Design and Test of Hydraulic Driving System for Undercarriage of Paddy Field Weeder

Abstract

1. Introduction

2. System Structure and Working Principle

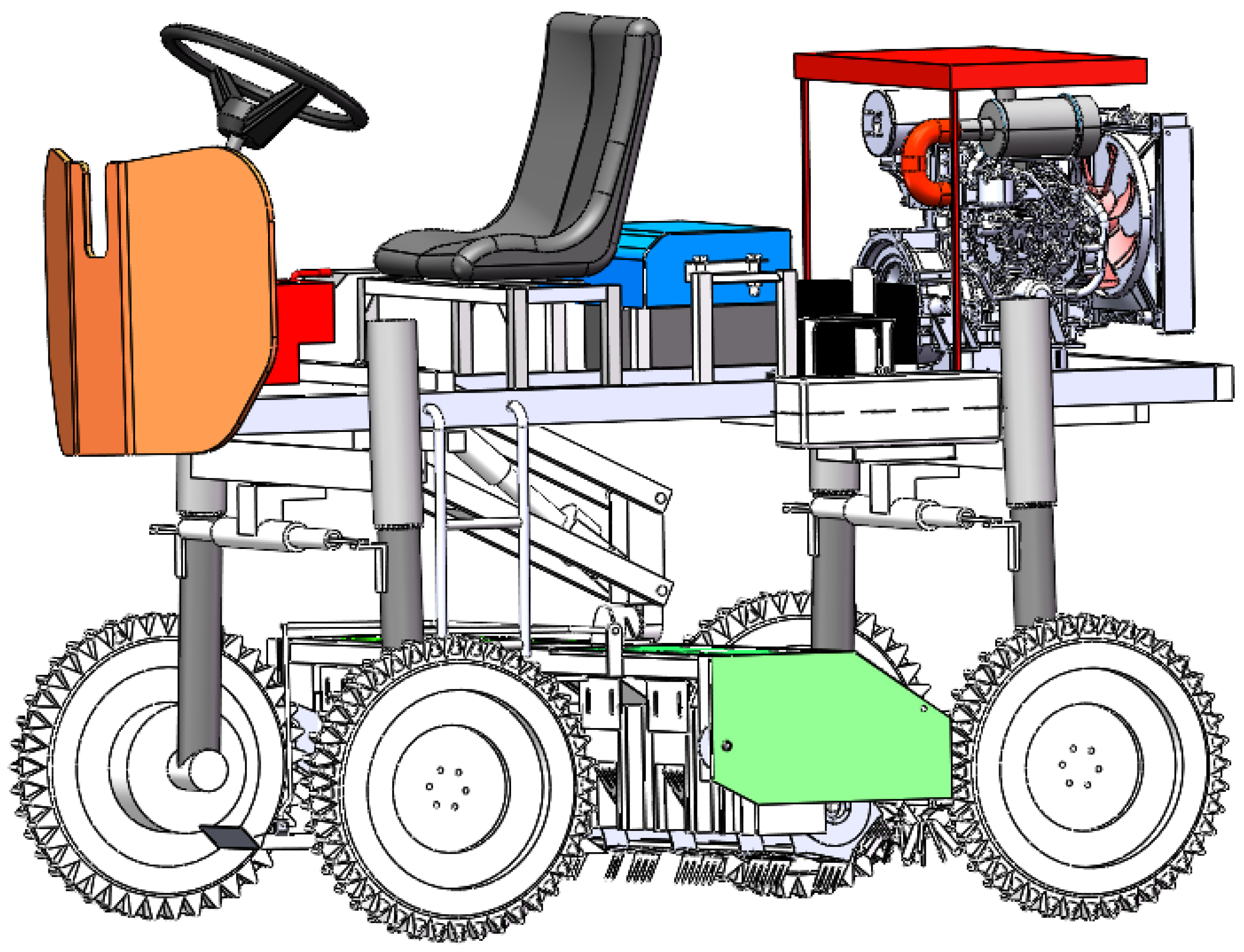

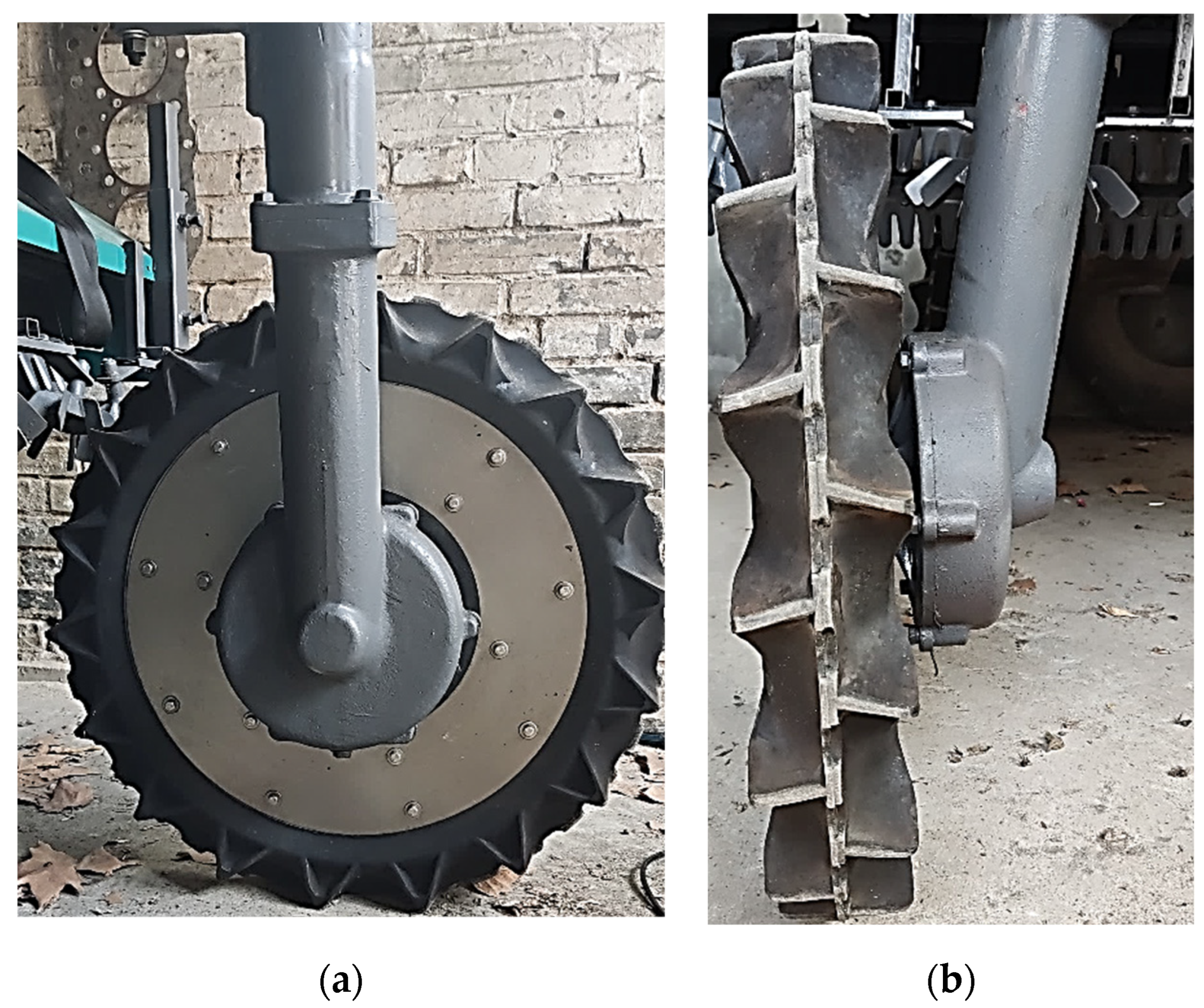

2.1. Chassis Structure

2.2. Working Principle

3. Walking Hydraulic System Design

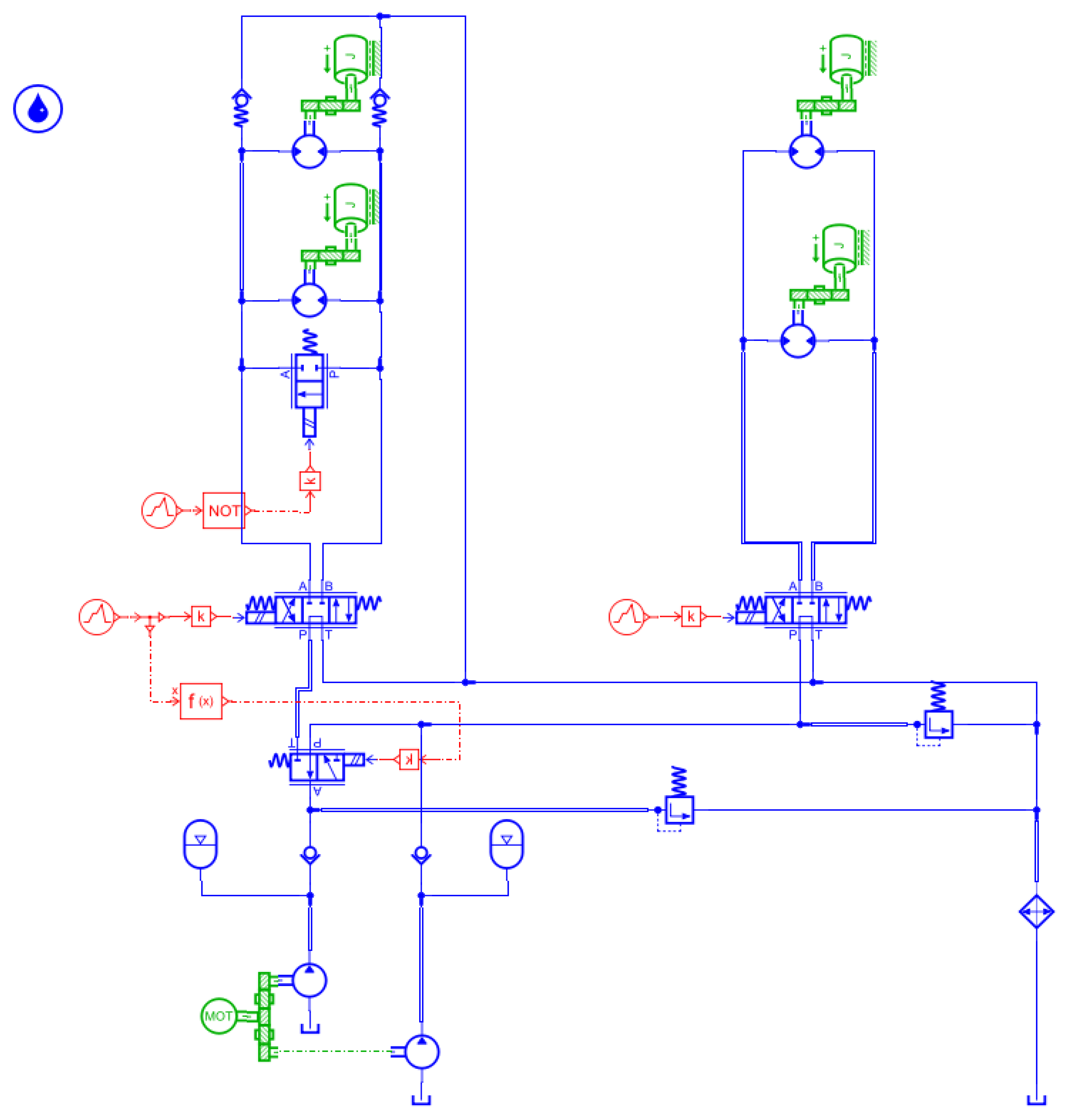

3.1. Principle of Hydraulic System

3.2. Calculation and Selection of Main Power Components

3.2.1. Calculation of Maximum Driving Resistance

3.2.2. Hydraulic Drive Motor Selection Calculation

3.2.3. Hydraulic Pump Selection Calculation

4. Simulation of Chassis Dynamics and Walking Hydraulic System

4.1. Chassis Dynamics Simulation

4.1.1. Chassis Modeling

4.1.2. Paddy Field Pavement Modeling

4.1.3. Analysis of Linear Driving Dynamics

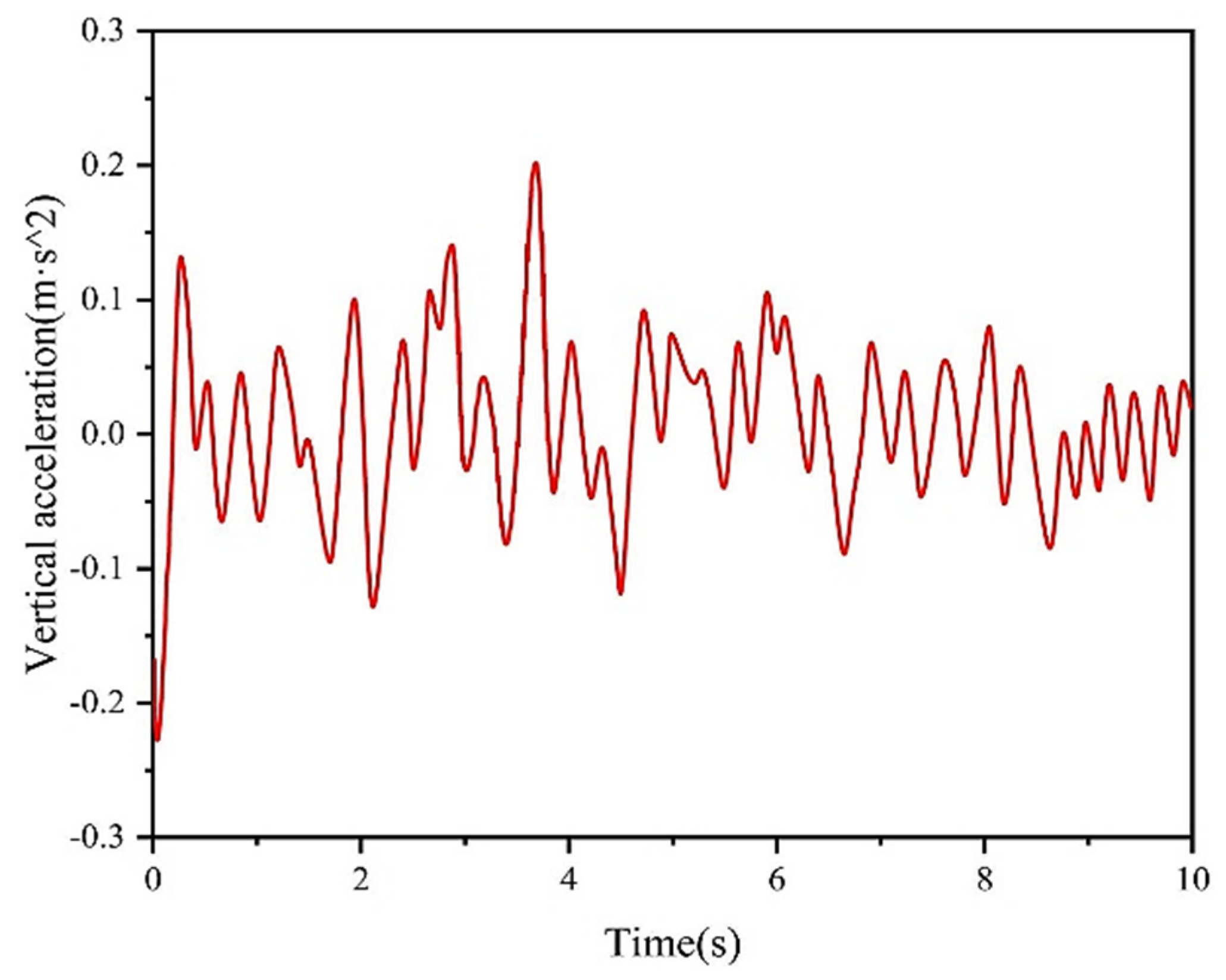

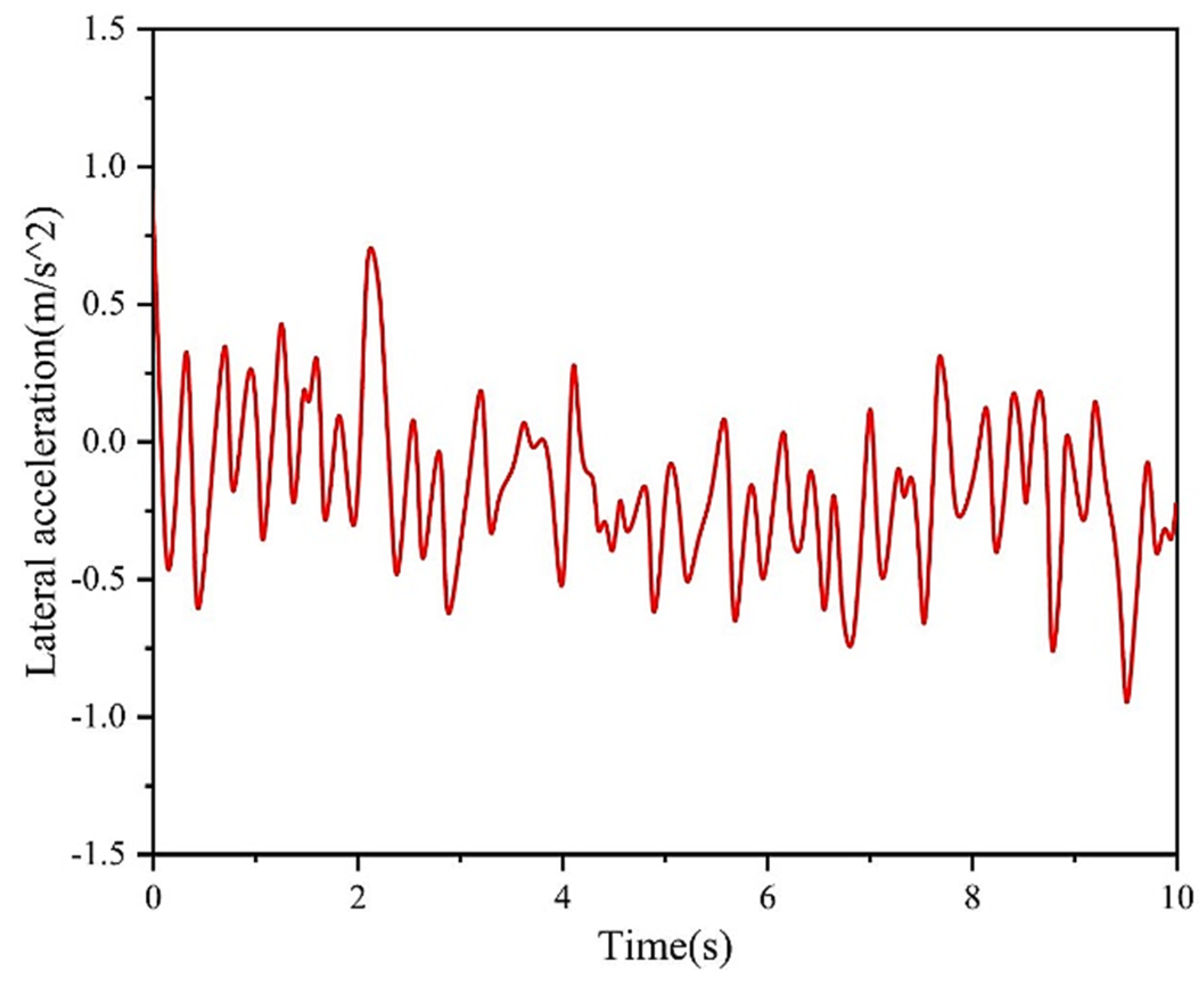

4.1.4. Steering Characteristic Analysis

4.2. Software Simulation of Chassis Walking Hydraulic System

4.2.1. Walking Hydraulic System Model

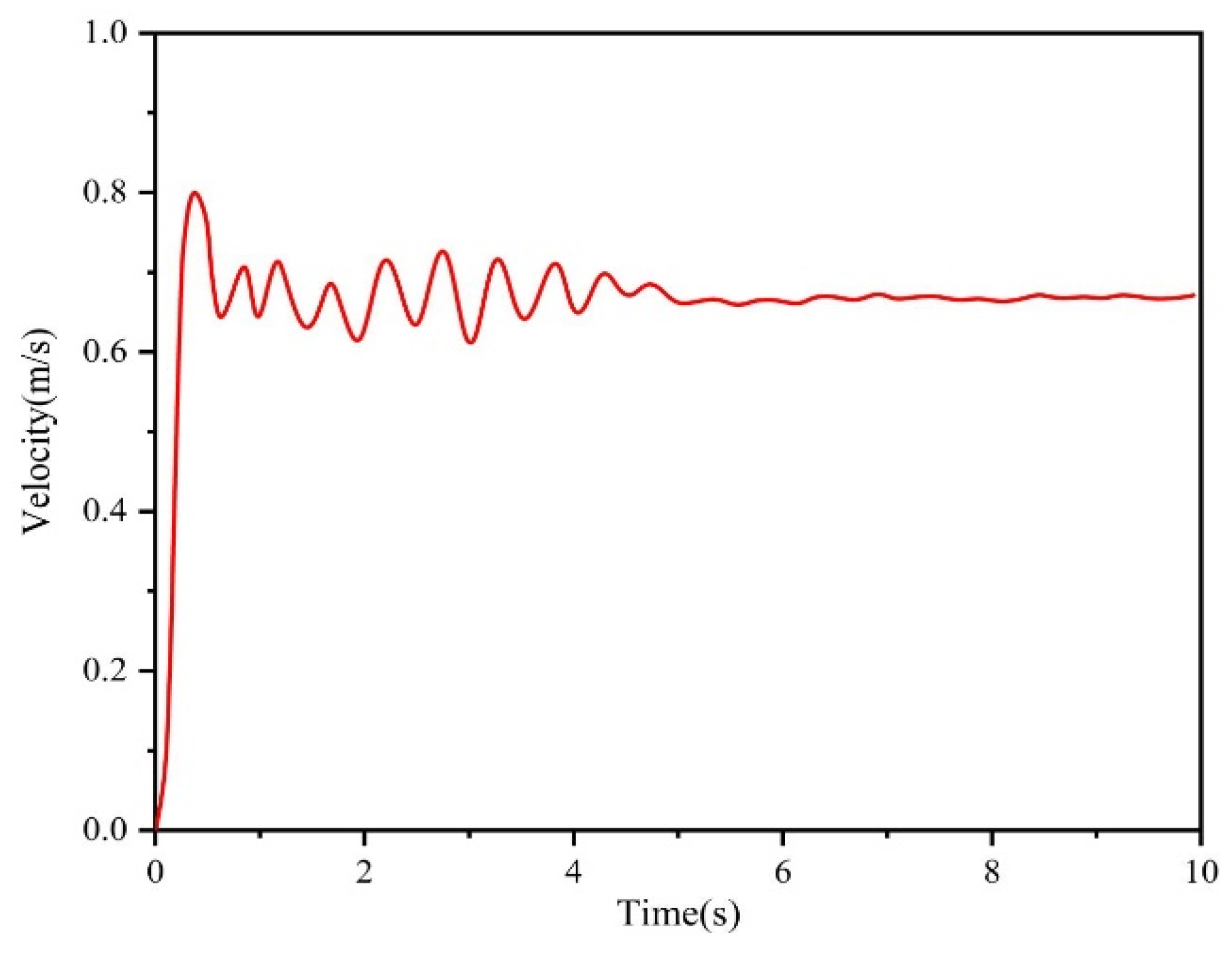

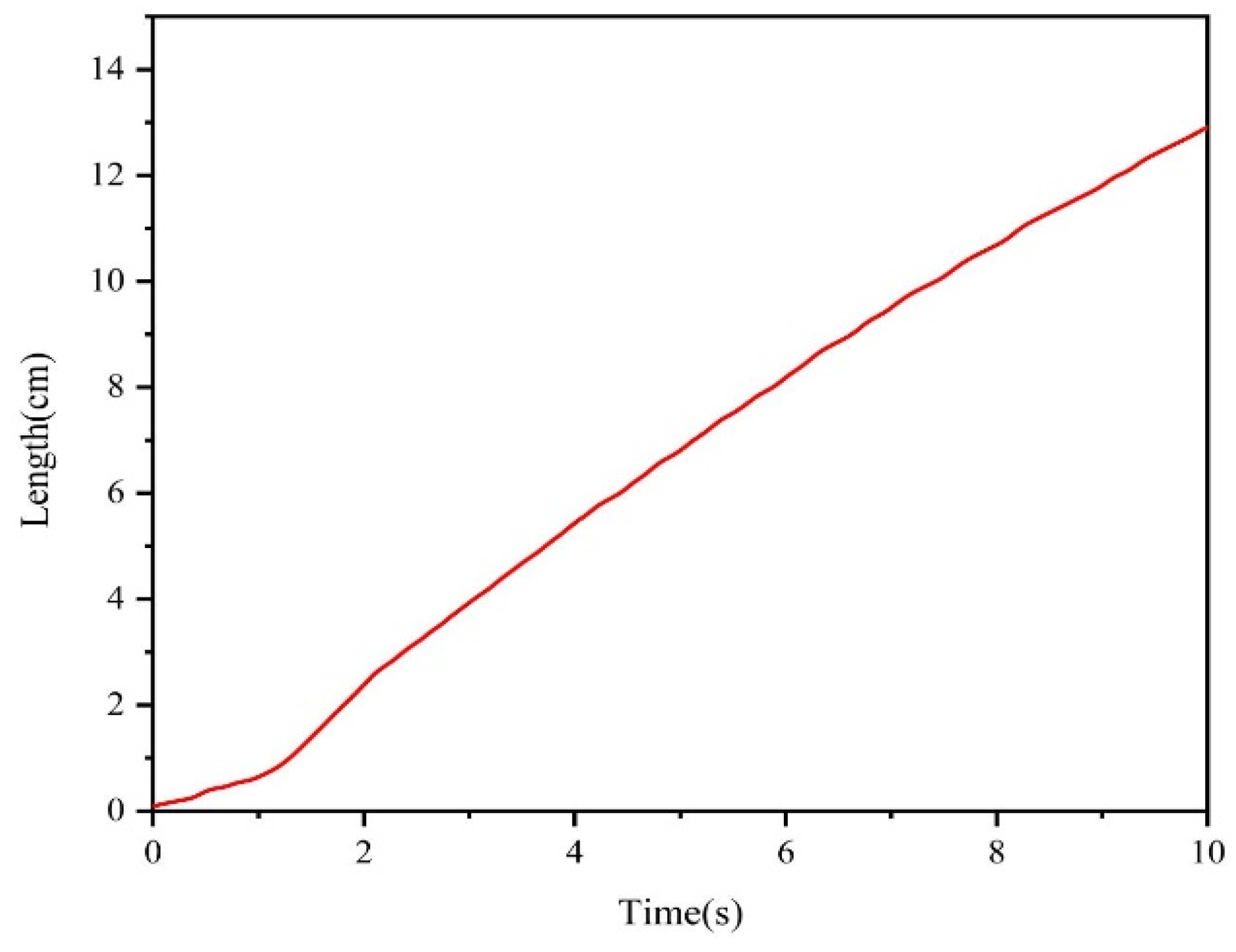

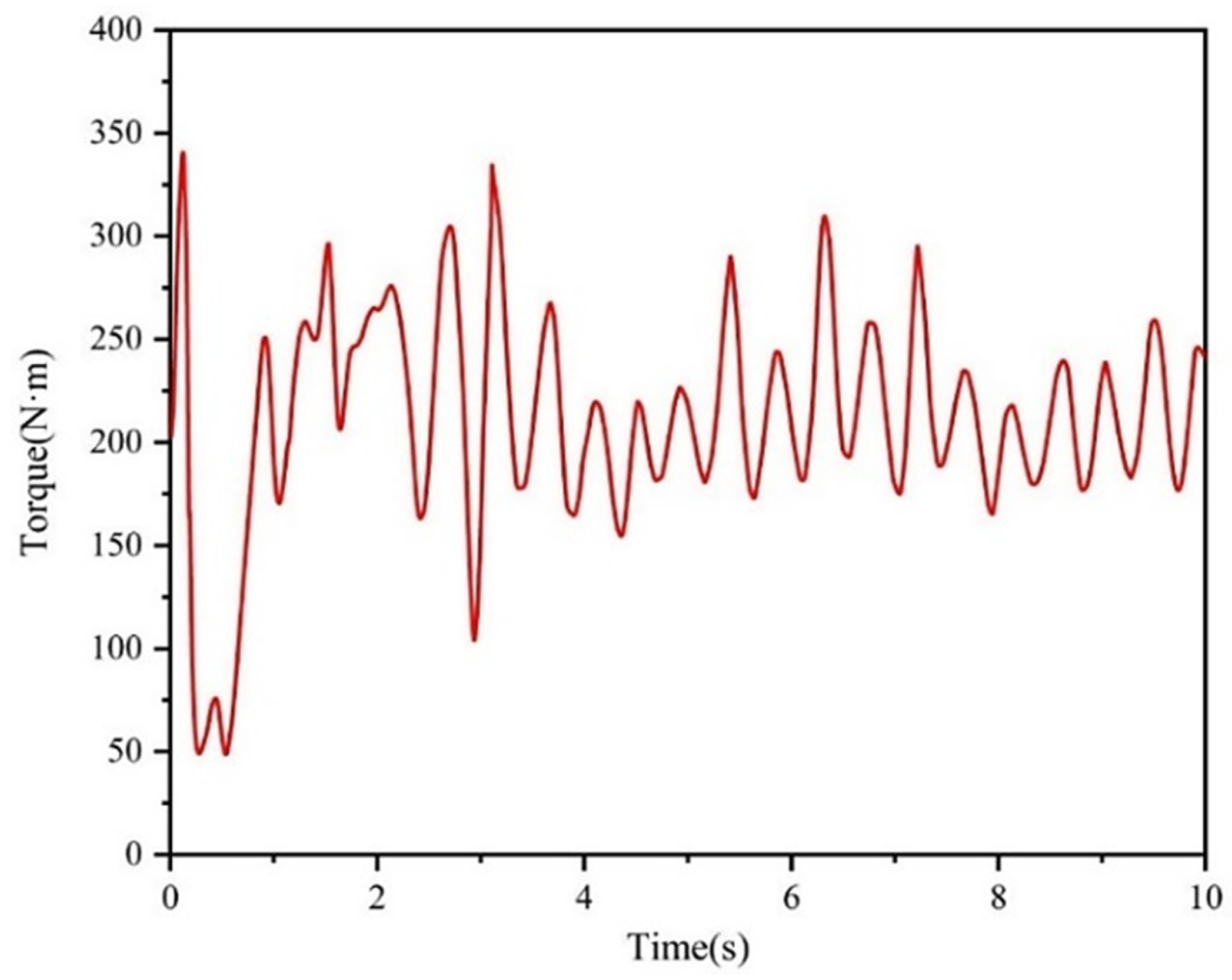

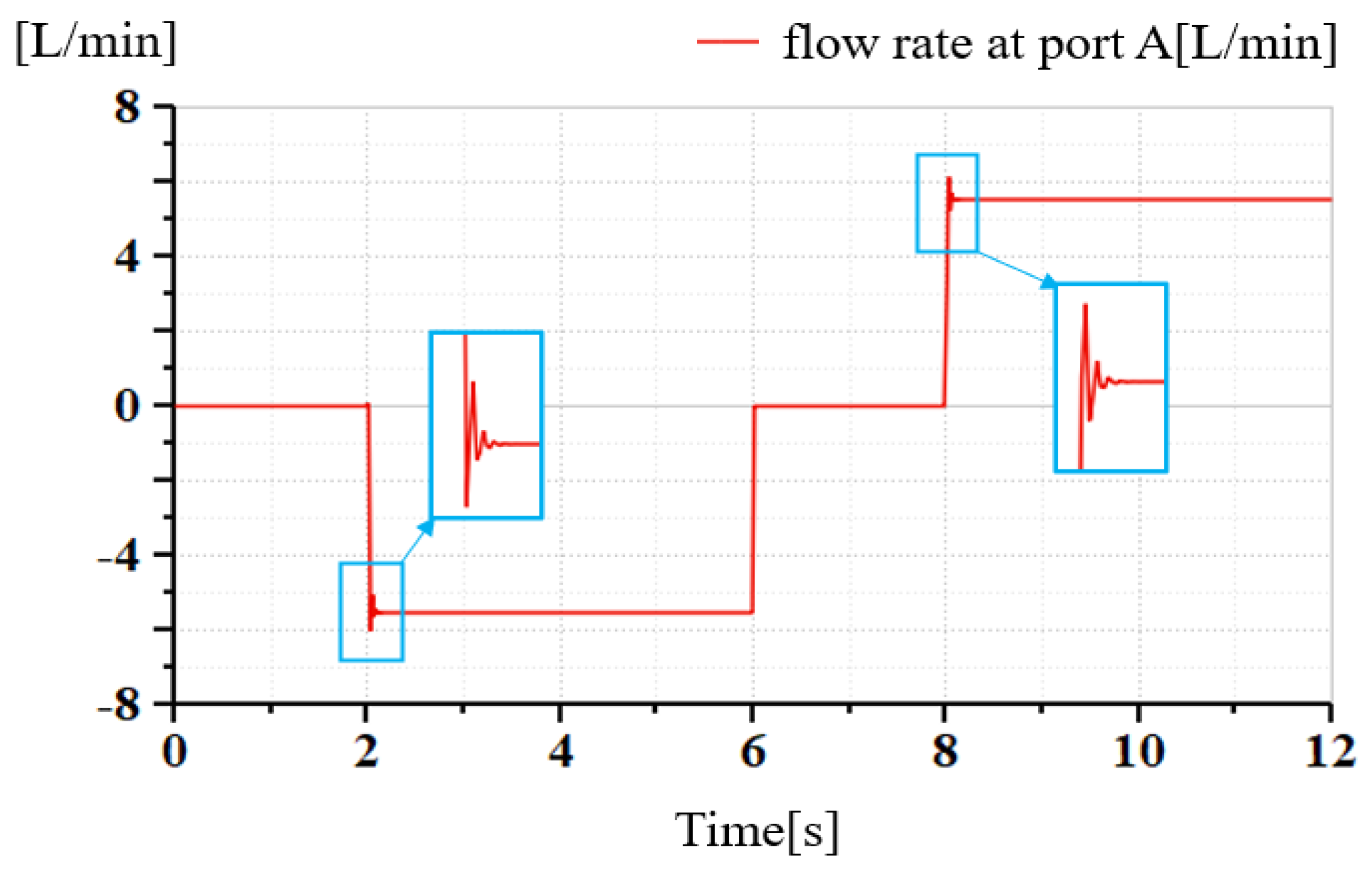

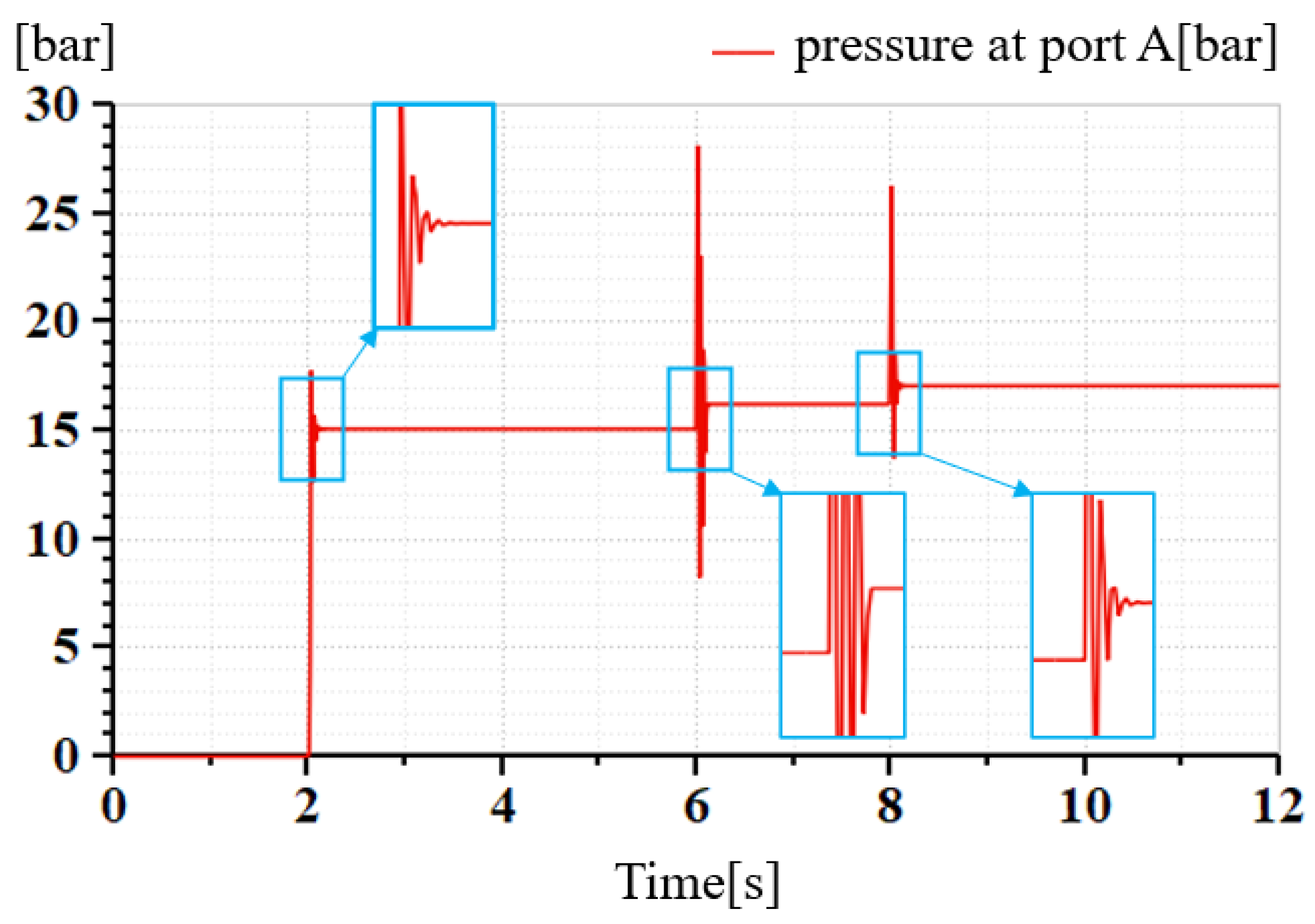

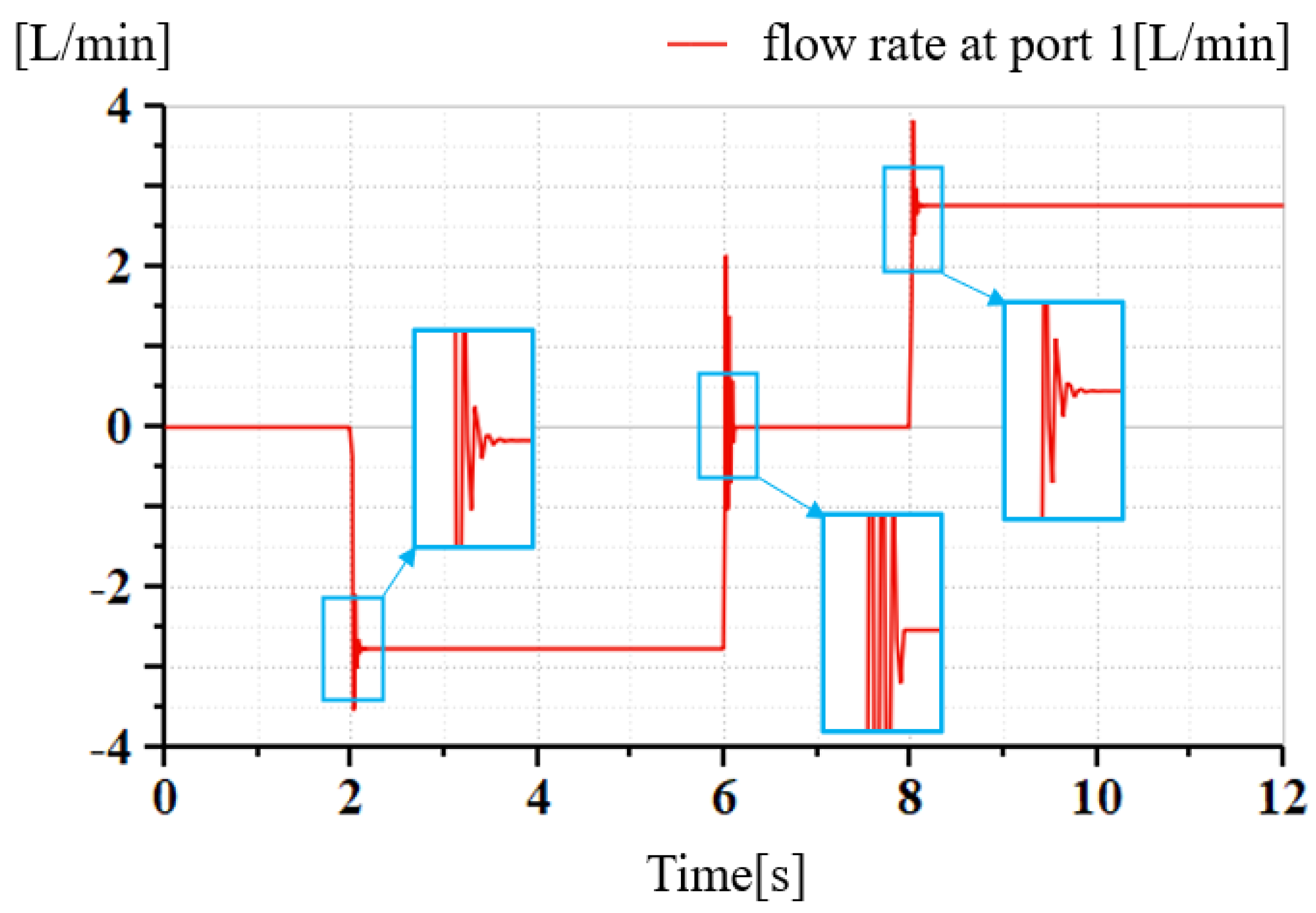

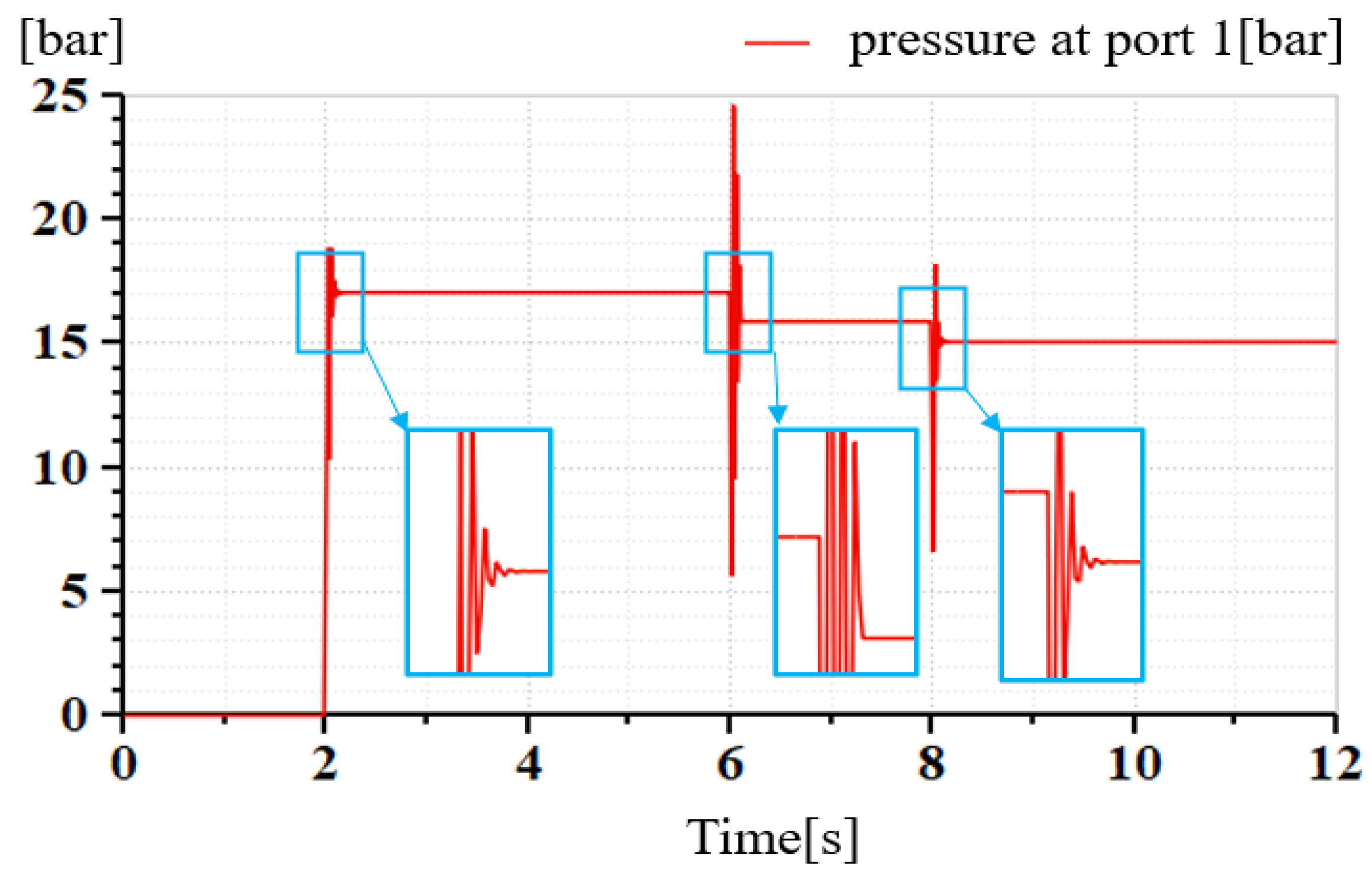

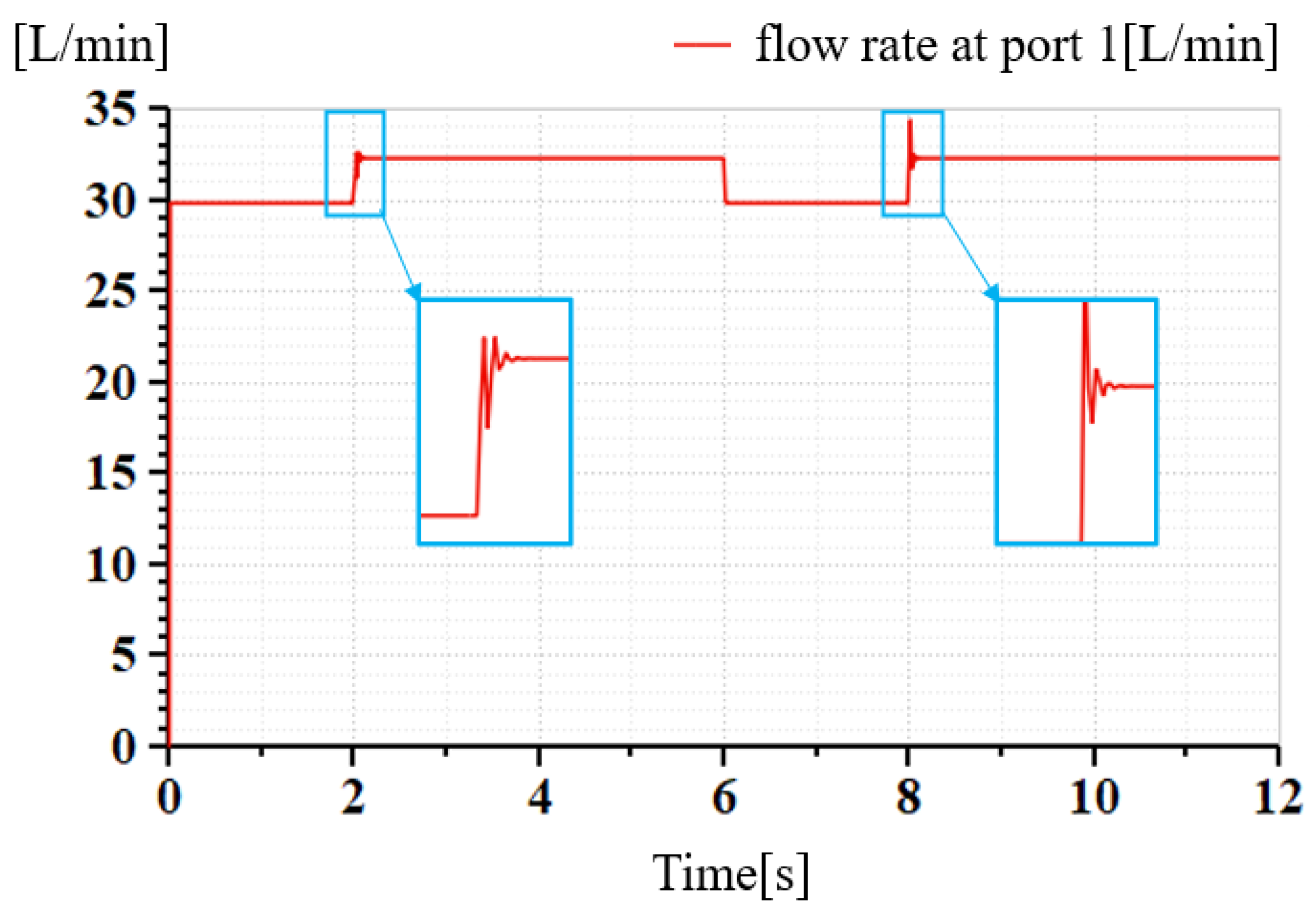

4.2.2. Travel Hydraulic Characteristics

5. Chassis Test

5.1. Linear Driving Offset Distance Test

5.1.1. Test Methods and Contents

- Test site: Guang Ping District, Nanjing Agricultural University.

- Test equipment: A stopwatch (CASIO HS-70W accurate to 1/100 s), tape measure (STANLEY 30-455 with a range of 200 m and precision markings at the millimeter level), marking line, and hydraulic drive weeder.

- Test method: Prior to commencing the test, the hydraulic-driven weeder was brought to a complete stop. A starting point was designated, and chalk was used to mark this point on the ground, serving as the reference line. A vertical line was drawn from this starting point, and the end point was marked 100 m away in a straight line. Reference and vertical reference lines were established at the same horizontal position to ensure accurate measurement. The weeder was then driven from the starting point to the end point at a speed of 0.7 m/s, maintaining a consistent trajectory throughout the test. During the test, a stopwatch was employed to record the time taken by the weeder to traverse the 100 m distance. Upon the completion of each test run, a tape measure was used to measure the vertical deviation distance of the calibration line from the reference line. The recorded time and deviation data were meticulously documented for each of the five test runs, noting both positive and negative deviations to the left and right, respectively, for a comprehensive analysis.

5.1.2. Test Results and Analysis

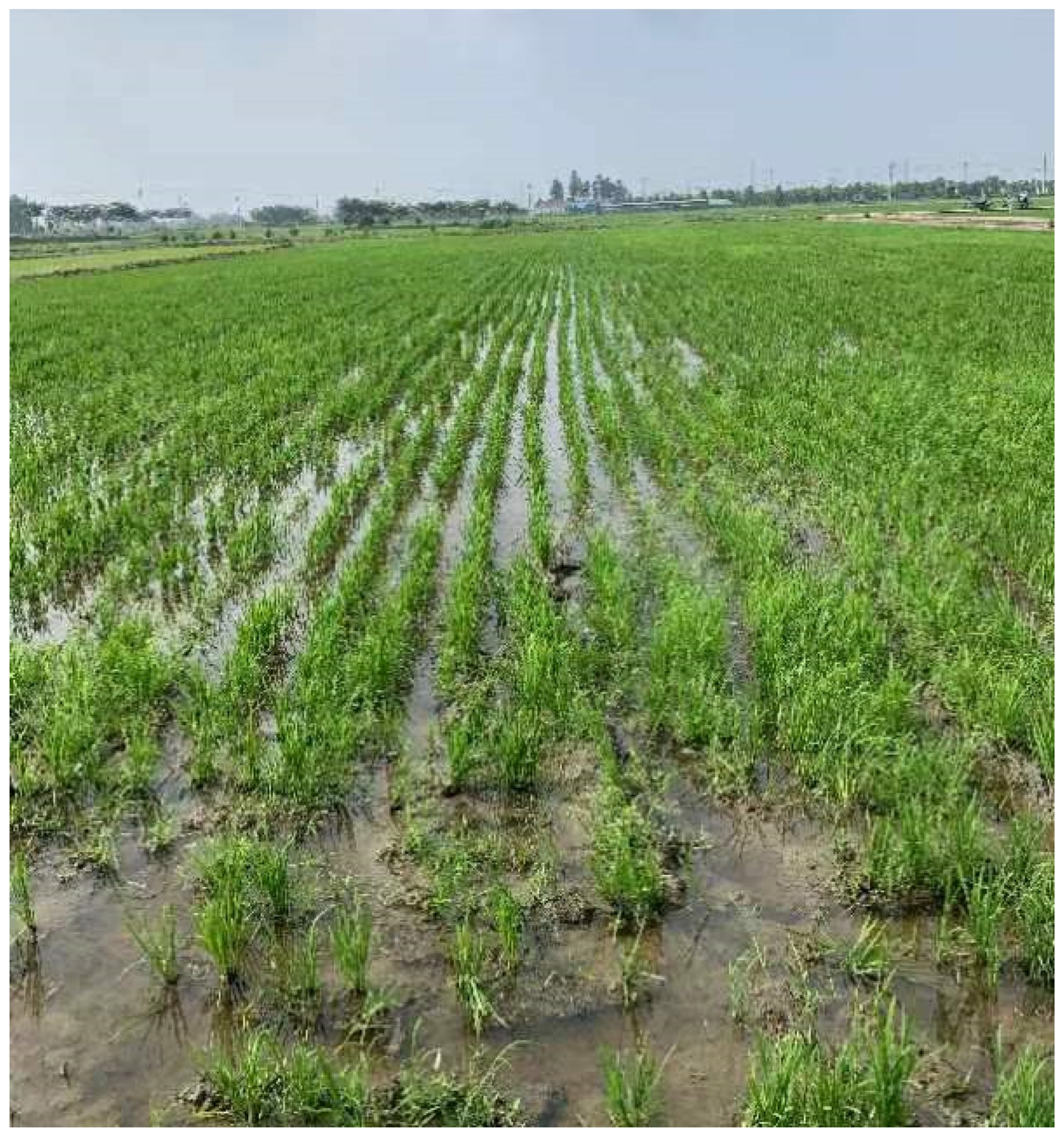

5.2. Slip Rate Test Experiment

5.2.1. Test Methods and Contents

- Test site: The rice–wheat Science and Technology Demonstration Center, Jintan District, Changzhou City, Jiangsu Province, with a subtropical monsoon climate, four distinct seasons, abundant precipitation, and mild climate, suitable for rice growth.

- Test equipment: A tape measure (STANLEY 30-455 with a range of 200 m and precision markings at the millimeter level), revolution counter (DTI ±0.1 revolution), and hydraulic drive weeder.

- Experimental sample field: A rice–wheat continuous cropping field, wherein the land uniformity of the experimental area is consistent.

- Test methods: The driving wheel of the weeder was selected as the experimental observation object, and the theoretical driving linear distance of the weeder’s driving wheel rotating 10 turns was calculated. The testing speed was 0.7 m/s. The actual driving distance was then measured with a meter ruler to calculate its slip rate. The revolution counter was used to measure the rotation times of the driving wheel of the weeder. To reduce the experimental errors, the average of three measurements was taken as the final result (Figure 18 and Figure 19).

5.2.2. Test Results and Analysis

6. Conclusions

- (1)

- The horizontal speed of the hydraulic chassis of the designed weeder fluctuated and stabilized at 0.7 m/s. The torque of the driving wheel stabilized at approximately 200 N·m, and the peak vertical acceleration reached 0.2 m/s2. The yaw speed and lateral acceleration of the chassis also fluctuated within the normal range during steering, and the driving remained relatively stable.

- (2)

- When the hydraulic chassis of the designed weeder was running, the flow rate of the reversing valve reached 4.5 L/min, and the peak flow of the hydraulic motor was 2.5 L/min. The selected hydraulic components addressed the requirements of the working conditions, the hydraulic motor flow and pressure changes were in a reasonable range, and the hydraulic system oil supply flow remained stable.

- (3)

- The drift rate of the weeder was 2.61%, and the average slip rate of the paddy field was 3.59% under the precondition of the weeder operating at a speed of 0.7 m/s. Thus, the future design of hydraulic systems under specific working conditions in actual production work can be guided by this study.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Bin Rahman, A.N.M.R.; Zhang, J. Trends in rice research: 2030 and beyond. Food Energy Secur. 2023, 12, e390. [Google Scholar] [CrossRef]

- Farooq, M.; Siddique, K.H.; Rehman, H.; Aziz, T.; Lee, D.-J.; Wahid, A. Rice direct seeding: Experiences, challenges and opportunities. Soil Tillage Res. 2011, 111, 87–98. [Google Scholar] [CrossRef]

- Monteiro, A.; Santos, S. Sustainable Approach to Weed Management: The Role of Precision Weed Management. Agronomy 2022, 12, 118. [Google Scholar] [CrossRef]

- Raza, A.; Ali, H.H.; Zaheer, M.S.; Iqbal, J.; Seleiman, M.F.; Sattar, J.; Ali, B.; Khan, S.; Arjumend, T.; Chauhan, B.S. Bio-ecology and the management of Chenopodium murale L.: A problematic weed in Asia. Crop Prot. 2023, 172, 106332. [Google Scholar] [CrossRef]

- Westwood, J.H.; Charudattan, R.; Duke, S.O.; Fennimore, S.A.; Marrone, P.; Slaughter, D.C.; Swanton, C.; Zollinger, R. Weed Management in 2050: Perspectives on the Future of Weed Science. Weed Sci. 2018, 66, 275–285. [Google Scholar] [CrossRef]

- Holt, J.S. Impact of Weed Control on Weeds: New Problems and Research Needs. Weed Technol. 1994, 8, 400–402. [Google Scholar] [CrossRef]

- Griepentrog, H.W.; Gulhom-Hansen, T.; Nielsen, J. First field results from intra-row rotor weeding. In Proceedings of the 7th European Weed Research Society Workshop on Physical and Cultural Weed Control, Salem, Germany, 11–14 March 2007. [Google Scholar]

- Tillett, N.; Hague, T.; Grundy, A.; Dedousis, A. Mechanical within-row weed control for transplanted crops using computer vision. Biosyst. Eng. 2008, 99, 171–178. [Google Scholar] [CrossRef]

- Shoji, K.; Itoh, K.; Kawahara, F.; Yoshida, Y.; Yamamoto, Y.; Sudo, K.-I. Micro-elevations in paddy fields affect the efficacy of mechanical weeding: Evaluation of weeding machines to control Monochoria vaginalisin herbicide-free farming. Weed Biol. Manag. 2013, 13, 45–52. [Google Scholar] [CrossRef]

- Jinw, W. Design of organic rice cultivation weeding. J. Northeast. Agric. Univ. 2013, 44, 107–112. [Google Scholar]

- Qi, L.; Ma, X.; Tan, Z.; Tan, Y.; Qiu, Q.; Yang, C.; Zhang, W. Development and experiment of marching-type inter-cultivation weeder for paddy. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2012, 28, 31–35. [Google Scholar]

- Matsuda, Y.; Kakutani, K.; Toyoda, H. Unattended Electric Weeder (UEW): A Novel Approach to Control Floor Weeds in Orchard Nurseries. Agronomy 2023, 13, 1954. [Google Scholar] [CrossRef]

- Wu, C.; Zhang, M.; Jin, C.; Tu, A.; Lu, Y.; Xiao, T. Design and experiment of 2BYS-6 type paddy weeding-cultivating machine. Nongye Jixie Xuebao (Trans. Chin. Soc. Agric. Mach.) 2009, 40, 51–54. [Google Scholar]

- Qi, L.; Zhao, L.; Ma, X.; Cui, H.; Zheng, W.; Lu, Y. Design and test of 3GY-1920 wide-swath type weeding-cultivating machine for paddy. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2017, 33, 47–55. [Google Scholar]

- Sanchez, J.; Gallandt, E.R. Functionality and efficacy of Franklin Robotics’ Tertill™ robotic weeder. Weed Technol. 2021, 35, 166–170. [Google Scholar] [CrossRef]

- Nissing, D.; Gessat, J.; Bitzer, T.; Seewald, A. Hydraulic chassis systems with electrically powered hydraulic steering and active roll control. ATZ Worldw. 2007, 109, 11–15. [Google Scholar] [CrossRef]

- Han, X.; Su, W.; Zhao, H.; Zheng, Y.; Hu, Q.; Wang, C. The applications of energy regeneration and conversion technologies based on hydraulic transmission systems: A review. Energy Convers. Manag. 2020, 205, 112413. [Google Scholar]

- Rossetti, A.; Macor, A. Continuous formulation of the layout of a hydromechanical transmission. Mech. Mach. Theory 2019, 133, 545–558. [Google Scholar] [CrossRef]

- Triet, H.H.; Ahn, K.K. Comparison and assessment of a hydraulic energy-saving system for hydrostatic drives. Proc. Inst. Mech. Eng. Part I J. Syst. Control. Eng. 2011, 225, 21–34. [Google Scholar] [CrossRef]

- Comellas, M.; Pijuan, J.; Nogués, M.; Roca, J. Efficiency analysis of a multiple axle vehicle with hydrostatic transmission overcoming obstacles. Veh. Syst. Dyn. 2018, 56, 55–77. [Google Scholar] [CrossRef]

- Morera-Torres, E.; Ocampo-Martinez, C.; Bianchi, F.D. Experimental Modelling and Optimal Torque Vectoring Control for 4WD Vehicles. IEEE Trans. Veh. Technol. 2022, 71, 4922–4932. [Google Scholar] [CrossRef]

- Qi, X.; Shang, Y.; Ding, Z.; Wei, W. Particularities and research progress of the cutting machinability of wood-plastic composites. Mater. Today Commun. 2023, 37, 106924. [Google Scholar] [CrossRef]

- Baek, S.-Y.; Baek, S.-M.; Jeon, H.-H.; Kim, W.-S.; Kim, Y.-S.; Sim, T.-Y.; Choi, K.-H.; Hong, S.-J.; Kim, H.; Kim, Y.-J. Traction Performance Evaluation of the Electric All-Wheel-Drive Tractor. Sensors 2022, 22, 785. [Google Scholar] [CrossRef] [PubMed]

- Yun, S.; Lee, W.; Park, J.; Guak, K. Development of a Virtual Environment Co-Simulation Platform for Evaluating Dynamic Characteristics of Self-Balancing Personal Mobility. IEEE Trans. Veh. Technol. 2021, 70, 2969–2978. [Google Scholar] [CrossRef]

- Tang, S.; Guo, Z.; Wang, G.; Wang, X. Comparative Performance Analysis of Different Travelling Mechanisms Based on RecurDyn. IOP Conf. Ser. Mater. Sci. Eng. 2020, 782, 42059. [Google Scholar] [CrossRef]

- Li, Y.; Dai, S.; Zheng, Y.; Tian, F.; Yan, X. Modeling and Kinematics Simulation of a Mecanum Wheel Platform in RecurDyn. J. Robot. 2018, 2018, 9373580. [Google Scholar] [CrossRef]

- Santos, M.; López, R.; de la Cruz, J.M. Fuzzy control of the vertical acceleration of fast ferries. Control Eng. Pract. 2005, 13, 305–313. [Google Scholar] [CrossRef]

- Zong, Z.; Sun, Y.; Jiang, Y. Experimental study of controlled T-foil for vertical acceleration reduction of a trimaran. J. Mar. Sci. Technol. 2019, 24, 553–564. [Google Scholar] [CrossRef]

- Cakici, F.; Yazici, H.; Alkan, A.D. Optimal control design for reducing vertical acceleration of a motor yacht form. Ocean Eng. 2018, 169, 636–650. [Google Scholar] [CrossRef]

- Ricco, M.; Zanchetta, M.; Rizzo, G.C.; Tavernini, D.; Sorniotti, A.; Chatzikomis, C.; Velardocchia, M.; Geraerts, M.; Dhaens, M. On the Design of Yaw Rate Control via Variable Front-to-Total Anti-Roll Moment Distribution. IEEE Trans. Veh. Technol. 2020, 69, 1388–1403. [Google Scholar] [CrossRef]

- Chen, T.; Xu, X.; Chen, L.; Jiang, H.; Cai, Y.; Li, Y. Estimation of longitudinal force, lateral vehicle speed and yaw rate for four-wheel independent driven electric vehicles. Mech. Syst. Signal Process. 2018, 101, 377–388. [Google Scholar] [CrossRef]

- Marino, R.; Scalzi, S. Asymptotic sideslip angle and yaw rate decoupling control in four-wheel steering vehicles. Veh. Syst. Dyn. 2010, 48, 999–1019. [Google Scholar] [CrossRef]

- Jagelčák, J.; Gnap, J.; Kostrzewski, M.; Kuba, O.; Frnda, J. Calculation of an Average Vehicle’s Sideways Acceleration on Small Roundabouts. Sensors 2022, 22, 4978. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, T. The influence of tyre transient side force properties on vehicle lateral acceleration for a time-varying vertical force. Veh. Syst. Dyn. 2018, 56, 734–752. [Google Scholar] [CrossRef]

- Lin, T.; Wang, L.; Huang, W.; Ren, H.; Fu, S.; Chen, Q. Performance analysis of an automatic idle speed control system with a hydraulic accumulator for pure electric construction machinery. Autom. Constr. 2017, 84, 184–194. [Google Scholar] [CrossRef]

- Kim, J.; Lee, J.; Kim, K. Numerical study on the effects of fuel viscosity and density on the injection rate performance of a solenoid diesel injector based on AMESim. Fuel 2019, 256, 115912. [Google Scholar] [CrossRef]

- Li, H.; Li, S.; Sun, W.; Wang, L.; Lv, D. The optimum matching control and dynamic analysis for air suspension of multi-axle vehicles with anti-roll hydraulically interconnected system. Mech. Syst. Signal Process. 2020, 139, 106605. [Google Scholar] [CrossRef]

- GB/T 15370.1-2012; General Requirement of Agricultural Tractors—Part 1: Under 50 kW Wheeled Tractors. National Standards of People’s Republic of China: Beijing, China, 2012.

- Zhang, C.; Li, C.; Zhao, C.; Li, L.; Gao, G.; Chen, X. Design of Hydrostatic Chassis Drive System for Large Plant Protection Machine. Agriculture 2022, 12, 1118. [Google Scholar] [CrossRef]

| Argument | Value/Type |

|---|---|

| Machine size (length × width × height)/(mm × mm × mm) | 2080 × 1650 × 1020 |

| Overall quality/kg | 1000 |

| Supporting power/kw | 15 |

| Driving mode | Four-wheel drive |

| Steering mode | Differential steering |

| Minimum adaptive line spacing/mm | 300 |

| Working width/mm | 1985 |

| Adaptive plant spacing/mm | 100 |

| Pavement | Peculiarity | Rolling Resistance Coefficient f | Maximum Adhesion Coefficient μ |

|---|---|---|---|

| Land for cultivation | Relatively soft | 0.10–0.250 | 0.40–0.50 |

| Wet mud floor | Changes in resistance, deep wheel printing | 0.10–0.15 | 0.50–0.60 |

| Paddy field | Drive wheel touches the bottom of the plow | 0.20–0.25 | 0.35–0.50 |

| Concrete pavement | Hardly any wheel marks | 0.01–0.02 | 0.80–0.90 |

| Quality Characteristic | Argument |

|---|---|

| Equivalent displacement (mL/r) | 81.5 |

| Maximum working pressure (MPa) | 22.5 |

| Maximum speed (rpm) | 650 |

| Maximum discharge (L/min) | 55 |

| Maximum output torque (N·m) | 650 |

| Quality Characteristic | Argument |

|---|---|

| Maximum displacement (mL/r) | 20 |

| Working pressure (MPa) | Rated 20 Peak 25 |

| Input/output speed (r/min) | 2500–3000 |

| Quality (kg) | 3.7 |

| Pilot Project | Data |

|---|---|

| Offset distance/m | 2.84 |

| 2.54 | |

| 2.23 | |

| 2.97 | |

| 2.47 | |

| Average deviation/m | 2.61 |

| Group Number | Actual Travel Distance/m | Theoretical Travel Distance/m | Slippage Rate/% |

|---|---|---|---|

| 1 | 25.36 | 26.70 | 5.01 |

| 2 | 25.83 | 26.70 | 3.27 |

| 3 | 26.03 | 26.70 | 2.49 |

| Average value | 37.14 | 26.70 | 3.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, M.; Zhao, Y.; Wang, H.; Xu, X.; Bartos, P.; Zhu, Y. Design and Test of Hydraulic Driving System for Undercarriage of Paddy Field Weeder. Agriculture 2024, 14, 595. https://doi.org/10.3390/agriculture14040595

Xiao M, Zhao Y, Wang H, Xu X, Bartos P, Zhu Y. Design and Test of Hydraulic Driving System for Undercarriage of Paddy Field Weeder. Agriculture. 2024; 14(4):595. https://doi.org/10.3390/agriculture14040595

Chicago/Turabian StyleXiao, Maohua, Yuxiang Zhao, Hongxiang Wang, Xiaomei Xu, Petr Bartos, and Yejun Zhu. 2024. "Design and Test of Hydraulic Driving System for Undercarriage of Paddy Field Weeder" Agriculture 14, no. 4: 595. https://doi.org/10.3390/agriculture14040595

APA StyleXiao, M., Zhao, Y., Wang, H., Xu, X., Bartos, P., & Zhu, Y. (2024). Design and Test of Hydraulic Driving System for Undercarriage of Paddy Field Weeder. Agriculture, 14(4), 595. https://doi.org/10.3390/agriculture14040595