Storage Conditions of Refrigerated Prickly Pears in Small Processing Industries

Abstract

1. Introduction

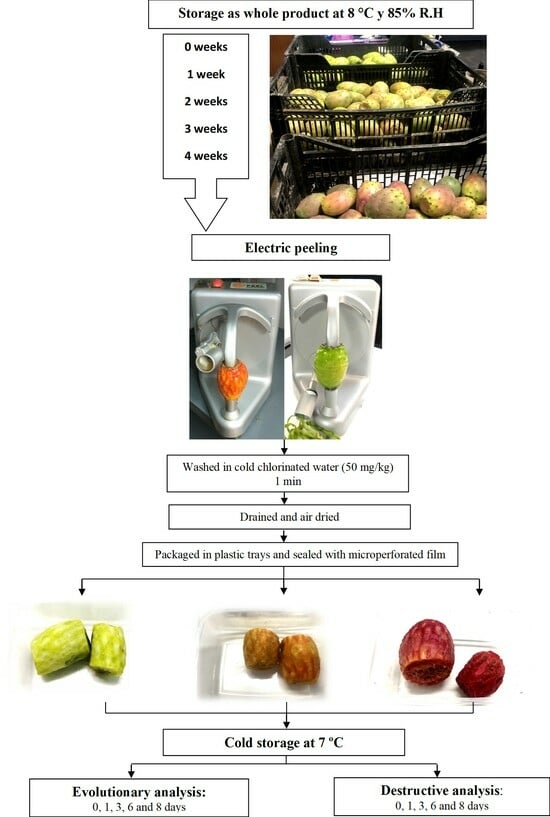

2. Materials and Methods

2.1. Plant Material, Sample Preparation, Packaging, and Storage

2.2. Proximate Composition Analysis

2.3. Physicochemical Analyses

2.4. Microbiological Analysis

2.5. Sensorial Evaluation

2.6. Gas Composition

2.7. Bioactive Compounds and Antioxidant Capacity Analysis

2.8. Data Presentation and Statistical Analysis

2.9. Ethical Statements

3. Results and Discussion

3.1. Plant Material Characterization

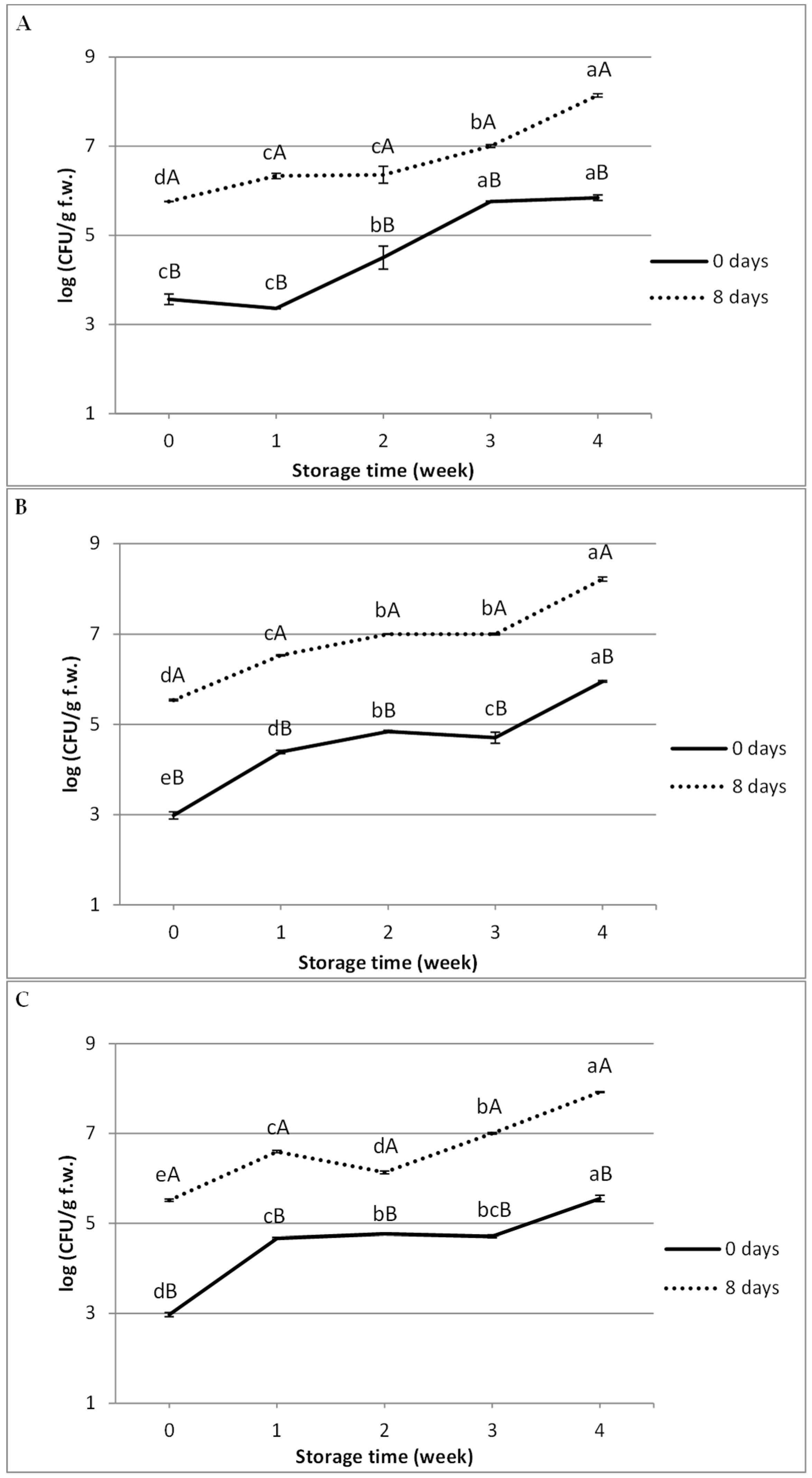

3.2. Microbiological Analysis

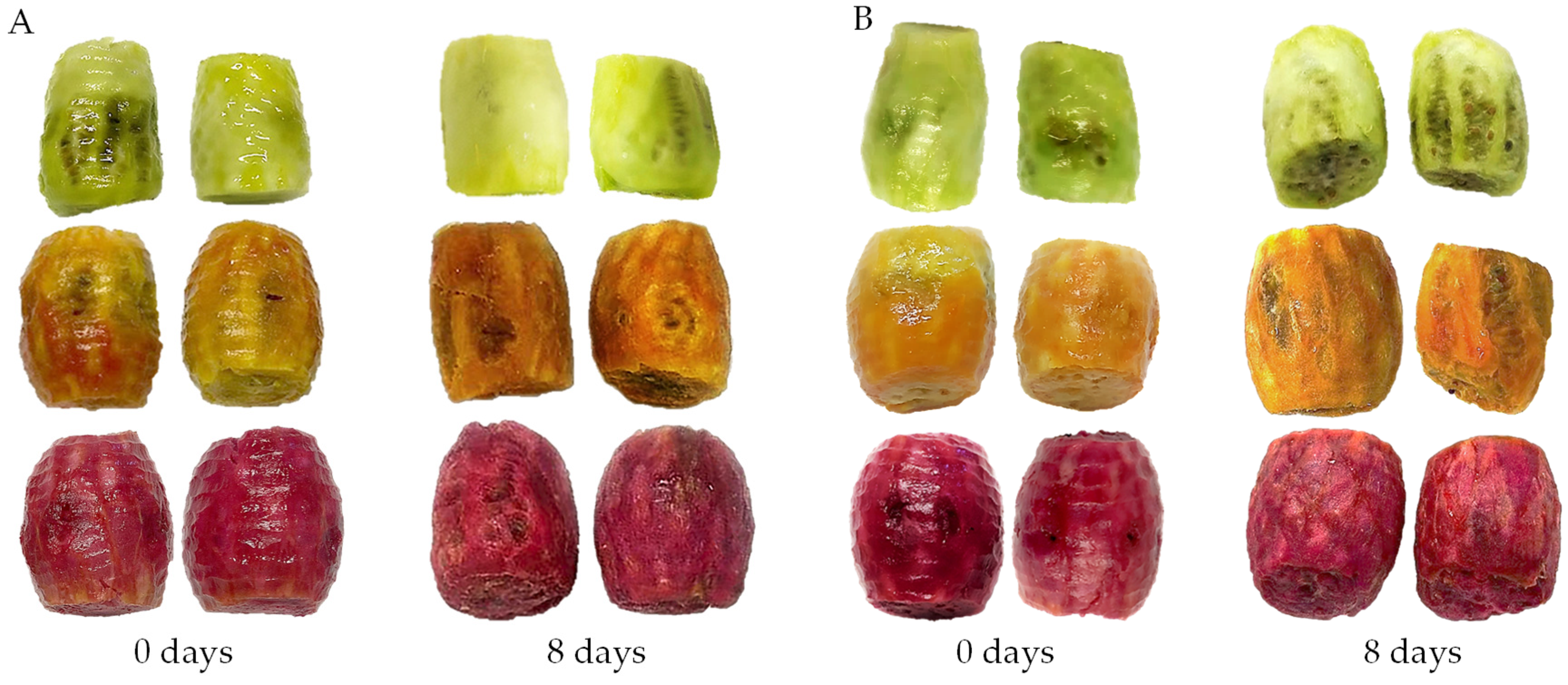

3.3. Sensorial Evaluation

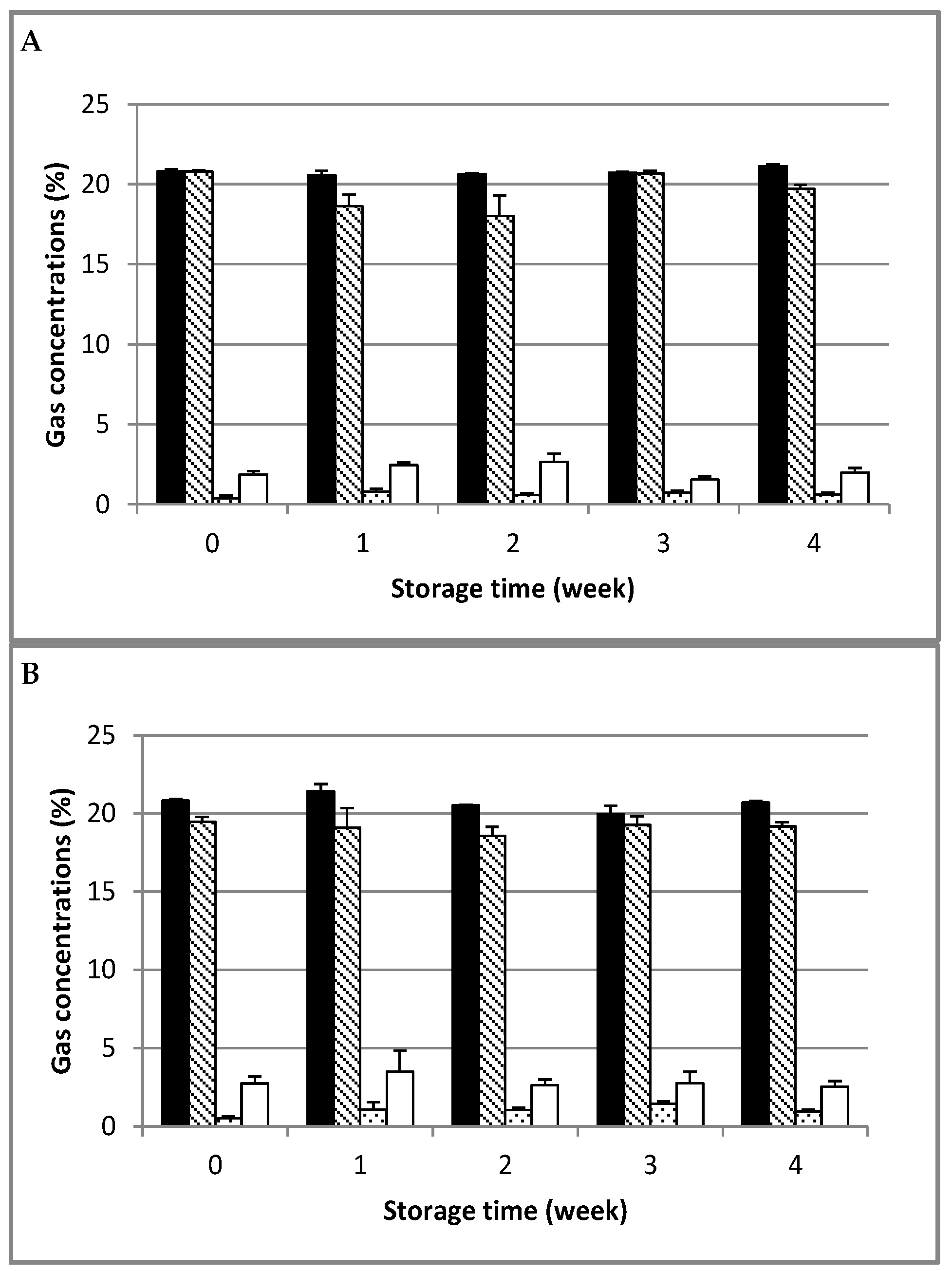

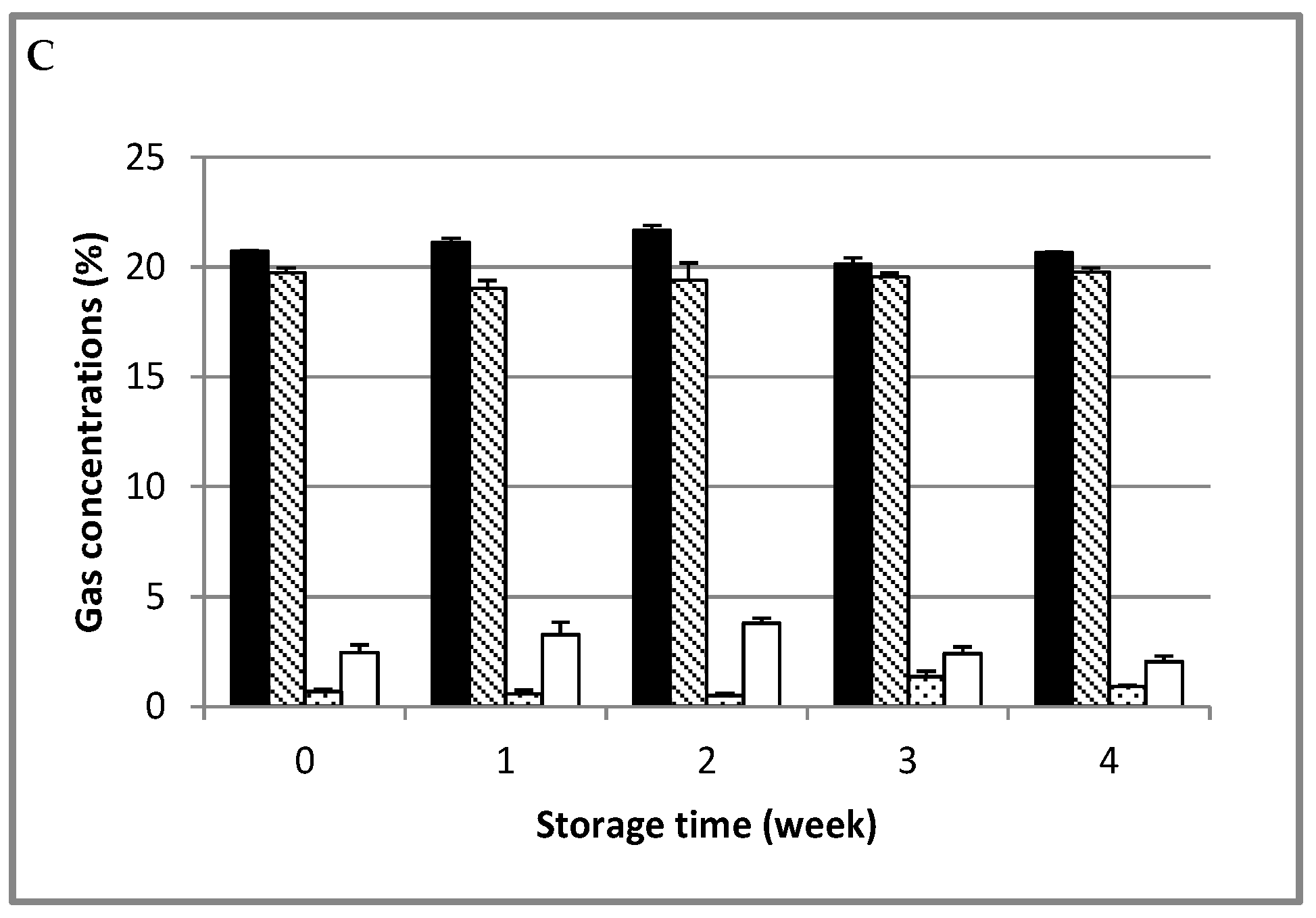

3.4. Gas Composition

3.5. Physicochemical Analyses

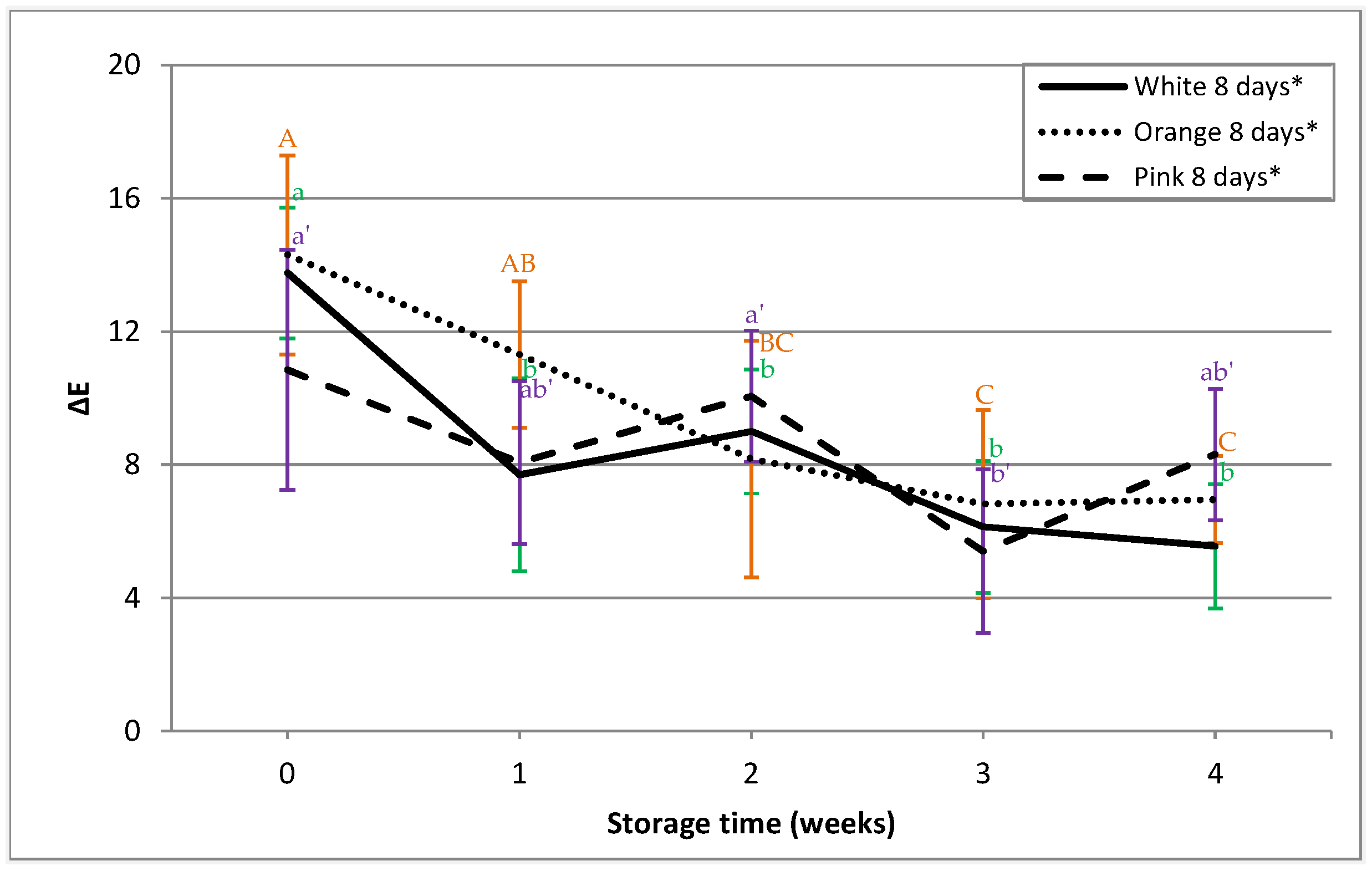

3.5.1. Color

3.5.2. Hardness and Texture

3.5.3. Total Soluble Solids Content (TSS), pH, and Total Acidity (TA)

3.5.4. Sugars

3.6. Bioactive Compounds and Antioxidant Capacity Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gil, M.I.; Aguayo, E.; Kader, A.A. Quality Changes and Nutrient Retention in Fresh-Cut versus Whole Fruits during Storage. J. Agric. Food Chem. 2006, 54, 4284–4296. [Google Scholar] [CrossRef]

- Panza, O.; Lacivita, V.; Conte, A.; Del Nobile, M.A. Quality Preservation of Ready-to-Eat Prickly Pears by Peels Recycling. Foods 2022, 11, 2016. [Google Scholar] [CrossRef]

- Hernández-Pérez, T.; Carrillo-López, A.; Guevara-Lara, F.; Cruz-Hernández, A.; Paredes-López, O. Biochemical and Nutritional Characterization of Three Prickly Pear Species with Different Ripening Behavior. Plant Foods Hum. Nutr. 2005, 60, 195–200. [Google Scholar] [CrossRef]

- Cano, M.P.; Gómez-Maqueo, A.; García-Cayuela, T.; Welti-Chanes, J. Characterization of Carotenoid Profile of Spanish Sanguinos and Verdal Prickly Pear (Opuntia ficus-indica, spp.) Tissues. Food Chem. 2017, 237, 612–622. [Google Scholar] [CrossRef]

- Silva, M.A.; Albuquerque, T.G.; Pereira, P.; Ramalho, R.; Vicente, F.; Oliveira, M.B.P.P.; Costa, H.S. Opuntia ficus-indica (L.) Mill.: A Multi-Benefit Potential to Be Exploited. Molecules 2021, 26, 951. [Google Scholar] [CrossRef]

- Gómez-Maqueo, A.; Steurer, D.; Welti-Chanes, J.; Cano, M.P. Bioaccessibility of Antioxidants in Prickly Pear Fruits Treated with High Hydrostatic Pressure: An Application for Healthier Foods. Molecules 2021, 26, 5252. [Google Scholar] [CrossRef]

- Gómez-Maqueo, A.; Antunes-Ricardo, M.; Welti-Chanes, J.; Cano, M.P. Digestive Stability and Bioaccessibility of Antioxidants in Prickly Pear Fruits from the Canary Islands: Healthy Foods and Ingredients. Antioxidants 2020, 9, 164. [Google Scholar] [CrossRef]

- Cefola, M.; Renna, M.; Pace, B. Marketability of Ready-to-Eat Cactus Pear as Affected by Temperature and Modified Atmosphere. J. Food Sci. Technol. 2014, 51, 25–33. [Google Scholar] [CrossRef]

- Piga, A.; Caro, A.D.; Pinna, I.; Agabbio, M. Changes in Ascorbic Acid, Polyphenol Content and Antioxidant Activity in Minimally Processed Cactus Pear Fruits. LWT Food Sci. Technol. 2003, 2, 257–262. [Google Scholar] [CrossRef]

- Gómez, P.A.; Camelo, A.F.L. Calidad Postcosecha de Tomates Almacenados en Atmósferas Controladas. Hortic. Bras. 2002, 20, 38–43. [Google Scholar] [CrossRef]

- Ulloa, L.; Sáenz, M.V.; Castro, J.; Ulloa, L.; Sáenz, M.V.; Castro, J. Efecto del Almacenamiento a Diferentes Temperaturas sobre el Desarrollo de Color Externo y la Calidad de Frutos de Piña cv. Dorada Extra Dulce. Agron. Costarric. 2015, 39, 9–20. [Google Scholar] [CrossRef]

- Díaz-Delgado, G.L.; Rodríguez-Rodríguez, E.M.; Dorta, E.; Lobo, M.G. Effects of Peeling, Film Packaging, and Cold Storage on the Quality of Minimally Processed Prickly Pears (Opuntia ficus-indica L. Mill.). Agriculture 2022, 12, 281. [Google Scholar] [CrossRef]

- Saberi Riseh, R.; Vatankhah, M.; Hassanisaadi, M.; Shafiei-Hematabad, Z.; Kennedy, J.F. Advancements in Coating Technologies: Unveiling the Potential of Chitosan for the Preservation of Fruits and Vegetables. Int. J. Biol. Macromol. 2024, 254, 127677. [Google Scholar] [CrossRef]

- Kahramanoglu, I.; Usanmaz, S.; Okatan, V.; Wan, C. Preserving Postharvest Storage Quality of Fresh-Cut Cactus Pears by Using Different Bio-Materials. CABI Agric. Biosci. 2020, 1, 7. [Google Scholar] [CrossRef]

- Ferreira Gomes, B.A.; Silveira Alexandre, A.C.; Vieira de Andrade, G.A.; Pereira Zanzini, A.P.; de Barros, H.E.; dos Santos Ferraz e Silva, L.M.; Costa, P.A.; de Barros Vilas Boas, E.V. Recent Advances in Processing and Preservation of Minimally Processed Fruits and Vegetables: A Review—Part 2: Physical Methods and Global Market Outlook. Food Chem. Adv. 2023, 2, 100304. [Google Scholar] [CrossRef]

- Del Nobile, M.A.; Conte, A.; Scrocco, C.; Brescia, I. New Strategies for Minimally Processed Cactus Pear Packaging. Innov. Food Sci. Emerg. Technol. 2009, 10, 356–362. [Google Scholar] [CrossRef]

- Silva, F.A.; Finkler, L.; Finkler, C.L.L. Effect of Edible Coatings Based on Alginate/Pectin on Quality Preservation of Minimally Processed “Espada” Mangoes. J. Food Sci. Technol. 2018, 55, 5055–5063. [Google Scholar] [CrossRef]

- Padrón Mederos, M.A.; Rodríguez-Galdón, B.; Díaz-Romero, C.; Lobo, G.; Rodríguez-Rodríguez, E. Quality Evaluation of Minimally Fresh-Cut Processed Pineapples. LWT 2020, 129, 109607. [Google Scholar] [CrossRef]

- Mphahlele, R.R.; Caleb, O.J.; Ngcobo, M.E.K. Effects of Packaging and Duration on Quality of Minimally Processed and Unpitted Litchi Cv. “Mauritius” under Low Storage Temperature. Heliyon 2020, 6, e03229. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC International, 20th ed.; AOAC International: Gaithersburg, MD, USA, 2016. [Google Scholar]

- Aguayo, E.; Allende, A.; Artés, F. Keeping Quality and Safety of Minimal Fresh Processed Melon. Eur. Food Res. Technol. 2003, 216, 494–499. [Google Scholar] [CrossRef]

- Horwitz, W.; Latimer, G.W.; Association of Official Analytical Chemists International. Official Methods of Analysis of AOAC International; AOAC International: Gaithersburg, MD, USA, 2006; ISBN 978-0-935584-77-6. [Google Scholar]

- Rodríguez-Galdón, B.; Tascón-Rodríguez, C.; Rodríguez-Rodríguez, E.M.; Díaz-Romero, C. Fructans and Major Compounds in Onion Cultivars (Allium cepa). J. Food Compos. Anal. 2009, 22, 25–32. [Google Scholar] [CrossRef]

- Real Decreto 3484/2000, de 29 de Diciembre, por el que se Establecen las Normas de Higiene para la Elaboración, Distribución y Comercio de Comidas Preparadas. Boletín Oficial del Estado (BOE), de 12 de Enero de 2001. Volume BOE-A-2001-809, pp. 1435–1441. Available online: https://www.boe.es/eli/es/rd/2000/12/29/3484/con (accessed on 20 December 2023).

- Escalona, V.H.; Aguayo, E.; Artés, F. Quality and Physiological Changes of Fresh-Cut Kohlrabi. HortScience 2003, 38, 1148–1152. [Google Scholar] [CrossRef]

- Karacay, E.; Ayhan, Z. Microbial, Physical, Chemical and Sensory Qualities of Minimally Processed and Modified Atmosphere Packaged “Ready To Eat” Orange Segments. Int. J. Food Prop. 2010, 13, 960–971. [Google Scholar] [CrossRef]

- Panadés, G.; Chiralt, A.; Fito, P.; Rodríguez, I.; Nuñez, M.; Albors, A.; Jiménez, R. Influence of Operating Conditions on Sensory Quality of Minimally Processed Osmotically Dehydrated Guava. J. Food Qual. 2003, 26, 91–103. [Google Scholar] [CrossRef]

- Kujala, T.S.; Loponen, J.M.; Klika, K.D.; Pihlaja, K. Phenolics and Betacyanins in Red Beetroot (Beta Vulgaris) Root: Distribution and Effect of Cold Storage on the Content of Total Phenolics and Three Individual Compounds. J. Agric. Food Chem. 2000, 48, 5338–5342. [Google Scholar] [CrossRef] [PubMed]

- Bondet, V.; Brand-Williams, W.; Berset, C. Kinetics and Mechanisms of Antioxidant Activity Using the DPPH. Free Radical Method. LWT Food Sci. Technol. 1997, 30, 609–615. [Google Scholar] [CrossRef]

- Allegra, A.; Sortino, G.; Miciletta, G.; Riotto, M.; Fasciana, T.; Inglese, P. The Influence of Harvest Period and Fruit Ripeness at Harvest on Minimally Processed Cactus Pears (Opuntia ficus-indica L. Mill.) Stored under Passive Atmosphere. Postharvest Biol. Technol. 2015, 104, 57–62. [Google Scholar] [CrossRef]

- Aghdam, M.S.; Bodbodak, S. Postharvest Heat Treatment for Mitigation of Chilling Injury in Fruits and Vegetables. Food Bioprocess Technol. 2014, 7, 37–53. [Google Scholar] [CrossRef]

- Acuña, L.E.; Aguirre, C.; Burdyn, L.; Carbajo, M.S.; Cocco, M.; Colodner, A.; Comerio, R.M.; Di Masi, S.; Flores, C.; Frusso, E.; et al. Manual de Poscosecha de Frutas. Manejo Integrado de Patógenos 2019. ISBN 978-987-833-312-0. Available online: https://alimentosargentinos.magyp.gob.ar/HomeAlimentos/PDA/documentos/manual_poscosecha_frutas_INTA.pdf (accessed on 20 December 2023).

- Garcia, E.; Barrett, D.M. Preservative Treatments for Fresh-Cut Fruits and Vegetables. In Fresh-Cut Fruits and Vegetables: Science, Technology, and Market; CRC Press: Boca Raton, FL, USA, 2002; pp. 267–303. [Google Scholar]

- Palma, A.; Continella, A.; Malfa, S.; D’aquino, S. Changes in Physiological and Some Nutritional, Nutraceuticals, Chemical-Physical, Microbiological and Sensory Quality Minimally Processed Cactus Pears Cvs “Bianca”, “Gialla” and “Rossa” Stored under Passive Modified Atmosphere. J. Sci. Food Agric. 2017, 98, 1839–1849. [Google Scholar] [CrossRef]

- Aguayo, E.; Requejo-Jackman, C.; Stanley, R.; Woolf, A. Effect of Calcium Ascorbate Treatments and Storage Atmosphere on Antioxidant Activity and Quality of Fresh-Cut Apple Slices. Postharvest Biol. Technol. 2010, 57, 52–60. [Google Scholar] [CrossRef]

- Ochoa Velasco, C.E.; Guerrero-Beltran, J. Postharvest Quality of Peeled Prickly Pear Fruit Treated with Acetic Acid and Chitosan. Postharvest Biol. Technol. 2014, 92, 139–145. [Google Scholar] [CrossRef]

- Marques, K.M.; Miguel, A.C.A.; Galati, V.C.; Morgado, C.M.A.; Mattiuz, C.F.M.; Mattiuz, B. Minimally Processed Prickly Pear Stored under Different Temperatures and Packaging. AJAR 2015, 10, 1810–1816. [Google Scholar] [CrossRef][Green Version]

- Martins, M.; Ribeiro, M.H.; Almeida, C.M.M. Physicochemical, Nutritional, and Medicinal Properties of Opuntia ficus-indica (L.) Mill. and Its Main Agro-Industrial Use: A Review. Plants 2023, 12, 1512. [Google Scholar] [CrossRef] [PubMed]

- Kyriacou, M.C.; Emmanouilidou, M.G.; Soteriou, G.A. Asynchronous Ripening Behavior of Cactus Pear (Opuntia ficus-indica) Cultivars with Respect to Physicochemical and Physiological Attributes. Food Chem. 2016, 211, 598–607. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.K.; Kader, A.A. Preharvest and Postharvest Factors Influencing Vitamin C Content of Horticultural Crops. Postharvest Biol. Technol. 2000, 20, 207–220. [Google Scholar] [CrossRef]

| White Prickly Pears | Orange Prickly Pears | Pink Prickly Pears | |

|---|---|---|---|

| Moisture (%) | 85.44 ± 0.45 | 84.45 ± 0.67 | 84.79 ± 0.82 |

| Protein (%) | 1.12 ± 0.10 | 0.95 ± 0.08 | 1.03 ± 0.07 |

| Fat (%) | 0.09 ± 0.01 | 0.07 ± 0.00 | 0.10 ± 0.00 |

| Ash (%) | 2.49 ± 0.34 | 3.22 ± 0.21 | 3.39 ± 0.16 |

| Total Dietary Fiber (%) | 5.08 ± 0.56 | 3.27 ± 0.10 | 3.81 ± 0.33 |

| Storage of Minimally Processed Fruit (Days) | |||||||

|---|---|---|---|---|---|---|---|

| White | Orange | Pink | |||||

| Storage Duration of Whole Fruit (Weeks) | 0 Days | 8 Days | 0 Days | 8 Days | 0 Days | 8 Days | |

| Psycrophiles log(CFU/g f.w.) | 0 weeks | 2.90 ± 0.12 b,B | 5.45 ± 0.04 e,A | 3.01 ± 0.10 b,B | 5.01 ± 0.01 d,A | 2.25 ± 0.06 e,B | 5.27 ± 0.02 b,A |

| 1 week | 3.41 ± 0.10 a,B | 5.92 ± 0.04 c,A | 3.07 ± 0.09 b,B | 5.96 ± 0.05 b,A | 3.05 ± 0.06 b,B | 5.90 ± 0.08 a,A | |

| 2 weeks | 2.47 ± 0.03 c,B | 5.72 ± 0.01 d,A | 2.75 ± 0.04 c,B | 5.54 ± 0.02 c,A | 3.41 ± 0.02 a,B | 5.07 ± 0.04 b,A | |

| 3 weeks | 2.91± 0.03 b,B | 6.57 ± 0.03 b,A | 3.26 ± 0.10 a,B | 6.14 ± 0.08 a,A | 2.50 ± 0.05 d,B | 5.14 ± 0.13 b,A | |

| 4 weeks * | 2.34 ± 0.10 c,B | 6.76 ± 0.01 a,A | 3.06 ± 0.06 b,B | 5.99 ± 0.01 b,A | 2.69 ± 0.02 c,B | 4.78 ± 0.24 c,A | |

| Mold and yeast log(CFU/g f.w.) | 0 weeks | 1.42 ± 0.17 c,B | 4.99 ± 0.02 e,A | 1.32 ± 0.17 d,B | 4.98 ± 0.05 c,A | 2.19 ± 0.07 b,B | 4.99 ± 0.03 c,A |

| 1week | 2.36 ± 0.05 b,B | 5.56 ± 0.04 d,A | 2.43 ± 0.16 b,B | 5.48 ± 0.19 b,A | 2.52 ± 0.20 a,B | 5.92 ± 0.04 a,A | |

| 2 weeks | 2.52 ± 0.02 b,B | 6.19 ± 0.02 b,A | 2.32 ± 0.06 b,B | 4.41 ± 0.07 d,A | 2.55 ± 0.11 a,B | 5.43 ± 0.04 b,A | |

| 3 weeks | 3.36 ± 0.03 a,B | 6.61 ± 0.09 a,A | 2.86 ± 0.05 a,B | 4.25 ± 0.13 d,A | 2.58 ± 0.07 a,B | 4.58 ± 0.02 d,A | |

| 4 weeks * | 2.38 ± 0.15 b,B | 6.08 ± 0.02 c,A | 1.87 ± 0.05 c,B | 5.92 ± 0.01 a,A | 2.38 ± 0.15 a,B | 4.61 ± 0.09 d,A | |

| Storage Duration of Whole Fruit (Weeks) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| White | Orange | Pink | |||||||

| Storage of Minimally Processed Fruit (Days) | 0 | 2 | 4 | 0 | 2 | 4 | 0 | 2 | 4 |

| 0 | 71 | 86 | 83 | 100 | 100 | 100 | 100 | 100 | 83 |

| 1 | 67 | 71 | 67 | 100 | 100 | 100 | 86 | 86 | 83 |

| 3 | 67 | 80 | 83 | 100 | 100 | 100 | 83 | 80 | 83 |

| 6 | 60 | 80 | 100 | 80 | 80 | 83 | 60 | 80 | 100 |

| 8 * | 80 | 80 | - | 100 | 80 | - | 80 | 80 | - |

| Storage of Minimally Processed Fruit (Days) | |||||||

|---|---|---|---|---|---|---|---|

| White | Orange | Pink | |||||

| Storage Duration of Whole Fruit (Weeks) | 0 Days | 8 Days | 0 Days | 8 Days | 0 Days | 8 Days | |

| L | 0 weeks | 52.6 ± 3.8 a,A | 45.0 ± 6.1 b,B | 49.0 ± 1.6 a,A | 47.1 ± 1.3 b,A | 31.4 ± 3.3 a,A | 35.6 ± 3.1 b,A |

| 1 week | 48.1 ± 2.6 b,A | 51.8 ± 4.2 a,A | 43.1 ± 3.8 b,B | 52.5 ± 3.0 a,A | 34.3 ± 1.2 a,A | 38.0 ± 5.4 ab,A | |

| 2 weeks | 51.2 ± 2.4 ab,A | 43.9 ± 2.7 b,B | 43.9 ± 1.6 b,A | 42.1 ± 2.2 c,A | 31.8 ± 1.2 a,B | 41.2 ± 2.1 a,A | |

| 3 weeks | 54.5 ± 3.1 a,A | 56.8 ± 3.1 a,A | 42.1 ± 2.8 b,B | 46.2 ± 1.4 b,A | 33.8 ± 3.7 a,A | 36.9 ± 3.5 ab,A | |

| 4 weeks * | 52.1 ± 2.1 a,B | 55.9 ± 1.7 a,A | 41.0 ± 2.3 b,A | 44.2 ± 2.2 bc,A | 30.7 ± 1.4 a,B | 35.7 ± 2.2 b,A | |

| H° | 0 weeks | 106.4 ± 1.3 a,A | 100.8 ± 4.4 ab,B | 67.9 ± 7.2 a,A | 70.5 ± 3.1 a,A | 24.6 ± 4.0 a,A | 16.7 ± 2.3 b,B |

| 1 week | 107.3 ± 2.4 a,A | 98.9 ± 2.2 b,B | 68.1 ± 7.1 a,A | 70.6 ± 5.3 a,A | 14.8 ± 1.5 b,B | 26.2 ± 2.4 a,A | |

| 2 weeks | 105.4 ± 3.1 a,A | 92.9 ± 2.0 c,B | 71.8 ± 4.9 a,A | 70.6 ± 6.1 a,A | 15.6 ± 1.1 b,B | 23.9 ± 2.9 a,A | |

| 3 weeks | 106.9 ± 2.2 a,A | 104.1 ± 2.1 a,A | 67.2 ± 2.8 a,A | 66.1 ± 3.7 ab,A | 16.0 ± 2.1 b,A | 16.2 ± 1.6 b,A | |

| 4 weeks * | 105.4 ± 1.8 a,A | 101.0 ± 3.2 ab,B | 65.7 ± 1.1 a,A | 61.7 ± 2.3 b,B | 16.3 ± 1.7 b,A | 18.1 ± 2.3 b,A | |

| C* | 0 weeks | 23.8 ± 2.3 a,A | 13.4 ± 4.1 c,B | 36.0 ± 3.3 a,A | 22.5 ± 0.9 b,B | 23.0 ± 3.5 a,A | 14.5 ± 2.2 b,B |

| 1 week | 15.2 ± 4.9 b,A | 19.4 ± 3.9 a,A | 23.3 ± 5.4 c,A | 28.6 ± 3.4 a,A | 21.2 ± 2.0 a,A | 18.4 ± 3.5 a,A | |

| 2 weeks | 20.5 ± 3.4 a,A | 15.5 ± 0.8 bc,B | 32.0 ± 1.8 ab,A | 25.5 ± 4.0 ab,B | 21.0 ± 1.6 a,A | 19.7 ± 1.0 aA | |

| 3 weeks | 20.7 ± 3.0 a,A | 20.8 ± 0.7 a,A | 28.8 ± 2.0 b,A | 24.2 ± 2.6 b,B | 20.8 ± 2.6 a,A | 18.7 ± 3.5 a,A | |

| 4 weeks * | 21.8 ± 2.2 a,A | 18.6 ± 1.9 ab,A | 29.2 ± 1.4 b,A | 23.5 ± 2.8 b,B | 27.2 ± 1.9 b,A | 21.8 ± 3.4 a,B | |

| WI | 0 weeks | 47.0 ± 4.2 a,A | 43.2 ± 5.2 b,A | 37.6 ± 2.4 ab,B | 42.5 ± 0.9 ab,A | 27.6 ± 3.3 ab,B | 34.0 ± 2.9 ab,A |

| 1 week | 45.7 ± 2.5 a,A | 47.9 ± 3.3 a,A | 38.3 ± 3.5 a,B | 44.4 ± 1.1 a,A | 30.9 ± 1.6 a,A | 35.2 ± 4.5 ab,A | |

| 2 weeks | 47.0 ± 1.4 a,A | 41.7 ± 2.4 b,B | 35.4 ± 2.2 ab,A | 36.6 ± 2.3 d,A | 28.7 ± 1.3 ab,B | 38.0 ± 2.1 a,A | |

| 3 weeks | 49.9 ± 3.6 a,A | 52.0 ± 2.6 a,A | 35.3 ± 2.2 ab,B | 40.9 ± 0.5 bc,A | 30.5 ± 4.0 a,A | 34.1 ± 2.6 ab,A | |

| 4 weeks * | 47.3 ± 2.3 a,B | 52.1 ± 1.2 a,A | 34.2 ± 2.0 b,B | 39.4 ± 2.1 c,A | 25.5 ± 0.7 b,B | 32.1 ± 2.4 b,A | |

| Storage of Minimally Processed Fruit (Days) | |||||||

|---|---|---|---|---|---|---|---|

| White | Orange | Pink | |||||

| Storage Time of Whole Fruit (Weeks) | 0 Days | 8 Days | 0 Days | 8 Days | 0 Days | 8 Days | |

| TSS (°Brix) | 0 weeks | 13.20 ± 0.53 a,A | 10.27 ± 0.31 c,B | 13.33 ± 0.99 b,A | 13.07 ± 0.12 b,A | 12.20 ± 0.20 a,A | 12.47 ± 0.23 ab,A |

| 1 week | 12.07 ± 0.42 c,A | 11.13 ± 0.31 b,B | 14.87 ± 0.31 a,A | 12.00 ± 0.40 c,B | 12.93 ± 0.61 a,A | 11.80 ± 0.53 b,A | |

| 2 weeks | 12.80 ± 0.35 b,A | 11.53 ± 0.29 b,B | 13.47 ± 0.12 b,A | 12.77 ± 0.12 b,B | 13.47 ± 0.61 a,A | 11.87 ± 0.64 b,B | |

| 3 weeks | 12.07 ± 0.12 c,A | 10.87± 0.23 bc,B | 14.20 ± 0.20 ab,A | 13.67 ± 0.31 a,A | 12.67 ± 0.42 a,A | 11.87 ± 0.42 b,A | |

| 4 weeks * | 12.80 ± 0.35 b,A | 12.20 ± 0.20 a,A | 13.93 ± 0.42 ab,A | 13.73 ± 0.23 a,A | 12.73 ± 0.64 a,A | 12.87 ± 0.42 a,A | |

| pH | 0 weeks | 6.79 ± 0.07 b,A | 5.98 ± 0.16 a,B | 6.42 ± 0.06 b,A | 6.21 ± 0.16 ab,A | 6.42 ± 0.03 a,A | 6.27 ± 0.09 b,A |

| 1 week | 6.76 ± 0.04 b,A | 6.41 ± 0.22 a,B | 6.79 ± 0.01 a,A | 6.06 ± 0.15 b,B | 6.55 ± 0.11 a,A | 5.79 ± 0.13 c,B | |

| 2 weeks | 7.07 ± 0.13 a,A | 5.82 ± 0.08 a,B | 6.30 ± 0.03 b,A | 5.28 ± 0.15 c,B | 6.30 ± 0.09 a,A | 6.39 ± 0.16 ab,A | |

| 3 weeks | 6.63 ± 0.15 b,A | 6.42 ± 0.23 a,A | 6.63 ± 0.16 a,A | 6.44 ± 0.08 a,A | 6.39 ± 0.06 a,A | 6.17 ± 0.19 b,A | |

| 4 weeks * | 6.70 ± 0.22 b,A | 6.21± 0.70 a,A | 6.35 ± 0.11 b,A | 6.07± 0.24 b,A | 6.55 ± 0.17 a,A | 6.55 ± 0.06 a,A | |

| TA (% citric acid) | 0 weeks | 0.028 ± 0.002 b,B | 0.063 ± 0.005 b,A | 0.043 ± 0.003 a,B | 0.051 ± 0.003 c,A | 0.047 ± 0.002 b,B | 0.059 ± 0.008 b,A |

| 1 week | 0.046 ± 0.003 a,B | 0.056 ± 0.002 c,A | 0.037 ± 0.001 b,B | 0.069 ± 0.001 b,A | 0.062 ± 0.004 a,B | 0.080 ± 0.008 a,A | |

| 2 weeks | 0.027 ± 0.002 b,B | 0.079 ± 0.002 a,A | 0.045 ± 0.003 a,B | 0.083 ± 0.002 a,A | 0.062 ± 0.005 a,A | 0.063 ± 0.005 b,A | |

| 3 weeks | 0.030 ± 0.004 b,B | 0.047 ± 0.002 d,A | 0.034 ± 0.002 b,B | 0.077 ± 0.009 b,A | 0.046 ± 0.002 b,B | 0.078 ± 0.008 a,A | |

| 4 weeks* | 0.031 ± 0.003 b,B | 0.056 ± 0.005 c,A | 0.043 ± 0.002 a,B | 0.075 ± 0.009 b,A | 0.045 ± 0.006 b,B | 0.072 ± 0.002 a,A | |

| Total sugar (g/100 g f.w.) | 0 weeks | 8.73 ± 0.37 c,B | 10.37 ± 0.16 a,A | 9.13 ± 0.01 d,B | 10.35 ± 0.25 a,A | 9.84 ± 0.32 c,A | 8.99 ± 0.08 b,B |

| 1 week | 8.79 ± 0.30 c,A | 9.52 ± 0.16 b,A | 11.70 ± 0.11 a,A | 10.20 ± 0.13 a,B | 11.18 ± 0.18 a,A | 7.05 ± 0.08 d,B | |

| 2 weeks | 9.39 ± 0.03 b,A | 8.34 ± 0.18 c,B | 11.30 ± 0.24 b,A | 9.14 ± 0.06 c,B | 9.66 ± 0.22 c,A | 9.92 ± 0.25 a,A | |

| 3 weeks | 8.67 ± 0.01 c,A | 8.72 ± 0.15 c,A | 10.57 ± 0.11 c,A | 9.53 ± 0.16 b,B | 8.71 ± 0.16 d,A | 7.89 ± 0.29 c,A | |

| 4 weeks * | 9.90 ± 0.10 a,A | 7.69± 0.23 d,B | 11.36 ± 0.16 b,A | 7.31 ± 0.04 d,B | 10.28 ± 0.14 b,A | 8.19 ± 0.06 c,B | |

| Fructose (g/100 g f.w.) | 0 weeks | 3.40 ± 0.24 d,B | 4.07 ± 0.05 b,A | 3.75 ± 0.01 c,B | 4.07 ± 0.14 a,A | 3.76 ± 0.19 cd,A | 3.59 ± 0.12 a,A |

| 1 week | 3.69 ± 0.05 b,B | 4.62 ± 0.06 a,A | 4.82 ± 0.08 a,A | 3.82 ± 0.15 a,B | 4.63 ± 0.11 a,A | 3.03 ± 0.15 b,B | |

| 2 weeks | 3.56 ± 0.01 bc,A | 3.61 ± 0.12 c,A | 4.62 ± 0.08 b,A | 3.41 ± 0.11 b,B | 4.42 ± 0.20 b,A | 3.44 ± 0.23 a,B | |

| 3 weeks | 3.48 ± 0.05 cd,A | 3.31 ± 0.05 d,A | 4.84 ± 0.08 a,A | 3.95 ± 0.03 a,B | 3.49 ± 0.13 d,A | 2.96 ± 0.15 b,A | |

| 4 weeks * | 4.12 ± 0.03 a,A | 3.20 ± 0.04 e,B | 4.60 ± 0.02 b,A | 2.94 ± 0.13 c,B | 4.30 ± 0.06 b,A | 3.47 ± 0.01 a,B | |

| Glucose (g/100 g f.w.) | 0 weeks | 5.10 ± 0.11 b,B | 6.18 ± 0.10 a,A | 5.23 ± 0.06 d,B | 6.18 ± 0.12 a,A | 5.71 ± 0.09 c,A | 5.22 ± 0.05 a,B |

| 1 week | 4.85 ± 0.21 c,A | 4.77 ± 0.06 c,A | 6.61 ± 0.16 a,A | 6.23 ± 0.01 a,B | 6.31 ± 0.07 a,A | 3.90 ± 0.06 d,B | |

| 2 weeks | 5.44 ± 0.03 a,A | 4.64 ± 0.11 c,B | 6.40 ± 0.11 b,A | 5.65 ± 0.08 b,B | 5.93 ± 0.02 b,A | 5.37 ± 0.05 a,B | |

| 3 weeks | 4.78 ± 0.02 c,A | 5.26 ± 0.21 b,A | 5.43 ± 0.21 c,A | 5.43 ± 0.14 b,A | 4.91 ± 0.02 d,A | 4.79 ± 0.13 b,A | |

| 4 weeks * | 5.58 ± 0.06 a,A | 4.38 ± 0.22 d,B | 6.52 ± 0.16 ab,A | 4.23 ± 0.13 c,B | 5.69 ± 0.08 c,A | 4.39 ± 0.06 c,B | |

| Sucrose (g/100 g f.w.) | 0 weeks | 0.23 ± 0.02 c,A | 0.13 ± 0.01 a,B | 0.15 ± 0.02 c,A | 0.10 ± 0.01 b,B | 0.37 ± 0.04 a,A | 0.18 ± 0.02 a,B |

| 1 week | 0.27 ± 0.04 b,A | 0.14 ± 0.04 a,B | 0.28 ± 0.04 ab,A | 0.15 ± 0.00 a,B | 0.24 ± 0.01 c,A | 0.13 ± 0.01 b,B | |

| 2 weeks | 0.40 ± 0.02 a,A | 0.11 ± 0.05 a,B | 0.28 ± 0.04 ab,A | 0.08 ± 0.01 b,B | 0.29 ± 0.03 b,A | 0.14 ± 0.01 b,B | |

| 3 weeks | 0.42 ± 0.01 a,A | 0.15 ± 0.01 a,B | 0.30 ± 0.01 a,A | 0.15 ± 0.01 a,B | 0.32 ± 0.01 b,A | 0.14 ± 0.01 b,B | |

| 4 weeks * | 0.21 ± 0.01 c,A | 0.12 ± 0.05 a,B | 0.25 ± 0.03 b,A | 0.11 ± 0.03 a,B | 0.31 ± 0.01 b,A | 0.18 ± 0.01 a,B | |

| Storage of Minimally Processed Fruit (Days) | |||||||

|---|---|---|---|---|---|---|---|

| White | Orange | Pink | |||||

| Storage Time of Whole Fruit (Weeks) | 0 Days | 8 Days | 0 Days | 8 Days | 0 Days | 8 Days | |

| Ascorbic acid (mg/100 g f.w.) | 0 weeks | 8.68 ± 0.80 a,A | 5.03 ± 0.07 a,B | 14.56 ± 1.21 a,A | 7.81 ± 0.64 a,B | 15.95 ± 1.02 a,A | 12.43 ± 0.65 a,B |

| 1 week | 7.43 ± 0.34 b,A | 4.02 ± 0.17 b,B | 15.30 ± 0.19 a,A | 4.85 ± 0.28 b,B | 15.17 ± 0.90 a,A | 5.59 ± 0.62 b,B | |

| 2 weeks | 7.64 ± 0.79 b,A | 3.81 ± 0.12 b,B | 10.18 ± 1.10 b,A | 2.31 ± 0.04 c,B | 8.95 ± 1.21 b,A | 3.17 ± 0.38 c,B | |

| 3 weeks | 4.18 ± 0.50 c,A | 1.82 ± 0.21 c,B | 5.83 ± 0.57 c,A | 1.40 ± 0.01 d,B | 5.45 ± 0.83 c,A | 1.21 ± 0.21 d,B | |

| 4 weeks * | 3.08 ± 0.13 d,A | 1.33 ± 0.06 d,B | 3.74 ± 0.33 d,A | 0.23 ± 0.03 e,B | 2.67 ± 0.24 d,A | 0.66 ± 0.06 d,B | |

| Antioxidant capacity (DPPH) (mg TE/100 g f.w.) | 0 weeks | 3.98 ± 0.10 a,A | 2.77 ± 0.08 a,B | 6.49 ± 0.14 a,A | 3.78 ± 0.08 a,B | 5.95 ± 0.18 a,A | 3.76 ± 0.11 a,B |

| 1week | 3.48 ± 0.22 b,A | 2.64 ± 0.05 b,B | 4.44 ± 0.27 b,A | 2.73 ± 0.02 b,B | 5.11 ± 0.18 b,A | 3.22 ± 0.07 b,B | |

| 2 weeks | 2.96 ± 0.06 c,A | 2.04 ± 0.05 c,B | 3.39 ± 0.16 c,A | 2.22 ± 0.06 c,B | 3.47 ± 0.18 c,A | 2.30 ± 0.06 c,B | |

| 3 weeks | 2.02 ± 0.02 a,A | 1.68 ± 0.03 d,B | 3.26 ± 0.06 cd,A | 2.00 ± 0.03 d,B | 3.70 ± 0.22 c,A | 2.17 ± 0.10 c,B | |

| 4 weeks * | 1.81 ± 0.06 a,A | 1.20 ± 0.02 e,B | 3.02 ± 0.06 d,A | 1.83 ± 0.06 e,B | 2.44 ± 0.07 d,A | 1.83 ± 0.02 d,B | |

| Total phenolics (mg GAE/100 g f.w.) | 0 weeks | 76.77 ± 2.04 a,A | 33.12 ± 3.17 d,B | 96.12 ± 3.07 a,A | 44.69 ± 8.90 b,B | 91.93 ± 2.76 a,A | 45.63 ± 9.50 d,B |

| 1 week | 80.30 ± 2.35 a,A | 49.80 ± 2.91 c,B | 54.25 ± 1.60 c,A | 61.31 ± 8.63 b,A | 87.29 ± 10.59 a,A | 83.81 ± 4.63 bc,A | |

| 2 weeks | 59.84 ± 3.87 b,B | 77.86 ± 4.13 b,A | 77.07 ± 0.97 b,A | 49.92 ± 6.79 b,B | 69.83 ± 4.71 b,A | 69.09 ± 14.51 cd,A | |

| 3 weeks | 79.46 ± 7.23 a,A | 90.92 ± 1.48 a,A | 92.10 ± 6.31 a,A | 90.91 ± 2.74 a,A | 93.92 ± 11.50 a,A | 95.99 ± 6.24 a,A | |

| 4 weeks * | 63.96 ± 6.88 b,A | 54.44 ± 3.59 c,A | 51.30 ± 0.27 c,A | 42.43 ± 7.18 b,A | 67.92 ± 8.08 b,A | 57.92 ± 6.46 d,A | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Díaz-Delgado, G.L.; Rodríguez-Rodríguez, E.M.; Cano, M.P.; Lobo, M.G. Storage Conditions of Refrigerated Prickly Pears in Small Processing Industries. Agriculture 2024, 14, 594. https://doi.org/10.3390/agriculture14040594

Díaz-Delgado GL, Rodríguez-Rodríguez EM, Cano MP, Lobo MG. Storage Conditions of Refrigerated Prickly Pears in Small Processing Industries. Agriculture. 2024; 14(4):594. https://doi.org/10.3390/agriculture14040594

Chicago/Turabian StyleDíaz-Delgado, Goretti L., Elena M. Rodríguez-Rodríguez, M. Pilar Cano, and M. Gloria Lobo. 2024. "Storage Conditions of Refrigerated Prickly Pears in Small Processing Industries" Agriculture 14, no. 4: 594. https://doi.org/10.3390/agriculture14040594

APA StyleDíaz-Delgado, G. L., Rodríguez-Rodríguez, E. M., Cano, M. P., & Lobo, M. G. (2024). Storage Conditions of Refrigerated Prickly Pears in Small Processing Industries. Agriculture, 14(4), 594. https://doi.org/10.3390/agriculture14040594