Preparation and Thermal Shock Resistance of Gd2O3 Doped La2Ce2O7 Thermal Barrier Coatings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Processing and Materials

2.2. Thermal Shock Test

2.3. Characterization

3. Results and Discussion

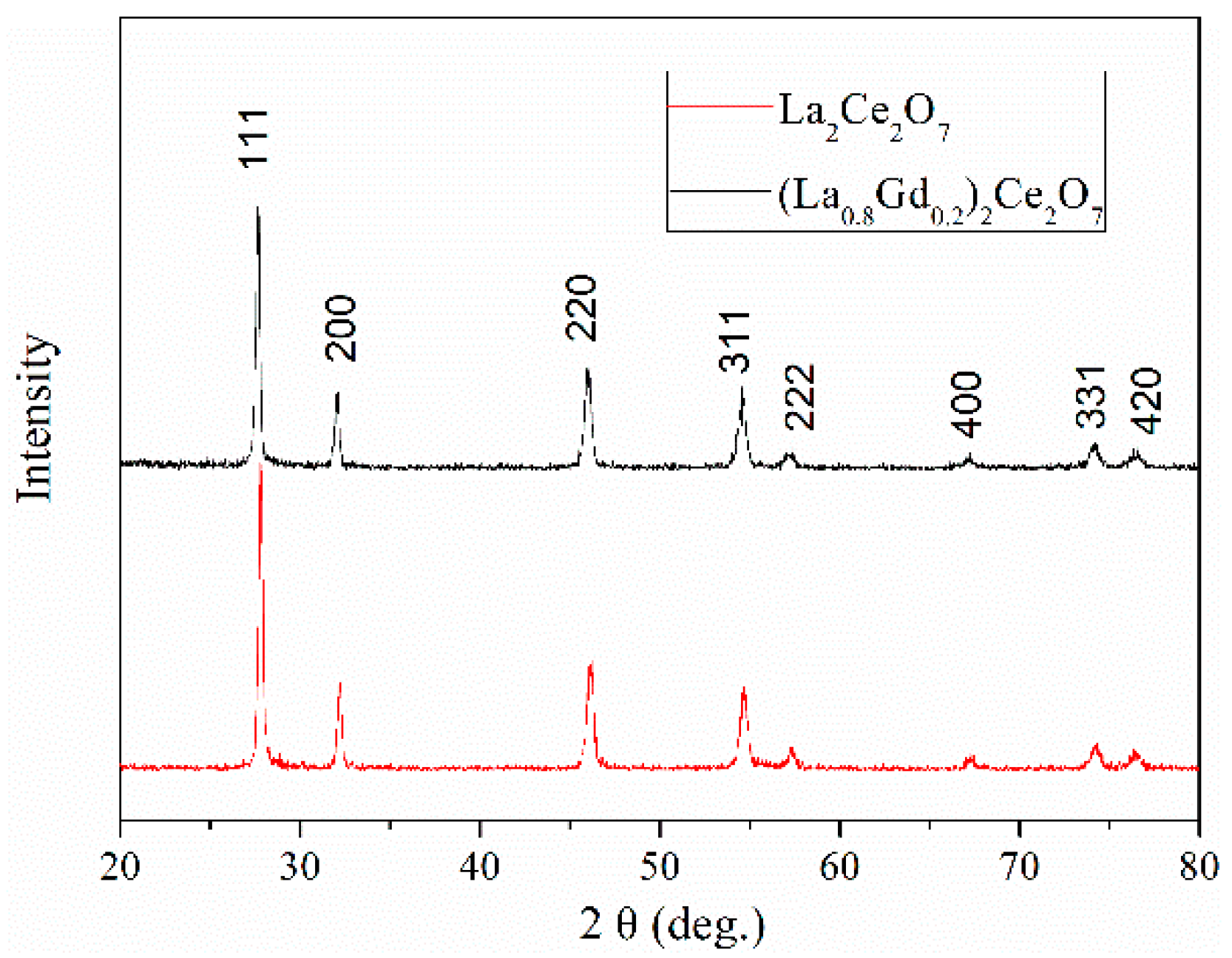

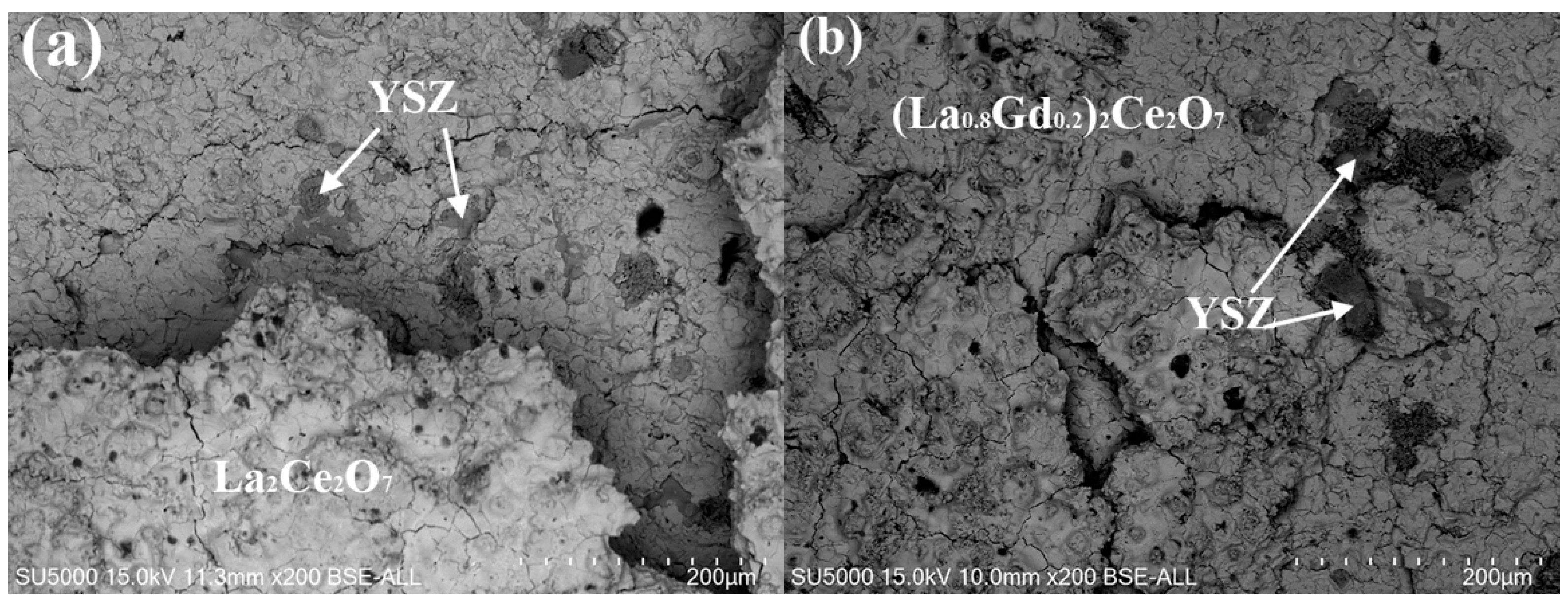

3.1. Preparation of the LGC Coating

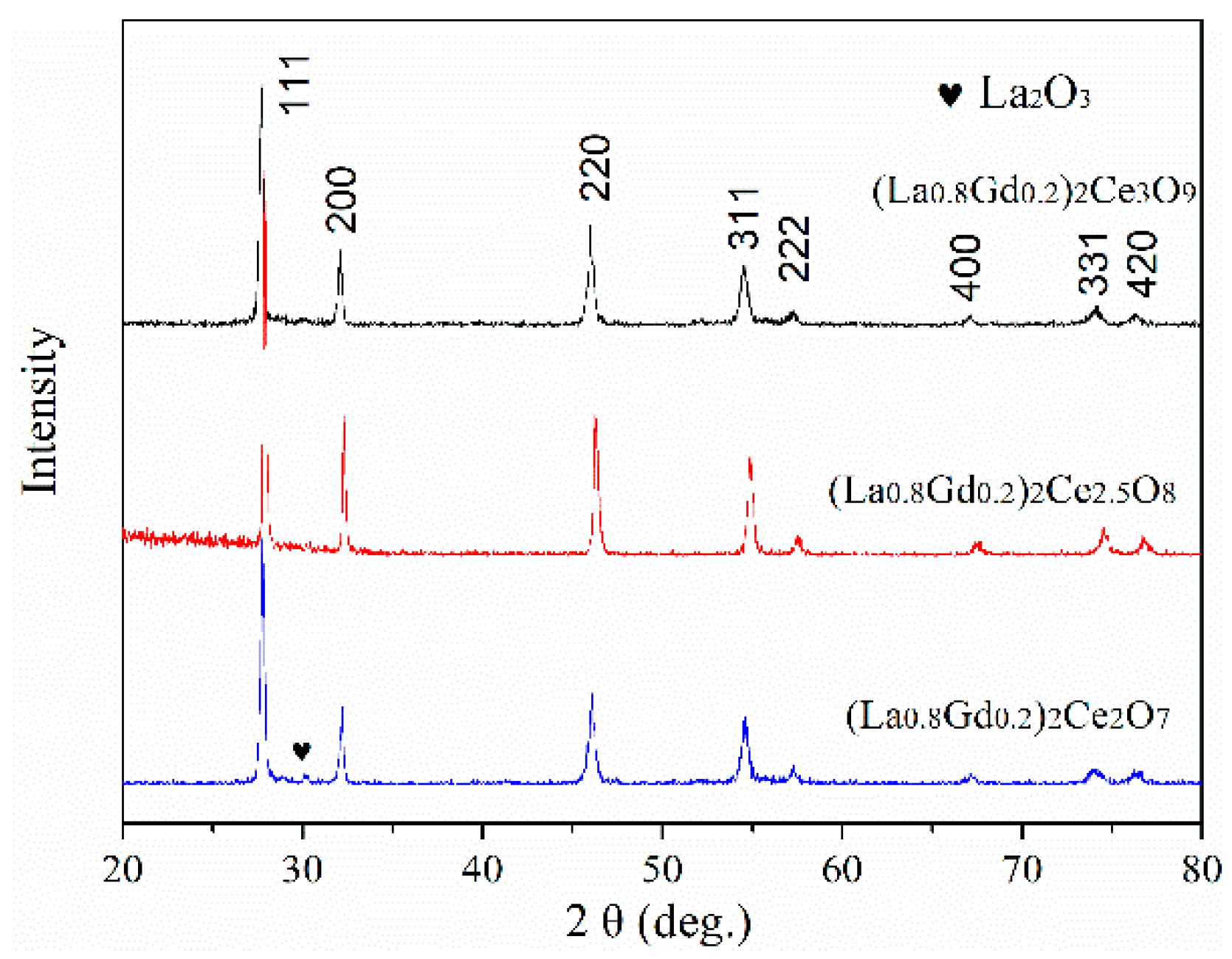

3.1.1. Effect of Spray Powder Composition

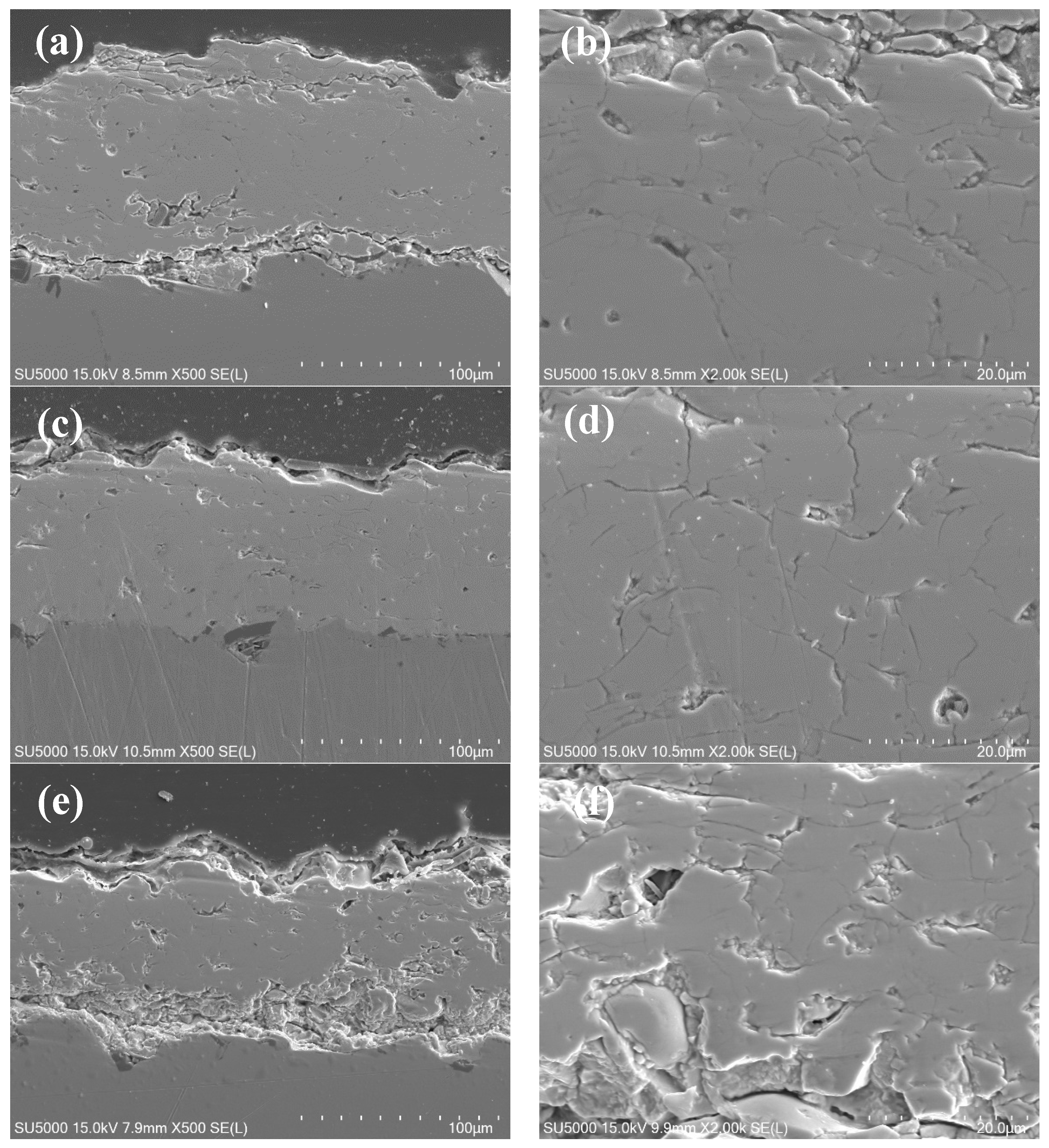

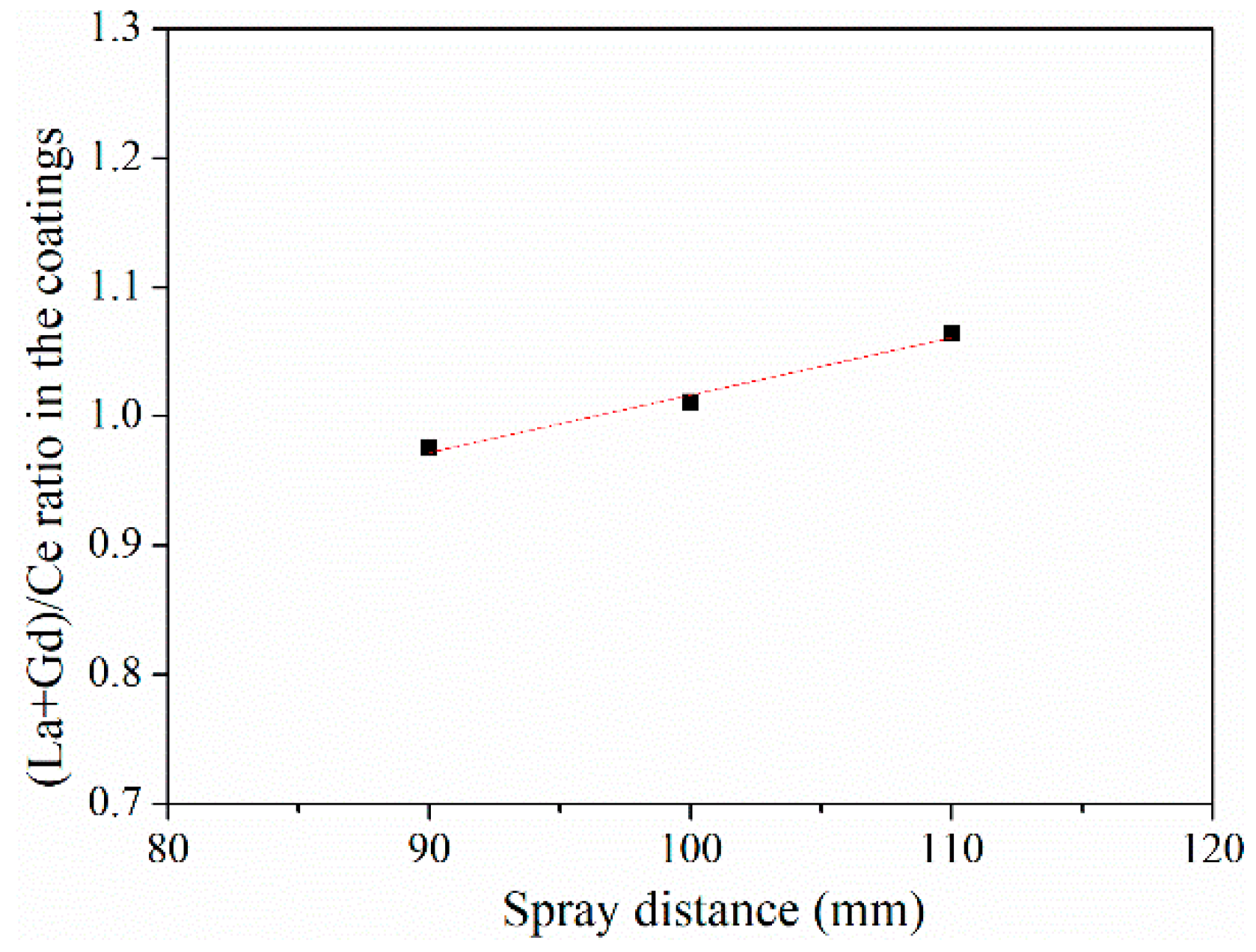

3.1.2. Effect of Spray Parameter

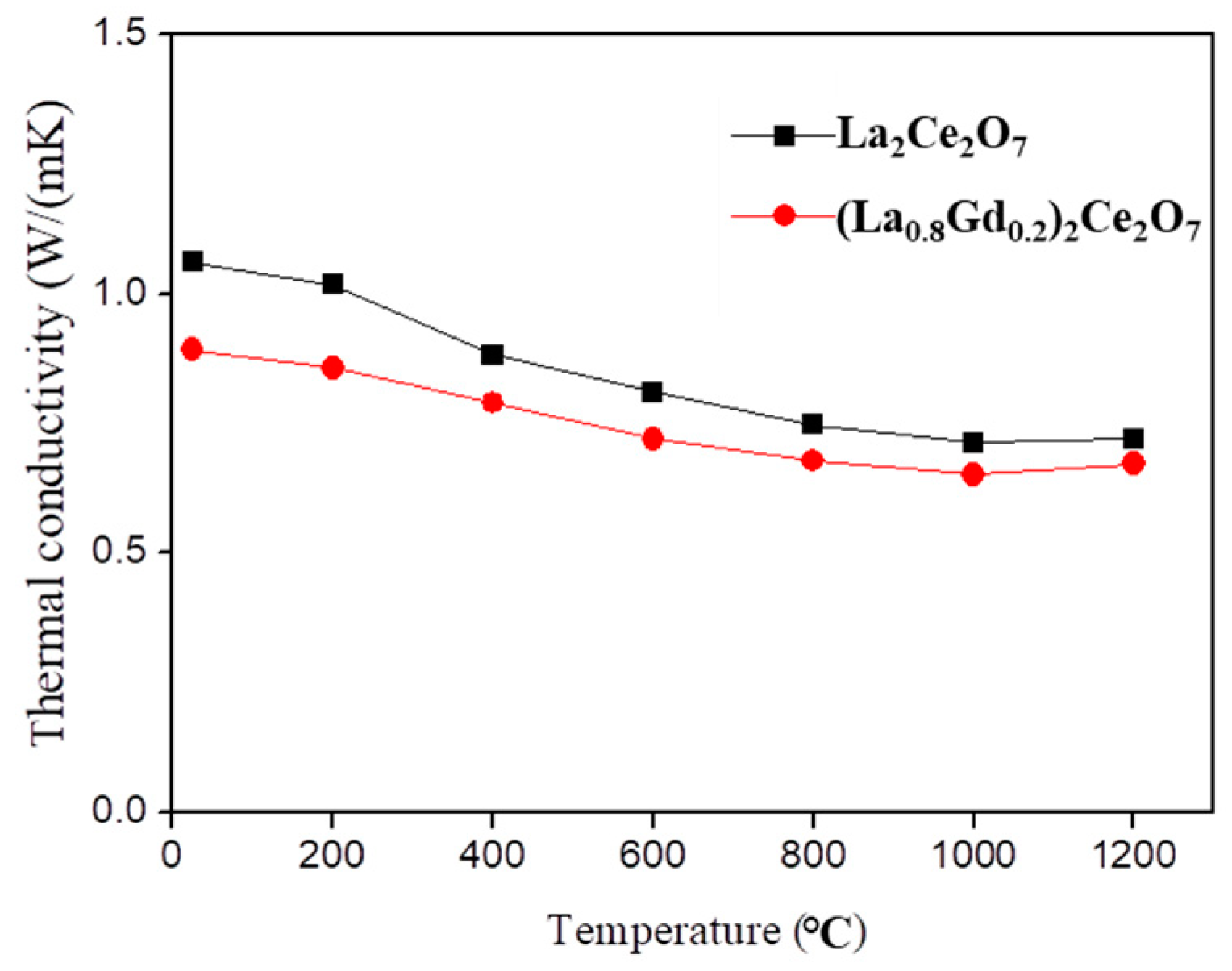

3.2. Thermal Conductivity

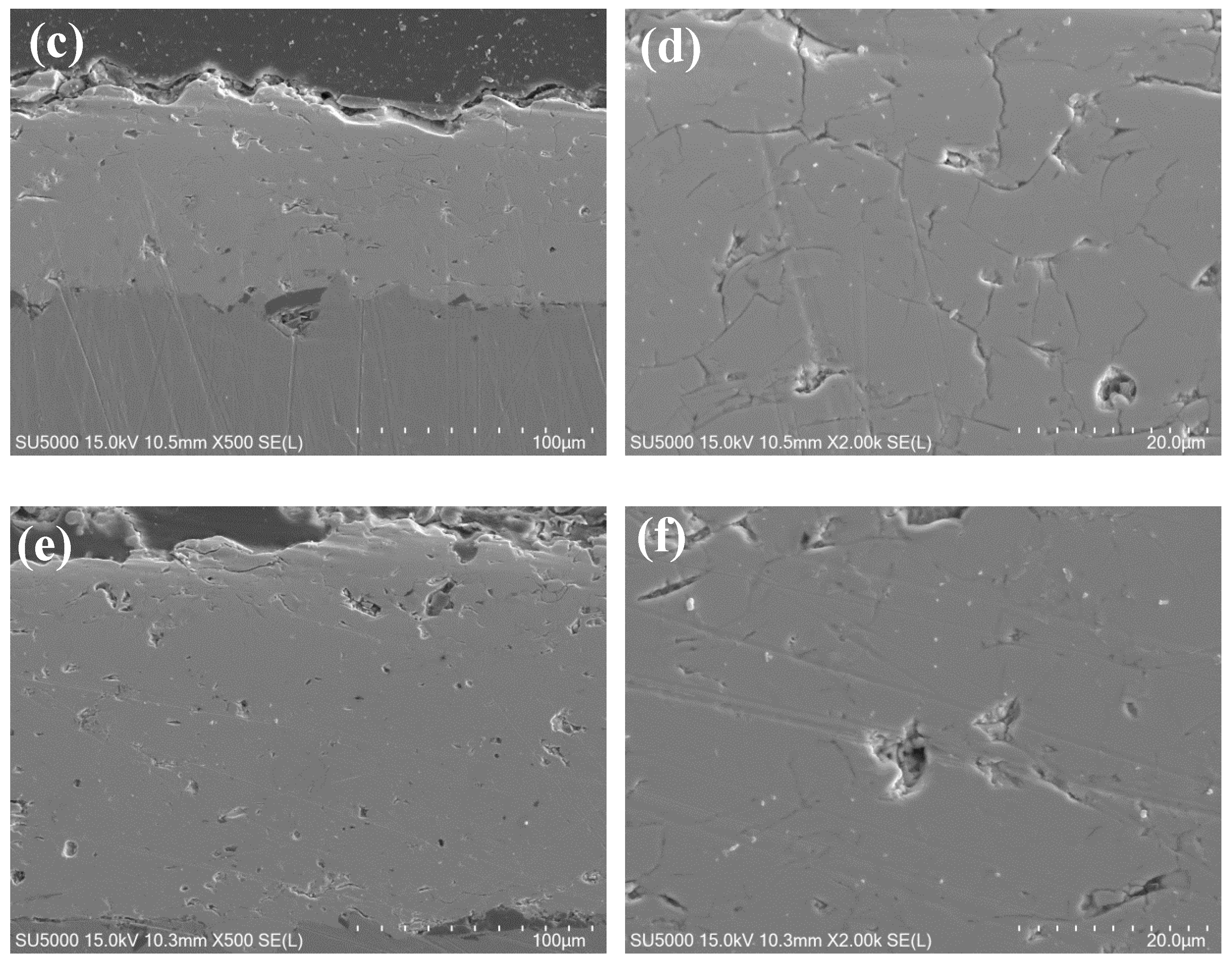

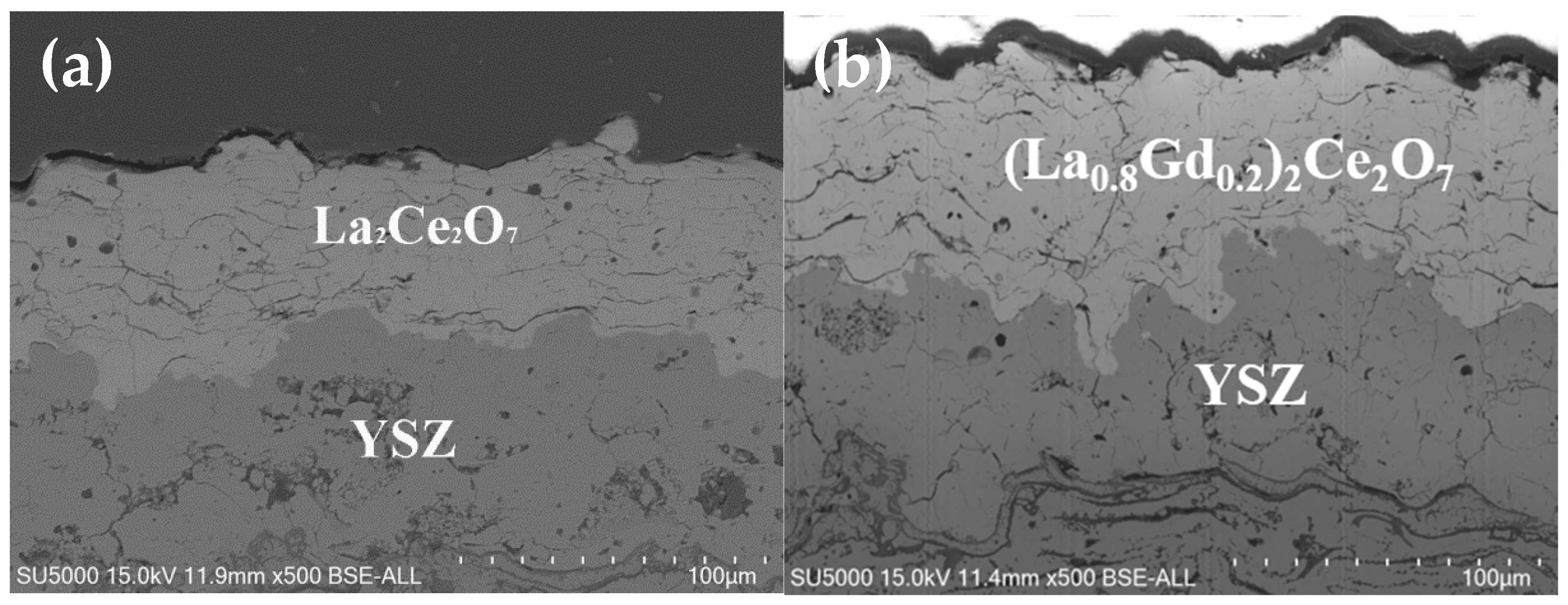

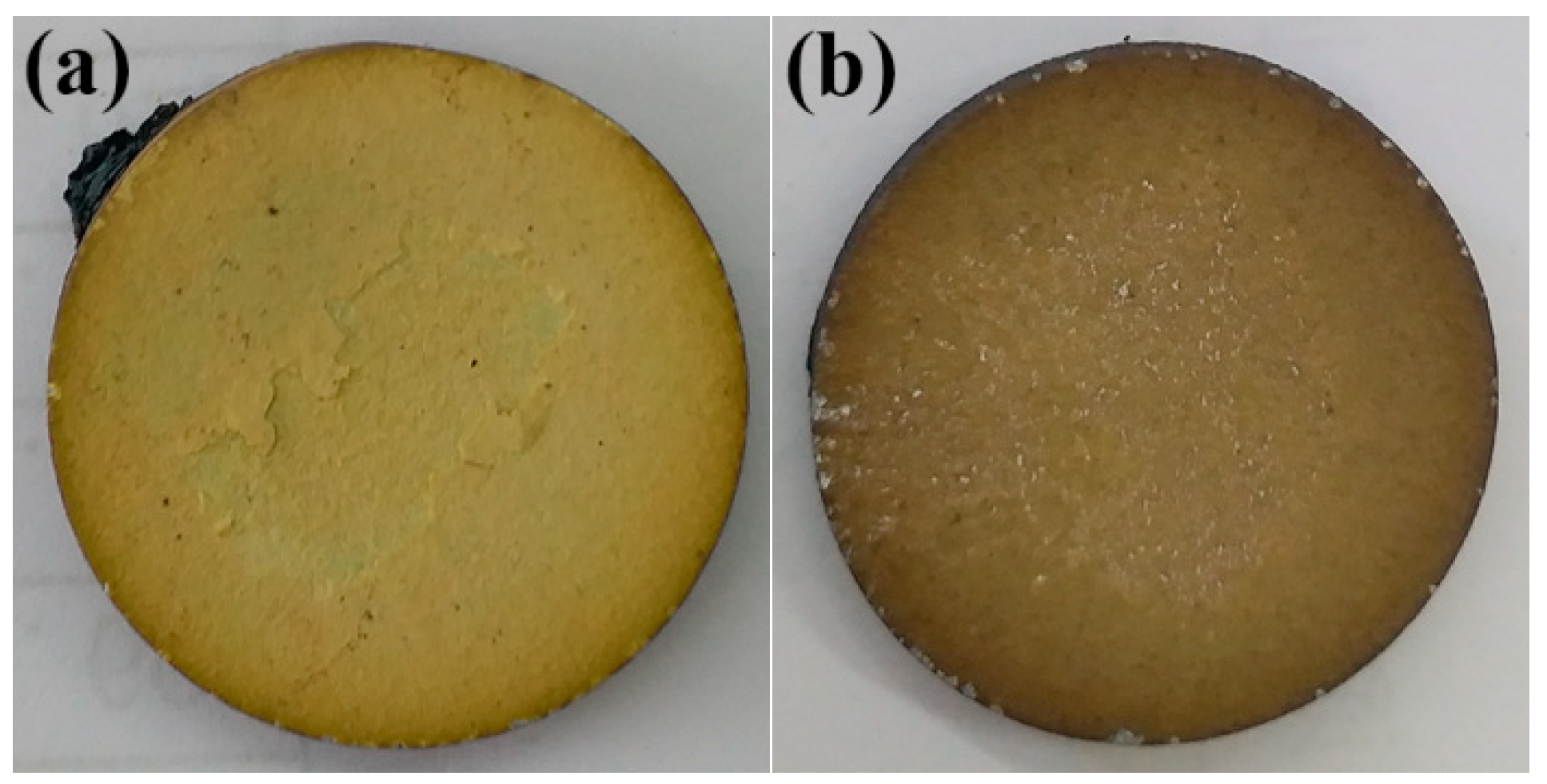

3.3. Thermal Shock Test of DCL TBCs

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Padture, N.P.; Gell, M.; Jordan, E.H. Thermal barrier coatings for gas-turbine engine applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef]

- Bennett, T.D.; Yu, F. A nondestructive technique for determining thermal properties of thermal barrier coatings. J. Appl. Phys. 2005, 97, 1–12. [Google Scholar] [CrossRef]

- Brindley, W.J.; Leonharat, T.A. Metallugraphic techniques for evaluation of thermal barrier coatings. Mater. Character. 1990, 24, 93–101. [Google Scholar] [CrossRef]

- Miller, R.A. Thermal barrier coatings for aircraft engines: History and directions. J. Therm. Spray Technol. 1997, 6, 35–42. [Google Scholar] [CrossRef] [Green Version]

- Niessen, K.V.; Gindrat, M.; Refke, A. Vapor phase deposition using plasma spray-PVD. J. Therm. Spray Technol. 2010, 19, 502–509. [Google Scholar] [CrossRef]

- Hospach, A.; Mauer, G.; Vaßen, R.; Stöver, D. Columnar-Structured thermal barrier coatings (TBCs) by thin film low-pressure plasma spraying (LPPS-TF). J. Therm. Spray Technol. 2011, 20, 116–120. [Google Scholar] [CrossRef]

- Gupta, M.; Li, X.H.; Markocsan, N.B.; Kjellman, B. Design of high lifetime suspension plasma sprayed thermal barrier coatings. J. Eur. Ceram. Soc. 2020, 3, 768–779. [Google Scholar] [CrossRef]

- Fan, W.; Bai, Y. Review of suspension and solution precursor plasma sprayed thermal barrier coatings. Ceram. Int. 2016, 42, 14299–14312. [Google Scholar] [CrossRef]

- Scliulz, U.; Terry, S.G.; Levi, C.G. Microstructure and texture of EB-PVD TBCs grown under different rotation modes. Mater. Sci. Eng. A 2003, 360, 319–329. [Google Scholar] [CrossRef]

- Kulkami, A.A.; Goland, A.; Herman, H.; Allen, A.J.; Ilavsky, J.; Long, G.G.; Johnson, C.A.; Ruud, J.A. Microstructure-property correlations in industrial thermal barrier coatings. J. Am. Ceram. Soc. 2004, 87, 1294–1300. [Google Scholar]

- Wright, P.K.; Evans, A.G. Mechanisms governing the performance of thermal barrier coatings. Mater. Sci. 1999, 4, 255–265. [Google Scholar] [CrossRef]

- Vassen, R.; Cao, X.Q.; Tietz, F.; Basu, D.; Stöver, D. Zirconates as new materials for thermal barrier coatings. J. Am. Ceram. Soc. 2000, 83, 2023–2028. [Google Scholar] [CrossRef]

- Basu, D.; Funke, C.; Steinbrech, R.W. Effect of heat treatment on elastic properties of separated thermal barrier coatings. J. Mater. Res. 1999, 14, 4643–4650. [Google Scholar] [CrossRef]

- Schulz, U. Phase transformation in EB-PVD yttria partially stabilized zirconia thermal barrier coatings during annealing. J. Am. Ceram. Soc. 2000, 83, 904–910. [Google Scholar] [CrossRef]

- Friedrich, C.; Gadow, R.; Schirmer, T. Lanthanum hexaaluminate-a new material for atmospheric plasma spraying of advanced thermal barrier coatings. J. Therm. Spray Technol. 2001, 10, 592–859. [Google Scholar] [CrossRef]

- Cao, X.Q.; Vassen, R.; Jungen, W.; Schwartz, S.; Tietz, F.; Stöver, D. Thermal stability of lanthanum zirconate plasma-sprayed coating. J. Am. Ceram. Soc. 2001, 84, 2086–2090. [Google Scholar] [CrossRef]

- Guo, L.; Guo, H.B.; Peng, H.; Gong, S. Thermophysical properties of Yb2O3 doped Gd2Zr2O7 and thermal cycling durability of (Gd0.9Yb0.1)2Zr2O7/YSZ thermal barrier coatings. J. Eur. Ceram. Soc. 2014, 34, 1255–1263. [Google Scholar] [CrossRef]

- Cao, X.Q.; Vassen, R.; Fischer, W.; Tietz, F.; Jungen, W.; Stöver, D. Lanthanum-cerium oxide as a thermal barrier-coating material for high-temperature applications. Adv. Mater. 2003, 15, 1438–1442. [Google Scholar] [CrossRef]

- Liu, Z.G.; Ouyang, J.H.; Zhou, Y. Effect of gadolinia on phase structure and thermal conductivity of ZrO2-4.5 mol%Y2O3 ceramics. Mater. Letter. 2008, 62, 3524–3526. [Google Scholar] [CrossRef]

- Guo, H.B.; Wang, Y.; Wang, L.; Gong, S.K. Thermo-physical properties and thermal shock resistance of segmented La2Ce2O7/YSZ thermal barrier coatings. J. Therm. Spray Technol. 2009, 18, 665–671. [Google Scholar] [CrossRef]

- Gao, L.H.; Guo, H.B.; Gong, S.K.; Xu, H.B. Plasma-sprayed La2Ce2O7 thermal barrier coatings against calcium-magnesium-alumina-silicate penetration. J. Eur. Ceram. Soc. 2014, 34, 2553–2561. [Google Scholar] [CrossRef]

- Ma, W.; Dong, H.Y.; Guo, H.B.; Gong, S.K.; Zheng, X.B. Thermal cycling behavior of La2Ce2O7/YSZ double-ceramic-layer thermal barrier coatings prepared by atmospheric plasma spraying. Surf. Coat. Technol. 2010, 204, 3366–3370. [Google Scholar] [CrossRef]

- Ma, W.; Gong, S.K.; Xu, H.B.; Cao, X.Q. On improving the phase stability and thermal expansion coefficients of lanthanum cerium oxide solid solutions. Scr. Mater. 2006, 54, 1505–1508. [Google Scholar] [CrossRef]

- Zhang, H.S.; Chen, X.G.; Li, G.; Wang, X.L.; Dang, X.D. Influence of Gd2O3 addition on thermophysical properties of La2Ce2O7 ceramics for thermal barrier coatings. J. Eur. Ceram. Soc. 2012, 32, 3693–3700. [Google Scholar]

- Zhang, H.S.; Wei, Y.; Li, G.; Chen, X.G.; Wang, X.L. Investigation about thermal conductivities of La2Ce2O7 doped with calcium or magnesium for thermal barrier coatings. J. Alloys Comp. 2012, 537, 141–146. [Google Scholar] [CrossRef]

- Gao, L.H.; Deng, X.; Peng, H.R.; Zhang, D.M. Preparation and thermal shock resistance of Gd2O3 doped La2Ce2O7 thermal barrier coatings. Therm. Spray Technol. 2020, 4, 22–28. [Google Scholar]

- Schulz, U.; Saruhan, B.; Fritscher, K.; Leyens, C. Review on advanced EB-PVD ceramic topcoats for TBC applications. Int. J. Appl. Ceram. Technol. 2004, 1, 302–315. [Google Scholar] [CrossRef]

- Wang, J.S.; Sun, J.B.; Zhang, H.; Dong, S.; Jiang, J.; Deng, L.; Zhou, X.; Cao, X. Effect of spraying power on microstructure and property of nanostructured YSZ thermal barrier coatings. J. Alloys Comp. 2018, 730, 471–482. [Google Scholar] [CrossRef]

- Leitner, J.D.; Chuchvalec, P.; Sedmidubsky, D. Estimation of heat capacity of solid mixed oxides. Thermochim. Acta 2003, 395, 27–46. [Google Scholar] [CrossRef]

- Beele, W.; Marijnissen, G.; Lieshout, A.V. The evolution of thermal barrier coatings status and upcoming solutions for today’s key issues. Surf. Coat. Technol. 1999, 120–121, 61–67. [Google Scholar] [CrossRef]

- Kuroda, S.; Clyne, T.W. The quenching stress in thermally sprayed coatings. Thin Solid Films 1991, 200, 49–66. [Google Scholar] [CrossRef]

- Schlichting, K.W.; Padture, N.P.; Klemens, P.G. Thermal conductivity of dense and porous yttria-stabilized zirconia. J. Mater. Sci. 2001, 36, 3003–3010. [Google Scholar] [CrossRef]

- Wu, J.; Wei, X.Z.; Padture, N.P.; Klemens, P.G.; Gell, M.; García, E.; Miranzo, P.; Osendi, M.I. Low-thermal-conductivity rare-earth zirconates for potential thermal-barrier-coating applications. J. Am. Ceram. Soc. 2002, 85, 3031–3035. [Google Scholar] [CrossRef]

- Hong, S.J.; Kim, S.J.; Han, W.K.; Kang, S.G. Thermal properties of La2O3–YSZ powder fabricated by heterogeneous precipitation. J. Alloys Comp. 2009, 486, 543–548. [Google Scholar] [CrossRef]

- Nicholls, J.R.; Lawson, K.J.; Johnstone, A.; Rickerby, D.S. Methods to reduce the thermal conductivity of EB-PVD TBCs. Surf. Coat. Technol. 2002, 151–152, 383–391. [Google Scholar] [CrossRef] [Green Version]

- Xu, Y.-X.; Liu, T.; Yang, G.-J.; Li, C.-J. Thermal stability of plasma-sprayed La2Ce2O7/YSZ composite coating. Ceram. Int. 2016, 42, 7950–7961. [Google Scholar] [CrossRef]

- Dong, H.; Wang, D.; Pei, Y.; Li, H.; Li, P.; Ma, W. Optimization and thermal cycling behavior of La2Ce2O7 thermal barrier coatings. Ceram. Int. 2013, 39, 1863–1870. [Google Scholar] [CrossRef]

- Nissley, D.M. Thermal barrier coating life modeling in aircraft gas turbine engines. J. Therm. Spray Technol. 1997, 6, 91–98. [Google Scholar] [CrossRef] [Green Version]

- Ganvir, A.; Joshi, S.; Markocsan, N.; Vassen, R. Tailoring columnar microstructure of axial suspension plasma sprayed TBCs for superior thermal shock performance. Mater. Des. 2018, 144, 192–208. [Google Scholar] [CrossRef]

| Plasma Gas (L/min) | Current (A) | Power (kW) | Spray Distance (mm) | Preheating Temperature (°C) |

|---|---|---|---|---|

| Ar 38 H2 14 | 600 | 42 | 100 | 200~250 °C |

| 650 | 46 | 100 | ||

| 550 | 38 | 100 | ||

| 600 | 42 | 90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, L.; Jia, F.; Lu, X. Preparation and Thermal Shock Resistance of Gd2O3 Doped La2Ce2O7 Thermal Barrier Coatings. Coatings 2021, 11, 1186. https://doi.org/10.3390/coatings11101186

Gao L, Jia F, Lu X. Preparation and Thermal Shock Resistance of Gd2O3 Doped La2Ce2O7 Thermal Barrier Coatings. Coatings. 2021; 11(10):1186. https://doi.org/10.3390/coatings11101186

Chicago/Turabian StyleGao, Lihua, Fang Jia, and Xiaoliang Lu. 2021. "Preparation and Thermal Shock Resistance of Gd2O3 Doped La2Ce2O7 Thermal Barrier Coatings" Coatings 11, no. 10: 1186. https://doi.org/10.3390/coatings11101186