Effect of Photoaging on the Structure, Optical Properties and Roughness of One-Shade Composite Restoratives

Abstract

:1. Introduction

2. Materials and Methods

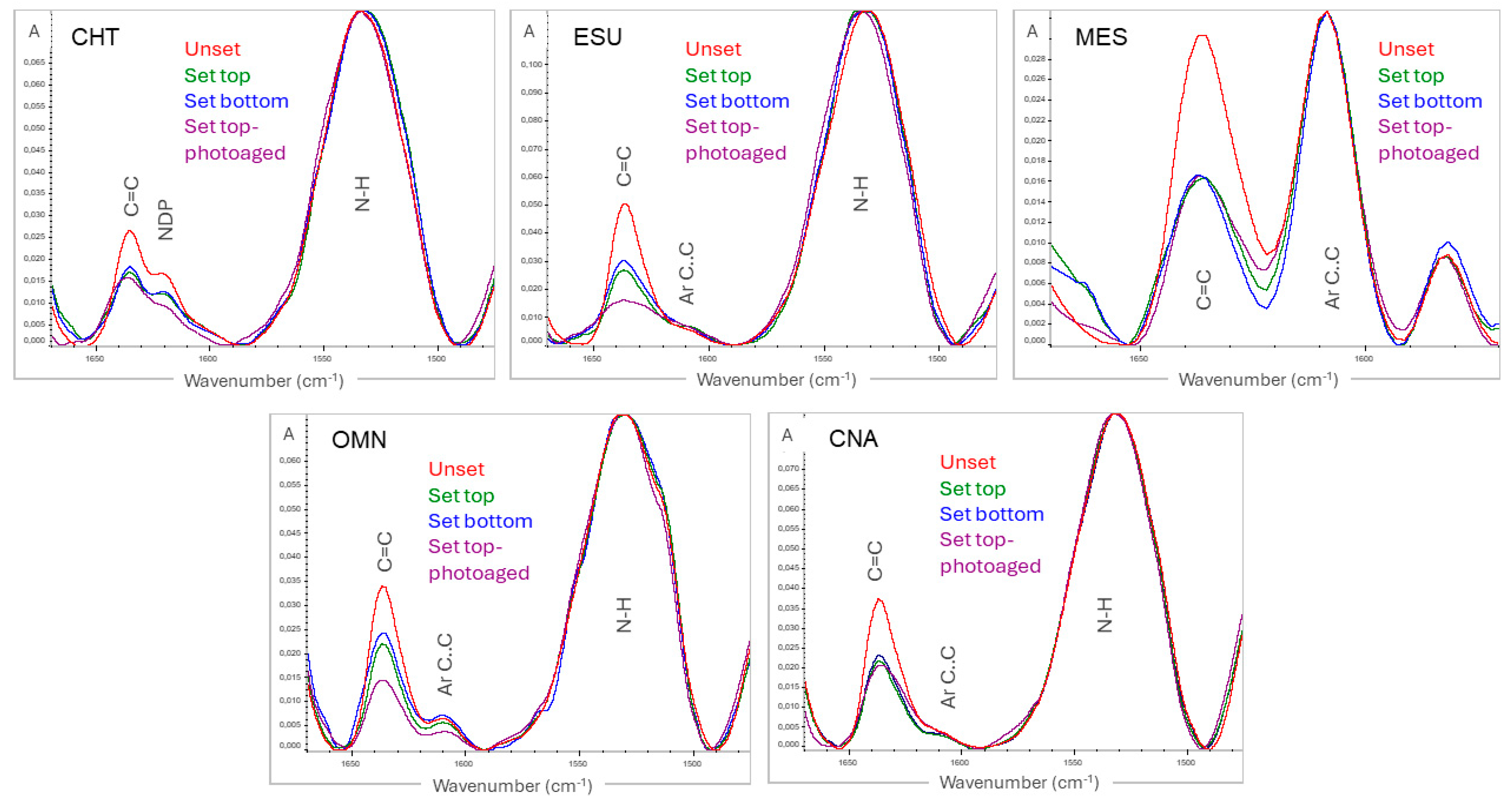

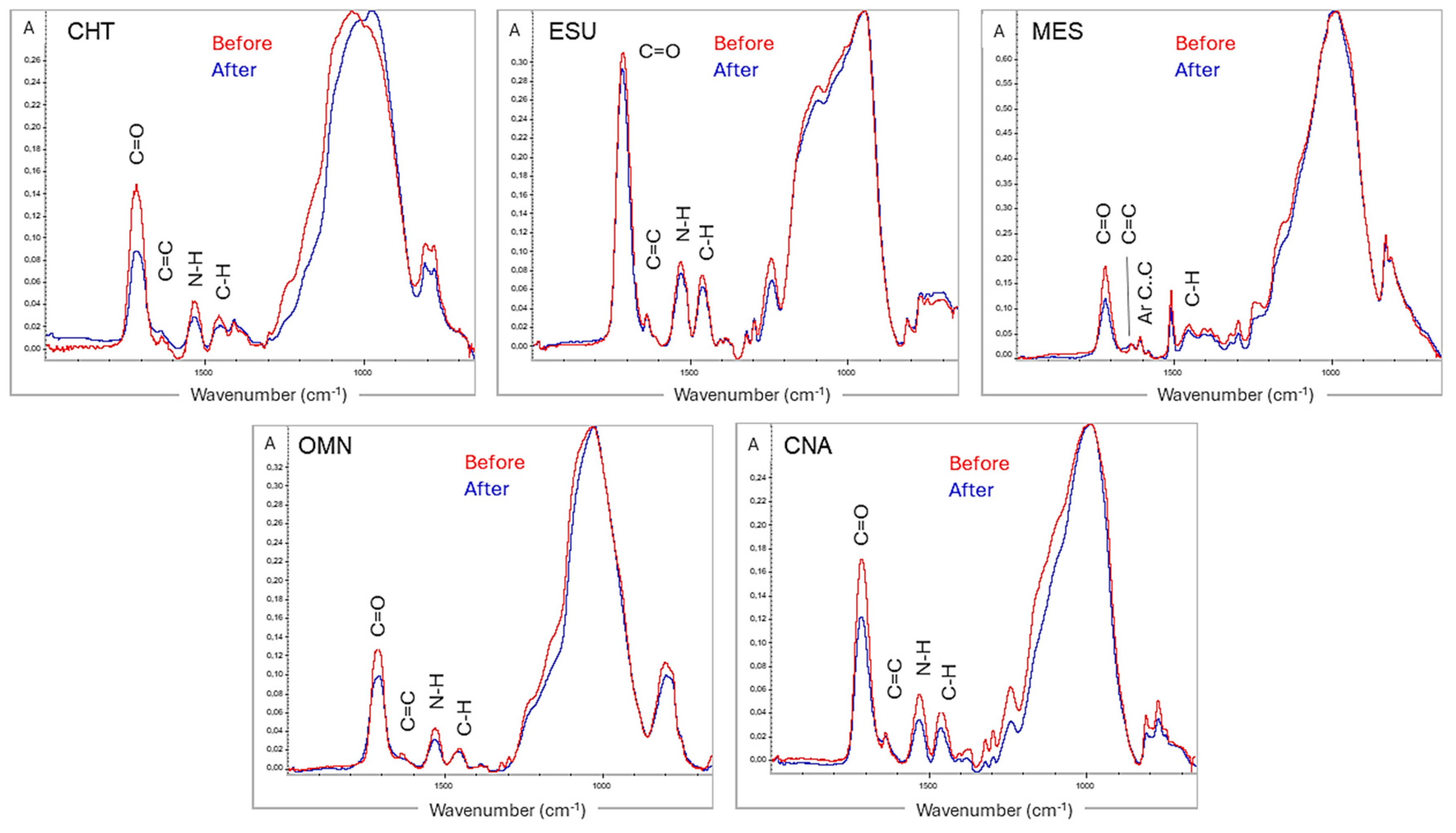

2.1. Degree of C=C Conversion and Structural Changes

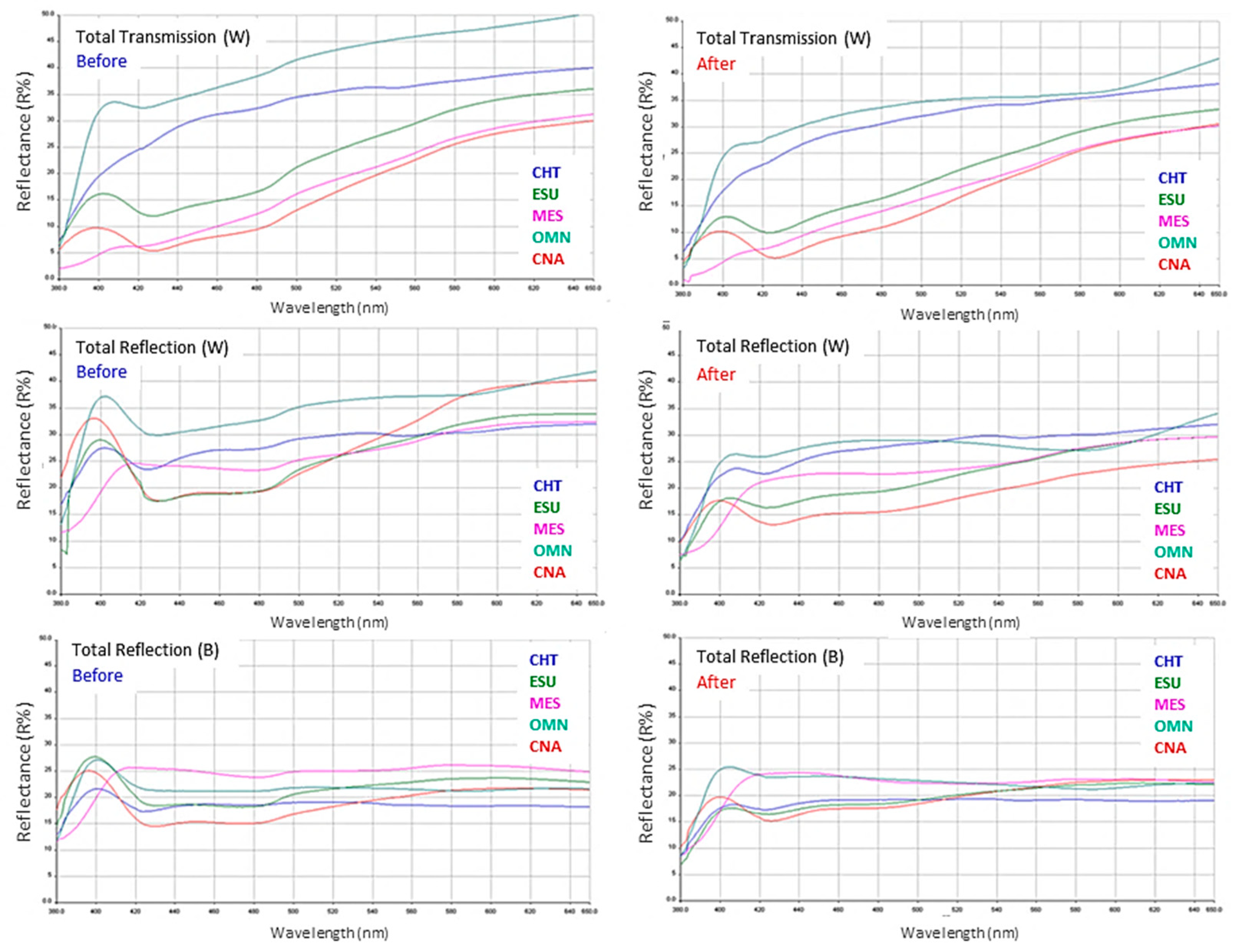

2.2. Assessment of Optical Properties

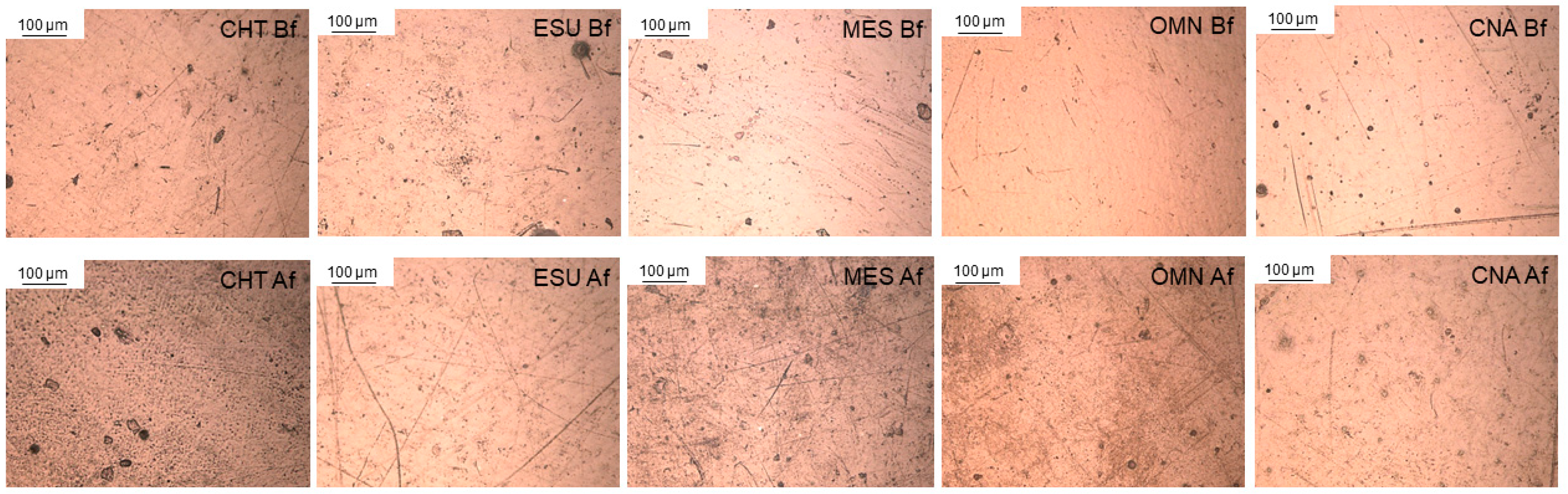

2.3. Roughness Measurements

2.4. Statistical Analysis

3. Results

3.1. Degree of C=C Conversion and Structural Changes

3.2. Assessment of Optical Properties

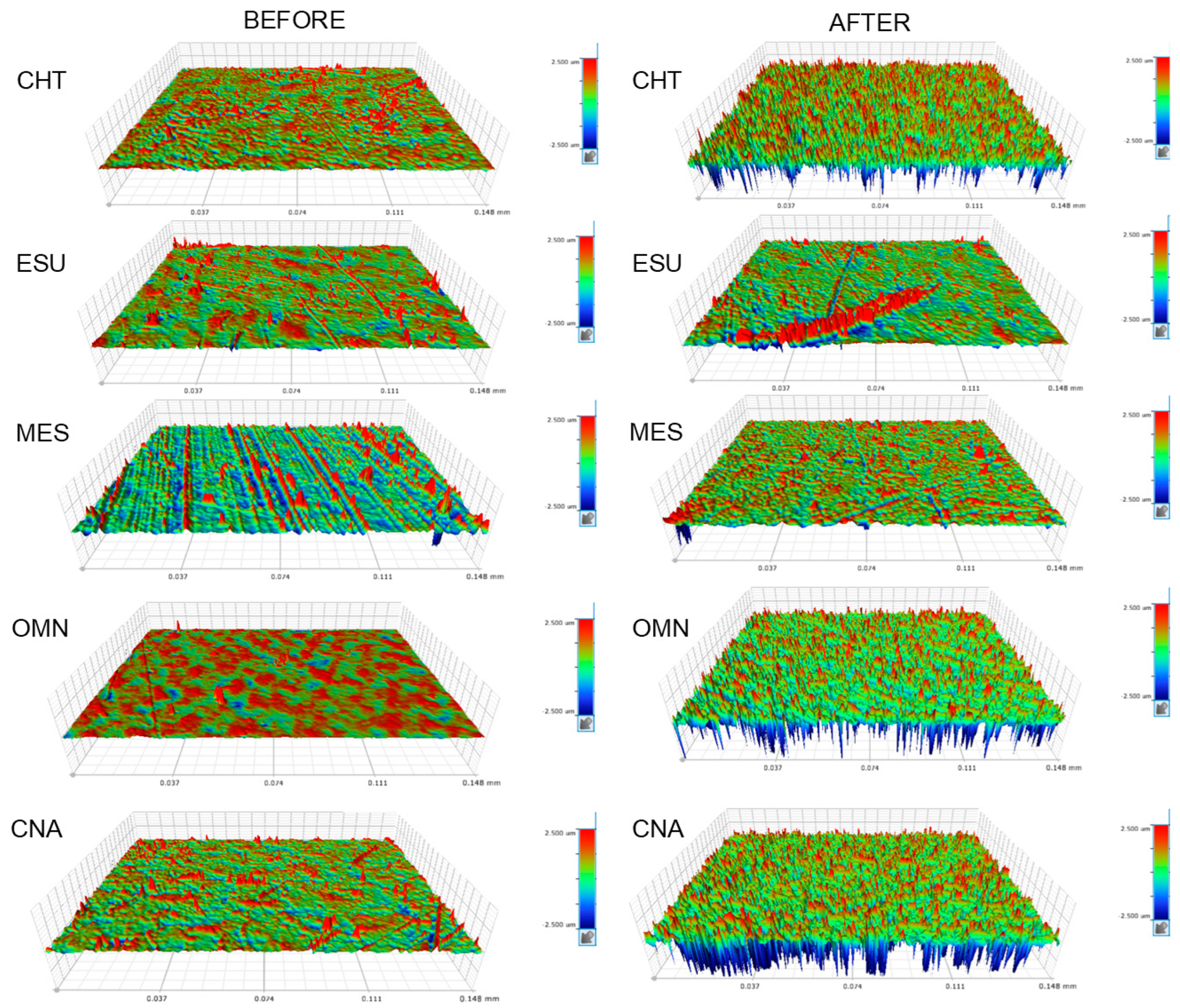

3.3. Roughness Measurements

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Samet, N.; Kwon, K.-R.; Good, P.; Weber, H.-P. Voids and Interlayer Gaps in Class 1 Posterior Composite Restorations: A Comparison between a Microlayer and a 2-Layer Technique. Quintessence Int. 2006, 37, 803–809. [Google Scholar] [PubMed]

- Ahmed, M.A.; Jouhar, R.; Khurshid, Z. Smart Monochromatic Composite: A Literature Review. Int. J. Dent. 2022, 2022, 2445394. [Google Scholar] [CrossRef]

- AlHamdan, E.M.; Bashiri, A.; Alnashmi, F.; Al-Saleh, S.; Al-shahrani, K.; Al-shahrani, S.; Alsharani, A.; Alzahrani, K.M.; Alqarawi, F.K.; Vohra, F.; et al. Evaluation of smart chromatic technology for a single-shade dental polymer resin: An in vitro study. Appl. Sci. Switz. 2021, 11, 10108. [Google Scholar] [CrossRef]

- Prodan, C.M.; Gasparik, C.; Ruiz-López, J.; Dudea, D. Color and Translucency Variation of a One-Shaded Resin-Based Composite after Repeated Heating Cycles and Staining. Mater. Basel Switz. 2023, 16, 3793. [Google Scholar] [CrossRef]

- Omnichroma Technical Report, Tokuyama Corp., Tokyo. 2019. Available online: https://omnichroma.com/us/wp-content/uploads/sites/4/2019/01/OMNI-Tech-Report-Color-Final.pdf (accessed on 24 March 2024).

- de Abreu, J.L.B.; Sampaio, C.S.; Benalcázar Jalkh, E.B.; Hirata, R. Analysis of the Color Matching of Universal Resin Composites in Anterior Restorations. J. Esthet. Restor. Dent. 2021, 33, 269–276. [Google Scholar] [CrossRef] [PubMed]

- Graf, N.; Ilie, N. Long-Term Mechanical Stability and Light Transmission Characteristics of One Shade Resin-Based Composites. J. Dent. 2022, 116, 103915. [Google Scholar] [CrossRef] [PubMed]

- Ilie, N. Universal Chromatic Resin-Based Composites: Aging Behavior Quantified by Quasi-Static and Viscoelastic Behavior Analysis. Bioengineering 2022, 9, 270. [Google Scholar] [CrossRef]

- Kedici Alp, C.; Arslandaş Dinçtürk, B.; Altınışık, H. The Effect of Food-Simulating Liquids on Surface Features of Single-Shade Universal Composites: An In Vitro Study. J. Int. Soc. Prev. Community Dent. 2023, 13, 157–165. [Google Scholar] [CrossRef]

- Yılmaz Atalı, P.; Doğu Kaya, B.; Manav Özen, A.; Tarçın, B.; Şenol, A.A.; Tüter Bayraktar, E.; Korkut, B.; Bilgin Göçmen, G.; Tağtekin, D.; Türkmen, C. Assessment of Micro-Hardness, Degree of Conversion, and Flexural Strength for Single-Shade Universal Resin Composites. Polymers 2022, 14, 4987. [Google Scholar] [CrossRef]

- Durand, L.B.; Ruiz-López, J.; Perez, B.G.; Ionescu, A.M.; Carrillo-Pérez, F.; Ghinea, R.; Pérez, M.M. Color, Lightness, Chroma, Hue, and Translucency Adjustment Potential of Resin Composites Using CIEDE2000 Color Difference Formula. J. Esthet. Restor. Dent. 2021, 33, 836–843. [Google Scholar] [CrossRef]

- Karabulut Gencer, B.; Acar, E.; Tarcın, B. Evaluation of Shade Matching in the Repair of Indirect Restorative Materials with Universal Shade Composites. Eur. Oral Res. 2023, 57, 41–48. [Google Scholar] [CrossRef] [PubMed]

- Kobayashi, S.; Nakajima, M.; Furusawa, K.; Tichy, A.; Hosaka, K.; Tagami, J. Color Adjustment Potential of Single-Shade Resin Composite to Various-Shade Human Teeth: Effect of Structural Color Phenomenon. Dent. Mater. J. 2021, 40, 1033–1040. [Google Scholar] [CrossRef] [PubMed]

- Lucena, C.; Ruiz-López, J.; Pulgar, R.; Della Bona, A.; Pérez, M.M. Optical Behavior of One-Shaded Resin-Based Composites. Dent. Mater. 2021, 37, 840–848. [Google Scholar] [CrossRef]

- Pereira Sanchez, N.; Powers, J.M.; Paravina, R.D. Instrumental and Visual Evaluation of the Color Adjustment Potential of Resin Composites. J. Esthet. Restor. Dent. 2019, 31, 465–470. [Google Scholar] [CrossRef] [PubMed]

- El-Rashidy, A.A.; Abdelraouf, R.M.; Habib, N.A. Effect of Two Artificial Aging Protocols on Color and Gloss of Single-Shade versus Multi-Shade Resin Composites. BMC Oral Health 2022, 22, 321. [Google Scholar] [CrossRef]

- Alshehri, A.; Alhalabi, F.; Mustafa, M.; Awad, M.M.; Alqhtani, M.; Almutairi, M.; Alhijab, F.; Jurado, C.A.; Fischer, N.G.; Nurrohman, H.; et al. Effects of Accelerated Aging on Color Stability and Surface Roughness of a Biomimetic Composite: An In Vitro Study. Biomim. Basel Switz. 2022, 7, 158. [Google Scholar] [CrossRef]

- Chen, S.; Zhu, J.; Yu, M.; Jin, C.; Huang, C. Effect of Aging and Bleaching on the Color Stability and Surface Roughness of a Recently Introduced Single-Shade Composite Resin. J. Dent. 2024, 143, 104917. [Google Scholar] [CrossRef]

- Sensi, L.; Winkler, C.; Geraldeli, S. Accelerated Aging Effects on Color Stability of Potentially Color Adjusting Resin-Based Composites. Oper. Dent. 2021, 46, 188–196. [Google Scholar] [CrossRef]

- Hayashi, K.; Kurokawa, H.; Saegusa, M.; Aoki, R.; Takamizawa, T.; Kamimoto, A.; Miyazaki, M. Influence of Surface Roughness of Universal Shade Resin Composites on Color Adjustment Potential. Dent. Mater. J. 2023, 42, 676–682. [Google Scholar] [CrossRef]

- Maesako, M.; Matsui, N.; Fujitani, M.; Garcia-Godoy, F.; Tsujimoto, A. Comparison of Surface Properties of Universal Shade and Conventional Resin-Based Composites after Degradation and Repolishing. Am. J. Dent. 2024, 37, 147–153. [Google Scholar]

- Shlyapintokh, V.Y.; Gol’Denberg, V.I. Effect of Photostabilizers on the Rate of Photodegradation of Polymethylmethacrylat. Eur. Polym. J. 1974, 10, 679–684. [Google Scholar] [CrossRef]

- Cohen, D.K. Glossary of Surface Texture Parameters; Michigan Metrology LLC.: Livonra, MI, USA, 2023. [Google Scholar]

- Vattanaseangsiri, T.; Khawpongampai, A.; Sittipholvanichkul, P.; Jittapiromsak, N.; Posritong, S.; Wayakanon, K. Influence of Restorative Material Translucency on the Chameleon Effect. Sci. Rep. 2022, 12, 8871. [Google Scholar] [CrossRef]

- Arimoto, A.; Nakajima, M.; Hosaka, K.; Nishimura, K.; Ikeda, M.; Foxton, R.M.; Tagami, J. Translucency, Opalescence and Light Transmission Characteristics of Light-Cured Resin Composites. Dent. Mater. 2010, 26, 1090–1097. [Google Scholar] [CrossRef]

- Tsai, C.W.; Wu, K.H.; Wang, J.C.; Shih, C.C. Synthesis, characterization, and properties of petroleum-based methacrylate polymers derived from tricyclodecane for microelectronics and optoelectronics applications. J. Indust. Engin. Chem. 2017, 53, 143–154. [Google Scholar] [CrossRef]

- Odian, G. Principles of Polymerization, 4th ed.; Wiley-Interscience: New York, NY, USA, 2004. [Google Scholar]

- Hadis, M.A.; Tomlins, P.H.; Shortall, A.C.; Palin, W.M. Dynamic Monitoring of Refractive Index Change through Photoactive Resins. Dent. Mater. 2010, 26, 1106–1112. [Google Scholar] [CrossRef]

- Dondi, M.; Blosi, M.; Gardini, D.; Zanelli, C. Ceramic pigments for digital decoration inks: An overview. Ceram. Forum Int. 2012, 89, E59–E64. [Google Scholar]

- Watts, D.C.; Amer, O.M.; Combe, E.C. Surface Hardness Development in Light-Cured Composites. Dent. Mater. Off. Publ. Acad. Dent. Mater. 1987, 3, 265–269. [Google Scholar] [CrossRef]

- Fink, J.K. 9—Acrylic Resins. In Reactive Polymers: Fundamentals and Applications, 3rd ed.; Fink, J.K., Ed.; Plastics Design Library; William Andrew Publishing: Norwich, NY, USA, 2018; pp. 325–344. [Google Scholar] [CrossRef]

- Burtscher, P. Stability of Radicals in Cured Composite Materials. Dent. Mater. 1993, 9, 218–221. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, H. A Review on Photochemical Effects of Common Plastics and Their Related Applications. J. Polym. Sci. 2024, 62, 969–997. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, J.; Yee Leung, K.M.; Wu, F. Color: An Important but Overlooked Factor for Plastic Photoaging and Microplastic Formation. Environ. Sci. Technol. 2022, 56, 9161–9163. [Google Scholar] [CrossRef]

- Barszczewska-Rybarek, I.M. A Guide through the Dental Dimethacrylate Polymer Network Structural Characterization and Interpretation of Physico-Mechanical Properties. Materials 2019, 12, 4057. [Google Scholar] [CrossRef] [PubMed]

- Queiroz, R.S.; Lima, J.P.M.D.; Malta, D.A.M.P.; Rastelli, A.N.D.S.; Cuin, A.; Porto Neto, S.D.T. Changes on Transmittance Mode of Different Composite Resins. Mater. Res. 2009, 12, 127–132. [Google Scholar] [CrossRef]

- Emami, N.; Sjödahl, M.; Söderholm, K.-J.M. How Filler Properties, Filler Fraction, Sample Thickness and Light Source Affect Light Attenuation in Particulate Filled Resin Composites. Dent. Mater. 2005, 21, 721–730. [Google Scholar] [CrossRef]

- Lee, Y.-K.; Lu, H.; Powers, J.M. Measurement of Opalescence of Resin Composites. Dent. Mater. 2005, 21, 1068–1074. [Google Scholar] [CrossRef] [PubMed]

- Tabatabaei, M.H.; Nahavandi, A.M.; Khorshidi, S.; Hashemikamangar, S.S. Fluorescence and Opalescence of Two Dental Composite Resins. Eur. J. Dent. 2019, 13, 527–534. [Google Scholar] [CrossRef] [PubMed]

- da Costa, J.; Vargas, M.; Swift, E.J.; Anderson, E.; Ritter, S. Color and Contrast Ratio of Resin Composites for Whitened Teeth. J. Dent. 2009, 37 (Suppl. 1), e27–e33. [Google Scholar] [CrossRef]

- Drubi-Filho, B.; da Fonseca Roberti Garcia, L.; Cruvinel, D.R.; Sousa, A.B.S.; de Carvalho Panzeri Pires-de-Souza, F. Color Stability of Modern Composites Subjected to Different Periods of Accelerated Artificial Aging. Braz. Dent. J. 2012, 23, 575–580. [Google Scholar] [CrossRef]

- Sarafianou, A.; Iosifidou, S.; Papadopoulos, T.; Eliades, G. Color Stability and Degree of Cure of Direct Composite Restoratives after Accelerated Aging. Oper. Dent. 2007, 32, 406–411. [Google Scholar] [CrossRef]

- Furuse, A.Y.; Gordon, K.; Rodrigues, F.P.; Silikas, N.; Watts, D.C. Colour-Stability and Gloss-Retention of Silorane and Dimethacrylate Composites with Accelerated Aging. J. Dent. 2008, 36, 945–952. [Google Scholar] [CrossRef]

- de Oliveira, D.C.R.S.; Souza-Júnior, E.J.; Prieto, L.T.; Coppini, E.K.; Maia, R.R.; Paulillo, L.A.M.S. Color Stability and Polymerization Behavior of Direct Esthetic Restorations. J. Esthet. Restor. Dent. 2014, 26, 288–295. [Google Scholar] [CrossRef]

- Takahashi, M.K.; Vieira, S.; Rached, R.N.; de Almeida, J.B.; Aguiar, M.; de Souza, E.M. Fluorescence Intensity of Resin Composites and Dental Tissues before and after Accelerated Aging: A Comparative Study. Oper. Dent. 2008, 33, 189–195. [Google Scholar] [CrossRef] [PubMed]

- Papadopoulos, T.; Sarafianou, A.; Hatzikyriakos, A. Colour Stability of Veneering Composites after Accelerated Aging. Eur. J. Dent. 2010, 4, 137–142. [Google Scholar] [CrossRef] [PubMed]

- Janda, R.; Roulet, J.-F.; Kaminsky, M.; Steffin, G.; Latta, M. Color Stability of Resin Matrix Restorative Materials as a Function of the Method of Light Activation. Eur. J. Oral Sci. 2004, 112, 280–285. [Google Scholar] [CrossRef] [PubMed]

- Ramos, N.C.; Luz, J.N.; Valera, M.C.; Melo, R.M.; Saavedra, G.; Bresciani, E. Color Stability of Resin Cements Exposed to Aging. Oper. Dent. 2019, 44, 609–614. [Google Scholar] [CrossRef]

- Turgut, S.; Bagis, B. Colour Stability of Laminate Veneers: An in Vitro Study. J. Dent. 2011, 39, e57–e64. [Google Scholar] [CrossRef]

- Khashayar, G.; Bain, P.A.; Salari, S.; Dozic, A.; Kleverlaan, C.J.; Feilzer, A.J. Perceptibility and Acceptability Thresholds for Colour Differences in Dentistry. J. Dent. 2014, 42, 637–644. [Google Scholar] [CrossRef]

- Lu, H.; Roeder, L.B.; Lei, L.; Powers, J.M. Effect of Surface Roughness on Stain Resistance of Dental Resin Composites. J. Esthet. Restor. Dent. 2005, 17, 102–108, discussion 109. [Google Scholar] [CrossRef]

- Gómez-Polo, C.; Montero, J.; Gómez-Polo, M.; Martin Casado, A. Comparison of the CIELab and CIEDE 2000 Color Difference Formulas on Gingival Color Space. J. Prosthodont. 2020, 29, 401–408. [Google Scholar] [CrossRef]

- Okazaki, M.; Douglas, W.H. Comparison of Surface Layer Properties of Composite Resins by ESCA, SEM and X-ray Diffractometry. Biomaterials 1984, 5, 284–288. [Google Scholar] [CrossRef]

- Brooksbank, A.; Owens, B.M.; Phebus, J.G.; Blen, B.J.; Wasson, W. Surface Sealant Effect on the Color Stability of a Composite Resin Following Ultraviolet Light Artificial Aging. Oper. Dent. 2019, 44, 322–330. [Google Scholar] [CrossRef]

- de Oliveira, D.C.R.S.; Ayres, A.P.A.; Rocha, M.G.; Giannini, M.; Puppin Rontani, R.M.; Ferracane, J.L.; Sinhoreti, M.A.C. Effect of Different In Vitro Aging Methods on Color Stability of a Dental Resin-Based Composite Using CIELAB and CIEDE2000 Color-Difference Formulas. J. Esthet. Restor. Dent. 2015, 27, 322–330. [Google Scholar] [CrossRef] [PubMed]

- Noie, F.; O’Keefe, K.L.; Powers, J.M. Color Stability of Resin Cements after Accelerated Aging. Int. J. Prosthodont. 1995, 8, 51–55. [Google Scholar]

| Material/Code | Composition * | Manufacturer |

|---|---|---|

| Charisma Topaz ONE (CHT) | RESIN: TCDU, TEGDMA, DUDMA, accelerators, initiators. FILLER: Barium aluminum fluoride glass, pre-polymerized fillers, highly discrete nanoparticles (59 wt%, 5 nm–5 μm). | Kulzer GmbH, Hanau, Germany |

| Majesty ES-2 Universal (MES) | RESIN: BisGMA, hydrophobic aromatic dimethacrylate, hydrophobic aliphatic dimethacrylate, camphorquinone, accelerators, initiators. FILLER: Silanated barium glass, pre-polymerized organic filler, pigments (78 wt%, 0.4–1.5 μm size, including inorganic filler of 40 vol%). | Kuraray Noritake Dental Inc., Okayama, Japan |

| Essentia Universal (ESU) | RESIN: UDMA, NPGDMA, BisEMA, TCDDMA, accelerators, initiators. FILLER: Barium glass fillers (700 nm), YbF3, pigments (81 wt%, 59 vol%). | GC Corp., Tokyo, Japan |

| Omnichroma (OMN) | RESIN: UDMA, TEGDMA, accelerators, initiators. FILLER: Spherical silica–zirconia filler (79 wt%, 68 vol%, mean particle size: 0.26 μm, particle size range: 0.2–0.4 μm), composite filler. | Tokuyama Corp., Tokyo, Japan |

| G-aenial anterior (CNA-Control, A2 shade) | RESIN: UDMA, NPGDMA, BisEMA TMPTMA, accelerators, initiators. FILLER: Pre-polymerized fillers. (16–17 μm), strontium glass (400 nm), lanthanoid fluoride (100 nm), silica glass (850 nm), fumed silica (16 nm), YbF3, pigments (76 wt%). | GC Corp., Tokyo, Japan |

| Material | DC% T Bf | DC% B Bf | DC% T Af | DC% B Af | ΔDC%T (Af-Bf) | ΔDC%B (Af-Bf) |

|---|---|---|---|---|---|---|

| CHT | 62.35 (2.71) a,A | 58.33 (1.66) a,A | 70.15 (0.73) a,A | 68.05 (1.18) a,A | 7.8 (2.3) a,A | 9.73 (1) a,A |

| ESU | 46.38 (2.1) b,A | 39.2 (0.89) b,B | 68.8 (1.16) a,A | 60.65 (1.35) b,Β | 22.43 (2.95) b,A | 21.36 (1.2) b,A |

| MES | 52.83 (1.79) c,A | 50.63 (1.27) c,d,A | 74.15 (2.77) a,b,A | 67 (2.38) a,c,A | 21.35 (3.27) b,A | 16.48 (1.6) c,B |

| OMN | 60.2 (3.77) a,A | 47.83 (4.46) d,B | 77.05 (1.48) b,A | 70.63 (3.96) a,A | 16.85 (2.4) b,A | 22.7 (2.36) b,B |

| CNA | 53.15 (1.26) c,A | 51.65 (1.84) e,A | 73.2 (4.9) a,b,A | 62.28 (3.73) b,c,B | 20.25 (4.6) b,A | 10.63 (2.5) a,B |

| Material | (C=O/R) T Bf | (C=O/R) T Af | Δ%Τ (Af-Bf) |

|---|---|---|---|

| CHT | 2.98 (0.18) A | 2.5 (0.38) B | −16.1 (1.88) a |

| ESU | 3.98 (0.31) A | 3.97 (0.16) A | −0.25 (0.01) b |

| MES | 5.38 (0.3) A | 5.12 (0.11) A | −4.83 (0.18) c |

| OMN | 3.21 (0.12) A | 2.91 (0.28) A | −9.34 (0.62) d |

| CNA | 3.49 (0.18) A | 2.94 (0.56) B | −15.76 (1.9) a |

| Material | L*Bf | L*Af | a*Bf | a*Af | b*Bf | b*Af |

|---|---|---|---|---|---|---|

| CHT | 61.62 (60.21/61.78) a,c,A | 58.18 (57.63/59.32) b,B | −0.61 (0.11) d,A | −0.38 (−0.41/0.28) b,B | 5.6 (0.3) d,A | 5.39 (0.27) c, A |

| ESU | 58.24 (57.61/58.68) d,e,A | 56.81 (56.32/57.8) b,A | 3.69 (0.2) c,A | 3.6 (3.47–3.71) a,A | 12.2 (1.32) c,A | 11.58 (0.48) a,A |

| MES | 56.9 (54.92/58.48) b,c,e,A | 58.63 (56.77/59.62) a,b,A | 3.48 (0.59) c,A | 4.3 (3.65–5.61) a,A | 8 (1.32) a,A | 6.82 (2.4) c,A |

| OMN | 69.86 (66.49–71.48) a,A | 63.28 (60/64.77) a,B | 0.92 (0.31) b,A | 0.88 (0.59/1.19) a,A | 8.3 (0.72) a,A | 2.53 (2.19) b,B |

| CNA | 55.48 (54.66–55.57) b,d,A | 52.75 (52.55/53.8) b,B | 6.23 (0.32) a,A | 5.16 (4.77/5.52) a,A | 15.78 (0.58) b,A | 12.6 (1.5) a,B |

| Material | TP Bf | TP Af | OP Bf | OP Af | CR Bf | CRAf | TT Bf | TT Af |

|---|---|---|---|---|---|---|---|---|

| CHT | 11.64 (0.7) a,A | 10.19 (0.94) a,B | 4.09 (0.34) a,A | 4.07 (0.34) a,A | 0.63 (0.04) a,A | 0.71 (0.05) a,b,c,A | 37.58 (1.73) a,A | 33.27 (1.45) a,B |

| ESU | 7.73 (1.07) b,A | 8.25 (1.42) a,B | 11.26 (1.23) b,A | 11.97 (0.65) b,A | 0.89 (0.1) b,c,A | 0.87 (0.08) a,b,c,A | 25.62 (3.2) b,A | 26.58 (1.17) b,A |

| MES | 7.53 (1.01) b,A | 10.29 (3.11) a,A | 23.3 (1.33) c,A | 19 (2.71) c,B | 0.99 (0.14) c,d,A | 0.76 (0.14) a,b,c,B | 24,35 (1.38) b,A | 23.56 (1.14) b,A |

| OMN | 18.46 (3.36) c,A | 10.87 (2.61) a,B | 3.15 (0.57) a,A | 4.24 (1.54) a,A | 0.55 (0.06) d,e,A | 0.66 (0.12) b,A | 43.88 (3.96) c,A | 38.47 (2.49) c,B |

| CNA | 10.07 (0.47) a, A | 7.4 (1.43) b,B | 16.73 (0.63) d,A | 17.25 (1.37) c,A | 0.75 (0.07) a,b,f,A | 0.88 (0.09) c,B | 24.62 (2.73) b,A | 24.81 (1.94) b,A |

| Material | ΔL* | Δa* | Δb* | ΔΕ | ΔTP | ΔOP | ΔCR | ΔTT |

|---|---|---|---|---|---|---|---|---|

| CHT | −2.56 (−3.67/−1.97) b | 0.18 (0.08) b | −0.39 (−0.54/0.03) a | 2.8 (0.88) d | −1.65 (−2.31/−0.75) b | −0.02 (0.27) c | 0.08 (0.08) a | −4.42 (3.21) a,b,c |

| ESU | −1.3 (−1.64/−0.48) b | −0.08 (0.19) b | −0.39 (1.49/0.2) a | 1.56 (0.3) c,d | 0.5 (−1.65/2.71) b | 0.71 (0.79) b | −0.01 (0.16) a,b,c,d | −0.62 (1.23) a,b,c |

| MES | 2.58 (−0.46/2.91) a | 1.08 (0.96) a | −1.56 (−2.81/0.55) b | 3.54 (0.64) b,d | 3.32 (0.42/4.82) a | −4.34 (1.99) d | −0.24 (0.15) b | −0.79 (0.54) a,b,c |

| OMN | −6.16 (−7.57/−5.89) c | −0.03 (0.41) b | −6.59 (−7.79/−3.3) c | 8.99 (1.23) a | −7.56 (−8.2/−6.99) d | 1.09 (1.41) a | 0.11 (0.15) a,c,d | −5.4 (4.34) b |

| CNA | −2.1 (−3.01/−1.17) b | −1.03 (0.59) c | −3.6 (−4.8/−1.53) d | 4.35 (0.81) b | −2.42 (−3.52/−1.95) c | 0.52 (1.83) b | 0.13 (0.16) a,c,d | −0.19 (2.19) c |

| Material | Sa Bf (nm) | SaAf (nm) | Sz Bf (μm) | Sz Af (μm) | Sdr Bf (%) | SdrAf (%) | Sds Bf (×103, 1/mm2) | Sds Af (×103, 1/mm2) | Sc Bf (μm3/ mm2 | Sc Af (μm3/ mm2) |

|---|---|---|---|---|---|---|---|---|---|---|

| CHT | 70.52 (8.63) a,A | 293.98 (28.56) a,B | 1.4 (0.59) a,A | 4.07 (0.34) a,B | 1.23 (1.02/1.62) a,A | 40.05 (37.22/44.49) a,B | 18.887 (3.687) a,A | 37.136 (2.333) a,B | 9.2 (1.64) a,A | 36.6 (5.27) a,B |

| ESU | 65,13 (8.46) b,A | 178.57 (16.58) b,B | 1.57 (0.17) a,A | 2.31 (0.24) b,B | 1.4 (1.01/1.67) a,A | 16.12 (13.8/18.02) b,B | 16.453 (2.969) a,A | 30.235 (1.407) b,e,B | 101.4 (22.7) a,A | 267.8 (16.96) b,B |

| MES | 116.95 (3.77) b,A | 119.44 (17.62) c,A | 1.79 (0.33) a,A | 2.06 (0.48) b,B | 2.71 (2.56/2.88) b,A | 3.82 (2.34/4.45) c,A | 14.546 (1.484) a,A | 18.977 (0.954) c,B | 197.6 (10.53) b,A | 180.8 (29.5) c,A |

| OMN | 55.77 (3.47) c,A | 165.28 (25.03) b,B | 0.9 (0.34) b,A | 1.91 (10.19) b,B | 0.41 (0.35/0.99) c,A | 12.3 (10.23/15.57) b,B | 24.763 (6.558) b,A | 29.635 (1.524) d,e,A | 84.6 (7.3) a,A | 256.6 (39.9) b,B |

| CNA | 73.82 (16.61) a,A | 171.92 (28.59) b,B | 1.8 (0.52) a,A | 2.28 (0.33) b,B | 1.92 (1.21/3.14) a,A | 12.54 (11.42/17.55) b,B | 15.745 (3.038) a,A | 28.099 (2.491) e,B | 113.8 (30.28) a,A | 253.8 (39.68) b,B |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petropoulou, A.; Dimitriadi, M.; Zinelis, S.; Antoniadou, M.; Eliades, G. Effect of Photoaging on the Structure, Optical Properties and Roughness of One-Shade Composite Restoratives. J. Funct. Biomater. 2024, 15, 245. https://doi.org/10.3390/jfb15090245

Petropoulou A, Dimitriadi M, Zinelis S, Antoniadou M, Eliades G. Effect of Photoaging on the Structure, Optical Properties and Roughness of One-Shade Composite Restoratives. Journal of Functional Biomaterials. 2024; 15(9):245. https://doi.org/10.3390/jfb15090245

Chicago/Turabian StylePetropoulou, Aikaterini, Maria Dimitriadi, Spiros Zinelis, Maria Antoniadou, and George Eliades. 2024. "Effect of Photoaging on the Structure, Optical Properties and Roughness of One-Shade Composite Restoratives" Journal of Functional Biomaterials 15, no. 9: 245. https://doi.org/10.3390/jfb15090245