1. Introduction

When ships operate in deep sea, such as offshore drilling, marine geological exploration, submarine cable laying, pipe-laying, etc., they usually need to be continually positioned on a fixed position. To carry out the abovementioned deep-sea operations, the position of the ship at sea needs to be determined first, and then continuous positioning is achieved through surface positioning technology. There are various methods used to determine the position of a ship at sea, among which the Differential Global Positioning System (DGPS)-based is more advanced and is of interest to many scholars [

1,

2,

3,

4,

5,

6,

7,

8]. As for the sea surface positioning technology, there are two main categories, namely, mooring positioning technology and dynamic positioning technology. The mooring positioning technology uses mooring devices to resist unknown external disturbances to keep the ship in a fixed position. However, due to the limitation of water depth in the deep sea, there are problems such as poor maneuverability and unreliable positioning, which affect the positioning effect. Dynamic positioning technology relies on the thrust generated by its own thruster system to compensate the unknown external disturbances and keep the ship in a certain state at the desired position on the sea surface.

The first dynamic positioning systems were born in the 1960s and were implemented using a PID with a low-pass filter control strategy [

9]. Dynamic positioning systems have been using Kalman filter theory and optimum control strategies since the 1970s and 1980s, when control theory began to take shape [

10,

11]. However, the above control methods were applied to linear models, which implied poor control because of the ship model with a highly nonlinear property. Therefore, most of the subsequent studies adopted nonlinear control methods. Since the 1990s, nonlinear control methods have been gradually utilized in dynamic positioning control systems. Grøvlen et al. presented a nonlinear control method grounded on the dynamic positioning control with a backstepping approach [

12]. In the paper, the ship position was measured by designing a nonlinear observer applied to the controller design. However, the backstepping method in the paper [

12] consisted of six steps, and its controller design process was tedious. In the paper [

13], a vector backstepping method was used to integrate the six states in the paper [

12] into two vectors, which in turn simplified the backstepping method from six steps to two steps, effectively simplifying the controller design process. At present, some of the literature on dynamic positioning is not about control methods but about methods to evaluate the capability and operability of dynamic positioning systems [

14,

15,

16,

17,

18].

However, few of the above studies considered the effects of unknown external disturbances during the ship’s operation at sea. To handle the external disturbances, a lot of work had been undertaken by many scholars. Do et al. used the vector backstepping approach to develop a robust output feedback control rule and considered the unknown external disturbances as constant value disturbances [

19]. However, disturbances from the ocean were bounded and unknown time-variant, and unknown environmental disturbances could lead to changes in the ship model [

20,

21]. In the paper [

22], the unknown time-varying disturbances and the ingestion of the ship model were considered, and a robust adaptive neural controller was designed for dynamic positioning. Radial basis neural network (RBFNN) was one of them, and it was utilized to manage the unidentified time-variant disturbances and model intake. However, due to the physical upper constraint on the thrust produced by the ship thruster, the amplitude of the control action needed to be limited in order to produce a good control effect for the designed control signal. The thruster input saturation issue was taken into account by Du et al. when designing the controller, and they added an auxiliary dynamic system to account for the input saturation and create a reliable nonlinear dynamic positioning control rule [

23]. In order to increase the control effect and reduce the complexity of the control law, the paper also used disturbance observer and dynamic surface approaches to handle the unknown time-varying disturbances and differential terms generated during the controller design phase, respectively. However, the control action generated in the paper [

23] generated large oscillations at the initial time. Poor control resulted from the thruster’s physical properties, making it impossible to provide the required action. To enable the thruster to carry out the generated control action, Hu et al. incorporated the thruster system dynamics equation into the controller architecture [

24]. The paper also introduced a disturbance observer to handle unknown time-varying disturbances and a command filter to handle the differential terms generated during the controller design.

There are many uncertainties in the marine environment, such as reefs, hazardous materials left over from war, other operating vessels, etc. Therefore, a safe operating area needs to be defined for dynamic positioning operation ships to prevent accidents, such as reefing and ship damage. Therefore, it is necessary to constrain the position of the dynamic positioning ship to make it work within a certain range. At this stage, the methods of ship position constraint are mainly divided into the following categories: artificial potential field method, path planning, BLF, preset performance control, reference regulation control, etc. Among them, the BLF method is widely used because of its easy controller combination, simple design and ease of validating the stability of the presented system, etc.

Tee et al. were the first to introduce the idea of barrier function into the design of a nonlinear constraint control system, combining the Lyapunov function with the barrier function and proposing the BLF [

25]. When the function variables tended to the preset boundary values, the BLF values tended to infinity. Therefore, when the Lyapunov of the overall control system was bounded, the constrained function variables were bounded to be within the bounded range, thus achieving the purpose of state constraint. Because of its ability to constrain the state of nonlinear systems, BLF is nowadays prevalently applied in the sphere of ship motion control. In the paper [

26], a nonlinear adaptive filtering based on the BLF was proposed for dynamic positioning output feedback control in which a neural network-based passive wave trap filter was applied to conjecture the uncertainty term in ship motion, and the creation of the vector for the intermediate control function was combined with the BLF to constrain the output state variables, resulting in an output feedback control law. BLF not only appeared in dynamic positioning control, but also applied in trajectory tracking control. Yin et al. applied BLF in ship trajectory tracking control to constrain the full state of the ship [

27]. In the paper [

28], based on the paper [

27], the BLF was improved to design a trajectory tracking controller with time-varying asymmetric output constraints. Kong et al. by introducing a class of time-varying continuous error constraint functions in the BLF. The tracking error was always within the set time-varying constraint bound [

29]. Qin et al., further aiming at improving the convergence speed of the system, applied a tangent type BLF for ship to design a trajectory tracking constraint controller based on finite-time stability so that its tracking error could converge to zero in finite time [

30].

However, it is challenging to obtain all the exact information during the actual ship operation since the ship state feedback control requires knowing the location and velocity information of the ship. Therefore, it is necessary to introduce a state observer to estimate the ship’s speed so that the ship only needs to know the location information to complete the control effect [

31,

32,

33,

34]. Since less information is required, both the control accuracy and the failure rate can be improved and reduced. For the state estimation problem, the extended state observer (ESO) could estimate the unknown ship speed as well as the total set of disturbances formed by the model parameter ingestion, unknown time-varying disturbances and nonlinear hydrodynamic damping terms. Applying the extended state observer to the controller design handles not only the ship speed unpredictability problem but also the unknown time-varying disturbances and unknown dynamics problem. Miao et al. designed the path-tracking control law by compensating the set total disturbances formed by the model ingestion, external disturbances, etc., through the reduced-order linear extended state observer [

35]. In the papers [

36,

37], finite-time ESOs were proposed in order to improve the observer convergence rate. However, the convergence time of the above observer was related to the initial value. To further improve the convergence speed of the observer, the papers [

38,

39] proposed an FDESO to estimate the unknown state and the set total disturbance and applied it to the controller design.

When operating in real marine environments, the thruster cannot fully execute the control signal to generate the corresponding thrust due to the thruster’s physical properties and the interference produced by the external environment on the thruster blades, resulting in a decrease in thrust efficiency. Therefore, in practical applications, to guarantee that the resulting control signal can permit good control of the actual thrust, the thruster system dynamics equation needs to be stressed during the control law design process. Sørensen et al. initially took into account the dynamics of the thruster system in dynamic positioning control system by introducing a linear thruster model equation [

40]. In order to achieve the best thrust, Berge et al. analyzed the thruster system dynamics in a robust overdrive ship experiment [

41]. The robust nonlinear dynamic positioning control design in the paper [

24] takes into account the dynamics of the thruster system, causing the control action produced by the control signal acting on the thruster to change gradually without sudden changes, as required by engineering reality. There are also some papers that use a thrust allocation algorithm in dynamic positioning prediction, and they also have good results [

42,

43,

44,

45].

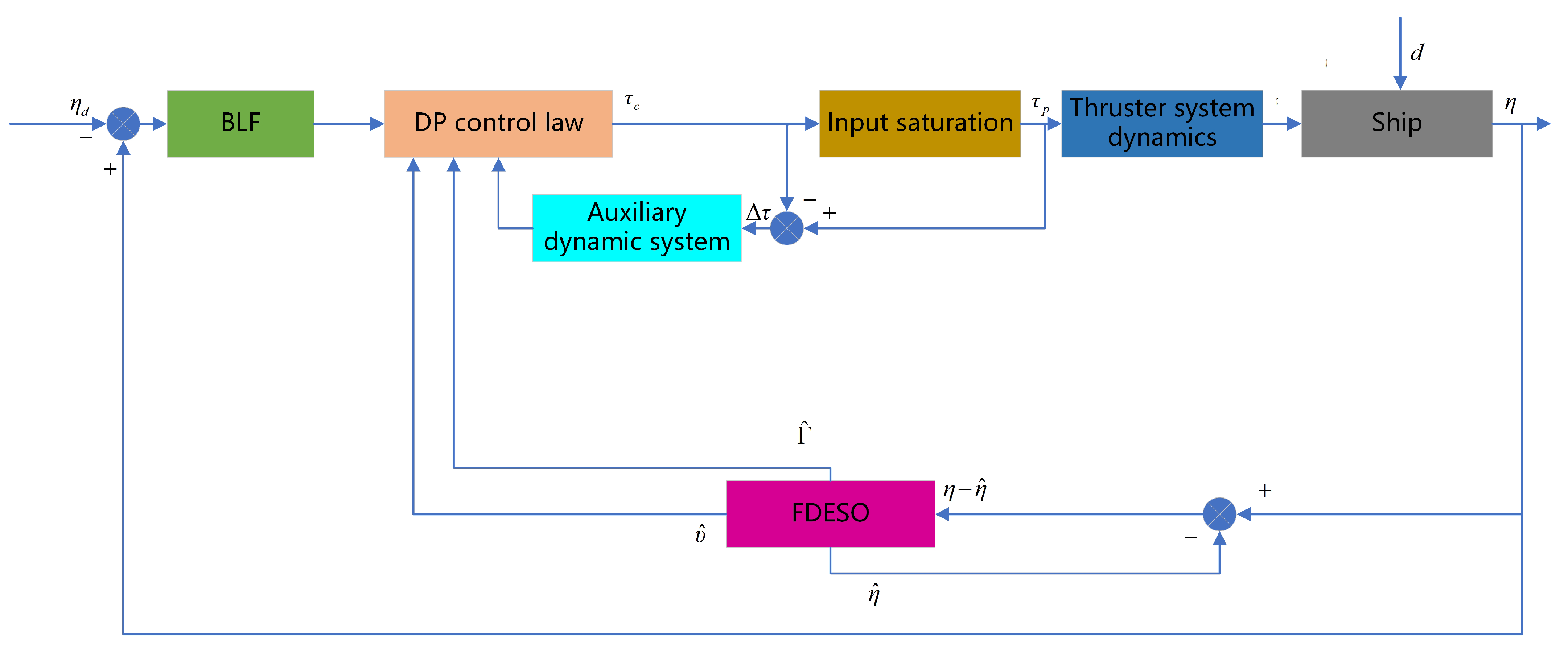

Based on the above, the problems of ship operating position limitation, unmeasurable ship speed, unknown time-varying disturbances, unknown dynamics and input saturation are simultaneously handled in this paper. The ship position is always within the dynamic positioning operation range by introducing the BLF to limit the ship position error. A FDESO is used to estimate the ship’s unmeasurable velocity as well as the set total disturbance, which consists of unknown time-varying disturbances and unknown dynamics. In order to ensure that the generated thrust signal adheres to engineering reality, the controller design takes the thruster system dynamic into account. The input saturation issue is dealt with via a finite-time auxiliary dynamic system. To combat unwanted errors, a robust control term is used. The proposed control law enables the ship position and yaw to be reached and keep the anticipated value with arbitrarily small errors, without exceeding the specified operating area throughout and with all signals in the closed-loop control system consistently and eventually bounded. The major contributions of this paper can be summarized as the following three points.

- 1.

Throughout the paper, as much as possible, the problems encountered by dynamic positioning systems in complex sea conditions are considered to make them more realistic. For example, there are effects, such as unmeasurable velocity, uncertainty of model parameters, uncertainty of external disturbances, physical characteristics of the thruster system and thruster input saturation. The aforementioned issues are addressed, respectively, using the FDESO, the thruster dynamics equation, and the finite-time auxiliary dynamic system. Among them, FDESO not only estimates the unknown ship speed, but also estimates the total set disturbance caused by unknown model parameters, unknown external disturbance, etc. In addition, a robust control term is introduced in the control strategy to improve the stability of the controlled system.

- 2.

In the controller design, the ship position is constrained to be within the set range. By introducing the BLF to constrain the ship position error, the ship position is always within the safe working range, which ensures the safety of the ship during operation.

- 3.

The paper improves the convergence speed of dynamic positioning control method in two ways.

The rest of this paper is shown below.

Section 2 gives the models, assumptions, and lemmas required in the controller design. The design of the FDESO-based dynamic positioning output feedback control rule for position-constrained ships is illustrated, and the system stability is examined in

Section 3. In

Section 4, lots of comparative simulations are designed, which illustrate the effectiveness and advantages of the control strategy.

Section 5 summaries the entire paper.

2. Problem Formulation and Preliminaries

, which denotes the Earth-fixed inertial frame, and

, which denotes the body-fixed frame, are shown in

Figure 1.

As is the case for the dynamic positioning control system, the three degrees of freedom of surge, sway and yaw are frequently taken into account in the field of ship motion control. The following diagram illustrates the nonlinear mathematical model of the ship’s dynamic location [

47].

where the ship’s location, expressed in the Earth’s coordinate system as

, includes the surge position

x, sway position

y and heading angle

of the ship. With surge velocity

u, sway velocity

v and yaw velocity

r being the projections of the velocity vector

in the three directions of the surge, sway and yaw on the ship body coordinate system, respectively,

is the ship velocity as it is represented in the body coordinate system.

is the rotation matrix to convert the physical quantities between the Earth and body coordinate systems, as follows:

where

,

.

and

are the mass matrix and linear damping matrix of the ship, respectively;

is the thrust generated by the thruster, where

is the surge thrust,

is the sway thrust, and

is the yaw thrust. The vector that disturbs the marine ecosystem is

.

A thruster system dynamics equation is inserted in the controller design as follows to allow the thrust produced by the thruster to make up for the loss of thrust efficiency caused by the actual maritime environment:

where

is the thruster dynamics matrix, as follows:

where

,

, and

are the equivalent thruster time constants in surge, sway and yaw. For a conventional thruster system,

can be approximated by the time constants corresponding to the main propellers;

and

can be approximated by the time constants to the tunnel and azimuth thrusters. Moreover, it is reasonable to assume that

.

Here,

is the thruster system’s control signal restricted because of real-world physical constraints, as in:

where

is the maximum thrust value that the thruster can generate, and

is the control signal generated by the designed control strategy. The difference between the restricted control signal

and the unrestrained control signal

is known as

.

Assumption 1. - 1.

The ship model parameter matrices M and D are unknown.

- 2.

The ship speed vector is unmeasurable.

- 3.

The marine environmental disturbance vector is bounded and unknown time-variant; there exists a positive constant that satisfies

Remark 1. First, the operational circumstances and environment have an impact on the ship. Additionally, the ship is exposed to unidentified time-variant disturbances, which cause the ship model matrices M and D to change. Secondly, most ships’ velocities are not measurable, leading to difficulties in their application in controller design. In addition, the disturbance vector acting on the ship is unknown time-varying and bounded because the ocean environment is constantly changing but energy-limited. Assumption 1 holds.

Since the ship model parameter matrices

M and

D ingest, we define

and

, where

,

are nominal values and

,

are uncertainty terms. Therefore, (

2) can be expressed as

where

is a composite uncertainty term that includes the model mass matrix and the linear damping matrix ingestion information;

,

,

,

,

,

,

and

are all ship model parameters, which will be given later.

Lemma 1 ([

48,

49])

. Consider the following system:where , () and satisfies , (), where , , and , are sufficiently small positive constants. The matrices formed by the observer gains , ():are Hurwitz matrices. Then, the system (12) is stable at fixed time and is stable for a time T:where , , , and , , , are positive definite non-singular matrices and satisfy , . Lemma 2 ([

50])

. For a positive definite continuous Lyapunov function , the independent variable is defined on . For the following form:where , , and , then the system is finite-time stable. Lemma 3 ([

51])

. For any positive constant (), let (), where (), and is an open set, consider the following system:where is the state vector of the system, and the function is segmentally continuous with respect to the variable t and satisfies the local Lipschitz condition on . Suppose there exists a continuously derivable positive definite function and () satisfying when , there iswhere , are functions. Let and . Ifwhere , and μ and λ are positive constants, then is satisfied for any . Establishing a reliable nonlinear output feedback dynamic positioning control system based on a BLF is the control goal of this study when some of the model parameters, velocity information and external disturbances are unknown, and there are positional limits on the ship. The proposed control law enables the ship position and heading angle to be reached and kept at the expected value with arbitrarily small errors, and all signals in the closed-loop control system are consistent and eventually bounded.

4. Simulation and Analysis

In this section, lots of dynamic positioning simulation experiments are used to demonstrate the efficacy of the suggested control technique. First, to verify that the output feedback control strategy in the speed-unmeasurable case can effectively recover the performance of the state feedback control strategy in the speed-measurable case, the output feedback control law

proposed in (

71) and the state feedback control law

proposed in (

62) of this paper were subjected to separate dynamic positioning simulation experiments and compared. Secondly, the output feedback control strategy

provided in this paper is contrasted with the output feedback control strategy provided in [

46], and then the effectiveness and superiority of introducing the BLF, introducing the FDESO and considering the thruster system dynamics are illustrated. Here, a supply vessel

Northern Clipper with dimensions of

m in length and

kg in mass is simulated with the nominal model parameters and thruster parameters shown in

Table 1 [

47]:

The thruster input saturation issue must be taken into account in the intended control strategy due to the physical constraints of the supply vessel thrusters.

Table 2 shows the thruster input saturation limits for the supply ship

Northern Clipper.

The unknown time-varying disturbance in the text is set as , where is taken from the first-order Markov process as the bias force and moment vector, is the time constant matrix, is the Gaussian white noise vector with mean 0, and is the diagonal matrix of the tuning . Set the disturbance scene parameters as , and .

The desired position and heading of the ship are set to , and the initial values of the initial state of the ship and some of the controller parameters are , , , , , , , . The design parameters are , , , , , , , , , , , , , , , , , , , , , , , , , .

4.1. Performance of Proposed Output Feedback Control Law

To verify the performance of the proposed output feedback control strategy in the case of unmeasurable speed, the output feedback control strategy

in (

71) is contrasted with the state feedback control strategy

in (

62) in the case of known speed, as shown in

Figure 3a–d. To verify the validity of the FDESO, the velocity observation

and the set total disturbance observation

are compared with the velocity true value

and the set total disturbance true value

, respectively, as shown in

Figure 3e,f.

Figure 3a,b show that the ship can achieve and maintain the desired location and direction

within a certain time under both output feedback and state feedback control laws, and the ship’s motion trajectory is within the position error bounded range

,

. The ship’s velocity

u,

v and

r are shown to be constrained in

Figure 3c, and the ship velocity produced by the output feedback control technique is nearly identical to the ship velocity produced by the state feedback.

Figure 3d indicates that the signals shift smoothly without abrupt changes, and the actual thrust generated by the thruster is within the thruster input saturation limits shown in

Table 2. Additionally, the thrusts produced by the output feedback approach and those produced by the state feedback technique are essentially identical. Therefore, the output feedback control strategy proposed in this paper can effectively recover the performance of the state feedback control strategy.

Figure 3e shows that the FDESO can effectively observe the unmeasurable velocity, and

Figure 3f indicates that the FDESO can estimate the unknown set of total thrusters. Therefore, the FDESO is effective.

4.2. Comparison with Existing DP Control Law

The dynamic positioning output feedback control strategy

based on the high-gain observer proposed in [

46] is compared with the dynamic positioning output feedback control law

based on the FDESO proposed in this paper to show the effectiveness and superiority of introducing BLF and FDESO, taking into account the dynamics of the thruster system. This comparison is shown in

Figure 4a–e.

Figure 4a,b indicate that the control strategy proposed in this paper can reach and stay on the desired position and heading

within a certain time, and the ship’s motion trajectory is within the position error limit

,

. Additionally, it takes about the same amount of time to get to the desired point as the control method of [

46].

Figure 4c,d show that both the FDESO proposed in this paper and the high-gain observer proposed in [

46] can effectively estimate the unmeasured velocity, and the estimation speed of the FDESO is faster than that of the high-gain observer.

Figure 4e illustrates that the actual thrust produced by the control strategy discussed in this paper and the control strategy in [

46] are both within the thruster input saturation limit, but the actual thrust signal produced in this paper changes smoothly without abrupt changes, whereas the actual thrust signal produced in [

46] has significant fluctuations at the beginning and clearly abrupt changes. As a result, the control technique provided in this work is more in tune with engineering realities than [

46].

4.3. Marine System Simulator Toolbox Simulations

It is necessary to plan the related experiments in order to test the suggested control strategy. However, because of the constraints of current engineering development, conducting actual ship testing to verify the applicability of the offered approach is very challenging. About 99 percent of the control systems that have been devised for ship dynamic positioning control cannot be tested on a real ship. However, this study can be replicated using the MSS toolbox, which is well-known in the area and whose disturbance model and ship model are accepted in that field. A semi-realistic ship and disturbance may be constructed using the MSS toolbox, and the developed control system can be utilized as a substitute for an engineering verification system.

The simulation example is a supply vessel from DP MotionRAO, the essential details of which are presented in

Table 3. The MSS toolbox contains the nominal values

and

of the parameters of its motion mathematical model. Also offered is a simulated comparison with the [

46] DP control legislation that is now in place.

In simulations, the sea state four is represented by the Jonswap wave spectrum type, significant wave height of 1.5 m, peak frequency of 0.76 rad/s, and mean wave direction of rad in the northeast frame. The mean wind angle is rad, and the wind speed is 5 m/s. The current direction is , and the current speed is 0.1 m/s.

To verify the performance of the proposed output feedback control strategy in the case of unmeasurable speed, the output feedback control strategy

in (

71) is compared with the state feedback control strategy

in (

62) in the case of known speed, as shown in

Figure 5a–d. To verify the validity of the FDESO, the velocity observation

and the set total disturbance observation

are compared with the velocity true value

and the set total disturbance true value

, respectively, as shown in

Figure 5e,f.

Figure 5a,b show that the ship can reach and stay on the desired location and orientation

within a certain time under both output feedback and state feedback control laws, and the ship’s motion trajectory is within the position error bounded range

,

.

Figure 5c shows that the ship velocity

u,

v and

r is bounded, and the ship velocity generated by the output feedback control strategy is basically the same as the ship velocity generated by the state feedback.

Figure 5d indicates that the actual thrust generated by the thruster is within the thruster input saturation limits shown in

Table 2, and the signals change smoothly without sudden changes. Moreover, the thrusts produced by the output feedback strategy are basically the same as that generated by the state feedback strategy. Therefore, the output feedback control strategy proposed in this paper can effectively recover the performance of the state feedback control strategy.

Figure 5e shows that the FDESO can effectively observe the unmeasurable velocity, and

Figure 5f indicates that the FDESO can estimate the unknown set of total thrusters. Therefore, the FDESO is effective.

The dynamic positioning output feedback control law

based on the high-gain observer proposed in [

46] is compared with the dynamic positioning output feedback control strategy

based on the FDESO proposed in this paper in order to demonstrate the effectiveness and superiority of introducing BLF and FDESO, taking into account the dynamics of the thruster system. This comparison is shown in

Figure 6a–e.

Figure 6a,b indicate that the control strategy presented in this paper can reach and stay on the desired location and direction

within a certain time, and the ship’s motion trajectory is within the position error limit

,

. In addition, it takes about the same amount of time to get to the desired point as the control method of [

46].

Figure 6c,d show that both the FDESO proposed in this paper and the high-gain observer proposed in [

46] can effectively estimate the unmeasured velocity, and the estimation speed of the FDESO is faster than that of the high-gain observer.

Figure 6e shows that the actual thrust produced by the control strategy discussed in this paper and the control strategy in [

46] are both within the thruster input saturation limit, but the actual thrust signal produced in this paper changes smoothly without abrupt changes, whereas the actual thrust signal produced in [

46] has significant fluctuations at the beginning and clearly abrupt changes.

In the MMS toolbox, the disturbance model is less energetic than white noise, as can be observed by comparing

Figure 3,

Figure 4,

Figure 5 and

Figure 6. Because of this, the ship using the toolbox produces less thruster force to mitigate the disruption than the initial supply ship did. The supply ship model using white noise as the disturbance provides control performance that is equivalent to that produced by the ship model and the semi-realistic disturbance in the MMS toolbox, despite the fact that both are capable of creating the required control effect. As a result, it can be shown that the study’s proposed control strategy is dependable and effective.

5. Conclusions

In this paper, the problems encountered in the actual dynamic positioning operation are considered. For example, there are problems, such as ship operation area limitation, unmeasurable speed, unknown time-varying disturbances, unknown dynamics and input saturation. By introducing the BLF to limit the ship position error, the ship position is always within the dynamic positioning operation range. The ship’s unmeasurable velocity and the set total disturbance consisting of unknown time-varying disturbances and unknown dynamics are estimated by an FDESO. The thruster system dynamics equation is considered in the controller design to make the generated thrust signal conform to the engineering reality. The input saturation issue is dealt with via a finite-time auxiliary dynamic system. To combat unwanted mistakes, one uses the robust control concept. A position-constrained dynamic ship positioning output feedback control rule that takes the dynamics of the thruster system into account is constructed by combining the aforementioned parts. The theoretical analysis section shows that the ship position and heading can eventually be maintained at the expected value and that the ship position remains within the designated operating area throughout. All signals in the designed dynamic positioning output feedback control system are eventually and consistently bounded. The simulation results show that the control law is effective and satisfies the engineering reality.

This paper improves the existing dynamic positioning technique by considering as many problems encountered in complex sea conditions as possible to make it more realistic. This paper also considers the effects of unmeasurable speed, the uncertainty of model parameters, the uncertainty of external disturbances, physical characteristics of the thruster system, and input saturation of the thruster system. In addition, in this paper, the ship position error is constrained by introducing BLF in the controller design so that the ship position is always kept within the safe working range, which ensures the safety of the ship during operation. Finally, this paper speeds up the convergence speed by introducing FDESO and a finite-time auxiliary dynamic system.

Since the ship model, actuation dynamics model and disturbance model used in the design of the controller in this paper deviate from the real physical model, the performance of the designed control law will be lower than expected when applied to the actual dynamic positioning.

The following two elements are included in upcoming work. To first achieve dynamic positioning control under various sea circumstances, the switching control technique is included into the dynamic positioning control. In order to achieve automated berthing control, the dynamic positioning control will also introduce the switching control technique and event triggering mechanism.