Energy Management of Sowing Unit for Extended-Range Electric Tractor Based on Improved CD-CS Fuzzy Rules

Abstract

1. Introduction

2. Materials and Methods

2.1. Architecture and Working Condition Modeling of Extended-Range Electric Tractor

2.1.1. Extended-Range Electric Tractor Architecture

2.1.2. Working Condition Modeling

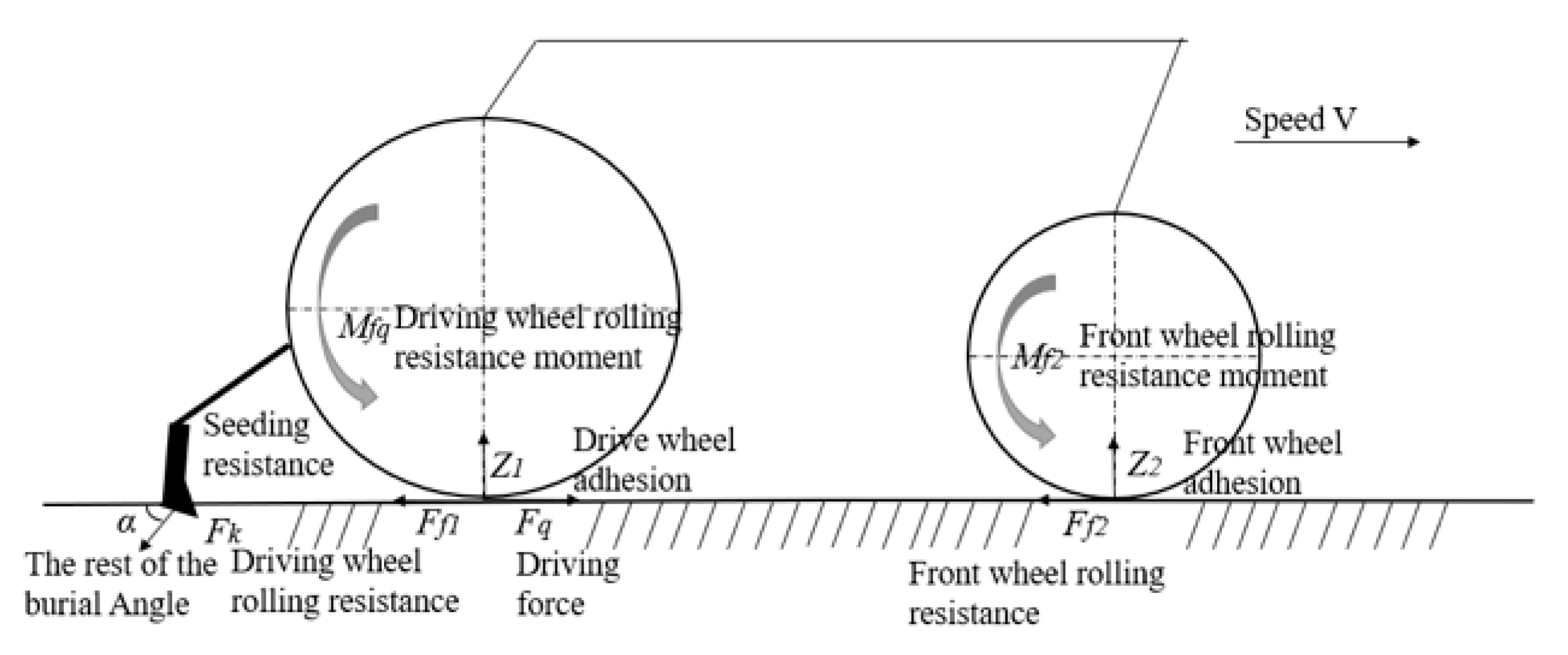

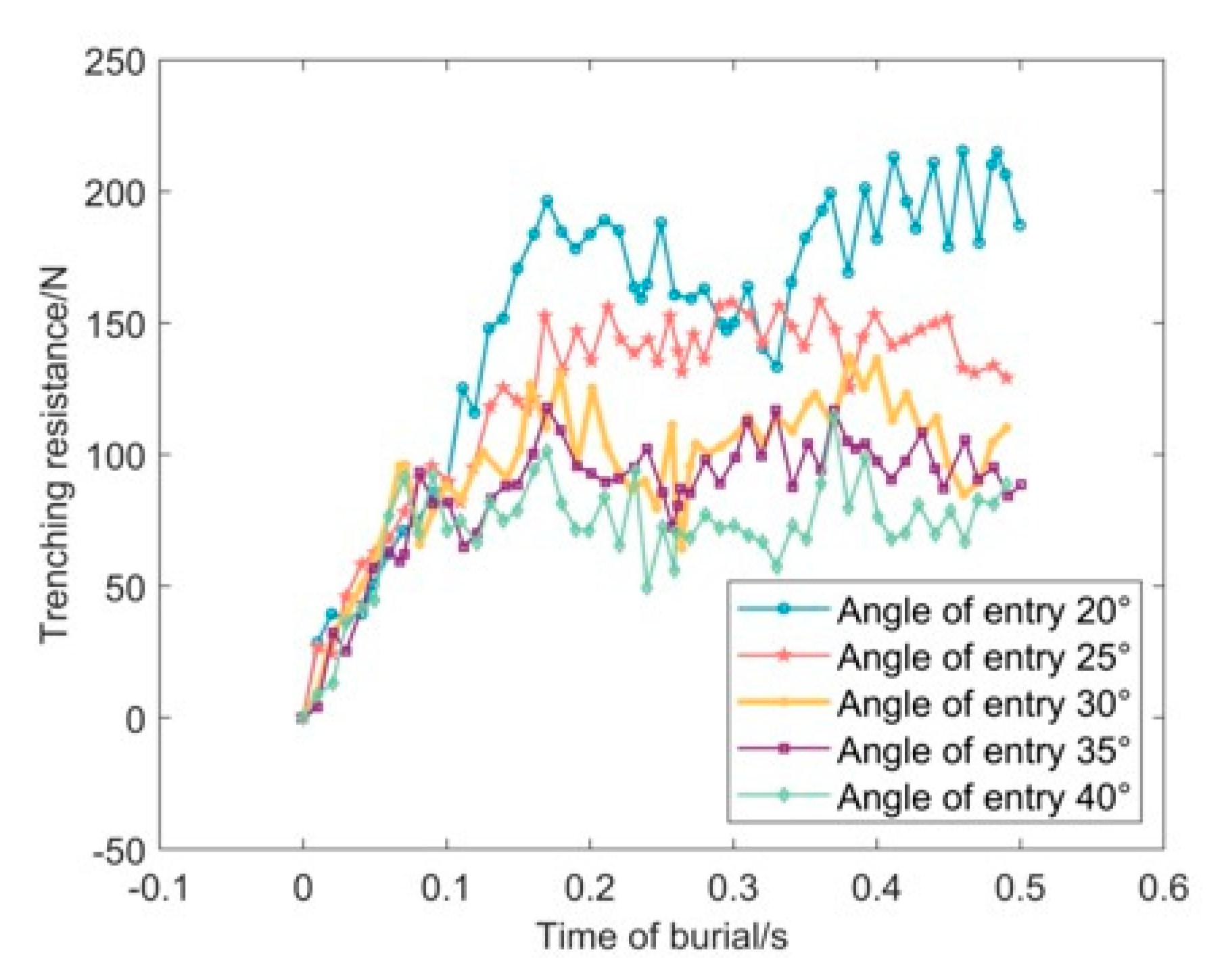

Dynamic Load Dynamics Model of Seeding Unit

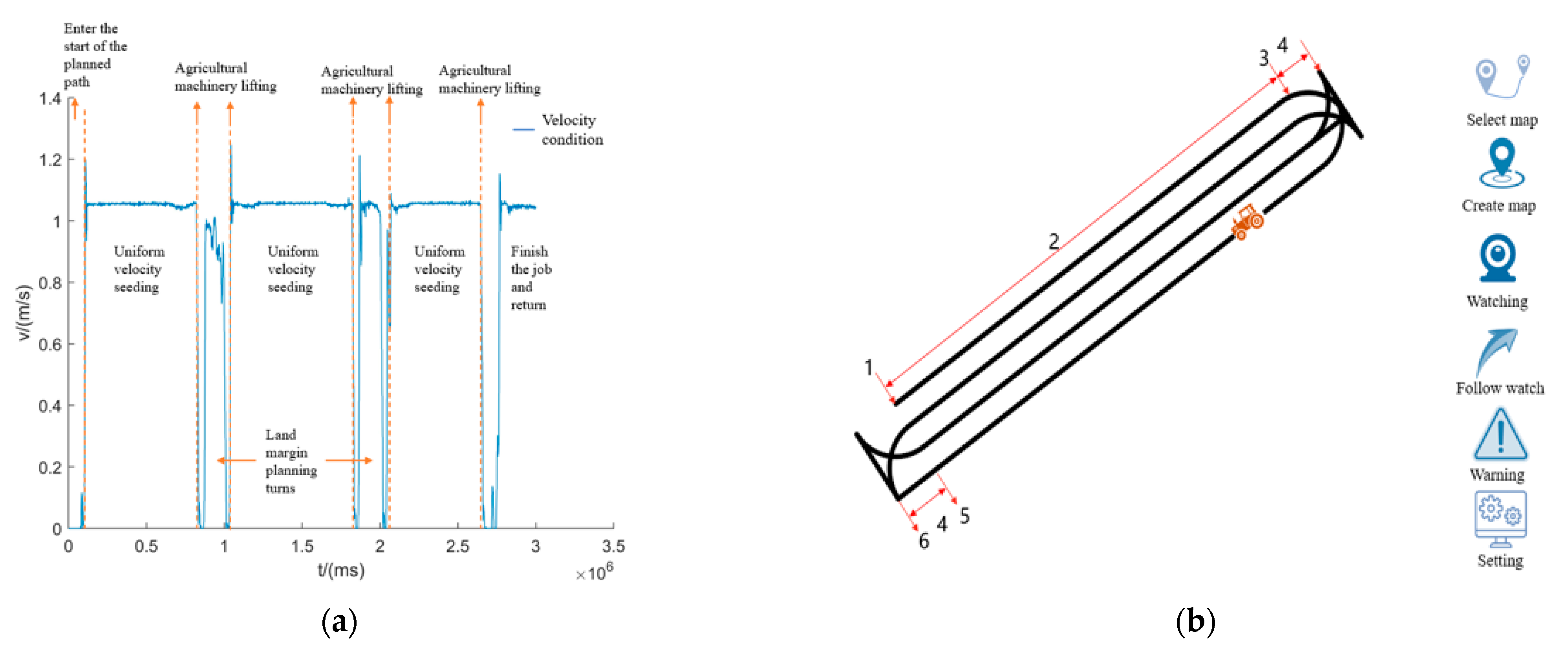

Cycle Condition

2.2. Key Components Design of an Extended-Range Electric Tractor

2.2.1. Driving Mode

2.2.2. Traction Motor Design

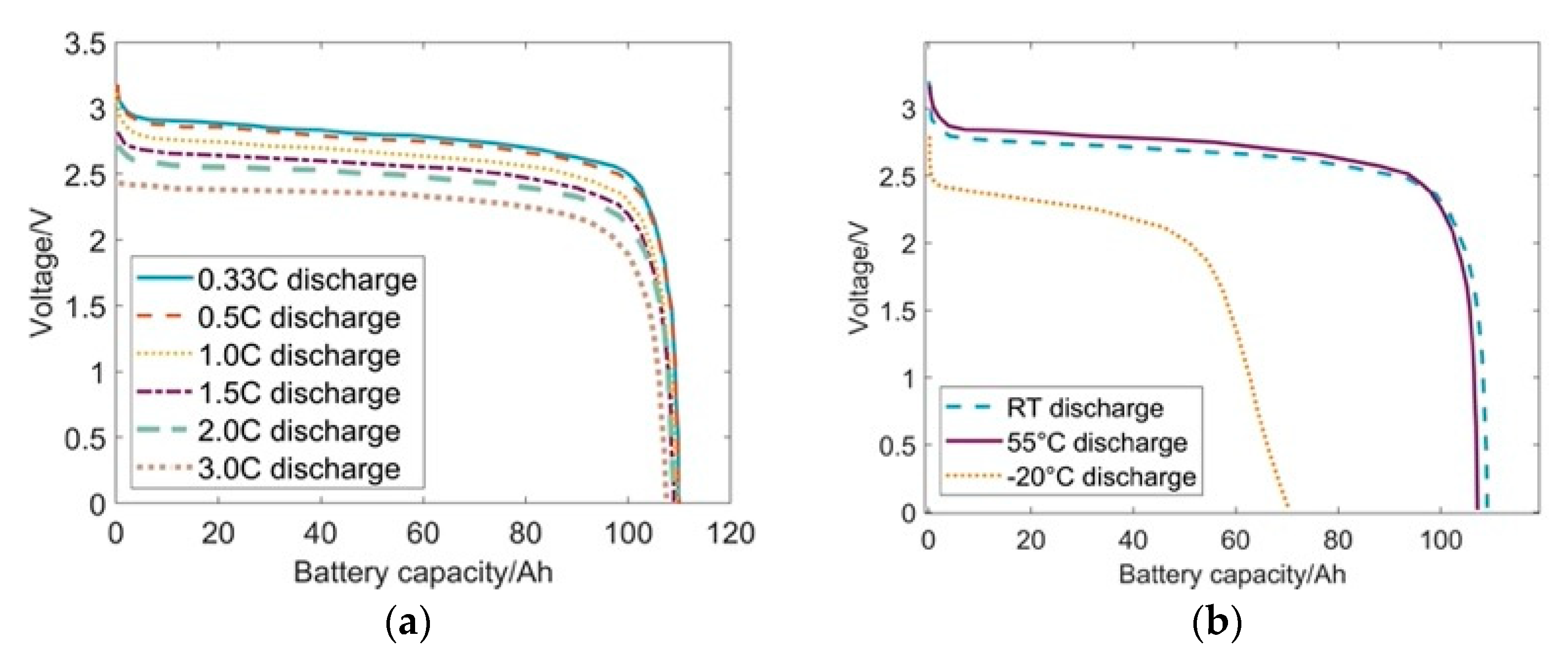

2.2.3. Power Battery Design

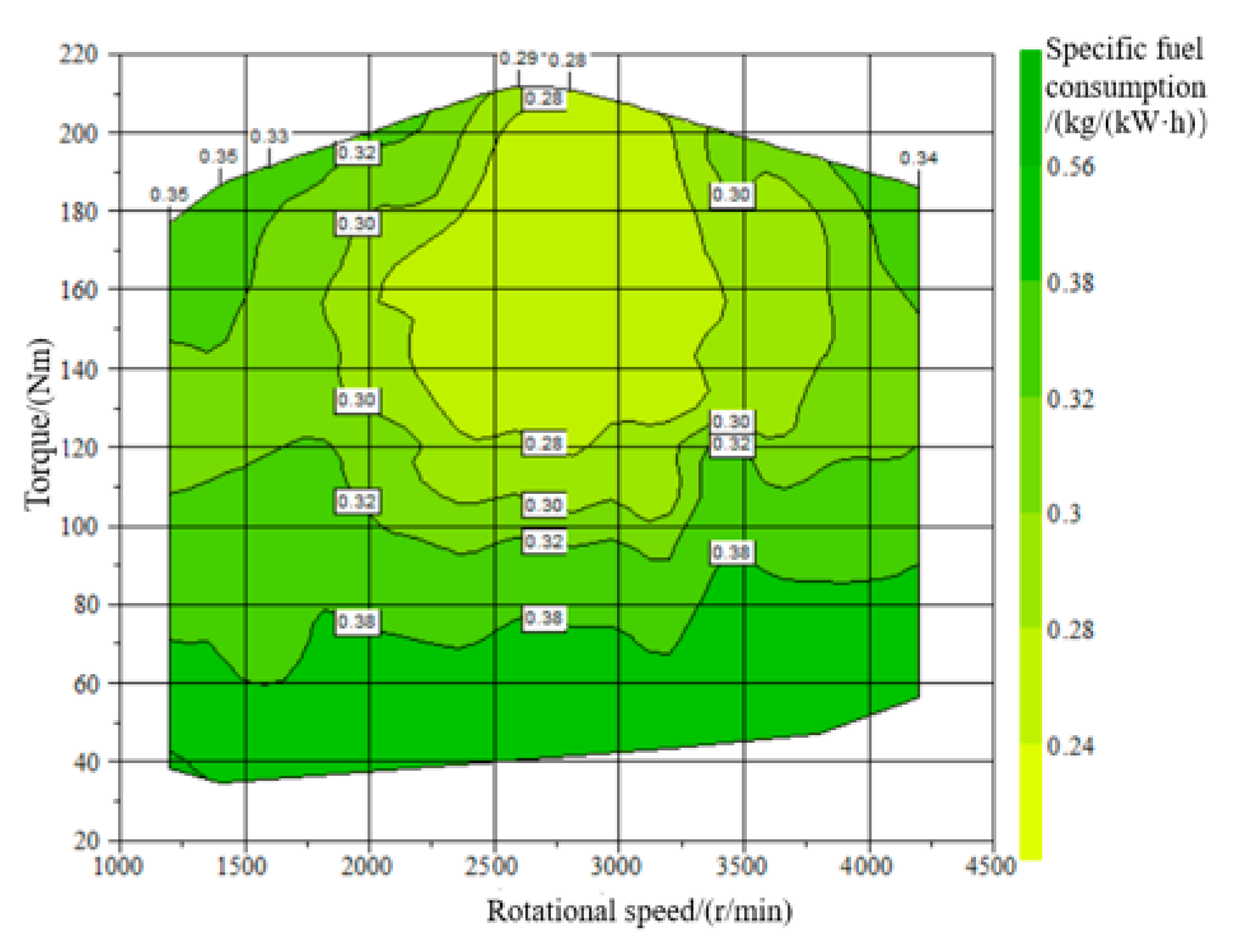

2.2.4. Design of Range Extender

2.3. Energy Management Strategies

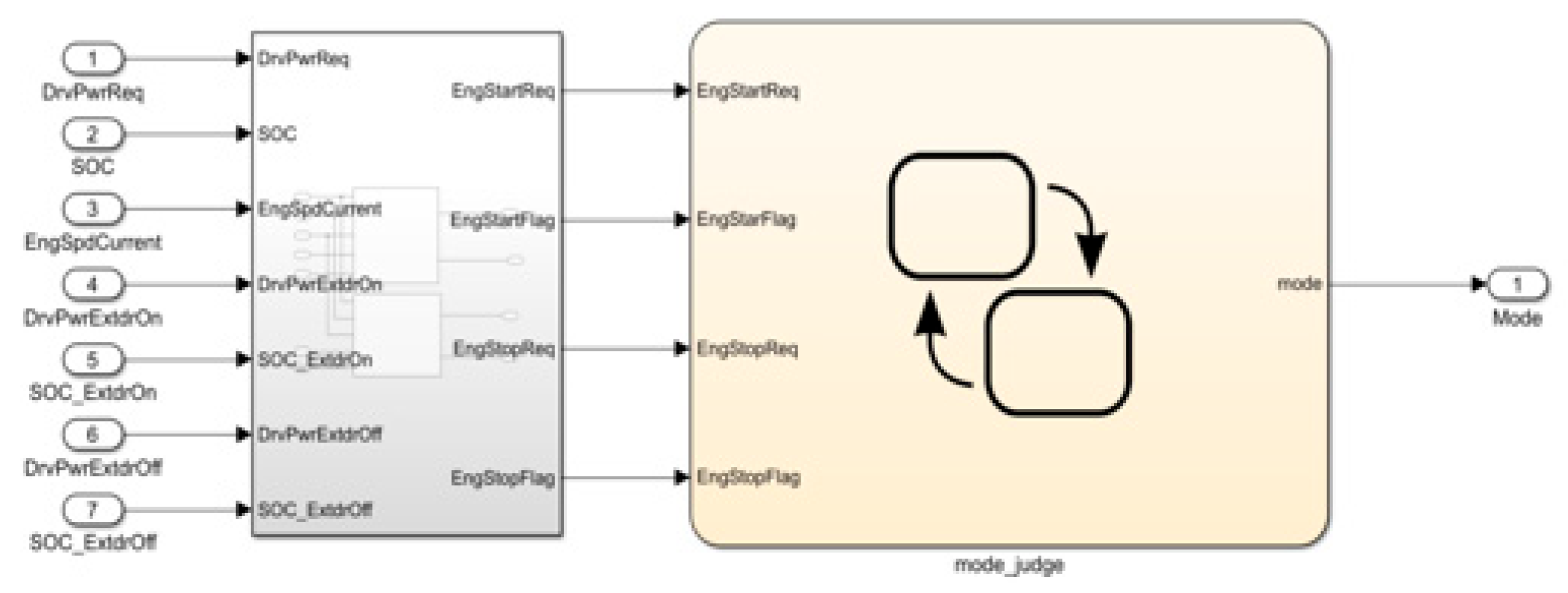

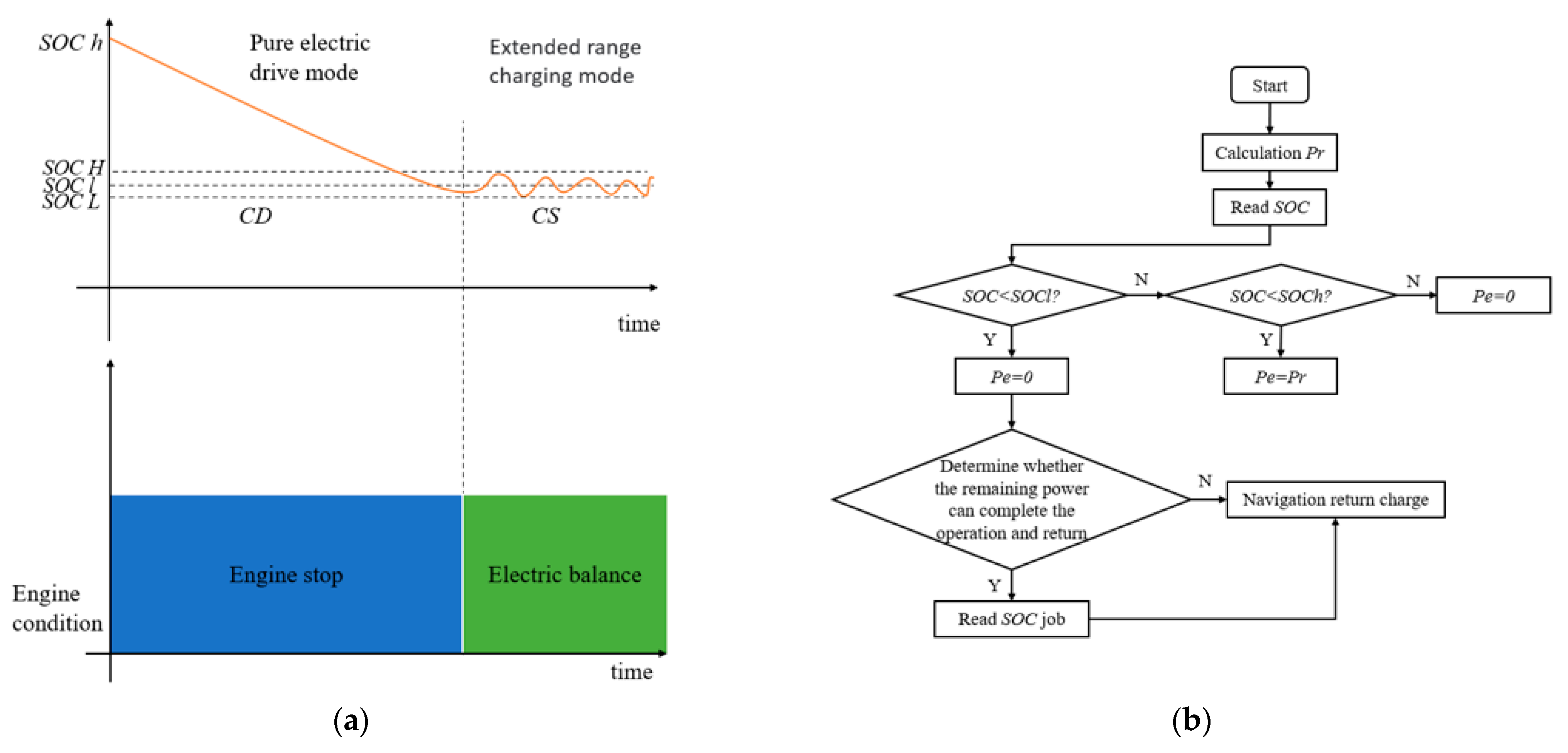

2.3.1. Rule-Based Energy Management Strategy

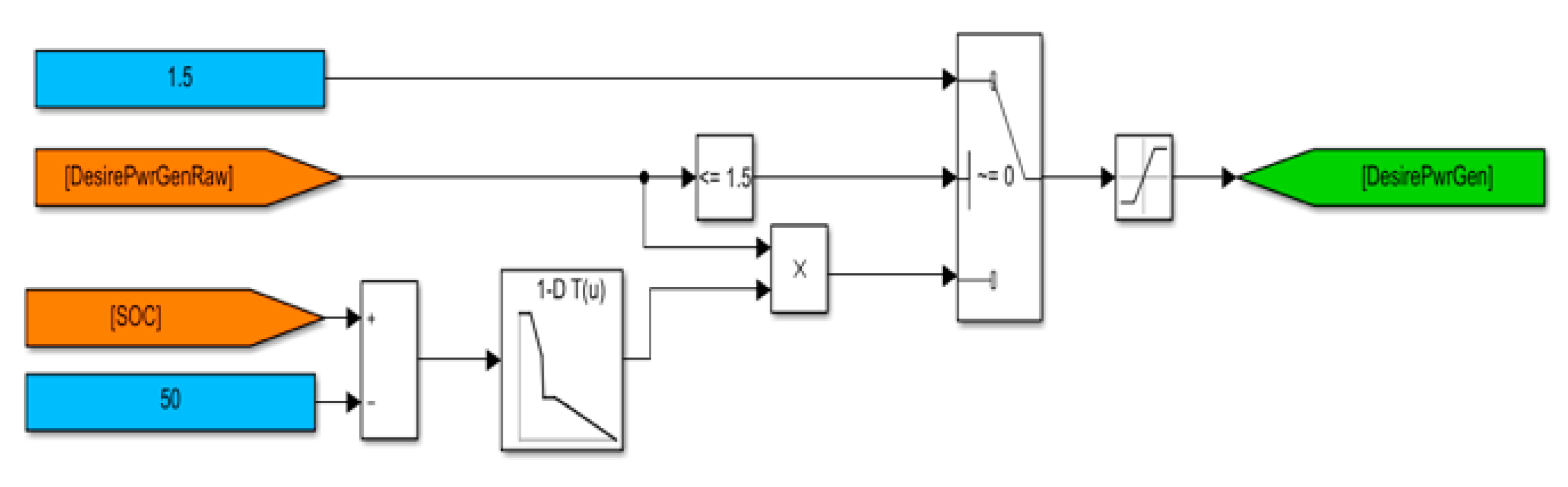

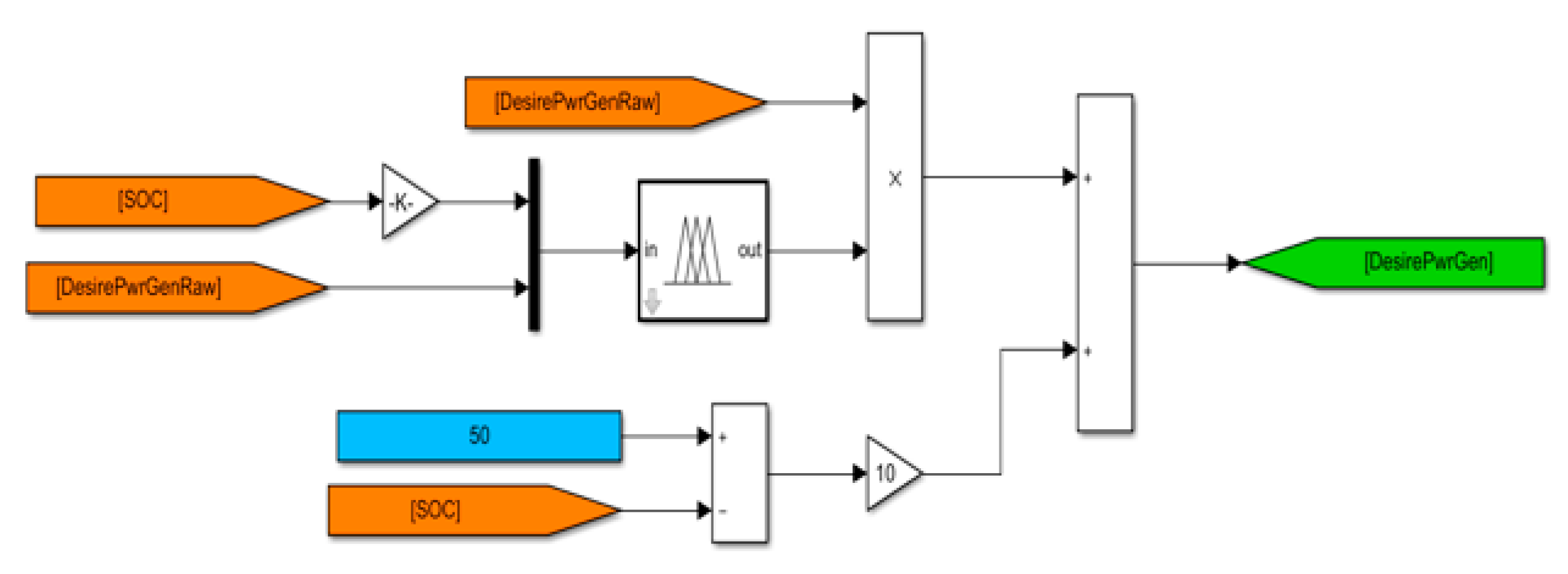

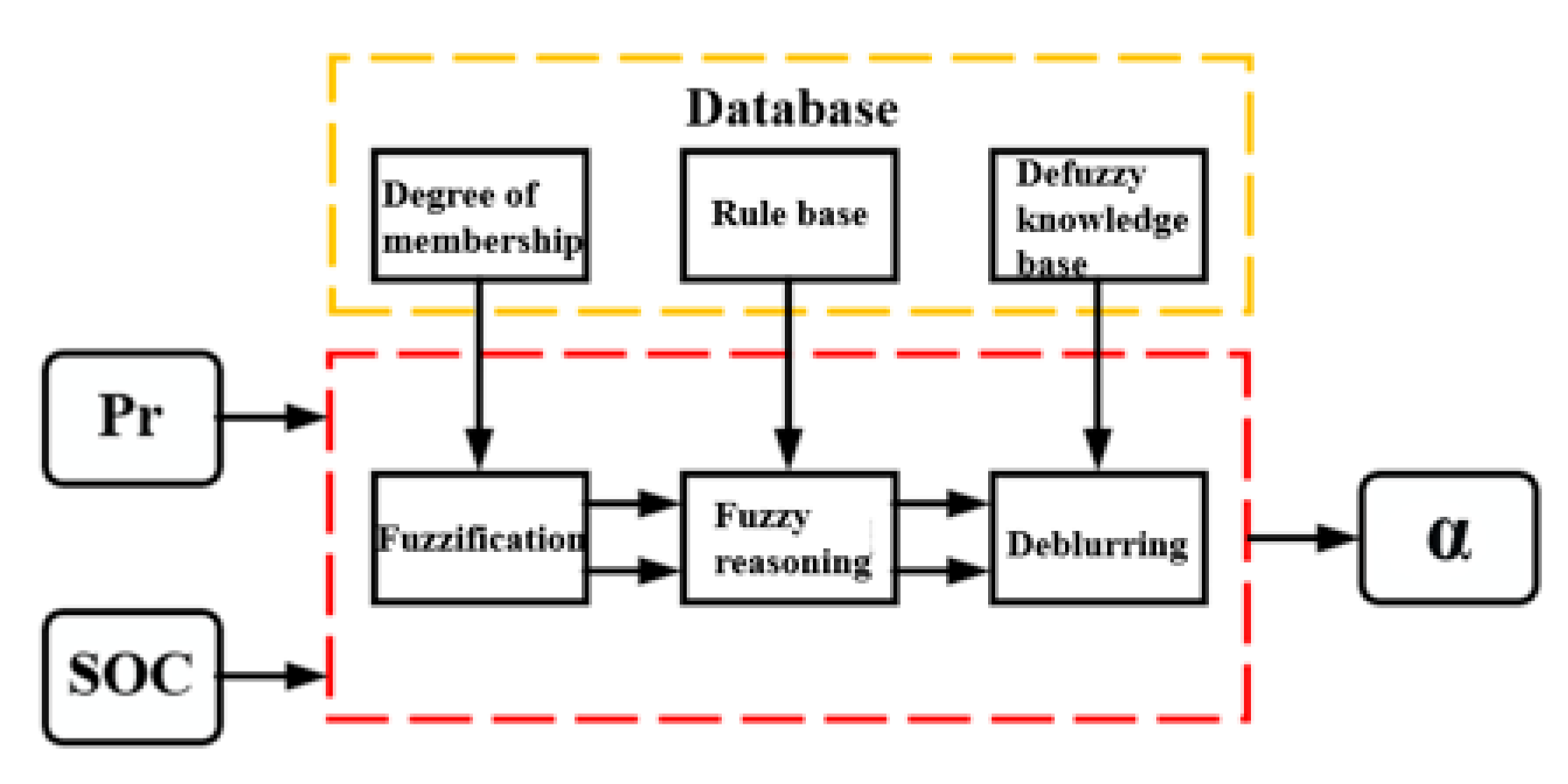

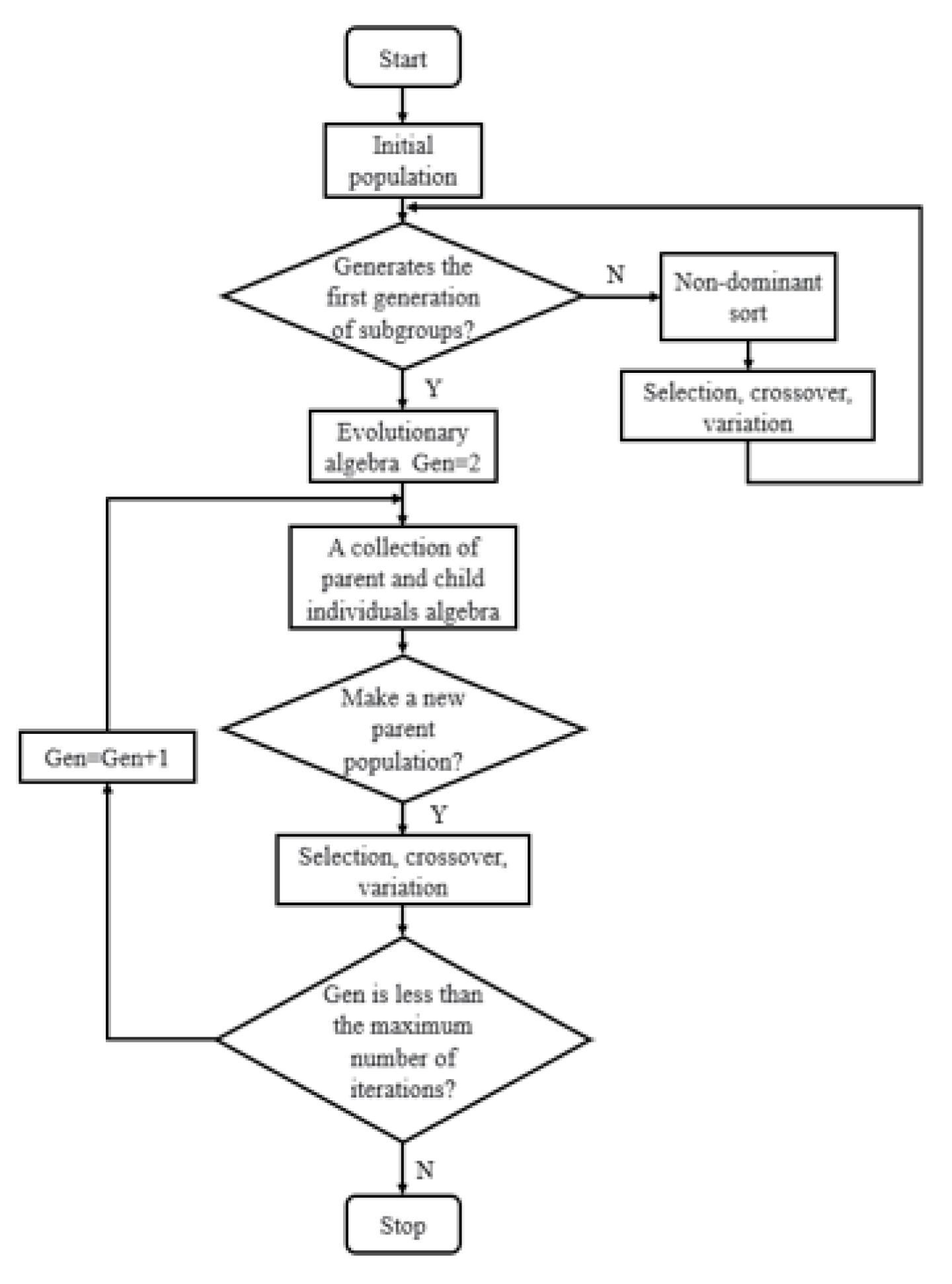

2.3.2. Fuzzy Adaptive Energy Management Strategy

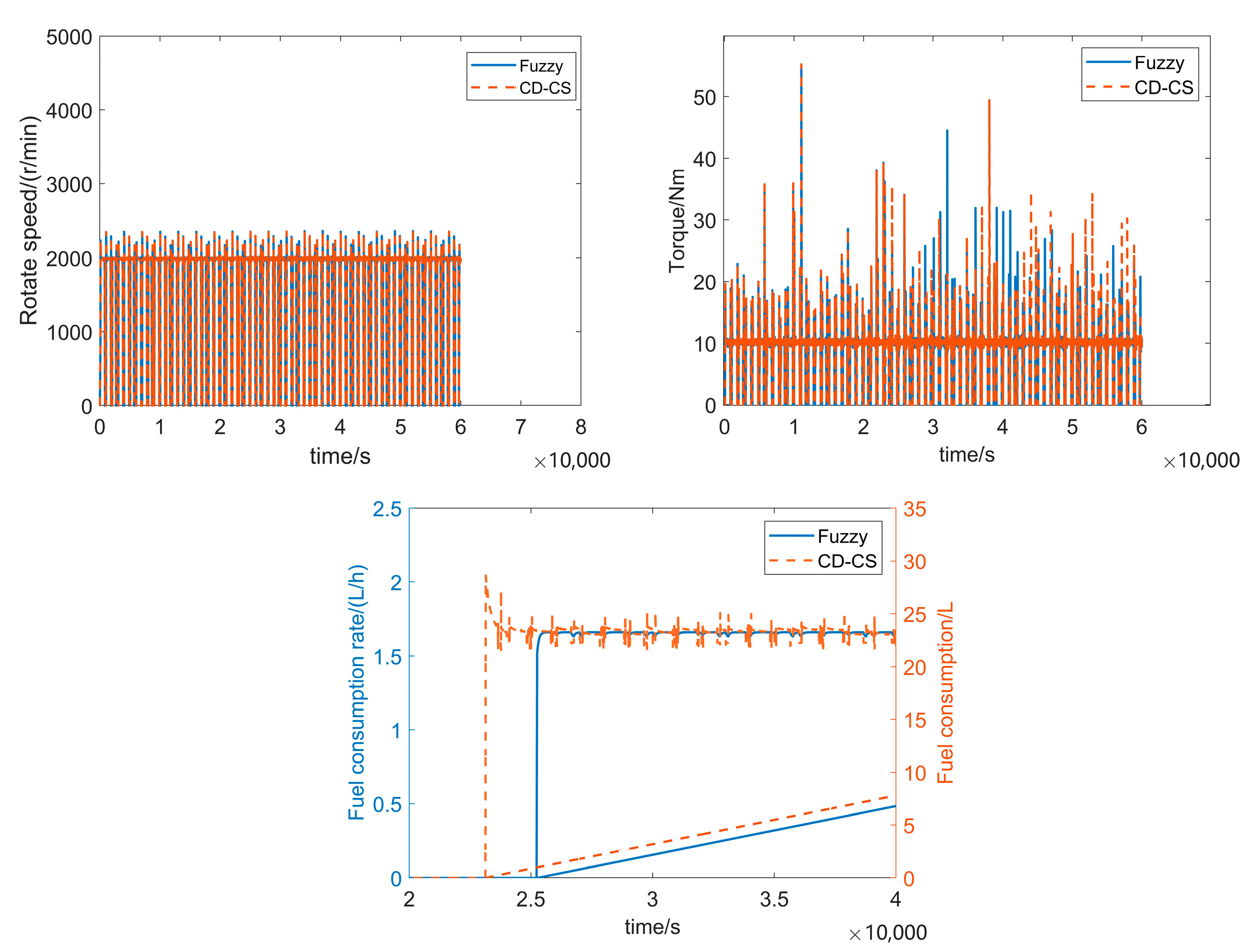

3. Results and Discussion

3.1. Hardware-In-The-Loop Test and Simulation Model

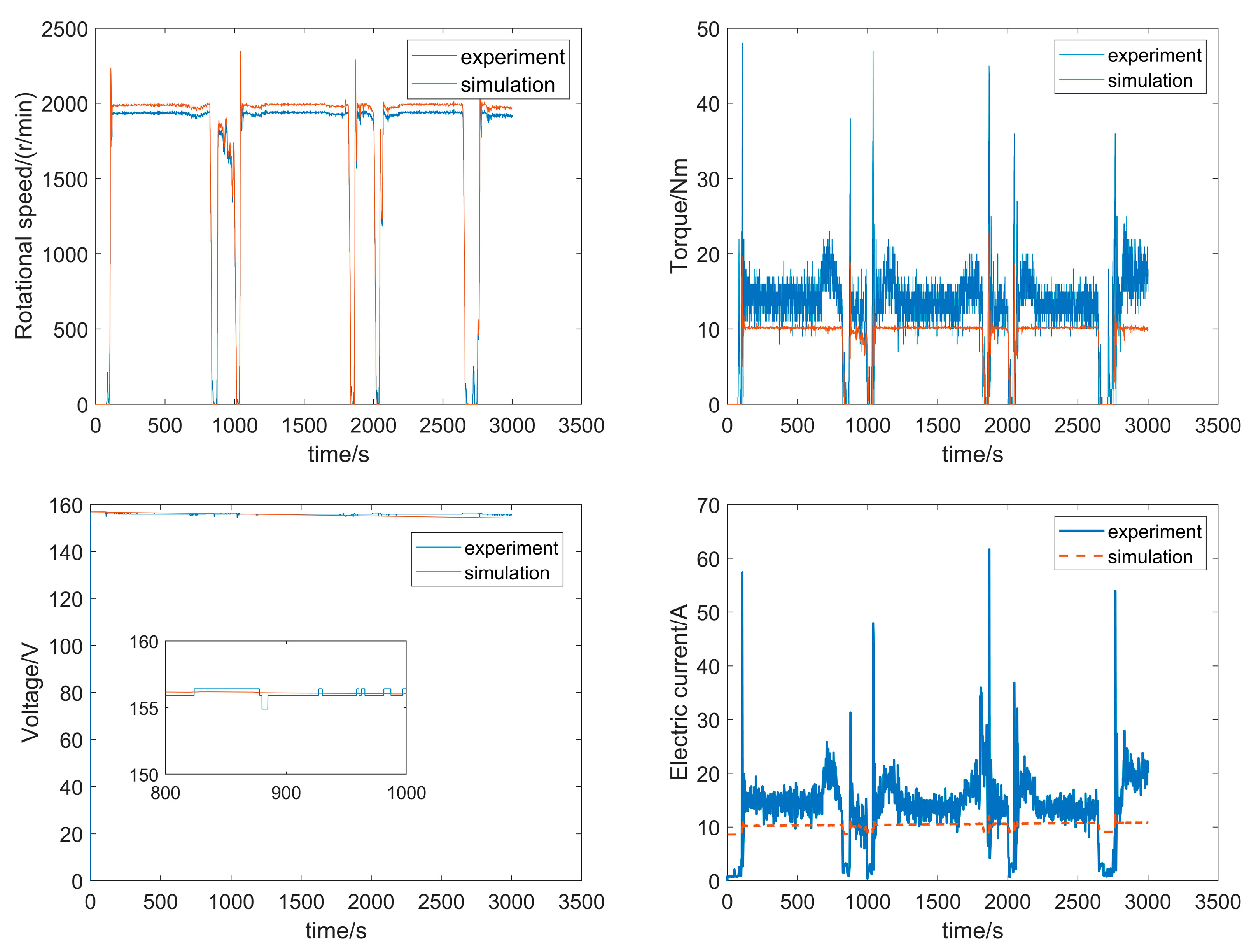

3.2. Data Analysis

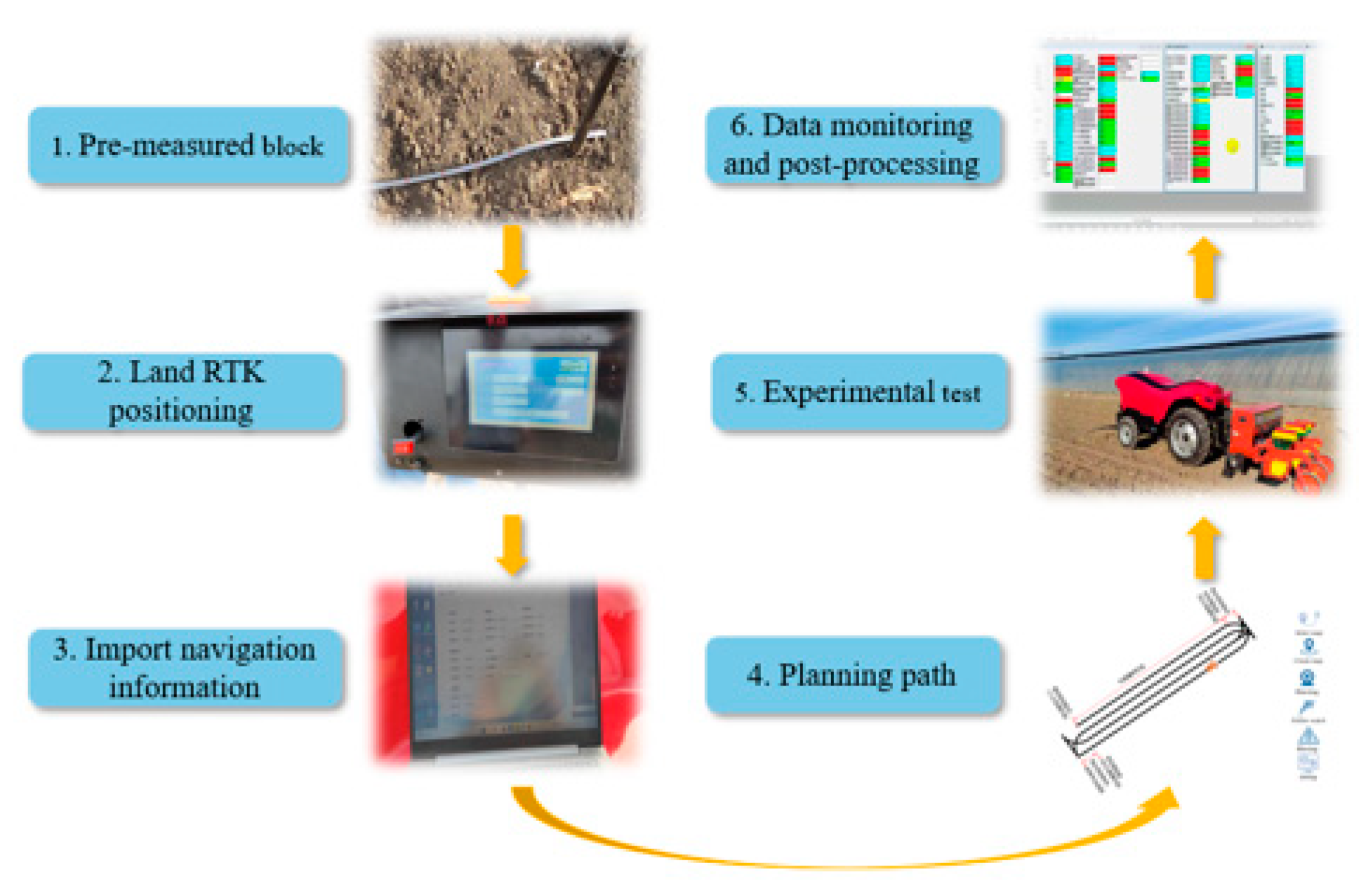

3.3. Field Experiment

- (1)

- Before the test, measure the size of the plot and estimate the seeding area;

- (2)

- Input the geographical information of the four points of the plot by the map point acquisition device, and generate a sowing area map. The real-time information is then read and input into the database through the CAN card connected to the computer, and the navigation detection interface is opened to monitor the navigation state;

- (3)

- According to the measured map, use the planning path interface to input the operation width and vehicle overall parameters, divide the sowing area, and plan the path;

- (4)

4. Conclusions

- (1)

- According to the sowing agronomic requirements of the unmanned agricultural machinery group, the whole machine model of the extended-range unmanned electric tractor was established to analyze the influence curve of the furrow angle on the whole machine resistance under the seeding condition, and transmission gear sealing and a constant speed ratio were adopted to realize the continuously variable speed.

- (2)

- According to the requirements of sowing agronomy, electric energy consumption is the main, fuel consumption is the auxiliary, and the purpose is to extend the battery life under the mode of pure electric drive. For improved power following the energy management strategy, a power consumption and power maintenance mode energy management strategy was proposed by adding a fuzzy control strategy with the aim at increasing mileage, optimizing the SOC correction factor to improve this strategy. The NSGA-II algorithm was used to optimize the fuzzy controller with the objective function of prolonging the working time in the power consumption stage. The simulation results of the proposed fuzzy strategy showed that prolonging the battery life of the battery consumption stage was 2131.9 s, which is a superior improvement.

- (3)

- By using the fuzzy strategy, the comparison between the actual test and simulation results showed that the SOC decreased by 7.21% in terms of power consumption in a cycle, while the simulation power consumption decreased by 4.94%. The power consumption error was within a reasonable range, which further verifies the feasibility of the established energy management model of the extended-range unmanned electric tractor seeding unit with a fuzzy strategy.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xie, B.; Wu, Z.; Mao, E. Development and prospect of key technologies on agricultural tractor. Trans. Chin. Soc. Agric. Mach. 2018, 49, 1–17. [Google Scholar]

- Zhan, W. Unmanned Dense Planting of Wheat Planting Design and Test of the Unit; Hebei Agricultural University: Baoding, China, 2022. [Google Scholar]

- Gonzalez-De-Soto, M.; Emmi, L.; Benavides, C.; Garcia, I.; Gonzalez-De-Santos, P. Reducing air pollution with hybrid-powered robotic tractors for precision agriculture. Biosyst. Eng. 2016, 143, 79–94. [Google Scholar] [CrossRef]

- Wang, H.; He, H.; Sun, L. Energy Consumption Analysis and Energy Management Strategy of a Pure Electric Cleaning Vehicle. J. Automot. Eng. 2022, 12, 137–146. [Google Scholar]

- Chen, H.; Xie, H.; Sun, L.; Shang, T. Research on Tractor Optimal Obstacle Avoidance Path Planning for Improving Navigation Accuracy and Avoiding Land Waste. Agriculture 2023, 13, 934. [Google Scholar] [CrossRef]

- Varshney, A.; Goyal, V. Re-evaluation on fuzzy logic controlled system by optimizing the membership functions. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Climent, H.; Pla, B.; Bares, P.; Pandey, V. Exploiting driving history for optimizing the energy management in plug-in hybrid electric vehicles. Energy Convers. Manag. 2021, 234, 113919. [Google Scholar] [CrossRef]

- Bai, Y.; He, H.; Li, J.; Li, S.; Wang, Y.X.; Yang, Q. Battery Anti-Aging Control for a Plug-in Hybrid Electric Vehicle with a Hierarchical Optimization Energy Management Strategy. J. Clean. Prod. 2019, 237, 117841. [Google Scholar] [CrossRef]

- Bayindir, K.Ç.; Gözüküçük, M.A.; Teke, A. A comprehensive overview of hybrid electric vehicle: Powertrain configurations, powertrain control techniques and electronic control units. Energy Convers. Manag. 2011, 52, 1305–1313. [Google Scholar] [CrossRef]

- Zhang, S.-L.; Wen, C.-K.; Ren, W.; Luo, Z.-H.; Xie, B.; Zhu, Z.-X.; Chen, Z.-J. A joint control method considering travel speed and slip for reducing energy consumption of rear wheel independent drive electric tractor in ploughing. Energy 2023, 263, 126008. [Google Scholar] [CrossRef]

- Xu, L.; Zhang, J.; Liu, M.; Zhou, Z.; Liu, C. Control algorithm and energy management strategy for extended range electric tractors. Int. J. Agric. Biol. Eng. 2017, 10, 35–44. [Google Scholar] [CrossRef]

- Fang, S.; Zhou, Z.; Xu, L. Energy Management Strategy of Series Hybrid Tractors. J. Henan Univ. Sci. Technol. Nat. Sci. Ed. 2015, 36, 61–66. [Google Scholar]

- Wang, Z.; Zhou, J.; Wang, X. Design and experiment of energy management model for rototiller group of extended range electric tractor. J. Agric. Mach. 2023, 13, 1–10. [Google Scholar]

- Zhang, J.; Feng, G.; Xu, L.; Wang, W.; Yan, X.; Liu, M. Energy Saving Control of Hybrid Tractor Based on Pontriagin Minimum Principle. World Electr. Veh. J. 2023, 14, 27. [Google Scholar] [CrossRef]

- Zhang, X. Design Theory and Performance Analysis of Electric Tractor Drive System. Int. J. Eng. Res. Technol. IJERT 2017, 6, 235–238. [Google Scholar]

- Li, T.H.; Xie, B.; Wang, D.Q.; Zhang, S.L.; Wu, L.P. Real-time Adaptive Energy Management Strategy for Electric Tractor Driven by Two Motors. Trans. Chin. Soc. Agric. Mach. 2020, 51, 530–543. [Google Scholar]

- Liu, M.; Lei, S.; Zhao, J.; Meng, Z.; Zhao, C.; Xu, L. Review of Development history and Research Status of Electric Tractor. Trans. Chin. Soc. Agric. Mach. 2022, 53, 348–364. [Google Scholar]

- Yu, Y.; Sun, Y.; Xia, C.; Han, J.; Shi, J.; Gao, H. Dual-layer fuzzy control energy Management Strategy for fuel cell vehicles. J. Chongqing Univ. Technol. Nat. Sci. 2022, 36, 21–28. (In Chinese) [Google Scholar]

- Yang, M.; Sun, X.; Deng, X.; Lu, Z.; Wang, T. Extrapolation of Tractor Traction Resistance Load Spectrum and Compilation of Loading Spectrum Based on Optimal Threshold Selection Using a Genetic Algorithm. Agriculture 2023, 13, 1133. [Google Scholar] [CrossRef]

- Qiu, Z.; Ma, Y.; Jin, X.; Ji, J.; He, Z. Dynamic modeling and Simulation of High Speed Trenching Resistance of Wheat planter. J. Agric. Mech. Res. 2019, 41, 52–58+109. [Google Scholar]

- Zhang, S.; Ren, W.; Xie, B.; Luo, Z.; Wen, C.; Chen, Z.; Zhu, Z.; Li, T. A combined control method of traction and ballast for an electric tractor in ploughing based on load transfer. Comput. Electron. Agric. 2023, 207, 107750. [Google Scholar] [CrossRef]

- Kang, H.; Jung, D.; Kim, M.; Min, K. Study of energy management strategy considering various working modes of plug-in hybrid electric tractor. Trans. Korean Soc. Mech. Eng. B 2013, 37, 181–186. [Google Scholar] [CrossRef]

- Zhu, Z.; Yang, Y.; Wang, D.; Cai, Y.; Lai, L. Energy saving performance of agricultural tractor equipped with Mechanic-Electronic-Hydraulic powertrain system. Agriculture 2022, 12, 436. [Google Scholar] [CrossRef]

- Yu, Y.; Hao, S.; Guo, S.; Tang, Z.; Chen, S. Motor Torque Distribution Strategy for Different Tillage Modes of Agricultural Electric Tractors. Agriculture 2022, 12, 1373. [Google Scholar] [CrossRef]

- Kim, N.; Rousseau, A.; Rask, E. Autonomie model validation with test data for 2010 Toyota Prius. Fuel 2012, 48, 46. [Google Scholar]

- Lee, H.S.; Kim, J.S.; Park, Y.I.; Cha, S.W. Rule-based power distribution in the power train of a parallel hybrid tractor for fuel savings. Int. J. Precis. Eng. Manuf.-Green Technol. 2016, 3, 231–237. [Google Scholar] [CrossRef]

- Shen, P.; Zhao, Z.; Zhan, X.; Li, J.; Guo, Q. Optimal energy management strategy for a plug-in hybrid electric commercial vehicle based on velocity prediction. Energy 2018, 155, 838–852. [Google Scholar] [CrossRef]

- Li, P.; Jiao, X.; Li, Y. Adaptive real-time energy management control strategy based on fuzzy inference system for plug-in hybrid electric vehicles. Control Eng. Pract. 2021, 107, 104703. [Google Scholar] [CrossRef]

- Mocera, F. A model-based design approach for a parallel hybrid electric tractor energy management strategy using hardware in the loop technique. Vehicles 2020, 3, 1–19. [Google Scholar] [CrossRef]

- Xie, B.; Wang, S.; Wu, X.; Wen, C.; Zhang, S.; Zhao, X. Design and hardware-in-the-loop test of a coupled drive system for electric tractor. Biosyst. Eng. 2022, 216, 165–185. [Google Scholar] [CrossRef]

| Component | Parameter | Numerical Value |

|---|---|---|

| Vehicle parameters | Complete machine quality | 2060 kg |

| Radius of front wheel | 0.382 m | |

| Rear wheel radius | 0.552 m | |

| Rolling resistance coefficient | 0.07 (operation) | |

| Wheelbase | 1.85 m | |

| Connection height | 0.6 m | |

| Motor | Rated torque | 160 Nm |

| Rated speed | 6800 r/min | |

| Range extender | Rated power | 30 kW |

| Battery pack | Battery cell | 3.2 V |

| Voltage | 144 V | |

| Gearbox | Total gear ratio | 106 |

| Mode 8 + 8 | |

|---|---|

| Forward gear | Reverse gear |

| I: | I: |

| II: | II: |

| III: | III: |

| IV: | IV: |

| V: | V: |

| VI: | VI: |

| VII: | VII: |

| VIII: | VIII: |

| Rear power output low speed: Rear power output high speed: | |

| Pr | SOC | ||

|---|---|---|---|

| L | M | H | |

| L | VL | L | M |

| M | L | M | H |

| H | M | H | VH |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Z.; Wang, J.; Xing, Y.; Li, S.; Yi, J.; Zhao, C. Energy Management of Sowing Unit for Extended-Range Electric Tractor Based on Improved CD-CS Fuzzy Rules. Agriculture 2023, 13, 1303. https://doi.org/10.3390/agriculture13071303

Wu Z, Wang J, Xing Y, Li S, Yi J, Zhao C. Energy Management of Sowing Unit for Extended-Range Electric Tractor Based on Improved CD-CS Fuzzy Rules. Agriculture. 2023; 13(7):1303. https://doi.org/10.3390/agriculture13071303

Chicago/Turabian StyleWu, Zhengkai, Jiazhong Wang, Yazhou Xing, Shanshan Li, Jinggang Yi, and Chunming Zhao. 2023. "Energy Management of Sowing Unit for Extended-Range Electric Tractor Based on Improved CD-CS Fuzzy Rules" Agriculture 13, no. 7: 1303. https://doi.org/10.3390/agriculture13071303

APA StyleWu, Z., Wang, J., Xing, Y., Li, S., Yi, J., & Zhao, C. (2023). Energy Management of Sowing Unit for Extended-Range Electric Tractor Based on Improved CD-CS Fuzzy Rules. Agriculture, 13(7), 1303. https://doi.org/10.3390/agriculture13071303