3.1. EB Modified Surface Topography and Microstructure

Figure 4a,b show the 3D topographic images and profile analysis of the micro-grooves (G; G1 hatch spacing 100 μm, G2 hatch spacing 200 μm) and the lined up unit cells of the bridge structures (B; B1 hatch spacing 100 μm, B2 hatch spacing 200 μm), respectively. Notice that the longitudinal, transversal and vertical directions were labelled (LD, TD and VD, respectively), the LD direction being the main direction of the structures: parallel to the micro-grooves in G1 and G2; and parallel to the central line of the bridges in B1 and B2. The TD profiles taken for the G1 and G2 specimens (

Figure 4a) are shown in

Figure 4c. It can be seen in both cases the 100 and 200 μm spacing between the micro-grooves in agreement with the design. A peak profile was found for the G1 specimen, while it had an asymmetric wave-like shape in the G2 specimen with a total height of almost half of that of the G1 profile. According to the literature [

19,

20,

21], the main influence on the total height of the protrusion is the beam current, i.e., an increase in the beam current directly leads to an increase in the height of the protrusion, although the scan frequency also has an influence. While Tändl and Enzinger [

21] observed that a decrease in the scan frequency leads to an increase in the height, Wang et al. [

19] found that such a decrease does not necessarily lead to an increase in the height and that there is a more complex relationship to the formation of protrusions; i.e., if the parameter combination is chosen such that the liquid metal reaches a certain high temperature with a low viscosity, the interaction of the surface tension and vapor pressure no longer contributes much to the formation of the protrusions. This may be the case in the present study because, although the scan frequency was lower in G2 compared with G1, the local energy input (heat input) was twice as high. As a result of the greater heat input, the molten metal downstream of the beam remained at a relatively high temperature for an extended period of time, so that it did not have a sufficient amount of time to cool and had not effectively piled up. The protrusions were wider rather than taller as the increase in the heat input resulted in a wider single bead width, which is also consistent with the literature [

20]. Additionally, the lateral dimensions of the single-bead lines in G2 were larger than the spacing between the subsequent lines, thus displacing the material from the previous lines, while the G1 strategy allowed for the accumulation of the material more effectively, despite the lower input energy (

Figure 4c).

The surface descriptors obtained from the 3D optical metrology of the representative areas for each structure are presented in

Table 2. The G1 structure produced a rougher surface than the G2 structure, with a larger S10z in correlation with the profiles shown in

Figure 4. The effective area of the G1 specimen was increased by 14%, while one of the G2 surfaces was increased by only 2.2%. The S

ku parameter indicated the roundness of both surfaces (S

ku < 3). On the other hand, the S

sk parameter indicated that the G1 surface had an even distribution of the peaks and valleys (S

sk near 0) while the valleys dominated the G2 surface, related to shape (S

sk < 0). It could be concluded that the G1 surface structuring was optimal in terms of the line spacing and input energy to produce a regular micro-groove topography with evenly distributed rounded peaks and valleys.

Figure 4b shows the 3D topographic image of the B2 sample. The profile plots in

Figure 4d correspond to the TD profiles of both the B1 and B2 specimens. The LD profiles for both B1 and B2 along the lines indicated as A and B in

Figure 4d are shown in

Figure 4e. The LD profiles along line C in

Figure 4e for both B1 and B2 are shown in

Figure 4f. It could be seen that both B1 and B2 consisted of a central structure, i.e., a bridge, with a total height of ~220 μm and ~350 μm, respectively. The bridges were spaced by ~5 mm in agreement with the design. It is worth noticing that the structures were not symmetrical in the TD, having a sharp valley at one end of each bridge (indicated with the arrows in

Figure 4d). This was due to the overlap of the bridges, i.e., a consecutive bridge removed the material from the previous one. It indicates that a further bridge width and spacing optimization would be necessary.

The LD profiles (

Figure 4e,f) revealed that micro-grooves in the TD were formed while maintaining the 100 and 200 μm spacing distances. These were more regular at the sides of the bridges (the B and C profiles) than at the top (the A profiles), where the surface was irregular. It was also observed that their total height increased towards the edges of the bridge (

Table 2).

The roughness parameters of the B1 and B2 samples in

Table 2 correspond primarily to the bridge structures. There was an increase in the area ratio, S

a, S

q and S

10z in the B2 specimen with respect to the B1 sample due to the larger amount of material which accumulated at the top part of the bridge because of the higher input energy (

Table 1,

Figure 4).

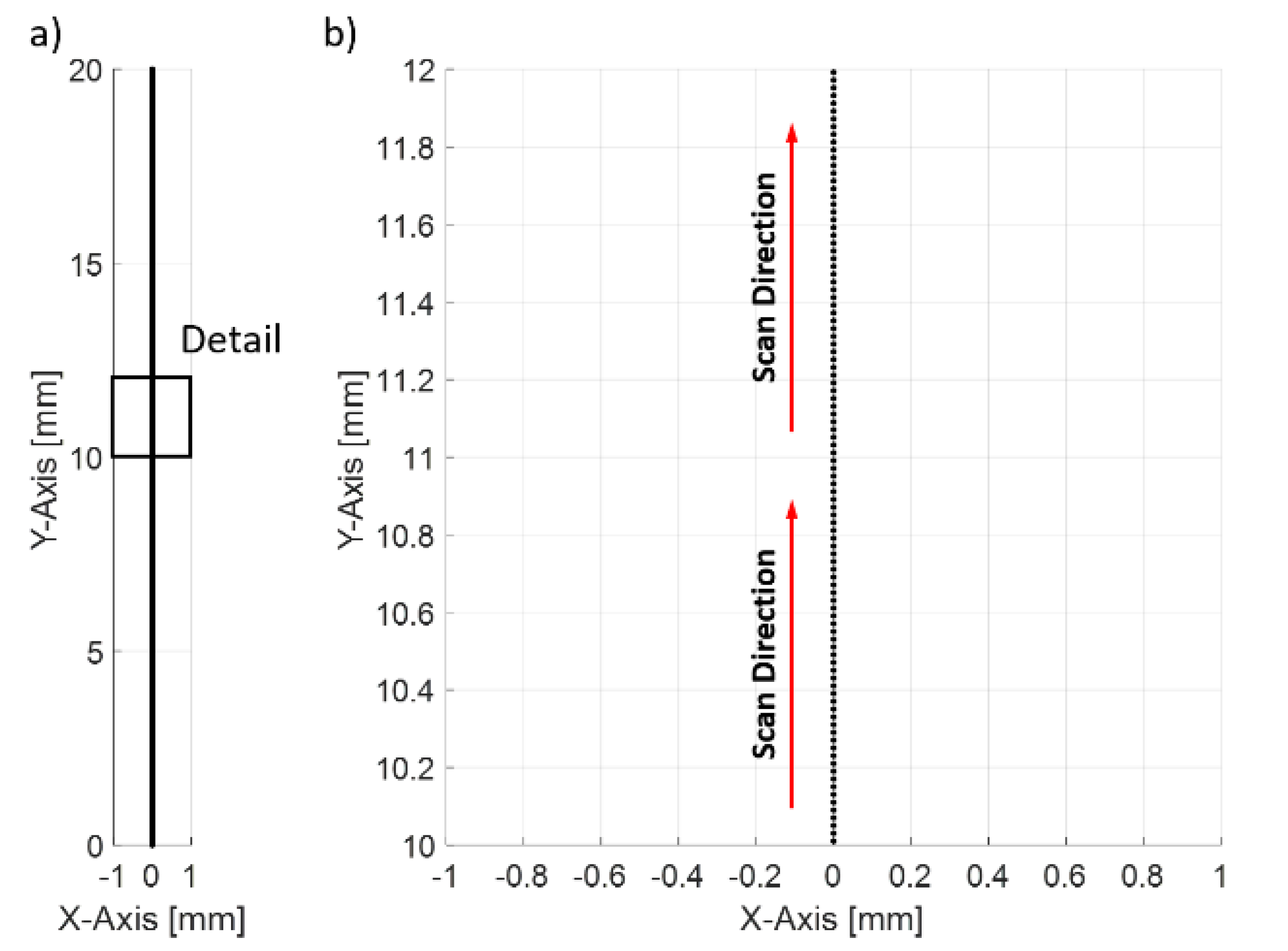

Considering the profiles shown in 4c (grooves) and 4e (bridge–position B), a similar height of the grooves for G2 (scan speed 500 mm/s and energy input 480 J/m), B1 (scan speed 500 mm/s, energy input 480 J/m) and B2 (scan speed 250 mm/s, energy input 960 J/m) can be observed. This confirms previous indications which showed that with a higher energy/heat input, the height of the grooves cannot be further increased. This is unlike the low heat input G1 (scan speed 1000 mm/s, energy input 240 J/m), which has a groove height twice as large. In addition to the formation of the microgrooves, there is also a macroscopic displacement of material: (1) for the grooves from one side to the other (

Figure 2c), since the deflection of the beam is unidirectional, and (2) for the bridge in the center (

Figure 3d), since the beam travels alternately. The amount of locally melted material can be related to the heat input, i.e., the higher the energy input, the more material which is melted and macroscopically displaced. This is of particular interest for the bridge structure, since the alternating beam travel causes the material in the centerline to be piled up from both sides. Consequently, for the higher energy input B2, a more pronounced macroscopic material displacement can be observed in the center (

Figure 4d).

Figure 5 shows the SEM images of the bare EB specimens and cross-sections.

Figure 5a,b shows the surface and cross-section of the M sample where a typical α’ martensitic microstructure was found within the prior β grains due to the rapid solidification that contrasts, with respect to the initial equiaxed α + β microstructure of the Ti6Al4V alloy (

Figure 5c). The relief formed at the surface by the grain boundaries and α’ needles was due to the solidification in a vacuum, as described by Ferraris et al. [

12].

Figure 5d,g,j,m demonstrates that the EB structuring was successful in producing reproducible micro-grooves with the hatch distance being set by the design in each case. These figures also shown that while the micro-grooves in G1 and G2 had a linear shape, these were curved in the B1 and B2 due to the different deflection and velocity of the beam. Images 5e, h, k and n show that the relief on the surface observed in image 5a was also replicated in the structured samples. Similarly, the α’ martensitic microstructure was seen in the cross-section of these samples (

Figure 5f,i,l,o).

3.4. Electrochemical Response

Figure 13 presents the OCP evolution during 1 h of immersion time before the potentiodynamic polarization of the non-treated and PEO-treated specimens. The non-treated samples had negative OCP values, while the PEO-treated samples showed higher values. Among the non-treated specimens, the EB-structured surfaces presented more negative OCPs.

Figure 14 presents the polarization curves of the non-treated and PEO-treated specimens. The corrosion potentials and current densities (E

corr and i

corr, respectively, obtained by Tafel extrapolation) as well as the initial potentials and currents of the passive segments (E

pass and i

pass) are given in

Table 7. The non-treated specimens showed a negative E

corr close to those shown during the OCP measurements, making the M specimen the noblest. The i

corr was one order of magnitude higher in the structured samples, with respect to the molten surface. In turn, the corrosion rates of the bare structured specimens were found to be one order of magnitude higher (1.1–3.4 μm/year), with respect to the molten surface (0.1 μm/year). At the same time, the polarization resistance decreased one order of magnitude for the groove and bridge structures. I

corr and CR were greater and the R

p was lower for the bare bridge structures than for the groove structures, indicating a correlation with larger surface features. These effects may be assigned to defects within the natural passive oxide layer. It may be assumed that this layer was homogeneous and compact on the flat molten surface while it became more defective due to tensile stresses at the top of the convex features, such as peaks in the grooves’ specimens and the top and the sharp edges of the bridge structures. Nevertheless, it is worth recalling that all the specimens presented a passive behavior.

The molten surface presented a passive region at 4.81 × 10−7 A·cm−2 above 0.6 V. A second passivation region beyond 1.3 V at about 1.5 × 10−6 A·cm−2 was observed, which extended above 3 V. The bare structured specimens had similar passivation regions (1 ÷ 2 × 10−6 A·cm−2) above ~0.1 V. All the EB-structured samples presented a sudden increase in current density beyond 10−5 A·cm−2, which was related to localized crevice corrosion, as demonstrated by the post-mortem analysis of the tested samples.

The 3D optical topographic images of the micro-canal specimens presented in

Figure 15 show that the initiation of the localized crevice corrosion started under the resin mask and spread laterally underneath it, reaching the nearby canals and advancing along the micro-canals (

Figure 15a, image taken on a sample right after the initiation of the current density increase). For longer immersion times, the corrosion region spread laterally to several micro-canals at the initiation point and at the exposed surface near the resin (

Figure 15b). At the same time, the corrosion advanced further along the micro-canals (

Figure 15c). In the case of the bridge structures (

Figure 16), crevice corrosion initiated at the overlapping areas beneath the resin. In this case, the corrosion spread laterally towards the outer parts of the bridge only at the initiation point (

Figure 16a), while within the exposed area of the surface, the corrosion advanced exclusively along the overlapping area (

Figure 16b). The formation of a loosely adherent light-brown gel on the surface accompanied the crevice corrosion.

The crevice corrosion takes place within the restricted volumes where oxidizing species, such as dissolved O

2, are consumed faster than what is replenished from the bulk solution, preventing the formation of new oxide. This situation also involves low pH levels with the hydrolysis of titanium chlorides that form hydrochloric acid and Ti hydroxides (Ti(OH)

x(4−x)), among other products [

25,

26,

27], and the generation of an electrochemical microcell between the crevice becomes the anode and the outer exposed surface becomes the cathode.

Such a localized corrosion has been reported previously in the literature which dealt with the electrochemical behavior of the DMLS Ti6Al4V pins, where the crevice corrosion appeared at the superficial porosity and imperfections [

25]. The Ti6Al4V alloys manufactured by laser-based powder bed fusion are characterized by an

α’/

α martensitic microstructure similar to the one formed in EB structures. Additionally, the formation of a light-brown gel was also reported and assigned to TiO

2·H

2O and TiO

3·H

2O, which presents a higher solubility and a worse adherence than TiO

2. The remnants of these oxides were observed to be adhered to the specimens shown in

Figure 15 and

Figure 16. It might be hypothesized that such products and oxides formed within the crevice extended outside the crevice and along the micro-canals and overlapping area, occluding these valleys and leading to under deposit corrosion.

Additional PDP tests were carried out on M specimens at the pH values of 7.5, 3.6 and 2 (

Figure 17). Localized corrosion, or any other type of corrosion whatsoever, was not observed in these specimens. This indicates that the consumption of the oxidizing species (i.e., dissolved O

2) within the restricted volume played a more dominant role in the localized crevice corrosion of EB-treated specimens than low pH levels.

Finally, a crevice appeared between 1 and 2 V for the G1 and B1 specimens and between 2.5 and 3 V for the G2 and B2 samples, indicating a correlation between the crevice potential and the hatch spacing. It is believed that is related to a greater number of possible crevice locations in G1 and B1, hence increasing the chances for localized corrosion.

All the PEO-treated specimens presented an identical electrochemical behavior with positive E

corr (~0.1 V) values, slightly lower than those of the OCP recorded. This shift is commonly observed for titanium and is related to the charging process of the electrode/solution interface capacitance. Despite the relatively slow scan rate used in this study (0.5 mV/s), which is a well-known strategy for minimizing this artefact [

28], PEO-treated specimens, unlike bare substrates, showed a sufficiently high charging current to shift the E

corr to significantly lower values than the OCP. The icorr values were found in the range between 2.5 and 4.5 × 10

−8 A·cm

−2, which are in agreement with the values reported for the PEO coatings on the AM Ti6A4V alloys in the biological media [

29]. The i

corr of the PEO-treated specimens was one order of magnitude higher than that of the bare molten surface and of the same order in comparison to the groove and bridge structures. This can be assigned to the microstructure of the inner barrier-like layer of the PEO coatings that is in intimate contact with the substrate. Such a layer is known to contain nano-pores that might explain the higher icorr and CR and lower Rp with respect to the molten surface. Nevertheless, these specimens presented a strong passive behavior and passive current densities lower than those of the un-treated specimens. All the samples reached a passive region at about 0.25 V (E

pass) and a passive current (i

pass) of ~8.83 × 10

−8 A·cm

−2. Up to 1.3 V, the current density decreased to 3.18 × 10

−8 A·cm

−2. Finally, the current density of the PEO-treated specimens increased rapidly beyond 1.5 V due to the oxygen evolution.

As a concluding remark, unlike the untreated structured surfaces, the PEO-treated samples did not reveal any sign of crevice corrosion. It would therefore be recommended that EB-structured Ti surfaces were treated via PEO to avoid this issue while enhancing the osteoconductivity of the surface.