Abstract

The aim of this comparative study is to analyze the influence of drilling technique on the radiographic, thermographic, and geomorphometric effects of dental implant drills and osteotomy site preparations. One hundred and twenty osteotomy site preparations were performed on sixty epoxy resin samples using three unused dental implant drill systems and four drilling techniques performed with a random distribution into the following study groups: Group A: drilling technique performed at 800 rpm with irrigation (n = 30); Group B: drilling technique performed at 45 rpm without irrigation (n = 30); Group C: drilling technique performed at 45 rpm with irrigation (n = 30); and Group D: drilling technique performed at 800 rpm without irrigation (n = 30). The osteotomy site preparation morphologies performed by the 4.1 mm diameter dental implant drills from each study group were analyzed and compared using a cone beam computed tomography (CBCT) scan. The termographic effects generated by the 4.1 mm diameter dental implant drills from each study group were registered using a termographic digital camera and the unused and 4.1 mm diameter dental implant drills that were used 30 times from each study group were exposed to a micro computed tomography (micro-CT) analysis to obtain a Standard Tessellation Language (STL) digital files that determined the wear comparison by geomorphometry. Statistically significant differences were observed between the thermographic and radiographic results of the study groups (p < 0.001). The effect of cooling significatively reduced the heat generation during osteotomy site preparation during high-speed drilling; furthermore, osteotomy site preparation was not affected by the wear of the dental implant drills after 30 uses, regardless of the drilling technique.

1. Introduction

Osseointegration is a direct connection between living bone and an endosseous implant at a microscopic level []. Furthermore, osseointegration is essential in the bone healing process around dental implants and hence in the dental implant prognosis []. Some authors have reported a success rate of 95% related to the survival of contemporary surface-modified dental implants after 10 years of follow-up [,,]. However, bone tissue healing around dental implants is considered multifactorial in nature, with many factors related to the heat generated during drilling at the implant site: pressure, status, movement, speed and duration of drilling by the operator, dental implant drill design, sharpness of the drill, irrigation system, dental implant system, cortical thickness, condition of the site, depth drilled, age of the patient, and bone density [,,,]. Heat produced by the drilling process during osteotomy site preparation might influence the development of osseointegration as bone tissues are very sensitive to thermal injury []. It has been reported that heat transferred to bone tissue may cause hyperemia, necrosis, and fibrosis or even increase osteoclast activity [,]. Eriksson and Albrektsson reported that a temperature threshold about 47 °C might cause irreversible damage to bone tissues and hence osseointegration failure when osteotomy is maintained for one minute [,,]. Scarano et al. reported that repeated use causes drills to wear and reduces their efficiency, and the temperature increases each time a drill is used []. Möhlhenrich et al. reported that the sharpness of the dental implant drill is directly related to the number of times it is used, the pressure applied, sterilization technique, bone density, construction material, and surface treatment [], and the waste of the dental implant drills could reduce their cutting capability and increase drilling time and seems to correlate with the increase in temperature []. In addition, sharpening could lead to a volumetric decrease of the dental implant drill and may influence the osteotomy site preparation and therefore the dental implant placement, because the shape of the dental implant drill correlates with the shape of the dental implant []. However, Kim et al. showed that lower drilling speeds do not increase the heat transferred to bone tissues despite the increasing working time []. The wear of dental implant drills have been previously analyzed by means of finite element analysis (FEA) [] and scanning electron microscopic (SEM) and energy-dispersive x-ray spectroscopic examinations []; however, none of these measurement procedures allows an accurate analysis of surface and volumetric wear experienced by the dental implant drill after clinical use, because FEA analysis performs a digital simulation and the SEM examination allows only a superficial analysis, preventing the volumetric changes measurement. However, geomorphometric technique allows an accurate measurement of both surface and volumetric changes between the non-use and continued use dental implant drill. Fons-Badal et al. used the geomorphometric technique to measure the volume gain after soft tissue graft surgery [] and Zubizarreta-Macho et al. used it to quantify accurately the area and volume of cement remaining and enamel removed after fixed multibracket appliance therapy debonding [].

The aim of this work was to analyze and compare the influence of the osteotomy technique on the radiographic, thermographic, and geomorphometric effects, with a null hypothesis (H0) stating that there will be no difference between the radiographic, thermographic, and geomorphometric results of drilling performed at 800 revolutions per minute (rpm) with irrigation, drilling performed at 45 rpm without irrigation, drilling performed at 45 rpm with irrigation, and the drilling technique performed at 800 rpm without irrigation.

2. Materials and Methods

2.1. Study Design

One hundred and twenty osteotomies were performed on sixty models (10 × 10 × 14 mm) of epoxy resin (Ref. 20-8130-128, EpoxiCure®, Buehler, IL, USA) using four drilling techniques and three 4.1 mm diameter unused dental implant drills (Ref. TSD2041HD, BioHorizons, Birmingham, AL, USA) randomly distributed (Epidat 4.1, Galicia, Spain) into the following study groups: Group A: drilling technique performed at 800 rpm with irrigation (n = 30); Group B: drilling technique performed at 45 rpm without irrigation (n = 30); Group C: drilling technique performed at 45 rpm with irrigation (n = 30); and Group D: drilling technique performed at 800 rpm without irrigation (n = 30). The randomized controlled experimental trial was performed at the Dental Centre of Innovation and Advanced Specialties at the Alfonso X el Sabio University (Madrid, Spain) between November and December 2019.

2.2. Experimental Procedure

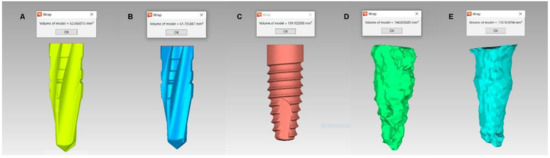

The sequence of dental implant drills was: 2.0 mm diameter dental implant drill (Ref.: TSD2020HD, BioHorizons, Birmingham, AL, USA), 2.5 mm diameter dental implant drill (Ref.: TSD2025HD, BioHorizons, Birmingham, AL, USA), 2.8 mm diameter dental implant drill (Ref.: TSD2028HD, BioHorizons, Birmingham, AL, USA), 3.2 mm diameter dental implant drill (Ref.: TSD2032HD, BioHorizons, Birmingham, AL, USA), 3.7 mm diameter dental implant drill (Ref.: TSD2037HD, BioHorizons, Birmingham, AL, USA), and 4.1 mm diameter dental implant drill (Ref.: TSD2041HD, BioHorizons, Birmingham, AL, USA). The drilling sequence was introduced in the epoxy resin models (Ref.: 20-8130-128. EpoxiCure®, Buehler, IL, USA) to a depth of 12 mm from the surface of the epoxy resin models (Ref.: 20-8130-128. EpoxiCure®, Buehler, IL, USA), according to the randomized drilling technique. A micro Computed Tomography (micro-CT) scan (Skyscan 1176, Bruker-MicroCT, Kontich) with the following exposure parameters: 160.0 kilovolt peak, 56.0–58.0 microamperes, 500.0 msec, 720 projections, 4 frames, a tungsten target between 0.25 and 0.375 mm, a 3 µm resolution, and a pixel size of 0.127 µm, was performed to obtain accurate Standard Tessellation Language (STL) digital files of the 4.1 mm diameter unused dental implant drills (Ref.: TSD2041HD. BioHorizons, Birmingham, AL, USA) (STL1) (Figure 1A), 4.1 mm diameter dental implant drills that had been used 30 times (Ref.: TSD2041HD. BioHorizons, Birmingham, AL, USA) (STL2) (Figure 1B), and the respective dental implants (4.6 × 12 mm, Ref.: TLX4612 BioHorizons, Birmingham, AL, USA) (STL3) (Figure 1C). Furthermore, the epoxy resin models (Ref.: 20-8130-128. EpoxiCure®, Buehler, IL, USA) were submitted to a cone-beam computed tomography (CBCT) scan (WhiteFox, Acteón Médico-Dental Ibérica S.A.U.-Satelec, Merignac, France) with the following exposure parameters: 105.0 kilovolt peak, 8.0 milliamperes, 7.20 s, and a field of view of 15 × 13 mm, to analyze the osteotomy site preparation measures performed by the 4.1 mm diameter dental implant drills (Ref.: TSD2041HD. BioHorizons, Birmingham, AL, USA). First (CBCT1) (Figure 1D) and 30th (CBCT30) CBCT scans (Figure 1E) of the osteotomy site preparations performed by each drilling technique were selected to compare the osteotomy cavities resulting from the wear of the dental implant drills (Ref.: TSD2041. BioHorizons, Birmingham, AL, USA). The osteotomy site preparations of all study groups were performed manually by a unique operator.

Figure 1.

(A) Standard tessellation language (STL) digital files of the unused dental implant drills; (B) dental implant drills that were used 30 times; (C) dental implant; (D) first and (E) 30th osteotomy CBCT scan to a depth of 12 mm.

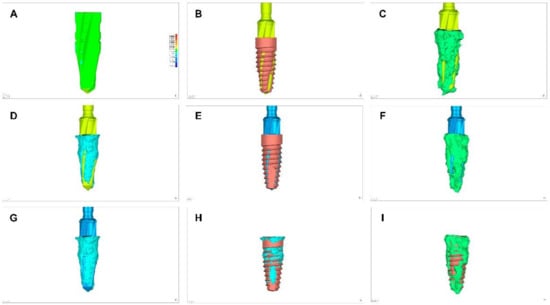

Once the STL1, STL2, STL3, CBCT1 scan, and CBCT30 scans were uploaded to a reverse engineering geomorphometric software (3D Geomagic Capture Wrap, 3D Systems©, Rock Hill, SC, USA) an alignment procedure of the STL digital files was done with the best fit algorithm. Afterwards, the following variables were analyzed: volume assessment differences between STL1 and STL2 (Figure 2A), STL1 and STL3 (Figure 2B), STL1 and CBCT1 (Figure 2C), STL1 and CBCT30 (Figure 2D), STL2 and STL3 (Figure 2E), STL2 and CBCT1 (Figure 2F), STL2 and CBCT30 (Figure 2G), STL3 and CBCT30 (Figure 2H), and STL3 and CBCT1 (Figure 2H). The spectrum between the alignment of STL1 and STL2 digital files was set at ±100 µm and the tolerance at ±10 µm.

Figure 2.

(A) Alignments procedures between STL1 and STL2; (B) STL1 and STL3; (C) STL1 and CBCT1; (D) STL1 and CBCT30; (E) STL2 and STL3; (F) STL2 and CBCT1; (G) STL2 and CBCT30; (H) STL3 and CBCT30; and (I) STL3 and CBCT1.

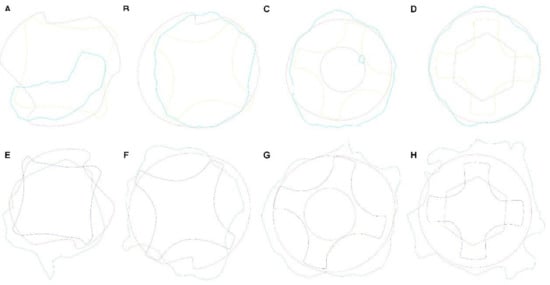

Area differences were analyzed after alignment of STL1, STL3, and CBCT1 at 1 mm (Figure 3A), 3 mm (Figure 3B), 7 mm (Figure 3C), and 11 mm (Figure 3D) from the 12 mm length. Furthermore, area differences were also analyzed after the alignment of STL2, STL3, and CBCT30 at 1 mm (Figure 3E), 3 mm (Figure 3F), 7 mm (Figure 3G), and 11 mm (Figure 3H) from the 12 mm length.

Figure 3.

(A–D) Cross-sections of the alignment of STL1, STL3, and CBCT1 and (E–H) STL2, STL3, and CBCT30 at 1, 3, 7, and 11 mm from the 12 mm length.

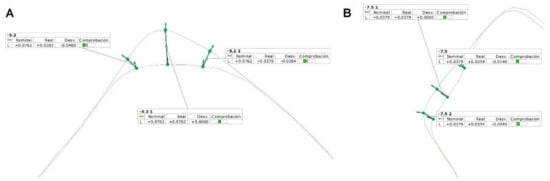

Additional area measurement was performed between STL1 and STL2 to determine the wear of the 4.1 mm diameter dental implant drill surface (Ref.: TSD2041HD. BioHorizons, Birmingham, AL, USA) after 30 uses (Figure 4A,B).

Figure 4.

(A) Alignment of the STL 1 (green) and STL 2 (red) digital files to analyze the wear at the cutting edge and (B) radial lands.

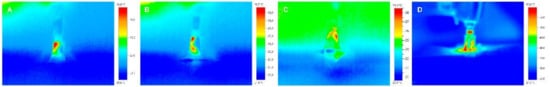

The heating effect generated by the 4.1 mm diameter dental implant drills (Ref.: TSD2041HD. BioHorizons, Birmingham, AL, USA) during the drilling techniques was analyzed by a termographic digital camera (Testo 875, Testo, Cabrils, Barcelona, Spain) placed at a distance of 2 cm from the epoxy resin model surface (Ref.: 20-8130-128. EpoxiCure®, Buehler, IL, USA) and calibrated with a thermal range of 0–100 °C. The heating effect was analyzed during the osteotomy site preparations in the 800 rpm with irrigation (Figure 5A), 45 rpm without irrigation (Figure 5B), 45 rpm with irrigation (Figure 5C), and 800 rpm without irrigation study groups (Figure 5D).

Figure 5.

(A) The heating effect was analyzed during the osteotomy sites preparations in the 800 rpm with irrigation; (B) 45 rpm without irrigation; (C) 45 rpm with irrigation; and (D) 800 rpm without irrigation study groups.

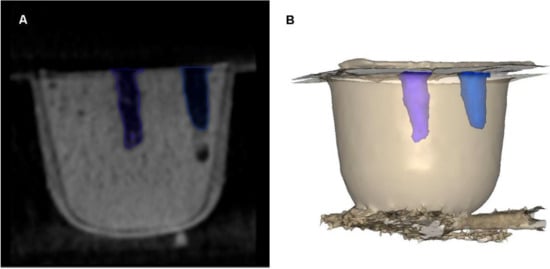

The osteotomy site preparations were submitted to a CBCT scan (WhiteFox, Acteón Médico-Dental Ibérica S.A.U.-Satelec, Merignac, France) with the previously-mentioned exposure parameters and the osteotomies were segmented (3D Geomagic Capture Wrap, 3D Systems©) to obtain the volume of the osteotomy site preparations (Figure 6A,B).

Figure 6.

(A) The osteotomy site preparations were submitted to a CBCT scan that was segmented to analyze the (B) osteotomy site preparation volume.

2.3. Statistical Tests

Statistical analysis of all variables was carried out using SAS 9.4 (SAS Institute Inc., Cary, NC, USA). Descriptive statistics were expressed as means and standard deviations (SD) for quantitative variables. Comparative analysis was performed by comparing the radiographic results (mm3) and thermographic results (°C) using ANOVA. In addition, descriptive analysis of the geomorphometric results (mm3) was performed. The statistical significance was set at p < 0.05.

3. Results

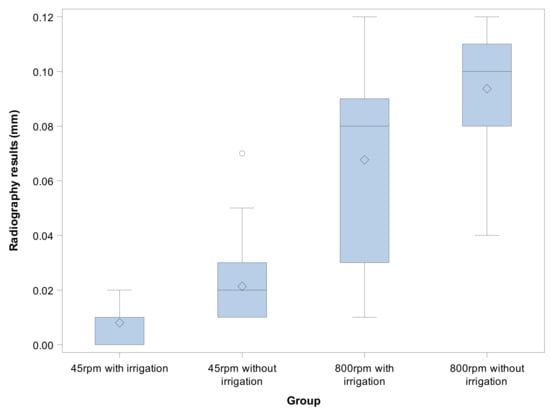

The means and SD values for radiographic results (mm3) of the study groups are displayed in Table 1 and Figure 7.

Table 1.

Descriptive statistics of the radiographic results (mm).

Figure 7.

Box plots of the radiographic results of the experimental groups. The horizontal line in each box represents median value.

The ANOVA revealed statistically significant differences between the radiographic results of the volume of osteotomy site preparations performed at 800 rpm with irrigation and the volume of osteotomy site preparations performed at 45 rpm without irrigation (p < 0.001), the volume of osteotomy site preparations performed at 800 rpm with irrigation, the volume of osteotomy site preparations performed at 800 rpm without irrigation (p < 0.001), the volume of osteotomy site preparations performed at 45 rpm without irrigation, and the volume of osteotomy site preparations performed at 800 rpm without irrigation (p < 0.001). However, no statistically significant differences were found between the radiographic results of the osteotomy site preparations performed at 45 rpm with irrigation and the osteotomy site preparations performed at 45 rpm without irrigation (p = 0.093) (Figure 7).

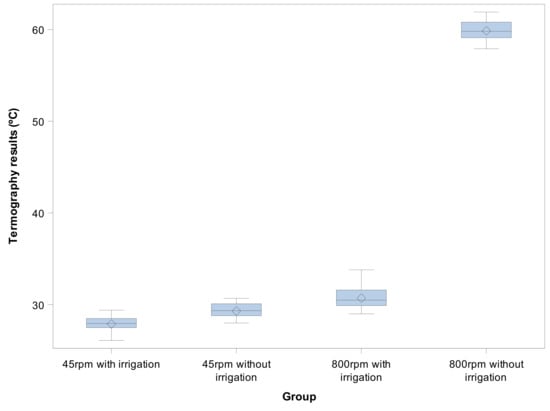

The means and SD values for termographic results (°C) of the study groups are displayed in Table 2 and Figure 8.

Table 2.

Descriptive statistics of the thermographic results (°C).

Figure 8.

Box plots of the thermographic results (°C) of the experimental groups. The horizontal line in each box represents the median value.

The ANOVA also revealed statistically significant differences between the thermographic results of the osteotomy site preparations performed at 45 rpm with irrigation and osteotomy site preparations performed at 45 rpm without irrigation (p < 0.001), the osteotomy site preparations performed at 800 rpm with irrigation and the osteotomy site preparations performed at 45 rpm without irrigation (p < 0.001), the osteotomy site preparations performed at 800 rpm with irrigation and the osteotomy site preparations performed at 800 rpm without irrigation (p < 0.001), and the osteotomy site preparations performed at 45 rpm without irrigation and the osteotomy site preparations performed at 800 rpm without irrigation (p < 0.001) (Figure 8).

Geomorphometric analysis showed a volumetric difference of 0.961 mm3 between the STL1 (62.666 mm3) and the STL2 (61.705 mm3) digital files of the 800 rpm with irrigation study group, a volumetric difference of 0.746 mm3 between the dental STL1 (62.284 mm3) and the STL2 (61.538 mm3) digital files of the 45 rpm without irrigation study group, a volumetric difference of 0.122 mm3 between the dental STL1 (62.349 mm3) and the STL2 (62.227 mm3) digital files of the 45 rpm with irrigation study group, and a volumetric difference of 1.082 mm3 between the STL1 (62.326 mm3) and the STL2 (61.244 mm3) digital files of the 800 rpm without irrigation study group. Wear of the STL2 digital file of the 800 rpm with irrigation, 45 rpm without irrigation, 45 rpm with irrigation, and 800 rpm without irrigation study groups were observed mainly in the cutting edges of the middle third. Area differences between the STL1, STL3, and CBCT1 at 1, 3, 7, and 11 mm and between STL2, STL3, and CBCT30 at 1, 3, 7, and 11 mm from the 12 mm length were not statistically significant (p > 0.05). The higher transverse deviations between osteotomy site preparations and dental implant drill were observed in the 800 rpm group without irrigation at 7 mm from the dental implant tip.

4. Discussion

The results obtained in the present study rejected the null hypothesis (H0) that states that there would be no difference between the radiographic, thermographic, and geomorphometric results of the drilling technique performed at 800 rpm with irrigation, the drilling technique performed at 45 rpm without irrigation, and the drilling technique performed at 800 rpm without irrigation.

The thermographic results of the drilling technique performed at 800 rpm with irrigation (30.720 ± 1.069) and the drilling technique performed at 800 rpm without irrigation (59.853 ± 1.168) highlighted the influence of the dental implant drill cooling during osteotomy site preparation and hence on the heat transferred to the peri-implant tissues. In addition, the higher wear of the dental implant drill used at 800 rpm without irrigation could reduce its cutting capacity and hence increase the drilling temperature, although it did not influence the osteotomy site preparation volumes. The heat generated by the dental implant drills during osteotomy site preparation and transmitted to the peri-implant tissues remains a concern because it can irreversibly affect to the survival of the peri-implant tissues and hence influence the dental implant osseointegration. Kniha et al. stated that a thermal threshold between 47 and 55 °C might cause bone necrosis. In addition, bone density has emerged as a determinant factor, with cancellous bone more susceptible to high temperatures than cortical bone []. However, Trisi et al. reported that an increase in temperature up to 60 °C maintained for one minute during osteotomy site preparation did not show statistically significant (p ˃ 0.05) effects on dental implant osseointegration; however, they recommended careful drilling procedures with sufficient irrigation to avoid peri-implant defects []. In addition, Favero et al. analyzed the influence of the drilling speed techniques and the irrigation effect on the bone tissue response and reported no statistically significant differences (p ˃ 0.05) on the neo-formed cortical bone tissue around dental implants using a low drilling speed (60 rpm) without irrigation (66.9 ± 6.8%) and high drilling speed techniques (1200 rpm) (67.3 ± 17.7%) after 6 weeks of healing []. In the present study, non-statistically significant (p ˃ 0.05) differences were observed between the 800 rpm with irrigation study group (30.720 ± 1.069) and the 45 rpm without irrigation study group (29.313 ± 0.773); however, statistically significant differences (p < 0.001) were obtained with respect to the 800 rpm without irrigation study group (59.853 ± 1.168), which suggests that irrigation is a more determinant factor than drilling speed in heating generation, especially in the 800 rpm without irrigation study group due the higher wear of the dental implant drill. Sener et al. also highlighted the relevance of irrigation and especially the temperature of the cooling agent to control the temperature generated during osteotomy site preparation []. Albrektsson et al. determined that preparing the implant site with external irrigation with saline at 25 °C rarely results in temperatures above the critical temperature (47 °C for 1 min.) [].

Low speed drilling procedures without irrigation have been proposed to prevent over-heating and subsequent damage to the peri-implant tissues and to obtain an amount of living bone that can be used in bone grafting. Anitua et al. described a new drilling approach based on biological criteria which proved to be compatible with peri-implant tissues and allowed harvest of living bone cells for using as bone grafts []. Kim et al. reported non-statistically significant temperature changes (p ˃ 0.05) (1.57–2.46 °C) between low-speed drilling (60 rpm) and conventional-speed drilling systems []. These results are aligned with the findings obtained in the present study where statistically significant differences were not observed (p > 0.05) between the 800 rpm with irrigation study group (30.720 ± 1.069) and the 45 rpm without irrigation study group (29.313 ± 0.773).

Chauchan et al. confirmed that the wear of the dental implant drills influences their cutting capacity and therefore the working time and the heat transmitted to the peri-implant tissues during osteotomy site preparation []. In addition, Tehemar described the factors affecting heat generation during implant site preparation and highlighted the importance of sterilization techniques, density of the bone sites, and surface treatment of the dental implant drills in keeping the integrity of dental implant drills []. Summer et al. compared the heat transferred to the peri-implant tissues between stainless steel and ceramic implant drills and did not find statistically significant differences (p > 0.05) regarding the heat transferred to the drilling site between both dental implant drill materials []. However, Oliveira et al. reported statistically significant (p < 0.05) thermal changes related to twisted stainless steel dental implant drills (1.6 °C) compared with ceramic dental implant drills (1.3 °C) during osteotomy site preparation. In addition, Oliveira et al. highlighted that the mean temperature statistically significantly (p < 0.0001) increased 0.9 °C at 8 mm drilling depth and 2 °C at 10 mm drilling depth with both dental implant drills and also reported that no signs of wear were detected after 50 uses []. These results are not aligned with the findings obtained in the present study where wear of up to 0.0762 mm was observed on the cutting edges of dental implant drills after 30 osteotomy site preparations.

The accurate analysis (tolerance at ±10 µm) of the surface and volumetric wear of dental implant drills after their use by means of the geomorphometric technique validates this measurement procedure for future studies in which it is necessary to analyze surface and volumetric changes. However, the accurate of this measurement technique is associated with the resolution of the STL digital files to be compared, therefore it is advisable to use digital files with a high density of tesellas such as those provided by micro-CT. Nevertheless, further clinical research is needed to determine the relevance of the wear of dental implant drills on heat generation and on the prognosis of dental implants.

5. Conclusions

In conclusion, within the limitations of this study, our results showed that the effect of cooling significantly reduces heat generation during osteotomy site preparation during high-speed drilling, and that the osteotomy site preparation is not affected by the wear of the dental implant drills after 30 uses, regardless the drilling technique.

Author Contributions

All of the authors contributed to the investigation, supervision, writing, review, and editing of the study. The study was conceptualized by L.F.d.S.J., F.M.R., R.R. and Á.Z.-M. Data curation, data visualization, and analysis were carried out by E.R.D., S.H.M. and J.A.P.-B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The authors would like to thank Silvia Cenzano Gutiérrez her invaluable assistance in this study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Buser, D.; Sennerby, L.; De Bruyn, H. Modern implant dentistry based on osseointegration: 50 Years of progress, current trends and open questions. Periodontol. 2000 2017, 73, 7–21. [Google Scholar] [CrossRef] [PubMed]

- Parithimarkalaignan, S.; Padmanabhan, T.V. Osseointegration: An update. J. Indian Prosthodont. Soc. 2013, 13, 2–6. [Google Scholar] [CrossRef] [PubMed]

- Chappuis, V.; Buser, R.; Brägger, U.; Bornstein, M.M.; Salvi, G.E.; Buser, D. Long-term outcomes of dental implants with a titanium plasma-sprayed surface: A 20-year prospective case series study in partially edentulous patients. Clin. Implant Dent. Relat. Res. 2013, 15, 780–790. [Google Scholar] [CrossRef] [PubMed]

- Dierens, M.; Vandeweghe, S.; Kisch, J.; Nilner, K.; De Bruyn, H. Long-term follow-up of turned single implants placed in periodontally healthy patients after 16–22 years: Radiographic and peri-implant outcome. Clin. Oral Implant. Res. 2012, 23, 197–204. [Google Scholar] [CrossRef] [PubMed]

- Vandeweghe, S.; Ferreira, D.; Vermeersch, L.; Mariën, M.; De Bruyn, H. Long-term retrospective follow-up of turned and moderately rough implants in the edentulous jaw. Clin. Oral Implant. Res. 2016, 27, 421–426. [Google Scholar] [CrossRef] [PubMed]

- Misir, A.F.; Sumer, M.; Yenisey, M.; Ergioglu, E. Effect of surgical drill guide on heat generated from implant drilling. J. Oral Maxillofac. Surg. 2009, 67, 2663–2668. [Google Scholar] [CrossRef] [PubMed]

- Scarano, A.; Piattelli, A.; Assenza, B.; Carinci, F.; Di Donato, L.; Romani, G.L.; Merla, A. Infrared thermographic evaluation of temperature modifications induced during implant site preparation with cylindrical versus conical drills. Clin. Implant Dent. Relat. Res. 2011, 13, 319–323. [Google Scholar] [CrossRef]

- Stelzle, F.; Frenkel, C.; Riemann, M.; Knipfer, C.; Stockmann, P.; Nkenke, E. The effect of load on heat production, thermal effects and expenditure of time during implant site preparation—An experimental ex vivo comparison between piezosurgery and conventional drilling. Clin. Oral Implant. Res. 2014, 25, e140–e148. [Google Scholar] [CrossRef]

- Marković, A.; Mišić, T.; Miličić, B.; Calvo-Guirado, J.L.; Aleksić, Z.; Ðinić, A. Heat generation during implant placement in low-density bone: Effect of surgical technique, insertion torque and implant macro design. Clin. Oral Implant. Res. 2013, 24, 798–805. [Google Scholar] [CrossRef]

- Mishra, S.K.; Chowdhary, R. Heat generated by dental implant drills during osteotomy-a review: Heat generated by dental implant drills. J. Indian Prosthodont. Soc. 2014, 14, 131–143. [Google Scholar] [CrossRef]

- Hein, C.; Inceoglu, S.; Juma, D.; Zuckerman, L. Heat Generation during Bone Drilling: A Comparison between Industrial and Orthopaedic Drill Bits. J. Orthop. Trauma 2017, 31, e55–e59. [Google Scholar] [CrossRef] [PubMed]

- Möhlhenrich, S.C.; Modabber, A.; Steiner, T.; Mitchell, D.A.; Hölzle, F. Heat generation and drill wear during dental implant site preparation: Systematic review. Br. J. Oral Maxillofac. Surg. 2015, 53, 679–689. [Google Scholar] [CrossRef] [PubMed]

- Chauhan, C.J.; Shah, D.N.; Sutaria, F.B. Various bio-mechanical factors affecting heat generation during osteotomy preparation: A systematic review. Indian J. Dent. Res. 2018, 29, 81–92. [Google Scholar] [CrossRef] [PubMed]

- Strbac, G.D.; Unger, E.; Donner, R.; Bijak, M.; Watzek, G.; Zechner, W. Thermal effects of a combined irrigation method during implant site drilling. A standardized in vitro study using a bovine rib model. Clin. Oral Implant. Res. 2014, 25, 665–674. [Google Scholar] [CrossRef] [PubMed]

- Strbac, G.D.; Giannis, K.; Unger, E.; Mittlböck, M.; Watzek, G.; Zechner, W. A novel standardized bone model for thermal evaluation of bone osteotomies with various irrigation methods. Clin. Oral Implant. Res. 2014, 25, 622–631. [Google Scholar] [CrossRef] [PubMed]

- Scarano, A.; Carinci, F.; Quaranta, A.; Di Iorio, D.; Assenza, B.; Piattelli, A. Effects of bur wear during implant site preparation: An in vitro study. Int. J. Immunopathol. Pharmacol. 2007, 20, 23–26. [Google Scholar] [CrossRef] [PubMed]

- Tabrizi, R.; Nazhvanai, A.D.; Farahmand, M.M.; Pourali, S.Y.; Hosseinpour, S. Do increased drilling speed and depth affect bone viability at implant site? Dent. Res. J. (Isfahan) 2017, 14, 331–335. [Google Scholar]

- Kim, S.J.; Yoo, J.; Kim, Y.S.; Shin, S.W. Temperature change in pig rib bone during implant site preparation by low-speed drilling. J. Appl. Oral Sci. 2010, 18, 522–527. [Google Scholar] [CrossRef]

- Koopaie, M.; Kolahdouz, S.; Kolahdouz, E.M. Comparison of wear and temperature of zirconia and tungsten carbide tools in drilling bone: In vitro and finite element analysis. Br. J. Oral Maxillofac. Surg. 2019, 57, 557–565. [Google Scholar] [CrossRef]

- Ercoli, C.; Funkenbusch, P.D.; Lee, H.J.; Moss, M.E.; Graser, G.N. The influence of drill wear on cutting efficiency and heat production during osteotomy preparation for dental implants: A study of drill durability. Int. J. Oral Maxillofac. Implant. 2004, 19, 335–349. [Google Scholar]

- Fons-Badal, C.; Alonso Pérez-Barquero, J.; Martínez-Martínez, N.; Faus-López, J.; Fons-Font, A.; Agustín-Panadero, R. A novel, fully digital approach to quantifying volume gain after soft tissue graft surgery. A pilot study. J. Clin. Periodontol. 2020, 47, 614–620. [Google Scholar] [CrossRef] [PubMed]

- Zubizarreta-Macho, Á.; Triduo, M.; Alonso Pérez-Barquero, J.; Guinot Barona, C.; Albaladejo Martínez, A. Novel Digital Technique to Quantify the Area and Volume of Cement Remaining and Enamel Removed after Fixed Multibracket Appliance Therapy Debonding: An In Vitro Study. J. Clin. Med. 2020, 9, 1098. [Google Scholar] [CrossRef] [PubMed]

- Kniha, K.; Heussen, N.; Weber, E.; Möhlhenrich, S.C.; Hölzle, F.; Modabber, A. Temperature Threshold Values of Bone Necrosis for Thermo-Explantation of Dental Implants-A Systematic Review on Preclinical In Vivo Research. Materials 2020, 13, 3461. [Google Scholar] [CrossRef] [PubMed]

- Trisi, P.; Berardini, M.; Falco, A.; Vulpiani, M.P.; Masciotra, L. Effect of 50 to 60 °C heating on osseointegration of dental implants in dense bone: An in vivo histological study. Implant Dent. 2014, 23, 516–521. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Favero, V.; Sakuma, S.; Apaza Alccayhuaman, K.A.; Benedetto, G.A.; Bengazi, F.; Botticelli, D. Healing at sites prepared using different drilling protocols. An experimental study in the tibiae of sheep. PLoS ONE 2018, 29, e0202957. [Google Scholar] [CrossRef] [PubMed]

- Sener, B.C.; Dergin, G.; Gursoy, B.; Kelesoglu, E.; Slih, I. Effects of irrigation temperature on heat control in vitro at different drilling depths. Clin. Oral Implant. Res. 2009, 20, 294–298. [Google Scholar] [CrossRef]

- Albrektsson, T.; Buser, D.; Sennerby, L. Crestal bone loss and oral implants. Clin. Implant Dent. Relat. Res. 2012, 14, 783–791. [Google Scholar] [CrossRef]

- Anitua, E.; Carda, C.; Andia, I. A novel drilling procedure and subsequent bone autograft preparation: A technical note. Int. J. Oral Maxillofac. Implant. 2007, 22, 138–145. [Google Scholar]

- Tehemar, S.H. Factors affecting heat generation during implant site preparation: A review of biologic observations and future considerations. Int. J. Oral Maxillofac. Implant. 1999, 14, 127–136. [Google Scholar]

- Sumer, M.; Misir, A.F.; Telcioglu, N.T.; Guler, A.U.; Yenisey, M. Comparison of heat generation during implant drilling using stainless steel and ceramic drills. J. Oral Maxillofac. Surg. 2011, 69, 1350–1354. [Google Scholar] [CrossRef]

- Oliveira, N.; Alaejos-Algarra, F.; Mareque-Bueno, J.; Ferrés-Padró, E.; Hernández-Alfaro, F. Thermal changes and drill wear in bovine bone during implant site preparation. A comparative in vitro study: Twisted stainless steel and ceramic drills. Clin. Oral Implant. Res. 2012, 23, 963–969. [Google Scholar] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).