Impact Analysis of Welding Sequence to Reduce Weld Deformation in Aluminum Hulls

Abstract

:1. Introduction

2. Experiment and Simulation Conditions

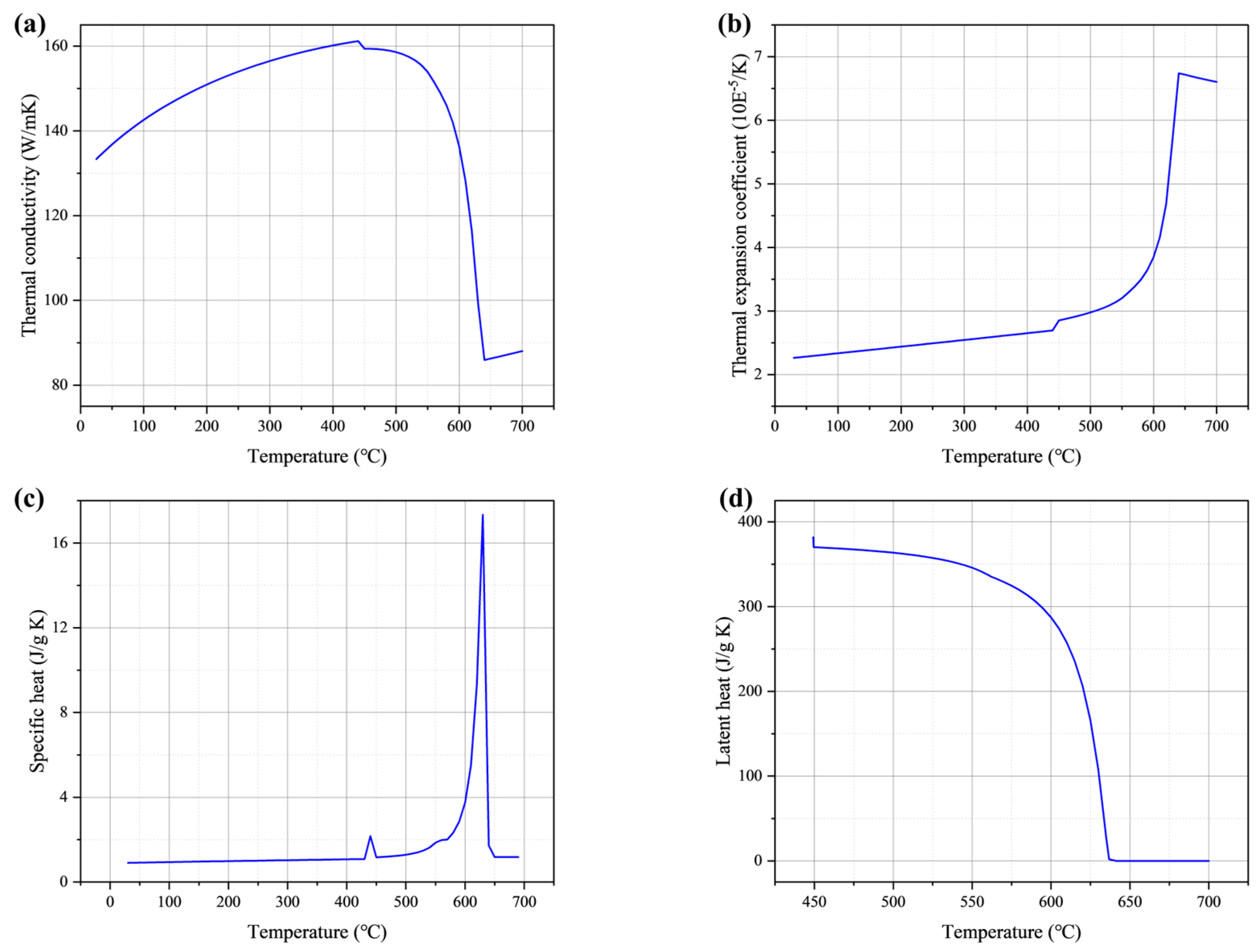

2.1. Materials

2.2. Welding Experiment Method

2.3. Deformation Measurement

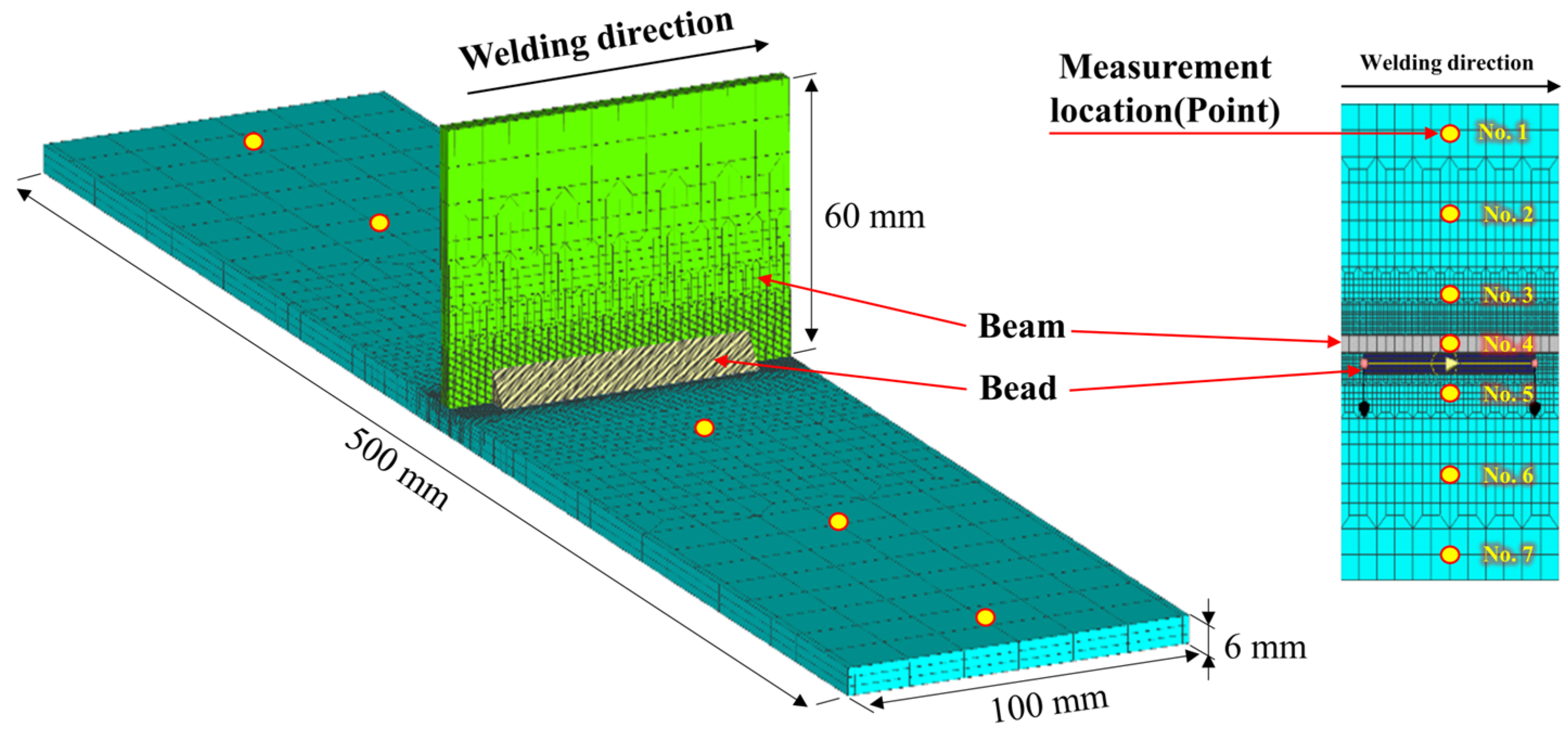

3. FEM Simulation Conditions

3.1. Physical Conditions

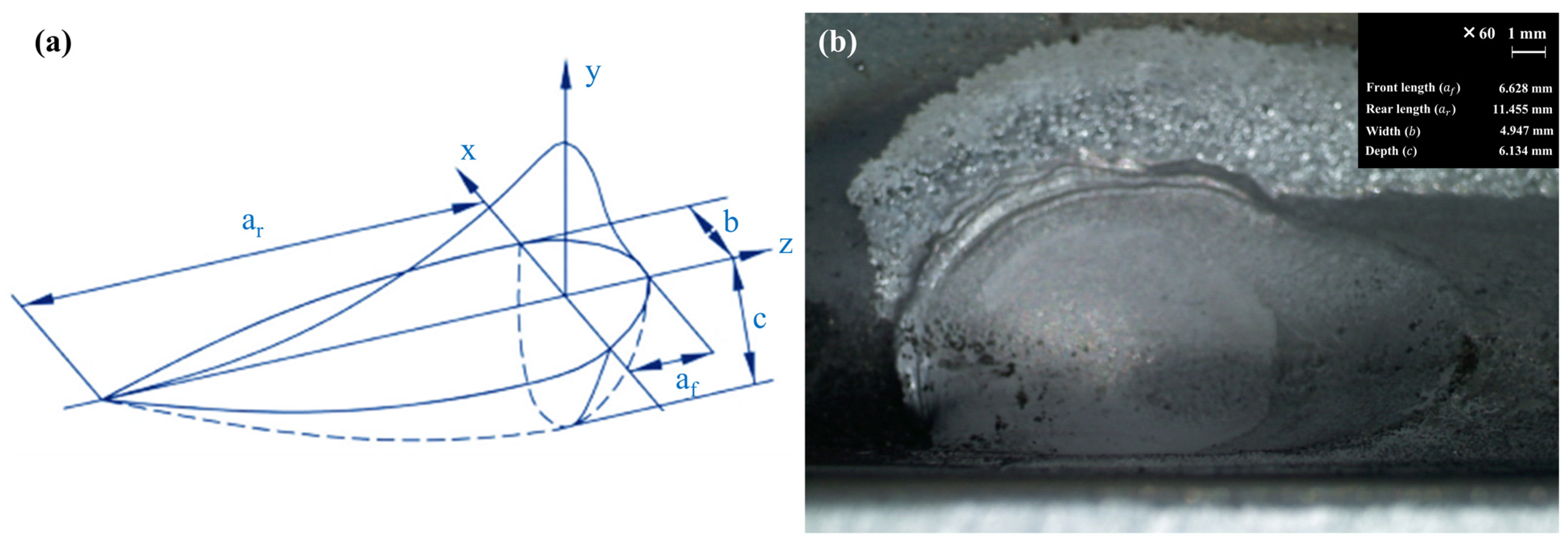

3.2. Welding Heat Source

3.3. Arc Efficiency

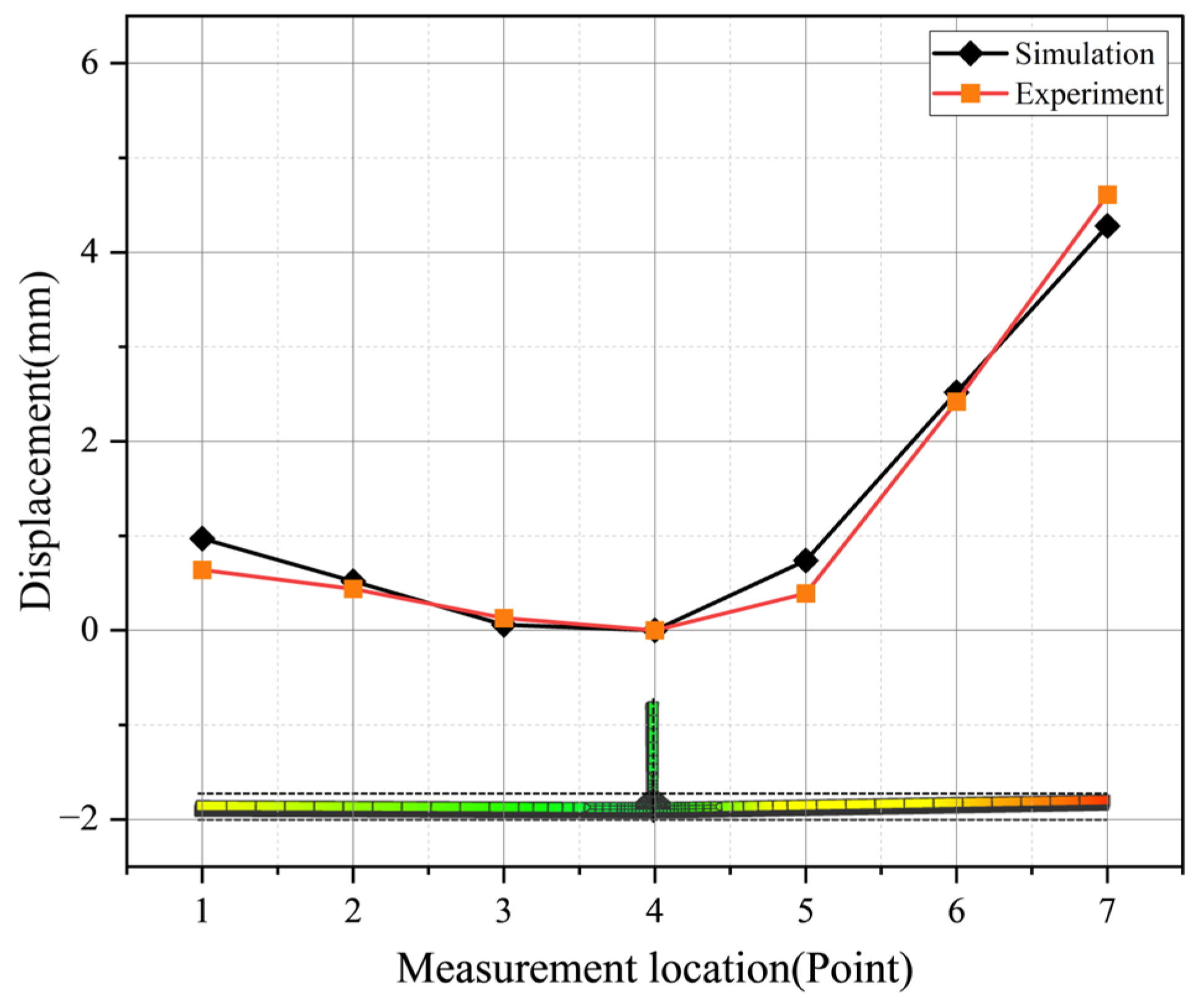

3.4. Simulation Condition Adequacy

4. FEM-Based Deformation Prediction

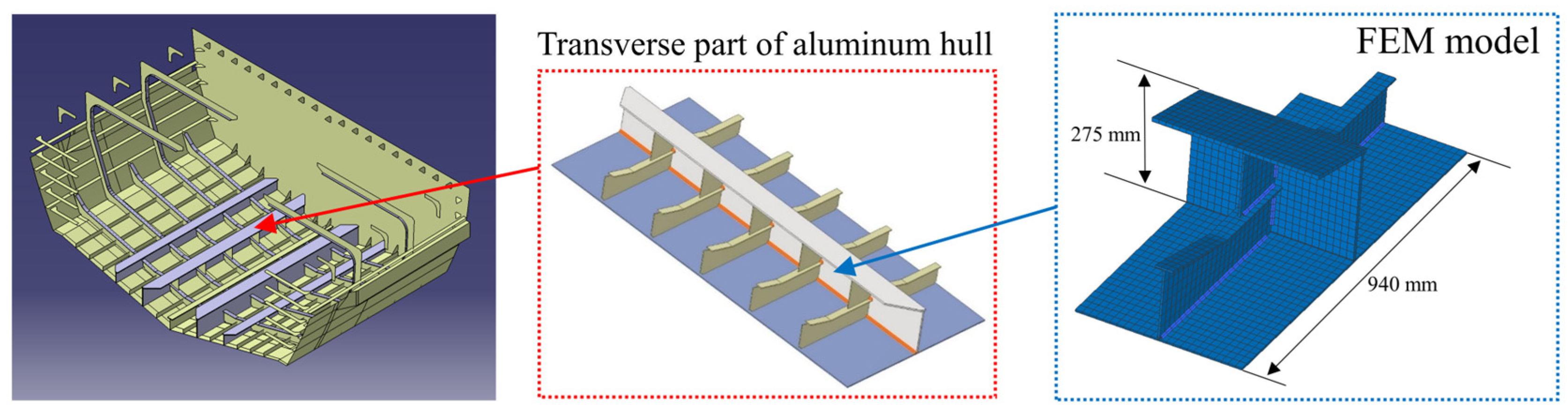

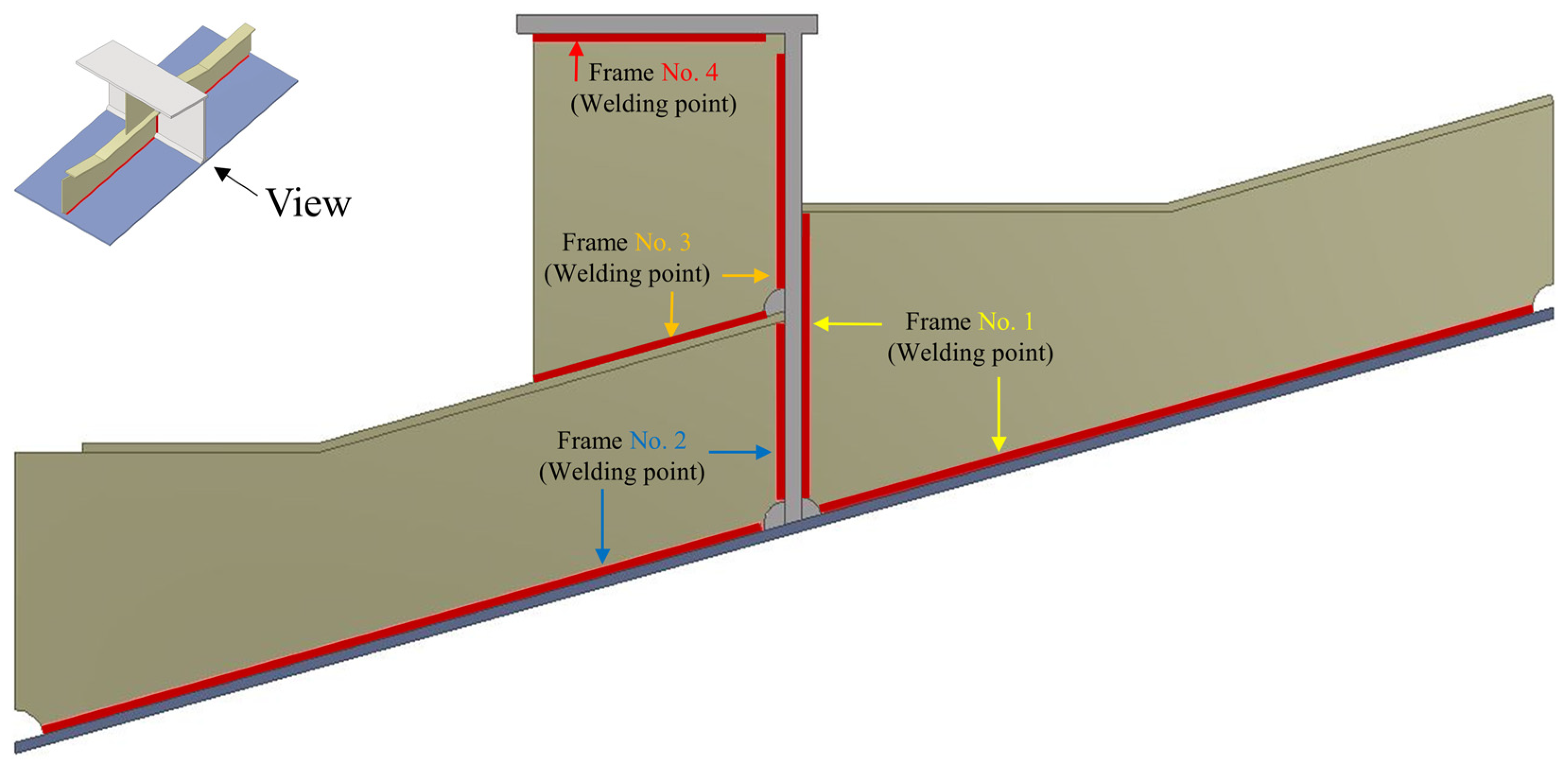

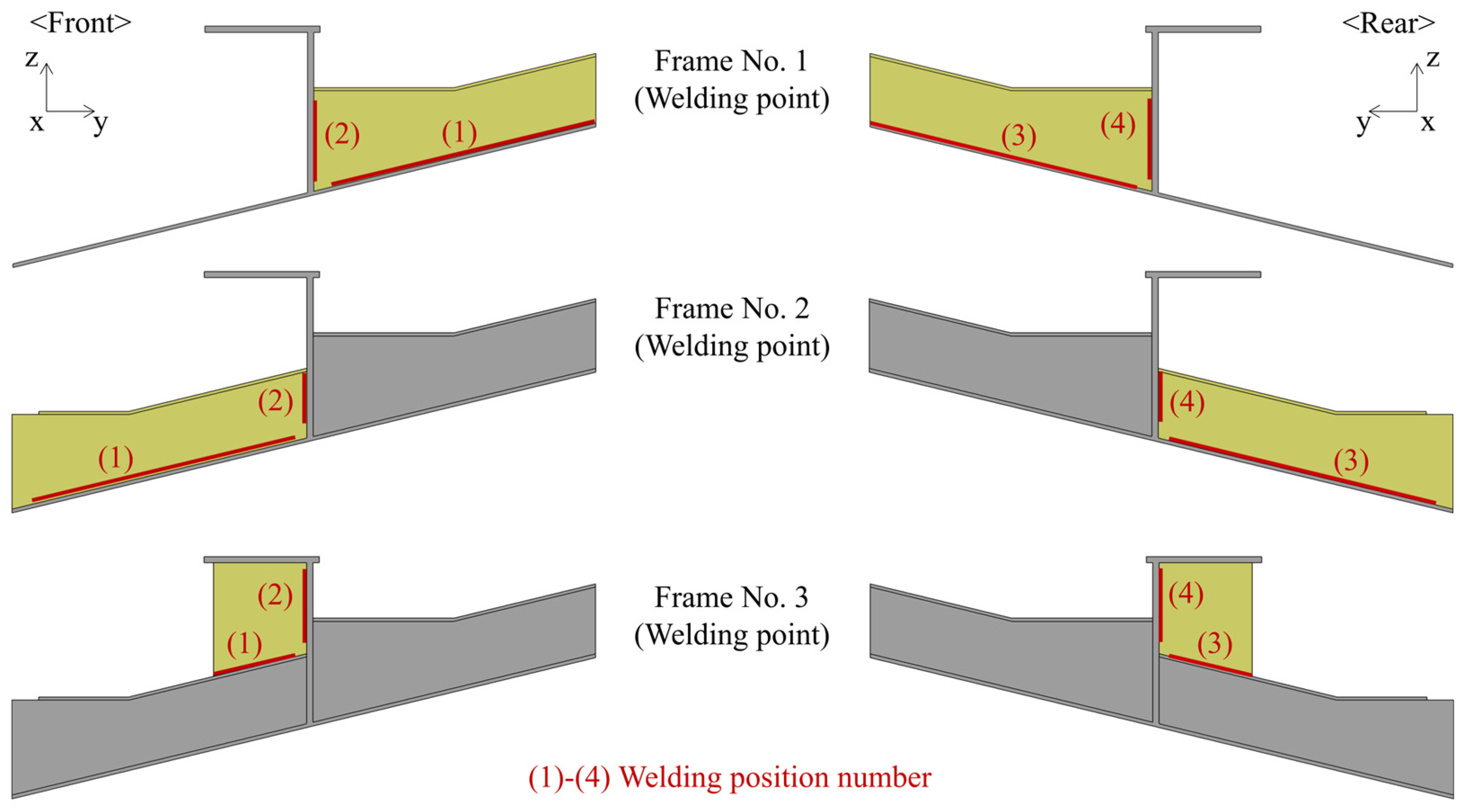

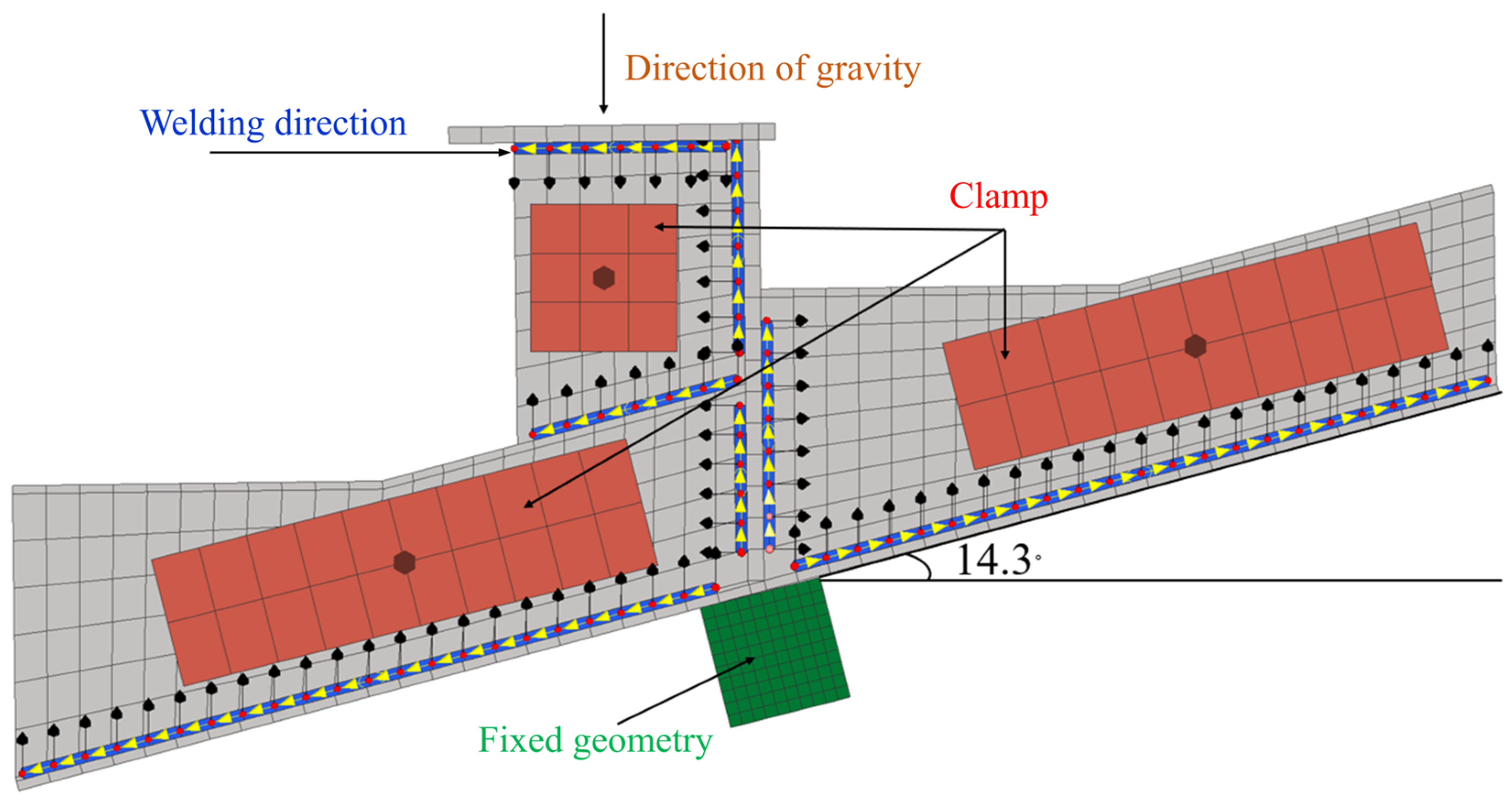

4.1. FEM Model

4.2. Welding Sequence Conditions

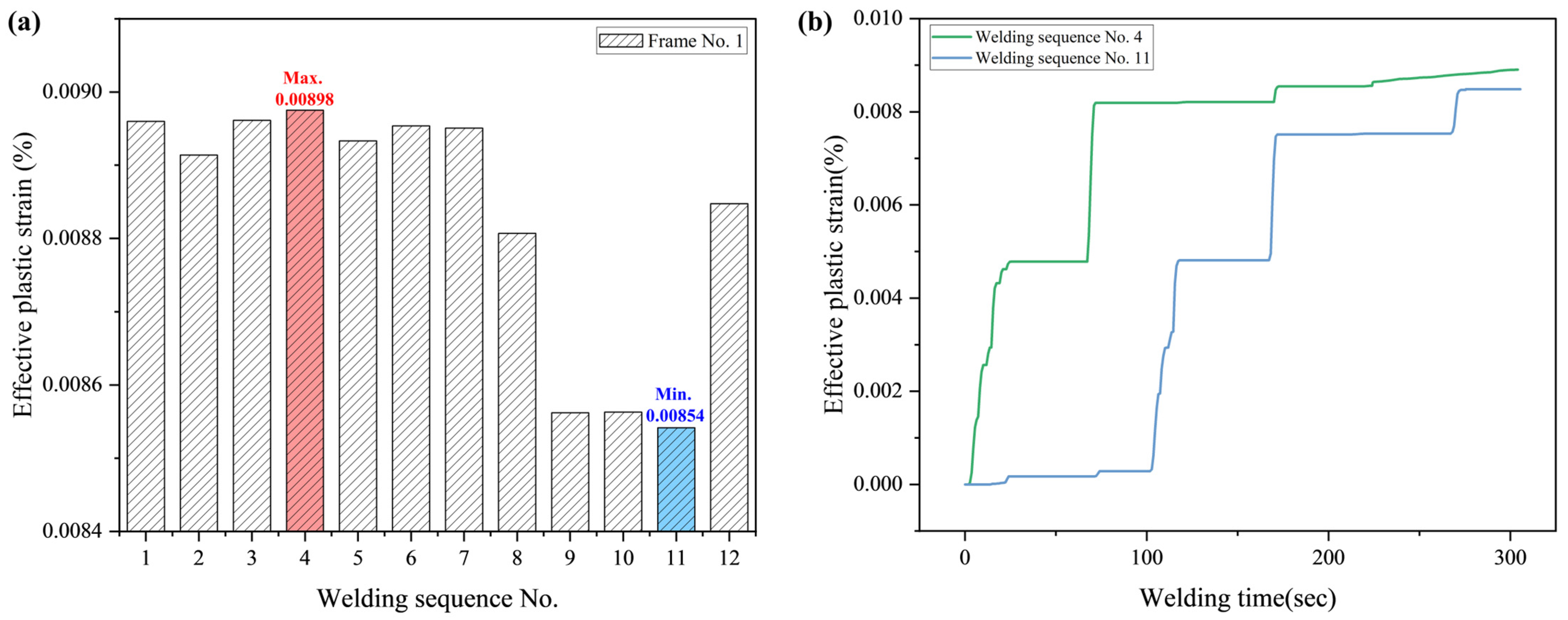

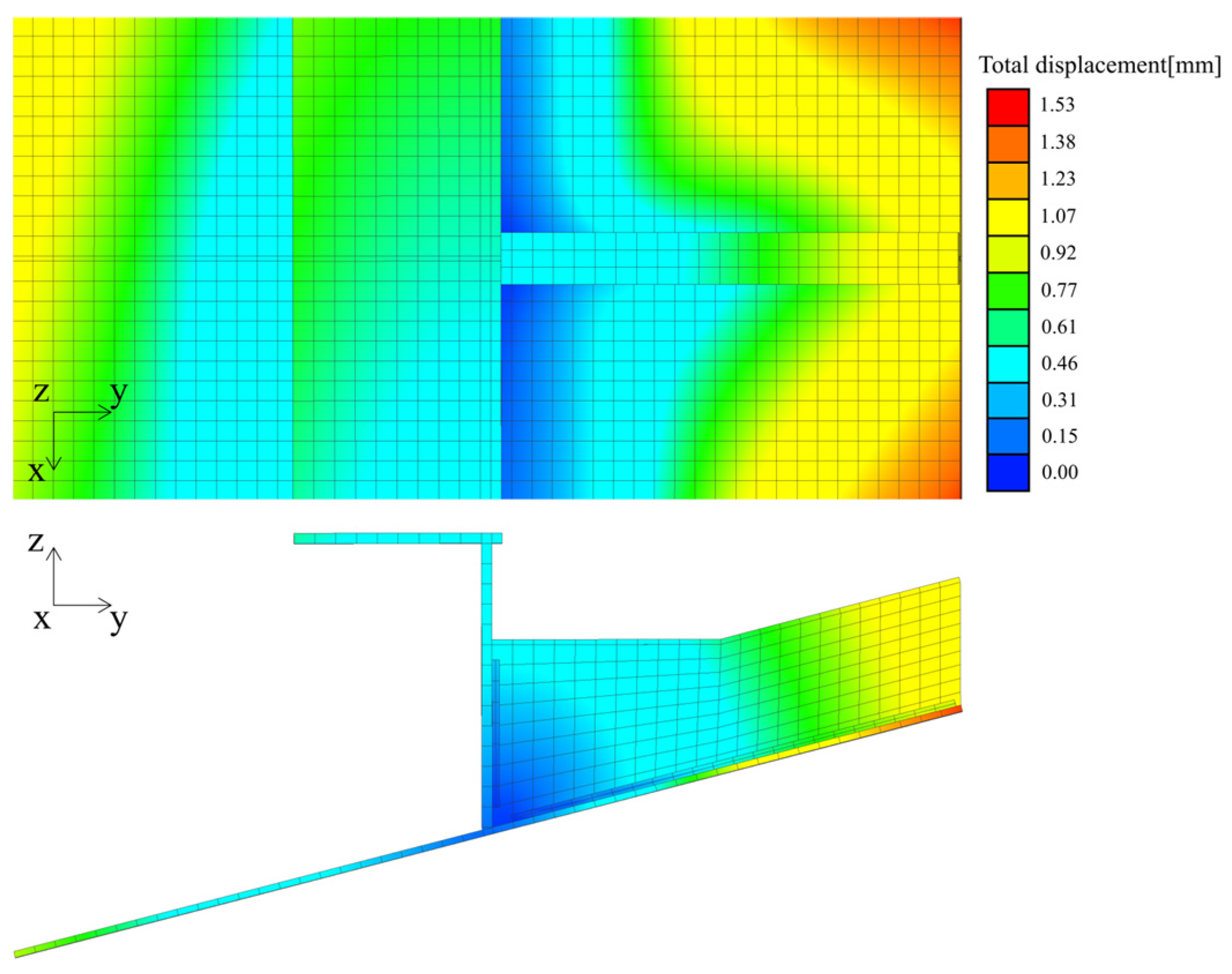

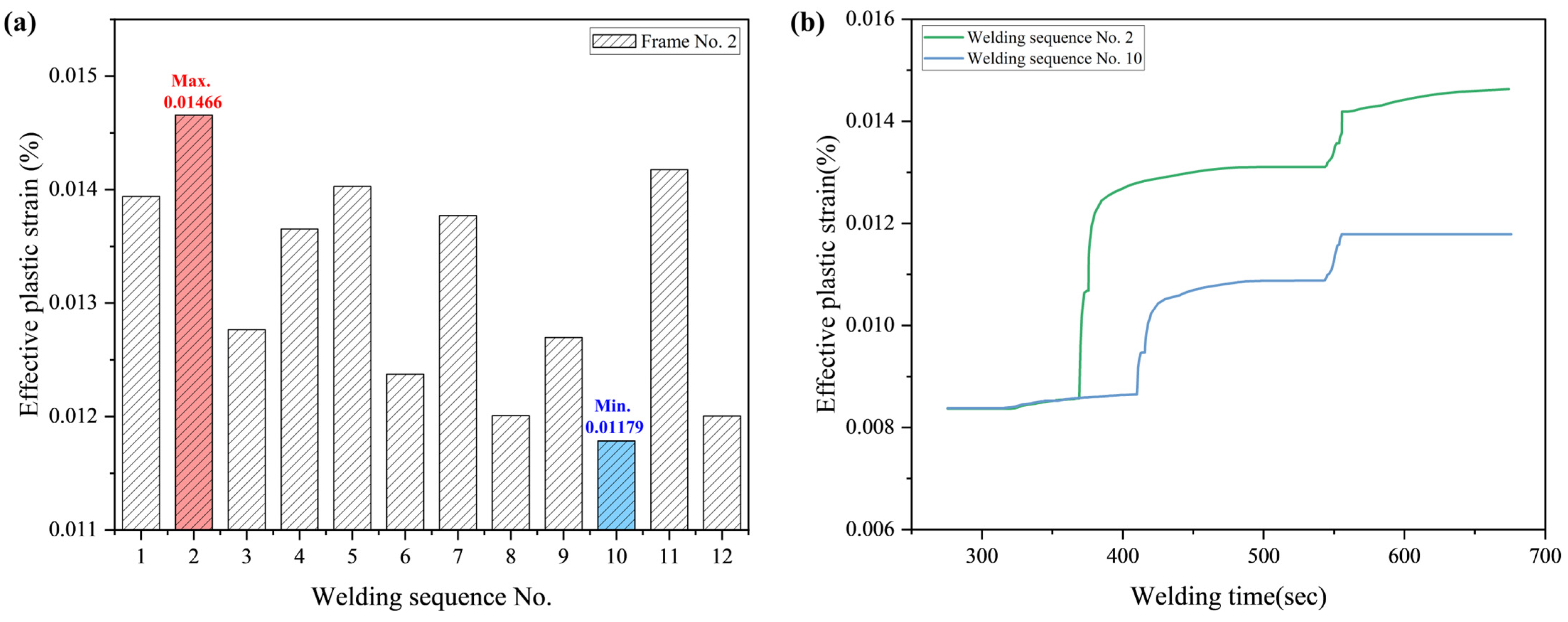

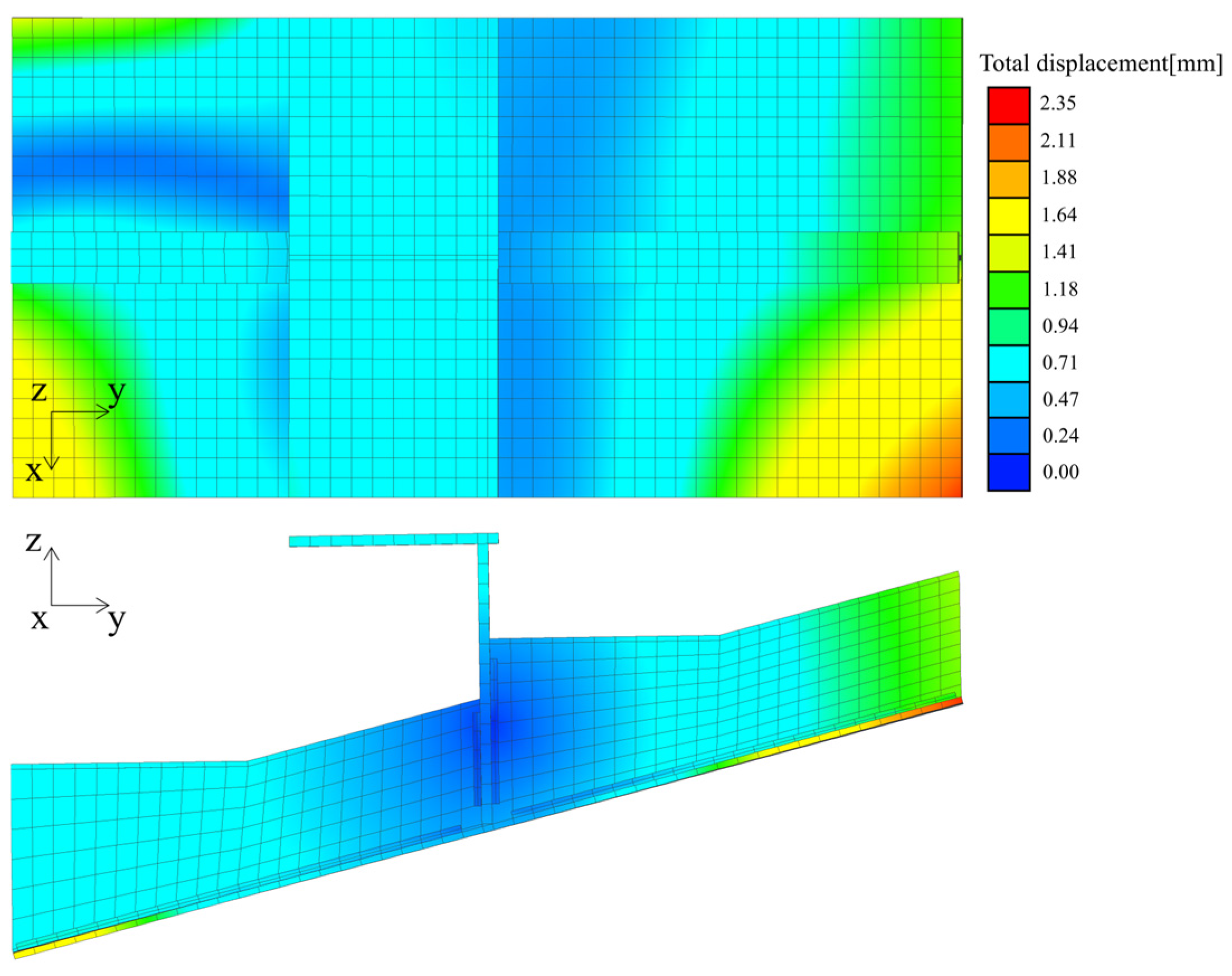

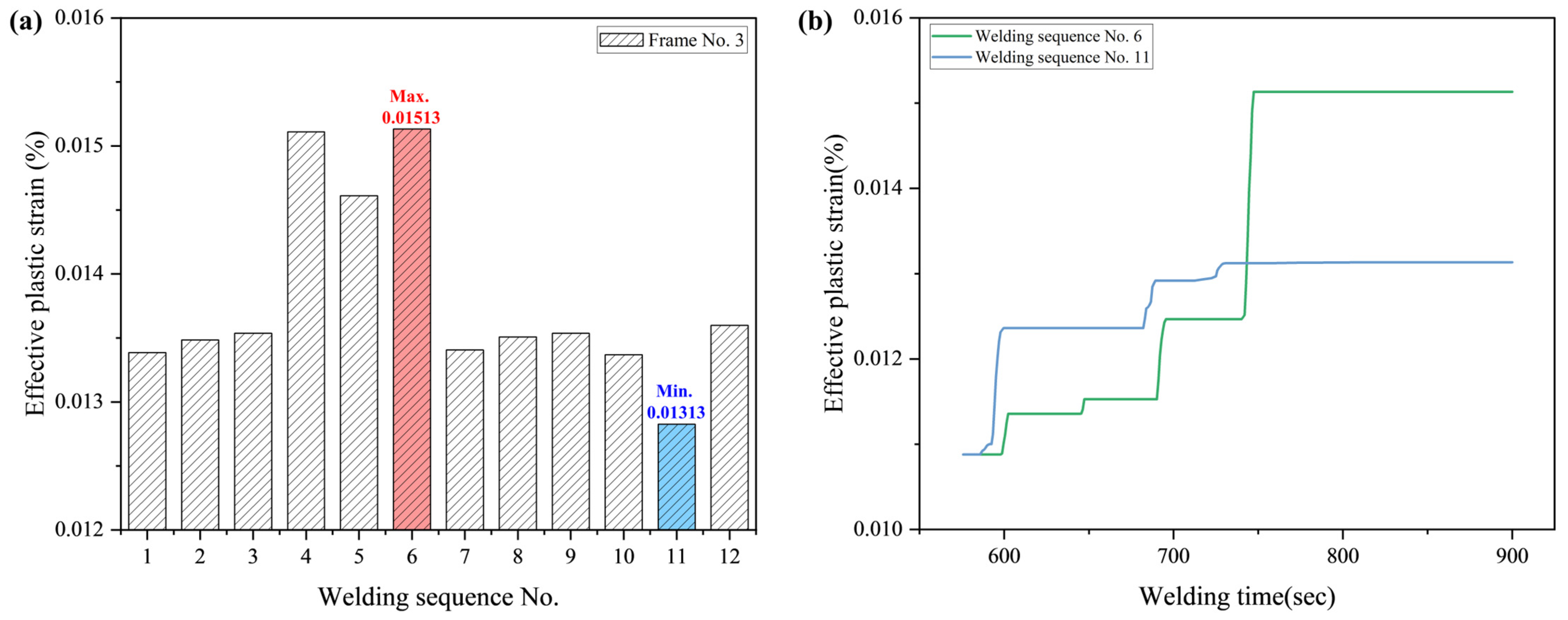

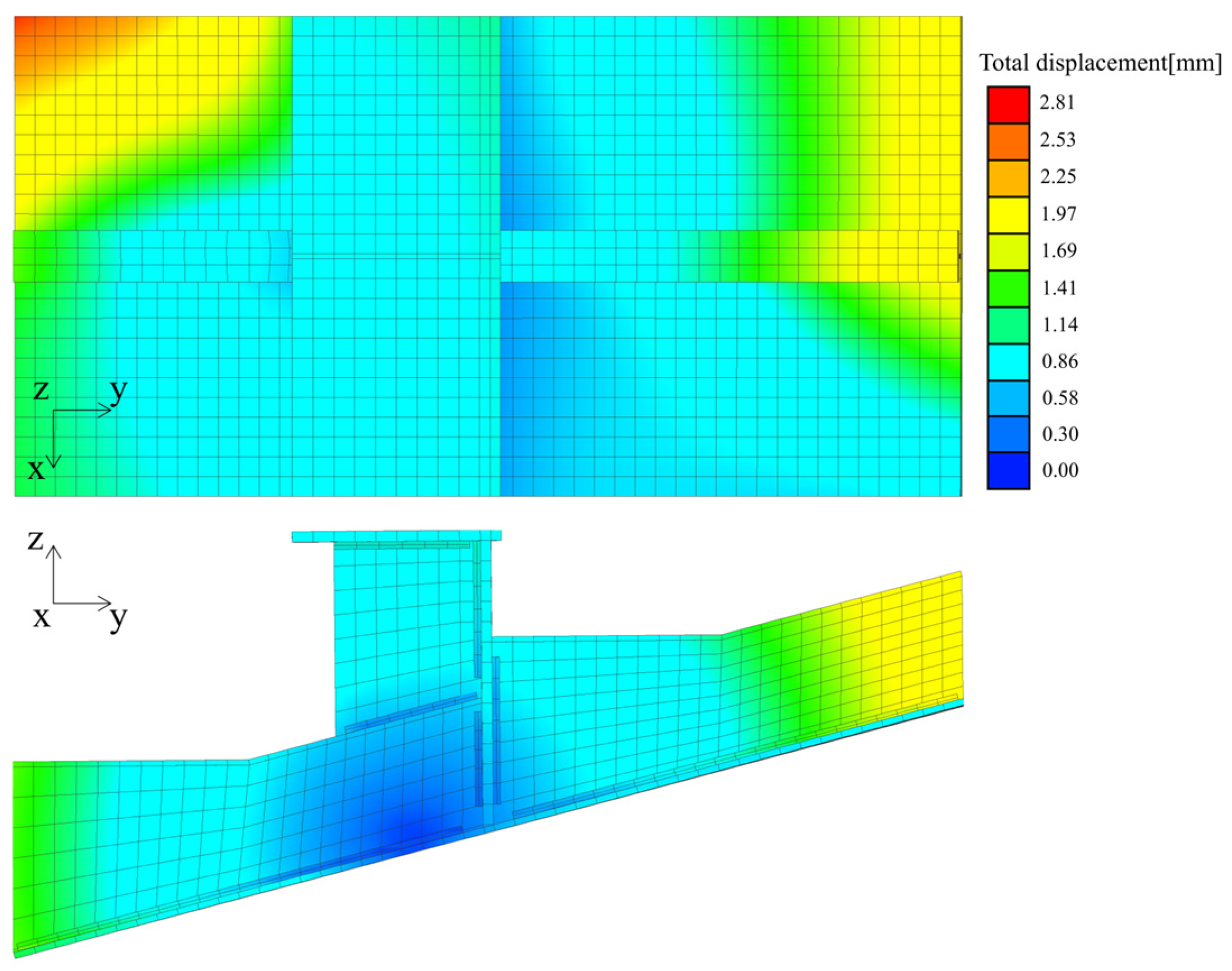

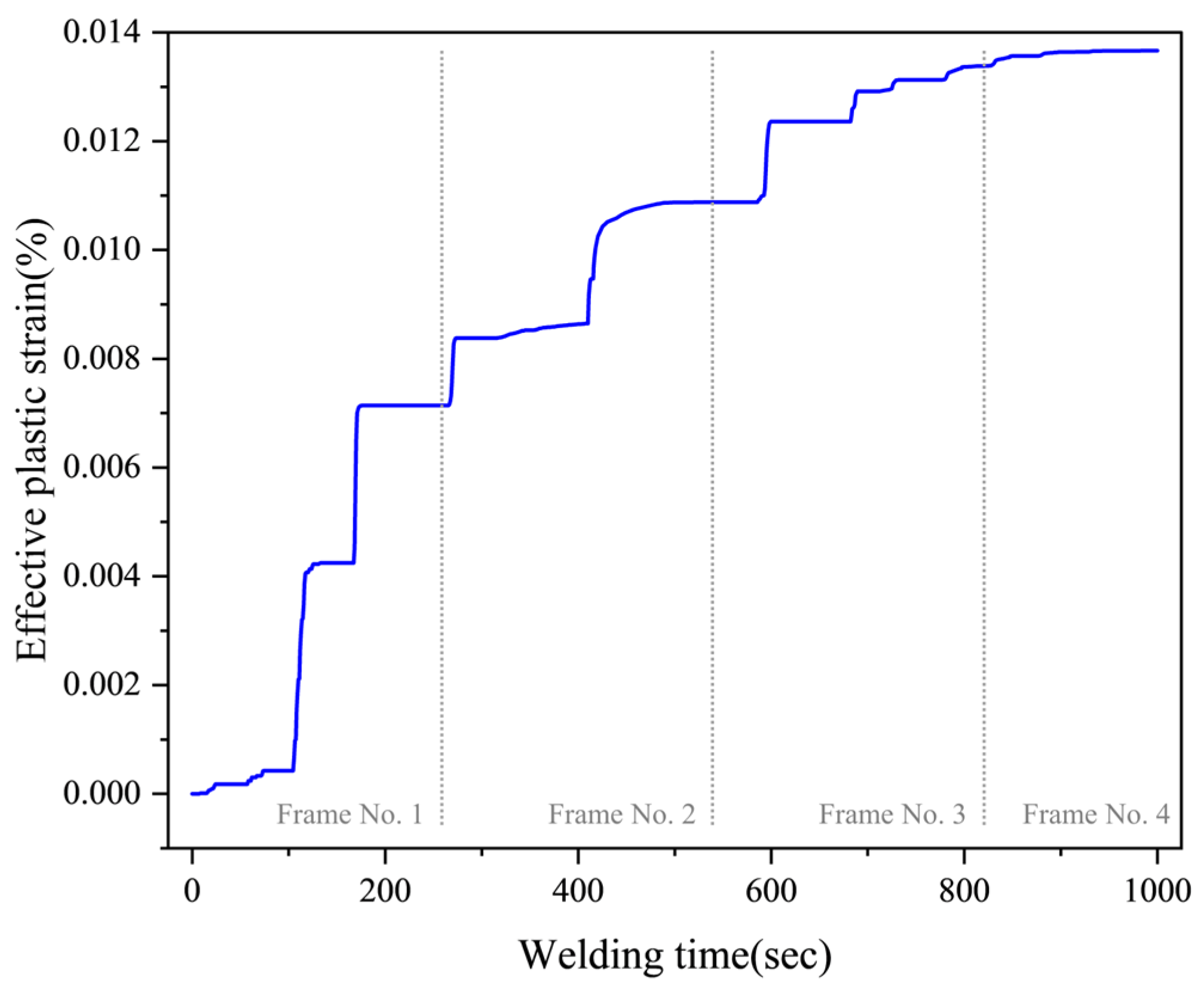

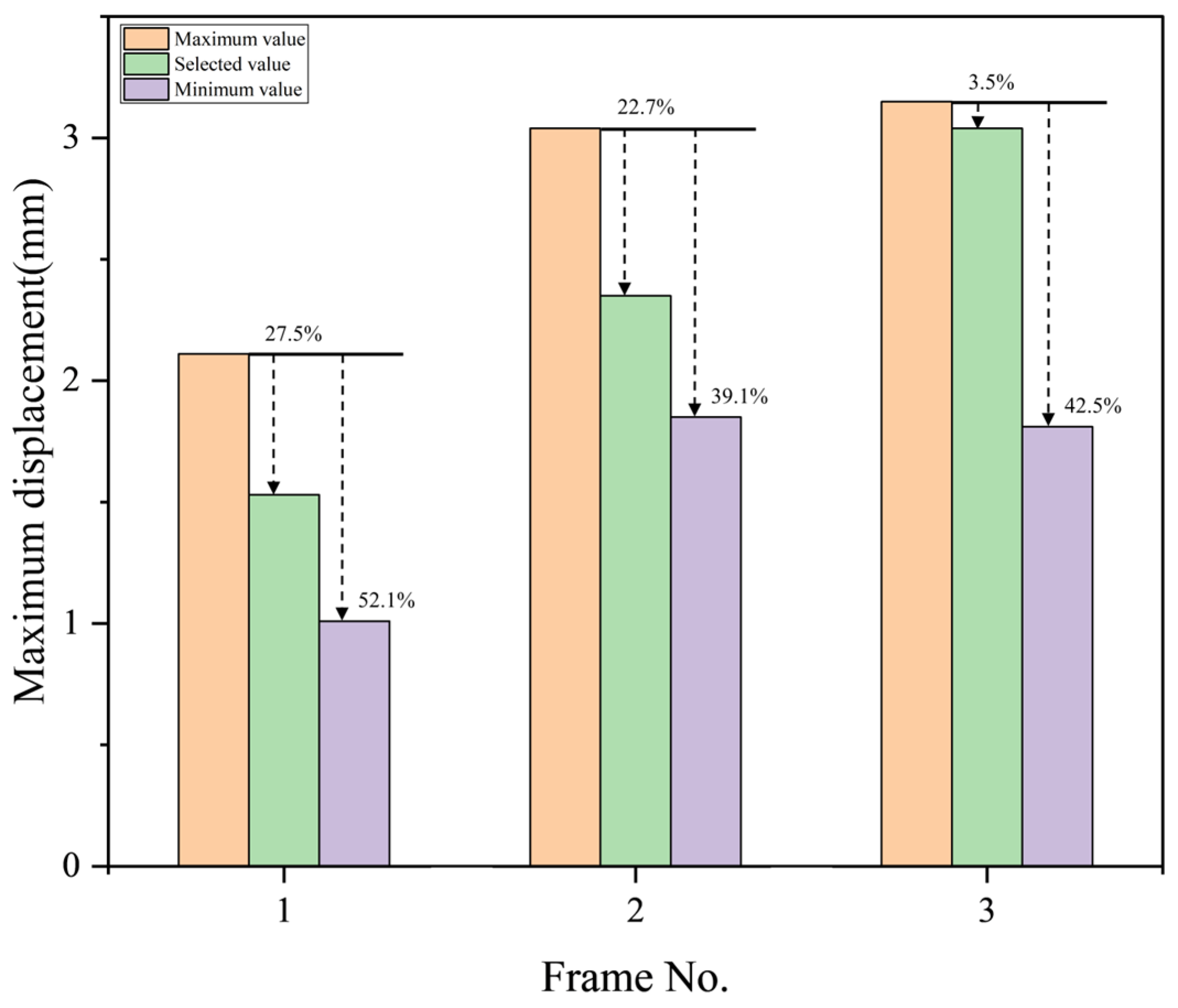

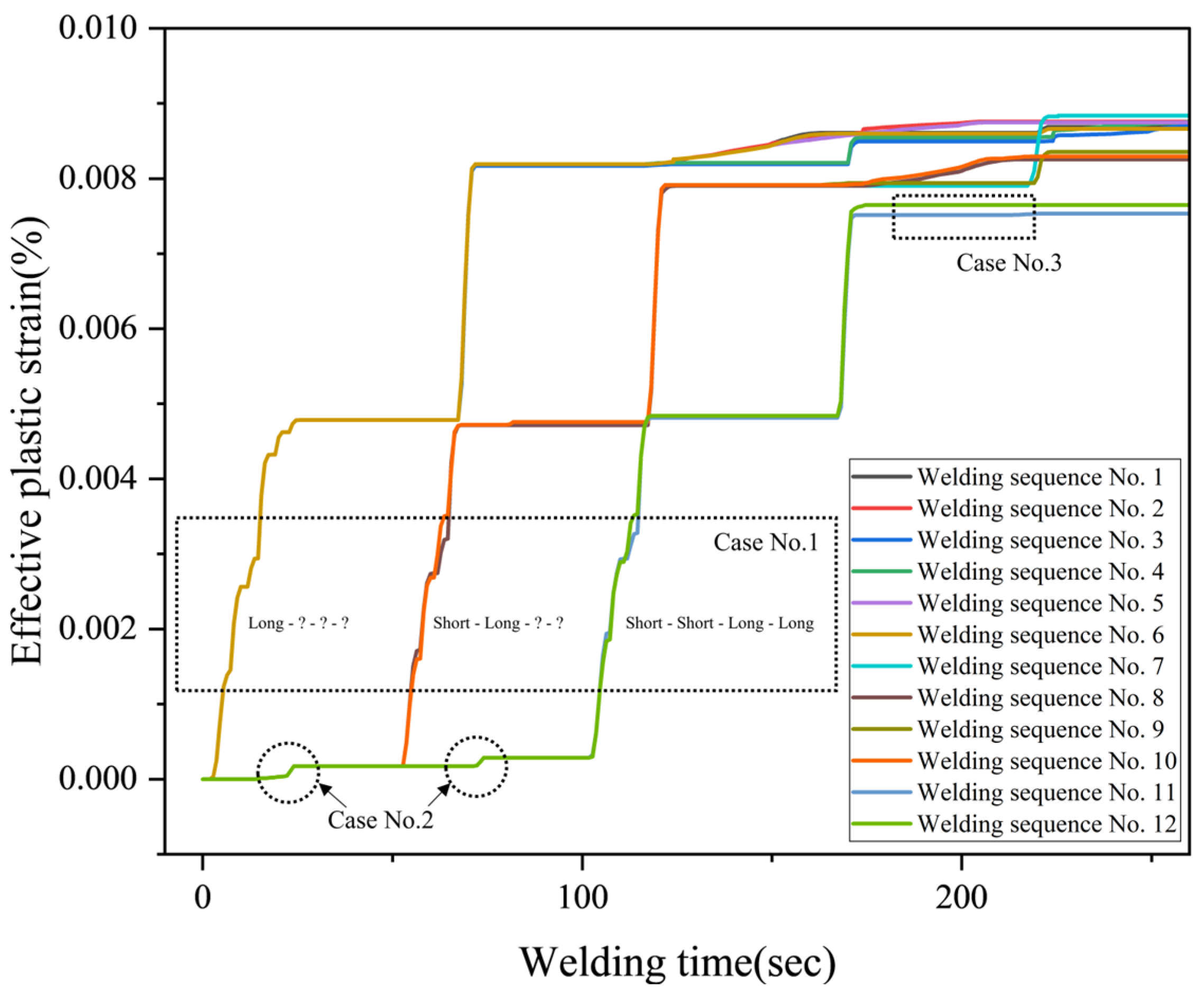

4.3. Simulation Results

4.4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hosseinabadi, O.F.; Khedmati, M.R. A Rreview on Ultimate Strength of Aluminium Structural Elements and Systems for Marine Applications. Ocean Eng. 2021, 232, 109153. [Google Scholar] [CrossRef]

- Wang, X.; Yu, Z.; Amdahl, J. Ultimate Strength of Welded Aluminium Stiffened Panels Under Combined Biaxial and Lateral Loads: A Numerical Investigation. Mar Struct. 2024, 97, 103654. [Google Scholar] [CrossRef]

- Xu, S.; Ma, J.; Lv, Y.; Shen, W.; Wu, Y.; Li, M. Fatigue Strength of Welded Joints of Marine Aluminum Alloy Extrusion Stiffened Plate Considering Welding Effects. Ocean Eng. 2024, 310, 118755. [Google Scholar] [CrossRef]

- Xavier, J.R.; Vinodhini, S.P.; Ramesh, B. Optimizing Aluminum Alloy Performance for Marine Superstructures: Advanced Nanocomposite Coating for Enhanced Corrosion Resistance, Flame Retardancy, and Mechanical Strength. Polym. Degrad. Stab. 2024, 227, 110847. [Google Scholar] [CrossRef]

- Kleppe, S.; Aalberg, A.; Langseth, M.; Fyllingen, Ø. Buckling Behavior of a Transversely Stiffened Aluminum Beam Flange. Ocean Eng. 2024, 307, 117960. [Google Scholar] [CrossRef]

- Ahmed, S.; Rahman, R.A.U.; Awan, A.; Ahmad, S.; Akram, W.; Amjad, M.; Yahya, M.Y.; Rahimian Koloor, S.S. Optimization of Process Parameters in Friction Stir Welding of Aluminum 5451 in Marine Applications. J. Mar. Sci. Eng. 2022, 10, 1539. [Google Scholar] [CrossRef]

- Wu, C.; Kim, J.W. Numerical Prediction of Deformation in Thin-Plate Welded Joints Using Equivalent Thermal Strain Method. Thin-Walled Struct. 2020, 157, 107033. [Google Scholar] [CrossRef]

- Woo, D.; Kitamura, M.; Takezawa, A. Systematic method for positioning clamps and strongbacks based on their influence on welding displacements. Ocean Eng. 2020, 202, 107084. [Google Scholar] [CrossRef]

- Khajeian, A.; Mahmoudi, A.H.; Mehmanparast, A. Shot Peening Effects on Residual Stresses Redistribution of Offshore Wind Monopile Multi-Pass Weldments. Mar Struct. 2019, 66, 106–120. [Google Scholar] [CrossRef]

- Jang, H.L.; Ryu, H.; Kang, S. A Study on the Effects of Welding Deformation According to Weld Sequence in Overlay-Welded Structures. Metals 2024, 14, 684. [Google Scholar] [CrossRef]

- Sun, J.; Nitschke Pagel, T.; Dilger, K. Influence of Strain-Hardening Models and Slopes on the Predicted Residual Stresses in Structural Steel S235 Weldments. J. Mater. Res. Technol. 2022, 19, 4044–4062. [Google Scholar] [CrossRef]

- Wahidi, S.I.; Oterkus, S.; Oterkus, E. Simulation of a Ship’s Block Panel Assembly Process: Optimizing Production Processes and Costs through Welding Robots. J. Mar. Sci. Eng. 2023, 11, 1506. [Google Scholar] [CrossRef]

- Woo, D.; Kitamura, M. Numerical Prediction of Welding Distortion Considering Gravity Force on General Ship Grillage Structure by Elastic Finite Element Method Using Inherent Strain. J. Mar. Sci. Eng. 2020, 8, 454. [Google Scholar] [CrossRef]

- Bhatti, A.A.; Barsoum, Z.; Murakawa, H.; Barsoum, I. Influence of Thermo-Mechanical Material Properties of Different Steel Grades on Welding Residual Stresses and Angular Distortion. Mater. Des. 2015, 65, 878–889. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, J.; Kang, S. A Study on Welding Deformation Prediction for Ship Blocks Using the Equivalent Strain Method Based on Inherent Strain. Appl. Sci. 2019, 9, 4906. [Google Scholar] [CrossRef]

- Yi, J.; Chen, Z.; Li, D.; Li, J.; Liu, J. Conditional generative adversarial network for welding deformation field prediction of butt-welded plates. J. Constr. Steel Res. 2022, 201, 107755. [Google Scholar] [CrossRef]

- Han, Y.H.; Lim, H.B.; Shin, T.S.; Yang, H.I. Prediction of Welding Deformation Using the Thermal Elastic–Plastic Finite Element Method by Considering Welding Interpass Temperature. Materials 2024, 17, 3656. [Google Scholar] [CrossRef]

- Li, L.; Luo, C.; Shen, J.; Zhang, Y. Numerical Prediction of Welding Deformation in Ship Block Subassemblies Via the Inhomogeneous Inherent Strain Method. J. Manuf. Process. 2022, 80, 860–873. [Google Scholar] [CrossRef]

- Murakawa, H.; Deng, D.; Ma, N.; Wang, J. Applications of inherent strain and interface element to simulation of welding deformation in thin plate structures. Comput. Mater. Sci. 2012, 51, 43–52. [Google Scholar]

- Lee, J.; Perrera, D.; Chung, H. Multi-Pass Welding Distortion Analysis Using Layered Shell Elements Based on Inherent Strain. J. Mar. Sci. Eng. 2021, 9, 632. [Google Scholar] [CrossRef]

- Ji, H.; Ma, J.; Wu, J. Analysis and Control of Welding Deformation for CFETR Vacuum Vessel PS2. Fusion Eng. Des. 2020, 154, 111521. [Google Scholar] [CrossRef]

- Wu, C.; Wang, C.; Kim, J.W. Welding Sequence Optimization to Reduce Welding Distortion Based on Coupled Artificial Neural Network and Swarm Intelligence Algorithm. Eng. Appl. Artif. Intell. 2022, 114, 105142. [Google Scholar] [CrossRef]

- Liu, B.; Yang, J.; Li, J.; Liao, X.; Yang, Q.; Zhang, J.; Hu, T.; Jiang, S. Research on Welding Deformation Control Technology of Battery Electric Vehicle Framed Aluminum Body. Prog. Nat. Sci. Mater. Int. 2024, 34, 108–121. [Google Scholar] [CrossRef]

- Meng, F.L.; Liu, A.G. Numerical Simulation for Residual Stress and Deformation of Surface Welding on Membrane Water-Wall. Appl. Mech. Mater. 2014, 490, 594–599. [Google Scholar] [CrossRef]

- Xu, F.; Zhao, Y.; Chen, J.; Liu, X.; Huang, Y. Experimental and Numerical Investigation on Residual Stress and Deformation of Welded I-Section Curved Steel Beams. Thin-Walled Struct. 2024, 199, 111821. [Google Scholar] [CrossRef]

- Moslemi, N.; Abdi, B.; Gohari, S.; Sudin, I.; Redzuan, N.; Ayob, A.; Ahmed, M.; Rhee, S.; Burvill, C. Influence of Welding Sequences on Induced Residual Stress and Distortion in Pipes. Constr. Build. Mater. 2022, 342, 127995. [Google Scholar] [CrossRef]

- Sun, J.; Dilger, K. Influence of Welding Sequence and External Restraint on Buckling Distortion in Thin-Plate Arc-Welded Joints. J. Adv. Join. Process. 2023, 8, 100157. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, G.; Pu, X.; Deng, D. Influence of Welding Sequence on Residual Stress Distribution and Deformation in Q345 Steel H-Section Butt-Welded Joint. J. Mater. Res. Technol. 2024, 32, 1–12. [Google Scholar] [CrossRef]

- Gao, Z.; Han, B.; Li, L.; Ma, G.; Niu, S. Numerical Simulation of Residual Stress in Post internal-Welding Process of Bimetal Composite Pipe and Optimization of Welding Sequence. Int. J. Pres. Ves. Pip. 2022, 199, 104730. [Google Scholar] [CrossRef]

- Li, C.; Zhai, H.; Liu, Z.; Ma, J.; Ji, H.; Liu, Q. Suppressing Welding Deformation Instability of Vacuum Vessel Considering External Restraint and Welding Sequence. Fusion Eng. Des. 2023, 196, 114007. [Google Scholar] [CrossRef]

- Su, Y.; Yang, X.; Wu, D.; Meng, T.; Li, W.; Feng, W.; Vairis, A. Optimizing Welding Sequence of TIG Cross-Joint of Invar Steel Using Residual Stresses and Deformations. J. Manuf. Process. 2023, 105, 232–245. [Google Scholar] [CrossRef]

- Woo, D.; Kitamura, M.; Takezawa, A. Method to systemically order welding sequence to efficiently mitigate welding displacement of a general ship grillage structure. Ships Offshore Struct. 2019, 15, 753–768. [Google Scholar] [CrossRef]

- Pyo, C.; Jeong, S.M.; Kim, J.; Park, M.; Shin, J.; Kim, Y.; Son, J.; Kim, J.H.; Kim, M.H. A Study on the Enhanced Process of Elaborate Heat Source Model Parameters for Flux Core Arc Welding of 9% Nickel Steel for Cryogenic Storage Tank. J. Mar. Sci. Eng. 2022, 10, 1810. [Google Scholar] [CrossRef]

- Goldak, J.; Chakravarti, A.; Bibby, M. A New Finite Element Model for Welding Heat Sources. Metall. Trans. B 1984, 15, 299–305. [Google Scholar] [CrossRef]

| Fe | Mg | Si | Al |

|---|---|---|---|

| 0.98 | 4.5 | 0.97 | Bal. |

| Fe | Mg | Si | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| 0.29 | 4.8 | 0.06 | 0.03 | 0.67 | 4.8 | 0.1 | 0.01 | 0.02 | Bal. |

| Variable | Level |

|---|---|

| Current (A) | 177 |

| Voltage (V) | 20.7 |

| Welding speed (cm/min) | 30 |

| CTWD (mm) | 15 |

| Bead working angle (°) | 45 |

| Shielding gas | 99.9% Ar |

| Flow rate (L/min) | 20 |

| Number | Welding Sequence | Number | Welding Sequence |

|---|---|---|---|

| 1 | 1-2-3-4 | 7 | 2-1-3-4 |

| 2 | 1-2-4-3 | 8 | 2-1-4-3 |

| 3 | 1-3-2-4 | 9 | 2-3-1-4 |

| 4 | 1-3-4-2 | 10 | 2-3-4-1 |

| 5 | 1-4-2-3 | 11 | 2-4-1-3 |

| 6 | 1-4-3-2 | 12 | 2-4-3-1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, C.; Woo, S.; Kim, J. Impact Analysis of Welding Sequence to Reduce Weld Deformation in Aluminum Hulls. J. Mar. Sci. Eng. 2024, 12, 1604. https://doi.org/10.3390/jmse12091604

Lee C, Woo S, Kim J. Impact Analysis of Welding Sequence to Reduce Weld Deformation in Aluminum Hulls. Journal of Marine Science and Engineering. 2024; 12(9):1604. https://doi.org/10.3390/jmse12091604

Chicago/Turabian StyleLee, Chungwoo, Suseong Woo, and Jisun Kim. 2024. "Impact Analysis of Welding Sequence to Reduce Weld Deformation in Aluminum Hulls" Journal of Marine Science and Engineering 12, no. 9: 1604. https://doi.org/10.3390/jmse12091604