Scalable Solution-Processed Fabrication Approach for High-Performance Silver Nanowire/MXene Hybrid Transparent Conductive Films

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Preparation of the Silver Nanowire/MXene Hybrid Film

2.3. Characterization

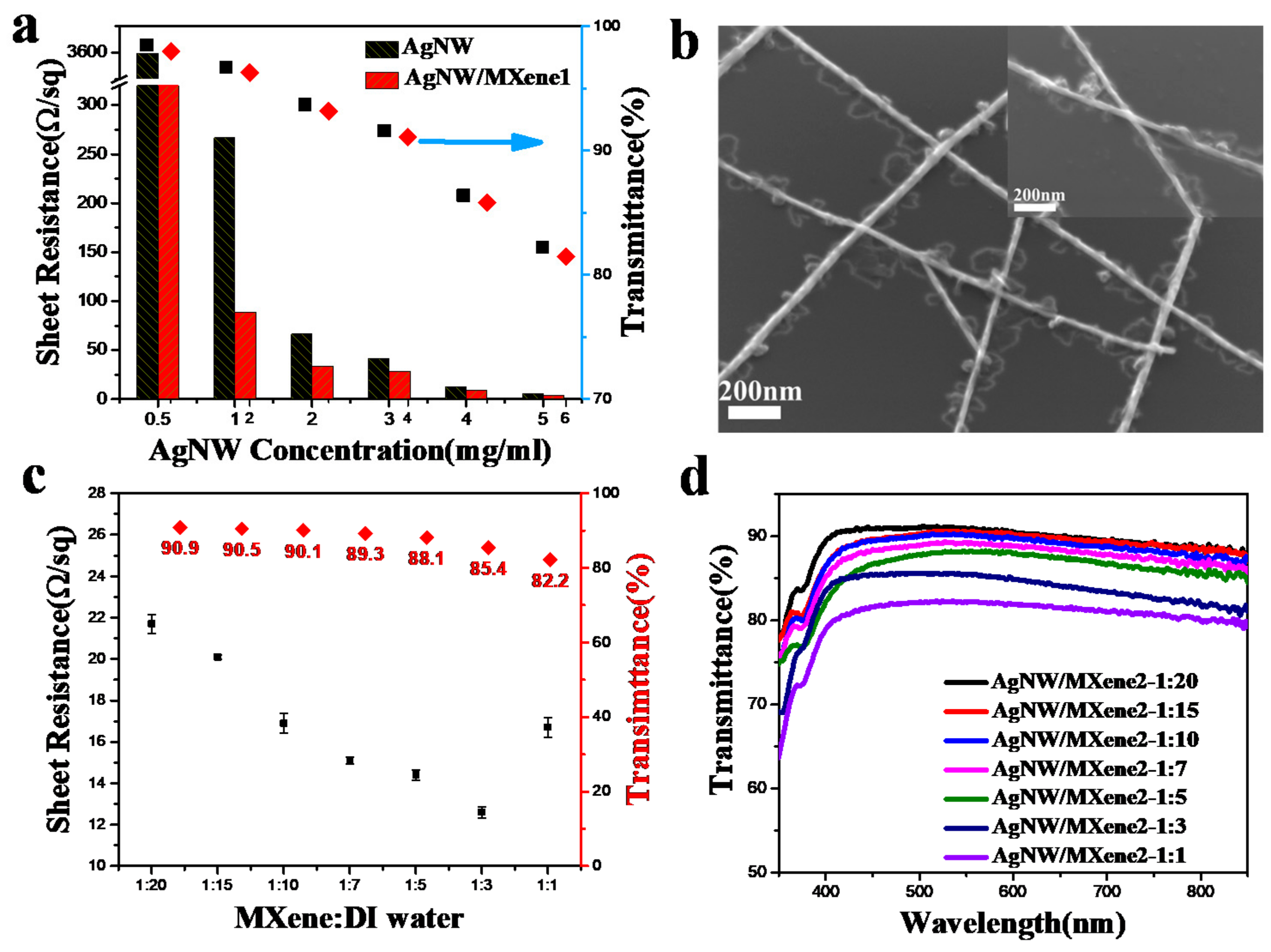

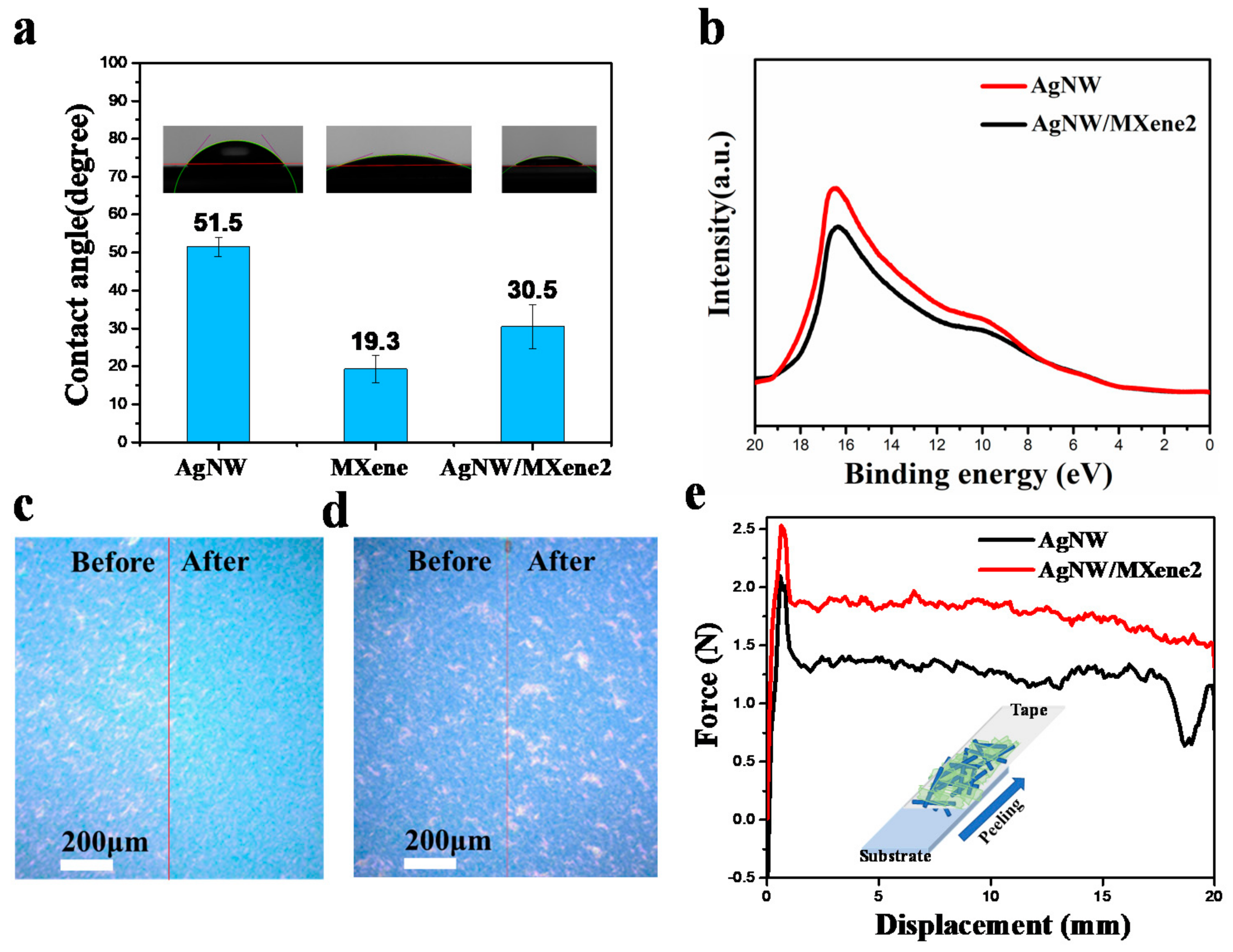

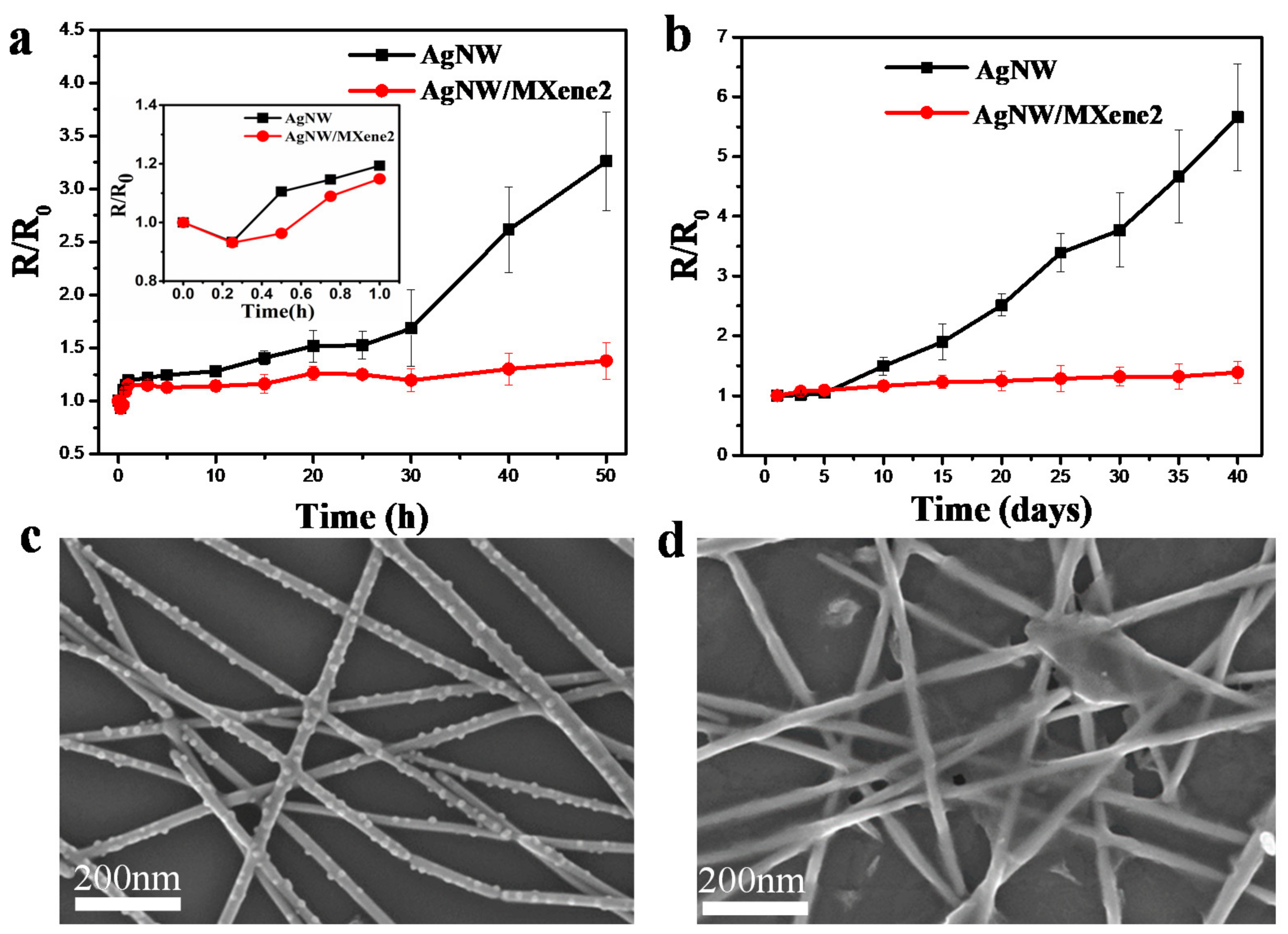

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sharma, S.; Shriwastava, S.; Kumar, S.; Bhatt, K.; Tripathi, C.C. Alternative transparent conducting electrode materials for flexible optoelectronic devices. Opto-Electron. Rev. 2018, 26, 223–235. [Google Scholar] [CrossRef]

- Preston, C.; Fang, Z.; Murray, J.; Zhu, H.L.; Dai, J.Q.; Munday, J.N.; Hu, L.B. Silver nanowire transparent conducting paper-based electrode with high optical haze. J. Mater. Chem. C 2014, 2, 1248–1254. [Google Scholar] [CrossRef]

- Han, T.-H.; Kim, H.; Kwon, S.-J.; Lee, T.-W. Graphene-based flexible electronic devices. Mater. Sci. Eng. R Rep. 2017, 118, 1–43. [Google Scholar] [CrossRef]

- Li, W.; Zhang, H.; Shi, S.; Xu, J.; Qin, X.; He, Q.; Yang, K.; Dai, W.; Liu, G.; Zhou, Q.; et al. Recent progress in silver nanowire networks for flexible organic electronics. J. Mater. Chem. C 2020, 8, 4636–4674. [Google Scholar] [CrossRef]

- Kim, J.H.; Joo, C.W.; Lee, J.; Seo, Y.K.; Han, J.W.; Oh, J.Y.; Kim, J.S.; Yu, S.; Lee, J.H.; Lee, J.I.; et al. Highly Conductive PEDOT: PSS Films with 1,3-Dimethyl-2-Imidazolidinone as Transparent Electrodes for Organic Light-Emitting Diodes. Macromol. Rapid Commun. 2016, 37, 1427–1433. [Google Scholar] [CrossRef]

- Wang, K.; Jin, Y.; Qian, B.; Wang, J.; Xiao, F. One-step aqueous fabrication of a silver nanowire composite transparent conductive film with high uniformity and stability. J. Mater. Chem. C 2020, 8, 4372–4384. [Google Scholar] [CrossRef]

- Li, L.J.; Zhang, B.; Zou, B.H.; Xie, R.J.; Zhang, T.; Li, S.; Zheng, B.; Wu, J.S.; Weng, J.N.; Zhang, W.N.; et al. Fabrication of Flexible Transparent Electrode with Enhanced Conductivity from Hierarchical Metal Grids. ACS Appl. Mater. Interfaces 2017, 9, 39110–39115. [Google Scholar] [CrossRef]

- Oh, J.S.; Oh, J.S.; Yeom, G.Y. Invisible Silver Nanomesh Skin Electrode via Mechanical Press Welding. Nanomaterials 2020, 10, 633. [Google Scholar] [CrossRef]

- Bi, Y.G.; Liu, Y.F.; Zhang, X.L.; Yin, D.; Wang, W.Q.; Feng, J.; Sun, H.B. Ultrathin Metal Films as the Transparent Electrode in ITO-Free Organic Optoelectronic Devices. Adv. Opt. Mater. 2019, 7, 23. [Google Scholar] [CrossRef]

- Ostfeld, A.E.; Catheline, A.; Ligsay, K.; Kim, K.-C.; Chen, Z.; Facchetti, A.; Fogden, S.; Arias, A.C. Single-walled carbon nanotube transparent conductive films fabricated by reductive dissolution and spray coating for organic photovoltaics. Appl. Phys. Lett. 2014, 105, 253301. [Google Scholar] [CrossRef]

- Soldano, C.; Stefani, A.; Biondo, V.; Basirico, L.; Turatti, G.; Generali, G.; Ortolani, L.; Morandi, V.; Veronese, G.P.; Rizzoli, R.; et al. ITO-Free Organic Light-Emitting Transistors with Graphene Gate Electrode. ACS Photonics 2014, 1, 1082–1088. [Google Scholar] [CrossRef]

- Shi, Y.; He, L.; Deng, Q.; Liu, Q.X.; Li, L.H.; Wang, W.; Xin, Z.Q. Synthesis and Applications of Silver Nanowires for Transparent Conductive Films. Micromachines 2019, 10, 330. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Liu, D.M.; Liang, Y.T.; Zhang, D.D.; Yan, H.; Zhang, Y.Z. Flexible transparent and conductive films of reduced-graphene-oxide wrapped silver nanowires. Mater. Lett. 2017, 201, 50–53. [Google Scholar] [CrossRef]

- Ge, Y.; Duan, X.; Zhang, M.; Mei, L.; Hu, J.; Hu, W.; Duan, X. Direct Room Temperature Welding and Chemical Protection of Silver Nanowire Thin Films for High Performance Transparent Conductors. J. Am. Chem. Soc. 2018, 140, 193–199. [Google Scholar] [CrossRef]

- Yang, X.; Du, D.X.; Xie, H.; Wang, Y.H.; Li, J.Z. Review of Silver Nanowire Based Transparent Conductive Film. Rare Metal Mater. Eng. 2019, 48, 1707–1716. [Google Scholar]

- Liu, J.; Zhang, L.; Li, C. Highly Stable, Transparent, and Conductive Electrode of Solution-Processed Silver Nanowire-MXene for Flexible Alternating-Current Electroluminescent Devices. Ind. Eng. Chem. Res. 2019, 58, 21485–21492. [Google Scholar] [CrossRef]

- Nishan Thilawala, K.G.; Kim, J.-K.; Lee, J.-M. Improvement of conductivity of graphene-silver nanowire hybrid through nitrogen doping using low power plasma treatment. J. Alloys Compd. 2019, 773, 1009–1017. [Google Scholar] [CrossRef]

- Zhang, R.; Engholm, M. Recent Progress on the Fabrication and Properties of Silver Nanowire-Based Transparent Electrodes. Nanomaterials 2018, 8, 628. [Google Scholar] [CrossRef]

- Martinez, P.M.; Ishteev, A.; Fahimi, A.; Velten, J.; Jurewicz, I.; Dalton, A.B.; Collins, S. Silver Nanowires on Carbon Nanotube Aerogel Sheets for Flexible, Transparent Electrodes. ACS Appl. Mater. Interfaces 2019, 11, 32235–32243. [Google Scholar] [CrossRef] [PubMed]

- Shin, D.H.; Seo, S.W.; Kim, J.M.; Lee, H.S.; Choi, S.-H. Graphene transparent conductive electrodes doped with graphene quantum dots-mixed silver nanowires for highly-flexible organic solar cells. J. Alloys Compd. 2018, 744, 1–6. [Google Scholar] [CrossRef]

- Liao, J.; Yang, M.; Zhang, W.; Zeng, D.; Ning, C.; Yuan, H. Spider silk-inspired universal strategy: Directional patching of one-dimensional nanomaterial-based flexible transparent electrodes for smart flexible electronics. Chem. Eng. J. 2020, 389, 123663. [Google Scholar] [CrossRef]

- Naguib, M.; Kurtoglu, M.; Presser, V.; Lu, J.; Niu, J.; Heon, M.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-dimensional nanocrystals produced by exfoliation of Ti3 AlC2. Adv. Mater. 2011, 23, 4248–4253. [Google Scholar] [CrossRef]

- Szuplewska, A.; Kulpińska, D.; Dybko, A.; Chudy, M.; Jastrzębska, A.M.; Olszyna, A.; Brzózka, Z. Future Applications of MXenes in Biotechnology, Nanomedicine, and Sensors. Trends Biotechnol. 2020, 38, 264–279. [Google Scholar] [CrossRef]

- Chen, J.; Huang, Q.; Huang, H.; Mao, L.; Liu, M.; Zhang, X.; Wei, Y. Recent progress and advances in the environmental applications of MXene related materials. Nanoscale 2020, 12, 3574–3592. [Google Scholar] [CrossRef]

- Zhan, X.; Si, C.; Zhou, J.; Sun, Z. MXene and MXene-based composites: Synthesis, properties and environment-related applications. Nanoscale Horiz. 2020, 5, 235–258. [Google Scholar] [CrossRef]

- Feng, A.; Hou, T.; Jia, Z.; Zhang, Y.; Zhang, F.; Wu, G. Preparation and Characterization of Epoxy Resin Filled with Ti3C2Tx MXene Nanosheets with Excellent Electric Conductivity. Nanomaterials 2020, 10, 162. [Google Scholar] [CrossRef]

- Kamysbayev, V.; Filatov, A.S.; Hu, H.; Rui, X.; Lagunas, F.; Wang, D.; Klie, R.F.; Talapin, D.V. Covalent surface modifications and superconductivity of two-dimensional metal carbide MXenes. Science 2020, 369, 979–983. [Google Scholar] [CrossRef] [PubMed]

- Tang, H.; Feng, H.; Wang, H.; Wan, X.; Lian, J. Highly Conducting MXene-Silver Nanowire Transparent Electrodes for Flexible Organic Solar Cells. ACS Appl. Mater. Interfaces 2019, 11, 25330–25337. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Wang, B.; Hu, H.; Zhang, J.; Wei, B.; Yang, L. Pseudo-Biological Highly Performance Transparent Electrodes Based on Capillary Force-Welded Hybrid AgNW Network. IEEE Access. 2019, 7, 177944–177953. [Google Scholar] [CrossRef]

- Chung, W.-H.; Park, S.-H.; Joo, S.-J.; Kim, H.-S. UV-assisted flash light welding process to fabricate silver nanowire/graphene on a PET substrate for transparent electrodes. Nano Res. 2018, 11, 2190–2203. [Google Scholar] [CrossRef]

- Ying, Y.; Liu, Y.; Wang, X.; Mao, Y.; Cao, W.; Hu, P. Two-dimensional titanium carbide for efficiently reductive removal of highly toxic chromium(VI) from water. ACS Appl. Mater. Interfaces 2015, 7, 1795–1803. [Google Scholar] [CrossRef] [PubMed]

- Naguib, M.; Unocic, R.R.; Armstrong, B.L.; Nanda, J. Large-scale delamination of multi-layers transition metal carbides and carbonitrides “MXenes”. Dalton Trans. 2015, 44, 9353–9358. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhang, J.; Gao, H.; Wang, Y.; Liu, Q.; Huang, S.; Guo, C.F.; Ren, Z. Capillary-Force-Induced Cold Welding in Silver-Nanowire-Based Flexible Transparent Electrodes. Nano Lett. 2017, 17, 1090–1096. [Google Scholar] [CrossRef]

- Svintradze, D.V. Generalization of the Kelvin equation for arbitrarily curved surfaces. Phys. Lett. A 2020, 384, 126412. [Google Scholar] [CrossRef]

- Fisher, L.; Israelachvili, J. Direct experimental verification of the Kelvin equation for capillary condensation. Nature 1979, 277, 548–549. [Google Scholar] [CrossRef]

- Liu, C.; Hao, S.; Chen, X.; Zong, B.; Mao, S. High Anti-Interference Ti3C2Tx MXene Field-Effect-Transistor-Based Alkali Indicator. ACS Appl. Mater. Interfaces 2020, 12, 32970–32978. [Google Scholar] [CrossRef]

- Hu, M.; Hu, T.; Li, Z.; Yang, Y.; Cheng, R.; Yang, J.; Cui, C. Surface Functional Groups and Interlayer Water Determine the Electrochemical Capacitance of Ti3C2 T x MXene. ACS Nano 2018, 12, 3578–3586. [Google Scholar] [CrossRef]

- Ko, D.; Gu, B.; Cheon, J.; Roh, J.-S.; Kim, C.S.; Jo, S.; Hyun, D.C. Decoupling the contributions to the enhancement of electrical conductivity in transparent silver nanowire/zinc oxide composite electrodes. Mater. Chem. Phys. 2019, 223, 634–640. [Google Scholar] [CrossRef]

- Kang, W.B.; Yan, C.Y.; Foo, C.Y.; Lee, P.S. Foldable Electrochromics Enabled by Nanopaper Transfer Method. Adv. Funct. Mater. 2015, 25, 4203–4210. [Google Scholar] [CrossRef]

- De, S.; Higgins, T.M.; Lyons, P.E.; Doherty, E.M.; Nirmalraj, P.N.; Blau, W.J.; Boland, J.J.; Coleman, J.N. Silver Nanowire Networks as Flexible, Transparent, Conducting Films: Extremely High DC to Optical Conductivity Ratios. ACS Nano 2009, 3, 1767–1774. [Google Scholar] [CrossRef]

- Zhou, W.; Chen, J.; Chen, J.; Zheng, C.; Gao, Z.; Mi, B.; Zhang, H.; Ma, Y. Ag Nanowire Films Coated with Graphene as Transparent Conductive Electrodes for Organic Light-Emitting Diodes. J. Nanosci. Nanotechnol. 2016, 16, 12609–12616. [Google Scholar] [CrossRef]

- Raman, V.; Cho, Y.-H.; Park, J.-H.; Chinnadurai, D.; Kim, H.-K. Impact of low temperature plasma annealing for flexible, transparent and conductive ITO/PEDOT:PSS composite electrode. J. Ind. Eng. Chem. 2021, 93, 423–429. [Google Scholar] [CrossRef]

- Gu, Z.Z.; Tian, Y.; Geng, H.Z.; Rhen, D.S.; Ethiraj, A.S.; Zhang, X.C.; Jing, L.C.; Wang, T.; Xu, Z.H.; Yuan, X.T. Highly conductive sandwich-structured CNT/PEDOT:PSS/CNT transparent conductive films for OLED electrodes. Appl. Nanosci. 2019, 9, 1971–1979. [Google Scholar] [CrossRef]

- Ding, S.; Tian, Y.H.; Jiu, J.T.; Suganuma, K. Highly conductive and transparent copper nanowire electrodes on surface coated flexible and heat-sensitive substrates. RSC Adv. 2018, 8, 2109–2115. [Google Scholar] [CrossRef]

- Naito, K.; Inuzuka, R.; Yoshinaga, N.; Mei, W. Transparent conducting films composed of graphene oxide/Ag nanowire/graphene oxide/PET. Synth. Met. 2018, 237, 50–55. [Google Scholar] [CrossRef]

- Lee, H.-J.; Song, Y.-S.; An, T.K.; Choi, W.-K.; Kim, S.-R. Ultrasmooth transparent conductive hybrid films of reduced graphene oxide and single-walled carbon nanotube by ultrasonic spraying. Synth. Met. 2016, 221, 340–344. [Google Scholar] [CrossRef]

- Lai, Y.T.; Tai, N.H. One-Step Process for High-Performance, Adhesive, Flexible Transparent Conductive Films Based on p-Type Reduced Graphene Oxides and Silver Nanowires. ACS Appl. Mater. Interfaces 2015, 7, 18553–18559. [Google Scholar] [CrossRef]

- Agresti, A.; Pazniak, A.; Pescetelli, S.; Di Vito, A.; Rossi, D.; Pecchia, A.; Auf Der Maur, M.; Liedl, A.; Larciprete, R.; Kuznetsov, D.V.; et al. Titanium-carbide MXenes for work function and interface engineering in perovskite solar cells. Nat. Mater. 2019, 18, 1228–1234. [Google Scholar] [CrossRef]

- Schultz, T.; Frey, N.C.; Hantanasirisakul, K.; Park, S.; May, S.J.; Shenoy, V.B.; Gogotsi, Y.; Koch, N. Surface Termination Dependent Work Function and Electronic Properties of Ti3C2Tx MXene. Chem. Mater. 2019, 31, 6590–6597. [Google Scholar] [CrossRef]

- Schmitt, P.; Eberlein, D.; Ebert, C.; Tranitz, M.; Eitner, U. Adhesion of Al-metallization in Ultra-sonic Soldering on the Al-rear Side of Solar Cells. Energy Procedia 2013, 38, 380–386. [Google Scholar] [CrossRef]

- Wu, S.; Cui, W.; Aghdassi, N.; Song, T.; Duhm, S.; Lee, S.-T.; Sun, B. Nanostructured Si/Organic Heterojunction Solar Cells with High Open-Circuit Voltage via Improving Junction Quality. Adv. Funct. Mater. 2016, 26, 5035–5041. [Google Scholar] [CrossRef]

- Chen, X.; Xu, G.; Zeng, G.; Gu, H.; Chen, H.; Xu, H.; Yao, H.; Li, Y.; Hou, J.; Li, Y. Realizing Ultrahigh Mechanical Flexibility and >15% Efficiency of Flexible Organic Solar Cells via a “Welding” Flexible Transparent Electrode. Adv. Mater. 2020, 32, e1908478. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.; Zhang, C.; Wu, M.; Zhang, J.; Ling, X.; Yang, L. Scalable Solution-Processed Fabrication Approach for High-Performance Silver Nanowire/MXene Hybrid Transparent Conductive Films. Nanomaterials 2021, 11, 1360. https://doi.org/10.3390/nano11061360

Wang P, Zhang C, Wu M, Zhang J, Ling X, Yang L. Scalable Solution-Processed Fabrication Approach for High-Performance Silver Nanowire/MXene Hybrid Transparent Conductive Films. Nanomaterials. 2021; 11(6):1360. https://doi.org/10.3390/nano11061360

Chicago/Turabian StyleWang, Pengchang, Chi Zhang, Majiaqi Wu, Jianhua Zhang, Xiao Ling, and Lianqiao Yang. 2021. "Scalable Solution-Processed Fabrication Approach for High-Performance Silver Nanowire/MXene Hybrid Transparent Conductive Films" Nanomaterials 11, no. 6: 1360. https://doi.org/10.3390/nano11061360

APA StyleWang, P., Zhang, C., Wu, M., Zhang, J., Ling, X., & Yang, L. (2021). Scalable Solution-Processed Fabrication Approach for High-Performance Silver Nanowire/MXene Hybrid Transparent Conductive Films. Nanomaterials, 11(6), 1360. https://doi.org/10.3390/nano11061360