The Design and Testing of a Combined Operation Machine for Corn Straw Crushing and Residual Film Recycling

Abstract

:1. Introduction

2. Machine Structure and the Working Principle

2.1. Corn Semi-Film Flat Planting Agronomic Model and Residual Film Recovery Conditions

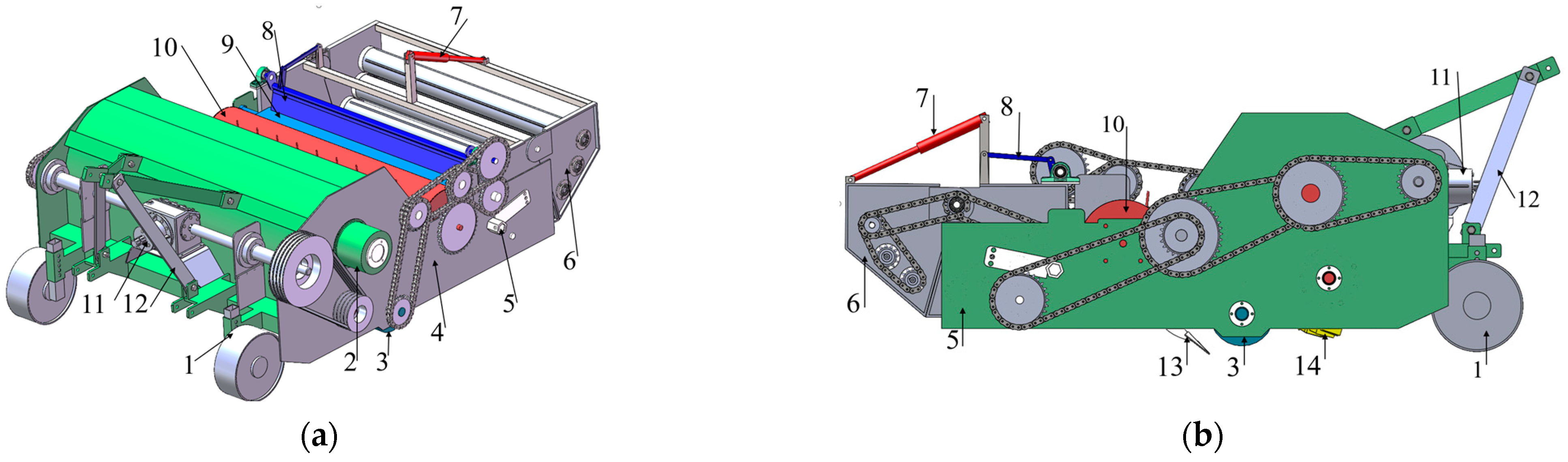

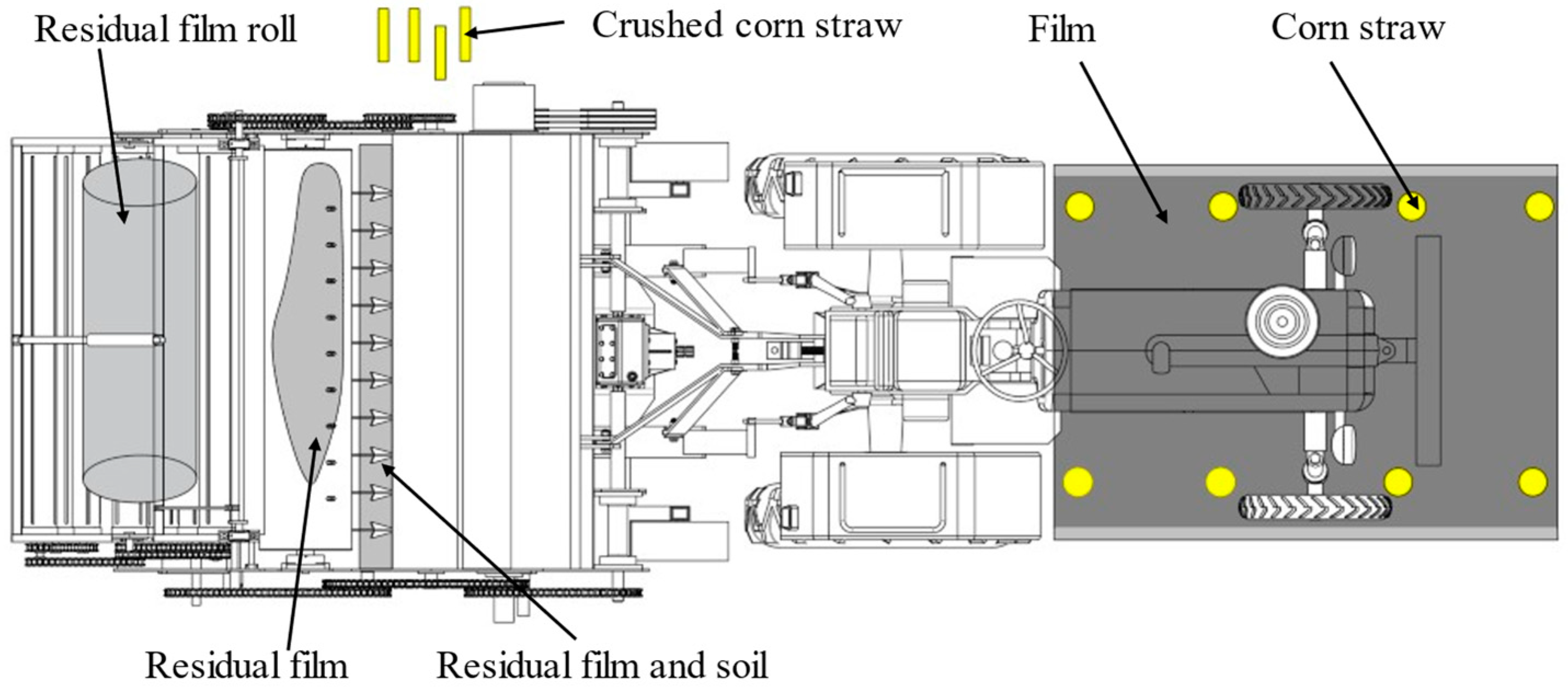

2.2. Overall Structure and Main Parameters

2.3. The Working Principle

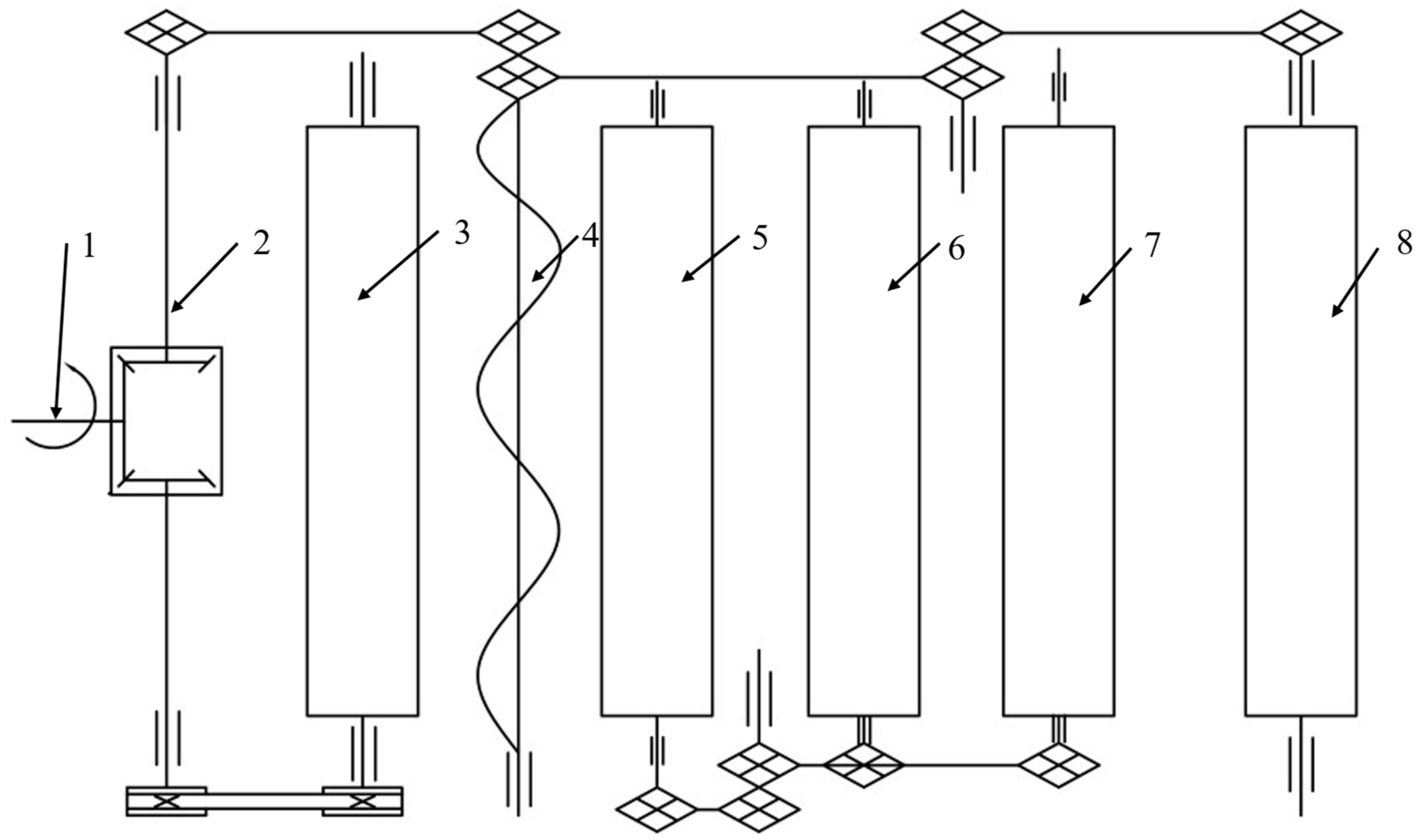

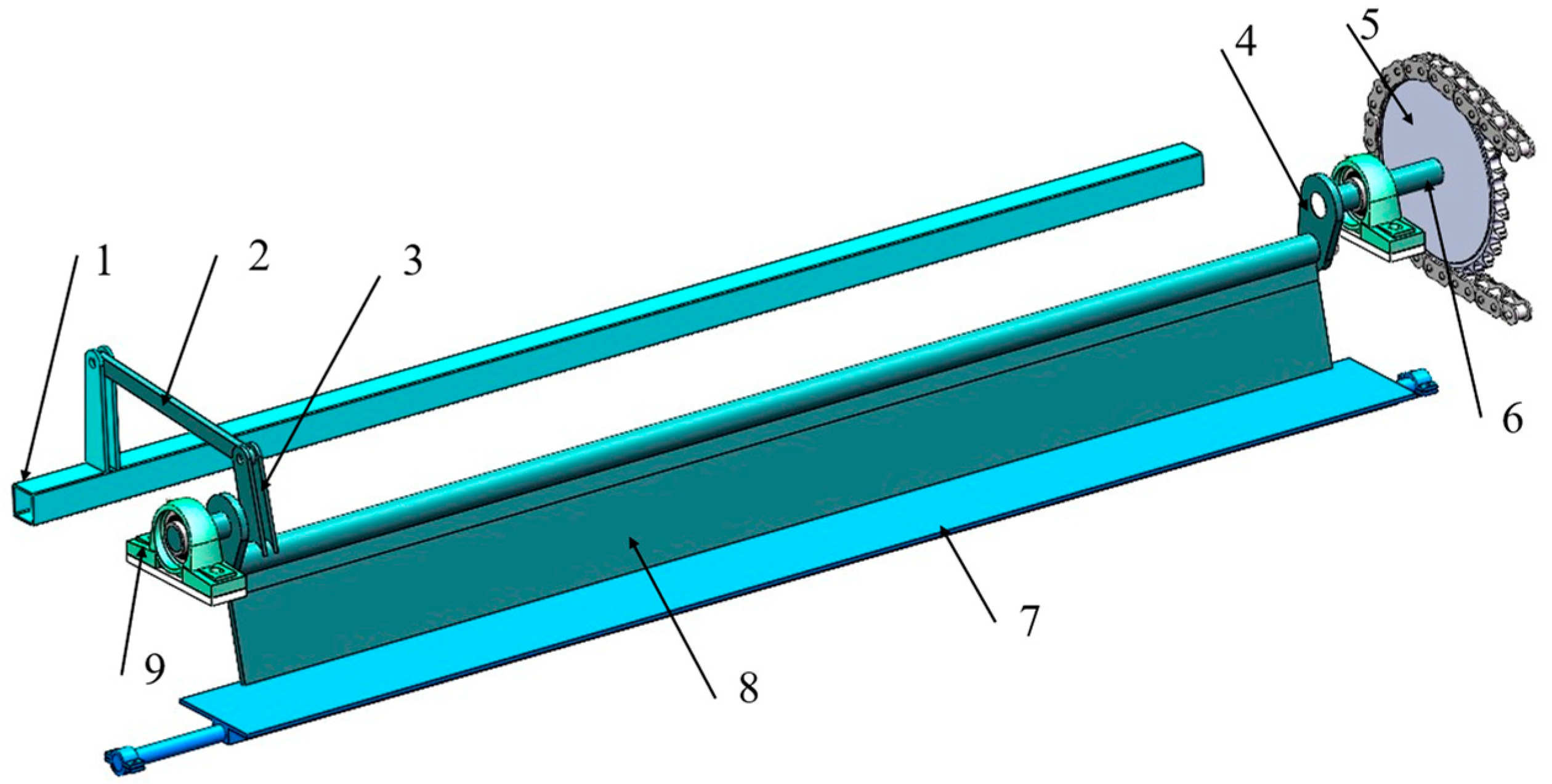

2.4. The Transmission System

3. Key Mechanical Structure Design and Parameterization

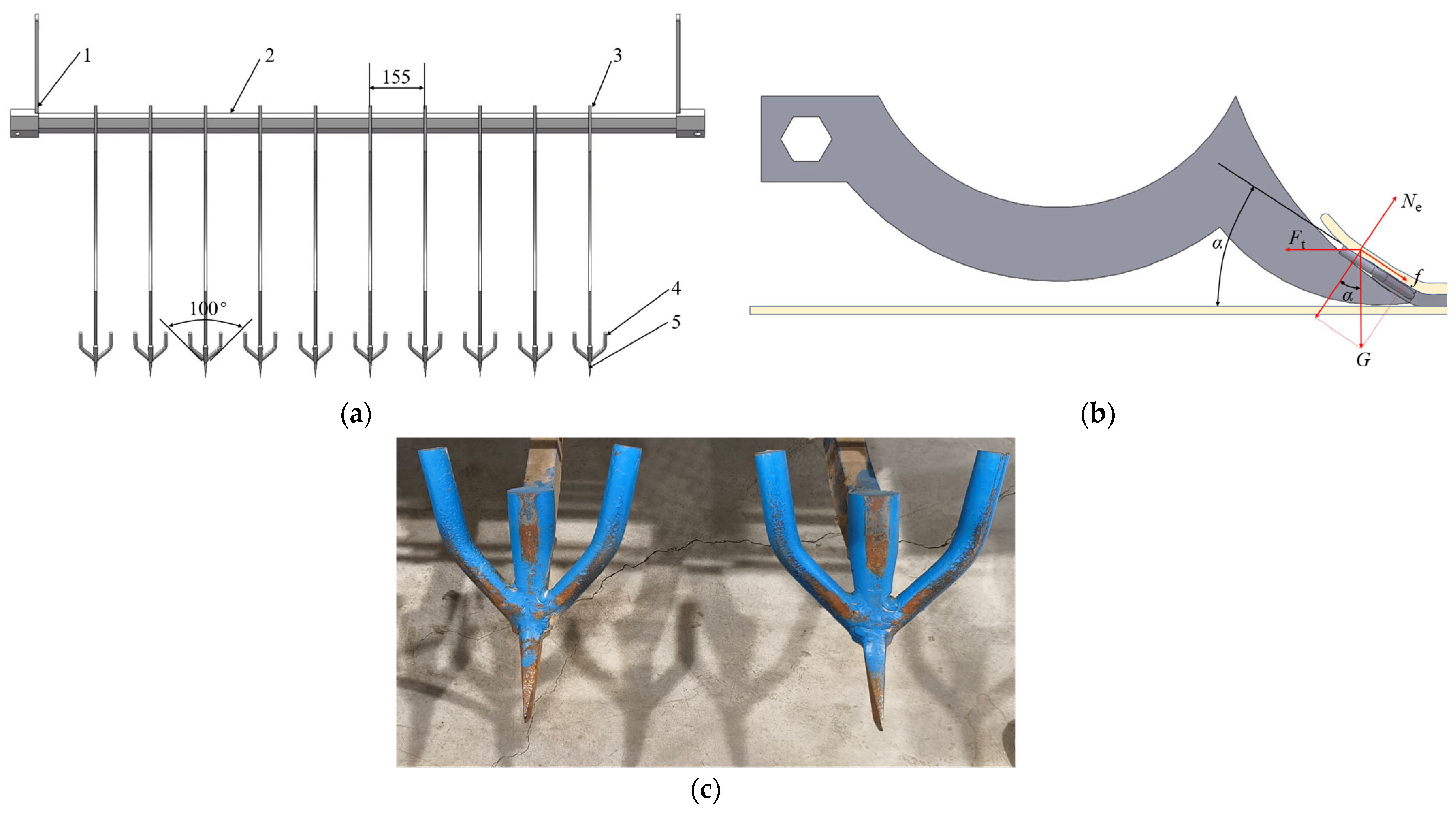

3.1. Corn Straw-Crushing and Returning Device

3.2. Residual Film Recycling Device

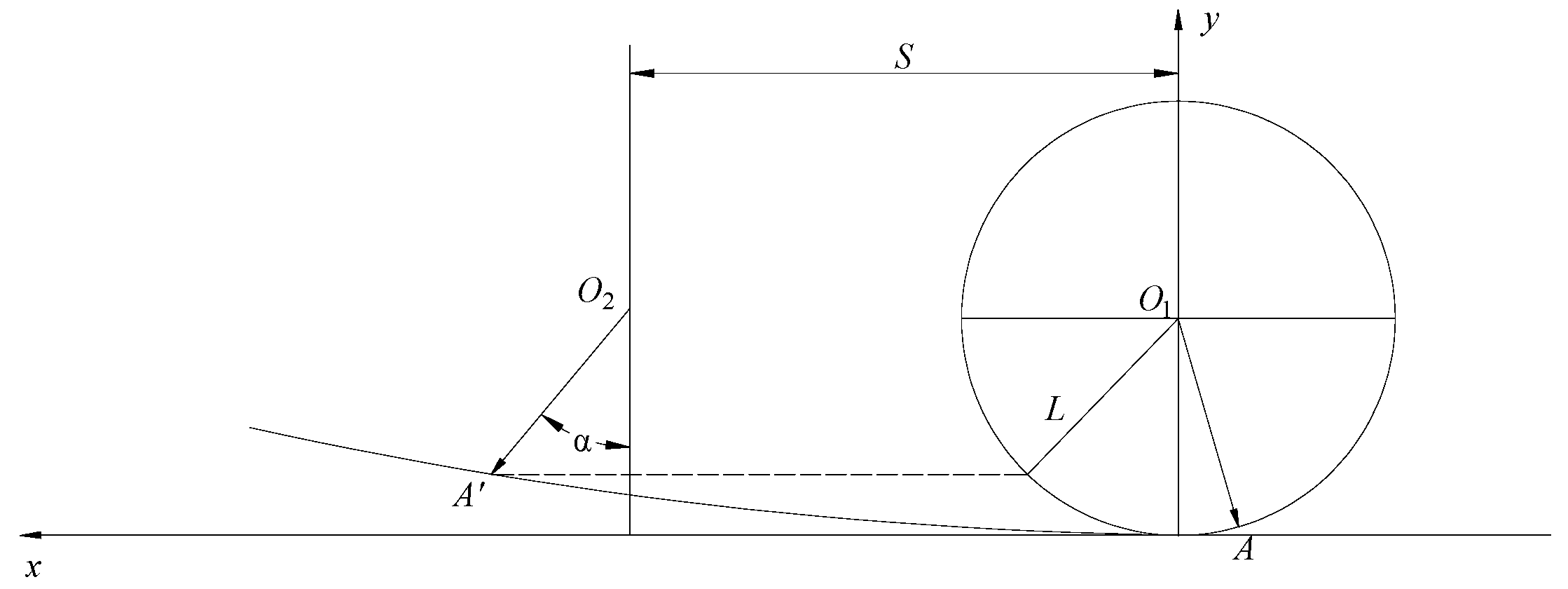

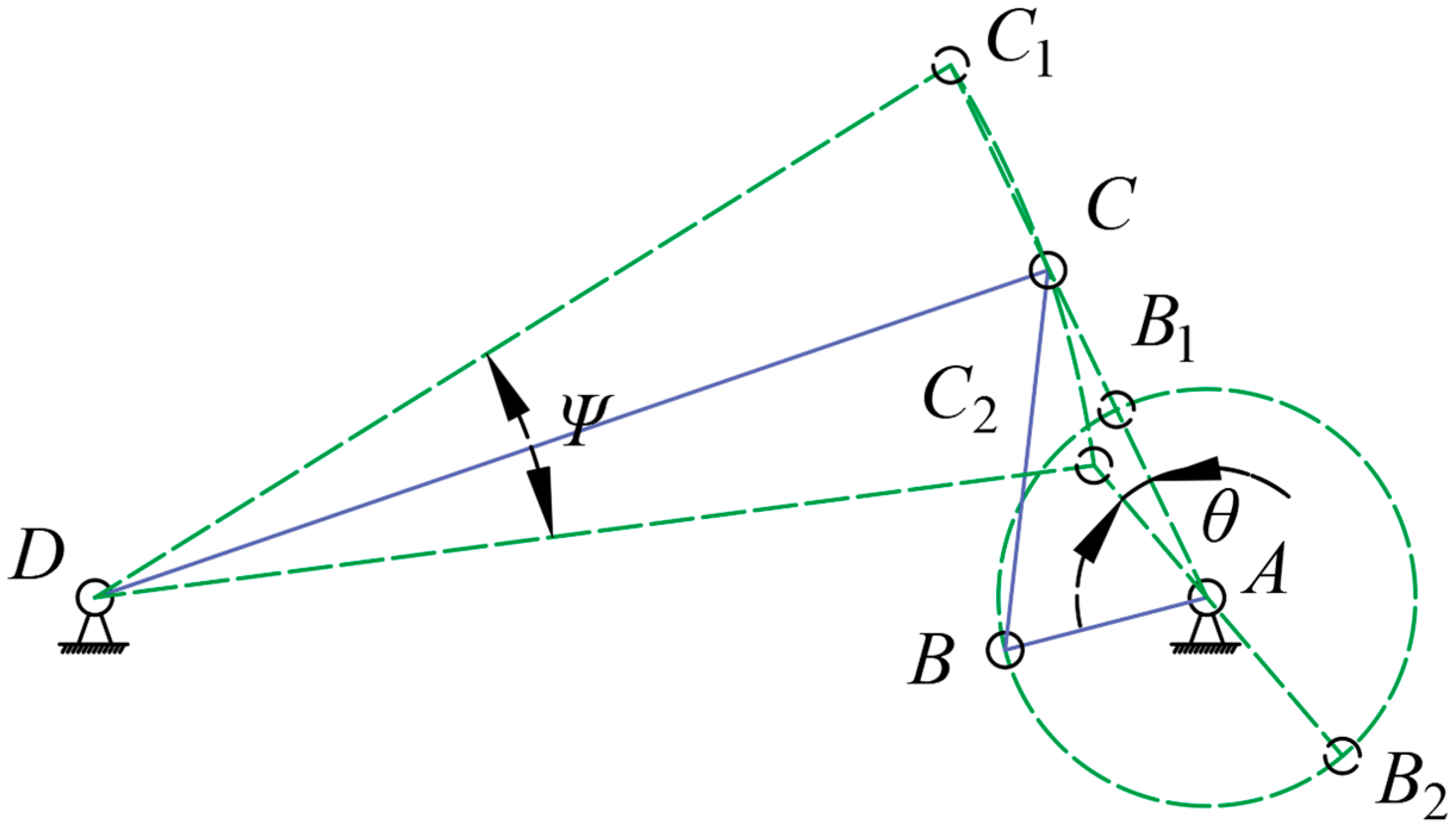

3.2.1. Film-Lifting Device

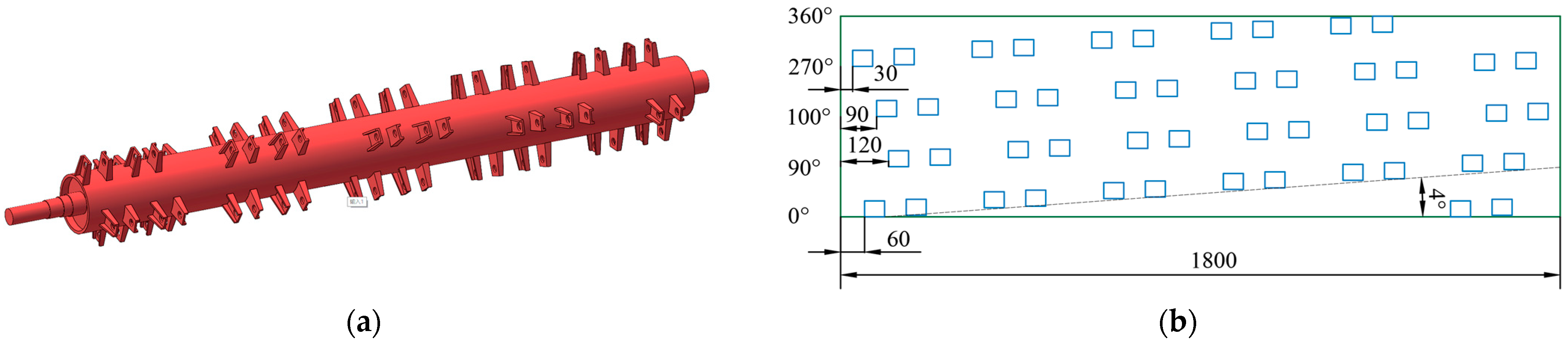

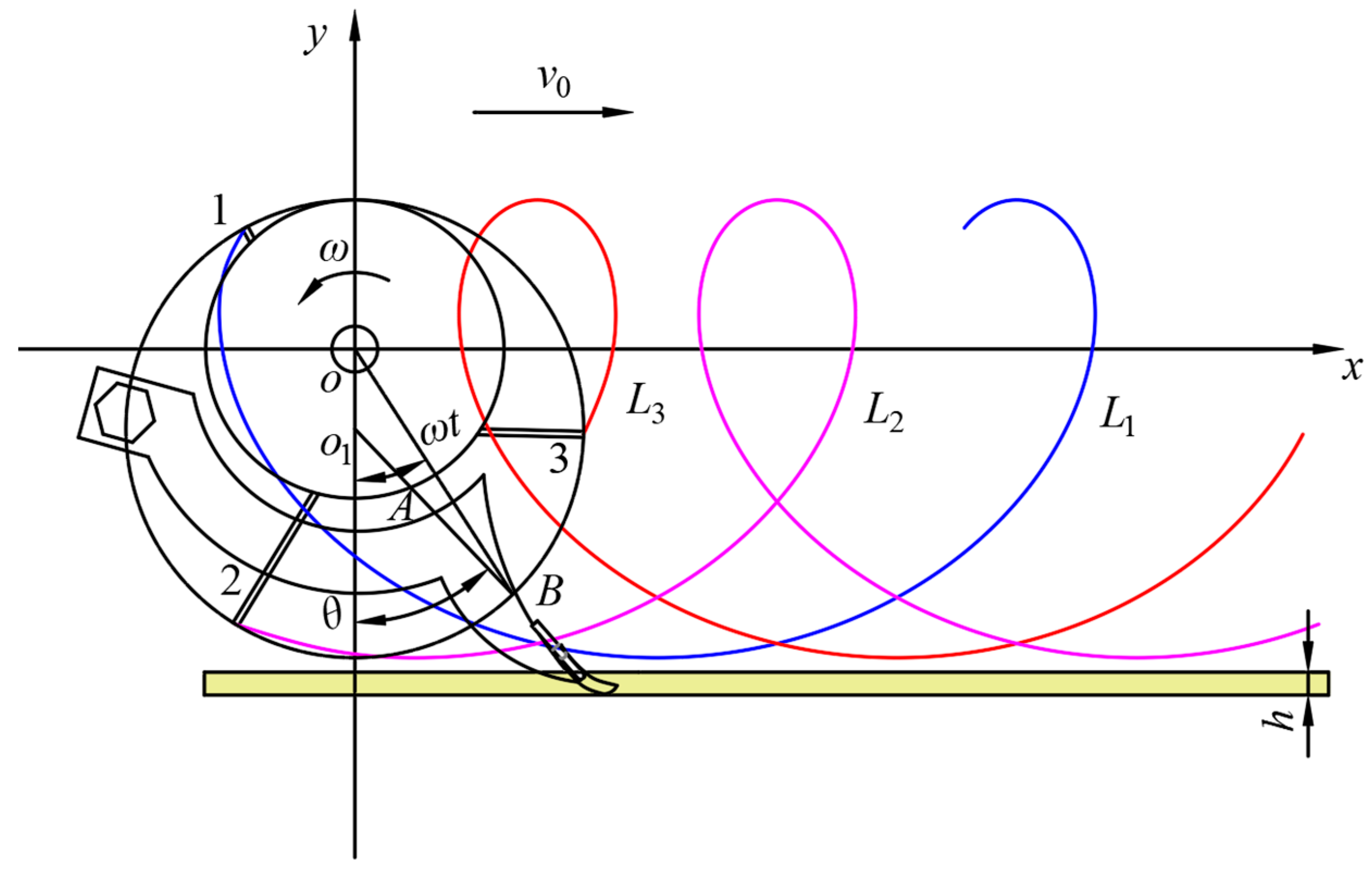

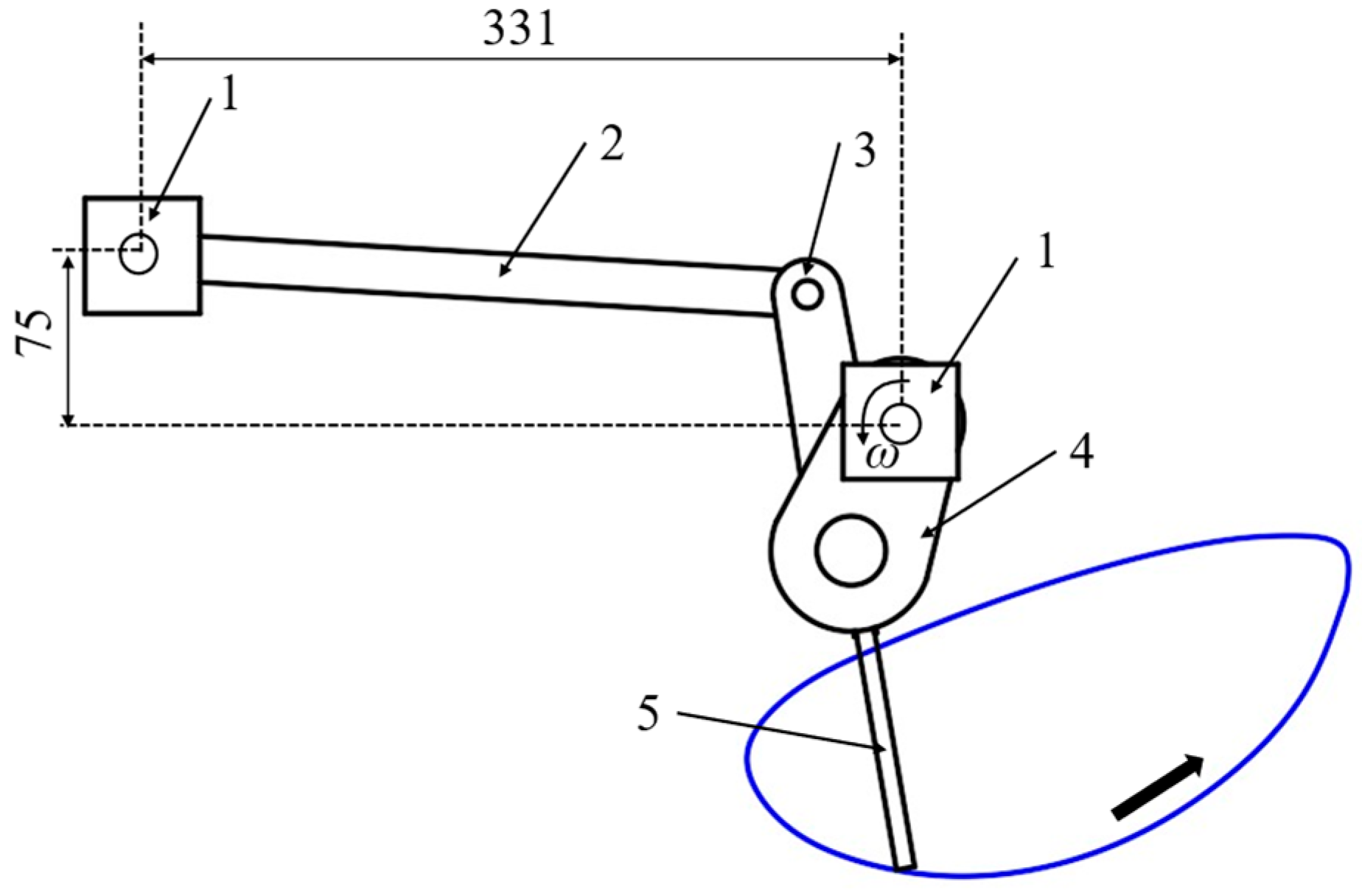

3.2.2. Film-Picking Device

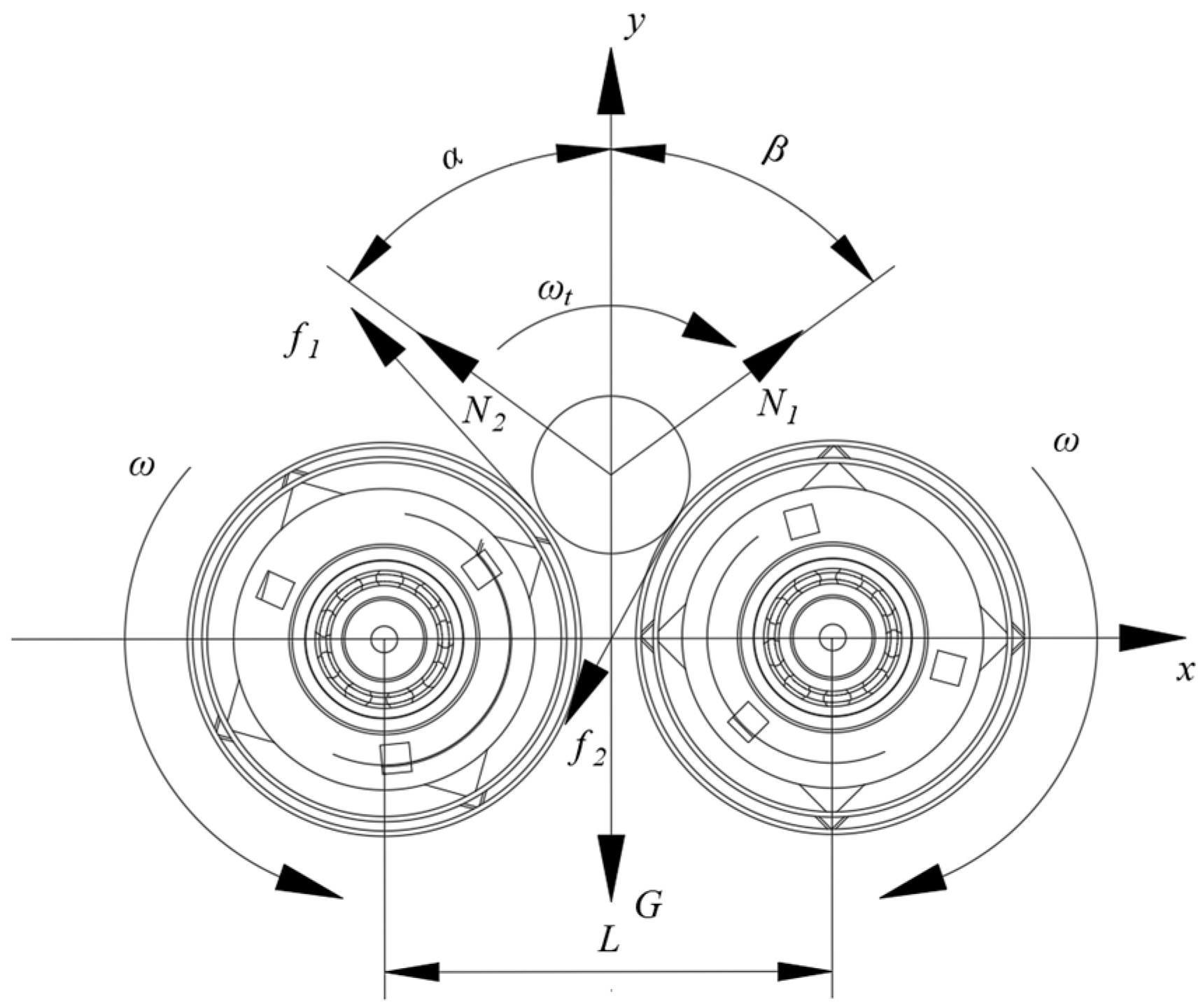

3.2.3. Film-Shifting Device

3.3. Film-Collecting Device

4. Results

4.1. Experimental Conditions

4.2. Test Factors and Test Indicators

4.3. Test Results and Analysis

4.3.1. Test Results

4.3.2. Experimental Regression Analysis

4.4. Analysis of the Influence of Interaction Factors on the Working Performance of the Machine

4.5. Parameter Optimization and Experimental Validation

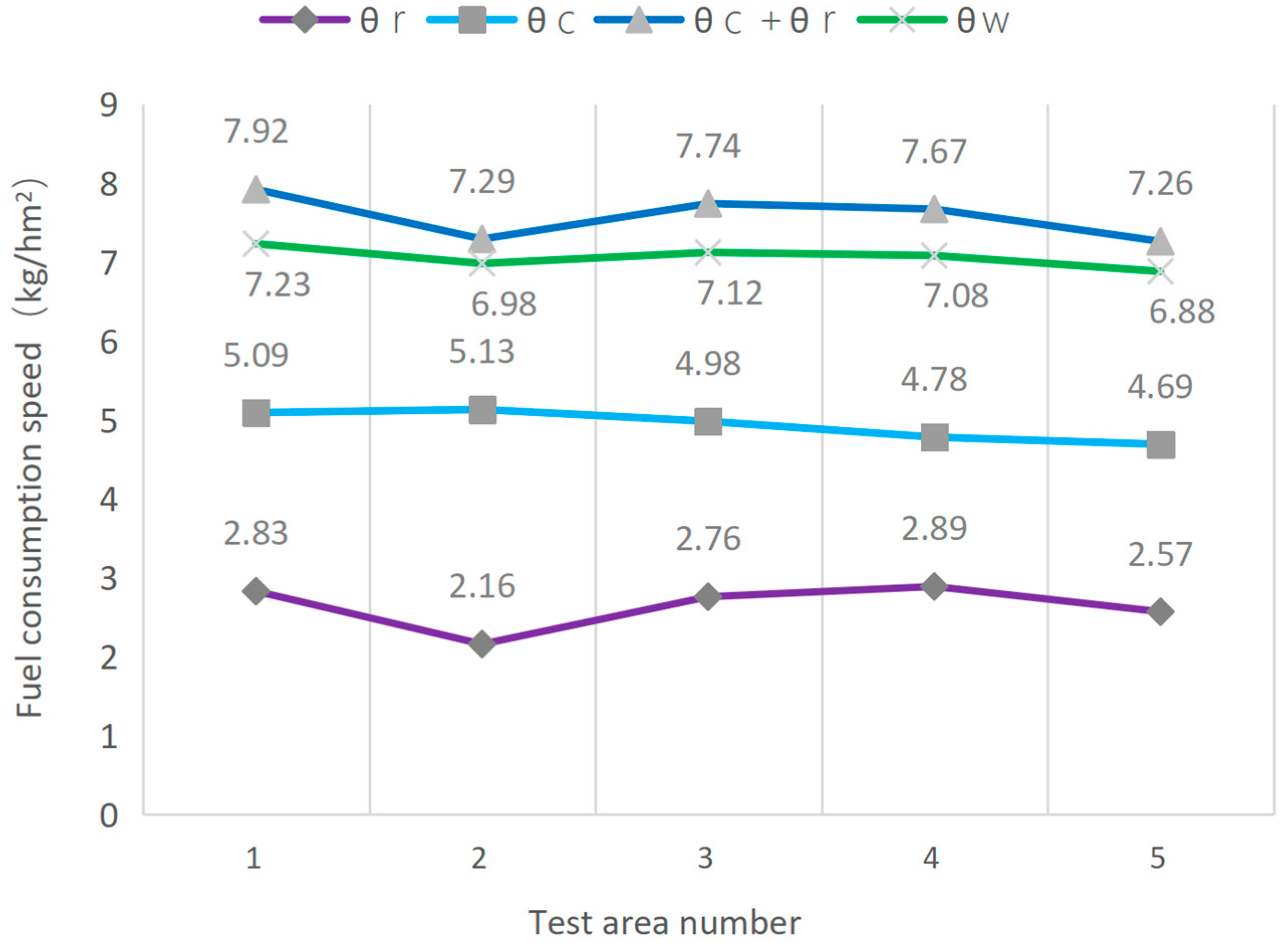

4.6. The Power Consumption Test

4.7. The Component Durability Test

5. Conclusions

- (1)

- This study addressed the negative impact of large corn stubble crops on residual film recovery in the Hexi irrigation area and designed a combined operation machine that can complete the tasks of corn straw crushing and returning, residual film recovery, and film impurity separation in a single operation. The working parameters of this machine meet agronomic requirements and can solve the problem of residual film recovery in large corn stubble crops in the Hexi irrigation area.

- (2)

- Through theoretical analysis, motion simulation, and performance testing, the structure and working parameters of key components such as the corn straw-crushing and returning device, the film-lifting device, the eccentric teeth shifting cylinder, the film-shifting device, and the film-collecting device were determined.

- (3)

- Using Design-Expert software, and setting the residual film recovery rate as the optimization objective, the optimal working parameters were determined: a film-lifting shovel insertion angle of 25.14°, an eccentric teeth shifting cylinder rotational speed of 80.96 r/min, and a machine operating speed of 4.03 km/h. The operating parameters were adjusted according to the actual situation, and then field tests were carried out. The results indicated a residual film impurity rate of 16.65%, a qualified rate of corn straw crushing of 88.51%, a residual film recovery rate of 91.96%, and a relative error between the tested and optimized values of 0.65%. Good durability of the key components and stable and reliable performance of the whole machine were achieved.

- (4)

- The machine improves working efficiency, reduces labor and impurities in recovered residual film, and meets market demand, thus bringing significant economic and ecological benefits.

- (5)

- The whole machine was noisy during operation, and after the operation’s completion, the residual film breakage rate was high, and there was a small amount of residual film on the film-shifting device. Most of the parameters of the machine are based on theoretical calculations. Future research will validate the operational parameters of the machine via simulation, enhance machine performance in different environments, optimize the structure to reduce noise and improve operational performance, expand the functions of the machine to meet the needs of mechanization of residual film recycling on a large scale, and contribute to the sustainable development and modernization of green agriculture.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Saputra, H.; Arief Soleh, M.; Sauman Hamdani, J.; Sayoko, A. The potential and differences between mulch and organic matter in reducing drought stress in plants–A review. Cogent Food Agric. 2025, 11, 2454342. [Google Scholar] [CrossRef]

- Liu, Z.Q.; Han, Y.Z. Application of Plastic Film Mulching on Agricultural Production. J. Liaoning Agric. Sci. 2024, 82–86. [Google Scholar]

- Zhao, Y.; Chen, X.G.; Wen, H.J.; Zheng, X.; Niu, Q.; Kang, J.M. Research status and prospect of residual membrane pollution control technology in farmland. J. Agric. Mech. 2017, 48, 1–14. [Google Scholar]

- He, W.; Yan, C.R.; Liu, S.; Chang, R.Q.; Wang, X.J.; Cao, S.L. The use of plastic mulch film in typical cotton planting regions and the associated environmental pollution. J. Agric. Environ. Sci. 2009, 2, 1618–1622. [Google Scholar]

- Wang, Z.C.; Li, X.Y.; Shi, H.B.; Sun, M.; Ding, T.; Wang, C.G. Effects of residual plastic film on soil hydrodynamic parameters and soil structure. J. Agric. Mech. 2015, 46, 101–106. [Google Scholar]

- Wang, J.R.; Liu, H.G.; Reaihan, E.; Gong, P.; Li, P.F.; Yang, C.K.; Li, L.; Xu, Y.B.; Dong, J.S.; Guo, Y. Assessing the impact of residual film on agriculture: A meta-analysis of soil moisture, salinity, and crop yield. Ecotoxicol. Environ. Saf. 2025, 289, 117665. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.J.; Tang, J.R.; Li, C.X.; He, H.Q.; Hung, H. Distribution and influencing factors of plastic film residues in topsoil of farm land in Gansu Province. J. Chin. J. Eco-Agric. 2024, 32, 456–467. [Google Scholar]

- Wang, J. Residual Film Recycling Technology in Farmland; Northwest A&F University Press: Yangling, China, 2012; pp. 12–19. [Google Scholar]

- Liang, R.Q.; Chen, X.G.; Zhang, B.C.; Meng, H.W.; Jiang, P.; Peng, X.B.; Kan, Z.; Li, W.M. The current problems and countermeasures of recovery methods and recycling of cotton residual film in Xinjiang. Agric. Eng. J. 2019, 35, 1–13. [Google Scholar]

- Yan, C.R.; He, W.Q.; Liu, E.K.; Lin, T.; Liu, S.; Liu, Q. Discussion on the concept and estimation method of crop film mulching safety period. J. Agric. Mech. 2015, 31, 1–4. [Google Scholar]

- Yan, C.R.; Liu, E.K.; Shu, F.; Liu, S.; He, W.Q. Characteristics and prevention and control technology of mulch and residual pollution in China. J. Agric. Resour. Environ. 2014, 31, 95–102. [Google Scholar]

- Shu, F. Study on the Utilization and Recovery of Agricultural Mulch Film and Its Financial Support Policy in China. Ph.D. Thesis, Chinese Academy of Agricultural Sciences, Beijing, China, 2014. [Google Scholar]

- Wang, Z.C.; Meng, Q.; Yu, L.H.; Yang, W.; Li, W.; Yang, J.; Yang, F. Characteristics of Microplastics in Agricultural Soils of Inner Mongolia Hetao Irrigation Area. Agric. Eng. J. 2020, 36, 204–209. [Google Scholar]

- Bai, R.H.; Fan, R.Q.; Xie, C.H.; Liu, Q.; Yan, C.R.; Cui, J.X.; He, W.Q. Microplastics are overestimated due to poor quality control of reagents. J. Hazard. Mater. 2023, 459, 132068. [Google Scholar] [CrossRef]

- Liu, X.; Shi, R.; Zhao, W.; Sun, W.; Li, P.; Li, H.; Zhang, H.; Wang, J.; Wang, G.; Dai, F. Study on the Characteristics of Residual Film–Soil–Root Stubble Complex in Maize Stubble Fields of the Hexi Corridor and Establishment of a Discrete Element Model. J. Agric. 2024, 14, 1542. [Google Scholar] [CrossRef]

- Li, W.T.; Han, X.Y.; Gao, Y.; Yang, S.W. Bibliometric Analysis of Plastic Film Recycling Machines in China Based on Core Journals from CNKI. J. Mod. Agric. Equip. 2025, 46, 88–93. [Google Scholar]

- Jiang, Y.X.; Qu, H.; Liu, X.F.; Zhang, H.C.; Zhou, X.; Zhang, L. Design and Experiment of Spade Tooth Film Lifting Device for Residual Film Recycling Machine. J. Trans. Chin. Soc. Agric. Mach. 2025, 56, 282–289. [Google Scholar]

- Tian, X.L.; Zhao, Y.; Chen, X.G.; Yan, L.M.; Wen, H.J.; Hou, H.X.; Ji, C. Development of 4JSM-2000A type combined operation machine for cotton stalk chopping and residual plastic film collecting. Agric. Eng. J. 2018, 34, 25–35. [Google Scholar]

- Yang, S.M.; Chen, X.G.; Yan, L.M.; Mo, Y.S.; Jiang, D.L.; Zhang, H.M. Design and experiment on belt-type curl-up film device for residual plastic film recycling machine. J. Agric. Mech. 2021, 52, 135–144. [Google Scholar]

- Jin, W.; Zhang, X.J.; Ding, Y.C.; Bai, S.H.; Liu, W.P.; Zhou, X.C. Experiment on suspension separation of residual film and impurity based on EDEM-Fluent coupling. J. Agric. Mech. 2022, 53, 89–98. [Google Scholar]

- Wang, X.F.; Hu, C.; Lu, B.; Ge, X.K.; Hou, S.L. Design and experiment of sprocket conveying residual film recycling machine of casting film. J. Agric. Mech. 2018, 49, 122–129. [Google Scholar]

- Niu, Q.; Ji, C.; Zhao, Y.; Chen, X.G.; Zhen, X.; Li, H.W. Design and test of pick-up and cleaning device of strip and residual film packer. J. Agric. Mech. 2017, 4, 101–107. [Google Scholar]

- Zhang, H.M.; Chen, X.G.; Yan, L.M.; Yang, S.M. Design and test of master-slave straw returning and residual film recycling combine machine. Agric. Eng. J. 2019, 3519, 11–19. [Google Scholar]

- Zhang, J.X.; Yang, C.; Guo, J.X.; Jiang, Y.X.; Zhang, H.C.; Zhang, L. Design and experiment of hob-type joint operation machine for silage corn root stubble plucking and residual plastic film collecting. Agric. Eng. J. 2018, 34, 25–34. [Google Scholar]

- Zhao, L.; Ma, S.H. Design and Experiment Analysis on Wind Sieve Soil Residual Film Separating Device. Agric. Res. 2013, 10, 174–177. [Google Scholar]

- Cao, S.L.; Xie, J.H.; Yang, Y.X.; Liu, Y.R.; Lu, Y.T. Design and experiment of side row cotton straw returning and residual film recovery combined machine. J. Jilin Univ. (Eng. Ed.) 2023, 53, 1–14. [Google Scholar]

- Wang, Z.Y.; Chen, X.G.; Yan, L.M.; Jiang, D.L.; Wang, M.E. Design and experiment on collecting and removing device for profile modeling residual plastic film collector. J. Agric. Mech. 2021, 52, 80–90. [Google Scholar]

- Xie, J.H.; Yang, Y.X.; Cao, S.L.; Zhang, Y.; Zhou, Y.B.; Ma, W.B. Design and experiments of rake type surface residual film recycling machine with guide chain. Agric. Eng. J. 2020, 36, 76–86. [Google Scholar]

- Wang, J.X.; Zhao, W.Y.; Dai, F.; Ma, J.M.; Xin, S.L. Design and test of collector for corn whole plastic film mulching on double ridges. For. Mach. Wood Work. Equip. 2018, 46, 26–30. [Google Scholar]

- Dai, F.; Zhao, W.Y.; Zhang, F.W.; Wu, Z.W.; Song, X.F.; Wu, Y.F. Optimization and experiment of operating performance of collector for corn whole plastic film mulching on double ridges. Agric. Eng. J. 2016, 32, 50–60. [Google Scholar]

- Dai, F.; Guo, X.H.; Zhao, W.Y.; Xin, D.L.; Liu, X.L.; Wu, Z.W. Design and experiment of canvas belt combined operation machine for potato digging and plastic film collecting. J. Agric. Mech. 2018, 49, 104–113. [Google Scholar]

- Xin, S.L.; Zhao, W.Y.; Dai, F.; Wang, J.X.; Liu, X.L.; Wu, Z.W. Improved design and experiment of collector for corn whole plastic film mulching on double ridges. J. Agric. Mech. 2018, 49 (Suppl. S1), 311–319. [Google Scholar]

- Wang, J.X.; Zhao, W.Y.; Liu, X.L.; Dai, F.; Xin, S.L.; Wu, Z.W. Improved design and experiment of collector for corn whole plastic film mulching on double ridges. J. Agric. Mech. 2021, 52, 119–128. [Google Scholar]

- Yang, Y.; Bai, S.H.; Ma, S.T. Overview of research on residual membrane recycling machine. Grain Sci. Technol. Econ. 2019, 44, 97–100. [Google Scholar]

- Wang, W.Y.; Wang, H.L.; Dai, W.; Zhang, M.; Ren, D.Z.; Wang, W. Study on the throwing device of residual film recycling machine for the plough layer. Comput. Electron. Agric. 2024, 227, 109679. [Google Scholar]

- Sun, Y.X.; Wang, C.L.; Hu, M.; Chen, Q.M. Comparative experiment of corn planting patterns in irrigation area. Gansu Agric. Sci. Technol. 2014, 2, 35–36. [Google Scholar]

- You, J.H.; Chen, X.G.; Zhang, B.H.; Wu, J. Design and test of 4JSM-2000 cotton stalk crushing and residual film recycling combined machine. Agric. Eng. J. 2017, 33, 10–16. [Google Scholar]

- Jia, C.B.; Cheng, H. Research on parametric study method of screw conveyor. Mach. Des. Manuf. 2015, 4, 206–208. [Google Scholar]

- Wulan, T.Y.; Wang, C.G.; Qi, S.H.; Wang, X.R.; Wang, H.C.; Wang, J.L. Theoretical model analysis and test of screw conveyor for rubbing and breaking corn straw. Agric. Eng. J. 2016, 32, 18–26. [Google Scholar]

- GB/T 25412–2021; Farm Waste Film-Pick Up Machines. Agricultural Mechanization: Xinjiang, China, 2021.

- GB/T 24675.6-2021; Conservation Tillage Equipment—Part 6: Smashed Straw Machine. Agricultural Machinery of Standardization Administration of China: Heilongjiang, China, 2021.

- Bono, F.M.; Cinquemani, S.; Radicioni, L.; Conese, C.; Tarabini, M. An approach for fault detection based on multibody simulations and feature selection algorithm. In NDE 4.0, Predictive Maintenance, and Communication and Energy Systems in a Globally Networked World; SPIE: Bellingham, WA, USA, 2022; pp. 117–125. [Google Scholar]

- GB/T 24643-2009; Fuel Consumption of Tractor Set During Field Operation—Test Methods. China Machinery Industry Federation: Heilongjiang, China, 2009.

| Type | Working Place | Recovery Rate (%) | Impurity Rate (%) | Crushing Corn Straw (Yes/No) | Cutting Corn Stubble (Yes/No) |

|---|---|---|---|---|---|

| COMOSRCSRARFR | Xinjiang Uygur Autonomous Region | 87.26 | 12.23 | YES | NO |

| CARDFPMRPFC | Xinjiang Uygur Autonomous Region | 90.45 | 17.08 | NO | NO |

| TCCRFRM | Xinjiang Uygur Autonomous Region | 88.73 | 23.42 | NO | NO |

| CFCWPFMODR | Gansu Province | 90.02 | 20.13 | NO | NO |

| 11FMS-120 | Gansu Province | 90.35 | 29.24 | NO | NO |

| Index | Data |

|---|---|

| Structural style | Trailed structure type |

| Supporting power (kW) | ≥66 |

| Size of the whole machine: (length × width × height) (m × m × m) | 3.08 × 2.11 × 1.56 |

| Total mass of the machine (kg) | 2500 |

| Working width (m) | 0.7~1.4 |

| Working depth (mm) | 0~100 |

| Residual film pickup rate (%) | ≥85 |

| Qualified rate of straw crushing length (%) | ≥90 |

| Residual film content rate (%) | ≤20 |

| Productivity (hm2·h−1) | 0.3~0.5 |

| Levels | Film-Lifting Shovel into the Soil Angle/(°) | Eccentric Teeth Shifting Cylinder Speed/(r/min) | Machine Forward Speed/km/h |

|---|---|---|---|

| −1 | 20 | 70 | 3.0 |

| 0 | 25 | 80 | 4.0 |

| 1 | 30 | 90 | 5.0 |

| Number | Film-Lifting Shovel into the Soil Angle/(°) | Eccentric Teeth Shifting Cylinder Speed/(r/min) | Machine Operating Speed/(km/h) | Rate of Recovery η/% |

|---|---|---|---|---|

| 1 | 20 | 70 | 4 | 85.12 |

| 2 | 30 | 70 | 4 | 87.34 |

| 3 | 20 | 90 | 4 | 86.16 |

| 4 | 30 | 90 | 4 | 89.06 |

| 5 | 25 | 70 | 3 | 84.36 |

| 6 | 25 | 90 | 3 | 86.52 |

| 7 | 25 | 70 | 5 | 81.91 |

| 8 | 20 | 80 | 3 | 84.63 |

| 9 | 30 | 80 | 3 | 87.63 |

| 10 | 20 | 80 | 5 | 83.52 |

| 11 | 25 | 90 | 5 | 84.62 |

| 12 | 25 | 80 | 4 | 93.34 |

| 13 | 30 | 80 | 5 | 86.26 |

| 14 | 25 | 80 | 4 | 92.06 |

| 15 | 25 | 80 | 4 | 93.11 |

| 16 | 25 | 80 | 4 | 92.09 |

| 17 | 25 | 80 | 4 | 92.04 |

| Source | Recovery Rate of the Residual Film | |||

|---|---|---|---|---|

| Degree of Freedom | Sum of Squares | F | p | |

| X1 | 1 | 15.13 | 35.89 | <0.0001 ** |

| X2 | 1 | 8.00 | 18.98 | 0.0005 ** |

| X3 | 1 | 6.13 | 14.53 | 0.0033 ** |

| X1X2 | 1 | 0.25 | 0.59 | 0.0066 ** |

| X1X3 | 1 | 0.00 | 0.00 | 0.4664 |

| X2X3 | 1 | 0.25 | 0.59 | 1.0000 |

| X12 | 1 | 20.38 | 48.36 | 0.4664 |

| X22 | 1 | 50.12 | 118.92 | 0.0002 ** |

| X32 | 1 | 113.85 | 270.16 | <0.0001 ** |

| Residual | 7 | 0.42 | ||

| Lack of fit | 3 | 0.58 | 1.94 | 0.2643 |

| Pure error | 4 | 0.30 | ||

| Total | 16 | |||

| Sports Event | Residual Film Recovery Rate/% |

|---|---|

| Test average | 91.96 |

| Optimal value | 92.56 |

| Relative error | 0.65 |

| Test Area Number | Residual Film Impurity Rate/% | Qualified Rate of Corn Straw-Crushing/% |

|---|---|---|

| 1 | 18.23 | 92.12 |

| 2 | 16.42 | 88.36 |

| 3 | 18.89 | 90.43 |

| 4 | 17.73 | 84.29 |

| 5 | 11.96 | 87.35 |

| Average value | 16.65 | 88.51 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Zhao, W.; Liu, X.; Dai, F.; Shi, R.; Zhang, K.; Wang, X.; Zhang, W.; Liang, J. The Design and Testing of a Combined Operation Machine for Corn Straw Crushing and Residual Film Recycling. Agriculture 2025, 15, 916. https://doi.org/10.3390/agriculture15090916

Wang J, Zhao W, Liu X, Dai F, Shi R, Zhang K, Wang X, Zhang W, Liang J. The Design and Testing of a Combined Operation Machine for Corn Straw Crushing and Residual Film Recycling. Agriculture. 2025; 15(9):916. https://doi.org/10.3390/agriculture15090916

Chicago/Turabian StyleWang, Jiuxin, Wuyun Zhao, Xiaolong Liu, Fei Dai, Ruijie Shi, Keping Zhang, Xiaoyang Wang, Wenhui Zhang, and Jiadong Liang. 2025. "The Design and Testing of a Combined Operation Machine for Corn Straw Crushing and Residual Film Recycling" Agriculture 15, no. 9: 916. https://doi.org/10.3390/agriculture15090916

APA StyleWang, J., Zhao, W., Liu, X., Dai, F., Shi, R., Zhang, K., Wang, X., Zhang, W., & Liang, J. (2025). The Design and Testing of a Combined Operation Machine for Corn Straw Crushing and Residual Film Recycling. Agriculture, 15(9), 916. https://doi.org/10.3390/agriculture15090916