ma, Y.T.; Liu, S.C. Performance investigation of transcritical carbon dioxide two-stage compression cycle with expander. Energy 2007, 32, 237–245. [Google Scholar] [CrossRef]

- Megdouli, K.; Tashtoush, B.M.; Ezzaalouni, Y.; Nahdi, E.; Mhimid, A.; Kairouani, L. Performance analysis of a new ejector expansion refrigeration cycle (NEERC) for power and cold: Exergy and energy points of view. Appl. Thermal Eng. 2017, 122, 39–48. [Google Scholar] [CrossRef]

- Sanchez, D.; Llopis, R.; Cabello, R.; Catalán-Gil, J.; Nebot-Andrés, L. Conversion of a direct to an indirect commercial (HFC134a/CO2) cascade refrigeration system: Energy impact analysis. Int. J. Refrig. 2017, 73, 183–199. [Google Scholar] [CrossRef]

- Megdouli, K.; Ejemni, N.; Nahdi, E.; Mhimid, A.; Kairouani, L. Thermodynamic analysis of a novel ejector expansion transcritical CO2/N2O cascade refrigeration (NEETCR) system for cooling applications at low temperatures. Energy 2017, 128, 586–600. [Google Scholar] [CrossRef]

- Ma, M.; Yu, J.; Wang, X. Performance evaluation and optimal configuration analysis of a CO2/NH3 cascade refrigeration system with falling film evaporator–condenser. Energy Convers. Manag. 2014, 79, 224–231. [Google Scholar] [CrossRef]

- Llopis, R.; Nebot-Andrés, L.; Sánchez, D.; Catalán-Gil, J.; Cabello, R. Subcooling methods for CO2 refrigeration cycles: A review. Int. J. Refrig. 2018, 93, 85–107. [Google Scholar] [CrossRef]

- Llopis, R.; Cabello, R.; Sánchez, D.; Torrella, E. Energy improvements of CO2 transcritical refrigeration cycles using dedicated mechanical subcooling. Int. J. Refrig. 2015, 55, 129–141. [Google Scholar] [CrossRef]

- Llopis, R.; Nebot-Andrés, L.; Cabello, R.; Sánchez, D.; Catalán-Gil, J. Experimental evaluation of a CO2 transcritical refrigeration plant with dedicated mechanical subcooling. Int. J. Refrig. 2016, 69, 361–368. [Google Scholar] [CrossRef]

- Nebot-Andres, L.; Llopis, R.; Sánchez, D.; Catalán-Gil, J.; Cabello, R. CO2 with Mechanical Subcooling vs. CO2 Cascade Cycles for Medium Temperature Commercial Refrigeration Applications Thermodynamic Analysis. Appl. Sci. 2017, 7, 955. [Google Scholar] [CrossRef]

- Dai, B.; Liu, S.; Li, H.; Sun, Z.; Song, M.; Yang, Q.; Ma, Y. Energetic performance of transcritical CO2 refrigeration cycles with mechanical subcooling using zeotropic mixture as refrigerant. Energy 2018, 150, 205–221. [Google Scholar] [CrossRef]

- Salajeghe, M.; Ameri, M. Effects of further cooling the gas cooler outlet refrigerant by an absorption chiller, on a transcritical CO2-compression refrigeration system. Int. J. Exergy 2016, 21, 110–125. [Google Scholar] [CrossRef]

- Mohammadi, S.M.H. Theoretical investigation on performance improvement of a low-temperature transcritical carbon dioxide compression refrigeration system by means of an absorption chiller after-cooler. Appl. Therm. Eng. 2018, 138, 264–279. [Google Scholar] [CrossRef]

- Mohammadi, K.; McGowan, J.G. A thermo-economic analysis of a combined cooling system for air conditioning and low to medium temperature refrigeration. J. Clean. Prod. 2019, 206, 580–597. [Google Scholar] [CrossRef]

- Cyklis, P. Two stage ecological hybrid sorption–compression refrigeration cycle. Int. J. Refrig. 2014, 48, 121–131. [Google Scholar] [CrossRef]

- Li, H.; Su, W.; Cao, L.; Chang, F.; Xia, W.; Dai, Y. Preliminary conceptual design and thermodynamic comparative study on vapor absorption refrigeration cycles integrated with a supercritical CO2 power cycle. Energy Convers. Manag. 2018, 161, 162–171. [Google Scholar] [CrossRef]

- Arora, A.; Singh, N.K.; Monga, S.; Kumar, O. Energy and exergy analysis of a combined transcritical CO2 compression refrigeration and single effect H2O-LiBr vapour absorption system. Int. J. Exergy 2011, 9, 453–471. [Google Scholar] [CrossRef]

- Sarkar, J. Performance optimization of transcritical CO2 refrigeration cycle with thermoelectric subcooler. Int. J. Energy Res. 2013, 37, 121–128. [Google Scholar] [CrossRef]

- Schoenfield, J.; Hwang, Y.; Radermacher, R. CO2 transcritical vapor compression cycle with thermoelectric subcooler. HVAC&R Res. 2012, 18, 297–311. [Google Scholar]

- Jamali, S.; Yari, M.; Mohammadkhani, F. Performance improvement of a transcritical CO2 refrigeration cycle using two-stage thermoelectric modules in sub-cooler and gas cooler. Int. J. Refrig. 2017, 74, 105–115. [Google Scholar] [CrossRef]

- Dai, B.; Liu, S.; Zhu, K.; Sun, Z.; Ma, Y. Thermodynamic performance evaluation of transcritical carbon dioxide refrigeration cycle integrated with thermoelectric subcooler and expander. Energy 2017, 122, 787–800. [Google Scholar] [CrossRef]

- Aprea, C.; Greco, C.; Maiorino, A. The application of a desiccant wheel to increase the energetic performances of a transcritical cycle. Energy Convers. Manag. 2015, 89, 222–230. [Google Scholar] [CrossRef]

- Aprea, C.; Greco, C.; Maiorino, A. The substitution of R134a with R744: An exergetic analysis based on experimental data. Int. J. Refrig. 2013, 36, 2148–2159. [Google Scholar] [CrossRef]

- F-Chart Software, Engineering Equation Solver (EES). 2015. Available online: http://www.fchart.com/ees (accessed on 15 October 2018).

- Brown, J.S.; Yana-Motta, S.F.; Domanski, P.A. Comparitive analysis of an automotive air conditioning systems operating with CO2 and R134a. Int. J. Refrig. 2002, 25, 19–32. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Performance analysis and optimization of an absorption chiller driven by nanofluid based solar flat plate collector. J. Clean. Prod. 2018, 174, 256–272. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C.; Symeou, C.; Antonopoulos, K.A. Energetic, exergetic and financial evaluation of a solar driven absorption chiller—A dynamic approach. Energy Convers. Manag. 2017, 137, 34–48. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Parametric analysis and optimization of a solar driven trigeneration system based on ORC and absorption heat pump. J. Clean. Prod. 2017, 161, 493–509. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. A Theoretical Comparative Study of CO2 Cascade Refrigeration Systems. Appl. Sci. 2019, 9, 790. [Google Scholar] [CrossRef]

- Gullo, P.; Elmegaard, B.; Cortella, G. Advanced exergy analysis of a R744 booster refrigeration system with parallel compression. Energy 2016, 107, 562–571. [Google Scholar] [CrossRef] [Green Version]

- Bellos, E.; Tzivanidis, C.; Pavlovic, S.; Stefanovic, V. Thermodynamic investigation of LiCl-H2O working pair in a double effect absorption chiller driven by parabolic trough collectors. Therm. Sci. Eng. Prog. 2017, 3, 75–87. [Google Scholar] [CrossRef]

- Venkateswari, R.; Sreejith, S. Factors influencing the efficiency of photovoltaic system. Renew. Sustain. Energy Rev. 2019, 101, 376–394. [Google Scholar] [CrossRef]

| Initial Data | Results | |||||

|---|---|---|---|---|---|---|

| Te (°C) | Phigh (bar) | Tc (°C) | ΔΤsc (°C) | COPexp | COPsim | Deviation |

| 0.0 | 82.8 | 28.36 | 0.00 | 2.57 | 2.612 | 1.63% |

| 0.0 | 89.6 | 33.51 | 0.00 | 1.93 | 2.063 | 6.89% |

| 0.0 | 102.6 | 41.69 | 0.00 | 1.32 | 1.372 | 3.94% |

| −10.0 | 77.6 | 27 | 0.00 | 1.91 | 1.897 | 0.68% |

| −10.0 | 82.5 | 32.79 | 0.00 | 1.44 | 1.477 | 2.57% |

| −10.0 | 101.9 | 41.09 | 0.00 | 0.98 | 0.933 | 4.80% |

| 0.0 | 78.6 | 29.71 | 13.28 | 2.85 | 3.090 | 8.42% |

| 0.0 | 81.6 | 34.78 | 12.07 | 2.35 | 2.581 | 9.83% |

| −10.0 | 77.3 | 33.42 | 13.03 | 1.78 | 1.828 | 2.70% |

| −10.0 | 107.1 | 40.48 | 15.62 | 1.27 | 1.211 | 4.65% |

| Examined Scenarios | Ref | M-SC | ACH-SC | |

|---|---|---|---|---|

| Work (kW) | Work (kW) | Work (kW) | Heat (kW) | |

| Tc = 35 °C-Te = −35 °C | 117.95 | 73.37 | 67.17 | 60.58 |

| Tc = 35 °C-Te = −25 °C | 80.65 | 53.68 | 46.83 | 57.73 |

| Tc = 35 °C-Te = −15 °C | 57.57 | 40.29 | 33.62 | 55.55 |

| Tc = 35 °C-Te = −5 °C | 41.25 | 30.08 | 25.15 | 51.14 |

| Tc = 35 °C-Te = 5 °C | 28.76 | 21.72 | 17.72 | 47.86 |

| Tc = 40 °C-Te = −35 °C | 149.75 | 78.99 | 61.85 | 117.80 |

| Tc = 40 °C-Te = −25 °C | 100.52 | 59.24 | 42.85 | 117.40 |

| Tc = 40 °C-Te = −15 °C | 71.79 | 45.35 | 37.69 | 65.34 |

| Tc = 40 °C-Te = −5 °C | 52.33 | 34.57 | 29.22 | 59.27 |

| Tc = 40 °C-Te = 5 °C | 37.88 | 25.74 | 22.82 | 51.58 |

| Tc = 45 °C-Te = −35 °C | 188.50 | 83.96 | 61.97 | 127.10 |

| Tc = 45 °C-Te = −25 °C | 123.52 | 63.57 | 42.68 | 127.30 |

| Tc = 45 °C-Te = −15 °C | 87.87 | 49.26 | 32.76 | 124.70 |

| Tc = 45 °C-Te = −5 °C | 64.64 | 38.21 | 32.23 | 69.39 |

| Tc = 45 °C-Te = 5 °C | 47.94 | 29.29 | 25.44 | 62.88 |

| Tc = 50 °C-Te = −35 °C | 236.52 | 89.29 | 62.15 | 137.00 |

| Tc = 50 °C-Te = −25 °C | 150.56 | 68.31 | 43.77 | 135.20 |

| Tc = 50 °C-Te = −15 °C | 106.18 | 53.59 | 33.59 | 134.90 |

| Tc = 50 °C-Te = −5 °C | 78.49 | 42.34 | 25.30 | 134.90 |

| Tc = 50 °C-Te = 5 °C | 59.28 | 33.38 | 28.53 | 71.23 |

| Examined Scenarios | COP | ηex | ||

|---|---|---|---|---|

| M-SC | ACH-SC | M-SC | ACH-SC | |

| Tc = 35 °C-Te = −35 °C | 60.77% | −7.67% | 60.81% | 54.87% |

| Tc = 35 °C-Te = −25 °C | 50.24% | −22.87% | 50.24% | 46.12% |

| Tc = 35 °C-Te = −15 °C | 42.89% | −35.46% | 42.87% | 38.30% |

| Tc = 35 °C-Te = −5 °C | 37.17% | −45.92% | 37.17% | 30.60% |

| Tc = 35 °C-Te = 5 °C | 32.38% | −56.14% | 32.40% | 23.00% |

| Tc = 40 °C-Te = −35 °C | 89.58% | −16.65% | 89.66% | 82.16% |

| Tc = 40 °C-Te = −25 °C | 69.68% | −37.26% | 69.71% | 59.23% |

| Tc = 40 °C-Te = −15 °C | 58.29% | −30.32% | 58.34% | 46.43% |

| Tc = 40 °C-Te = −5 °C | 51.39% | −40.87% | 51.43% | 37.01% |

| Tc = 40 °C-Te = 5 °C | 47.16% | −49.09% | 47.08% | 29.49% |

| Tc = 45 °C-Te = −35 °C | 124.51% | −0.30% | 124.63% | 114.97% |

| Tc = 45 °C-Te = −25 °C | 94.29% | −27.32% | 94.36% | 80.20% |

| Tc = 45 °C-Te = −15 °C | 78.38% | −44.21% | 78.34% | 58.16% |

| Tc = 45 °C-Te = −5 °C | 69.17% | −36.39% | 69.09% | 44.25% |

| Tc = 45 °C-Te = 5 °C | 63.66% | −45.73% | 63.67% | 35.53% |

| Tc = 50 °C-Te = −35 °C | 164.90% | 18.76% | 164.88% | 153.33% |

| Tc = 50 °C-Te = −25 °C | 120.42% | −15.87% | 120.48% | 103.21% |

| Tc = 50 °C-Te = −15 °C | 98.13% | −36.99% | 98.15% | 74.02% |

| Tc = 50 °C-Te = −5 °C | 85.40% | −50.99% | 85.40% | 54.60% |

| Tc = 50 °C-Te = 5 °C | 77.59% | −40.60% | 77.58% | 42.62% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bellos, E.; Tzivanidis, C. CO2 Transcritical Refrigeration Cycle with Dedicated Subcooling: Mechanical Compression vs. Absorption Chiller. Appl. Sci. 2019, 9, 1605. https://doi.org/10.3390/app9081605

Bellos E, Tzivanidis C. CO2 Transcritical Refrigeration Cycle with Dedicated Subcooling: Mechanical Compression vs. Absorption Chiller. Applied Sciences. 2019; 9(8):1605. https://doi.org/10.3390/app9081605

Chicago/Turabian StyleBellos, Evangelos, and Christos Tzivanidis. 2019. "CO2 Transcritical Refrigeration Cycle with Dedicated Subcooling: Mechanical Compression vs. Absorption Chiller" Applied Sciences 9, no. 8: 1605. https://doi.org/10.3390/app9081605

APA StyleBellos, E., & Tzivanidis, C. (2019). CO2 Transcritical Refrigeration Cycle with Dedicated Subcooling: Mechanical Compression vs. Absorption Chiller. Applied Sciences, 9(8), 1605. https://doi.org/10.3390/app9081605