Properties of Hafnium and Aluminium Silicates Coatings Obtained by PLD

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussions

3.1. Morphological Investigations

3.2. Compositional Investigations

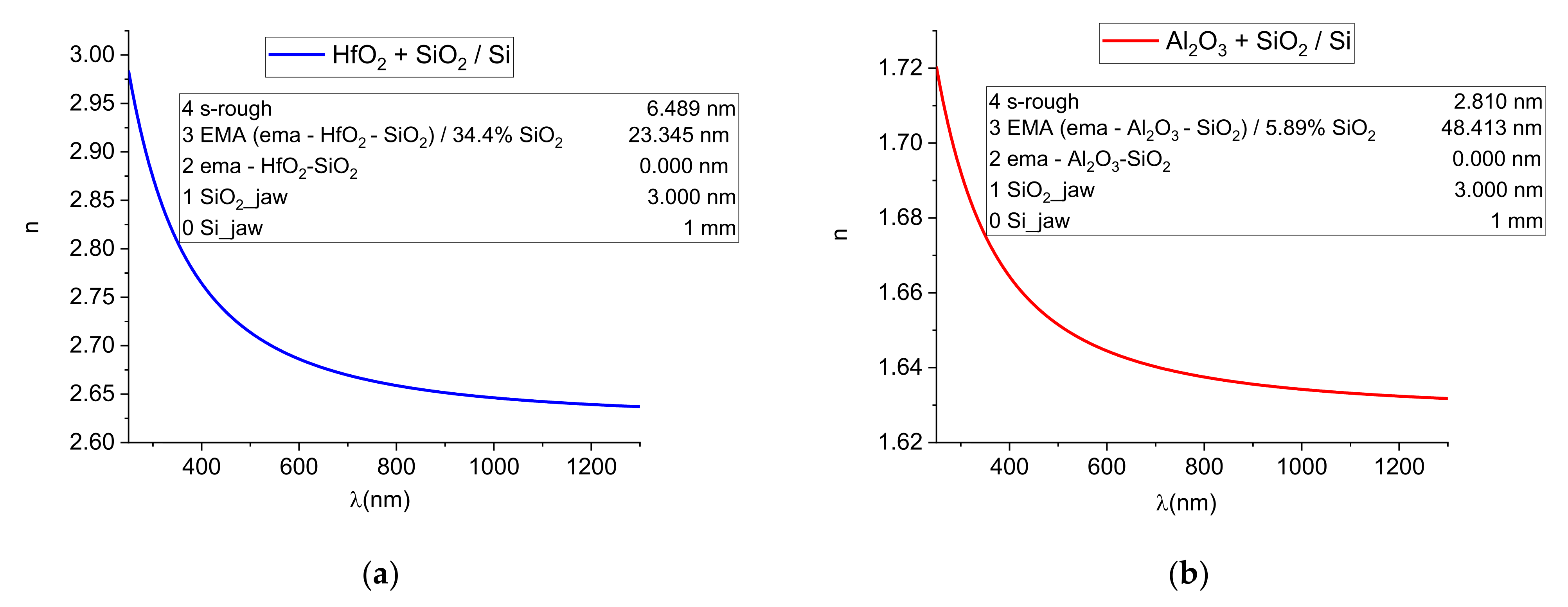

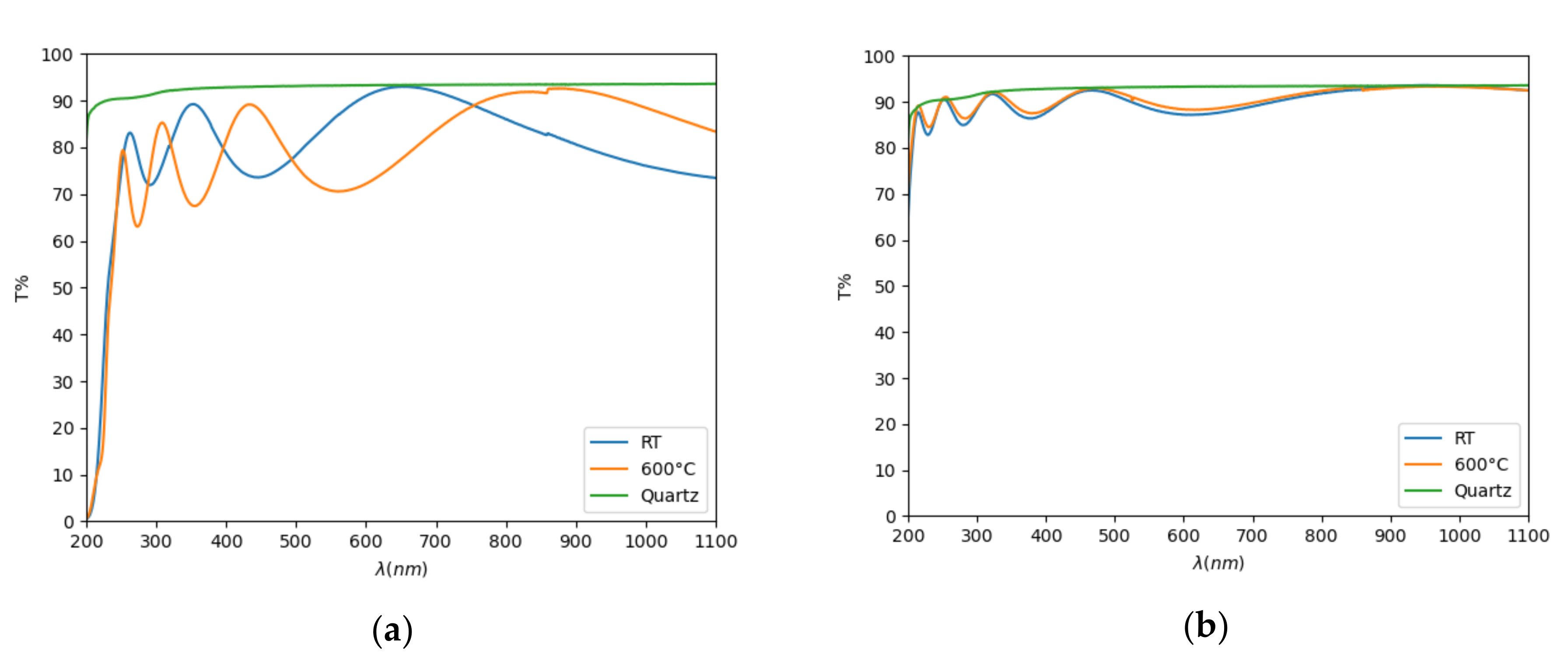

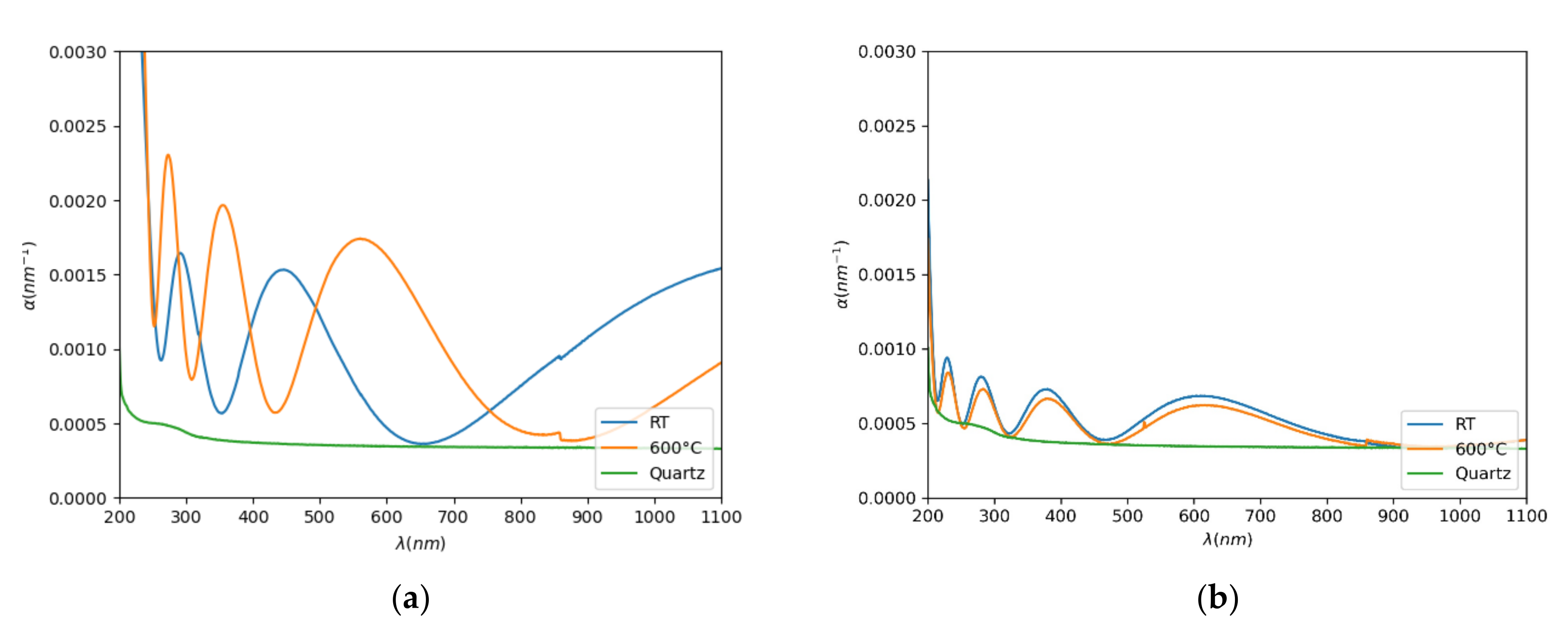

3.3. Investigations of Optical Properties

3.4. Laser Induced Damage Threshold Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yao, R.H.; Zheng, Z.K.; Xiong, M.; Zhang, X.C.; Li, X.Q.; Ning, H.L.; Fang, Z.Q.; Xie, W.G.; Lu, X.B.; Peng, J.B. Low-temperature fabrication of sputtered high-k HfO2 gate dielectric for flexible a-IGZO thin film transistors. Appl. Phys. Lett. 2018, 112, 103503. [Google Scholar] [CrossRef]

- Woo, C.H.; Ahn, C.H.; Kwon, Y.H.; Han, J.H.; Cho, H.K. Transparent and flexible oxide thin-film-transistors using an aluminum oxide gate insulator grown at low temperature by atomic layer deposition. Met. Mater. Int. 2012, 18, 1055–1060. [Google Scholar] [CrossRef]

- Bellucci, A.; Sabbatella, G.; Girolami, M.; Mastellone, M.; Serpente, V.; Mezzi, A.; Kaciulis, S.; Paci, B.; Generosi, A.; Polini, R.; et al. Dielectric Micro- and Sub-Micrometric Spacers for High-Temperature Energy Converters. Energy Technol. 2021, 9, 2000788. [Google Scholar] [CrossRef]

- Glunz, S.W.; Feldmann, F. SiO2 surface passivation layers–a key technology for silicon solar cells. Sol. Energy Mater. Sol. Cells 2018, 185, 260–269. [Google Scholar] [CrossRef]

- Rehman, M.A.; Akhtar, I.; Choi, W.; Akbar, K.; Farooq, A.; Hussain, S.; Shehzad, M.A.; Chun, S.H.; Jung, J.; Seo, Y. Influence of an Al2O3 interlayer in a directly grown graphene-silicon Schottky junction solar cell. Carbon 2018, 132, 157–164. [Google Scholar] [CrossRef]

- Wei, H.Y.; Shi, J.J.; Xu, X.; Xiao, J.Y.; Luo, J.H.; Dong, J.; Lv, S.T.; Zhu, L.F.; Wu, H.J.; Li, D.M.; et al. Enhanced charge collection with ultrathin AlOx electron blocking layer for hole-transporting material-free perovskite solar cell. Phys. Chem. Chem. Phys. 2015, 17, 4937–4944. [Google Scholar] [CrossRef]

- Raut, H.K.; Ganesh, V.A.; Nair, A.S.; Ramakrishna, S. Anti-reflective coatings: A critical, in-depth review. Energy Environ. Sci. 2011, 4, 3779–3804. [Google Scholar] [CrossRef]

- Zhu, M.P.; Xu, N.; Roshanzadeh, B.; Boyd, S.T.P.; Rudolph, W.; Chai, Y.J.; Shao, J.D. Nanolaminate-based design for UV laser mirror coatings. Light Sci. Appl. 2020, 9, 20. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Filipescu, M.; Palla-Papavlu, A.; Bercea, A.; Rusen, L.; Cernaianu, M.O.; Ion, V.; Dinescu, M. Antireflective coatings with high damage threshold prepared by laser ablation. Appl. Phys. A Mater. Sci. Process. 2019, 125, 815. [Google Scholar] [CrossRef]

- Stolz, C.J.; Thomas, M.D.; Griffin, A.J. BDS thin film damage competition. Laser-Induced Damage in Optical Materials. In Proceedings of the SPIE, Boulder, CO, USA, 2 September 2008; Volume 7132, pp. 71320C-1–71320C-7. [Google Scholar]

- Ďurák, M.; Velpula, P.K.; Kramer, D.; Cupal, J.; Medřík, T.; Hřebíček, J.; Golasowski, J.; Peceli, D.; Kozlová, M.; Rus, B. Laser-induced damage threshold tests of ultrafast multilayer dielectric coatings in various environmental conditions relevant for operation of ELI beamlines laser systems. Opt. Eng. 2016, 56, 011024. [Google Scholar] [CrossRef]

- Kambayashi, H.; Nomura, T.; Ueda, H.; Harada, K.; Morozumi, Y.; Hasebe, K.; Teramoto, A.; Sugawa, S.; Ohmi, T. High Quality SiO2/Al2O3 Gate Stack for GaN Metal–Oxide–Semiconductor Field-Effect Transistor. Jpn. J. Appl. Phys. 2013, 52, 04CF09. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Y.; Chen, X.; Li, C.Y.; Ding, X.W. Low-voltage-drive and high output current InGaZnO thin-film transistors with novel SiO2/HfO2/SiO2 structure. Mol. Cryst. Liq. Cryst. 2017, 651, 228–234. [Google Scholar] [CrossRef]

- Houssa, M.; Pantisano, L.; Ragnarsson, L.Å.; Degraeve, R.; Schram, T.; Pourtois, G.; De Gendt, S.; Groeseneken, G.; Heynsab, M.M. Electrical properties of high-κ gate dielectrics: Challenges, current issues, and possible solutions. Mater. Sci. Eng. R Rep. 2006, 51, 37–85. [Google Scholar] [CrossRef]

- Lee, S.; Yun, D.J.; Rhee, S.W.; Yong, K. Atomic layer deposition of hafnium silicate film for high mobility pentacene thin film transistor applications. J. Mater. Chem. 2009, 19, 6857–6864. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.; Kim, J.H.; Kwon, D.W.; Park, E.; Park, T.; Kim, H.W.; Park, B.G. Electrical Characteristics of Metal-Oxide-Semiconductor Capacitor with High-κ/Metal Gate Using Oxygen Scavenging Process. J. Nanosci. Nanotechnol. 2016, 16, 4897–4900. [Google Scholar] [CrossRef] [PubMed]

- Abadias, G.; Chason, E.; Keckes, J.; Sebastiani, M.; Thompson, G.B.; Barthel, E.; Doll, G.L.; Murray, C.E.; Stoessel, C.H.; Martinu, L. Review Article: Stress in thin films and coatings: Current status, challenges, and prospects. J. Vac. Sci. Technol. A 2018, 36, 020801. [Google Scholar] [CrossRef] [Green Version]

- Gao, Y.N.; Xu, Y.L.; Lu, J.G.; Zhang, J.H.; Li, X.F. Solution processable amorphous hafnium silicate dielectrics and their application in oxide thin film transistors. J. Mater. Chem. C 2015, 3, 11497–11504. [Google Scholar] [CrossRef]

- Apblett, A.W.; Cheatham, L.K.; Barron, A.R. Chemical vapour deposition of aluminium silicate thin films. J. Mater. Chem. 1991, 1, 143–144. [Google Scholar] [CrossRef]

- Cosnier, V.; Olivier, M.; Théret, G.; André, B. HfO2–SiO2 interface in PVD coatings. J. Vac. Sci. Technol. A 2001, 19, 2267–2271. [Google Scholar] [CrossRef]

- Hill, D.H.; Bartynski, R.A.; Nguyen, N.V.; Davydov, A.C.; Chandler-Horowitz, D.; Frank, M.M. The relationship between local order, long range order, and sub-band-gap defects in hafnium oxide and hafnium silicate films. J. Appl. Phys. 2008, 103, 093712. [Google Scholar] [CrossRef]

- Kuo, D.H.; Cheung, B.Y.; Wu, R.J. Amorphous aluminum silicate films by metal-organic chemical vapor deposition using aluminum-tri-sec-butoxide and tetraethyl orthosilicate. J. Non-Cryst. Solids 2003, 324, 159–171. [Google Scholar] [CrossRef]

- Filipescu, M.; Scarisoreanu, N.; Craciun, V.; Mitu, B.; Purice, A.; Moldovan, A.; Ion, V.; Toma, O.; Dinescu, M. High-k dielectric oxides obtained by PLD as solution for gates dielectric in MOS devices. Appl. Surf. Sci. 2007, 253, 8184–8191. [Google Scholar] [CrossRef]

- Fujiwara, H. Spectroscopic Ellipsometry: Principles and Applications; John Wiley & Sons Ltd.: Tokyo, Japan, 2007. [Google Scholar]

- International Standard ISO 21254:2011. In Laser and Laser-Related Equipment—Test Methods for Laser-Induced Damage Threshold. ISO21254-1:2011–Part 1: “Definition and General Principles” ISO 21254-2:2011–Part 2: “Threshold, Determination”; ISO 21254-3:2011–Part 3: “Assurance of Laser Power (Energy) Handling, Capabilities”; ISO 21254-4:2011–Part 4: “Inspection, Detection and Measurement“; International Organization for Standardization: Geneva, Switzerland, 2011.

- Stratan, A.; Zorila, A.; Rusen, L.; Simion, S.; Blanaru, C.; Fenic, C.; Neagu, L.; Nemes, G. Automated test station for laser-induced damage threshold measurements according to ISO 21254-1,2,3,4 standards in Laser-Induced Damage in Optical Materials. Proc. SPIE 2012, 8530, 85301Y. [Google Scholar]

- Zorila, A.; Rusen, L.; Stratan, A.; Nemes, G. Measuring the effective pulse duration of nanosecond and femtosecond laser pulses for laser-induced damage experiments. Opt. Eng. 2013, 52, 054203. [Google Scholar] [CrossRef]

- Stratan, A.; Zorila, A.; Rusen, L.; Nemes, G. Measuring effective area of spots from pulsed laser beams. Opt. Eng. 2014, 53, 122513. [Google Scholar] [CrossRef]

- Gerasimova, A.K.; Aliev, V.S.; Kruchinin, V.N.; Badmaeva, I.A.; Voronkovskii, V.A.; Bortnikov, S.G. Optical properties of HfOx (x < 2) films grown by ion beam sputtering-deposition method. Mater. Res. Express 2019, 6, 016423. [Google Scholar]

- Chichkov, B.N.; Momma, C.; Nolte, S.; von Alvensleben, F.; Tünnermann, A. Femtosecond, picosecond and nanosecond laser ablation of solids. Appl. Phys. A 1996, 63, 109–115. [Google Scholar] [CrossRef]

- Hamad, A.H. Effects of Different Laser Pulse Regimes (Nanosecond, Picosecond and Femtosecond) on the Ablation of Materials for Production of Nanoparticles in Liquid Solution. In High Energy and Short Pulse Lasers; Viskup, R., Ed.; IntechOpen: London, UK, 2016; pp. 305–325. [Google Scholar]

- Ristau, D.; Jupé, M.; Starke, K. Laser damage thresholds of optical coatings. Thin Solid Films 2009, 518, 1607–1613. [Google Scholar] [CrossRef]

- Gallais, L.; Mangote, B.; Zerrad, M.; Commandré, M.; Melninkaitis, A.; Mirauskas, J.; Jeskevic, M.; Sirutkaitis, V. Laser-induced damage of hafnia coatings as a function of pulse duration in the femtosecond to nanosecond range. Appl. Opt. 2011, 50, C178–C187. [Google Scholar] [CrossRef] [PubMed]

- Kičas, S.; Batavičiūtė, G.; Juškevičius, K.; Tolenis, T.; Drazdys, R.; Buzelis, R.; Melninkaitis, A. Characterization and application of HfO2-SiO2 mixtures produced by ion-beam sputtering technology. Laser Induc. Damage Opt. Mater. 2013, 8885, 888521. [Google Scholar]

- Field, E.; Bellum, J.; Kletecka, D. How laser damage resistance of HfO2/SiO2 optical coatings is affected by embedded contamination caused by pausing the deposition process. Pacific Rim Laser Damage Opt. Mater. High-Power Lasers 2015, 9532, 95320J. [Google Scholar]

- Guo, K.S.; Wang, Y.Z.; Chen, R.Y.; Zhang, Y.H.; Sytchkova, A.; Zhu, M.P.; Yi, K.; He, H.B.; Shao, J.D. Laser-induced layers peeling of sputtering coatings at 1064 nm wavelength. Sci. Rep. 2021, 11, 3783. [Google Scholar]

- Negres, R.A.; Stolz, C.J.; Thomas, M.D.; Caputo, M. 1064-nm, nanosecond laser mirror thin film damage competition. Laser-Induc. Damage Opt. Mater. 2019, 11173, 111730N. [Google Scholar]

| Sample No. | Target | Substrate | No. Pulses | Tsubstrate (°C) |

|---|---|---|---|---|

| S1 | ½ HfO2 + ½ Si | Si (100) | 20,000 | RT |

| S2 | ½ HfO2 + ½ Si | quartz | 144,000 | RT |

| S3 | ½ HfO2 + ½ Si | quartz | 144,000 | 600 |

| S4 | ½ Al2O3 + ½ Si | Si (100) | 40,000 | RT |

| S5 | ½ Al2O3 + ½ Si | quartz | 200,000 | 600 |

| S6 | ½ Al2O3 + ½ Si | quartz | 200,000 | RT |

| Sample No. | O 1s (atomic %) | Al 2p (atomic %) | Si 2p (atomic %) | Hf 4f (atomic %) |

|---|---|---|---|---|

| S2 (HfSixOy at RT) | 64.42 | - | 15.24 | 20.34 |

| S3 (HfSixOy at 600 °C) | 62.55 | - | 14.63 | 22.81 |

| S6 (AlSixOy at RT) | 51.14 | 46.83 | 2.03 | - |

| S5 (AlSixOy at 600 °C) | 57.45 | 40.05 | 2.51 | - |

| Sample | An | Bn | Thickness (nm) | Roughness (nm) | MSE |

|---|---|---|---|---|---|

| S1 HfSixOy | 2.203 | 0.015 | 23.3 | 6.4 | 0.6965 |

| S4 AlSixOy | 1.624 | 0.006 | 48.7 | 2.4 | 0.72 |

| EMA (38.6% SiO2 + 61.4% Al2O3) | 49.3 | 1.4 | - | ||

| Sample | Number of Pulses | 1 | 2 | 5 | 10 | 20 | 50 | 100 | 200 | 500 |

|---|---|---|---|---|---|---|---|---|---|---|

| S3 HfSixOy @ 600 °C | H0(N) (J/cm2) | 7.98 | 6.15 | 2.53 | 1.65 | 1.32 | 0.74 | 0.53 | 0.53 | 0.47 |

| H50(N) (J/cm2) | 10.66 | 7.80 | 4.08 | 2.92 | 2.53 | 1.93 | 1.67 | 1.39 | 1.33 | |

| S2 HfSixOy @ RT | H0(N) (J/cm2) | 7.80 | 7.22 | 5.56 | 3.81 | 3.36 | 3.49 | 2.39 | 2.24 | 2.24 |

| H50(N) (J/cm2) | 10.98 | 8.98 | 7.47 | 5.99 | 5.72 | 4.90 | 4.22 | 4.08 | 4.03 | |

| S5 AlSixOy @ 600 °C | H0(N) (J/cm2) | 10.6 | 9.11 | 8.92 | 8.89 | 8.8 | 8.74 | 8.93 | 9.11 | 9.03 |

| H50(N) (J/cm2) | 12.9 | 11.23 | 11.13 | 11.07 | 10.98 | 10.93 | 10.62 | 10.42 | 10.32 | |

| S6 AlSixOy @ RT | H0(N) (J/cm2) | 8.5 | 8.09 | 8.09 | 8.11 | 8.13 | 7.95 | 7.83 | 6.62 | 7.14 |

| H50(N) (J/cm2) | 14.6 | 13.67 | 13.67 | 13.44 | 13.23 | 13.60 | 12.24 | 10.68 | 9.77 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sirjita, E.N.; Rusen, L.; Brajnicov, S.; Craciun, C.; Ion, V.; Filipescu, M.; Dinescu, M. Properties of Hafnium and Aluminium Silicates Coatings Obtained by PLD. Coatings 2021, 11, 753. https://doi.org/10.3390/coatings11070753

Sirjita EN, Rusen L, Brajnicov S, Craciun C, Ion V, Filipescu M, Dinescu M. Properties of Hafnium and Aluminium Silicates Coatings Obtained by PLD. Coatings. 2021; 11(7):753. https://doi.org/10.3390/coatings11070753

Chicago/Turabian StyleSirjita, Eduard N., Laurentiu Rusen, Simona Brajnicov, Cristina Craciun, Valentin Ion, Mihaela Filipescu, and Maria Dinescu. 2021. "Properties of Hafnium and Aluminium Silicates Coatings Obtained by PLD" Coatings 11, no. 7: 753. https://doi.org/10.3390/coatings11070753

APA StyleSirjita, E. N., Rusen, L., Brajnicov, S., Craciun, C., Ion, V., Filipescu, M., & Dinescu, M. (2021). Properties of Hafnium and Aluminium Silicates Coatings Obtained by PLD. Coatings, 11(7), 753. https://doi.org/10.3390/coatings11070753