Laser Cladding-Based Surface Modification of Carbon Steel and High-Alloy Steel for Extreme Condition Applications

Abstract

:1. Introduction

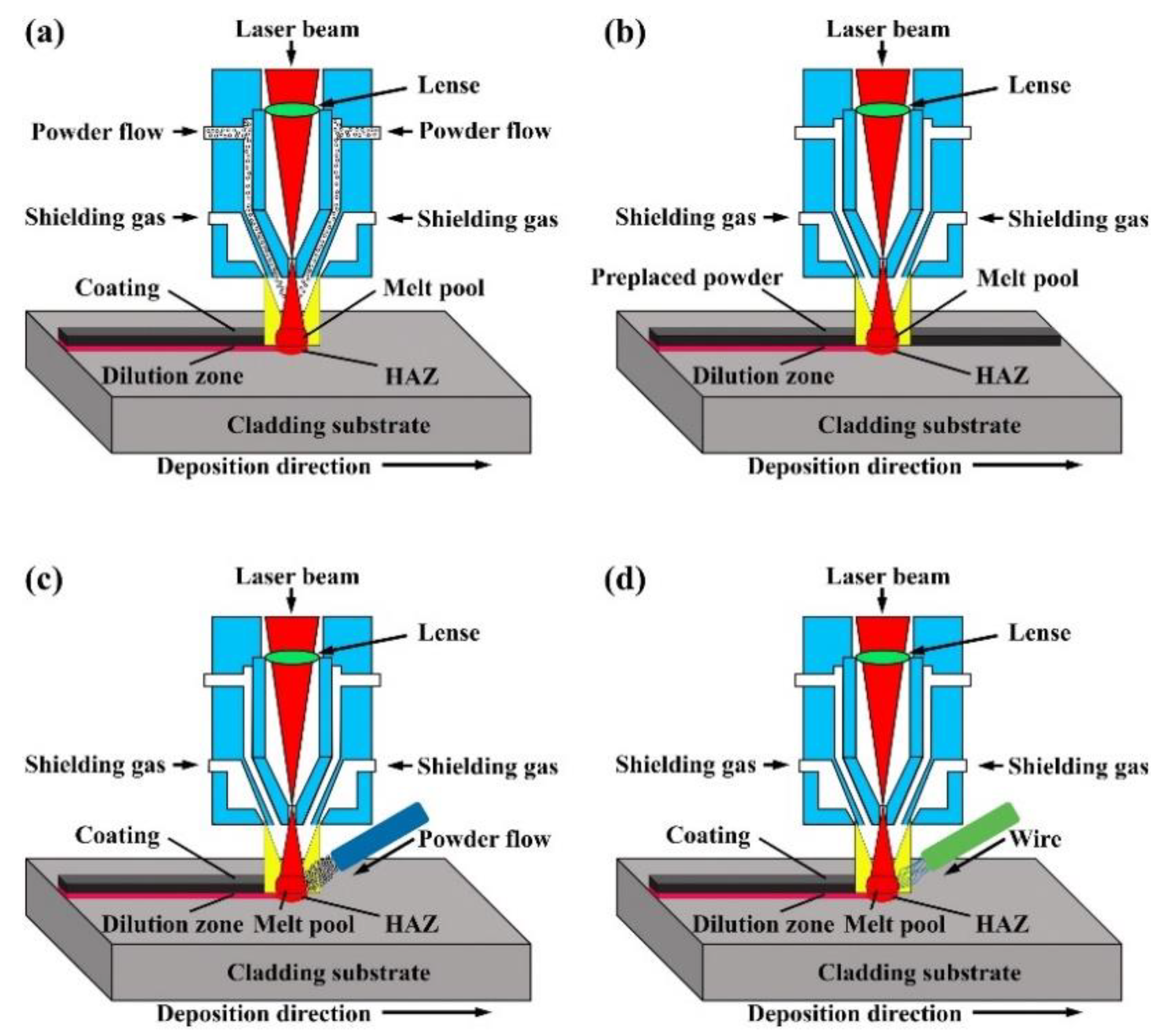

2. Laser Cladding Process

3. Laser Cladding of Carbon Steel

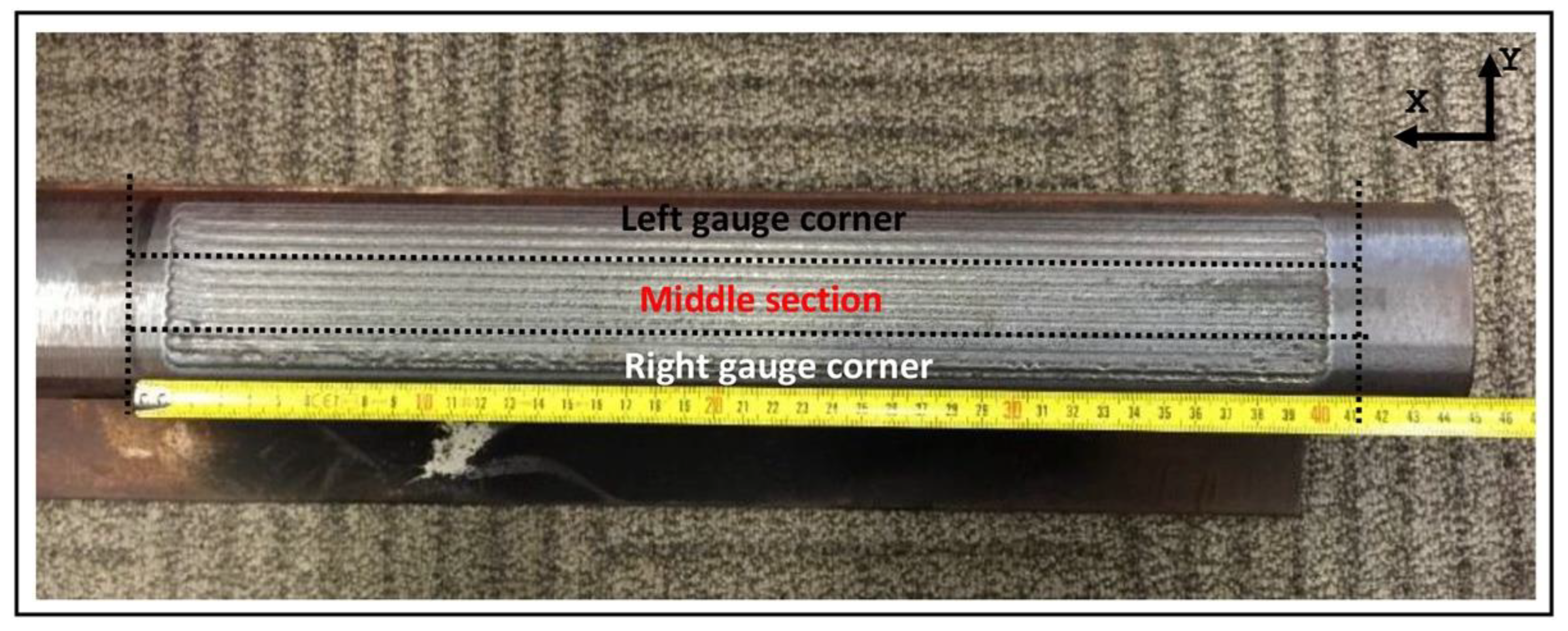

3.1. LC of 17-4 PH Stainless Steel on E355DD Steel Substrate

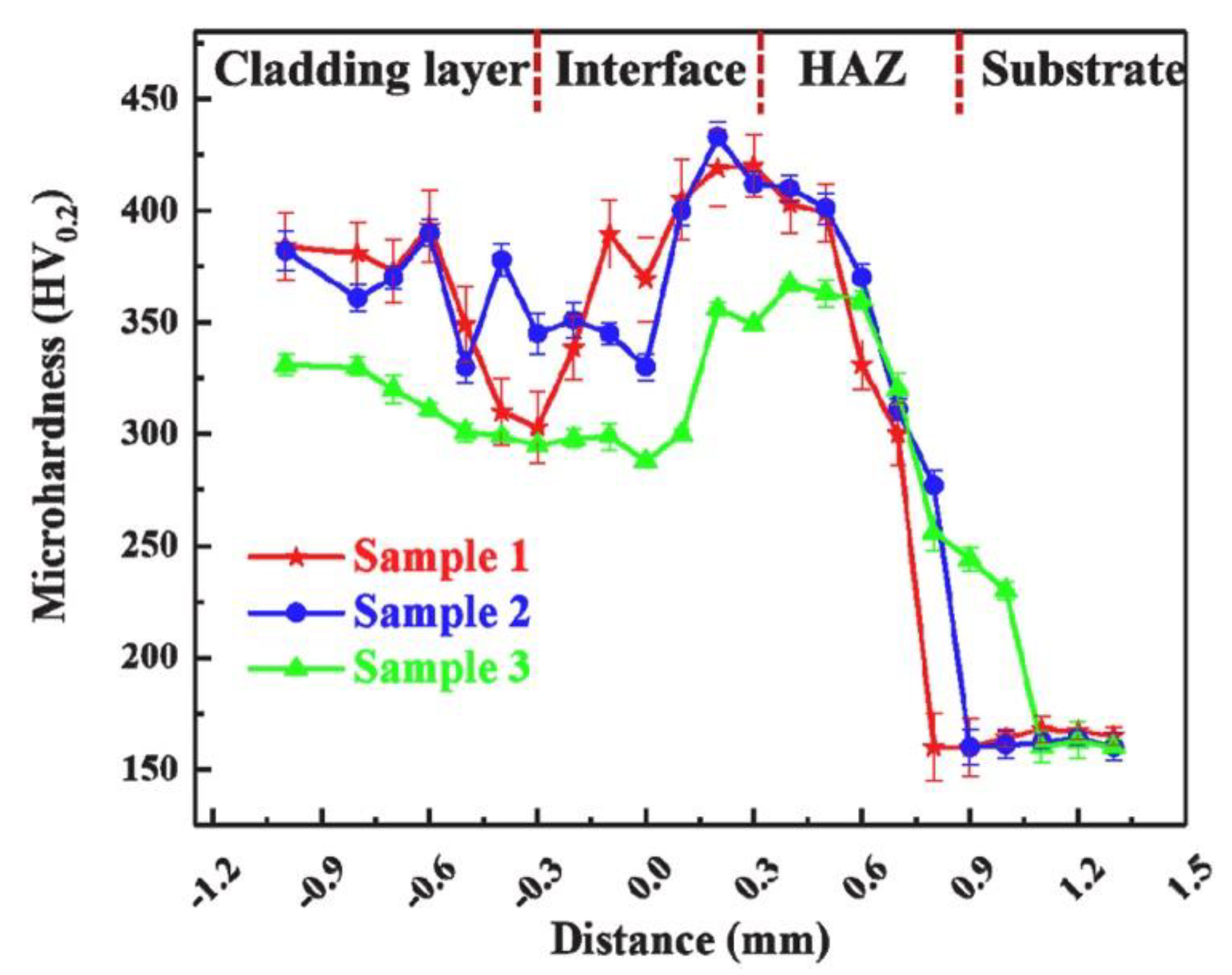

3.2. LC of Ni-Cr-Mo-W-xSi on 20 G Steel Substrate

3.3. LC of Composites on Steel Substrate

3.4. LC of Stellite on Steel Substrate

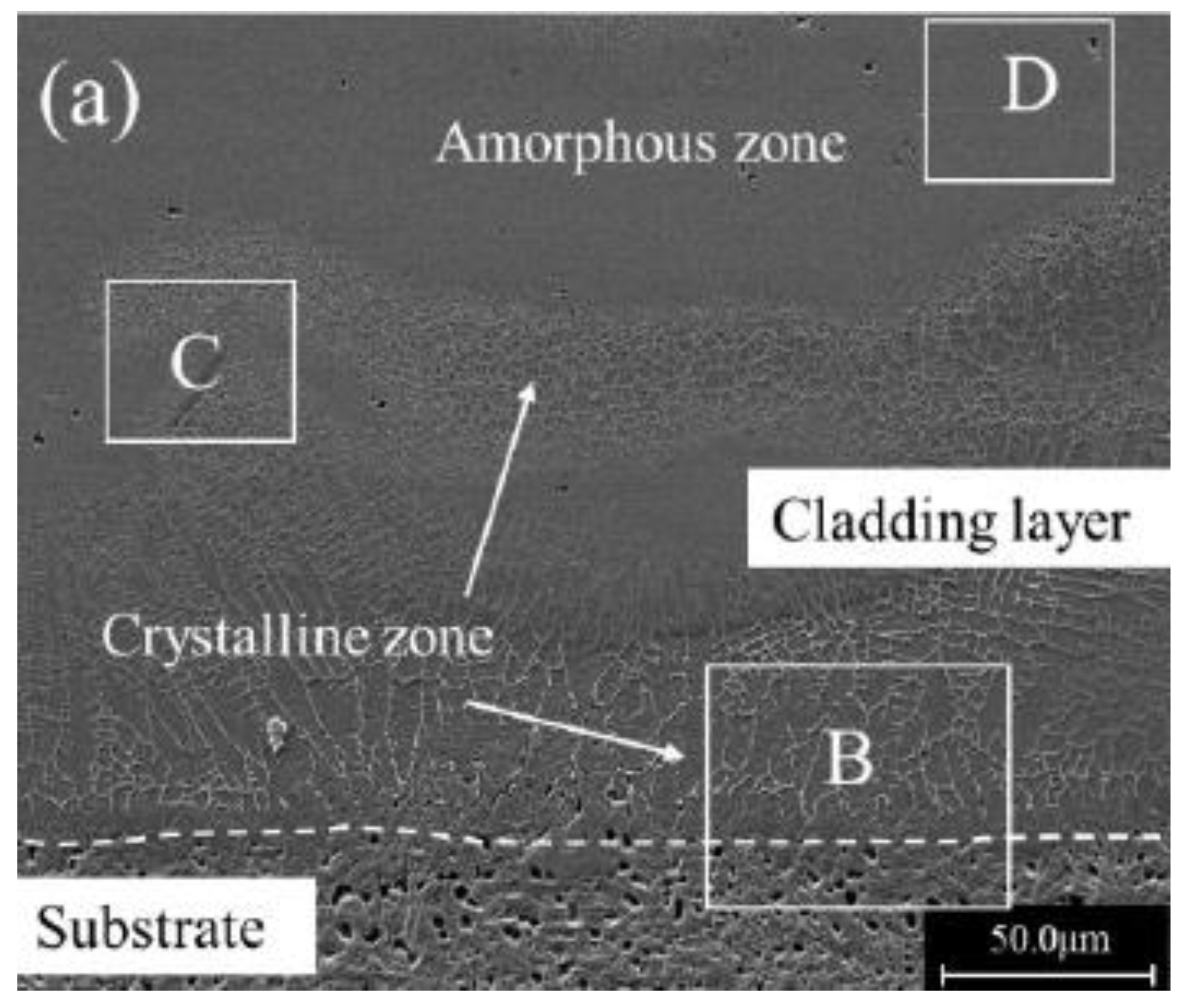

3.5. LC of Metallic Glasses on Steel Substrate

4. Laser Cladding of High-Alloy Steels

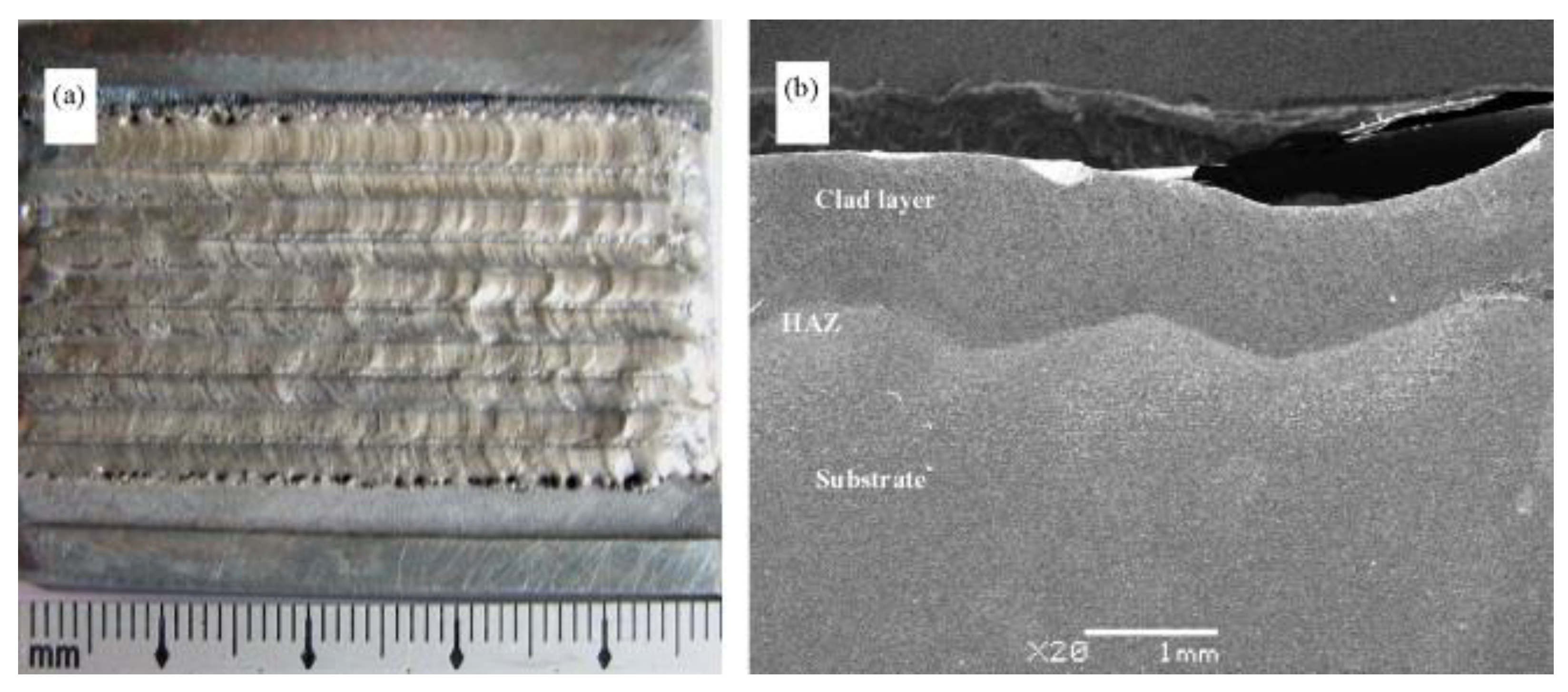

4.1. LC of Co-Based or Ni-Based Alloys on Stainless Steel

4.2. LC on Tool, Die, and Armor Steels

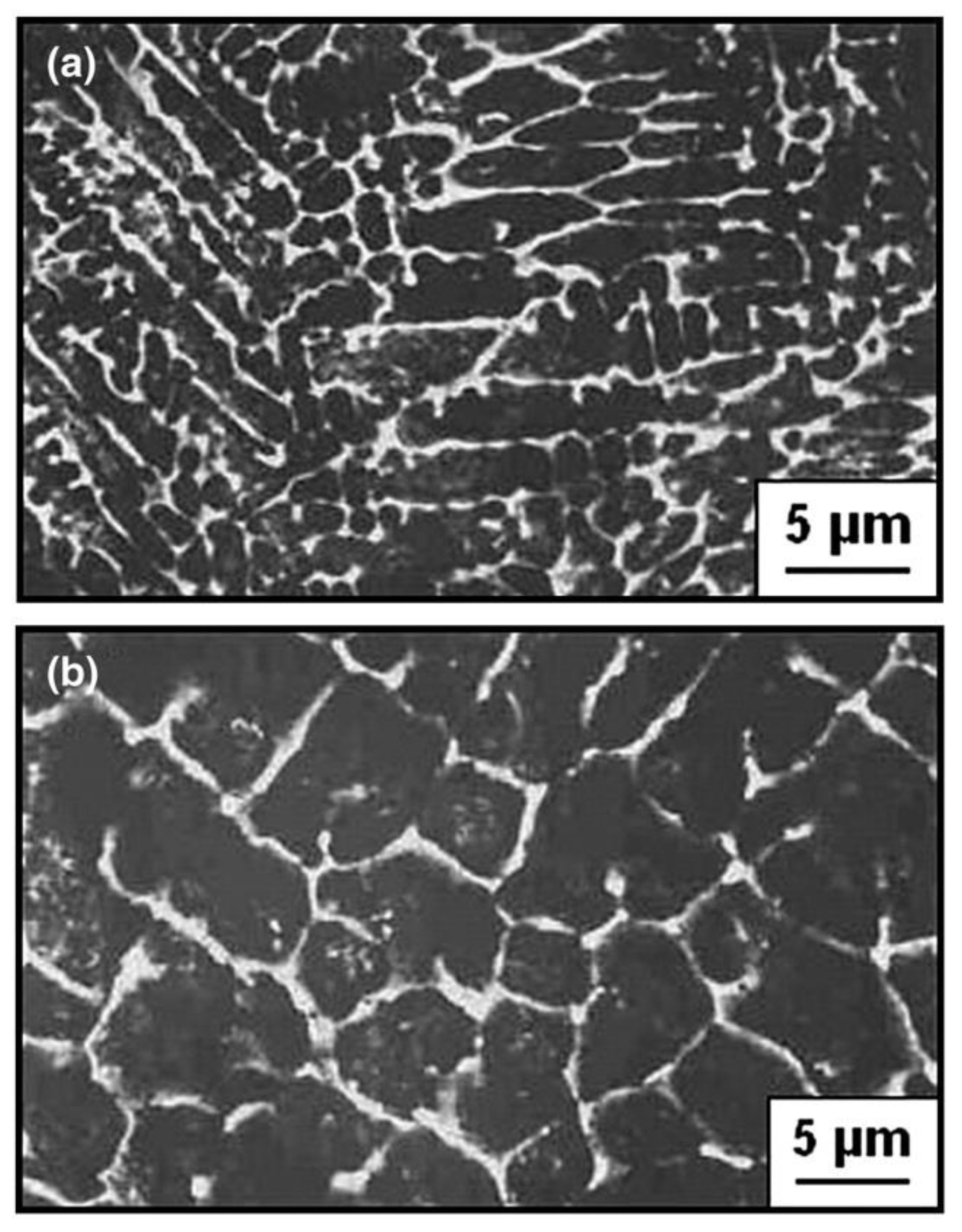

4.3. LC of Amorphous Materials on Alloy Steels

5. Applications of LC Process

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AC | Alternating Current |

| COF | Coefficient of Friction |

| CPM | Crucible Particle Metallurgy |

| DC | Direct Current |

| FSP | Friction Stir Processing |

| FSW | Friction Stir Welding |

| LC | Laser Cladding |

| SEM | Scanning Electron Microscopy |

| PEO | Plasma Electrolytic Oxidation |

| UTS | Ultimate Tensile Strength |

| YS | Yield Strength |

References

- Zhang, C.; Dong, Y.; Ye, C. Recent Developments and Novel Applications of Laser Shock Peening: A Review. Adv. Eng. Mater. 2021, 23, 2001216. [Google Scholar] [CrossRef]

- Kishore, A.; John, M.; Ralls, A.M.; Jose, S.A.; Kuruveri, U.B.; Menezes, P.L. Ultrasonic Nanocrystal Surface Modification: Processes, Characterization, Properties, and Applications. Nanomaterials 2022, 12, 1415. [Google Scholar] [CrossRef]

- John, M.; Ralls, A.M.; Dooley, S.C.; Thazhathidathil, A.K.V.; Perka, A.K.; Kuruveri, U.B.; Menezes, P.L. Ultrasonic Surface Rolling Process: Properties, Characterization, and Applications. Appl. Sci. 2021, 11, 10986. [Google Scholar] [CrossRef]

- Bhat, K.U.; Panemangalore, D.B.; Kuruveri, S.B.; John, M.; Menezes, P.L. Surface Modification of 6xxx Series Aluminum Alloys. Coatings 2022, 12, 180. [Google Scholar] [CrossRef]

- Kushwaha, A.K.; John, M.; Misra, M.; Menezes, P.L. Nanocrystalline Materials: Synthesis, Characterization, Properties, and Applications. Crystals 2021, 11, 1317. [Google Scholar] [CrossRef]

- John, M.; Diaz, O.; Esparza, A.; Fliegler, A.; Ocenosak, D.; Van Dorn, C.; Bhat, K.U.; Menezes, P.L. Welding Techniques for High Entropy Alloys: Processes, Properties, Characterization, and Challenges. Materials 2022, 15, 2273. [Google Scholar] [CrossRef]

- John, M.; Kalvala, P.R.; Misra, M.; Menezes, P.L. Peening Techniques for Surface Modification: Processes, Properties, and Applications. Materials 2021, 14, 3841. [Google Scholar] [CrossRef]

- Azhari, A.; Sulaiman, S.; Rao, A.K.P. A Review on the Application of Peening Processes for Surface Treatment. IOP Conf. Ser. Mater. Sci. Eng. 2016, 114, 012002. [Google Scholar] [CrossRef]

- Koshuro, V.; Fomina, M.; Fomin, A. High-Hardness Carbide Coatings and Their Production on X82WMoCrV6-5-4 Steel Using Induction Physical Vapor Deposition. Compos. Struct. 2022, 281, 115045. [Google Scholar] [CrossRef]

- An, Q.; Chen, J.; Tao, Z.; Ming, W.; Chen, M. Experimental Investigation on Tool Wear Characteristics of PVD and CVD Coatings during Face Milling of Ti 6242S and Ti-555 Titanium Alloys. Int. J. Refract. Met. Hard Mater. 2020, 86, 105091. [Google Scholar] [CrossRef]

- Daram, P.; Banjongprasert, C. The Influence of Post Treatments on the Microstructure and Corrosion Behavior of Thermally Sprayed NiCrMoAl Alloy Coating. Surf. Coat. Technol. 2020, 384, 125166. [Google Scholar] [CrossRef]

- Kuo, T.-Y.; Chin, W.-H.; Chien, C.-S.; Hsieh, Y.-H. Mechanical and Biological Properties of Graded Porous Tantalum Coatings Deposited on Titanium Alloy Implants by Vacuum Plasma Spraying. Surf. Coat. Technol. 2019, 372, 399–409. [Google Scholar] [CrossRef]

- Ralls, A.M.; Daroonparvar, M.; Sikdar, S.; Rahman, M.H.; Monwar, M.; Watson, K.; Kay, C.M.; Menezes, P.L. Tribological and Corrosion Behavior of High Pressure Cold Sprayed Duplex 316 L Stainless Steel. Tribol. Int. 2022, 169, 107471. [Google Scholar] [CrossRef]

- Wu, J.; Mao, C.; Wei, K.; Hu, J. Titanium-Modified Plasma Nitriding Layer and Enhanced Properties for 42CrMo Steel. J. Mater. Res. Technol. 2022, 18, 3819–3825. [Google Scholar] [CrossRef]

- Sezgin, C.T.; Hayat, F. The Effects of Boriding Process on Tribological Properties and Corrosive Behavior of a Novel High Manganese Steel. J. Mater. Processing Technol. 2022, 300, 117421. [Google Scholar] [CrossRef]

- Wan, H.; Lu, H.; Ren, Y.; Ma, C.; Chen, Y.; Xin, Z.; Cheng, L.; He, K.; Tu, X.; Han, Q.; et al. Strengthening Mechanisms and Tensile Properties of 20Cr2Mn2Mo Processed by Laser Shock Peening and Vacuum Carbonitriding. Surf. Coat. Technol. 2022, 439, 128462. [Google Scholar] [CrossRef]

- Yan, Y.; Luo, Z.; Liu, K.; Zhang, C.; Wang, M.; Wang, X. Effect of Cryogenic Treatment on the Microstructure and Wear Resistance of 17Cr2Ni2MoVNb Carburizing Gear Steel. Coatings 2022, 12, 281. [Google Scholar] [CrossRef]

- Cacko, R.; Chmielewski, T.; Hudycz, M.; Golański, D. New Approach of Friction AlN Ceramics Metallization with the Initial FEM Verification. Archiv. Civ. Mech. Eng. 2020, 20, 90. [Google Scholar] [CrossRef]

- Draper, C.W.; Poate, J.M. Laser Surface Alloying. Int. Met. Rev. 1985, 30, 85–108. [Google Scholar] [CrossRef]

- Jiang, W.; Wang, S.; Deng, Y.; Guo, X. Microstructure Stability and High Temperature Wear Behavior of an Austenite Aging Steel Coating by Laser Cladding. Mater. Charact. 2022, 184, 111700. [Google Scholar] [CrossRef]

- Zhu, L.; Xue, P.; Lan, Q.; Meng, G.; Ren, Y.; Yang, Z.; Xu, P.; Liu, Z. Recent Research and Development Status of Laser Cladding: A Review. Opt. Laser Technol. 2021, 138, 106915. [Google Scholar] [CrossRef]

- Lai, Q.; Abrahams, R.; Yan, W.; Qiu, C.; Mutton, P.; Paradowska, A.; Soodi, M. Investigation of a Novel Functionally Graded Material for the Repair of Premium Hypereutectoid Rails Using Laser Cladding Technology. Compos. Part B Eng. 2017, 130, 174–191. [Google Scholar] [CrossRef]

- Nie, M.H.; Zhang, S.; Wang, Z.Y.; Zhang, C.H.; Chen, H.T.; Chen, J. Effect of Laser Power on Microstructure and Interfacial Bonding Strength of Laser Cladding 17-4PH Stainless Steel Coatings. Mater. Chem. Phys. 2022, 275, 125236. [Google Scholar] [CrossRef]

- Leunda, J.; Soriano, C.; Sanz, C.; Navas, V.G. Laser Cladding of Vanadium-Carbide Tool Steels for Die Repair. Phys. Procedia 2011, 12, 345–352. [Google Scholar] [CrossRef]

- Cui, C.; Nie, J.; Li, Y.; Guan, Q.; Cai, J.; Zhang, P.; Wu, J. Wear Resistance of FeCrAlNbNi Alloyed Zone via Laser Surface Alloying on 304 Stainless Steel. Metals 2022, 12, 467. [Google Scholar] [CrossRef]

- Wu, C.L.; Xu, T.Z.; Wang, Z.Y.; Zhang, C.H.; Zhang, S.; Ni, C.L.; Zhang, D.X. Laser Surface Alloying of FeCoCrAlNiTi High Entropy Alloy Composite Coatings Reinforced with TiC on 304 Stainless Steel to Enhance Wear Behavior. Ceram. Int. 2022, 48, 20690–20698. [Google Scholar] [CrossRef]

- Lia, F.; Park, J.; Tressler, J.; Martukanitz, R. Partitioning of Laser Energy during Directed Energy Deposition. Addit. Manuf. 2017, 18, 31–39. [Google Scholar] [CrossRef]

- Singh, S.; Goyal, D.K.; Kumar, P.; Bansal, A. Laser Cladding Technique for Erosive Wear Applications: A Review. Mater. Res. Express 2020, 7, 012007. [Google Scholar] [CrossRef]

- Basu, A.; Samant, A.N.; Harimkar, S.P.; Majumdar, J.D.; Manna, I.; Dahotre, N.B. Laser Surface Coating of Fe–Cr–Mo–Y–B–C Bulk Metallic Glass Composition on AISI 4140 Steel. Surf. Coat. Technol. 2008, 202, 2623–2631. [Google Scholar] [CrossRef]

- Sugiyama, K.; Harada, K.; Hattori, S. Influence of Impact Angle of Solid Particles on Erosion by Slurry Jet. Wear 2008, 265, 713–720. [Google Scholar] [CrossRef]

- Wang, S.L.; Zhang, Z.Y.; Gong, Y.B.; Nie, G.M. Microstructures and Corrosion Resistance of Fe-Based Amorphous/Nanocrystalline Coating Fabricated by Laser Cladding. J. Alloys Compd. 2017, 728, 1116–1123. [Google Scholar] [CrossRef]

- Lepski, D.; Brückner, F. Laser Cladding. In The Theory of Laser Materials Processing; Dowden, J., Ed.; Springer Series in Materials Science; Springer: Dordrecht, The Netherlands, 2009; Volume 119, pp. 235–279. ISBN 978-1-4020-9339-5. [Google Scholar]

- Wang, Q.; Zeng, X.; Chen, C.; Lian, G.; Huang, X. An Integrated Method for Multi-Objective Optimization of Multi-Pass Fe50/TiC Laser Cladding on AISI 1045 Steel Based on Grey Relational Analysis and Principal Component Analysis. Coatings 2020, 10, 151. [Google Scholar] [CrossRef]

- Shepeleva, L.; Medres, B.; Kaplan, W.D.; Bamberger, M.; Weisheit, A. Laser Cladding of Turbine Blades. Surf. Coat. Technol. 2000, 125, 45–48. [Google Scholar] [CrossRef]

- Sexton, L.; Lavin, S.; Byrne, G.; Kennedy, A. Laser Cladding of Aerospace Materials. J. Mater. Processing Technol. 2002, 122, 63–68. [Google Scholar] [CrossRef]

- Pei, Y.T.; De Hosson, J.T.M. Functionally Graded Materials Produced by Laser Cladding. Acta Mater. 2000, 48, 2617–2624. [Google Scholar] [CrossRef]

- Barekat, M.; Shoja Razavi, R.; Ghasemi, A. Nd:YAG Laser Cladding of Co–Cr–Mo Alloy on γ-TiAl Substrate. Opt. Laser Technol. 2016, 80, 145–152. [Google Scholar] [CrossRef]

- Parekh, R.; Buddu, R.K.; Patel, R.I. Multiphysics Simulation of Laser Cladding Process to Study the Effect of Process Parameters on Clad Geometry. Procedia Technol. 2016, 23, 529–536. [Google Scholar] [CrossRef]

- Li, M.; Han, B.; Song, L.; He, Q. Enhanced Surface Layers by Laser Cladding and Ion Sulfurization Processing towards Improved Wear-Resistance and Self-Lubrication Performances. Appl. Surf. Sci. 2020, 503, 144226. [Google Scholar] [CrossRef]

- Vilar, R. Laser Cladding. J. Laser Appl. 1999, 11, 64–79. [Google Scholar] [CrossRef]

- Gupta, D.; Mordike, B.L.; Shariff, S.M.; Padmanabhan, G.; Manna, I.; Majumdar, J.D. Laser Surface Cladding of EN19 Steel with Stellite 6 for Improved Wear Resistance. Lasers in Eng. 2010, 19, 317–330. [Google Scholar]

- Liu, H.; Li, X.; Hua, P.; Song, K.; Teng, P.; Zhou, W. Microstructure and Properties of Laser-Cladded Fe50Mn30Co10Cr10 High Entropy Alloy Coatings. J. Spray Tech. 2022, 31, 991–999. [Google Scholar] [CrossRef]

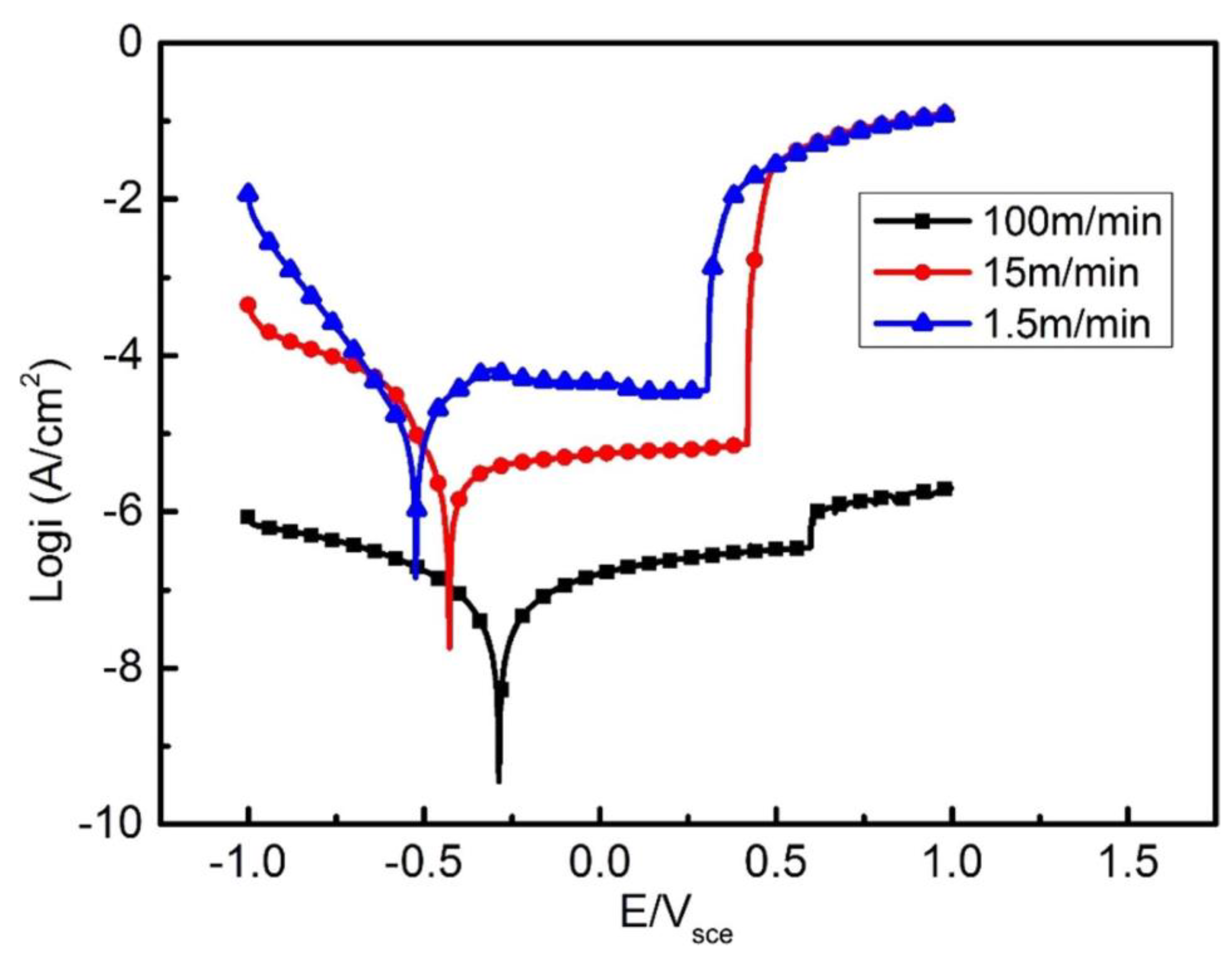

- Wang, H.; Cheng, Y.; Zhang, X.; Yang, J.; Cao, C. Effect of Laser Scanning Speed on Microstructure and Properties of Fe Based Amorphous/Nanocrystalline Cladding Coatings. Mater. Chem. Phys. 2020, 250, 123091. [Google Scholar] [CrossRef]

- Han, L.; Phatak, K.M.; Liou, F.W. Modeling of Laser Cladding with Powder Injection. Met. Mater. Trans. B 2004, 35, 1139–1150. [Google Scholar] [CrossRef]

- Liu, Y.; Ding, Y.; Yang, L.; Sun, R.; Zhang, T.; Yang, X. Research and Progress of Laser Cladding on Engineering Alloys: A Review. J. Manuf. Processes 2021, 66, 341–363. [Google Scholar] [CrossRef]

- Hung, C.-F.; Lin, J. Solidification Model of Laser Cladding with Wire Feeding Technique. J. Laser Appl. 2004, 16, 140–146. [Google Scholar] [CrossRef]

- Hofman, J.T.; De Lange, D.F.; Pathiraj, B.; Meijer, J. FEM Modeling and Experimental Verification for Dilution Control in Laser Cladding. J. Mater. Processing Technol. 2011, 211, 187–196. [Google Scholar] [CrossRef]

- Wu, Z.; Qian, M.; Brandt, M.; Matthews, N. Ultra-High-Speed Laser Cladding of Stellite® 6 Alloy on Mild Steel. JOM 2020, 72, 4632–4638. [Google Scholar] [CrossRef]

- Shen, F.; Tao, W.; Li, L.; Zhou, Y.; Wang, W.; Wang, S. Effect of Microstructure on the Corrosion Resistance of Coatings by Extreme High Speed Laser Cladding. Appl. Surf. Sci. 2020, 517, 146085. [Google Scholar] [CrossRef]

- Song, C.; Wang, W.; Ren, Z.; Zhao, Y.; Zhou, L. Numerical and Experimental Study on the Properties of Laser Cladding of 6061Al Alloy. Trans. Indian Inst. Met. 2022, 75, 1355–1364. [Google Scholar] [CrossRef]

- Jin, L.; Jiang, K.; Kang, L.; Yan, B. Laser Cladding on Copper with Composite Powder C-Al2O3-Cu. J. Mater. Eng. Perform. 2022, 31, 1317–1324. [Google Scholar] [CrossRef]

- Liu, J.; Yu, H.; Chen, C.; Weng, F.; Dai, J. Research and Development Status of Laser Cladding on Magnesium Alloys: A Review. Opt. Lasers Eng. 2017, 93, 195–210. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Q.; Xie, J.; Yang, X.; Peng, P.; Wang, Y.; Li, M.; Ryu, C.H.; Joo, Y.H.; Jeong, I.W.; et al. Enhanced Surface Composite Coating on Ti811 Alloy by Laser Cladding towards Improved Nano-Hardness. Ceram. Int. 2022, 48, 18773–18783. [Google Scholar] [CrossRef]

- Cheng, F.T.; Lo, K.H.; Man, H.C. NiTi Cladding on Stainless Steel by TIG Surfacing Process Part II. Corrosion Behavior. Surf. Coat. Technol. 2003, 172, 316–321. [Google Scholar] [CrossRef]

- Giudice, F.; Sili, A. Weld Metal Microstructure Prediction in Laser Beam Welding of Austenitic Stainless Steel. Appl. Sci. 2021, 11, 1463. [Google Scholar] [CrossRef]

- Missori, S.; Sili, A. Prediction of Weld Metal Microstructure in Laser Beam Welded Clad Steel. Metallurgist 2018, 62, 84–92. [Google Scholar] [CrossRef]

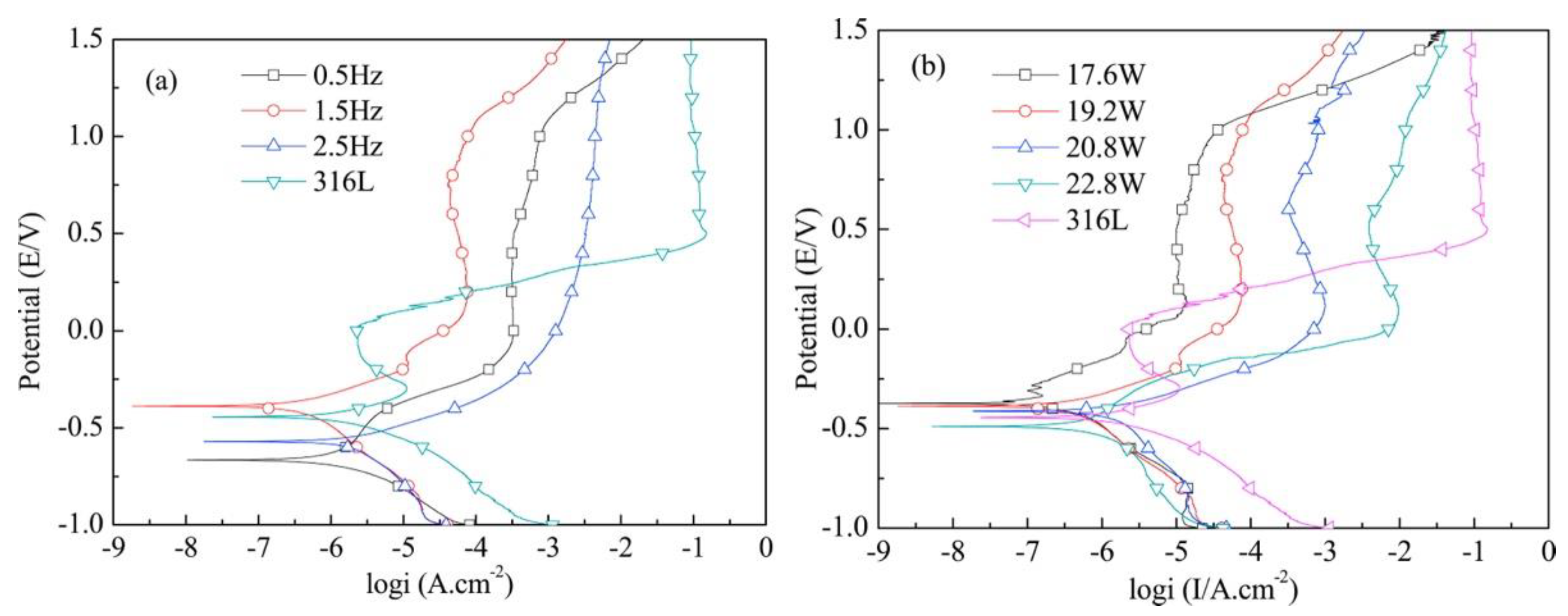

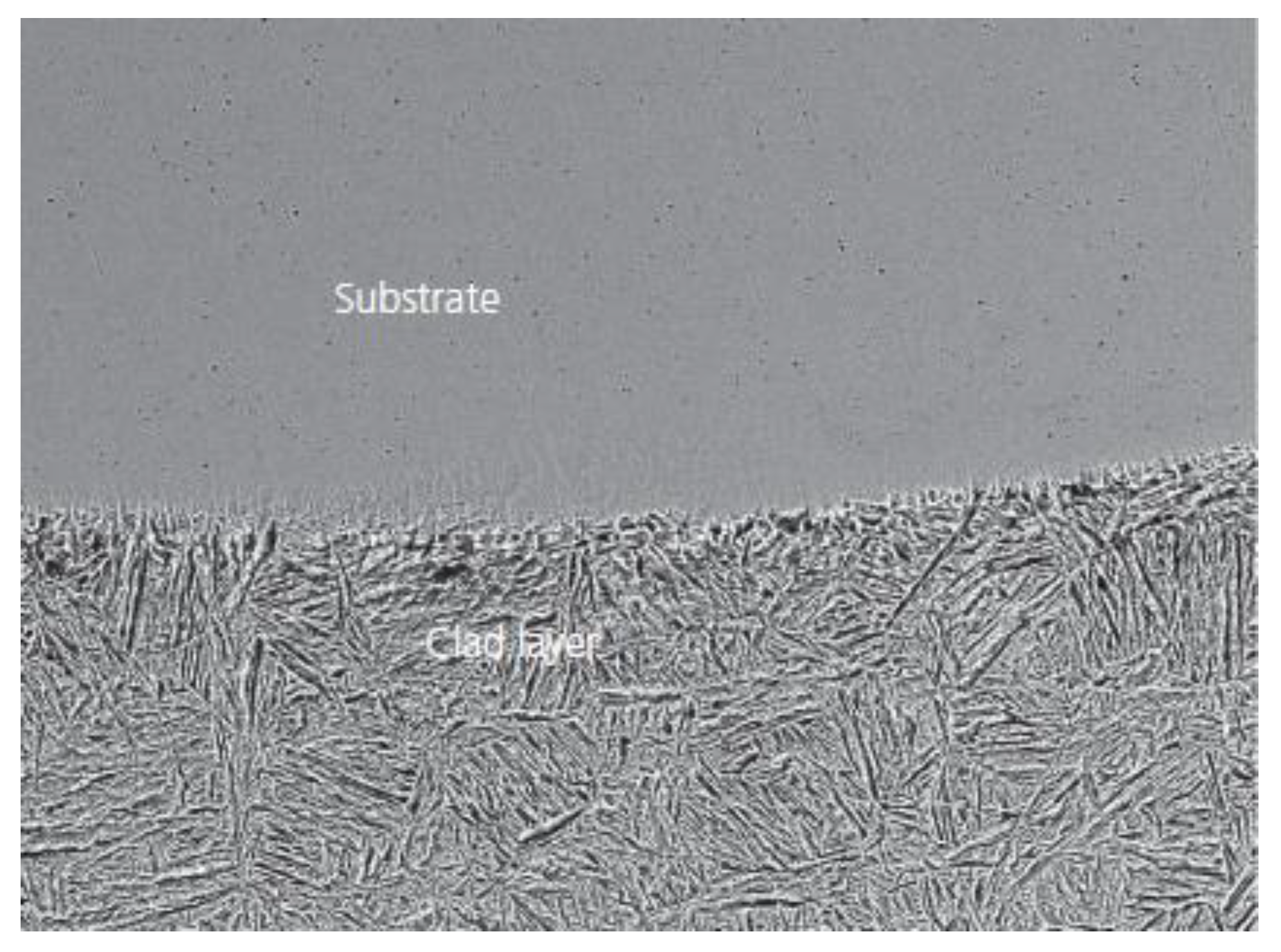

- Liu, C.; Liu, Z.; Gao, Y.; Zheng, C.; Wang, X. Investigation on the Corrosion Behavior of Ni-Cr-Mo-W-XSi Laser Cladding Coating in H2S Corrosion Environment. Appl. Surf. Sci. 2022, 578, 152061. [Google Scholar] [CrossRef]

- Almeida, N.C.; Candido, L.C.; Faria, G.L.; Fernandes de Lima, M.S.; Trindade, V.B. Laser Cladding and Thermal Spray Coatings on Steel Pipe Serving the Oil and Gas Industry. J. Mater. Sci. Eng. 2016, 5, 2169-0022. [Google Scholar] [CrossRef]

- Du, B.; Zou, Z.; Wang, X.; Qu, S. Laser Cladding of in Situ TiB2/Fe Composite Coating on Steel. Appl. Surf. Sci. 2008, 254, 6489–6494. [Google Scholar] [CrossRef]

- Li, J.; Zhu, Z.; Peng, Y.; Shen, G. A Comparative Study on Microstructure Evolution and Wear Resistance of Different-Sized Tungsten Carbide Modified Fe-Based Laser Cladding Coatings. Opt. Laser Technol. 2022, 147, 107672. [Google Scholar] [CrossRef]

- Furukawa, M.; Horita, Z.; Nemoto, M.; Valiev, R.Z.; Langdon, T.G. Microhardness Measurements and the Hall-Petch Relationship in an AlMg Alloy with Submicrometer Grain Size. Acta Mater. 1996, 44, 4619–4629. [Google Scholar] [CrossRef]

- Li, K.; Li, D.; Liu, D.; Pei, G.; Sun, L. Microstructure Evolution and Mechanical Properties of Multiple-Layer Laser Cladding Coating of 308L Stainless Steel. Appl. Surf. Sci. 2015, 340, 143–150. [Google Scholar] [CrossRef]

- Zhang, H.; Shi, Y.; Kutsuna, M.; Xu, G.J. Laser Cladding of Colmonoy 6 Powder on AISI316L Austenitic Stainless Steel. Nucl. Eng. Des. 2010, 240, 2691–2696. [Google Scholar] [CrossRef]

- Dutta Majumdar, J.; Kumar, A.; Li, L. Direct Laser Cladding of SiC Dispersed AISI 316L Stainless Steel. Tribol. Int. 2009, 42, 750–753. [Google Scholar] [CrossRef]

- Zhang, B.; He, B.; Wang, H. Microstructural Investigation and Mechanical Performance of Laser Cladding Repaired Bainite Steel with AerMet100 Steel. Surf. Coat. Technol. 2022, 440, 128498. [Google Scholar] [CrossRef]

- Liu, J.; Li, J.; Cheng, X.; Wang, H. Microstructures and Tensile Properties of Laser Cladded AerMet100 Steel Coating on 300 M Steel. J. Mater. Sci. Technol. 2018, 34, 643–652. [Google Scholar] [CrossRef]

- Srisungsitthisunti, P.; Kaewprachum, B.; Yang, Z.; Gao, G. Real-Time Quality Monitoring of Laser Cladding Process on Rail Steel by an Infrared Camera. Metals 2022, 12, 825. [Google Scholar] [CrossRef]

- Huang, F.; Liu, E.; Qin, Y.; Wang, Q.; Jin, Y.; Wen, L.; Chang, H. A Study of Multi-Pass Laser-Cladding 2205 Duplex Stainless Steel Coating: Microstructure, Electrochemical Corrosion Behavior, and Wear-Resistance Properties. Coatings 2022, 12, 229. [Google Scholar] [CrossRef]

- Xu, P.; Lin, C.; Zhou, C.; Yi, X. Wear and Corrosion Resistance of Laser Cladding AISI 304 Stainless Steel/Al2O3 Composite Coatings. Surf. Coat. Technol. 2014, 238, 9–14. [Google Scholar] [CrossRef]

- El Cheikh, H.; Courant, B.; Branchu, S.; Huang, X.; Hascoët, J.-Y.; Guillén, R. Direct Laser Fabrication Process with Coaxial Powder Projection of 316L Steel. Geometrical Characteristics and Microstructure Characterization of Wall Structures. Opt. Lasers Eng. 2012, 50, 1779–1784. [Google Scholar] [CrossRef]

- Gargarella, P.; Almeida, A.; Vilar, R.; Afonso, C.R.M.; Peripolli, S.; Rios, C.T.; Bolfarini, C.; Botta, W.J.; Kiminami, C.S. Formation of Fe-Based Glassy Matrix Composite Coatings by Laser Processing. Surf. Coat. Technol. 2014, 240, 336–343. [Google Scholar] [CrossRef]

- Katakam, S.; Kumar, V.; Santhanakrishnan, S.; Rajamure, R.; Samimi, P.; Dahotre, N.B. Laser Assisted Fe-Based Bulk Amorphous Coating: Thermal Effects and Corrosion. J. Alloys Compd. 2014, 604, 266–272. [Google Scholar] [CrossRef]

- Hu, Y.L.; Lin, X.; Song, K.; Jiang, X.Y.; Yang, H.O.; Huang, W.D. Effect of Heat Input on Cracking in Laser Solid Formed DZ4125 Superalloy. Opt. Laser Technol. 2016, 86, 1–7. [Google Scholar] [CrossRef]

- Kołodziejczak, P.; Golański, D.; Chmielewski, T.; Chmielewski, M. Microstructure of Rhenium Doped Ni-Cr Deposits Produced by Laser Cladding. Materials 2021, 14, 2745. [Google Scholar] [CrossRef] [PubMed]

- Pereira, J.C.; Zambrano, J.C.; Rayón, E.; Yañez, A.; Amigó, V. Mechanical and Microstructural Characterization of MCrAlY Coatings Produced by Laser Cladding: The Influence of the Ni, Co and Al Content. Surf. Coat. Technol. 2018, 338, 22–31. [Google Scholar] [CrossRef]

- Kaul, R.; Ganesh, P.; Albert, S.K.; Jaiswal, A.; Lalla, N.P.; Gupta, A.; Paul, C.P.; Nath, A.K. Laser Cladding of Austenitic Stainless Steel with Hardfacing Alloy Nickel Base. Surf. Eng. 2003, 19, 269–273. [Google Scholar] [CrossRef]

- Tobar, M.J.; Amado, J.M.; Yáñez, A.; Pereira, J.C.; Amigó, V. Laser Cladding of MCrAlY Coatings on Stainless Steel. Phys. Procedia 2014, 56, 276–283. [Google Scholar] [CrossRef]

- Kusmoko, A.; Dunne, D.; Li, H.; Nolan, D. Laser Cladding of Stainless Steel Substrates with Stellite 6. MSF 2013, 773–774, 573–589. [Google Scholar] [CrossRef]

- Chen, J.; Xue, L. Laser Cladding of CPM Tool Steels on Hardened H13 Hot-Work Steel for Low-Cost High-Performance Automotive Tooling. JOM 2012, 64, 688–693. [Google Scholar] [CrossRef]

- Jiang, W.; Wang, S.; Wang, L. High Temperature Wear Performance of Laser Cladding Maraging Steel with Low Nickel on AISI H13 Steel. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 7264–7272. [Google Scholar] [CrossRef]

- Altuncu, E.; Tarım, M. Laser Cladding of Martensitic Stainless Steels on Armor Steels. Emerg. Mater. Res. 2020, 9, 1–4. [Google Scholar] [CrossRef]

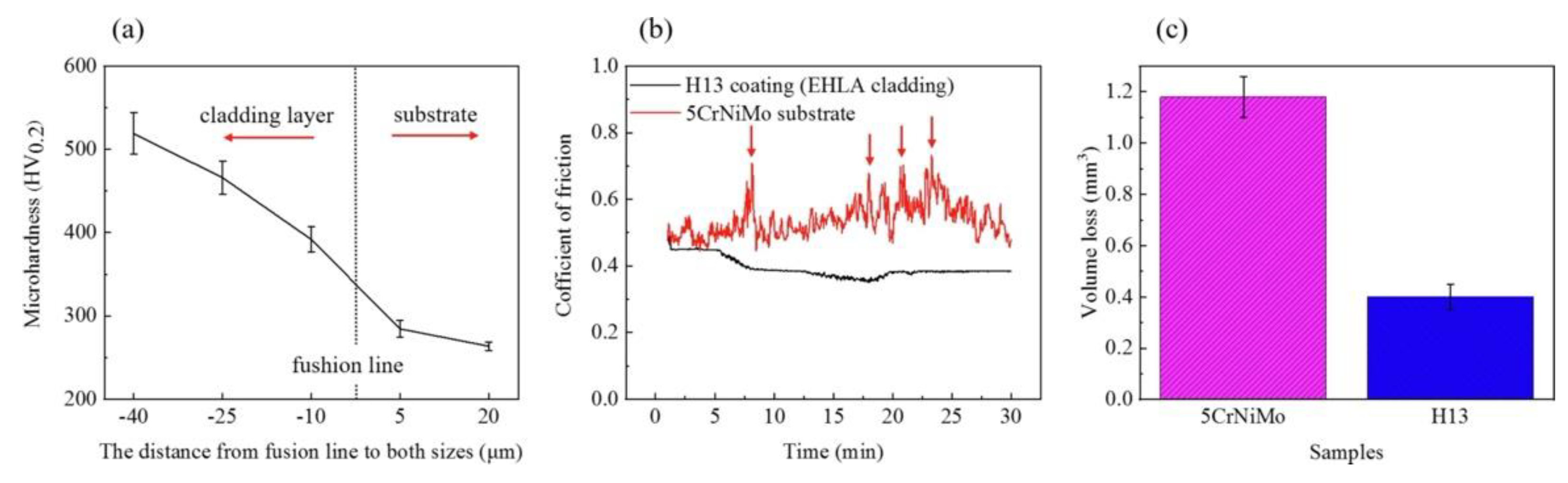

- Yan, Q.; Yang, K.; Wang, Z.; Chen, M.; Sun, G.; Ni, Z. Surface Roughness Optimization and High-Temperature Wear Performance of H13 Coating Fabricated by Extreme High-Speed Laser Cladding. Opt. Laser Technol. 2022, 149, 107823. [Google Scholar] [CrossRef]

- Hou, X.; Du, D.; Chang, B.; Ma, N. Influence of Scanning Speed on Microstructure and Properties of Laser Cladded Fe-Based Amorphous Coatings. Materials 2019, 12, 1279. [Google Scholar] [CrossRef] [PubMed]

- Rahman Rashid, R.A.; Barr, C.J.; Palanisamy, S.; Nazari, K.A.; Orchowski, N.; Matthews, N.; Dargusch, M.S. Effect of Clad Orientation on the Mechanical Properties of Laser-Clad Repaired Ultra-High Strength 300 M Steel. Surf. Coat. Technol. 2019, 380, 125090. [Google Scholar] [CrossRef]

- Niederhauser, S.; Karlsson, B. Fatigue Behaviour of Co–Cr Laser Cladded Steel Plates for Railway Applications. Wear 2005, 258, 1156–1164. [Google Scholar] [CrossRef]

- Wang, X.; Lei, L.; Yu, H. A Review on Microstructural Features and Mechanical Properties of Wheels/Rails Cladded by Laser Cladding. Micromachines 2021, 12, 152. [Google Scholar] [CrossRef]

- Zhu, Y.; Yang, Y.; Mu, X.; Wang, W.; Yao, Z.; Yang, H. Study on Wear and RCF Performance of Repaired Damage Railway Wheels: Assessing Laser Cladding to Repair Local Defects on Wheels. Wear 2019, 430–431, 126–136. [Google Scholar] [CrossRef]

- Piasecki, A.; Bartkowski, D.; Młynarczyk, A.; Dudziak, A.; Gościański, M.; Kasprowiak, M. Laser Cladding of Stellite 6 on Low Carbon Steel for Repairing Components in Automotive Applications Using Disk Laser. Arch. Mech. Technol. Autom. 2013, 33, 25–34. [Google Scholar]

- Chen, J.; Xue, L. Laser Cladding of Wear Resistant CPM 9V Tool Steel on Hardened H13 Substrate for Potential Automotive Tooling Applications. Mater. Sci. Technol. 2010, 2459–2470. [Google Scholar]

- Pereira, J.C.; Zambrano, J.C.; Tobar, M.J.; Yañez, A.; Amigó, V. High Temperature Oxidation Behavior of Laser Cladding MCrAlY Coatings on Austenitic Stainless Steel. Surf. Coat. Technol. 2015, 270, 243–248. [Google Scholar] [CrossRef]

- Rottwinkel, B.; Nölke, C.; Kaierle, S.; Wesling, V. Crack Repair of Single Crystal Turbine Blades Using Laser Cladding Technology. Procedia CIRP 2014, 22, 263–267. [Google Scholar] [CrossRef]

- Quazi, M.M.; Fazal, M.A.; Haseeb, A.S.M.A.; Yusof, F.; Masjuki, H.H.; Arslan, A. A Review to the Laser Cladding of Self-Lubricating Composite Coatings. Lasers Manuf. Mater. Process. 2016, 3, 67–99. [Google Scholar] [CrossRef]

- Bartkowski, D.; Bartkowska, A. Wear Resistance in the Soil of Stellite-6/WC Coatings Produced Using Laser Cladding Method. Int. J. Refract. Met. Hard Mater. 2017, 64, 20–26. [Google Scholar] [CrossRef]

- Singh, S.; Goyal, D.K.; Kumar, P.; Bansal, A. Influence of Laser Cladding Parameters on Slurry Erosion Performance of NiCrSiBC + 50WC Claddings. Int. J. Refract. Met. Hard Mater. 2022, 105, 105825. [Google Scholar] [CrossRef]

- Paul, C.P.; Gandhi, B.K.; Bhargava, P.; Dwivedi, D.K.; Kukreja, L.M. Cobalt-Free Laser Cladding on AISI Type 316L Stainless Steel for Improved Cavitation and Slurry Erosion Wear Behavior. J. Mater. Eng. Perform. 2014, 23, 4463–4471. [Google Scholar] [CrossRef]

- Wang, P.; Yang, Y.; Ding, G.; Qu, J.; Shao, H. Laser Cladding Coating against Erosion-Corrosion Wear and Its Application to Mining Machine Parts. Wear 1997, 209, 96–100. [Google Scholar] [CrossRef]

- Radionova, L.V.; Samodurova, M.N.; Sarafanov, A.E.; Bykov, V.A.; Glebov, L.A.; Pashkeev, K.Y. Elevation of the Wear Resistance of Roller Dies for the Production of Wires from Titanium Alloys. Metallurgist 2021, 64, 1188–1197. [Google Scholar] [CrossRef]

| Substrate/Powder | LC Parameters | Observation |

|---|---|---|

| 316L stainless steel/308 stainless steel [62] | IPG YLS—5000 fiber laser; Laser power—4000 W; Scanning speed—8 mm/s; Wire feeding speed—40 mm/s; Overlapping rate—49%; Interlayer-movement—1 mm |

|

| AISI 316L/Calmonoy 6 [63] | DAIHEN ELA-2001 axial-flow laser; Wavelength—10.6 μm; Carrier gas—Argon |

|

| AISI 316L/blend of SiC and AISI 316L [64] | Laser line diode laser; Laser power—1500W; Spot size—3.5 mm × 2 mm; Carrier gas—Argon |

|

| Bianite steel/AerMet100 steel [65] | Laser power—4000 W; Scanning speed—20 mm/s; Beam diameter—6 mm; Powder feeding rate—25 g/min; Interlayer movement—1 mm |

|

| H13 steel/austenitic aging steel [20] | Laser power—4000 W; Scanning speed—5 mm/s; Beam diameter—0.7 mm; Overlapping rate—50%; |

|

| 20G steel/Ni-Cr-Mo-W-xSi [57] | Laser power—3000 W; Scanning speed—10 cm/s; Overlapping rate—50%; Clad layer thickness—500 μm |

|

| 300 M steel/AerMet 100 steel [66] | Laser power—6400 W; Scanning speed—300 mm/min; Powder feed rate—1500 g/h; Beam diameter—8 mm; Overlapping rate—50% |

|

| U75V, U20Mn/Inconel 625 [67] | Laser power—500 W; 800 W; 1000 W; Scanning speed—3 mm/s and 6 mm/s; Powder feed rate—15 g/min; Beam diameter—8 mm |

|

| Q235 carbon steel/2205 duplex stainless [68] | Laser power—1900 W; 2100 W; 2300 W; 2500 W; Beam diameter—5 mm; Scanning speed—5 mm/s; Overlapping rate—40% |

|

| 45 steel/AISI 304 L stainless steel, 304/Al2O3 [69] |

|

|

| Low-carbon steel/316 stainless steel [70] |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

John, M.; Kuruveri, U.B.; Menezes, P.L. Laser Cladding-Based Surface Modification of Carbon Steel and High-Alloy Steel for Extreme Condition Applications. Coatings 2022, 12, 1444. https://doi.org/10.3390/coatings12101444

John M, Kuruveri UB, Menezes PL. Laser Cladding-Based Surface Modification of Carbon Steel and High-Alloy Steel for Extreme Condition Applications. Coatings. 2022; 12(10):1444. https://doi.org/10.3390/coatings12101444

Chicago/Turabian StyleJohn, Merbin, Udaya Bhat Kuruveri, and Pradeep L. Menezes. 2022. "Laser Cladding-Based Surface Modification of Carbon Steel and High-Alloy Steel for Extreme Condition Applications" Coatings 12, no. 10: 1444. https://doi.org/10.3390/coatings12101444

APA StyleJohn, M., Kuruveri, U. B., & Menezes, P. L. (2022). Laser Cladding-Based Surface Modification of Carbon Steel and High-Alloy Steel for Extreme Condition Applications. Coatings, 12(10), 1444. https://doi.org/10.3390/coatings12101444