An Integrated Potato-Planting Machine with Full-Film Mulching and Ridged Row Soil Covering

Abstract

:1. Introduction

2. Materials and Methods

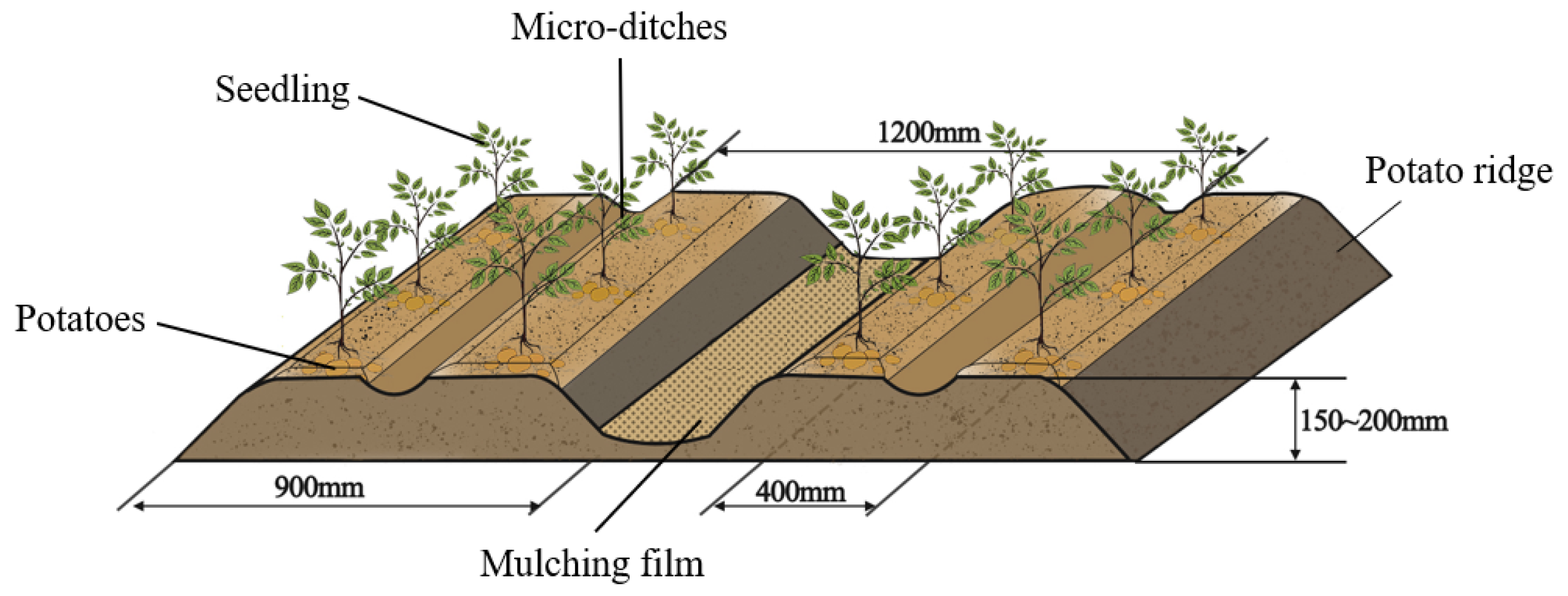

2.1. Potato Planting Requirements

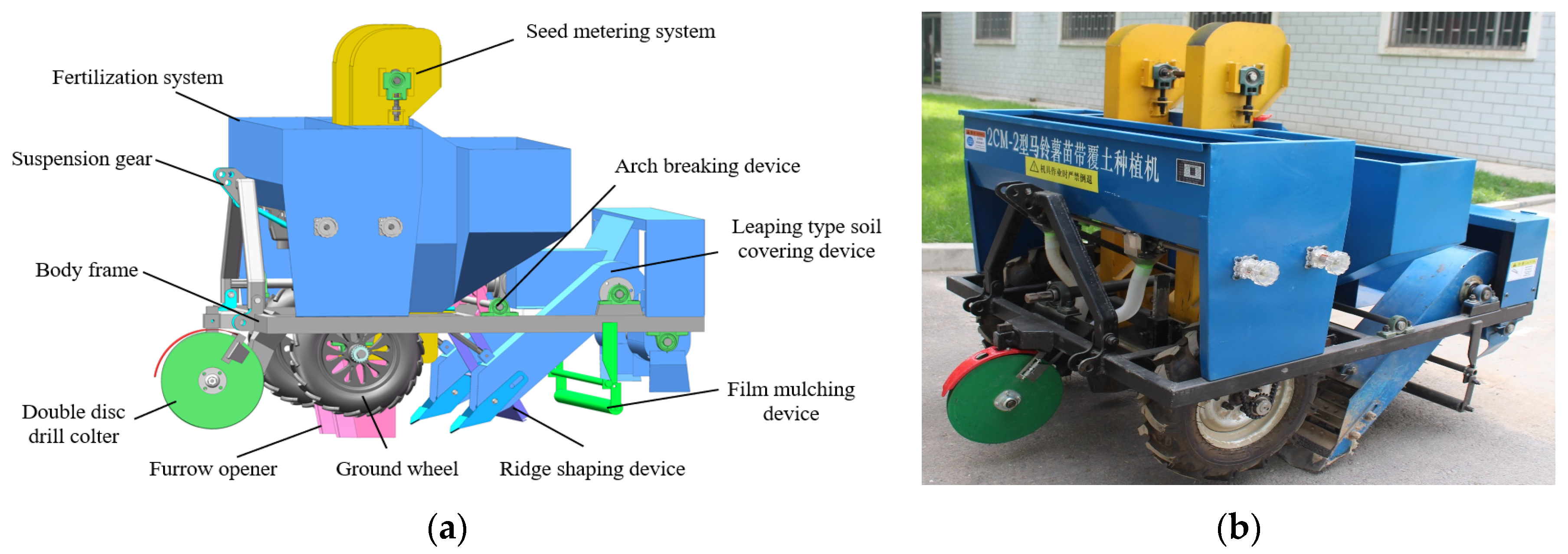

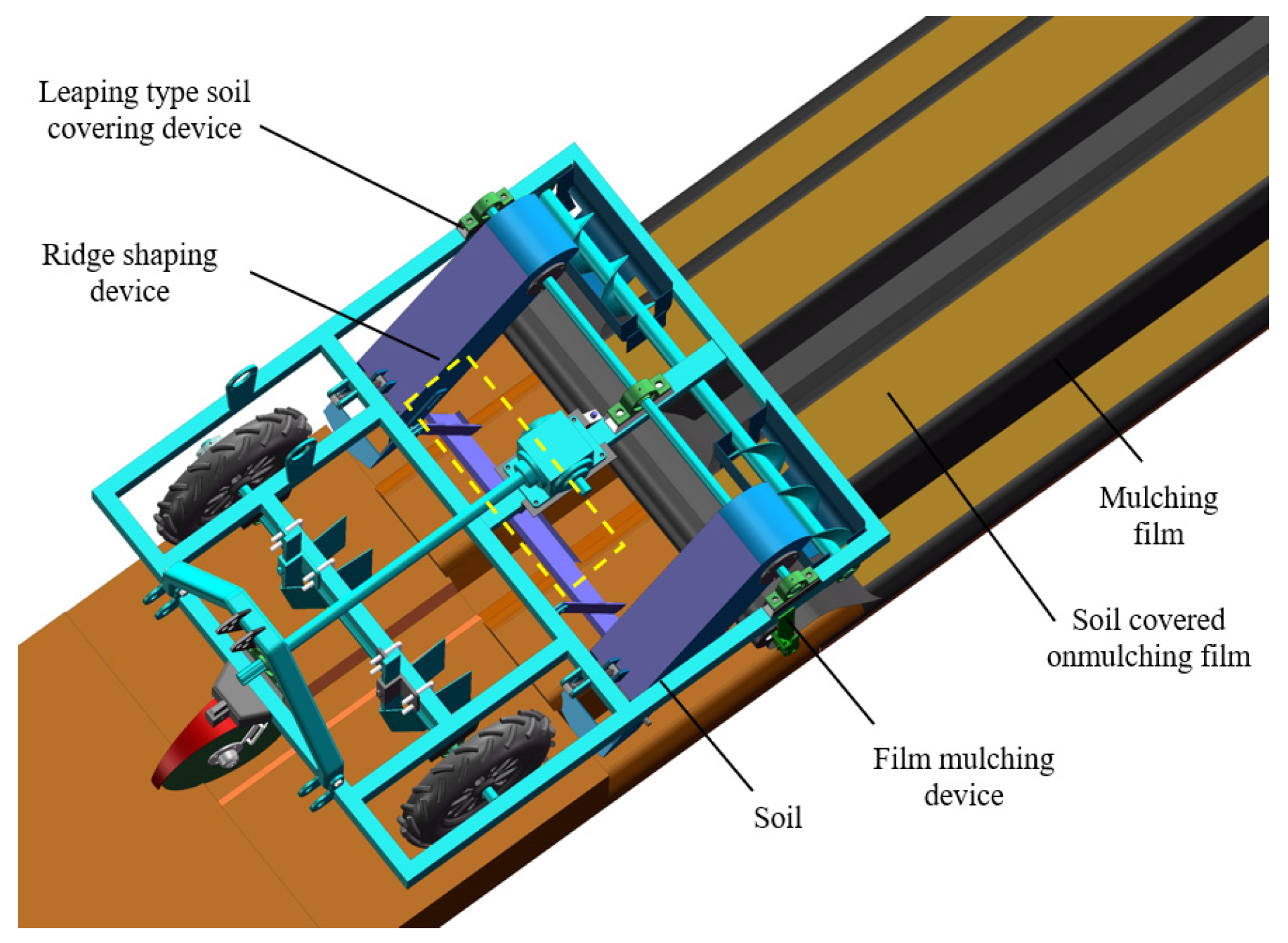

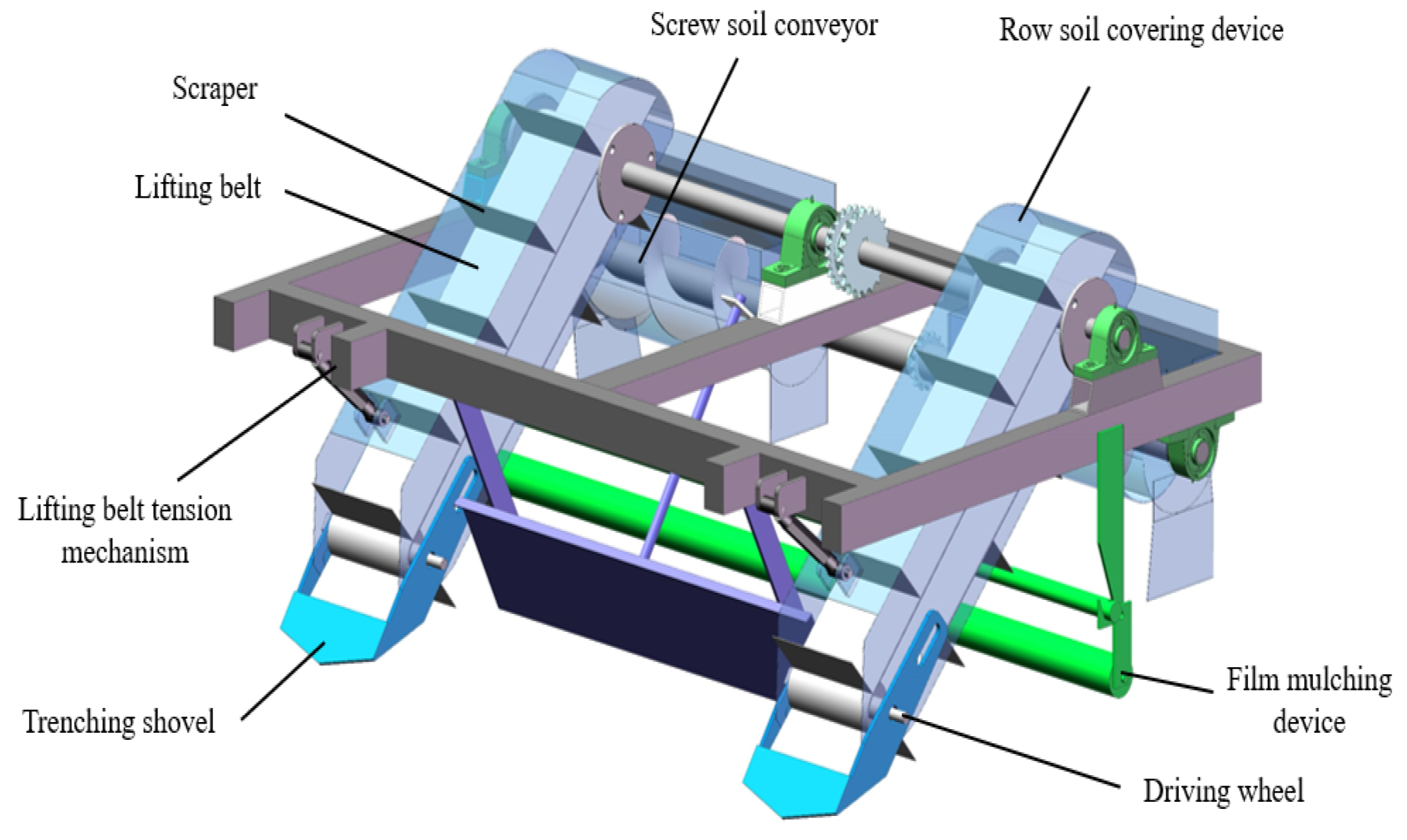

2.2. General Structure of Integrated Potato-Planting Machine with Full-Film Covering, Micro-Ditch on Ridges, and Soil Covering of Seed Rows

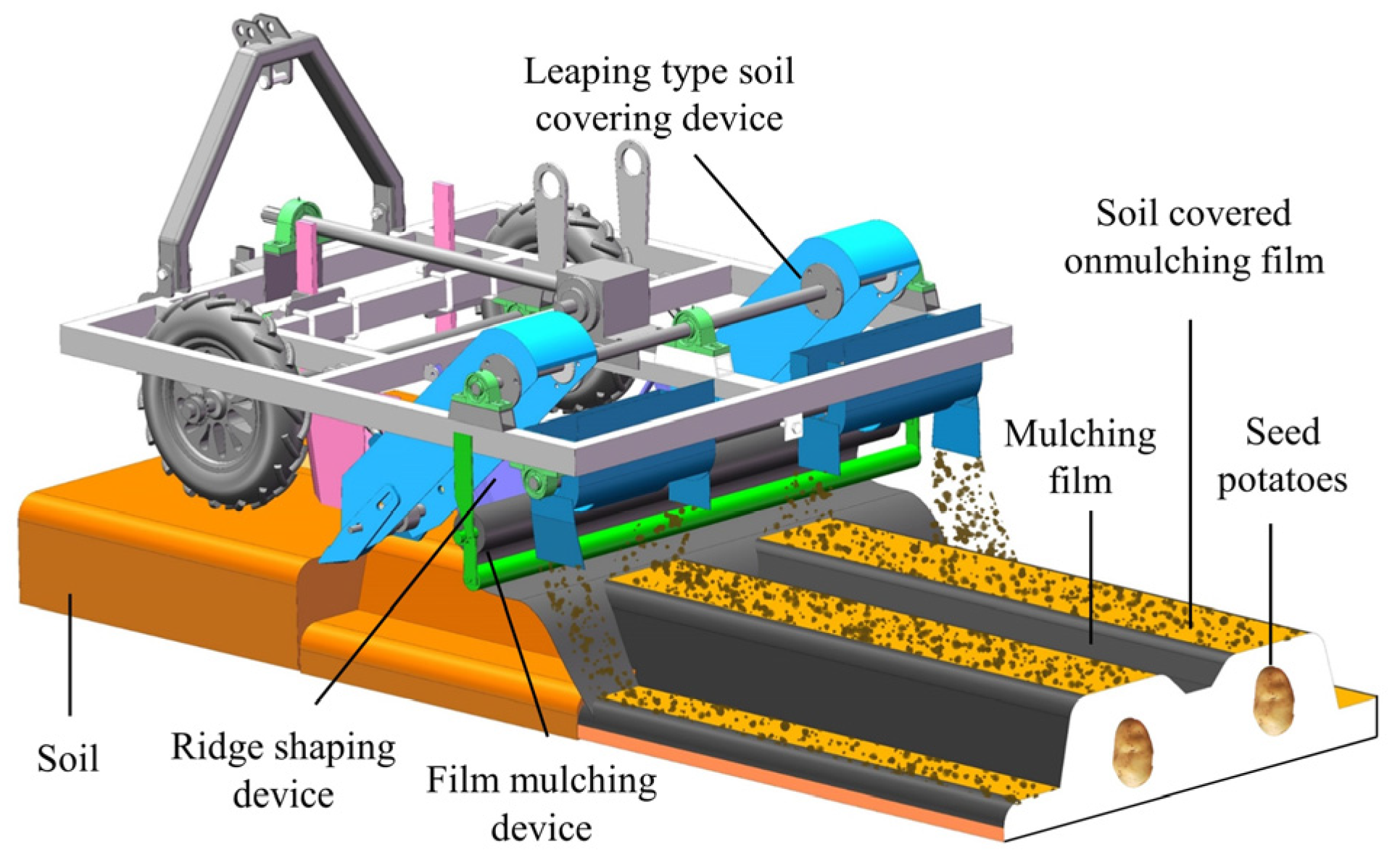

2.3. Principles of Operation

3. Design of Main Working Parts

3.1. Fertilizer Drainage System

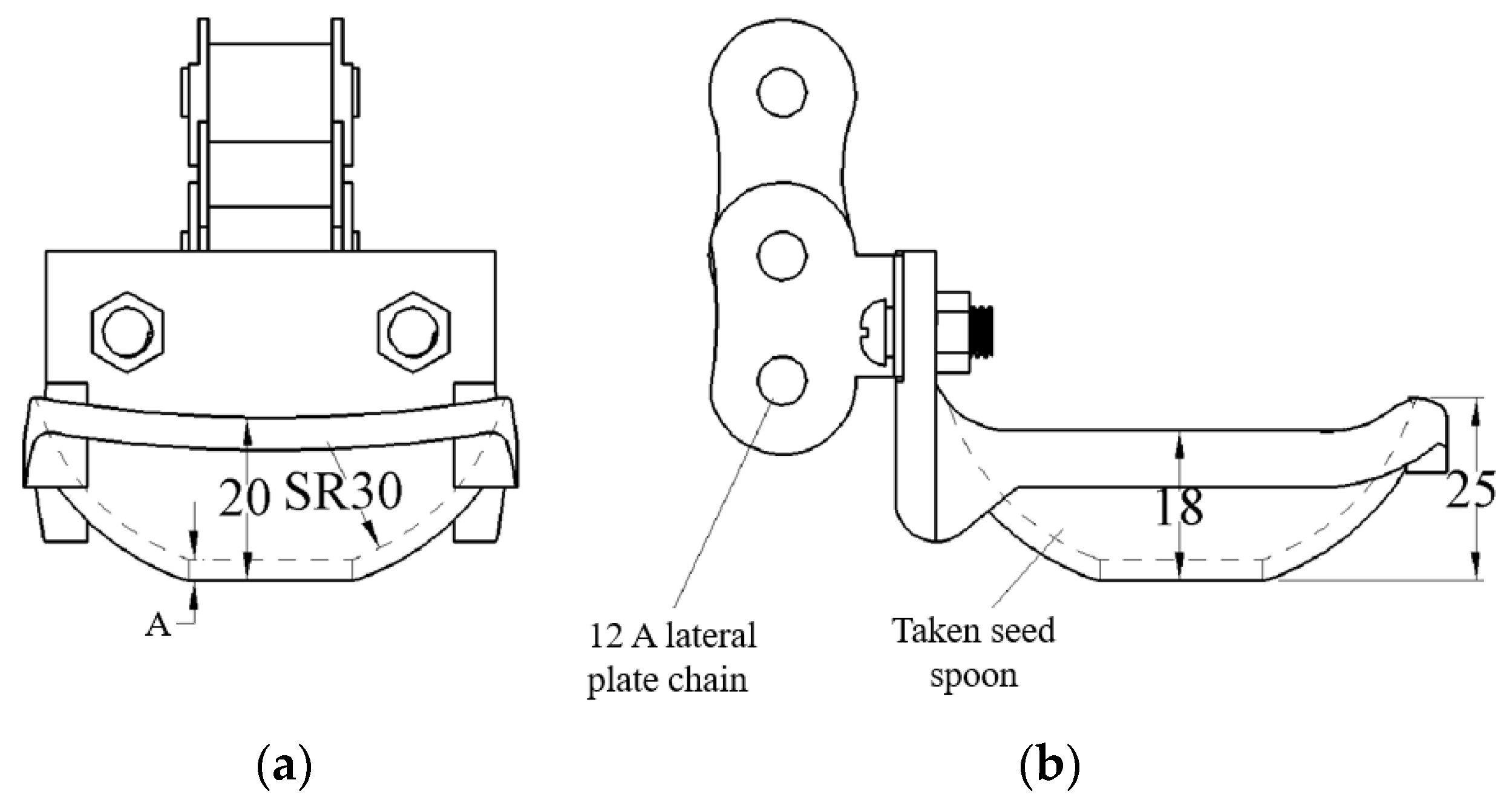

3.2. Seed Discharge Systems

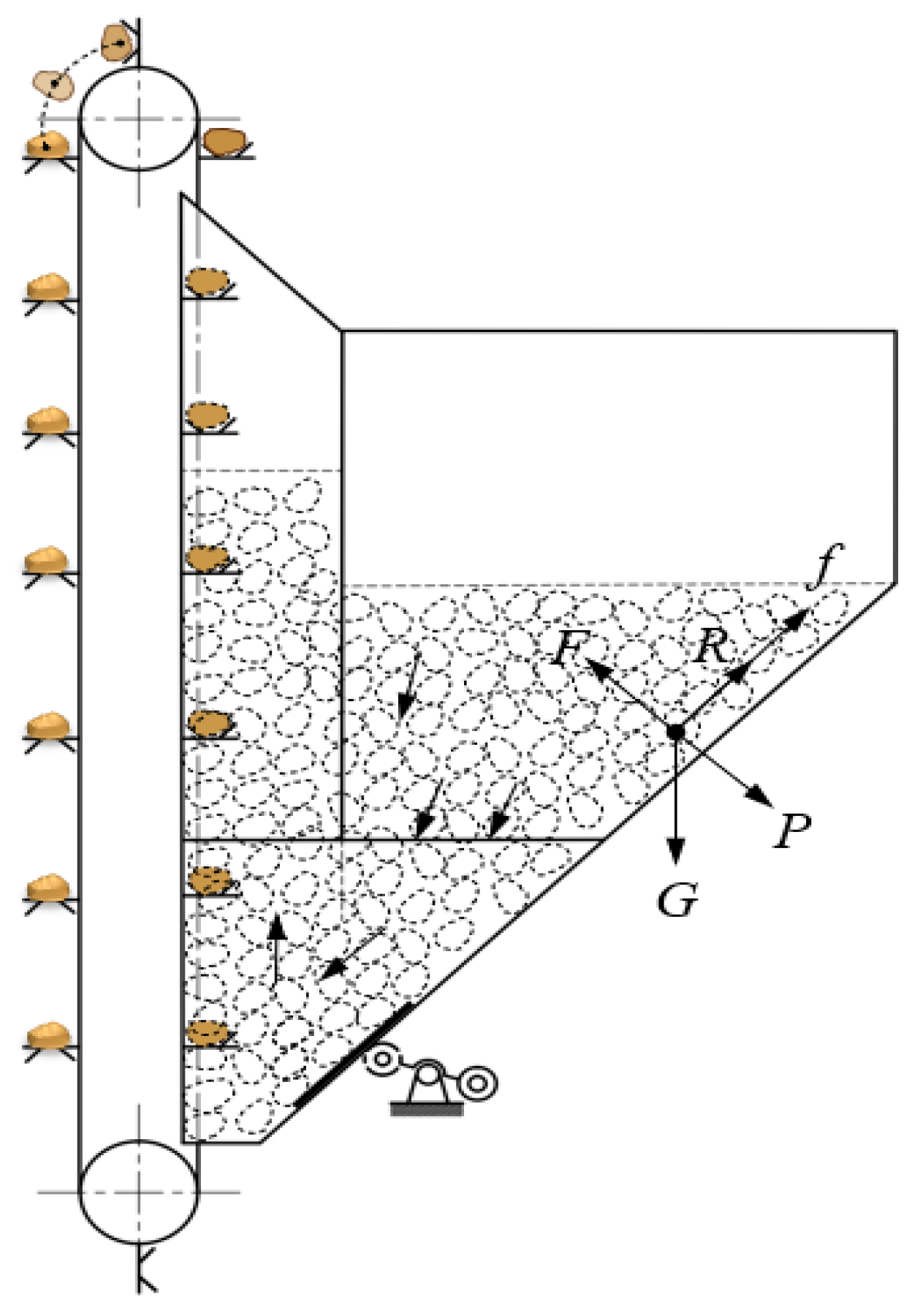

3.2.1. Trapezoidal Seed Boxes

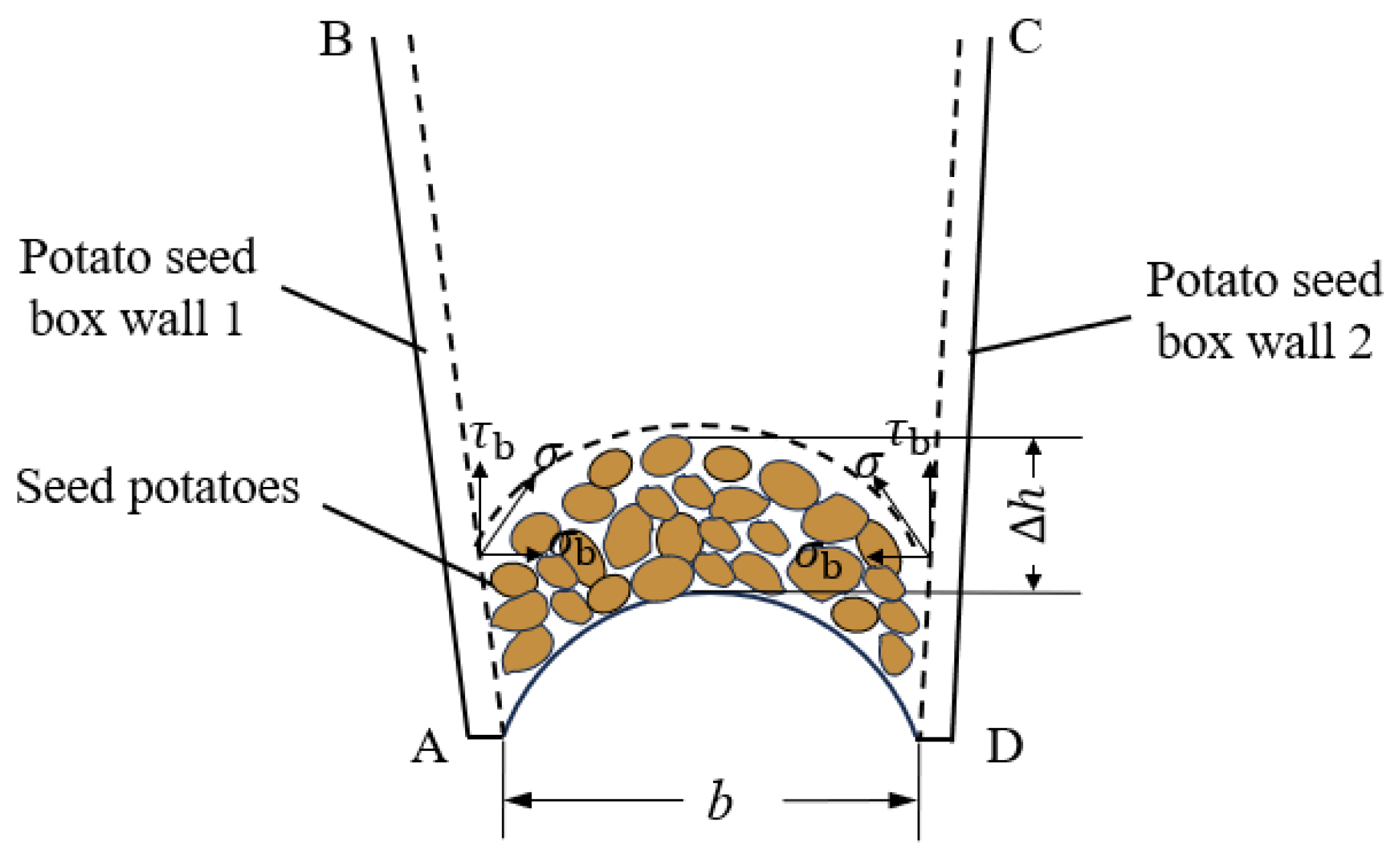

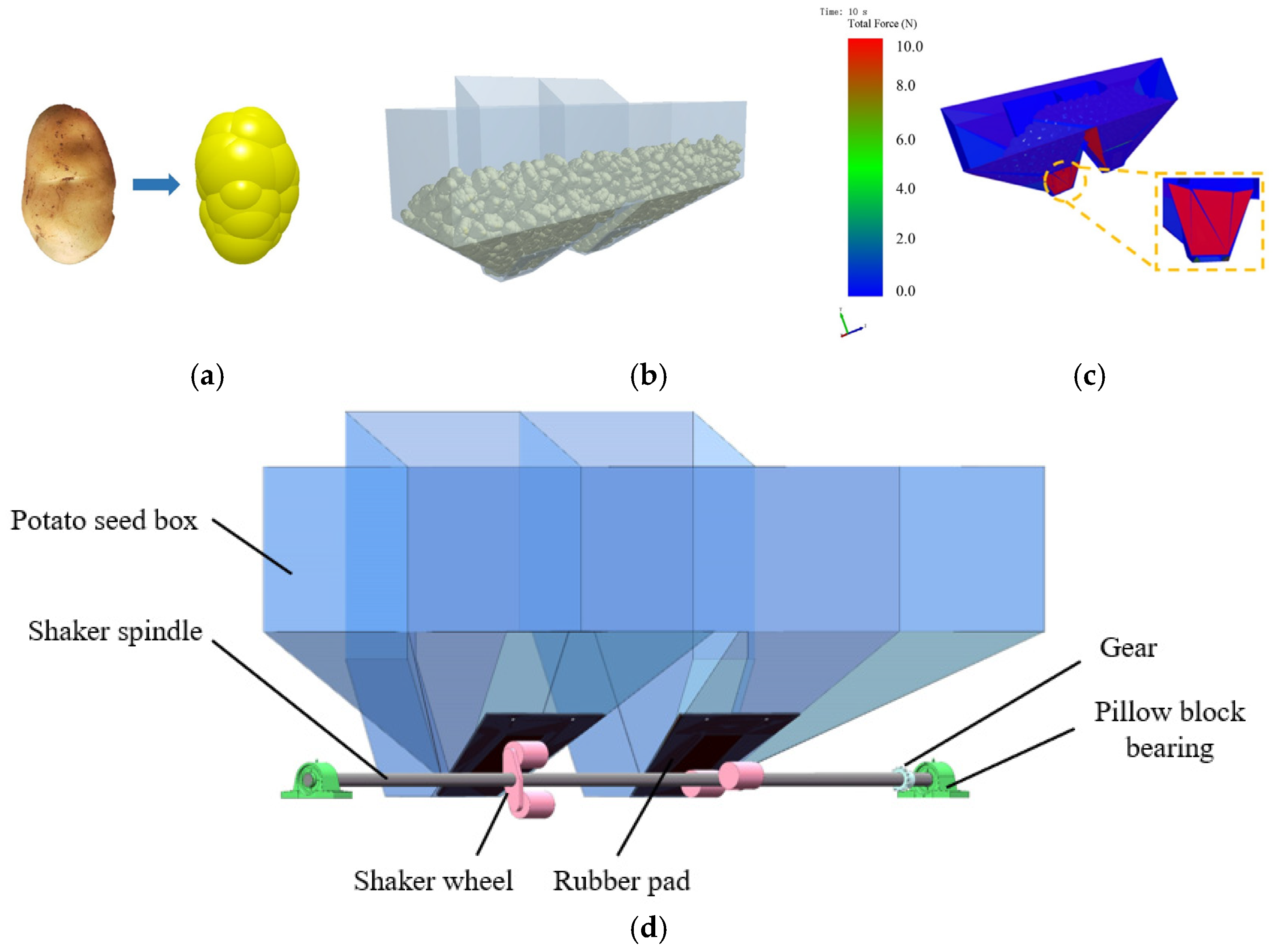

3.2.2. Arch Breakers

3.3. Sharp and Wing-Shaped Furrow Opener

3.4. Ridge-Shaping Device

3.5. Cross-Over Film-Mulching Device

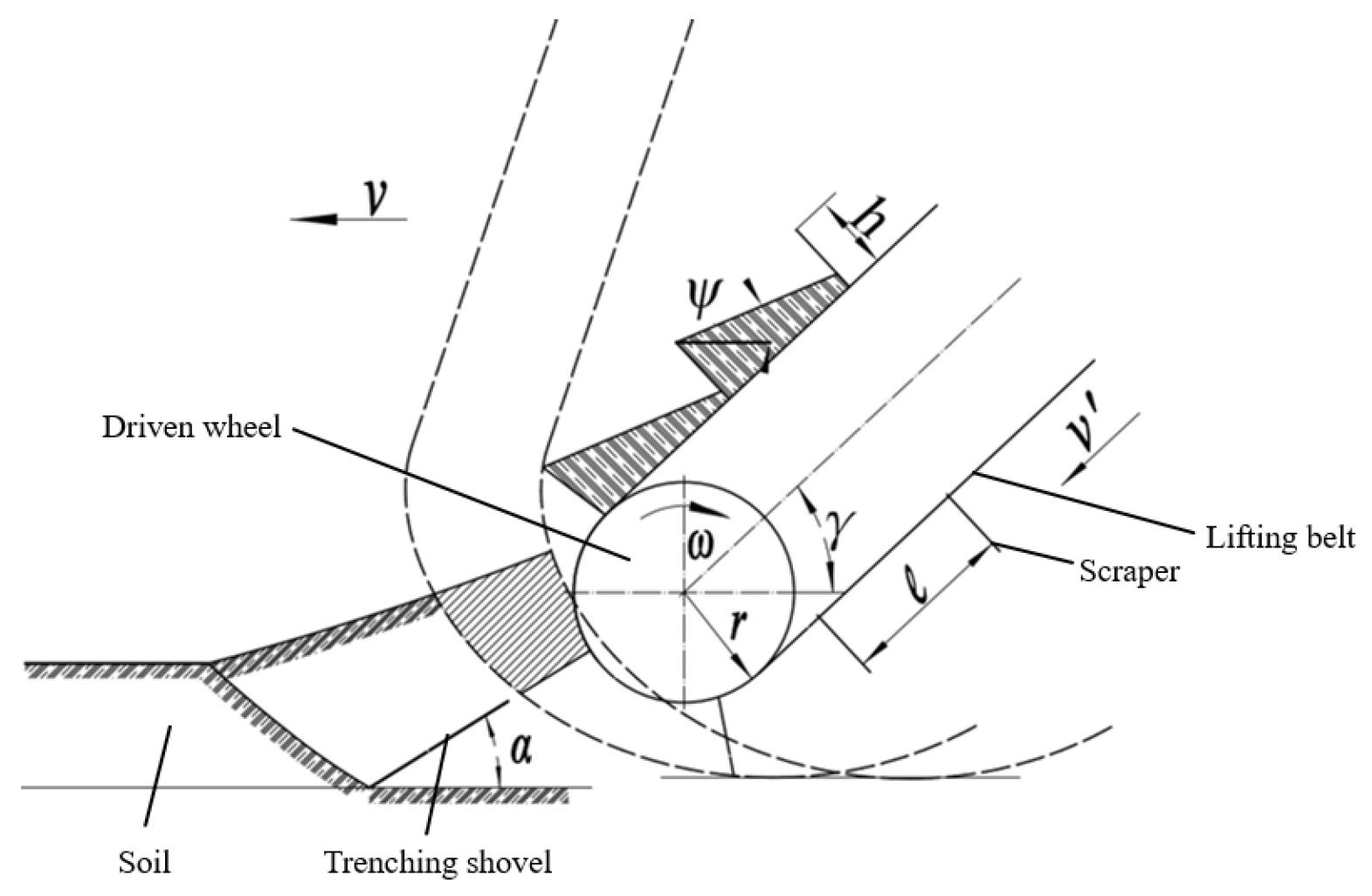

3.5.1. Trenching and Extraction Shovels

3.5.2. Scraper Lift Belt

3.5.3. Counter-Row Mulching Devices

4. Results

4.1. Experiment Conditions

4.2. Experiment Program and Methodology

5. Conclusions

- The main components of the prototype machine were thoroughly analyzed and designed. Specifically, the structure and working parameters of the seed discharge system, the sharp and wing-shaped furrow opener, and the straddling film-mulching device were meticulously determined. Additionally, the working mechanism of the core components was carefully analyzed. The designed straddle-type film-mulching device effectively meets the agronomic requirements of full-film seed row mulching. Furthermore, the seed discharge system consists of a seed replenishment box, a seed discharge box, and an arch-breaking device. This system has the ability to adjust the seed capacity of the seed discharge box, thereby enhancing the overall performance of the seed discharge system.

- The field trials have shown that the qualified rate of sowing depth under the film with the integrated machine for fertilizing, ridging, and full-film covering of seed rows and soil covering is 85%. The qualified index of seed potato spacing is 90%, the repetitive seeding index is 6%, and the missed seeding index is 3%. The qualified rate for seed row covering soil width is 94%, the qualified rate for seed row covering soil thickness is 93%, the qualified rate of adjacent row spacing is 88%, and the degree of mechanical damage to the light-transmitting surface of the mulch film is 30.2 mm/m2. All of the field performance experiment indexes meet the requirements of the national and industry standards.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, W.; Liu, X.L.; Zhang, H. Design of potato fertilization, sowing, ridge and full film mulching, seed row mulching. Trans. CSAE 2017, 20, 14–22. [Google Scholar]

- Jia, J.X.; Yang, D.Q.; Li, J.D. A review of potato cultivation agronomy and mechanized production technology. J. Agric. Mech. Res. 2010, 32, 1–6. [Google Scholar]

- Yang, L.S.; Wang, C.; He, P.H. Optimal Soil Thickness Test on Potato Film Overburden in Northwest China. J. Agric. 2016, 6, 60. [Google Scholar]

- Zhang, Y.L.; Wang, F.X. Influence of different plastic film mulches and wetted soil percentages on potato grown under drip irrigation. Agric. Water Manag. 2017, 180, 160–171. [Google Scholar] [CrossRef]

- Li, D.; Sun, W.; Shi, L.N. Parameter simulation design and experiment of crossing device of covering soil on film. Agric. Res. Arid Areas 2018, 36, 281–287. [Google Scholar]

- Liu, Q.; Sun, W.; Zhang, H.; Liu, X.; Li, H.; Simionescu, P.A. Numerical Simulation and Experiment of the Emergence of Young Potato Sprouts through Soil-covered Plastic Mulching. Agron. J. 2023, 115, 2791–2800. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, H.; Simionescu, P. Numerical Optimization and Experimental Validation of a Five-Link Mechanism, Potato Planter. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 6883–6892. [Google Scholar] [CrossRef]

- Sun, W. Study on Effect of the Potato Self-Puncture and the Full Film Covering Soil Technology; Gansu Agricultural University: Lan Zhou, China, 2014. [Google Scholar]

- Yang, L.; Xi, Z.; Li, L. Cultivation Technology of Potato High Ridge Film Covering Soil with Natural Broken Film and Seedling Emergence. China Veg. 2010, 11, 47–48. [Google Scholar]

- Mao, Q.; Xie, J.B.; Duan, H.B. Development Status and Future Forecast of Field Potato Sowing Mechanization at Home and Abroad. In Proceedings of the 2011 Annual Meeting of the Society for Agricultural Engineering, Chongqing, China, 21–24 October 2011; Chinese Society of Agricultural Engineering (CSAE): Beijing, China, 2011. [Google Scholar]

- Lv, J.Q.; Wang, Y.B.; Li, Z.H. Performance analysis and test of scooping spoon potato seeder with deflector. Trans. Chin. Soc. Agric. Eng. 2017, 33, 19–28. [Google Scholar]

- Lv, J.Q.; Yang, Y.; Shang, Q.Q. Optimization experiment of zero-speed seeding performance of positive pressure blowing of air-suction potato seeder. Trans. Chin. Soc. Agric. Eng. 2016, 32, 9. [Google Scholar] [CrossRef]

- Niu, K.; Yuan, Y.W.; Luo, M. Design and test of double-layer seed box potato chop device. Trans. Chin. Soc. Agric. Eng. 2016, 32, 32–39. [Google Scholar]

- Sun, W.; Shi, L.R.; Wang, D. Design and test of whole plastic-film mulching on double ridges potato planter. Energy Educ. Sci. Technol. Part A Energy Sci. Res. 2014, 32, 1317–1324. [Google Scholar]

- Duan, H.B.; Chen, Z.P.; Song, B.T. Design and experiment of triangle chain half cup spoon potato precision planter in hilly and mountainous areas. Chin. J. Agric. Mach. 2019, 50, 96–104. [Google Scholar]

- Yang, J.Z.; Lv, J.Q.; Li, X.M. Research of 2CMF-4 potato-planting machine with hanging configuration. J. Agric. Mech. Res. 2010, 32, 127–130. [Google Scholar]

- Zhao, M.Q.; Dou, W.G.; Zhao, S.J. The devolopment of the 2BSL-2 model of potato ridging planter. J. Inn. Mong. Agric. Univ. 2001, 22, 101–104. [Google Scholar]

- Dai, F.; Xin, S.L.; Zhao, W.Y. Design and experiment of combined potato planting machine for covering soil on top of full film surface. Trans. Chin. Soc. Agric. Mach. 2017, 48, 76–83. [Google Scholar]

- Ning, S.; Xu, T.S.; Song, L.T.; Wang, R.J.; Wei, Y.Y. Variable rate fertilization system with adjustable active feed-roll length. Int. J. Agric. Biol. Eng. 2015, 8, 19–26. [Google Scholar]

- Chinese Academy of Agricultural Mechanization. Agricultural Machinery Design Manual; China Machine Press: Beijing, China, 1988. [Google Scholar]

- Gao, X.; Hao, L. Study on fertilizer experiment of 2CMG-4 type potato planter. J. Agric. Mech. Res. 2016, 38, 205–208. [Google Scholar]

- Sun, W.; Wang, G.P.; Wu, J.M. Design and experiment on loss sowing testing and compensation system of spoon-chain potato metering device. Trans. Chin. Soc. Agric. Eng. 2016, 32, 8–15. [Google Scholar]

- Lv, J.Q.; Wang, P.R.; Yang, X.H. Design and experiment of seed clearing device of Scoop Type potato planter. Trans. Chin. Soc. Agric. Mach. 2019, 50, 51–60. [Google Scholar]

- Huang, S.Y. Granular Mechanics; China Machine Press: Beijing, China, 1993. [Google Scholar]

- Barletta, D.; Berry, R.J.; Larsson, S.H. Assessment on bulk solids best practice techniques for flow characterization and storage/handling equipment design for biomass materials of different classes. Fuel Process. Technol. 2015, 138, 540–554. [Google Scholar] [CrossRef]

- EDEM Software for Bulk and Granular Material Simulation, Altair, Troy, Michigan, USA. Available online: https://altair.com/edem/ (accessed on 10 April 2024).

- Shi, L.R.; Sun, W.; Zhao, W.Y. Parameter determination and verification of discrete element simulation model for mechanical seeding of potato. Trans. Chin. Soc. Agric. Eng. 2018, 34, 35–42. [Google Scholar]

- Dai, F.; Zhao, W.Y.; Song, X.F. Operating Parameter Optimization and Experiment of Device with Elevating and Covering Soil on Plastic-film. Trans. Chin. Soc. Agric. Mach. 2017, 48, 88–96. [Google Scholar]

- Wang, Y.; Sun, W.; Zhang, Y. Simulation of Soil Temperature Field of Potato Ridge Sowing with White Film Mulch and Soil Covering the Seed Band. Am. J. Potato Res. 2020, 97, 405–419. [Google Scholar] [CrossRef]

- Sun, W.; Liu, X.L.; Shi, L.R. Covering soil on plastic-film characteristics of scraper lifting belt mechanism. J. Mech. Eng. 2016, 52, 38–45. [Google Scholar] [CrossRef]

- Agricultural Machinery College. Agricultural Machinery; China Agricultural Machinery Press: Beijing, China, 1981. [Google Scholar]

- NY/T 1415-2007; Technical Specification for Quality Evaluation of Potato Planter. Standards of China: Beijing, China, 2007.

- GB/T 25417-2010; Technical Conditions for Potato-Planting Machines. Standards of China: Beijing, China, 2010.

- NY/T 987-2006; Operation Quality of Film Mulching Hole Seeder. Standards of China: Beijing, China, 2006.

- Liu, Q.; Sun, W.; Wang, H.; Meng, Y. Design and Field Test of a Leaping Type Soil-Covering Device on Plastic Film. Agriculture 2023, 13, 1680. [Google Scholar] [CrossRef]

- Sun, W.; Simionescu, P.A. Parameter Analysis and Field Tests of a Double Crank Multi-Rod under Plastic-Film Hill-Drop Mechanism Potato Planter. Am. J. Potato Res. 2020, 97, 256–264. [Google Scholar] [CrossRef]

| Material Parameter | |||

| Materials | Density | Shear Modulus | Poisson Ratio |

| Potato seed | 1048 | 1.366 | 0.57 |

| Seed box (steel plate) | 7800 | 70,000 | 0.30 |

| Contact Parameter | |||

| Collision Form | Collision Recovery Coefficient | Static Friction Factor | Dynamic Friction Factor |

| Plant potatoes and plant potatoes | 0.79 | 0.452 | 0.242 |

| Plant potato and seed box | 0.71 | 0.445 | 0.269 |

| Index | Potato Planter Prototype | 2CM-2 Potato Planter | Technical Requirement |

|---|---|---|---|

| Qualified rate of sowing depth (%) | 85.0 | 84.0 | ≥80.0 |

| Qualified index of seed tuber spacing (%) | 90.0 | 87.0 | ≥85.0 |

| Reseeding index (%) | 6.0 | 7.0 | ≤20.0 |

| Miss-seeding index (%) | 3.0 | 4.2 | ≤10.0 |

| Qualified rate of soil width covered on planting line (%) | 94.0 | — | ≥90.0 |

| Qualified rate of soil depth covered on planting line (%) | 93.0 | — | ≥90.0 |

| Qualified rate of adjacent row spacing (%) | 88.0 | — | ≥80.0 |

| Damage degree of plastic film (daylight passing/surface area, mm/m2) | 30.2 | 51.3 | ≤55.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Sun, W.; Wang, H.; Wang, J.; Simionescu, P.A. An Integrated Potato-Planting Machine with Full-Film Mulching and Ridged Row Soil Covering. Agriculture 2024, 14, 860. https://doi.org/10.3390/agriculture14060860

Li J, Sun W, Wang H, Wang J, Simionescu PA. An Integrated Potato-Planting Machine with Full-Film Mulching and Ridged Row Soil Covering. Agriculture. 2024; 14(6):860. https://doi.org/10.3390/agriculture14060860

Chicago/Turabian StyleLi, Jianwei, Wei Sun, Hucun Wang, Juanling Wang, and Petru A. Simionescu. 2024. "An Integrated Potato-Planting Machine with Full-Film Mulching and Ridged Row Soil Covering" Agriculture 14, no. 6: 860. https://doi.org/10.3390/agriculture14060860

APA StyleLi, J., Sun, W., Wang, H., Wang, J., & Simionescu, P. A. (2024). An Integrated Potato-Planting Machine with Full-Film Mulching and Ridged Row Soil Covering. Agriculture, 14(6), 860. https://doi.org/10.3390/agriculture14060860