Study on the Temperature and Water Distribution of Hot Air in Red Loam Based on Soil Continuous Cropping Obstacles

Abstract

1. Introduction

2. Materials and Methods

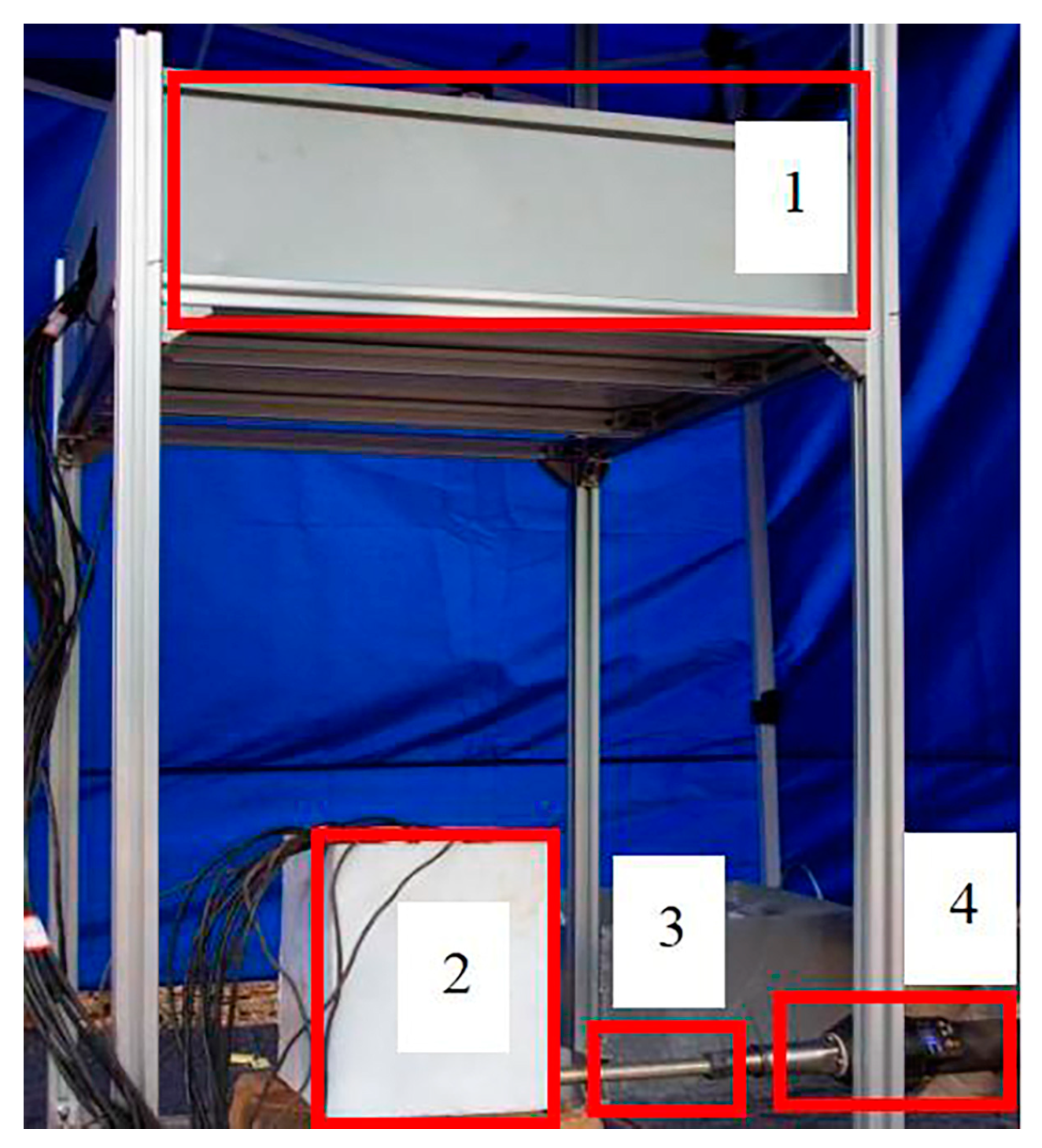

2.1. Test Materials and Equipment

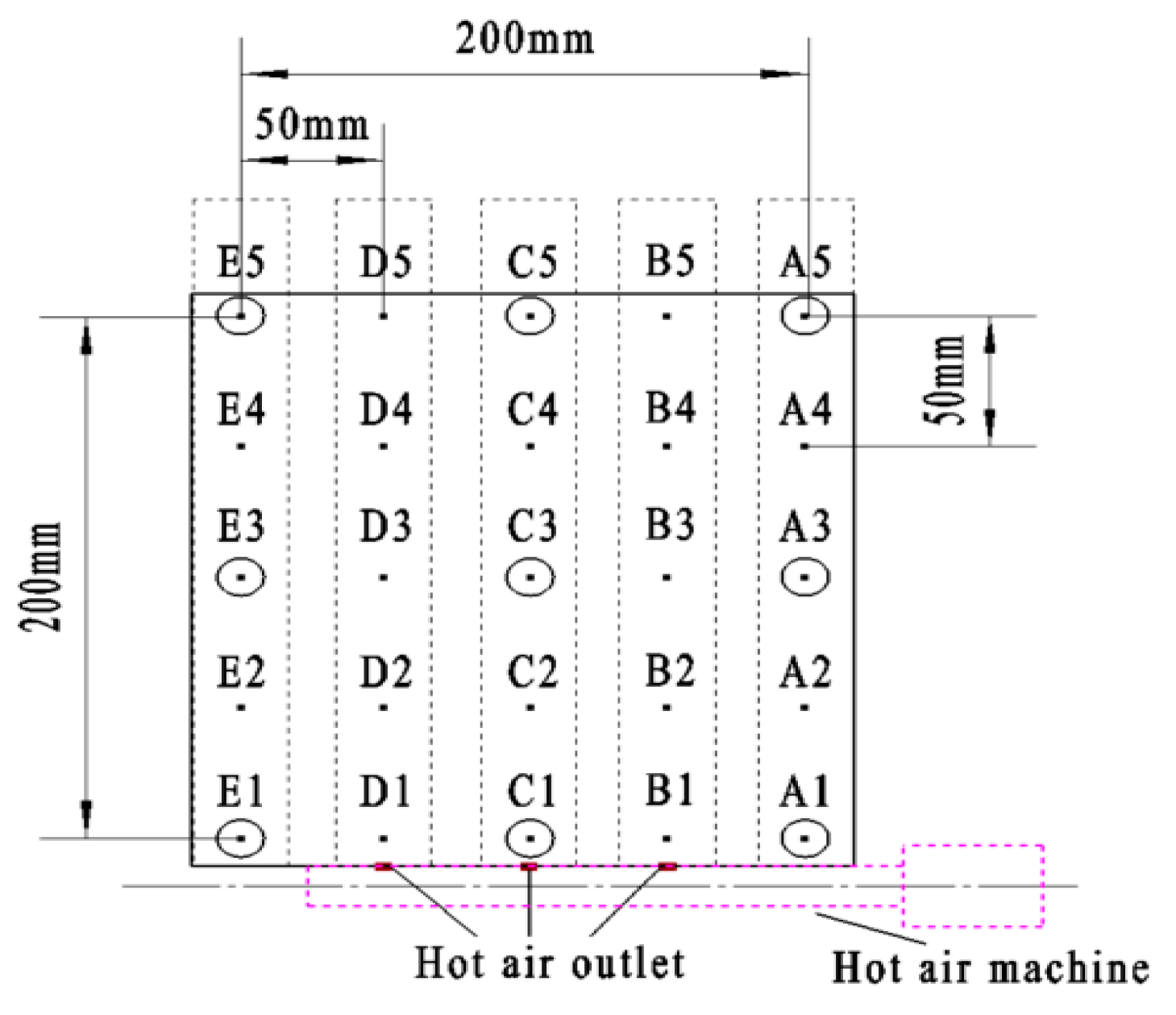

2.2. Test Process

2.3. Simulation of Hot Air Heat and Mass Transfer

2.3.1. Selection of a Mathematical Model

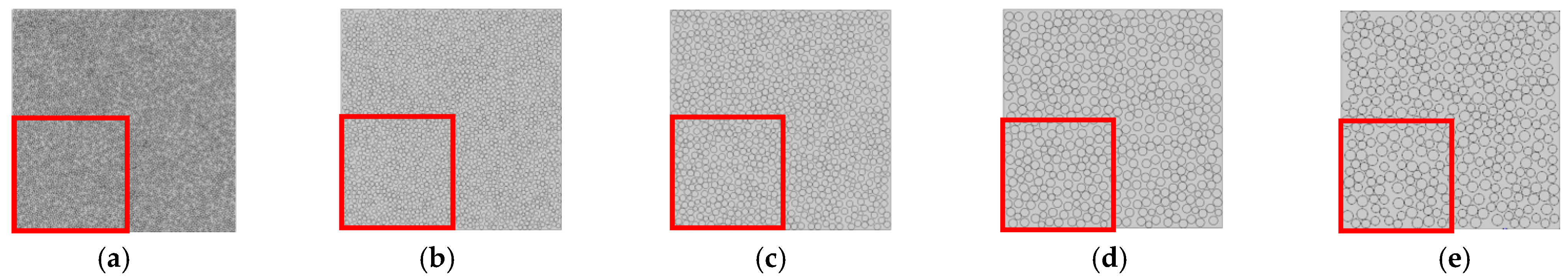

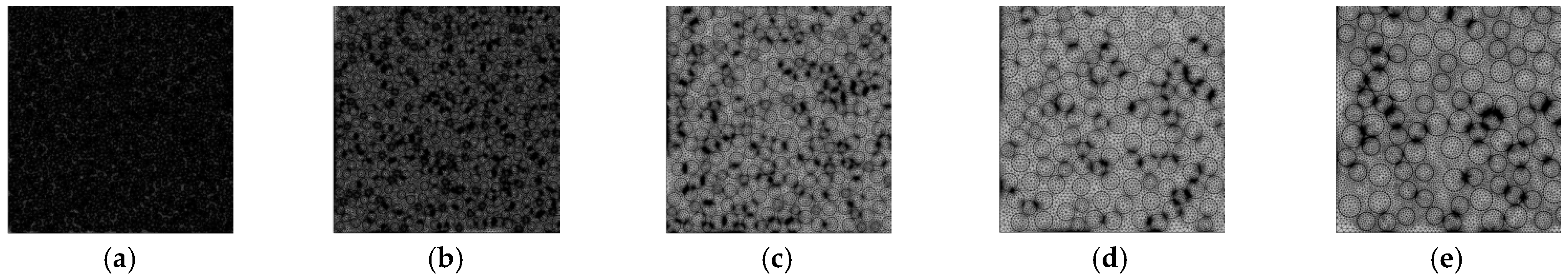

2.3.2. Soil Pattern Establishment

2.3.3. Establishment of Soil Hot Air Heating Model

3. Results

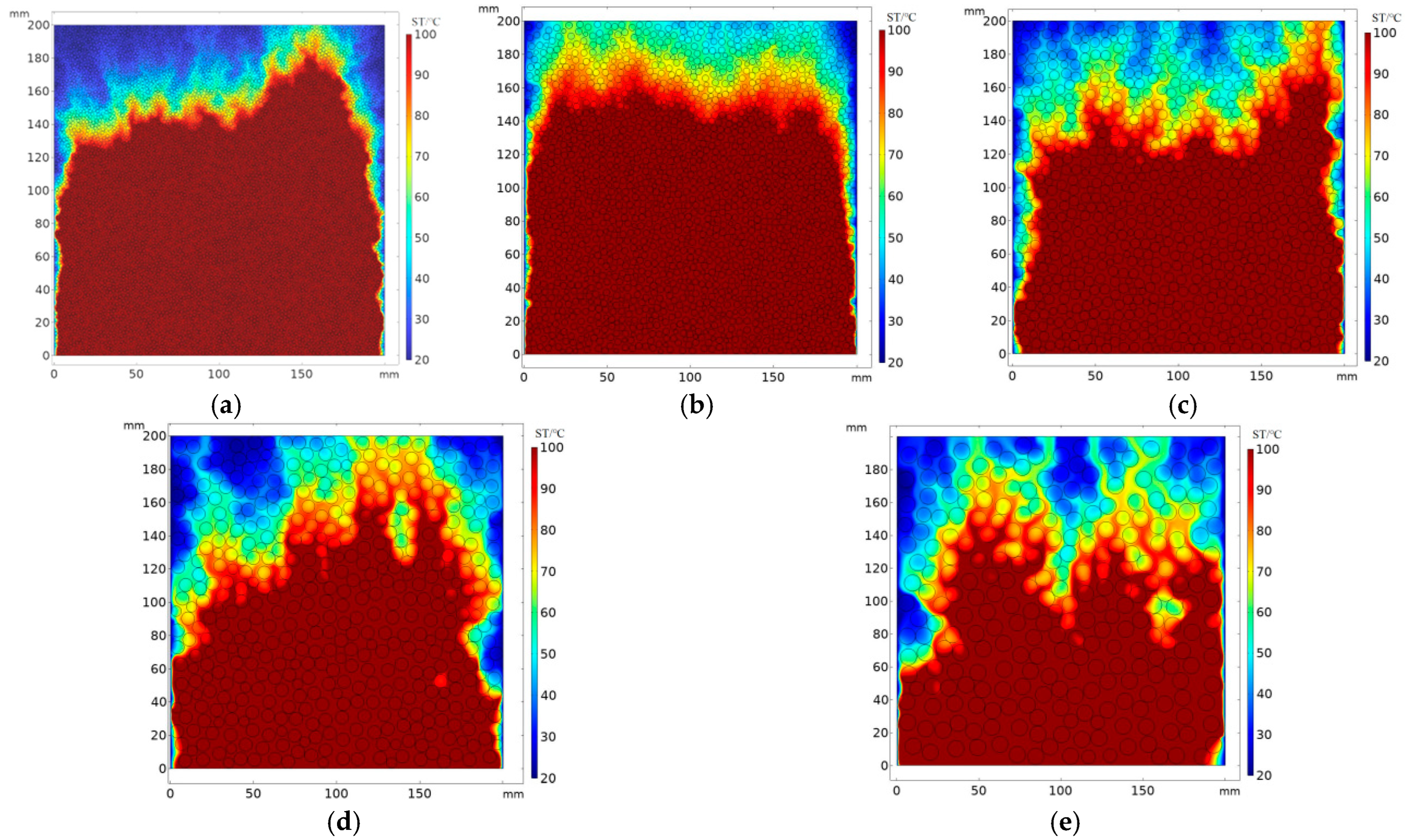

3.1. Simulation Result Analysis

3.2. Analysis of Test Results

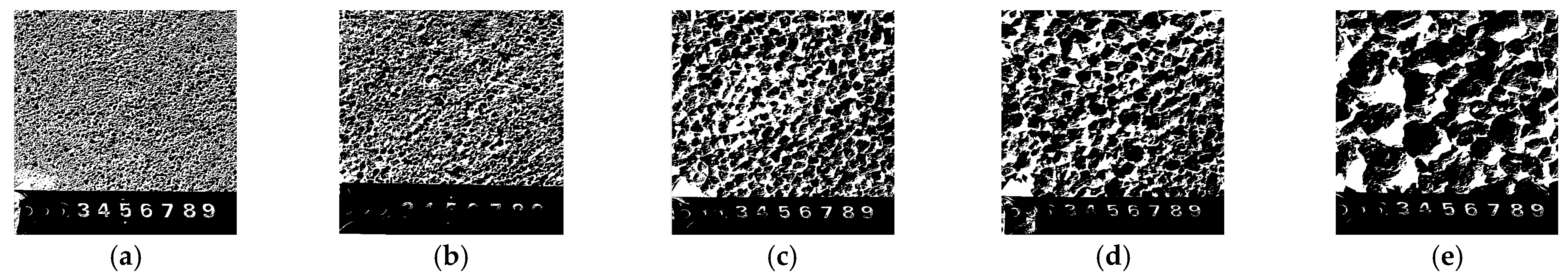

3.2.1. Analysis of Soil Pore Structure

3.2.2. Analysis of Soil Temperature

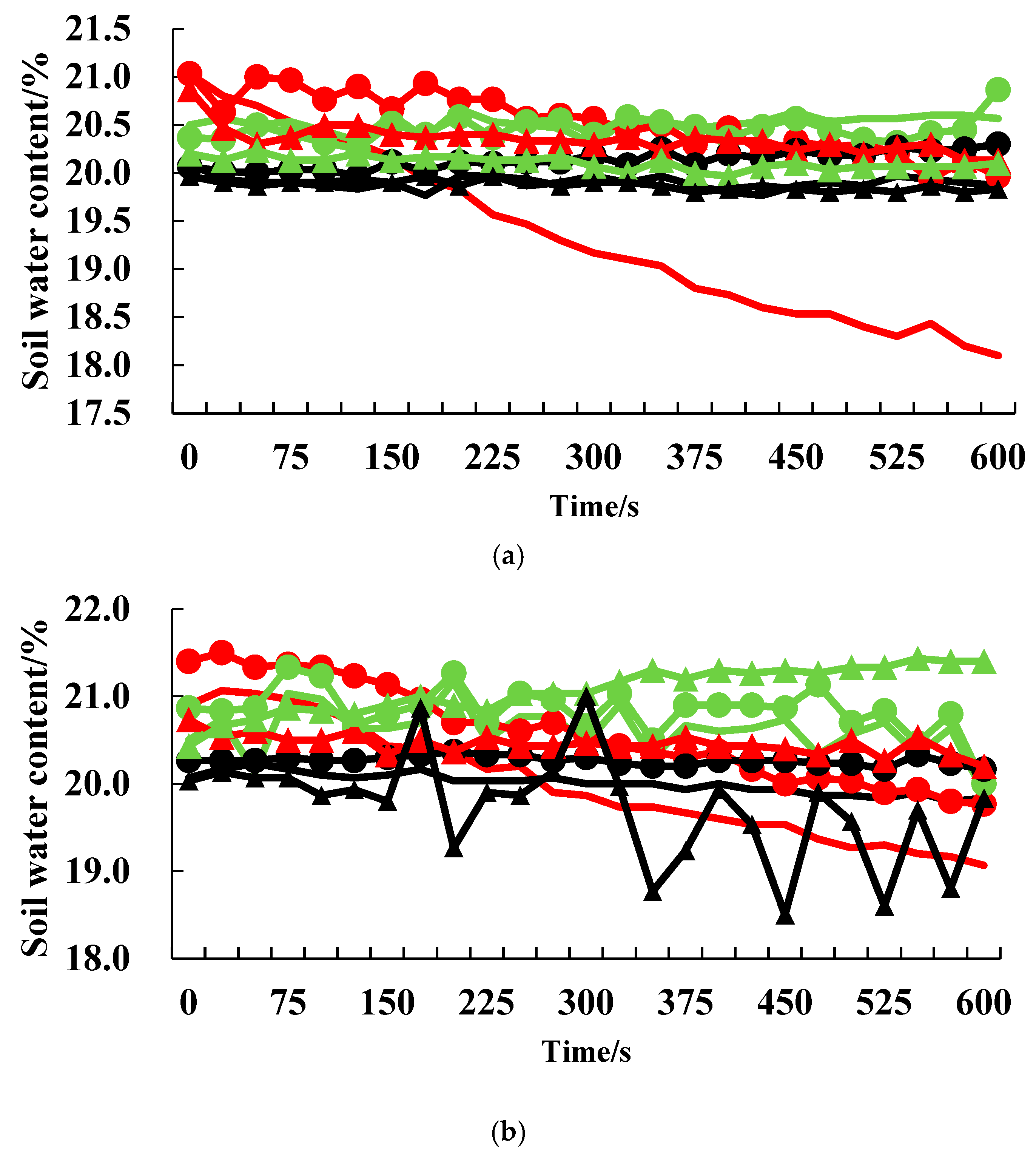

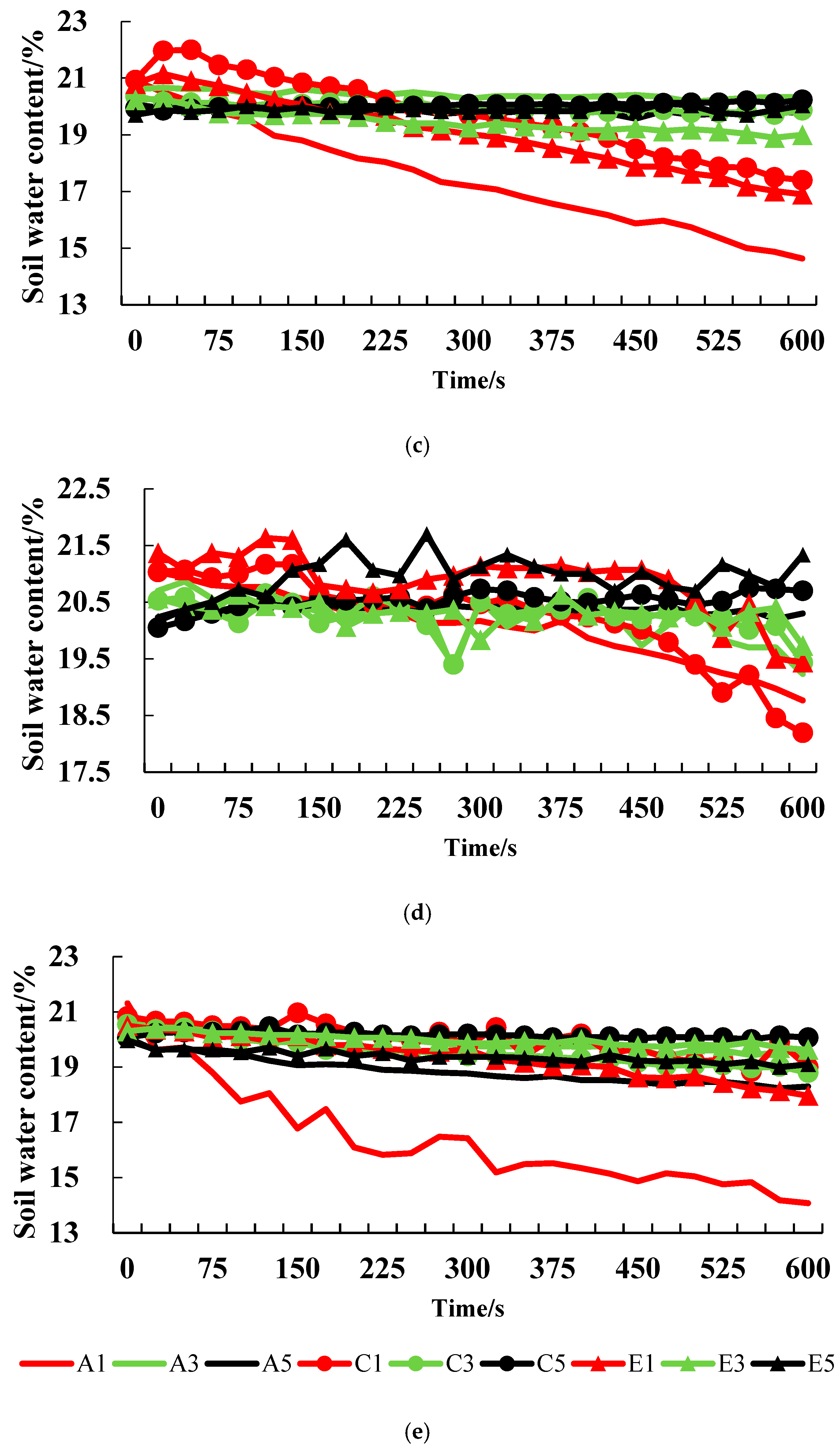

3.2.3. Analysis of Soil Water Content

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, J.L. Research progress on root rot of Panax notoginseng and its biological control. Rural Econ. Sci.-Technol. 2022, 33, 50–52. (in Chinese). [Google Scholar]

- Song, Y.; Wang, S.B.; Zhang, Y.J.; Li, L.; Zhang, Y.Q.; Yang, Z.J. Progress in research and application of soil steam disinfection technology. J. Chin. Agric. Mech. 2022, 43, 199–206. (in Chinese). [Google Scholar]

- Nishimura, A.; Asai, M.; Shibuya, T.; Kurokawa, S.; Nakamura, H. A steaming method for killing weed seeds produced in the current year under untilled conditions. Crop Prot. 2015, 71, 125–131. [Google Scholar] [CrossRef]

- Van Loenen, M.C.A.; Turbett, Y.; Mullins, C.E.; Feilden, N.E.H.; Wilson, M.J.; Leifert, C.; Seel, W.E. Low temperature-short duration steaming of soil kills soil-borne pathogens, nematode pests and weed seeds. Eur. J. Plant Pathol. 2003, 109, 993–1002. [Google Scholar] [CrossRef]

- Gay, P.; Piccarolo, P.; Aimonino, D.R.; Tortia, C. A high efficiency steam soil disinfestation system, part I: Physical background and steam supply optimisation. Biosyst. Eng. 2010, 107, 74–85. [Google Scholar] [CrossRef]

- Gay, P.; Piccarolo, P.; Aimonino, D.R.; Tortia, C. A high efficiency steam soil disinfestation system, part II: Design and testing. Biosyst. Eng. 2010, 107, 194–201. [Google Scholar] [CrossRef]

- Peruzzi, A.; Raffaelli, M.; Ginanni, M.; Fontanelli, M.; Frasconi, C. An innovative self-propelled machine for soil disinfection using steam and chemicals in an exothermic reaction. Biosyst. Eng. 2011, 110, 434–442. [Google Scholar] [CrossRef]

- Wang, X.G. Research progress on continuous cropping obstacle of rhizome medicinal plants. Heilongjiang Agric. Sci. 2024, 3, 110–115. (in Chinese). [Google Scholar]

- Zhang, Y.J.; Song, Y.; Yang, Z.J.; Yang, W.C.; Ameen, M.; Chen, J.; Wang, D.; Huang, G.L. Effects of steam disinfection pipe structure parameters on the heating efficiency of red loam steam disinfection. Trans. CSAE 2023, 39, 112–121. (in Chinese). [Google Scholar]

- Zheng, Q.S.; Hu, Z.Y.; Li, P.G.; Ni, L.; Huang, G.Y.; Yao, Y.; Zhou, L.Y. Effects of air parameters on sewage sludge drying characteristics and regression analyses of drying model coefficients. Appl. Therm. Eng. 2021, 198, 117501. [Google Scholar] [CrossRef]

- Wulyapash, W.; Phongphiphat, A.; Towprayoon, S. Comparative study of hot air drying and microwave drying for dewatered sludge. Clean Technol. Environ. Policy 2022, 24, 423–436. [Google Scholar] [CrossRef]

- Yang, Z.J.; Wang, X.C.; Ameen, M. Influence of soil particle size on the temperature field and energy consumption of injected steam soil disinfection. Processes 2020, 8, 241. [Google Scholar] [CrossRef]

- Zhang, Z.B.; Zhou, H.; Zhao, Q.G.; Lin, H.; Peng, X. Characteristics of cracks in two paddy soils and their impacts on preferential flow. Geoderma 2014, 228–229, 114–121. [Google Scholar] [CrossRef]

- Philip, J.R.; De Vries, D.A. Moisture movement in porous materials under temperature gradients. Eos Trans. Am. Geophys. Union 1957, 38, 222–232. [Google Scholar]

- Yang, Z.J.; Wang, X.C.; Ameen, M. Influence of the spacing of steam-injecting pipes on the energy consumption and soil temperature field for clay-Loam disinfection. Energies 2019, 12, 3209. [Google Scholar] [CrossRef]

- Yang, S.M.; Tao, W.S. Heat Transfer; Higher Education Press: Beijing, China, 2006; p. 559. [Google Scholar]

- Lin, D.Y. Soil Science; China Forestry Press: Beijing, China, 2002; pp. 61–66. [Google Scholar]

- Yang, Z.J.; Wang, D.; Ameen, M.; Chen, J.; Zeng, Z.X.; Sun, Z.W.; Wang, D.B.; Qian, Z.Y.; Zhang, Y.J. Influence of pore structure on steam disinfection heat and mass transfer in Yunnan red loam. Therm. Sci. Eng. Prog. 2024, 47, 102312. [Google Scholar]

| Soil Temperature °C | Soil Water Content % | Soil Particle Density (kg/m3) | Soil Specific Heat (J/(kg·K)) | Soil Thermal Conductivity (W/(m·K)) |

|---|---|---|---|---|

| 25 ± 2.5 | 20 ± 1.5 | 1760 | 1753 | 0.484 |

| Ambient Temperature °C | Hot Air Velocity (m/s) | Hot Air Fan Temperature °C | Hot Air Density (J/(kg·K)) | Hot Air Thermal Conductivity (W/(m·K)) | Hot Air Specific Heat (kJ/(kg·K)) |

|---|---|---|---|---|---|

| 25 ± 2.5 | 2.65 | 200 | 1753 | 3.93 × 102 | 1.026 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Ameen, M.; Yang, Y.; Xue, A.; Chen, J.; Yang, J.; Fang, P.; Lai, Y.; Liu, J.; Wang, Y.; et al. Study on the Temperature and Water Distribution of Hot Air in Red Loam Based on Soil Continuous Cropping Obstacles. Agriculture 2024, 14, 588. https://doi.org/10.3390/agriculture14040588

Yang Z, Ameen M, Yang Y, Xue A, Chen J, Yang J, Fang P, Lai Y, Liu J, Wang Y, et al. Study on the Temperature and Water Distribution of Hot Air in Red Loam Based on Soil Continuous Cropping Obstacles. Agriculture. 2024; 14(4):588. https://doi.org/10.3390/agriculture14040588

Chicago/Turabian StyleYang, Zhenjie, Muhammad Ameen, Yilu Yang, Anyan Xue, Junyu Chen, Junyou Yang, Pengcheng Fang, Yu Lai, Junqian Liu, Yuhan Wang, and et al. 2024. "Study on the Temperature and Water Distribution of Hot Air in Red Loam Based on Soil Continuous Cropping Obstacles" Agriculture 14, no. 4: 588. https://doi.org/10.3390/agriculture14040588

APA StyleYang, Z., Ameen, M., Yang, Y., Xue, A., Chen, J., Yang, J., Fang, P., Lai, Y., Liu, J., Wang, Y., & Zhang, Y. (2024). Study on the Temperature and Water Distribution of Hot Air in Red Loam Based on Soil Continuous Cropping Obstacles. Agriculture, 14(4), 588. https://doi.org/10.3390/agriculture14040588