1. Introduction

Moisture content (MC) is an important index of tea quality [

1]. In most tea processing methods, the last step of drying plays a decisive role in the tea’s MC. At present, tea processing mainly depends on the subjective experience of the producer or the fixed parameters of the processing machine. The former consumes manpower and cannot be quantified, while the latter ignores the different initial conditions of each batch of tea. In this case, dried tea has a high rate of tea damage caused by excessive drying, or the drying is insufficient and the MC is too high, which necessitates repeated drying and affects the taste or causes mold to breed. Therefore, rapid and nondestructive MC detection before tea drying may help the dryer automatically adjust the specific parameters during operation to improve the production efficiency and quality.

At present, the MC detection technology used for processing tea is mainly divided into the direct method and the indirect method [

2]. The direct method determines the MC of the sample by weighing the moisture loss of the sample at a certain temperature [

3,

4]. The direct method usually includes the constant-temperature oven method and the rapid moisture determination method. The advantage of this method is that the MC is measured accurately. The disadvantage is that the determination period is long, and the determination process is destructive to the sample, so it is only widely used in a laboratory setting. There has been much research into the indirect method, including capacitance [

5], machine vision [

6,

7], near-infrared spectroscopy [

8,

9], hyperspectral [

10], microwave, and so on. The capacitance method needs to be calibrated before each measurement, and the measured material needs to be in full contact with the electrode plate to ensure accurate measurement. Thus, it is only suitable for measuring lower water content. Machine vision has high requirements of fixed light. When collecting information, it can only focus on the information on the tea’s surface, ignoring the internal state of the tea. Due to its weak penetration, the reflected light received by the near-infrared spectrum can only provide the moisture distribution on the surface of the tea, losing the internal distribution. Although hyperspectral imaging technology can extract rich information, it is not convenient for rapid tea water content measurements because it needs to be in a specific experimental space over a long period of time during each process.

Due to higher quality penetration and the advantages of nondestructive and rapid detection, the microwave measurement method is gradually being applied in crop MC detection [

11,

12,

13,

14,

15]. Shivling et al. [

16] developed a patch antenna based on microwave resonance technology. At a frequency of 5 GHz, it was observed that the change in tea MC would cause a change in resonance frequency and S

11 parameter regularity, and the linear model parameters were calculated to be suitable for the prediction of tea MC. However, the authors only studied tea with a low MC (2–10%). Based on the microwave free-space method, Wu et al. [

17] optimized the microwave attenuation and phase shift characteristic signals at 2–10 GHz frequency using an ant colony optimization algorithm. The three main models of support vector regression (SVR), extreme gradient boosting (XGBoost), and multilayer perceptron (MLP) were used to predict the MC of tea, which ranged from 16.25% to 77.65%. The determination coefficient (R

2) result was 0.994 and the mean absolute error (MAE) result was 0.349, representing a significant improvement in the accuracy of the model. However, unlike other crops, tea has different stacking densities in a fixed space due to its own characteristics. Authors have not paid sufficient attention to the influence of tea stacking density on microwave signals. Yigit et al. [

18] used a vector network analyzer based on the microwave free-space method to collect the scattering parameters (SPs) of three crops at different frequency points ranging from 1–2.48 GHz. Three machine learning algorithms, K-nearest neighbor (KNN), SVR, and artificial neural network (ANN), were established to predict the MC of grains by using the data set constructed from the frequency, S

11, S

21, and MC. The method used by these authors skips the conventional steps of calculating the dielectric constant and uses the SPs to directly obtain the MC of the crop. The problem of phase ambiguity is thus avoided and the measurement steps are simplified. However, the authors did not study the feasibility analysis of crops with complex surfaces, measured thicknesses, and a high MC.

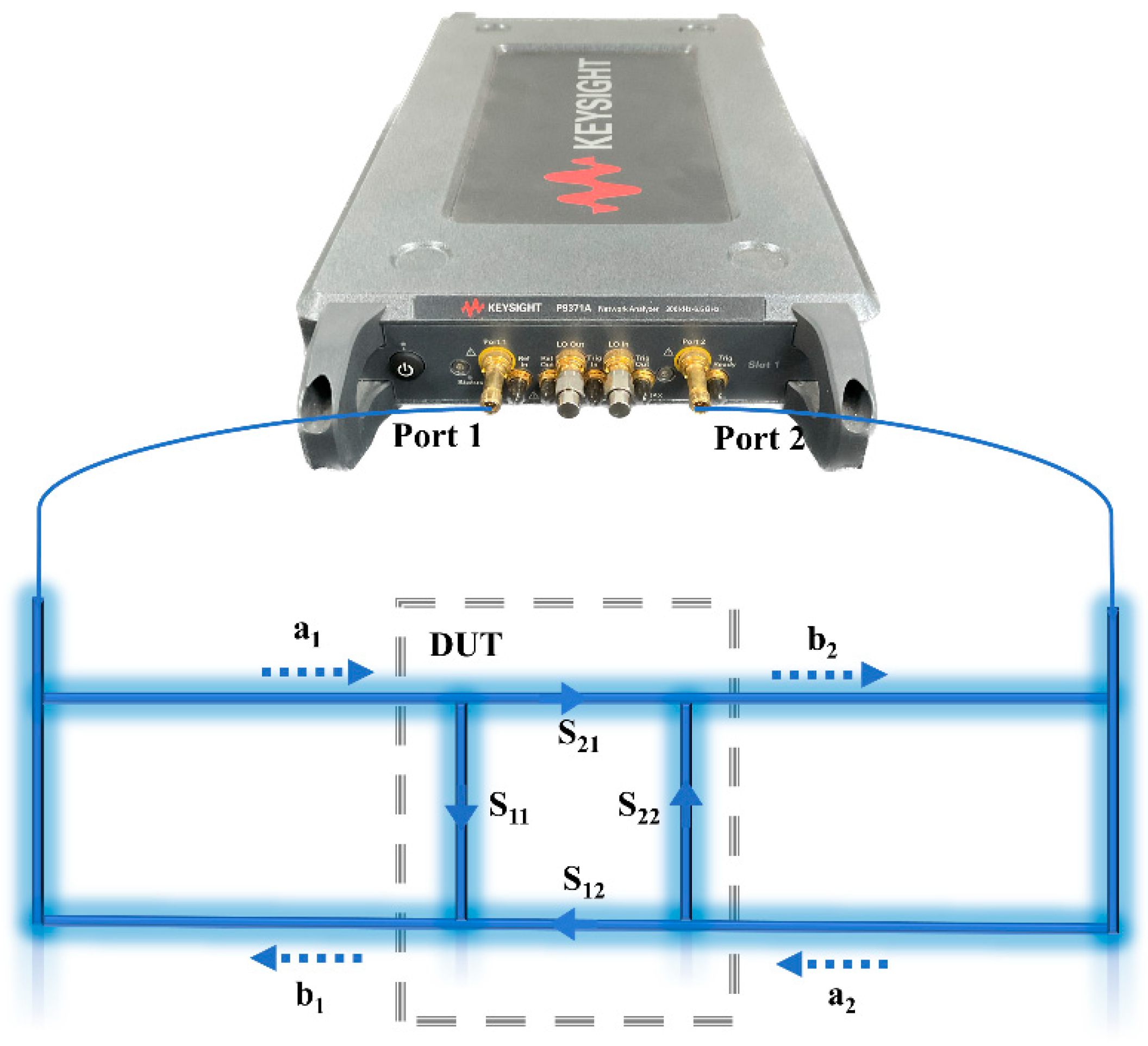

To address the limitations of current tea MC detection methods, this study used the free-space method to explore the effects of different green tea MC levels and related factors on the SPs. The SPs were measured with a vector network analyzer (VNA), and the extracted data were modeled using back propagation (BP), random forest (RF), and decision tree (DT) prediction models to establish the levels of tea MC. This method skips the measuring instrument calibration process and exerts the influence of the device on the measurement data into the learning algorithm. Different from the previous method of combining the MC with the dielectric constant, the MC of tea using this method is instead measured by establishing the relationship between the MC and the SPs. At the same time, the influences of thickness and bulk density are added to improve the accuracy of the model to a certain extent. This method can measure the MC of tea faster and more accurately than other current methods, signifying its value in various applications.

5. Conclusions

In this study, the changes in tea SPs were measured under different MCs, thicknesses, and bulk densities and analyzed using the controlling variable method. A prediction model for measuring the MC of tea from the SPs based on the free-space method was established. The following conclusions were reached:

Under the same thickness and bulk density, the relationship between S

21A and MC in SPs is the strongest (however, the introduction of other SPs will also improve the accuracy of the model, so other parameters cannot be ignored in modeling). The increase in MC will cause a decrease in S

21A, showing a negative correlation; under the same MC and bulk density, the increase in thickness will cause a decrease in S

21A, showing a negative correlation; and under the same MC and thickness, the increase in bulk density will cause a decrease in S

21A, showing a negative correlation. This study addressed the flaw in Wu et al. [

17], namely that the authors did not consider the influence of tea density on microwave signals, and also addressed the limitations of Yigit et al. [

18], which accounted for neither complex surface crops nor the possible related effects of thickness and bulk density.

In order to accurately predict the moisture content of tea, the moisture content, thickness, and bulk density were retrieved using frequency and S21A as inputs when constructing the moisture content prediction model. The results show that the R2 between moisture content and frequency and S21A was the highest, followed by thickness and bulk density. Subsequently, the frequency, SPs, thickness, and bulk density were divided into different combinations as inputs, and three models (BP, DT, and RF) were used to establish the MC prediction model. At the same time, the influence of thickness and bulk density as variables and fixed amounts on the performance of the model was explored. The results show that the model was more accurate when the thickness and bulk density were used as variables. Among them, the RF model had the best performance, the MAE value could reach 0.242, the RMSE value was 0.614, and the R2 value was 0.998. Compared to the traditional method of converting SPs through complex permittivity, this process is simpler and more effective.