Nanobeams with Internal Discontinuities: A Local/Nonlocal Approach

Abstract

:1. Introduction

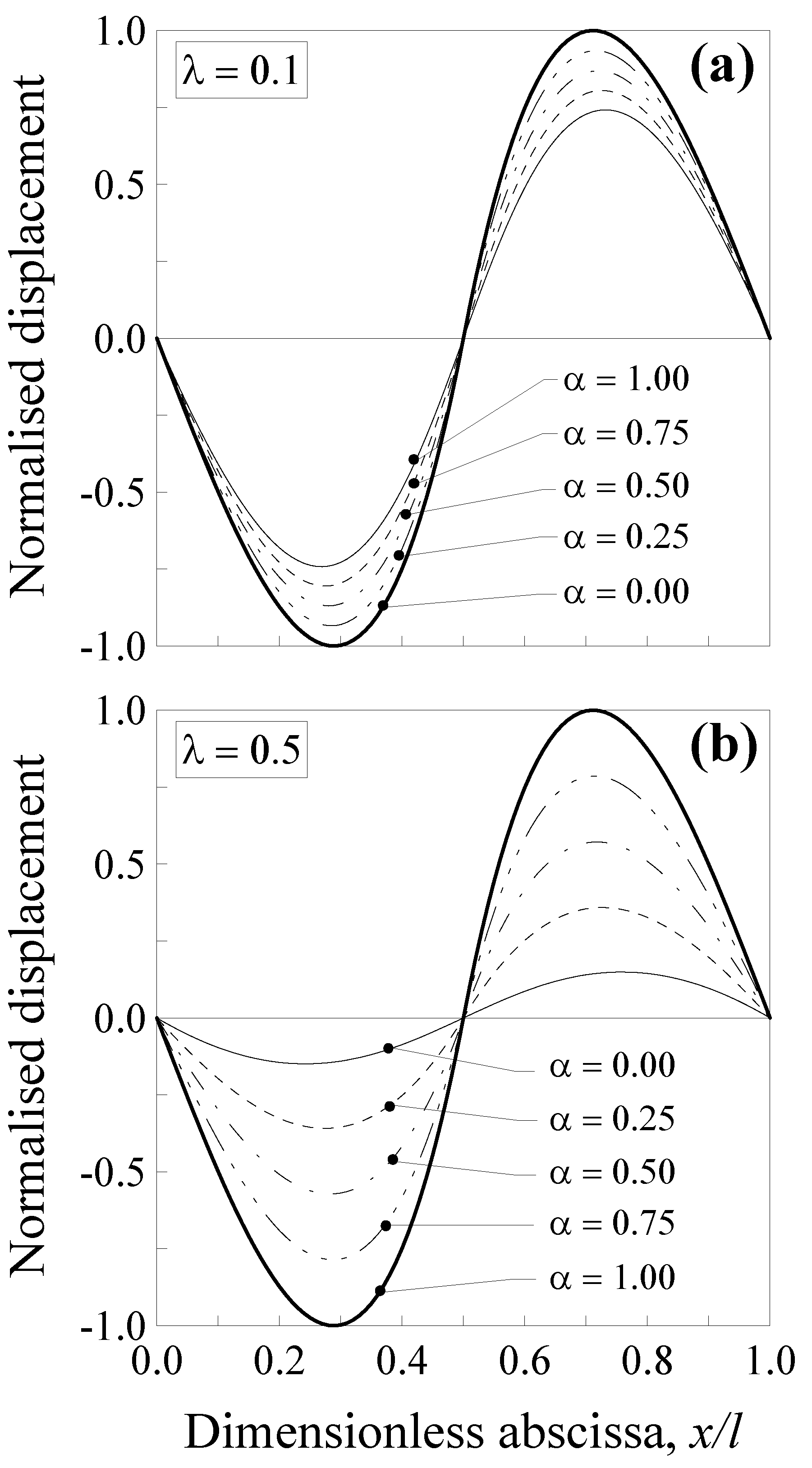

2. The Two-Phase Local/Nonlocal SDM in the Presence of Internal Discontinuities

2.1. Integral Formulation

2.2. Differential Formulation

2.3. Solution

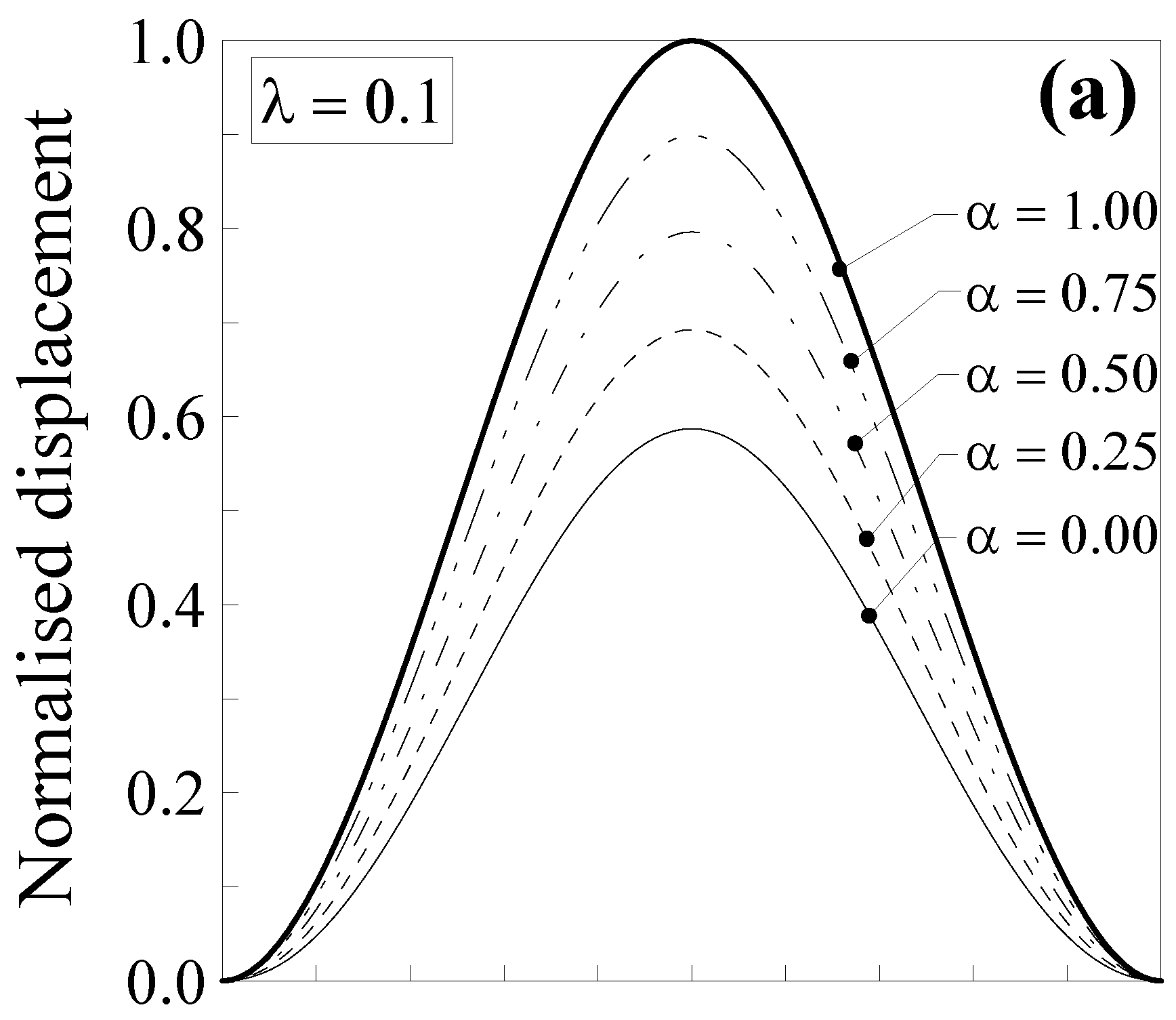

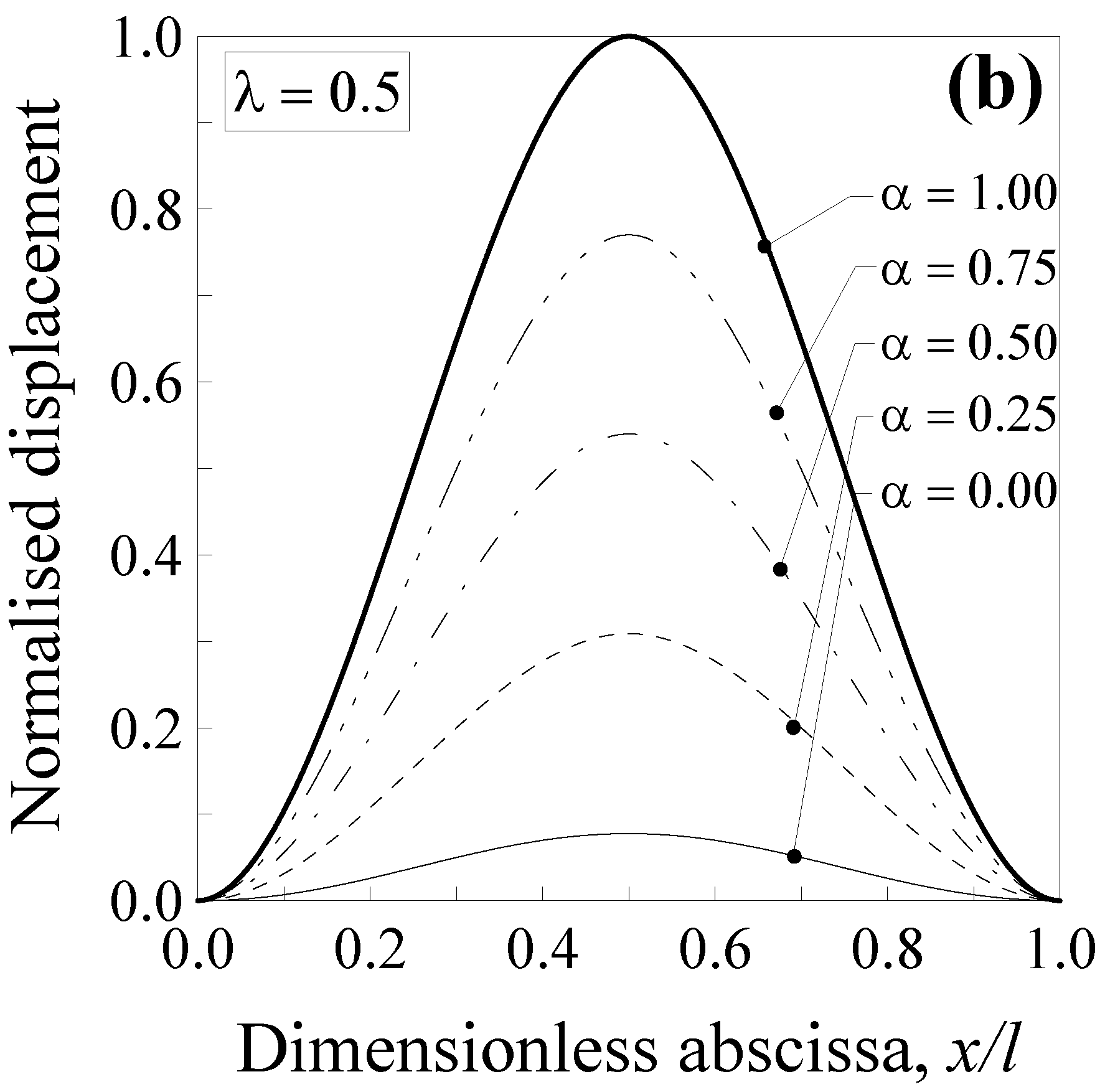

3. Applications: Uncracked Nanobeams

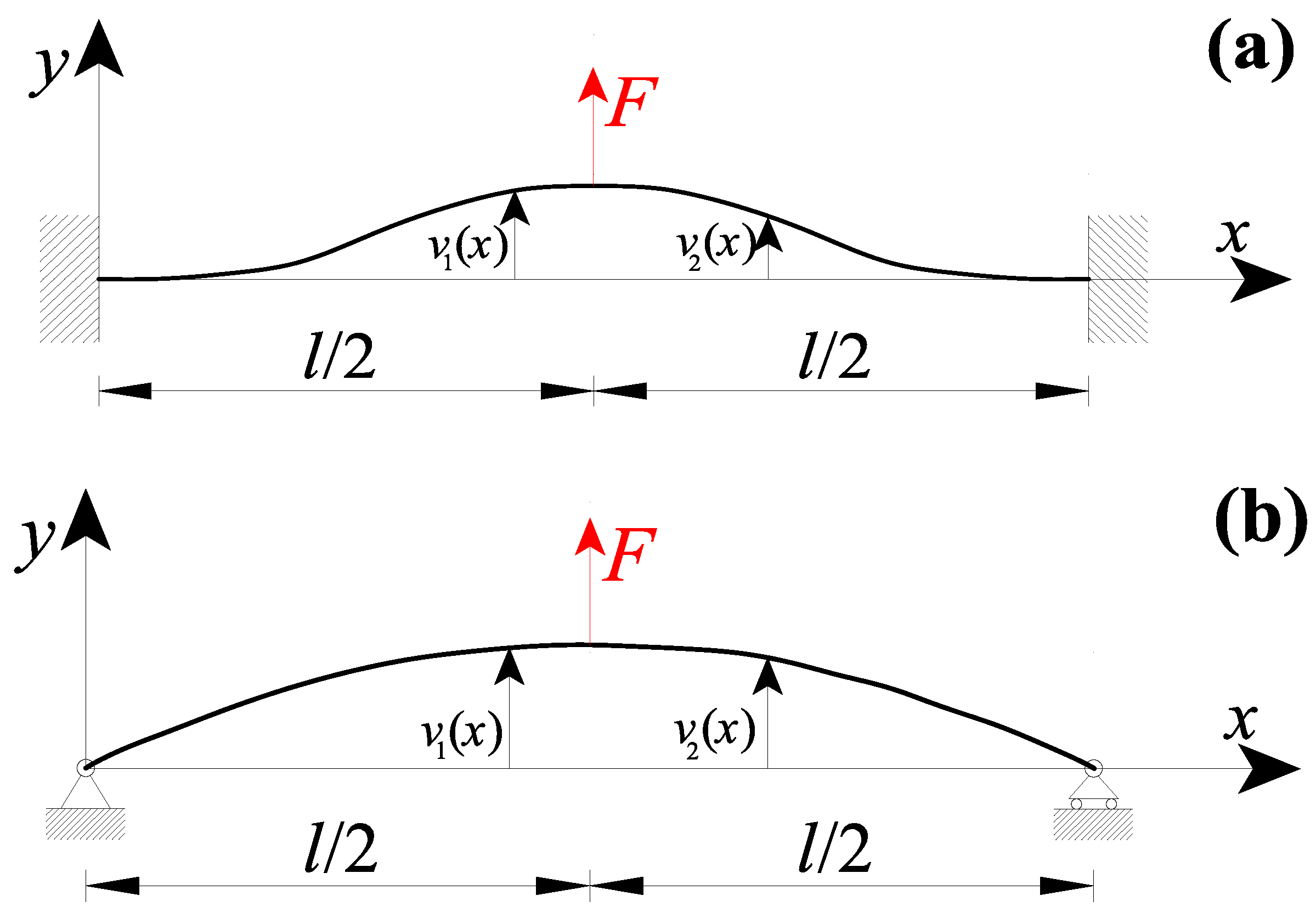

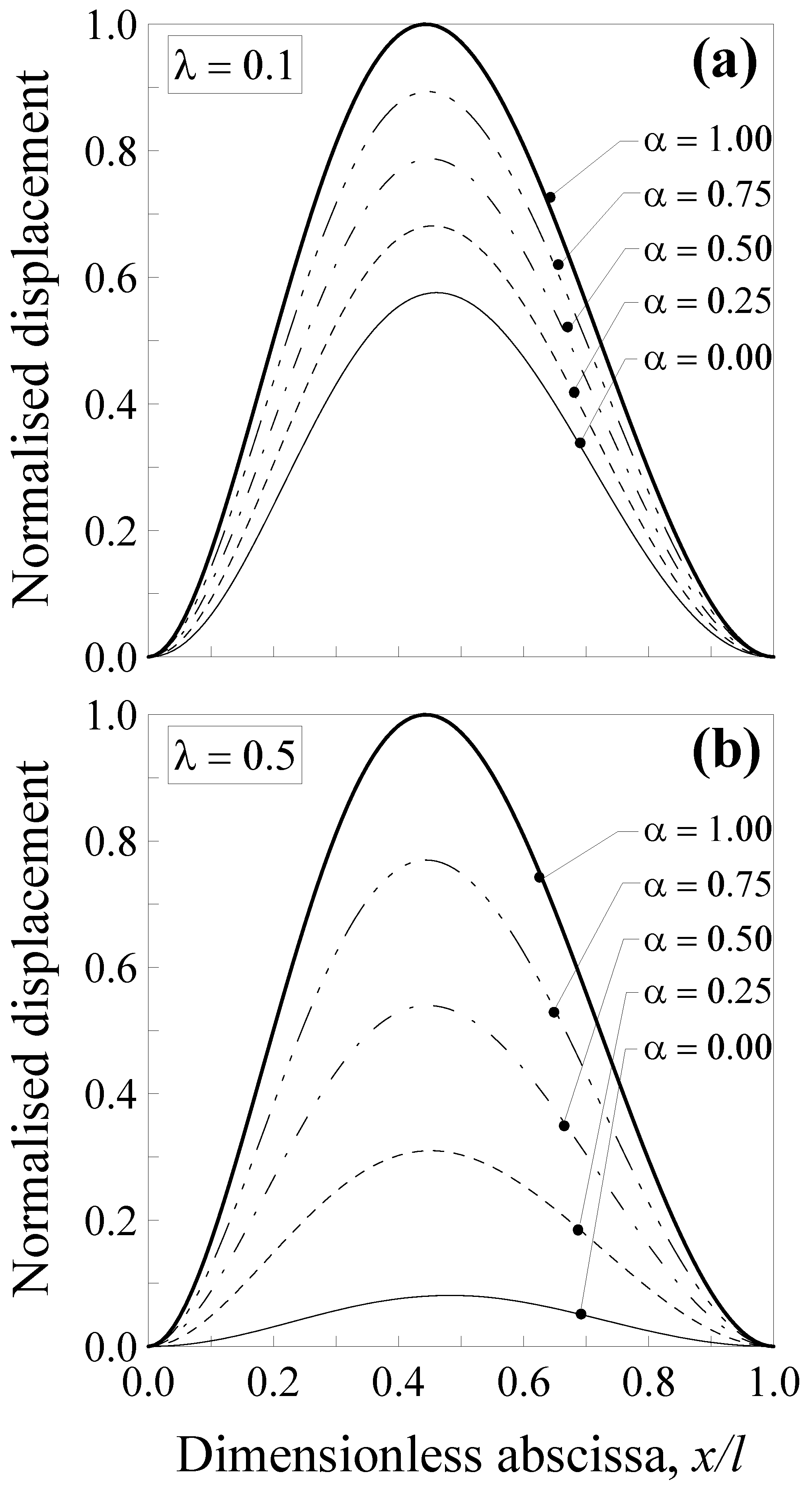

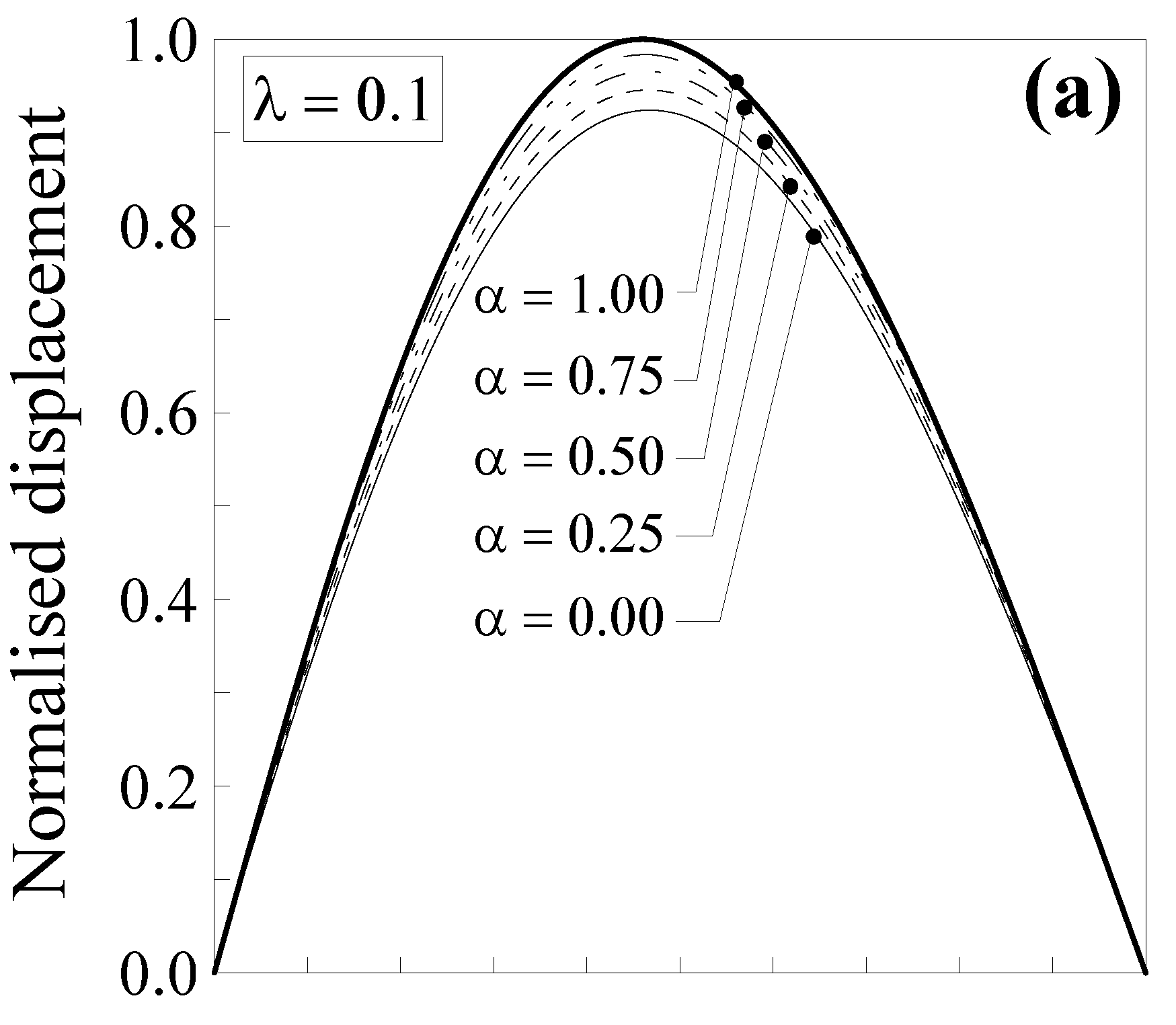

3.1. Nanobeams with a Concentrated Force in the Midsection

- (i)

- six kinematic boundary conditions (KBCs):

- (ii)

- two static boundary conditions (SBCs):

- (i)

- four kinematic boundary conditions (KBCs):

- (ii)

- two static boundary conditions (SBCs) at the nanobeam extremities:

- (iii)

- and the two static boundary conditions (SBCs)at the internal discontinuity point of Equation (19a,b).

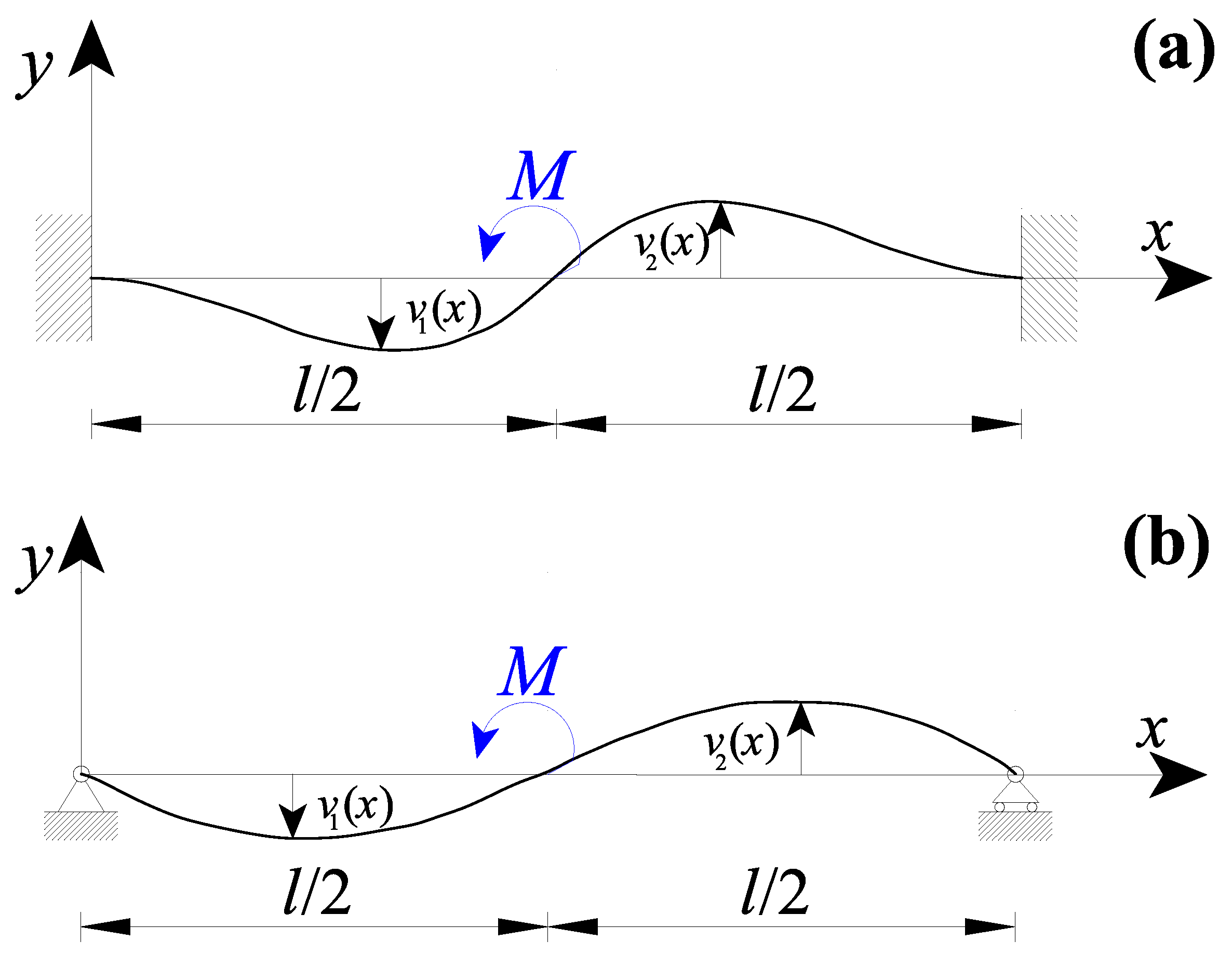

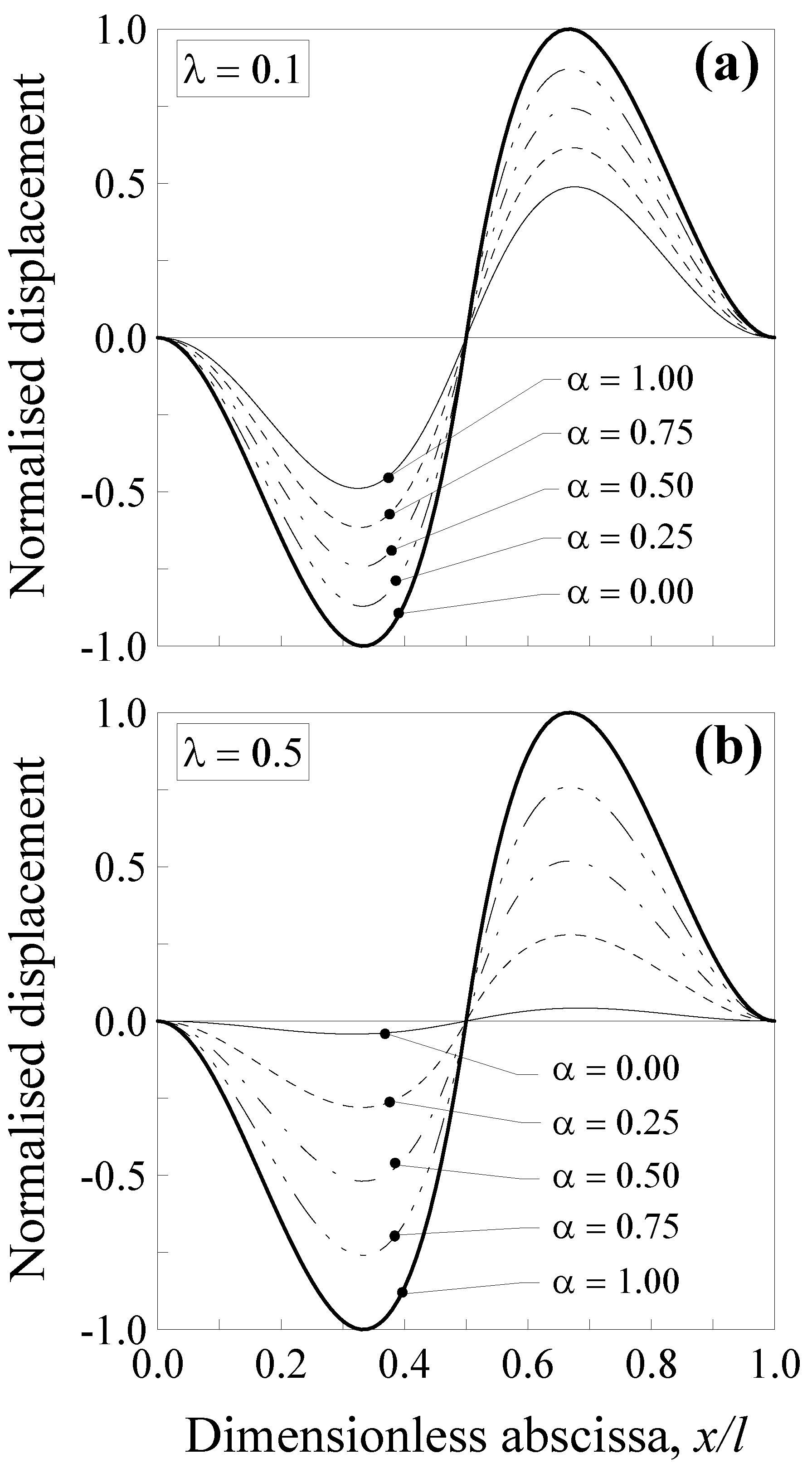

3.2. Nanobeams with a Concentrated Couple in the Midsection

- (i)

- the six kinematic boundary conditions (KBCs) of Equation (18a–f);

- (ii)

- and two static boundary conditions (SBCs):

- (i)

- the four kinematic boundary conditions (KBCs) of Equation (20a–d);

- (ii)

- the two static boundary conditions (SBCs) at the nanobeam extremities of Equation (21a,b);

- (iii)

- and the two static boundary conditions (SBCs) at the internal discontinuity point of Equation (22a,b).

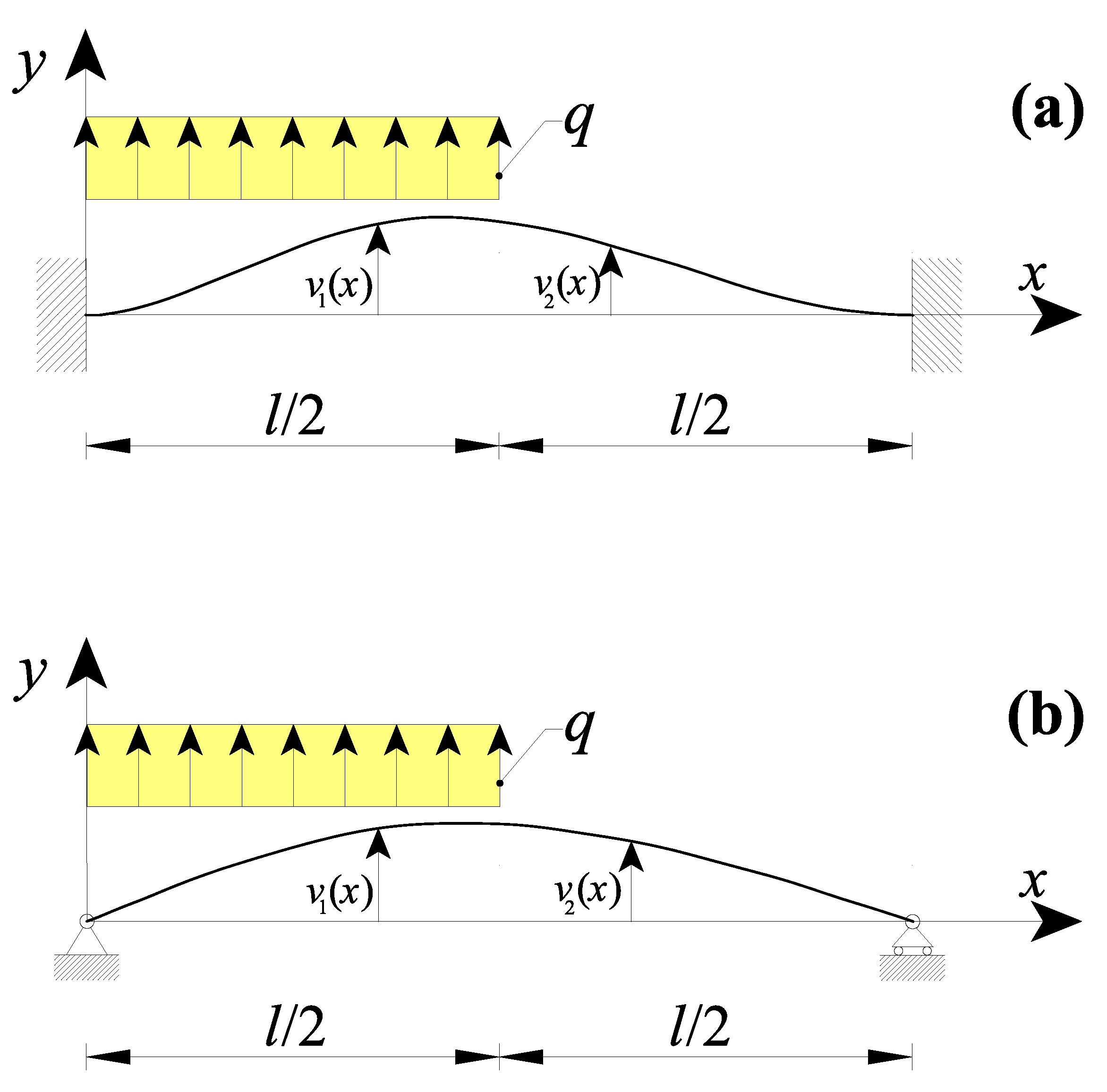

3.3. Nanobeams with a Non-Uniform Distributed Load

- (i)

- the six kinematic boundary conditions (KBCs) of Equation (18a–f);

- (ii)

- and two static boundary conditions (SBCs):

- (i)

- the four kinematic boundary conditions (KBCs) of Equation (20a–d);

- (ii)

- two static boundary conditions (SBCs) at the nanobeam extremities:

- (iii)

- and the two static boundary conditions (SBCs) at the internal discontinuity point of Equation (23a,b).

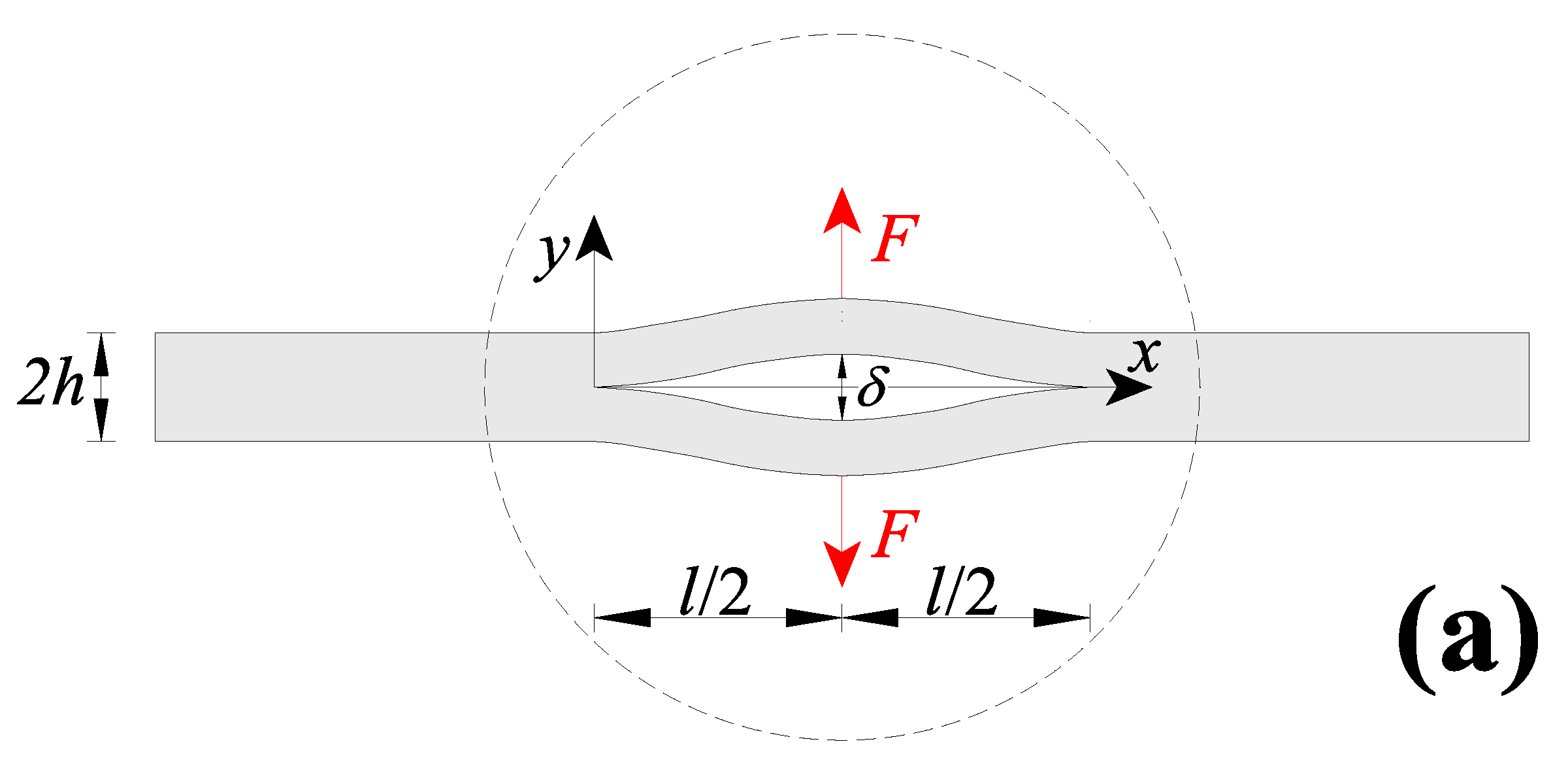

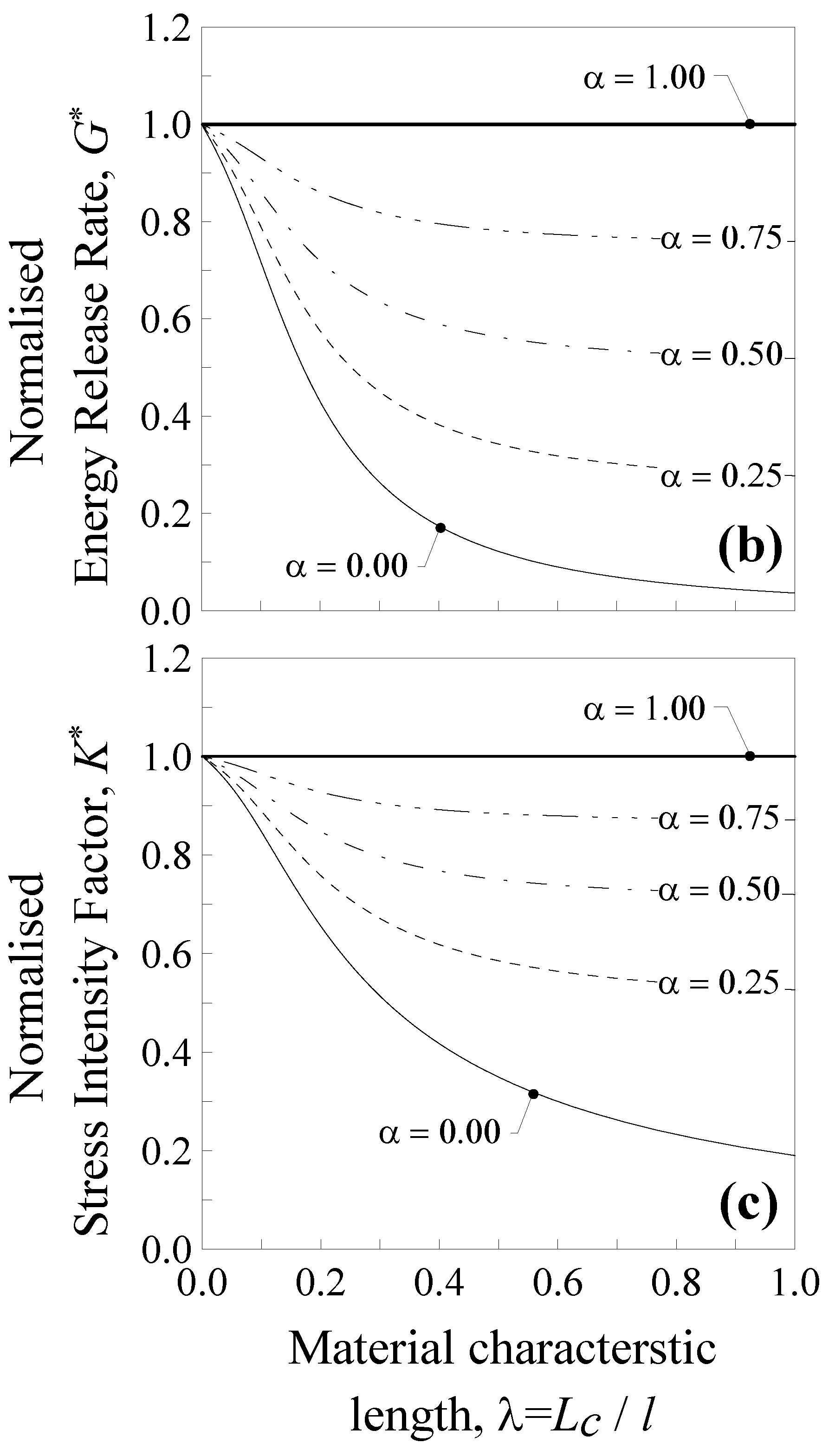

4. Application: Cracked Nanobeam

Energy Release Rate and Stress Intensity Factor

5. Conclusions

- (i)

- high degree of nonlocality, that is, greater values of the dimensionless characteristic length and small values of the mixture parameter cause a stiffer behaviour of the nanobeam with respect to the large-scale counterpart, especially for the double-clamped nanobeams;

- (ii)

- by increasing the value of the mixture parameter up to the unit, the nanobeam behaves as a large-scale beam according to the classical local Bernoulli–Euler model; and

- (iii)

- the combined use of both mixture parameter and dimensionless characteristic length allows us to improve the applicability of the SDM. This is possible, since, while the dimensionless characteristic length depends on the material microstructures through the characteristic length, Lc, and this parameter is a constant for a nanobeam with a fixed length and made of a given material, so the mixture parameter may be calibrated in order to properly describe the behaviour of real nanostructures.

Author Contributions

Funding

Conflicts of Interest

References

- Bhushan, B. Nanotribology and nanomechanics of MEMS/NEMS and BioMEMS/BioNEMS materials and devices. Microelectron. Eng. 2007, 84, 387–412. [Google Scholar] [CrossRef]

- Rezaiee-Pajand, M.; Mokhtari, M. Size dependent buckling analysis of nano sandwich beams by two schemes. Mech. Adv. Mater. Struct. 2020, 27, 975–990. [Google Scholar] [CrossRef]

- Ferreira, M.C.; Pimentel, B.; Andrade, V.; Zverev, V.; Gimaev, R.R.; Pomorov, A.S.; Pyatakov, A.; Alekhina, Y.; Komlev, A.; Makarova, L.; et al. Understanding the dependence of nanoparticles magnetothermal properties on their size for hyperthermia applications: A case study for la-sr manganites. Nanomaterials 2021, 11, 1826. [Google Scholar] [CrossRef] [PubMed]

- Du, B.W.; Chu, C.Y.; Lin, C.C.; Ko, F.H. The multifunctionally graded system for a controlled size effect on iron oxide–gold based core-shell nanoparticles. Nanomaterials 2021, 11, 1695. [Google Scholar] [CrossRef] [PubMed]

- Jin, X.; Wen, X.; Lim, S.; Joshi, R. Size-dependent ion adsorption in graphene oxide membranes. Nanomaterials 2021, 11, 1676. [Google Scholar] [CrossRef]

- Phung-Van, P.; Ferreira, A.J.M.; Nguyen-Xuan, H.; Thai, C.H. Scale-dependent nonlocal strain gradient isogeometric analysis of metal foam nanoscale plates with various porosity distributions. Compos. Struct. 2021, 268, 113949. [Google Scholar] [CrossRef]

- Fang, T.H.; Li, W.L.; Tao, N.R.; Lu, K. Revealing Extraordinary Intrinsic Tensile Plasticity in Gradient Nano-Grained Copper. Science 2011, 331, 1587–1590. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.L.; Jiang, P.; Chena, L.; Yuan, F.; Zhu, Y.T. Extraordinary strain hardening by gradient structure. Proc. Natl. Acad. Sci. USA 2014, 111, 7197–7201. [Google Scholar] [CrossRef] [Green Version]

- Peng, C.; Zhan, Y.; Lou, J. Size-dependent fracture mode transition in copper nanowires. Small 2012, 8, 1889–1894. [Google Scholar] [CrossRef]

- Li, X.F.; Wang, B.L. Bending and fracture properties of small scale elastic beams—A nonlocal analysis. Appl. Mech. Mater. 2012, 152–154, 1417–1426. [Google Scholar] [CrossRef]

- Yan, Z.; Jiang, L. Size-dependent bending and vibration behaviour of piezoelectric nanobeams due to flexoelectricity. J. Phys. D Appl. Phys. 2013, 46, 355502. [Google Scholar] [CrossRef]

- Li, Y.S.; Ma, P.; Wang, W. Bending, buckling, and free vibration of magnetoelectroelastic nanobeam based on nonlocal theory. J. Intell. Mater. Syst. Struct. 2016, 27, 1139–1149. [Google Scholar] [CrossRef]

- Wang, Y.; Xie, K.; Fu, T.; Shi, C. Bending and elastic vibration of a novel functionally graded polymer nanocomposite beam reinforced by graphene nanoplatelets. Nanomaterials 2019, 9, 1690. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Malikan, M.; Eremeyev, V.A. On nonlinear bending study of a piezo-flexomagnetic nanobeam based on an analytical-numerical solution. Nanomaterials 2020, 10, 1762. [Google Scholar] [CrossRef] [PubMed]

- Vaccaro, M.S.; Pinnola, F.P.; de Sciarra, F.M.; Barretta, R. Elastostatics of bernoulli–euler beams resting on displacement-driven nonlocal foundation. Nanomaterials 2021, 11, 573. [Google Scholar] [CrossRef]

- Ugolotti, A.; Di Valentin, C. Ab-initio spectroscopic characterization of melem-based graphitic carbon nitride polymorphs. Nanomaterials 2021, 11, 1863. [Google Scholar] [CrossRef]

- Bellussi, F.M.; Sáenz Ezquerro, C.; Laspalas, M.; Chiminelli, A. Effects of graphene oxidation on interaction energy and interfacial thermal conductivity of polymer nanocomposite: A molecular dynamics approach. Nanomaterials 2021, 11, 1709. [Google Scholar] [CrossRef]

- Liu, D. Free vibration of functionally graded graphene platelets reinforced magnetic nanocomposite beams resting on elastic foundation. Nanomaterials 2020, 10, 2193. [Google Scholar] [CrossRef]

- Kiani, K.; Żur, K.K. Dynamic behavior of magnetically affected rod-like nanostructures with multiple defects via nonlocal-integral/differential-based models. Nanomaterials 2020, 10, 2306. [Google Scholar] [CrossRef] [PubMed]

- Monaco, G.T.; Fantuzzi, N.; Fabbrocino, F.; Luciano, R. Critical temperatures for vibrations and buckling of magneto-electro-elastic nonlocal strain gradient plates. Nanomaterials 2021, 11, 1–18. [Google Scholar]

- Penna, R.; Feo, L.; Fortunato, A.; Luciano, R. Nonlinear free vibrations analysis of geometrically imperfect FG nano-beams based on stress-driven nonlocal elasticity with initial pretension force. Compos. Struct. 2021, 255, 112856. [Google Scholar] [CrossRef]

- Lu, L.; Wang, S.; Li, M.; Guo, X. Free vibration and dynamic stability of functionally graded composite microtubes reinforced with graphene platelets. Compos. Struct. 2021, 272, 114231. [Google Scholar] [CrossRef]

- Arefi, M. Electro-mechanical vibration characteristics of piezoelectric nano shells. Thin-Walled Struct. 2020, 155, 106912. [Google Scholar] [CrossRef]

- Żur, K.K.; Arefi, M.; Kim, J.; Reddy, J.N. Free vibration and buckling analyses of magneto-electro-elastic FGM nanoplates based on nonlocal modified higher-order sinusoidal shear deformation theory. Compos. Part B Eng. 2020, 182, 107601. [Google Scholar] [CrossRef]

- Arefi, M.; Bidgoli, E.M.R.; Dimitri, R.; Tornabene, F.; Reddy, J.N. Size-dependent free vibrations of FG polymer composite curved nanobeams reinforced with graphene nanoplatelets resting on Pasternak foundations. Appl. Sci. 2018, 9, 1580. [Google Scholar] [CrossRef] [Green Version]

- Cornacchia, F.; Fabbrocino, F.; Fantuzzi, N.; Luciano, R.; Penna, R. Analytical solution of cross- and angle-ply nano plates with strain gradient theory for linear vibrations and buckling. Mech. Adv. Mater. Struct. 2021, 8, 1201–1215. [Google Scholar] [CrossRef]

- Tocci Monaco, G.; Fantuzzi, N.; Fabbrocino, F.; Luciano, R. Hygro-thermal vibrations and buckling of laminated nanoplates via nonlocal strain gradient theory. Compos. Struct. 2021, 262, 113337. [Google Scholar] [CrossRef]

- Arefi, M.; Amabili, M. A comprehensive electro-magneto-elastic buckling and bending analyses of three-layered doubly curved nanoshell, based on nonlocal three-dimensional theory. Compos. Struct. 2021, 257, 113100. [Google Scholar] [CrossRef]

- Wang, H.; Li, X.; Tang, G.; Shen, Z. Effect of Surface Stress on Stress Intensity Factors of a Nanoscale Crack via Double Cantilever Beam Model. J. Nanosci. Nanotechnol. 2013, 13, 477–482. [Google Scholar] [CrossRef]

- Luo, S.S.; You, Z.S.; Lu, L. Intrinsic fracture toughness of bulk nanostructured Cu with nanoscale deformation twins. Scr. Mater. 2017, 133, 1–4. [Google Scholar] [CrossRef]

- Romano, G.; Barretta, R. Stress-driven versus strain-driven nonlocal integral model for elastic nano-beams. Compos. Part B Eng. 2017, 114, 184–188. [Google Scholar] [CrossRef]

- Romano, G.; Barretta, R. Nonlocal elasticity in nanobeams: The stress-driven integral model. Int. J. Eng. Sci. 2017, 115, 14–27. [Google Scholar] [CrossRef]

- Apuzzo, A.; Barretta, R.; Luciano, R.; Marotti de Sciarra, F.; Penna, R. Free vibrations of Bernoulli-Euler nano-beams by the stress-driven nonlocal integral model. Compos. Part B Eng. 2017, 123, 105–111. [Google Scholar] [CrossRef]

- Barretta, R.; Fazelzadeh, S.A.; Feo, L.; Ghavanloo, E.; Luciano, R. Nonlocal inflected nano-beams: A stress-driven approach of bi-Helmholtz type. Compos. Struct. 2018, 200, 239–245. [Google Scholar] [CrossRef]

- Darban, H.; Fabbrocino, F.; Feo, L.; Luciano, R. Size-dependent buckling analysis of nanobeams resting on two-parameter elastic foundation through stress-driven nonlocal elasticity model. Mech. Adv. Mater. Struct. 2020, in press. [Google Scholar] [CrossRef]

- Darban, H.; Luciano, R.; Caporale, A.; Fabbrocino, F. Higher modes of buckling in shear deformable nanobeams. Int. J. Eng. Sci. 2020, 154, 103338. [Google Scholar] [CrossRef]

- Luciano, R.; Caporale, A.; Darban, H.; Bartolomeo, C. Variational approaches for bending and buckling of non-local stress-driven Timoshenko nano-beams for smart materials. Mech. Res. Commun. 2020, 103, 103470. [Google Scholar] [CrossRef]

- Luciano, R.; Darban, H.; Bartolomeo, C.; Fabbrocino, F.; Scorza, D. Free flexural vibrations of nanobeams with non-classical boundary conditions using stress-driven nonlocal model. Mech. Res. Commun. 2020, 107, 103536. [Google Scholar] [CrossRef]

- Eringen, A.C. Nonlocal polar elastic continua. Int. J. Eng. Sci. 1972, 10, 1–16. [Google Scholar] [CrossRef]

- Eringen, A.C.; Edelen, D.G.B. On nonlocal elasticity. Int. J. Eng. Sci. 1972, 10, 233–248. [Google Scholar] [CrossRef]

- Peddieson, J.; Buchanan, G.R.; McNitt, R.P. Application of nonlocal continuum models to nanotechnology. Int. J. Eng. Sci. 2003, 41, 305–312. [Google Scholar] [CrossRef]

- Romano, G.; Barretta, R.; Diaco, M.; Marotti de Sciarra, F. Constitutive boundary conditions and paradoxes in nonlocal elastic nano-beams. Int. J. Mech. Sci. 2017, 121, 151–156. [Google Scholar] [CrossRef]

- Apuzzo, A.; Barretta, R.; Fabbrocino, F.; Faghidian, S.A.; Luciano, R.; Marotta De Sciarra, F. Axial and torsional free vibrations of elastic nano-beams by stress-driven two-phase elasticity. J. Appl. Comput. Mech. 2019, 5, 402–413. [Google Scholar]

- Barretta, R.; Diaco, M.; Feo, L.; Luciano, R.; Marotti De Sciarra, F.; Penna, R. Stress-driven integral elastic theory for torsion of nano-beams. Mech. Res. Commun. 2018, 87, 35–41. [Google Scholar] [CrossRef]

- Barretta, R.; Fabbrocino, F.; Luciano, R.; Marotti De Sciarra, F.; Ruta, G. Buckling loads of nano-beams in stress-driven nonlocal elasticity. Mech. Adv. Mater. Struct. 2020, 27, 869–875. [Google Scholar] [CrossRef]

- Barretta, R.; Faghidian, S.A.; Luciano, R. Longitudinal vibrations of nano-rods by stress-driven integral elasticity. Mech. Adv. Mater. Struct. 2020, 26, 1307–1315. [Google Scholar] [CrossRef]

- Romano, G.; Barretta, R.; Diaco, M. On nonlocal integral models for elastic nano-beams. Int. J. Mech. Sci. 2017, 131–132, 490–499. [Google Scholar] [CrossRef]

- Barretta, R.; Fabbrocino, F.; Luciano, R.; De Sciarra, F.M. Closed-form solutions in stress-driven two-phase integral elasticity for bending of functionally graded nano-beams. Phys. E 2018, 97, 13–30. [Google Scholar] [CrossRef]

- Apuzzo, A.; Bartolomeo, C.; Luciano, R.; Scorza, D. Novel local/nonlocal formulation of the stress-driven model through closed form solution for higher vibrations modes. Compos. Struct. 2020, 252, 112688. [Google Scholar] [CrossRef]

- Caporale, A.; Darban, H.; Luciano, R. Exact closed-form solutions for nonlocal beams with loading discontinuities. Mech. Adv. Mater. Struct. 2020. [Google Scholar] [CrossRef]

- Vantadori, S.; Luciano, R.; Scorza, D.; Darban, H. Fracture analysis of nanobeams based on the stress-driven non-local theory of elasticity. Mech. Adv. Mater. Struct. 2020, in press. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scorza, D.; Vantadori, S.; Luciano, R. Nanobeams with Internal Discontinuities: A Local/Nonlocal Approach. Nanomaterials 2021, 11, 2651. https://doi.org/10.3390/nano11102651

Scorza D, Vantadori S, Luciano R. Nanobeams with Internal Discontinuities: A Local/Nonlocal Approach. Nanomaterials. 2021; 11(10):2651. https://doi.org/10.3390/nano11102651

Chicago/Turabian StyleScorza, Daniela, Sabrina Vantadori, and Raimondo Luciano. 2021. "Nanobeams with Internal Discontinuities: A Local/Nonlocal Approach" Nanomaterials 11, no. 10: 2651. https://doi.org/10.3390/nano11102651

APA StyleScorza, D., Vantadori, S., & Luciano, R. (2021). Nanobeams with Internal Discontinuities: A Local/Nonlocal Approach. Nanomaterials, 11(10), 2651. https://doi.org/10.3390/nano11102651