The Development of a Draft Force Prediction Model for Agricultural Tractors Based on the Discrete Element Method in Loam and Clay Loam

Abstract

1. Introduction

2. Materials and Methods

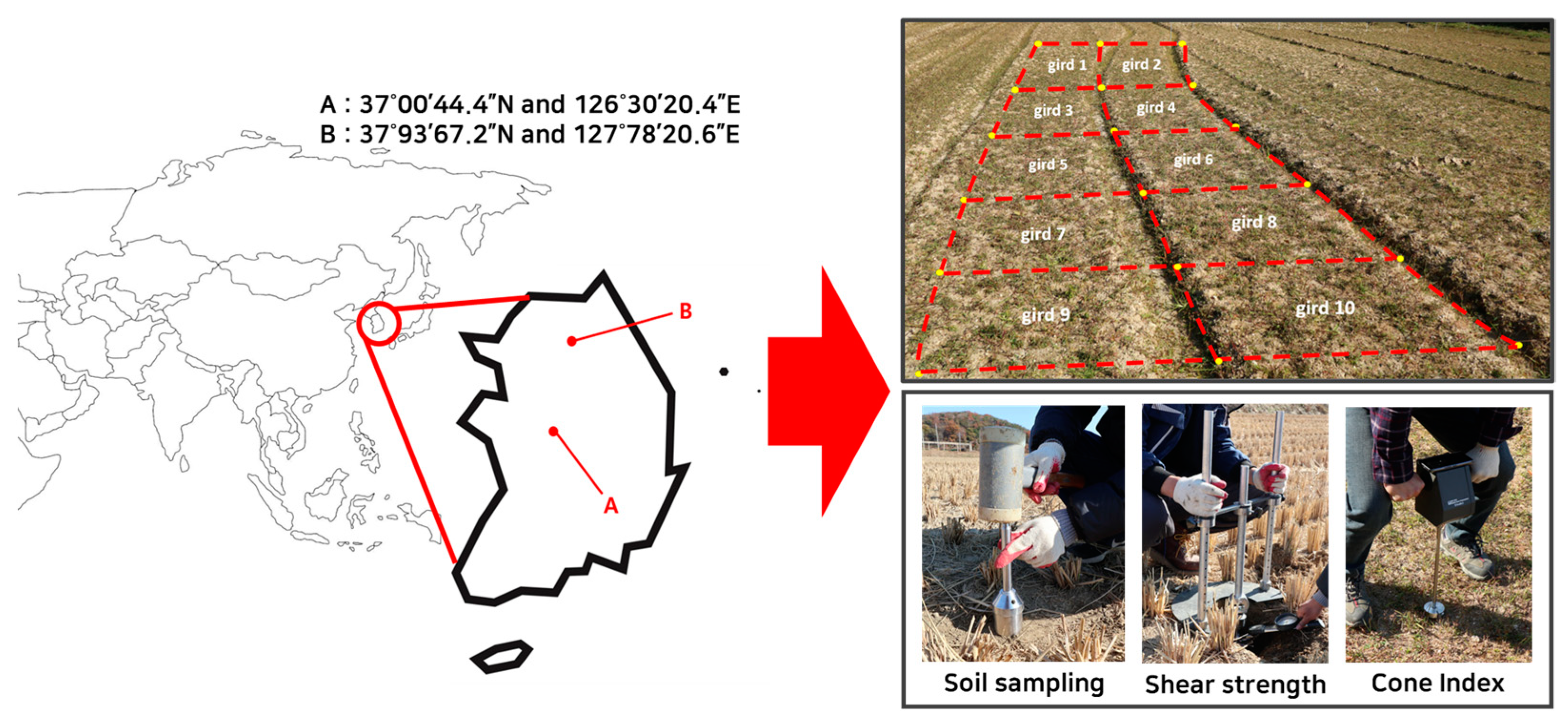

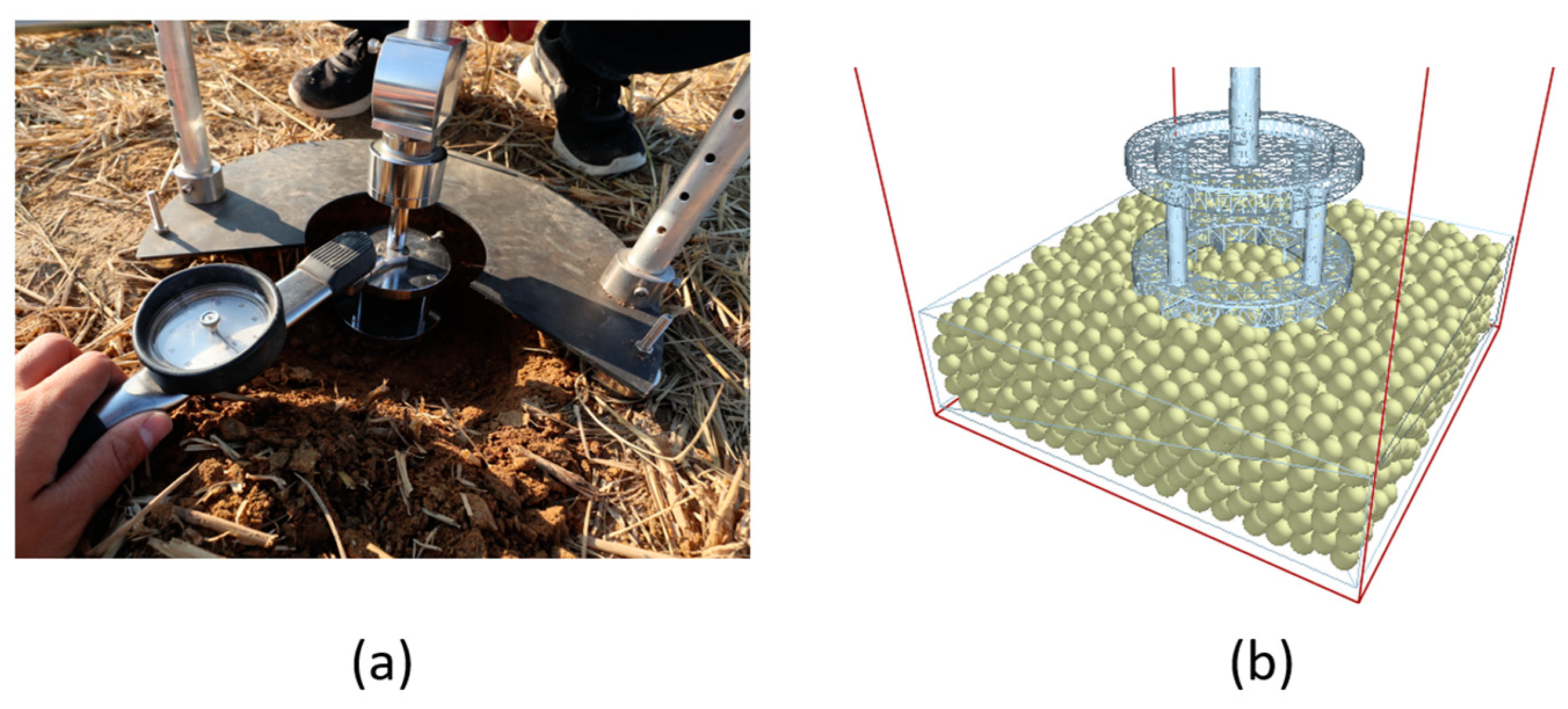

2.1. Measurement of Field Soil Properties

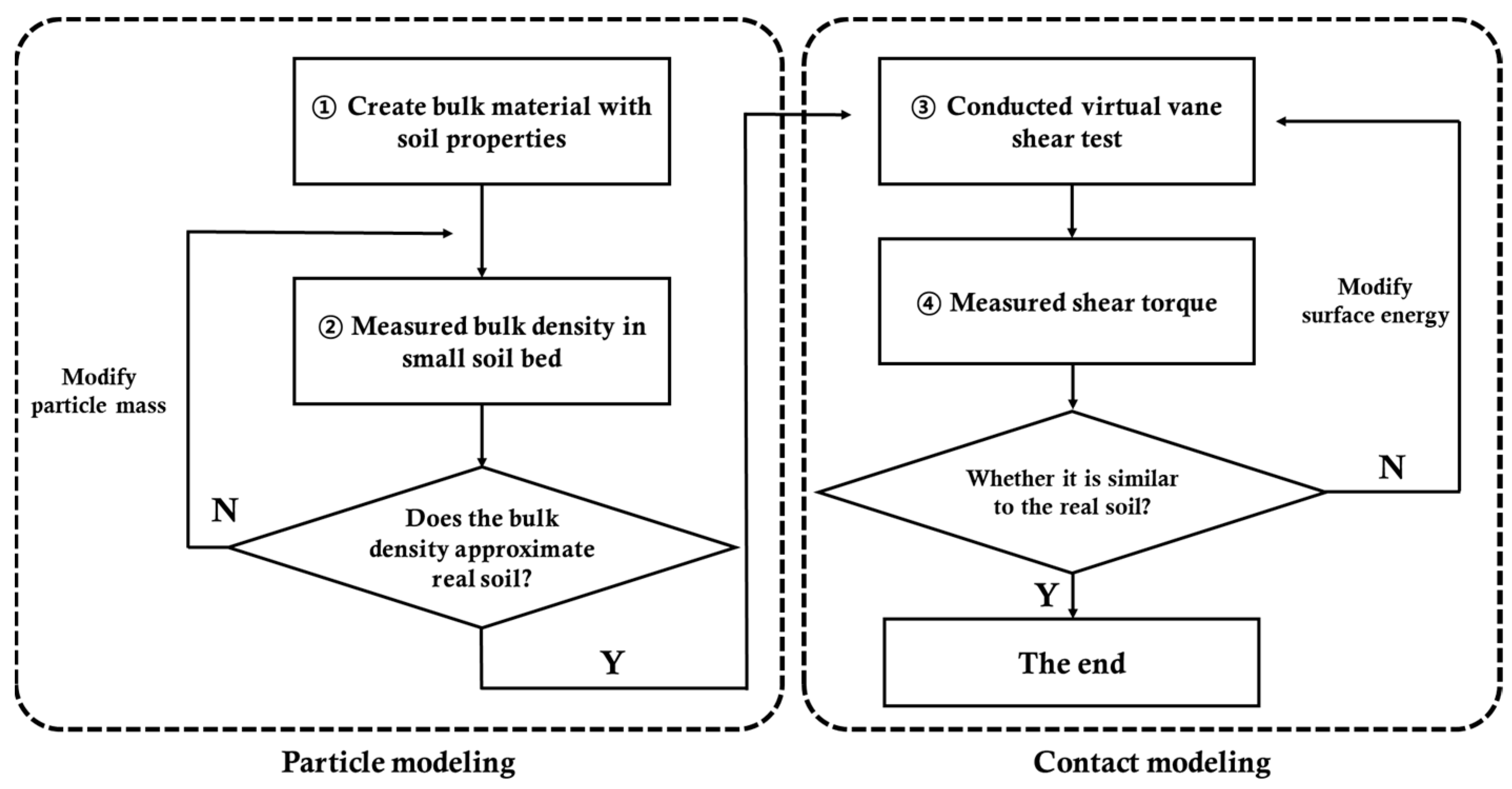

2.2. Modeling Cohesive Soil with DEM

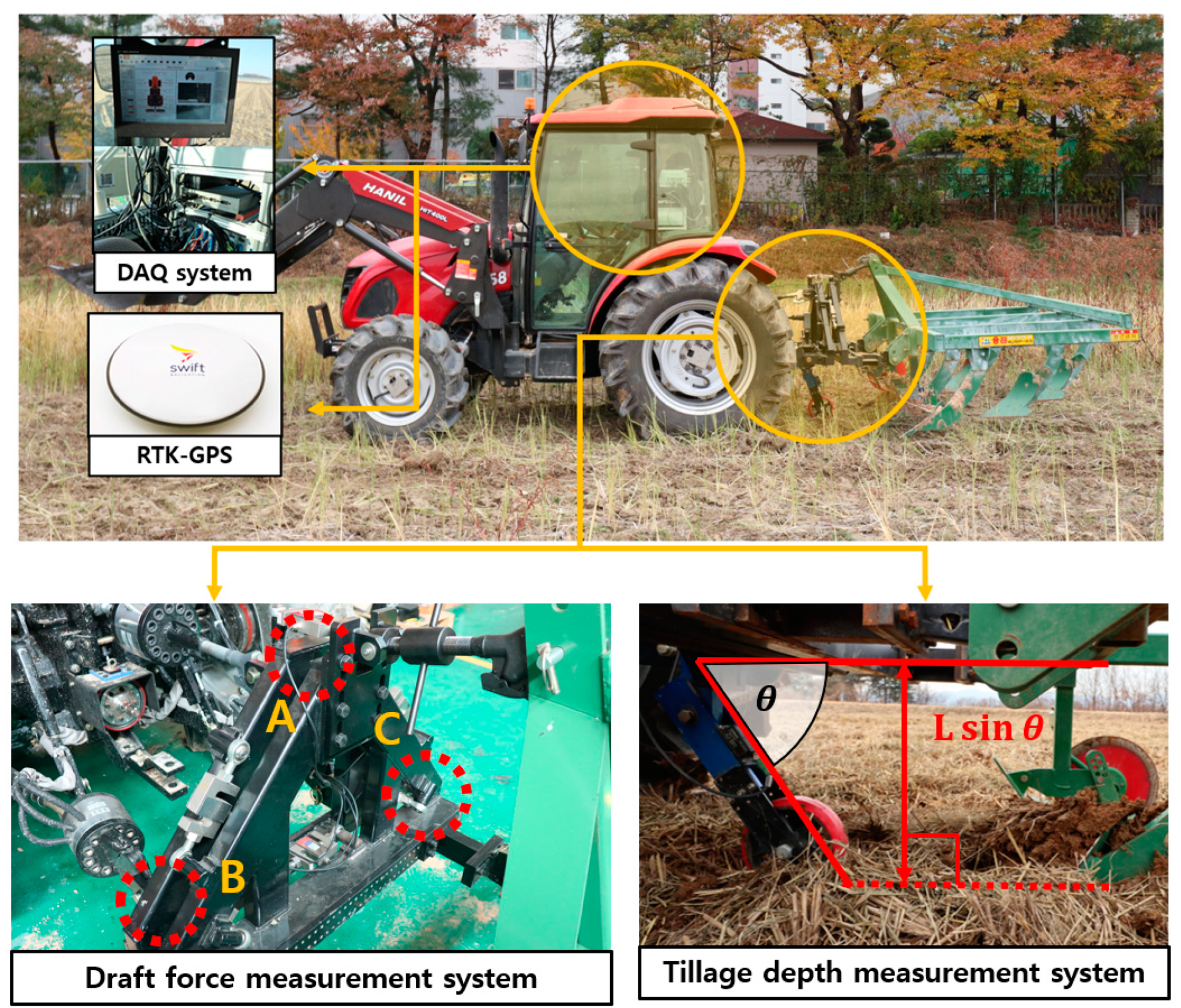

2.3. Design a Working Load Measurement System

2.3.1. Tractor-Implement System

2.3.2. Working Load Measurement System

2.4. Field Experimental Design

2.5. Theoretical Method for Draft Force Prediction

3. Results

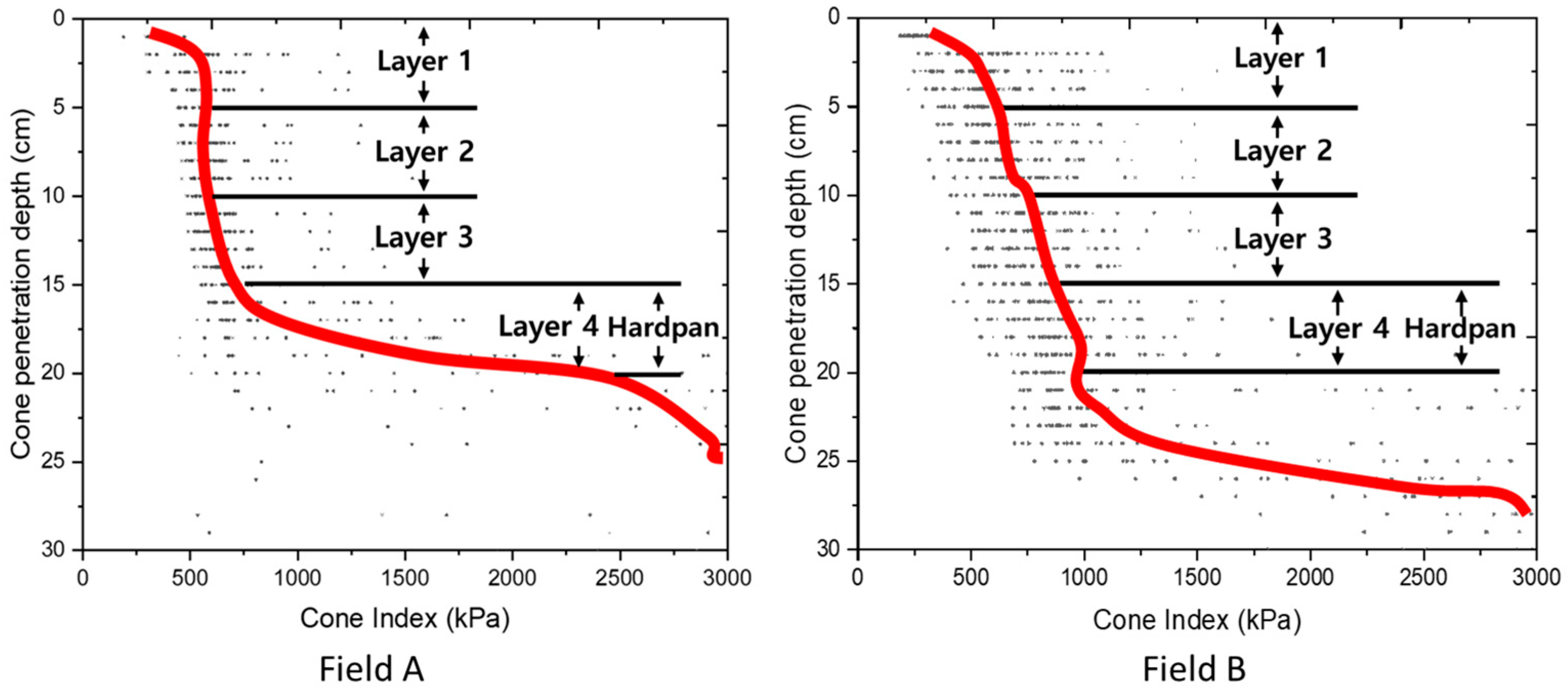

3.1. Result of Soil Properties Measurement

3.2. Soil Modeling and Calibration Using DEM

3.3. Prediction of Draft Force Based on DEM Simulations

3.3.1. Results of Draft Force Measurements from Actual Field Tests

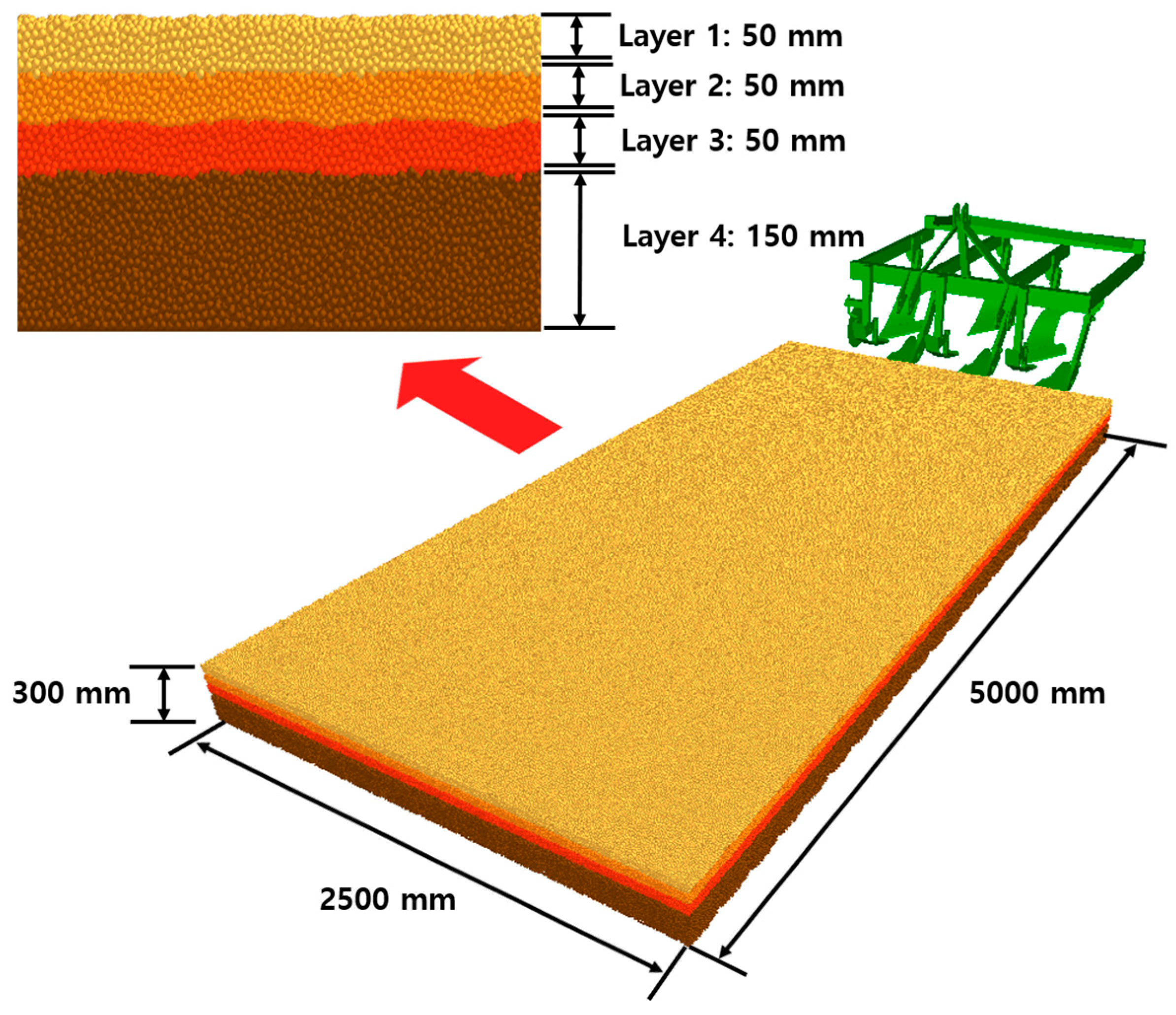

3.3.2. Creating a Virtual Soil Bed for Simulation

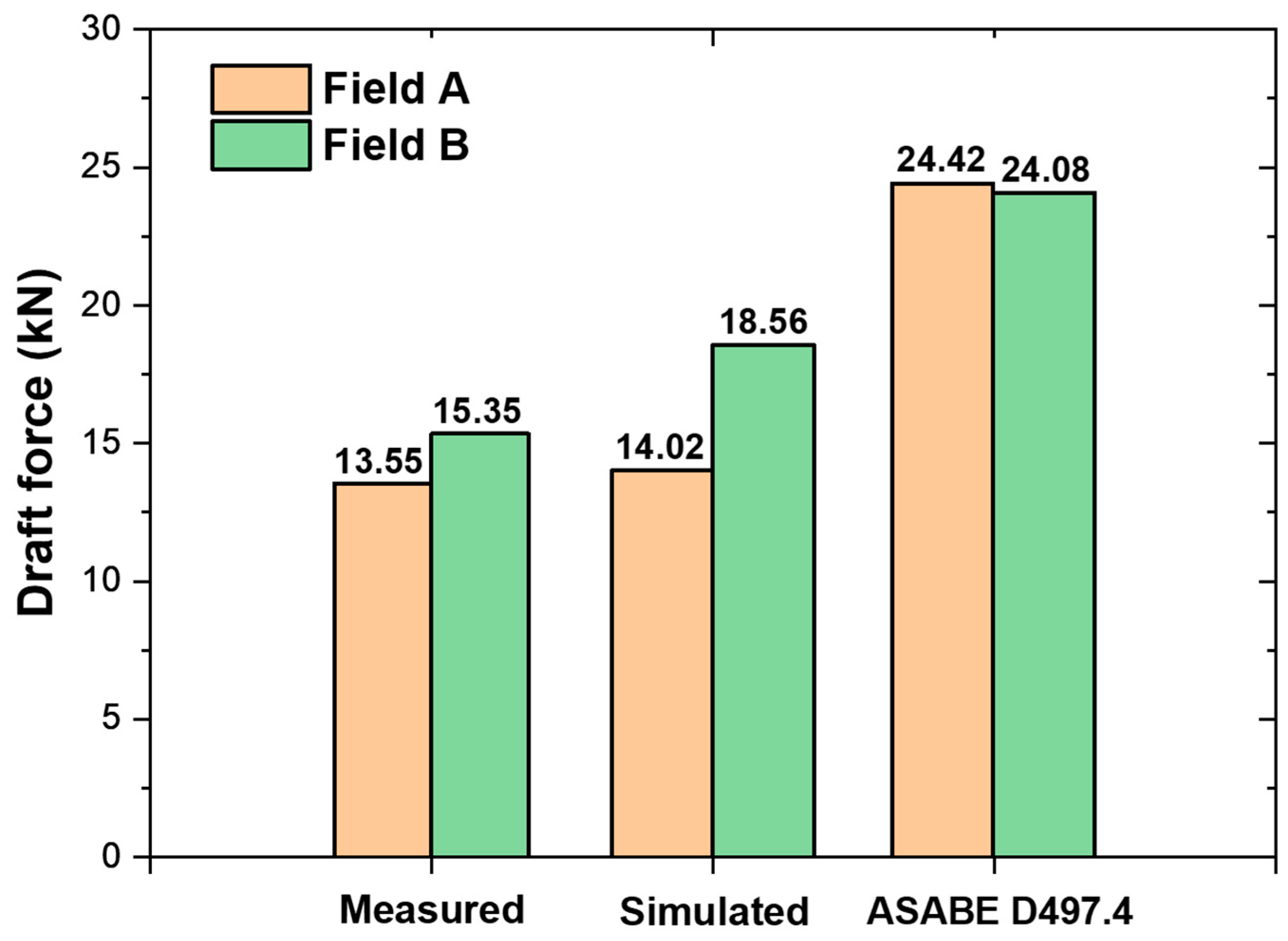

3.3.3. Accuracy Verification of DEM Simulation for Draft Force Prediction

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Mahatale, Y.V.; Tathod, D.V.; Chavan, V.K. Performance of Reversible Mold Board Plow. In Emerging Technologies in Agricultural Engineering; Apple Academic Press: Palm Bay, FL, USA, 2017; pp. 137–163. [Google Scholar]

- Kim, W.-S.; Kim, Y.-J.; Park, S.-U.; Nam, K.-C.; Choi, C.-H. Analysis of Traction Performance for an Agricultural Tractor According to Soil Moisture Content during Plow Tillage. In Proceedings of the 2019 ASABE Annual International Meeting, Boston, MA, USA, 7–9 July 2019; pp. 2–7. [Google Scholar]

- Raper, R.L. Force requirements and soil disruption of straight and bentleg subsoilers for conservation tillage systems. Appl. Eng. Agric. 2005, 21, 787–794. [Google Scholar] [CrossRef]

- Kim, Y.S.; Kim, W.S.; Baek, S.Y.; Baek, S.M.; Kim, Y.J.; Lee, S.D.; Kim, Y.J. Analysis of Tillage Depth and Gear Selection for Mechanical Load and Fuel Efficiency of an Agricultural Tractor Using an Agricultural Field Measuring System. Sensors 2020, 20, 2450. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.S.; Kim, T.J.; Kim, Y.J.; Lee, S.D.; Park, S.U.; Kim, W.S. Development of a Real-Time Tillage Depth Measurement System for Agricultural Tractors: Application to the Effect Analysis of Tillage Depth on Draft Force during Plow Tillage. Sensors 2020, 20, 912. [Google Scholar] [CrossRef] [PubMed]

- Aikins, K.A.; Ucgul, M.; Barr, J.B.; Awuah, E.; Antille, D.L.; Jensen, T.A.; Desbiolles, J.M.A. Review of Discrete Element Method Simulations of Soil Tillage and Furrow Opening. Agriculture 2023, 13, 541. [Google Scholar] [CrossRef]

- Fielke, J.M. Finite Element Modelling of the Interaction of the Cutting Edge of Tillage Implements with Soil. J. Agric. Eng. Res. 1999, 74, 91–101. [Google Scholar] [CrossRef]

- Ucgul, M.; Saunders, C.; Fielke, J.M. Comparison of the Discrete Element and Finite Element Methods to Model the Interaction of Soil and Tool Cutting Edge. Biosyst. Eng. 2018, 169, 199–208. [Google Scholar] [CrossRef]

- Bentaher, H.; Ibrahmi, A.; Hamza, E.; Hbaieb, M.; Kantchev, G.; Maalej, A.; Arnold, W. Finite Element Simulation of Moldboard–Soil Interaction. Soil Tillage Res. 2013, 134, 11–16. [Google Scholar] [CrossRef]

- Ibrahmi, A.; Bentaher, H.; Hbaieb, M.; Maalej, A.; Mouazen, A.M. Study the Effect of Tool Geometry and Operational Conditions on Mouldboard Plough Forces and Energy Requirement: Part 1. Finite Element Simulation. Comput. Electron. Agric. 2015, 117, 258–267. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, S.; Pan, H.; Zheng, Z.; Huang, Y.; Zhu, R. Effect of Soil Particle Size on Soil-Subsoiler Interactions Using the Discrete Element Method Simulations. Biosyst. Eng. 2019, 182, 138–150. [Google Scholar] [CrossRef]

- Obermayr, M.; Dressler, K.; Vrettos, C.; Eberhard, P. Prediction of Draft Forces in Cohesionless Soil with the Discrete Element Method. J. Terramech. 2011, 48, 347–358. [Google Scholar] [CrossRef]

- Ucgul, M.; Fielke, J.M.; Saunders, C. Three-Dimensional Discrete Element Modelling (DEM) of Tillage: Accounting for Soil Cohesion and Adhesion. Biosyst. Eng. 2015, 129, 298–306. [Google Scholar] [CrossRef]

- Tekeste, M.Z.; Balvanz, L.R.; Hatfield, J.L.; Ghorbani, S. Discrete Element Modeling of Cultivator Sweep-to-Soil Interaction: Worn and Hardened Edges Effects on Soil-Tool Forces and Soil Flow. J. Terramech. 2019, 82, 1–11. [Google Scholar] [CrossRef]

- Bravo, E.L.; Tijskens, E.; Suárez, M.H.; Gonzalez Cueto, O.; Ramon, H. Prediction Model for Non-Inversion Soil Tillage Implemented on Discrete Element Method. Comput. Electron. Agric. 2014, 106, 120–127. [Google Scholar] [CrossRef]

- DEM Solutions Ltd. Theory Reference Guide, Version 2.6; DEM Solutions Ltd.: Edinburgh, UK, 2014. [Google Scholar]

- Morrisey, J.P.; Thakur, S.C.; Ooi, J.Y. EDEM Contact Model: Adhesive Elasto-Plastic Model. Granul. Matter 2014, 16, 383–400. [Google Scholar]

- Kim, Y.S.; Siddique, M.A.A.; Kim, W.S.; Kim, Y.J.; Lee, S.D.; Lee, D.K.; Hwang, S.J.; Nam, J.S.; Park, S.U.; Lim, R.G. DEM Simulation for Draft Force Prediction of Moldboard Plow According to the Tillage Depth in Cohesive Soil. Comput. Electron. Agric. 2021, 189, 106368. [Google Scholar] [CrossRef]

- Tan, K.H. Soil Sampling, Preparation, and Analysis; CRC Press: New York, NY, USA, 1995; ISBN 0-8247-9675-6. [Google Scholar]

- O’Kelly, B.C.; Sivakumar, V. Water Content Determinations for Peat and Other Organic Soils Using the Oven-Drying Method. Dry. Technol. 2014, 32, 631–643. [Google Scholar] [CrossRef]

- Klute, A.; Bradford, J.M.; Gupta, S.C. Compressibility. Methods Soil Anal. Part 1—Physical Mineral. Methods. Soil Sci. Soc. Am. Am. Soc. Agron. 1986, 377–382. [Google Scholar] [CrossRef]

- Ditzler, C.; Scheffe, K.; Monger, H.C. USDA Handbook 18; Government Printing Office: Washington, DC, USA, 2017. [Google Scholar]

- Thien, S.J. A Flow Diagram for Teaching Texture-by-Feel Analysis. J. Agron. Educ. 1979, 8, 54–55. [Google Scholar] [CrossRef]

- Ibrahim, N.M.; Rahim, N.L.; Amat, R.C.; Salehuddin, S.; Ariffin, N.A. Determination of Plasticity Index and Compression Index of Soil at Perlis. APCBEE Procedia 2012, 4, 94–98. [Google Scholar] [CrossRef][Green Version]

- D4318-10; Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils (D4318-10), Report. ASTM International Standard: West Conshohocken, PA, USA, 2010.

- Kim, W.S.; Kim, Y.J.; Baek, S.M.; Baek, S.Y.; Moon, S.P.; Lee, N.G.; Kim, T.J.; Siddique, A.A.; Jeon, H.H.; Kim, Y.S. Effect of the Cone Index on the Work Load of the Agricultural Tractor. J. Drive Control 2020, 17, 9–18. [Google Scholar] [CrossRef]

- Benjamin, J.G.; Cruse, R.M. Tillage Effects on Shear Strength and Bulk Density of Soil Aggregates. Soil Tillage Res. 1987, 9, 255–263. [Google Scholar] [CrossRef]

- ASABE Standards EP542; Procedure for Using and Reporting Data Obtained with the Soil Cone Penetrometer. ASAE: St. Joseph, MI, USA, 2009; Volume 1999.

- ASABE Standards S313.3; Soil Cone Penetrometer. ASAE: St. Joseph, MI, USA, 2005; Volume 1999.

- Srivastava, A.K.; Goering, C.E.; Rohrbach, R.P.; Buckmaster, D.R. Engineering Principles of Agricultural Machines, 2nd ed.; The American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2006. [Google Scholar]

- Hang, C.; Gao, X.; Yuan, M.; Huang, Y.; Zhu, R. Discrete Element Simulations and Experiments of Soil Disturbance as Affected by the Tine Spacing of Subsoiler. Biosyst. Eng. 2018, 168, 73–82. [Google Scholar] [CrossRef]

- Saunders, C.; Ucgul, M.; Godwin, R.J. Discrete Element Method (DEM) Simulation to Improve Performance of a Mouldboard Skimmer. Soil Tillage Res. 2021, 205, 104764. [Google Scholar] [CrossRef]

- Bolotov, A.G.; Shein, E.V.; Makarychev, S.V. Water Retention Capacity of Soils in the Altai Region. Eurasian Soil Sci. 2019, 52, 187–192. [Google Scholar] [CrossRef]

- Ahmadi, I. Development and Assessment of a Draft Force Calculator for Disk Plow Using the Laws of Classical Mechanics. Soil Tillage Res. 2016, 163, 32–40. [Google Scholar] [CrossRef]

- Palmer, R.A. American Society of Agricultural Engineers. Science 1953, 118, 3. [Google Scholar] [CrossRef]

- Savitzky, A.; Golay, M.J.E. Smoothing and Differentiation of Data. Anal. Chem. 1964, 36, 1627–1639. [Google Scholar] [CrossRef]

- Ranjbar, I.; Rashidi, M.; Lehmali, H.F.; Mirmoradi, M.; Abdolalizadeh, E. Modeling of Double Action Disc Harrow Draft Force Based on Tillage Depth and Forward Speed. Middle East J. Sci. Res. 2013, 17, 1061–1067. [Google Scholar]

- Al-Suhaibani, S.A.M.F.; Wahby, A.M.; Aboukarima, I.S.T. Study on the Effect of Soil Moisture Content and Plowing Speed on Draft Requirements of a Moldboard Plow. J. Adv. Agric. 2015, 4, 477–486. [Google Scholar]

| Properties | Value |

|---|---|

| Particle size of soil | Radii 5 mm |

| Particle mass of soil | Calibrated |

| Shear modulus | Measured |

| Young’s modulus | Measured |

| Static friction coefficient of soil–soil | 0.4 |

| Rolling friction coefficient of plough layer | 0.58 |

| Rolling friction coefficient of hardpan layer | 0.25 |

| Static friction coefficient of soil–steel | 0.24 |

| Rolling friction coefficient of plough layer-steel | 0.34 |

| Rolling friction coefficient of hardpan layer-steel | 0.14 |

| Restitution coefficient of soil–soil | 0.2 |

| Restitution coefficient of soil–steel | 0.3 |

| Properties | Value |

|---|---|

| Constant pull-off force | 0 |

| Surface energy | Calibrated |

| Tensile exponent | 5 |

| Tangential stiff multiplier | 0.28571 |

| Slope exponent | 1.5 |

| Contact plasticity ratio | 0.75 |

| Item | Specification | |

|---|---|---|

| Company | TYM | |

| Model | TX58 | |

| Wheel base (mm) | 2155 | |

| Length × width × height (mm) | 3695 × 1848 × 2560 | |

| Engine | Rated power (kW) | 42 @ 2000 rpm |

| Max torque (Nm) | 211.8 @ 1600 rpm | |

| Transmission gear selection | Main 4 stage/Sub 6 stage | |

| PTO gear selection | 1st 540 rpm | |

| 2nd 750 rpm | ||

| 3rd 1000 rpm | ||

| Tire (inch) | Front 11.2–20 | |

| Rear 14.9–30 | ||

| Maximum travel speed (km/h) | 33.8 | |

| Item | Specification |

|---|---|

| Product name | WJSP-6S |

| Manufacturing company | Woongjin |

| Type | Moldboard plow |

| Length × width × height (mm) | 1930 × 1800 × 1235 |

| Rake angle (deg) | 30.76 |

| Tillage width (mm) | 270 |

| Share length (mm) | 360 |

| Share form | Pointed |

| Required power (kW) | 40–52 |

| Maximum tillage depth (mm) | Up to 200 |

| Coulter type | Skid jig/Plain coulter with spring |

| Coulter diameters (mm) | 340 |

| Number of furrows | 3 |

| Required travel speed (km/h) | 5–8 |

| Field | Properties | Soil Layer | |||

|---|---|---|---|---|---|

| Layer 1 (0~5 cm) | Layer 2 (5~10 cm) | Layer 3 (10~15 cm) | Layer 4 (15~20 cm) | ||

| A | Bulk density (g/cm3) | 1.50 | 1.60 | 1.72 | 1.90 |

| Moisture contents (%) | 32.21 | 34.20 | 28.72 | 24.23 | |

| Cone index (kPa) | 465.48 | 547.92 | 636.96 | 1900.2 | |

| Shear strength (kPa) | 25.19 | 30.87 | 32.90 | 42.25 | |

| B | Bulk density (g/cm3) | 1.90 | 1.91 | 1.96 | 2.02 |

| Moisture contents (%) | 26.56 | 23.81 | 22.49 | 20.24 | |

| Cone index (kPa) | 707.56 | 868.44 | 1063.16 | 2153.64 | |

| Shear strength (kPa) | 65.32 | 68.24 | 72.14 | 93.10 | |

| Field | Soil Layer | Procedure | Particle Mass (kg) | Bulk Density (kg/m3) | Calibration Error (%) | |

|---|---|---|---|---|---|---|

| Simulated | Measured | |||||

| A | Layer 1 | Initial | 0.00144 | 1538.90 | 1496.58 | 2.83 |

| Calibrated | 0.00138 | 1508.42 | 0.79 | |||

| Layer 2 | Initial | 0.00144 | 1559.09 | 1597.01 | 2.37 | |

| Calibrated | 0.00147 | 1597.44 | 0.03 | |||

| Layer 3 | Initial | 0.00144 | 1557.89 | 1715.29 | 9.18 | |

| Calibrated | 0.00159 | 1714.88 | 0.02 | |||

| Layer 4 | Initial | 0.00144 | 1565.49 | 1904.46 | 17.80 | |

| Calibrated | 0.00175 | 1904.81 | 0.02 | |||

| B | Layer 1 | Initial | 0.00144 | 1269.91 | 1899.8 | 33.16 |

| Calibrated | 0.00174 | 1901.43 | 0.09 | |||

| Layer 2 | Initial | 0.00144 | 1269.91 | 1905.64 | 33.36 | |

| Calibrated | 0.00175 | 1912.36 | 0.35 | |||

| Layer 3 | Initial | 0.00144 | 1905.69 | 1955.48 | 35.05 | |

| Calibrated | 0.00179 | 1956.07 | 0.03 | |||

| Layer 4 | Initial | 0.00144 | 1269.91 | 2021.54 | 37.18 | |

| Calibrated | 0.00185 | 2021.64 | 0.005 | |||

| Field | Soil Layer | Procedure | Surface Energy (j/m2) | Shearing Torque (Nm) | Calibration Error (%) | |

|---|---|---|---|---|---|---|

| Simulated | Measured | |||||

| A | Layer 1 | Initial | 100 | 4.73 | 5.17 | 8.51 |

| Calibrated | 130 | 5.13 | 0.77 | |||

| Layer 2 | Initial | 100 | 5.11 | 6.33 | 19.27 | |

| Calibrated | 150 | 6.32 | 0.16 | |||

| Layer 3 | Initial | 100 | 3.81 | 6.75 | 43.56 | |

| Calibrated | 260 | 6.69 | 0.89 | |||

| Layer 4 | Initial | 100 | 3.91 | 8.67 | 54.9 | |

| Calibrated | 330 | 8.64 | 0.35 | |||

| B | Layer 1 | Initial | 100 | 12.14 | 13.4 | 9.4 |

| Calibrated | 100 | 13.55 | 1.19 | |||

| Layer 2 | Initial | 100 | 12.56 | 14 | 10.29 | |

| Calibrated | 300 | 13.84 | 1.14 | |||

| Layer 3 | Initial | 100 | 11.93 | 14.8 | 19.39 | |

| Calibrated | 500 | 15 | 1.35 | |||

| Layer 4 | Initial | 100 | 11.55 | 19.1 | 39.53 | |

| Calibrated | 900 | 19.2 | 0.52 | |||

| Field A | Field B | ||||

|---|---|---|---|---|---|

| Tillage Depth (cm) | Travel Speed (km/h) | Draft Force (kN) | Tillage Depth (cm) | Travel Speed (km/h) | Draft Force (kN) |

| 15 | 5.89 ± 0.35 | 11.61 | 15 | 5.83 ± 0.51 | 13.71 |

| 16 | 5.85 ± 0.31 | 12.11 | 16 | 5.68 ± 0.65 | 14.72 |

| 17 | 5.77 ± 0.33 | 12.64 | 17 | 5.47 ± 0.59 | 14.86 |

| 18 | 5.62 ± 0.34 | 13.29 | 18 | 5.61 ± 0.51 | 15.18 |

| 19 | 5.41 ± 0.39 | 13.53 | 19 | 4.99 ± 0.80 | 17.80 |

| 20 | 5.25 ± 0.48 | 14.30 | 20 | 4.97 ± 0.71 | 16.81 |

| Field | Tillage Depth (cm) | Travel Speed (km/h) | Draft Force (kN) | Predicted Error (%) | |

|---|---|---|---|---|---|

| Simulated | Measured | ||||

| A | 16.5 | 5.63 | 14.02 | 12.38 | 13.25 |

| B | 5.43 | 18.56 | 14.79 | 25.49 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bae, B.-M.; Kim, Y.-S.; Kim, W.-S.; Kim, Y.-J.; Lee, S.-D.; Kim, T.-J. The Development of a Draft Force Prediction Model for Agricultural Tractors Based on the Discrete Element Method in Loam and Clay Loam. Agriculture 2023, 13, 2205. https://doi.org/10.3390/agriculture13122205

Bae B-M, Kim Y-S, Kim W-S, Kim Y-J, Lee S-D, Kim T-J. The Development of a Draft Force Prediction Model for Agricultural Tractors Based on the Discrete Element Method in Loam and Clay Loam. Agriculture. 2023; 13(12):2205. https://doi.org/10.3390/agriculture13122205

Chicago/Turabian StyleBae, Bo-Min, Yeon-Soo Kim, Wan-Soo Kim, Yong-Joo Kim, Sang-Dae Lee, and Taek-Jin Kim. 2023. "The Development of a Draft Force Prediction Model for Agricultural Tractors Based on the Discrete Element Method in Loam and Clay Loam" Agriculture 13, no. 12: 2205. https://doi.org/10.3390/agriculture13122205

APA StyleBae, B.-M., Kim, Y.-S., Kim, W.-S., Kim, Y.-J., Lee, S.-D., & Kim, T.-J. (2023). The Development of a Draft Force Prediction Model for Agricultural Tractors Based on the Discrete Element Method in Loam and Clay Loam. Agriculture, 13(12), 2205. https://doi.org/10.3390/agriculture13122205