Moisture Vapor Resistance of Coated and Laminated Breathable Fabrics Using Evaporative Wet Heat Transfer Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Specimens

2.2. Measurement of the Fabric Structural Parameters

2.3. Measurement of the Breathability of the Fabric Specimens

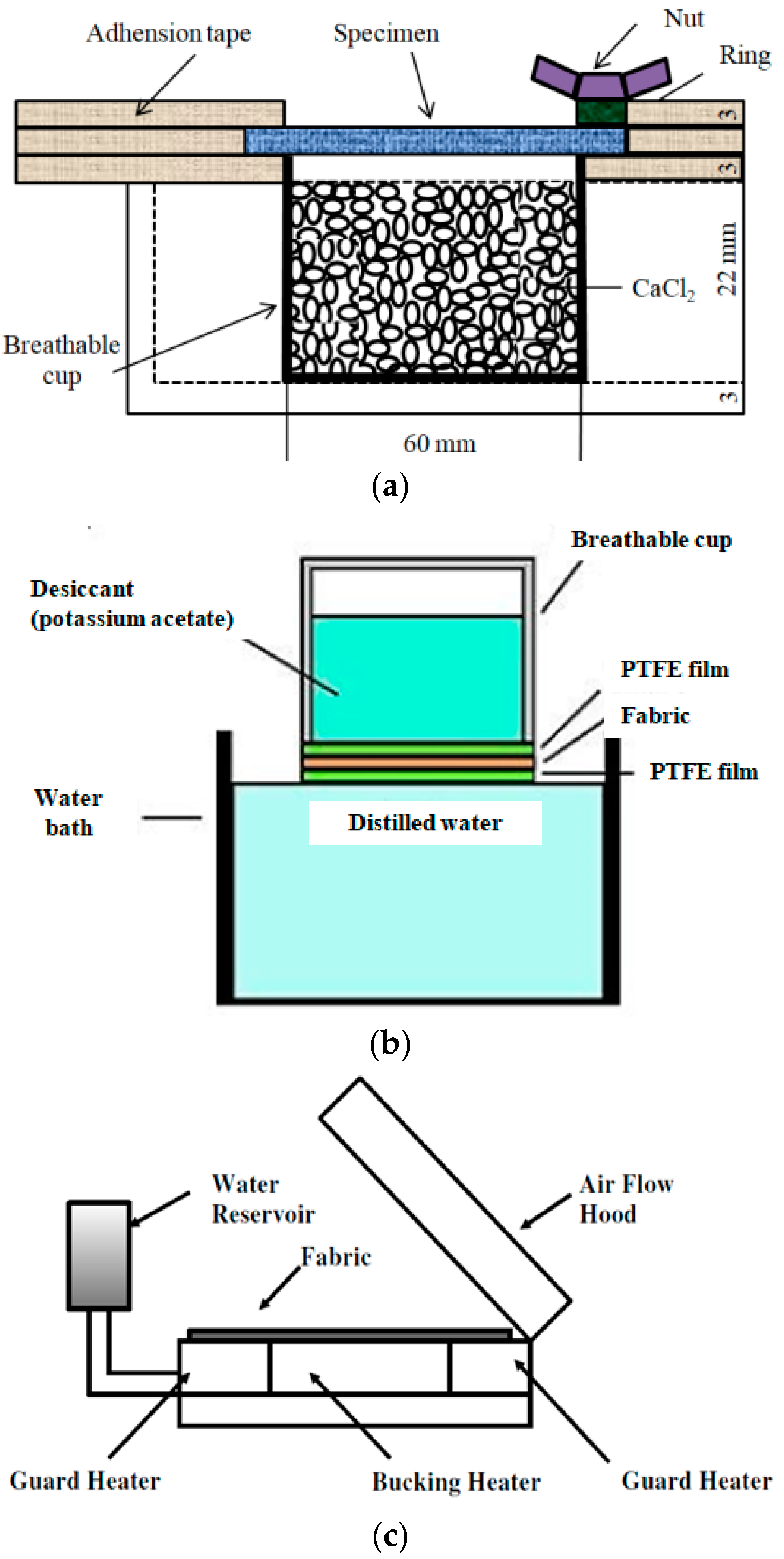

2.3.1. Measurement of the Water Vapor Transmission Rate

2.3.2. Measurement of the WVP

2.3.3. Measurement of the Moisture Vapor Resistance

3. Results and Discussion

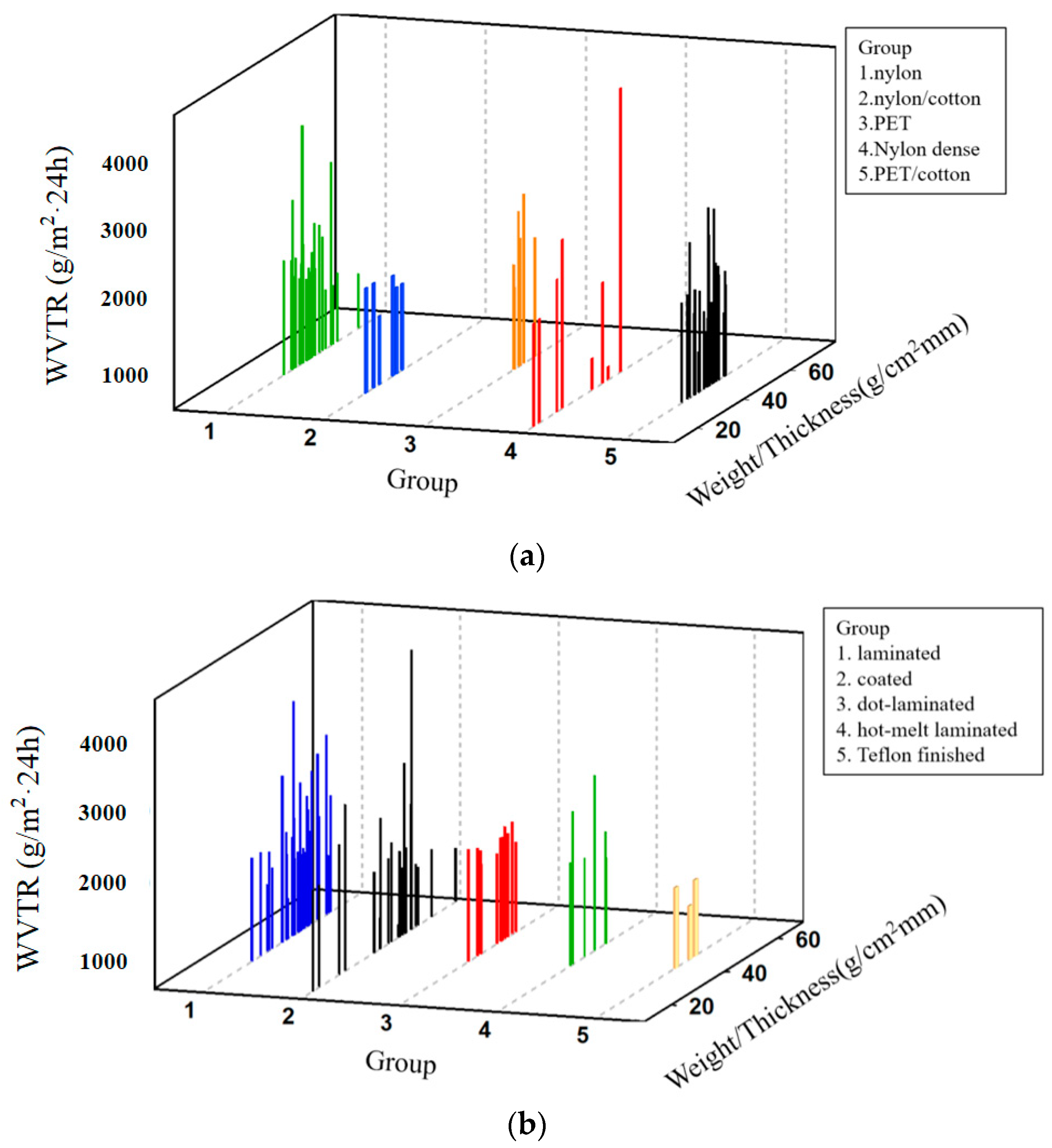

3.1. WVTR Using the Upright Cup Method (ASTM E96-80)

3.2. Water Vapor Permeability Using the Inverted Cup Method (JIS L 1099B-1)

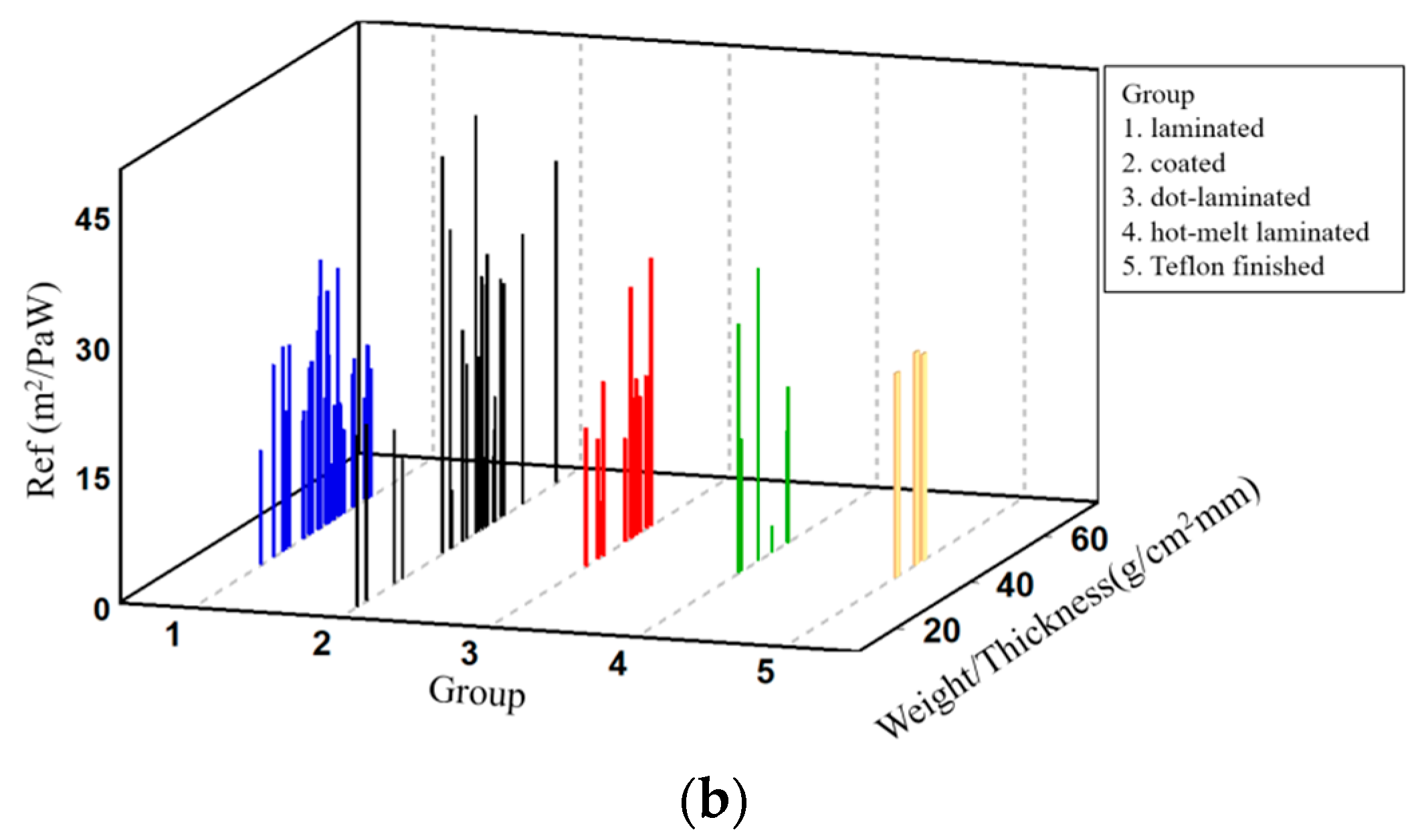

3.3. Moisture Vapor Resistance Using Evaporative Wet Heat Transfer Method

3.4. Correlation Analysis between the Measuring Methods of Breathability

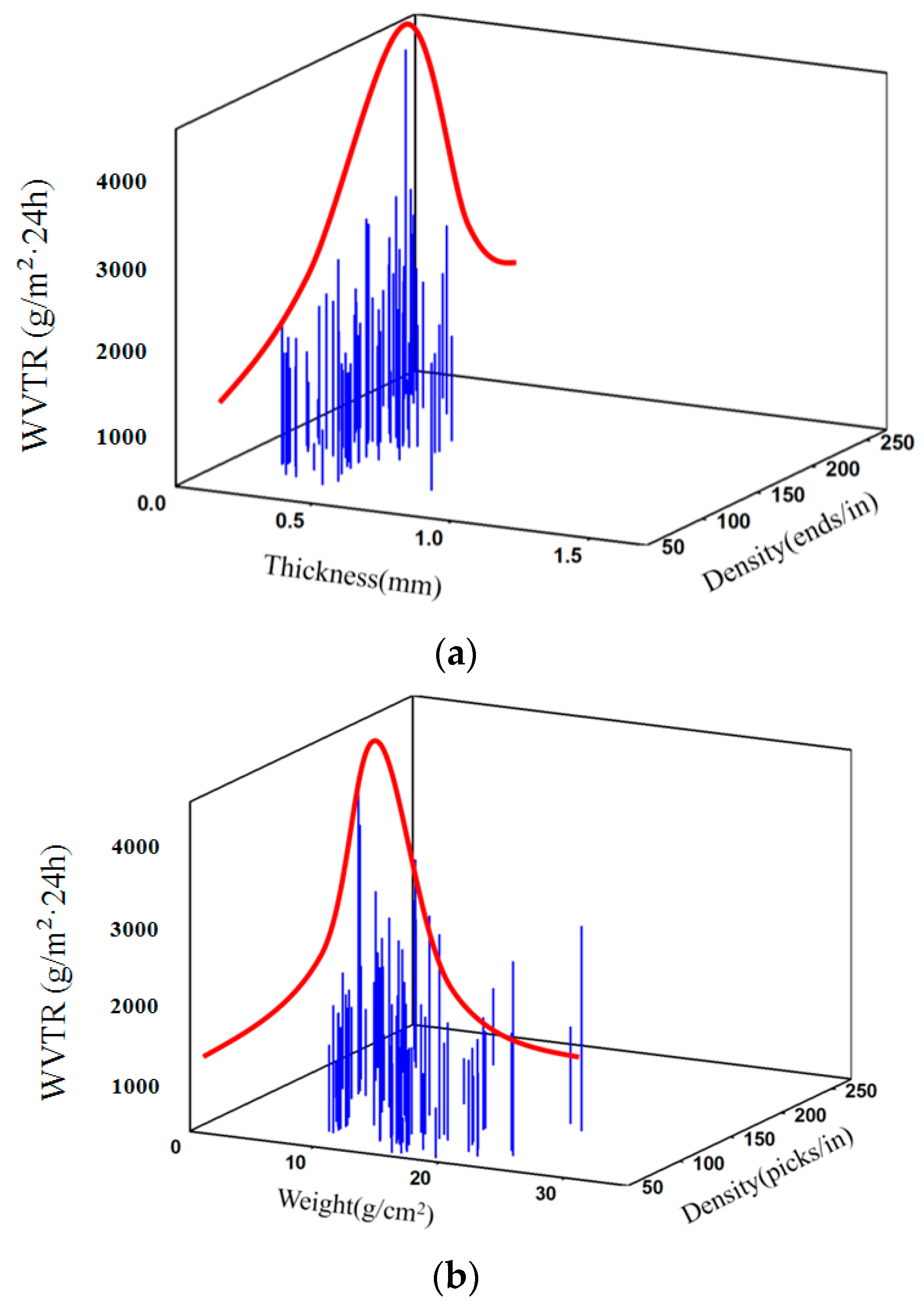

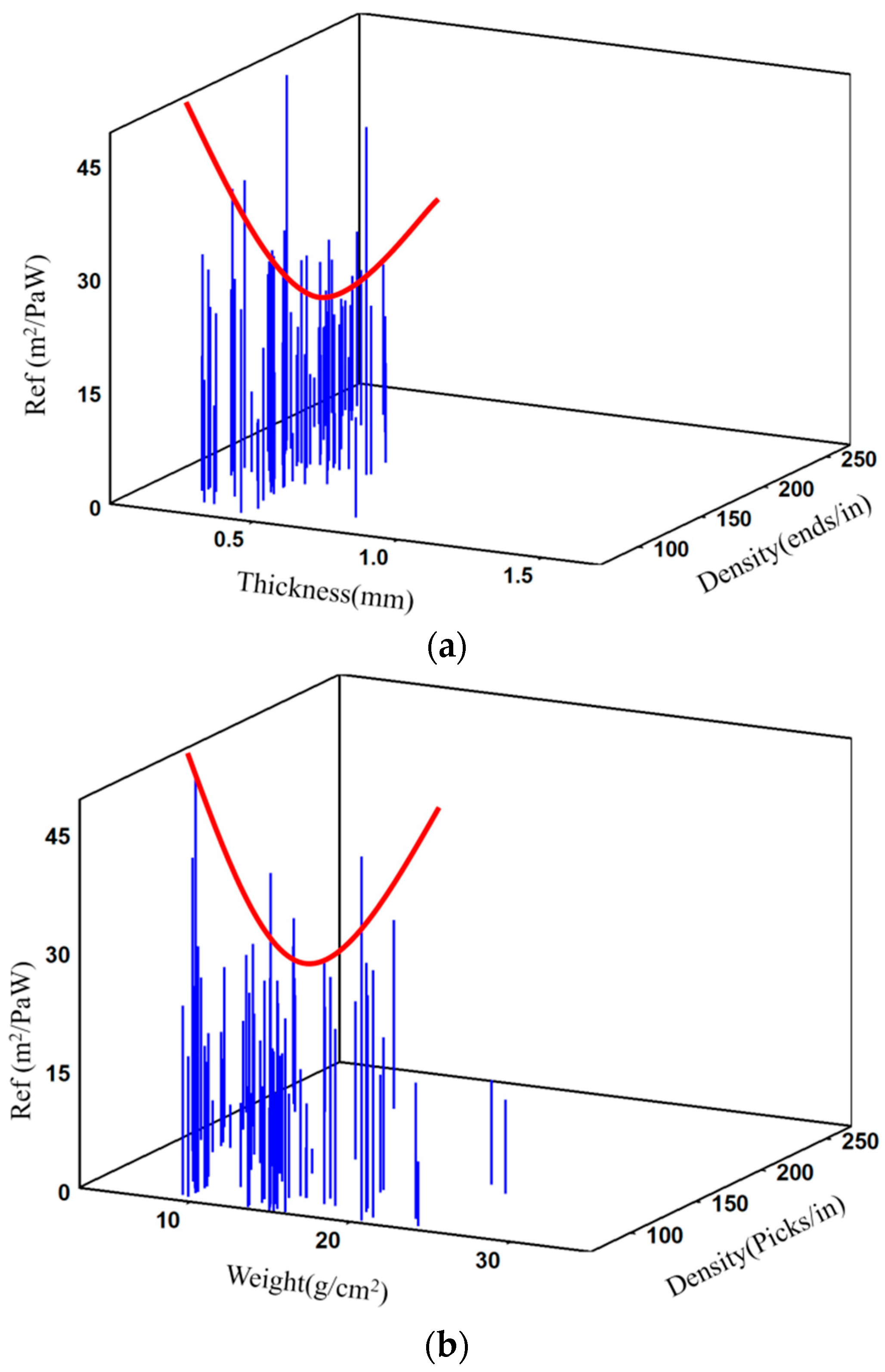

3.5. Regression Analysis between the Breathability and Fabric Structural Parameters

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, L.; Feng, X.; Du, Y.; Li, Y. Characterization of liquid moisture transport performance of wool knitted fabrics. Text. Res. J. 2007, 77, 951–956. [Google Scholar] [CrossRef]

- Das, B.; Das, A.; Kothari, V.K.; Fangueiro, R.; Araújo, M.D. Studies on moisture transmission properties of PV-blended fabrics. J. Text. Inst. 2009, 100, 588–597. [Google Scholar] [CrossRef]

- Rego, J.M.; Verdu, P.; Nieto, J.; Blanes, M. Comfort analysis of woven cotton/polyester fabrics modified with a new elastic fiber, part 2: Detailed study of mechanical, thermo-physiological and skin sensorial properties. Text. Res. J. 2010, 80, 206–215. [Google Scholar] [CrossRef]

- Du, Y.; Li, J. Dynamic moisture absorption behavior of polyester-cotton fabric and mathematical model. Text. Res. J. 2010, 80, 1793–1802. [Google Scholar] [CrossRef]

- Gorjanc, D.Š.; Dimitrovski, K.; Bizjak, M. Thermal and water vapor resistance of the elastic and conventional cotton fabrics. Text. Res. J. 2012, 82, 1498–1506. [Google Scholar] [CrossRef]

- Yoo, H.S.; Hu, Y.S.; Kim, E.A. Effects of heat and moisture transport in fabrics and garments determined with a vertical plate sweating skin model. Text. Res. J. 2000, 70, 542–549. [Google Scholar] [CrossRef]

- Yoo, S.J.; Kim, E.A. Effects of multilayer clothing system array on water vapor transfer and condensation in cold weather clothing ensemble. Text. Res. J. 2008, 78, 189–197. [Google Scholar] [CrossRef]

- Yoo, S.J.; Kim, E.A. Wear trial assessment of layer structure effects on vapor permeability and condensation in a cold weather clothing ensemble. Text. Res. J. 2012, 82, 1079–1091. [Google Scholar] [CrossRef]

- Lee, S.S.; Obendorf, S.K. Statistical modeling of water vapor transport through woven fabrics. Text. Res. J. 2012, 82, 211–219. [Google Scholar] [CrossRef]

- Kim, J.O.; Spivak, S.M. Dynamic moisture vapor transfer through textiles—Part II: Further techniques for microclimate moisture and temperature measurement. Text. Res. J. 1994, 64, 112–121. [Google Scholar] [CrossRef]

- Cubric, I.S.; Skenderi, Z.; Havenith, G. Impact of raw material, yarn and fabric parameters, and finishing on water vapor resistance. Text. Res. J. 2013, 83, 1215–1228. [Google Scholar] [CrossRef] [Green Version]

- Salz, P. Testing the Quality of Breathable Textiles, Performance of Protective Clothing: Second Symposium, ASTM Special Technical Publication 989; Mandorf, F.Z., Sagar, R., Bielson, A.P., Eds.; American Society for Testing and Materials: Philadelphia, PA, USA, 1988; p. 295. [Google Scholar]

- Lomax, G.R. Hydrophilic polyurethane coatings. J. Coat. Fabr. 1990, 20, 88–107. [Google Scholar] [CrossRef]

- Gibson, P.W. Factors influencing steady-state heat and water vapor transfer measurement for clothing materials. Text. Res. J. 1993, 63, 749–764. [Google Scholar] [CrossRef]

- Gibson, P.W.; Kendrick, C.E.; Rivin, D.; Charmchi, M.; Sicuranza, L. An automated water vapour diffusion test method for fabrics, laminates, and films. J. Coat. Fabr. 1995, 24, 322–345. [Google Scholar] [CrossRef]

- Gibson, P.W.; Kendrick, C.E.; Rivin, D.; Charmchi, M. An automated dynamic water vapour permeation test method. Perform. Prot. Cloth. 1997, 6, 93–107. [Google Scholar] [CrossRef]

- Dolhan, P.A. A comparison of apparatus used to measure water vapour resistance. J. Coat. Fabr. 1987, 17, 96–109. [Google Scholar] [CrossRef]

- Congalton, D. Heat and moisture transport through textiles and clothing ensembles utilizing the Hohenstein skin model. J. Coat. Fabr. 1999, 28, 183–196. [Google Scholar]

- Grettlon, J.C.; Brook, D.B.; Dyson, H.M.; Harlock, S.C. A correlation between test methods used to measure moisture vapor transmission through fabrics. J. Coat. Fabr. 1996, 25, 301–311. [Google Scholar] [CrossRef]

- McCullough, E.A.; Kwon, M.; Shim, H. A comparison of standard methods for measuring water vapour permeability of fabrics. Meas. Sci. Technol. 2003, 14, 1402–1408. [Google Scholar] [CrossRef]

- Huang, J. Review of test methods for measuring water vapor transfer properties of fabrics. Cell. Polym. 2007, 26, 167–191. [Google Scholar] [CrossRef]

- Huang, J.; Qian, X. Comparison of test methods for measuring water vapor permeability of fabrics. Text. Res. J. 2008, 78, 342–352. [Google Scholar] [CrossRef]

- ASTM E96-80. Standard Test Methods for Water Vapor Transmission of Materials; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar] [CrossRef]

- JIS L 1099; Testing Methods for Water Vapor Permeability of Textiles: JIS L 1099B-1; Upright Cup Method CH3COOH Test. 2012. Available online: http://www,jisc.go.jp (accessed on 6 May 2021).

- ISO 11092. Physiological Effects—Measurement of Thermal and Water-Vapour Resistance under Steady-State Conditions (Sweating Guarded-Hot Plate Test); International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- BS 7209. Specification for Water Vapour Permeable Apparel Fabrics; British Standards Institution (BSI): London, UK, 2012. [Google Scholar]

- Jakšič, D. Analytical method for determinating resistance to water vapor flow through flat fabrics. Tekstilec 1988, 31, 169–178. [Google Scholar]

- Hes, L. Permetest Instrument; Sensora Instruments & Consulting: Liberec, Czech Republic, 2005. [Google Scholar]

| Specimen Group | Materials | No. of Specimens | Specimen Group | Surface Modification Method | No. of Specimens |

|---|---|---|---|---|---|

| 1 | Nylon fabric | 24 | 1 | Laminated | 39 |

| 2 | Nylon/cotton fabric | 6 | 2 | Coated | 14 |

| 3 | PET fabric | 13 | 3 | Dotlaminated | 11 |

| 4 | Nylon dense fabric | 8 | 4 | Hot-meltlaminated | 6 |

| 5 | PET/cotton fabric | 22 | 5 | Teflon finished | 3 |

| Total | 73 | 73 |

| Specimen No. | Fiber Material | Surface Modification Method | Fabric Structural Parameters | Specimen No. | Fiber Material | Surface Modification Method | Fabric Structural Parameters | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thickness (mm) | Weight (g/cm2) | Warp Density (ends/inch) | Weft Density (picks/inch) | Thickness (mm) | Weight (g/cm2) | Warp Density (ends/inch) | Weft Density (picks/inch) | ||||||

| 1 | N/D | L | 0.125 | 35.52 | 290 | 150 | 38 | N/C | 0.759 | 21.64 | 92 | 67 | |

| 2 | N | 0.439 | 24.82 | 88 | 130 | 39 | P/C | 0.427 | 22.94 | 128 | 84 | ||

| 3 | P | 0.276 | 11.75 | 125 | 80 | 40 | N | C | 0.391 | 15.67 | 160 | 56 | |

| 4 | P | 0.317 | 14.93 | 120 | 80 | 41 | N | 0.276 | 14.18 | 125 | 80 | ||

| 5 | P | 0.305 | 16.52 | 120 | 80 | 42 | P | 0.544 | 20.44 | 150 | 73 | ||

| 6 | P | 0.31 | 16.92 | 120 | 80 | 43 | N | 0.366 | 15.74 | 125 | 72 | ||

| 7 | P | 0.327 | 16.47 | 120 | 80 | 44 | N | 0.32 | 15.10 | 125 | 71 | ||

| 8 | P/C | 0.344 | 16.10 | 165 | 65 | 45 | N | 0.349 | 20.68 | 120 | 79 | ||

| 9 | P | 0.305 | 15.02 | 100 | 75 | 46 | N | 0.398 | 19.76 | 110 | 85 | ||

| 10 | P | 0.19 | 9.70 | 220 | 120 | 47 | P | 0.337 | 16.60 | 150 | 96 | ||

| 11 | P | 0.178 | 9.48 | 180 | 130 | 48 | P | 0.212 | 10.94 | 135 | 97 | ||

| 12 | N | 0.413 | 19.16 | 80 | 56 | 49 | N | 0.154 | 10.51 | 133 | 125 | ||

| 13 | N | 0.305 | 14.18 | 130 | 80 | 50 | P/C | 0.251 | 13.38 | 140 | 85 | ||

| 14 | P/C | 0.313 | 14.45 | 130 | 80 | 51 | N | 0.359 | 17.29 | 163 | 67 | ||

| 15 | P/C | 0.301 | 14.51 | 170 | 90 | 52 | P/C | 0.486 | 23.81 | 132 | 75 | ||

| 16 | N | 0.298 | 13.24 | 155 | 75 | 53 | N | 0.359 | 19.45 | 156 | 90 | ||

| 17 | N | 0.144 | 8.26 | 210 | 140 | 54 | P/C | D | 0.166 | 8.28 | 140 | 105 | |

| 18 | N/D | 0.120 | 6.01 | 210 | 130 | 55 | P/C | 0.173 | 9.33 | 105 | 84 | ||

| 19 | P/C | 0.137 | 6.46 | 136 | 144 | 56 | N | 0.178 | 9.38 | 103 | 76 | ||

| 20 | N/D | 0.125 | 5.99 | 205 | 136 | 57 | N | 0.193 | 9.34 | 105 | 82 | ||

| 21 | N | 0.139 | 5.03 | 165 | 210 | 58 | P/C | 0.181 | 9.24 | 170 | 92 | ||

| 22 | N/D | 0.129 | 5.15 | 220 | 170 | 59 | N | 0.413 | 16.35 | 154 | 57 | ||

| 23 | N | 0.120 | 5.92 | 320 | 200 | 60 | P | 0.254 | 12.45 | 150 | 110 | ||

| 24 | N/D | 0.149 | 7.40 | 208 | 205 | 61 | N | 0.327 | 15.36 | 155 | 93 | ||

| 25 | P/C | 0.251 | 8.79 | 88 | 88 | 62 | N | 0.410 | 14.85 | 150 | 95 | ||

| 26 | N/D | 0.122 | 5.34 | 240 | 175 | 63 | P/C | 0.376 | 15.34 | 130 | 93 | ||

| 27 | N/D | 0.137 | 5.67 | 225 | 190 | 64 | N | 0.405 | 16.57 | 100 | 60 | ||

| 28 | P/C | 0.222 | 10.38 | 190 | 128 | 65 | N/D | H | 0.349 | 13.43 | 210 | 72 | |

| 29 | P | 0.198 | 11.51 | 165 | 120 | 66 | P/C | 0.381 | 16.35 | 122 | 57 | ||

| 30 | N | 0.298 | 13.64 | 151 | 80 | 67 | P/C | 0.281 | 13.10 | 156 | 125 | ||

| 31 | P/C | 0.378 | 16.87 | 112 | 88 | 68 | P/C | 0.291 | 14.77 | 87 | 72 | ||

| 32 | N/C | 0.552 | 17.56 | 152 | 88 | 69 | P/C | 0.386 | 14.49 | 120 | 76 | ||

| 33 | N/C | 0.525 | 23.11 | 170 | 140 | 70 | P/C | 0.183 | 9.33 | 173 | 89 | ||

| 34 | N/C | 0.461 | 18.44 | 155 | 112 | 71 | N | T | 0.186 | 8.88 | 108 | 78 | |

| 35 | N/C | 0.305 | 10.46 | 285 | 220 | 72 | P/C | 0.176 | 8.04 | 127 | 96 | ||

| 36 | P/C | 0.327 | 13.79 | 180 | 150 | 73 | P/C | 0.227 | 9.18 | 103 | 85 | ||

| 37 | N/C | 0.442 | 18.38 | 152 | 115 | ||||||||

| Fiber Materials | ISO/ASTM | ASTM/ JIS | ISO/JIS | Surface Modification Method | ISO/ASTM | ASTM/ JIS | ISO/JIS |

|---|---|---|---|---|---|---|---|

| Total specimens | −0.537 b | −0.104 | 0.021 | Total specimens | −0.537 b | −0.104 | 0.021 |

| PET | −0.833 | 0.064 | −0.002 | Laminated | −0.437 | 0.024 | 0.032 |

| Nylon | −0.616 b | 0.183 | −0.063 | Coated | −0.715 a | −0.325 | 0.276 |

| Etc. | −0.384 | 0.132 | 0.112 | Dot−laminated | −0.258 | −0.268 | −0.478 |

| Hot melt laminated | −0.710 a | −0.710 | 0.138 |

| Material and Surface Modifacation Method | Measurement Method | Structural Parameter (x) | Regression Equation | R2 | p-Value |

|---|---|---|---|---|---|

| PET | ASTM-96 | T | y = −58,963.6x2 − 53,250.8x + 9562.7 | 0.802 | <0.05 * |

| W | y = −42.6x2 − 1320.4x + 11,533.3 | 0.844 | <0.05 * | ||

| W/T | y = −50.5x2 + 5486.7x − 146,199.9 | 0.637 | <0.1 | ||

| ISO 11092 | T | y = 648.4x2 − 220.0x + 31.15 | 0.839 | <0.05 * | |

| W | y = 0.202x2 − 2.63x + 18.33 | 0.847 | <0.05 * | ||

| JIS L 1099B-1 | D | y = −403x2 + 1015.8x − 55,872 | 0.829 | <0.05 * | |

| Laminated | ASTM-96 | W | y = −69.4x2 + 1769.5x − 8727.5 | 0.640 | <0.1 |

| D | y = −0.83x2 − 175.8x + 10,927.1 | 0.659 | <0.1 | ||

| ISO 11092 | T | y = 1715.1x2 − 909.6x + 127.1 | 0.872 | <0.05 * | |

| D | y = 0.002x2 + 4.74x − 220.4 | 0.734 | <0.05 * | ||

| W | y = 1.21x2 − 31.5x + 196.0 | 0.611 | <0.1 | ||

| JIS L 1099B-1 | W/T | y = −37.5x2 − 2907.9x + 65,027.7 | 0.663 | <0.1 |

| Material and Surface Modifacation Method | Measurement Method | Regression Equation | R2 | p-Value |

|---|---|---|---|---|

| PET | ASTM-96 | y = 1863.5 − 116.3W − 4.6W/T − 13.8D | 0.887 | <0.05 * |

| ISO 11092 | y = −13.4 + 2.5W + 0.05W/T + 0.02D | 0.831 | <0.05 * | |

| Laminated | ASTM-96 | y = 60,386.4 − 147,757.2T + 2855.1W − 1116.4W/T − 10.2D | 0.947 | <0.01 ** |

| ISO 11092 | y = −2065.7 + 5016.8T − 91.6W + 37.6W/T + 0.77D | 0.943 | <0.01 ** | |

| JIS L 1099B-1 | y = 118,939 + 307,656T − 6113W + 2665W/T − 15.8D | 0.878 | <0.05 * |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.-A. Moisture Vapor Resistance of Coated and Laminated Breathable Fabrics Using Evaporative Wet Heat Transfer Method. Coatings 2021, 11, 1157. https://doi.org/10.3390/coatings11101157

Kim H-A. Moisture Vapor Resistance of Coated and Laminated Breathable Fabrics Using Evaporative Wet Heat Transfer Method. Coatings. 2021; 11(10):1157. https://doi.org/10.3390/coatings11101157

Chicago/Turabian StyleKim, Hyun-Ah. 2021. "Moisture Vapor Resistance of Coated and Laminated Breathable Fabrics Using Evaporative Wet Heat Transfer Method" Coatings 11, no. 10: 1157. https://doi.org/10.3390/coatings11101157

APA StyleKim, H.-A. (2021). Moisture Vapor Resistance of Coated and Laminated Breathable Fabrics Using Evaporative Wet Heat Transfer Method. Coatings, 11(10), 1157. https://doi.org/10.3390/coatings11101157