Bonding and Thermal-Mechanical Property of Gradient NiCoCrAlY/YSZ Thermal Barrier Coatings with Millimeter Level Thickness

Abstract

1. Introduction

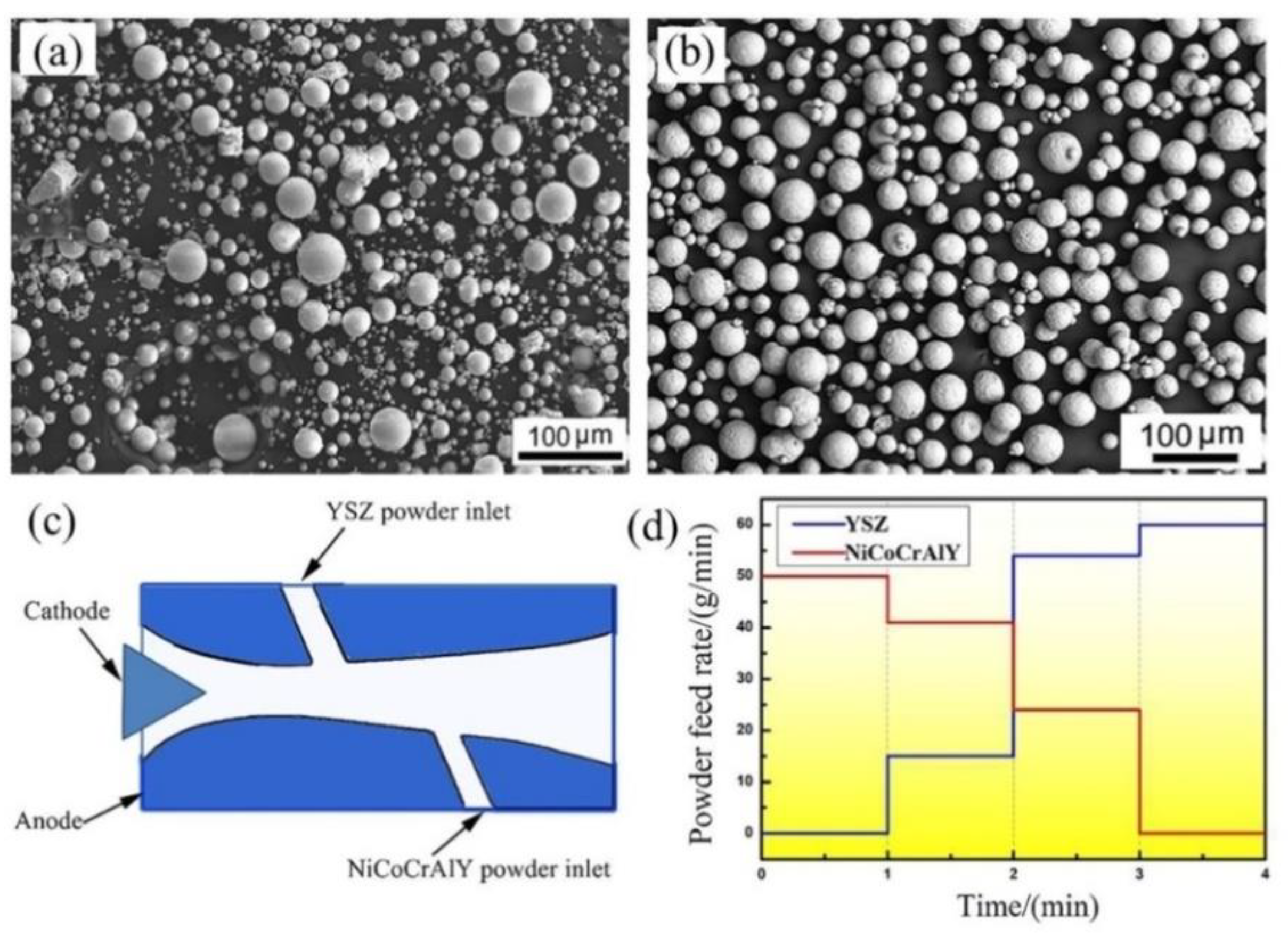

2. Experimental Procedure

3. Results and Discussion

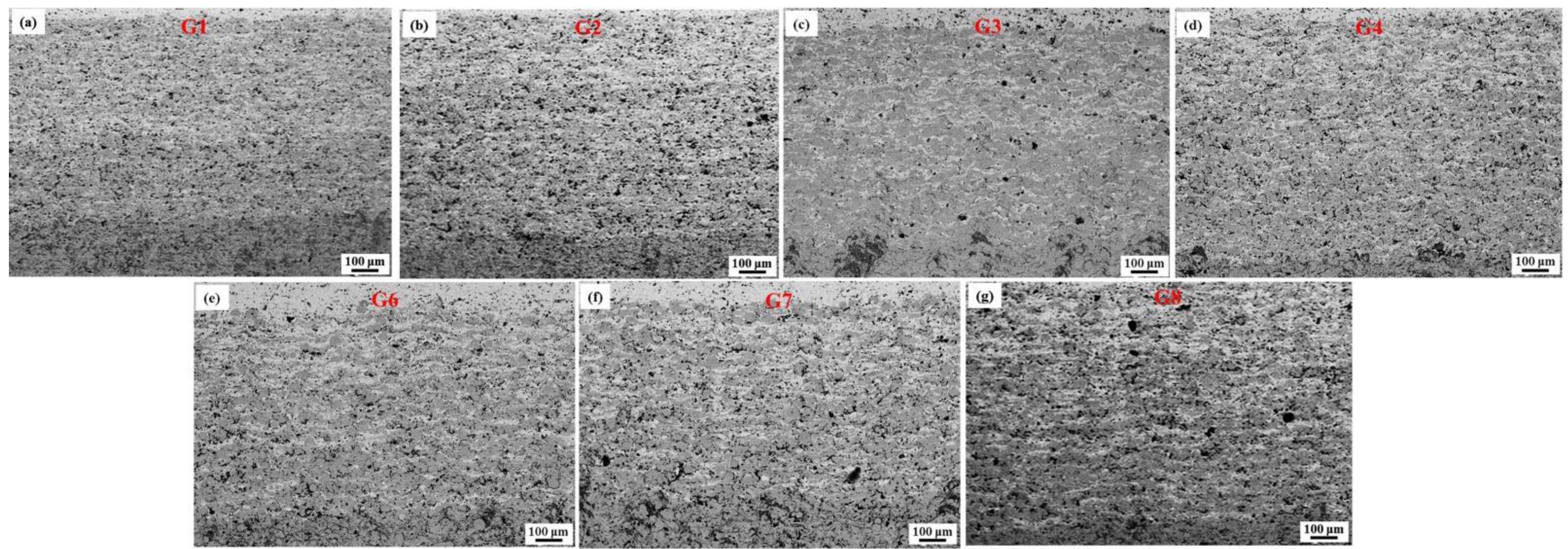

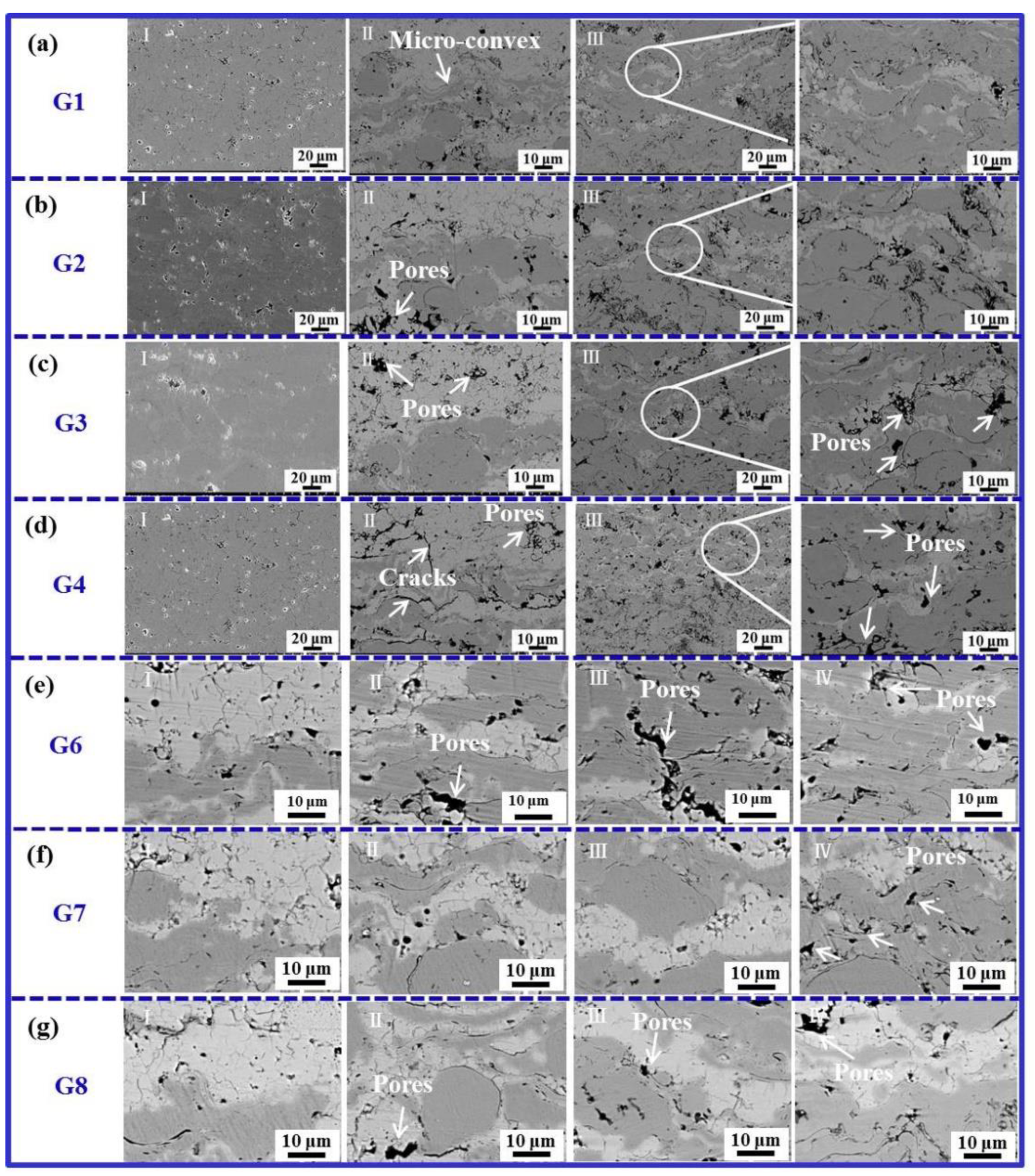

3.1. Microstructure of As-Sprayed Gradient Coatings

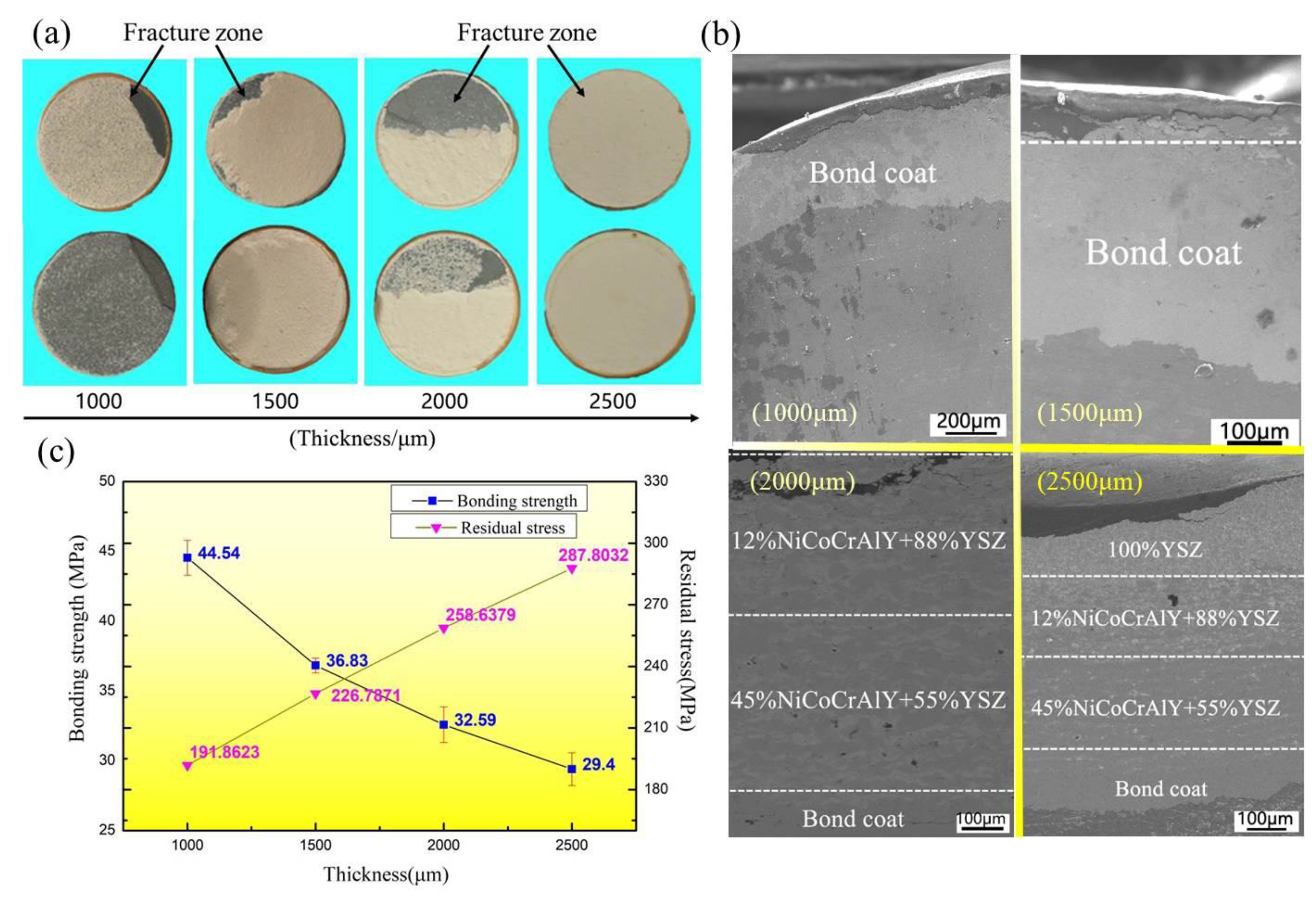

3.2. Bonding Strength

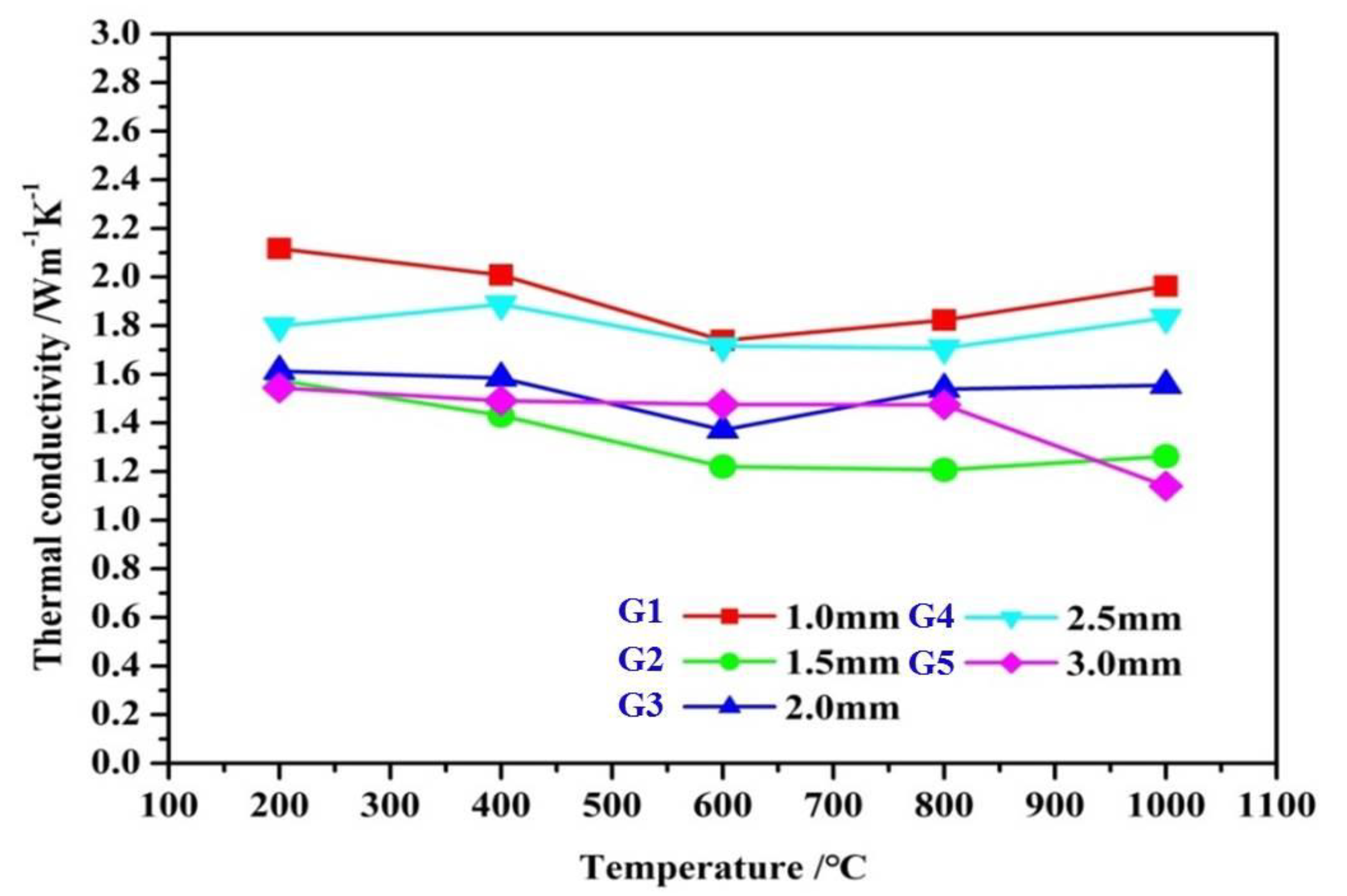

3.3. Thermal Conductivity

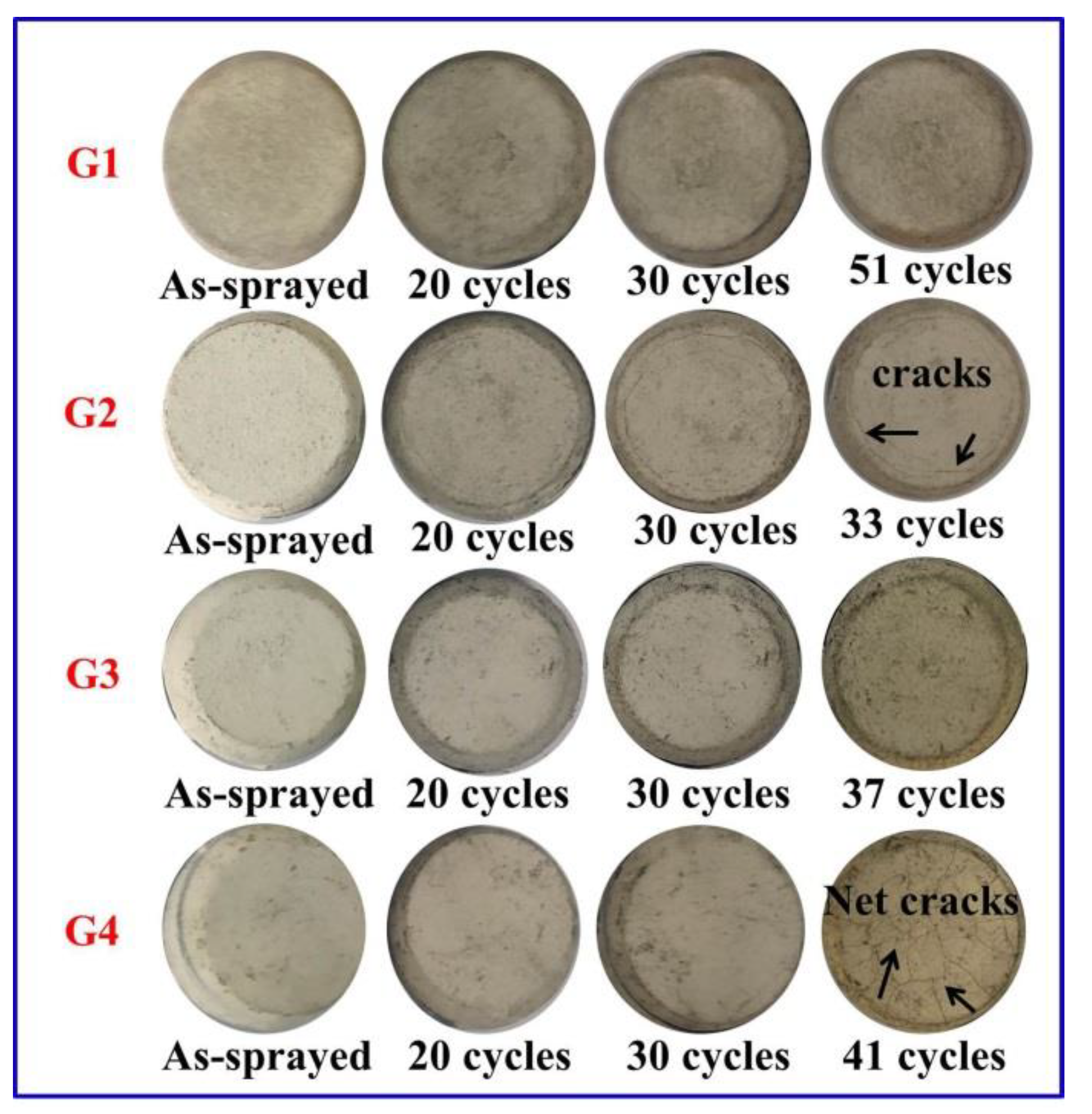

3.4. Thermal Cycling Property and Microstructural Evolution

4. Conclusions

- (1)

- The 1000-μm-thickness gradient NiCoCrAlY/YSZ TBCs coatings with some micro-convexity showed a higher bonding strength and thermal cycling performance compared to common TBCs.

- (2)

- The residual stress of the coating increased with the increase of coating thickness, which was accompanied by a decrease of bonding strength. The bond strength and residual stress of gradient coatings thus had a negative correlation.

- (3)

- The residual stress at the different layers led to different fracture positions, which gradually shifted from the NiCoCrAlY bond coat to NiCoCrAlY/YSZ the transition zone and finally to the YSZ top coat when the coating thickness increased from 1000 to 3000 μm.

- (4)

- Some coarse cracks initiated and propagated at the bottom region of TBCs, which were originated by thermal expansion mismatch stress and caused the failure of the gradient coating between the “BC” layer and substrate.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schulz, U.; Leyens, C.; Fritscher, K.; Peters, M.; Saruhan-Brings, B.; Lavigne, O.; Dorvaux, J.-M.; Poulain, M.; Mévrel, R.; Caliez, M. Some recent trends in research and technology of advanced thermal barrier coatings. Aerosp. Sci. Technol. 2003, 7, 73–80. [Google Scholar] [CrossRef]

- Karadge, M.; Zhao, X.; Preuss, M.; Xiao, P. Microtexture of the thermally grown alumina in commercial thermal barrier coatings. Scr. Mater. 2006, 54, 639–644. [Google Scholar] [CrossRef]

- Portinha, A.; Teixeira, V.; Carneiro, J.; Beghi, M.; Bottani, C.E.; Franco, N.; Vassen, R.; Stoever, D.; Sequeira, A. Residual stresses and elastic modulus of thermal barrier coatings graded in porosity. Surf. Coat. Technol. 2004, 188–189, 120–128. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.; Sun, X.G.; He, J.Q.; Pan, Z.Y.; Wang, C.H. Finite element simulation of residual stress of double-ceramic-layer La2Zr2O7/8YSZ thermal barrier coatings using birth and death element technique. Comput. Mater. Sci. 2012, 53, 117–127. [Google Scholar] [CrossRef]

- Bansal, P.; Shipway, P.H.; Leen, S.B. Effect of particle impact on residual stress development in HVOF sprayed coatings. J. Therm. Spray Technol. 2006, 15, 570–575. [Google Scholar] [CrossRef]

- Peng, Y.; Zhang, C.; Zhou, H.; Liu, L. On the bonding strength in thermally sprayed Fe-based amorphous coatings. Surf. Coat. Technol. 2013, 218, 17–22. [Google Scholar] [CrossRef]

- Guo, H.; Vaßen, R.; Stöver, D. Atmospheric plasma sprayed thick thermal barrier coatings with high segmentation crack density. Surf. Coat. Technol. 2004, 186, 353–363. [Google Scholar] [CrossRef]

- Guo, H.; Vaßen, R.; Stöver, D. Thermophysical properties and thermal cycling behavior of plasma sprayed thick thermal barrier coatings. Surf. Coat. Technol. 2005, 192, 48–56. [Google Scholar] [CrossRef]

- Karger, M.; Vaßen, R.; Stöver, D. Atmospheric plasma sprayed thermal barrier coatings with high segmentation crack densities: Spraying process, microstructure and thermal cycling behavior. Surf. Coat. Technol. 2011, 206, 16–23. [Google Scholar] [CrossRef]

- Tsipas, S.; Golosnoy, I. Effect of substrate temperature on the microstructure and properties of thick plasma-sprayed YSZ TBCs. J. Eur. Ceram. Soc. 2011, 31, 2923–2929. [Google Scholar] [CrossRef]

- Bilston, L.E.; Tan, K. Measurement of passive skeletal muscle mechanical properties in vivo: Recent progress, clinical applications, and remaining challenges. Ann. Biomed. Eng. 2015, 43, 261–273. [Google Scholar] [CrossRef] [PubMed]

- Ahmaniemi, S.; Vippola, M.; Vuoristo, P.; Mäntylä, T.; Cernuschi, F.; Lutterotti, L. Modified thick thermal barrier coatings: Microstructural characterization. J. Eur. Ceram. Soc. 2004, 24, 2247–2258. [Google Scholar] [CrossRef]

- Ahmaniemi, S.; Tuominen, J.; Vippola, M.; Vuoristo, P.; Cernuschi, F.; Gualco, C.; Bonadei, A.; Di Maggio, R. Characterization of modified thick thermal barrier coatings. J. Therm. Spray Technol. 2004, 13, 361–369. [Google Scholar] [CrossRef]

- Chen, H.; Liu, Y.; Gao, Y.; Tao, S.; Luo, H. Design, preparation, and characterization of graded YSZ/La2Zr2O7 thermal barrier coatings. J. Am. Ceram. Soc. 2010, 93, 1732–1740. [Google Scholar]

- Fang, X.; Zhang, G.; Feng, X. Performance of TBCs system due to the different thicknesses of top ceramic layer. Ceram. Int. 2015, 41, 2840–2846. [Google Scholar] [CrossRef]

- Jadhav, A.; Padture, N.P.; Wu, F.; Jordan, E.H.; Maurice, G. Thick ceramic thermal barrier coatings with high durability deposited using solu-tion-precursor plasma spray. Mater. Sci. Eng. A 2005, 405, 313–320. [Google Scholar] [CrossRef]

- Bai, Y.; Fan, W.; Liu, K.; Kang, Y.; Gao, Y.; Ma, F. Gradient La2Ce2O7/YSZ thermal barrier coatings tailored by synchronous dual powder feeding system. Mater. Lett. 2018, 219, 55–58. [Google Scholar] [CrossRef]

- Guo, L.; Li, M.; Ye, F. Phase stability and thermal conductivity of RE2O3 (RE = La, Nd, Gd, Yb) and Yb2O3 co-doped Y2O3 stabilized ZrO2 ceramics. Ceram. Int. 2016, 42, 7360–7365. [Google Scholar] [CrossRef]

- Berger-Keller, N.; Bertrand, G.; Filiatre, C.; Meunier, C.; Coddet, C. Microstructure of plasma-sprayed titania coatings deposited from spray-dried powder. Surf. Coat. Technol. 2003, 168, 281–290. [Google Scholar] [CrossRef]

- Tsai, Z.; Jau, P.; Kuo, N.; Kao, J.; Lin, K.; Chang, F.; Yang, E.; Wang, H. A high-range-accuracy and high-sensitivity harmonic radar using pulse pseu-dorandom code for bee searching. IEEE Trans. Microw. Theory Tech. 2013, 61, 66–675. [Google Scholar] [CrossRef]

- Yao, S.-W.; Li, C.-J.; Tian, J.-J.; Yang, G.-J.; Li, C.-X. Conditions and mechanisms for the bonding of a molten ceramic droplet to a substrate after high-speed impact. Acta Mater. 2016, 119, 9–25. [Google Scholar] [CrossRef]

- Schmitt, M.P.; Rai, A.K.; Bhattacharya, R.; Zhu, D.; Wolfe, D.E. Multilayer thermal barrier coating (TBC) architectures utilizing rare earth doped YSZ and rare earth pyrochlores. Surf. Coat. Technol. 2014, 251, 56–63. [Google Scholar] [CrossRef]

- Stokes, J.; Looney, L. Residual stress in HVOF thermally sprayed thick deposits. Surf. Coat. Technol. 2004, 177-178, 18–23. [Google Scholar] [CrossRef]

- Wang, J.; Sun, J.; Zhang, H.; Dong, S.; Jiang, J.; Deng, L.; Zhou, X.; Cao, X. Effect of spraying power on microstructure and property of nanostructured YSZ thermal barrier coatings. J. Alloys Compd. 2018, 730, 471–482. [Google Scholar] [CrossRef]

- Schlichting, K.; Vaidyanathan, K.V.; Sohn, Y.; Jordan, E.H.; Gell, M.; Padture, N.P. Application of Cr3+ photoluminescence piezo-spectroscopy to plasma-sprayed thermal barrier coatings for residual stress measurement. Mater. Sci. Eng. A 2000, 291, 68–77. [Google Scholar] [CrossRef]

- Dokur, M.M.; Goller, G. Processing and characterization of CYSZ/Al2O3 and CYSZ/Al2O3 + YSZ multilayered thermal barrier coatings. Surf. Coat. Technol. 2014, 258, 804–813. [Google Scholar] [CrossRef]

- Khor, K.A.; Gu, Y.W.; Dong, Z.L. Plasma spraying of functionally graded yttria stabilized zirconia/NiCoCrAlY coating system using composite powders. J. Therm. Spray Technol. 2000, 9, 245–249. [Google Scholar] [CrossRef]

- Ghasemi, R.; Vakilifard, H. Plasma-sprayed nanostructured YSZ thermal barrier coatings: Thermal insulation capability and adhesion strength. Ceram. Int. 2017, 43, 8556–8856. [Google Scholar] [CrossRef]

- Rauf, A.; Yu, Q.; Jin, L.; Zhou, C. Microstructure and thermal properties of nanostructured lanthana-doped yt-tria-stabilized zirconia thermal barrier coatings by air plasma spraying. Scr. Mater. 2012, 66, 109–112. [Google Scholar] [CrossRef]

- Clarke, D.R. Materials selection guidelines for low thermal conductivity thermal barrier coatings. Surf. Coat. Technol. 2003, 163-164, 67–74. [Google Scholar] [CrossRef]

- Evans, A.; Hutchinson, J. The mechanics of coating delamination in thermal gradients. Surf. Coat. Technol. 2007, 201, 7905–7916. [Google Scholar] [CrossRef]

- Wang, Y.; Bai, Y.; Yuan, T.; Chen, H.; Kang, Y.; Shi, W.; Song, X.; Li, B. Failure analysis of fine-lamellar structured YSZ based thermal barrier coatings with submicro/nano-grains. Surf. Coat. Technol. 2017, 319, 95–103. [Google Scholar] [CrossRef]

- Cortese, B.; Caschera, D.; De Caro, T.; Ingo, G.M. Micro-chemical and -morphological features of heat treated plasma sprayed zirconia-based thermal barrier coatings. Thin Solid Films 2013, 549, 321–329. [Google Scholar] [CrossRef]

- Paul, S.; Cipitria, A.; Tsipas, S.A.; Clyne, T. Sintering characteristics of plasma sprayed zirconia coatings containing different stabilisers. Surf. Coat. Technol. 2009, 203, 1069–1074. [Google Scholar] [CrossRef]

- Lv, B.; Fan, X.; Xie, H.; Wang, T. Effect of neck formation on the sintering of air-plasma-sprayed thermal barrier coating system. J. Eur. Ceram. Soc. 2017, 37, 811–821. [Google Scholar] [CrossRef]

- Wang, Y.; Bai, Y.; Liu, K.; Wang, J.; Kang, Y.; Li, J.; Chen, H.; Li, B. Microstructural evolution of plasma sprayed submicron-/nano-zirconia-based thermal barrier coatings. Appl. Surf. Sci. 2016, 363, 101–112. [Google Scholar] [CrossRef]

- Loghman-Estarki, M.; Razavi, R.S.; Jamali, H. Thermal stability and sintering behavior of plasma sprayed nanostructured 7YSZ, 15YSZ and 5.5SYSZ coatings at elevated temperatures. Ceram. Int. 2016, 42, 14374–14383. [Google Scholar] [CrossRef]

- Collin, M.; Rowcliffe, D. The morphology of thermal cracks in brittle materials. J. Eur. Ceram. Soc. 2002, 22, 435–445. [Google Scholar] [CrossRef]

- Huang, W.; Zhao, Y.; Fan, X.; Meng, X.; Wang, Y.; Cai, X.; Cao, X.; Wang, Z. Effect of bond coats on thermal shock resistance of thermal barrier coatings deposited onto polymer matrix composites via air plasma spray process. J. Therm. Spray Technol. 2013, 22, 918–925. [Google Scholar] [CrossRef]

| Sample | Thickness/mm | Bond Layer NiCoCrAlY/mm | Gradient Layer (NiCoCrAlY:YSZ)/mm | Top Layer YSZ (mm) |

|---|---|---|---|---|

| G1 | 1.0 | 0.2 | Layer 1-0.2 (4:6) + Layer 2-0.3 (2:8) | 0.3 |

| G2 | 1.5 | 0.3 | Layer 1-0.3 (4:6) + Layer 2-0.4 (2:8) | 0.5 |

| G3 | 2.0 | 0.2 | Layer 1-0.6 (4:6) + Layer 2-0.4 (2:8) | 0.9 |

| G4 | 2.5 | 0.4 | Layer 1-0.5 (4:6) + Layer 2-0.5 (2:8) | 1.1 |

| G5 | 3.0 | 0.2 | Layer 1-0.8 (4:6) + Layer 2-0.8 (2:8) | 1.2 |

| G6 | 1.5 | 0.3 | Layer 1-0.3 (6:4) + Layer 2-0.3 (4:6) | 0.6 |

| G7 | 2.0 | 0.4 | Layer 1-0.4 (6:4) + Layer 2-0.4 (4:6) | 0.8 |

| G8 | 2.5 | 0.5 | Layer 1-0.6 (6:4) + Layer 2-0.6 (4:6) | 0.8 |

| Samples | Thickness (mm) | Bonding Strength (MPa) | Fraction Location | Average Bonding Strength (MPa) |

|---|---|---|---|---|

| G1-1 | 1 | 44.43 | 100% BC | 44.54 |

| G1-2 | 43.35 | BC/GC | ||

| G1-3 | 45.84 | BC/GC | ||

| G2-1 | 1.5 | 37.19 | GC,BC/GC | 36.83 |

| G2-2 | 35.21 | GC,BC/GC | ||

| G2-3 | 38.09 | BC/GC | ||

| G3-1 | 2 | 31.68 | GC/TC | 32.59 |

| G3-2 | 23.97 | GC/TC | ||

| G3-3 | 24.10 | GC/TC | ||

| G4-1 | 2.5 | 28.37 | 100% TC | 29.40 |

| G4-2 | 30.68 | 100% TC | ||

| G4-3 | 29.16 | 100% TC | ||

| G5-1 | 3 | 20.18 | 100% TC | 21.10 |

| G5-2 | 22.20 | 100% TC | ||

| G5-3 | 20.92 | 100% TC | ||

| G6-1 | 1.5 | 27.42 | 100% BC | 24.62 |

| G6-2 | 21.98 | BC/GC | ||

| G6-3 | 24.45 | BC/GC | ||

| G7-1 | 2 | 24.36 | 100% BC | 23.50 |

| G7-2 | 23.21 | GC/TC | ||

| G7-3 | 22.95 | GC/TC | ||

| G8-1 | 2.5 | 17.17 | GC/TC | 21.44 |

| G8-2 | 26.77 | 100% TC | ||

| G8-3 | 20.39 | 100% TC |

| Study | Composition | Spraying Method | Bonding Strength/MPa |

|---|---|---|---|

| X. Fang [15] | NiCrCoAlY (50 μm)–YSZ (400 μm) | SPS | 10.83 |

| M.M. Dokur [26] | NiCoCrAlY (100 ± 10 μm)–CYSZ/Al2O3 (12 layers)–YSZ (400 ± 20 μm) | HVOF + APS | 11.5 ± 1.7 |

| K.A. Khor [27] | NiCoCrAlY(150 μm)–75%NiCoCrAlY + 25% YSZ(200 μm)–50% NiCoCrAlY + 50% YSZ(200 μm)–YSZ(200 μm) | APS | 23 ± 2 |

| R.Ghasemi [28] | NiCrAlY (250 μm)–conventional YSZ (250 μm) | APS | 25.25 |

| R.Ghasemi [28] | NiCrAlY (250 μm)-nanostructure YSZ (250 μm) | APS | 38.21 |

| This study | NiCoCrAlY (220 μm)–45% NiCoCrAlY + 55%YSZ (200 μm)–12% NiCoCrAlY + 88%YSZ (250 μm)–YSZ(330 μm) | SAPS | 44.54 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Liu, Q.; Zheng, Q.; Li, T.; Chong, N.; Bai, Y. Bonding and Thermal-Mechanical Property of Gradient NiCoCrAlY/YSZ Thermal Barrier Coatings with Millimeter Level Thickness. Coatings 2021, 11, 600. https://doi.org/10.3390/coatings11050600

Wang Y, Liu Q, Zheng Q, Li T, Chong N, Bai Y. Bonding and Thermal-Mechanical Property of Gradient NiCoCrAlY/YSZ Thermal Barrier Coatings with Millimeter Level Thickness. Coatings. 2021; 11(5):600. https://doi.org/10.3390/coatings11050600

Chicago/Turabian StyleWang, Yu, Qi Liu, Quansheng Zheng, Tianqing Li, Nanjing Chong, and Yu Bai. 2021. "Bonding and Thermal-Mechanical Property of Gradient NiCoCrAlY/YSZ Thermal Barrier Coatings with Millimeter Level Thickness" Coatings 11, no. 5: 600. https://doi.org/10.3390/coatings11050600

APA StyleWang, Y., Liu, Q., Zheng, Q., Li, T., Chong, N., & Bai, Y. (2021). Bonding and Thermal-Mechanical Property of Gradient NiCoCrAlY/YSZ Thermal Barrier Coatings with Millimeter Level Thickness. Coatings, 11(5), 600. https://doi.org/10.3390/coatings11050600