A Split-Ring Resonator-Loaded Honeycomb Sandwich Structure for Broadband Microwave Absorption

Abstract

1. Introduction

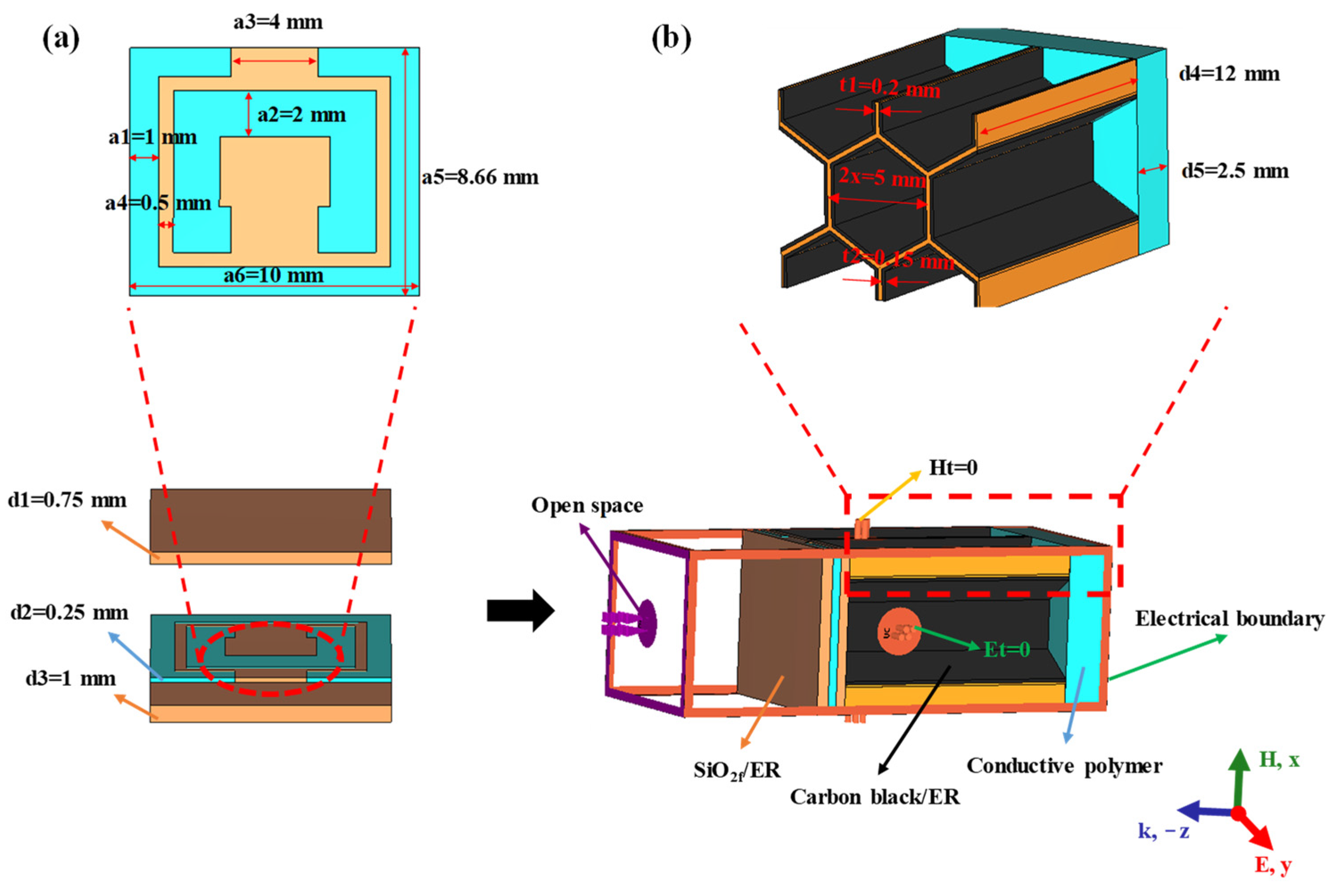

2. Experiment and Simulation Method

2.1. Material Fabrication

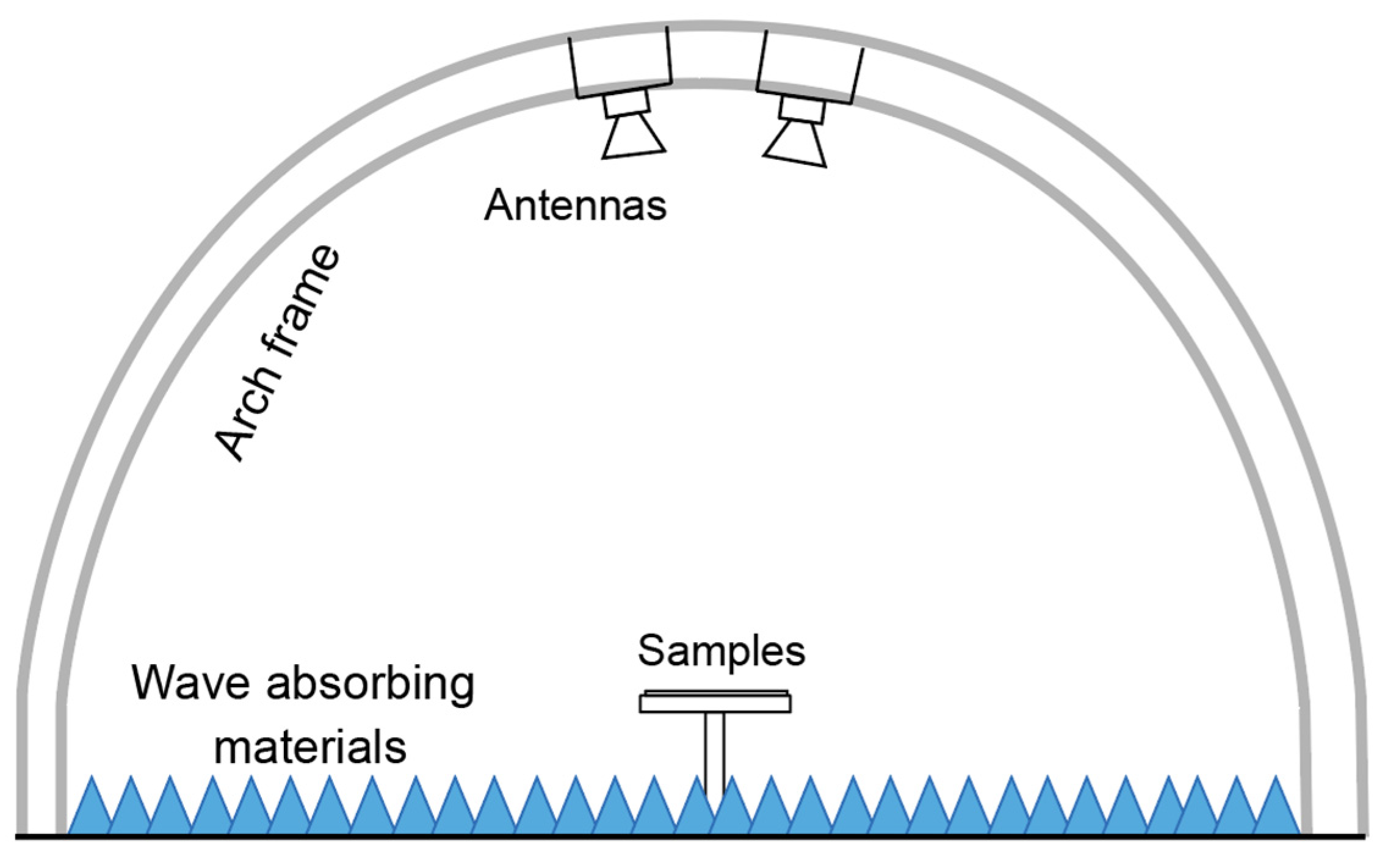

2.2. Characterization, Simulation and Calculation

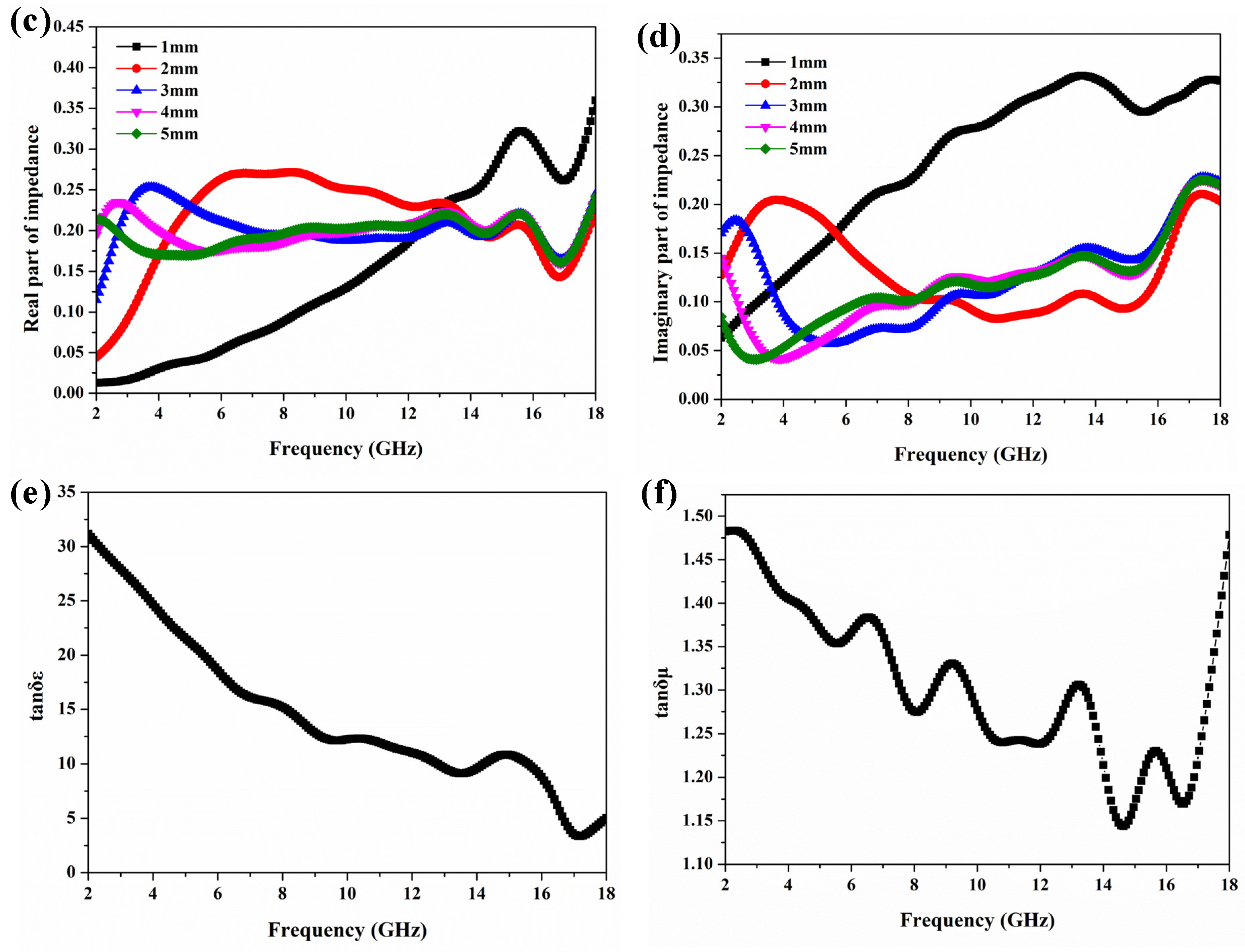

3. Results and Discussion

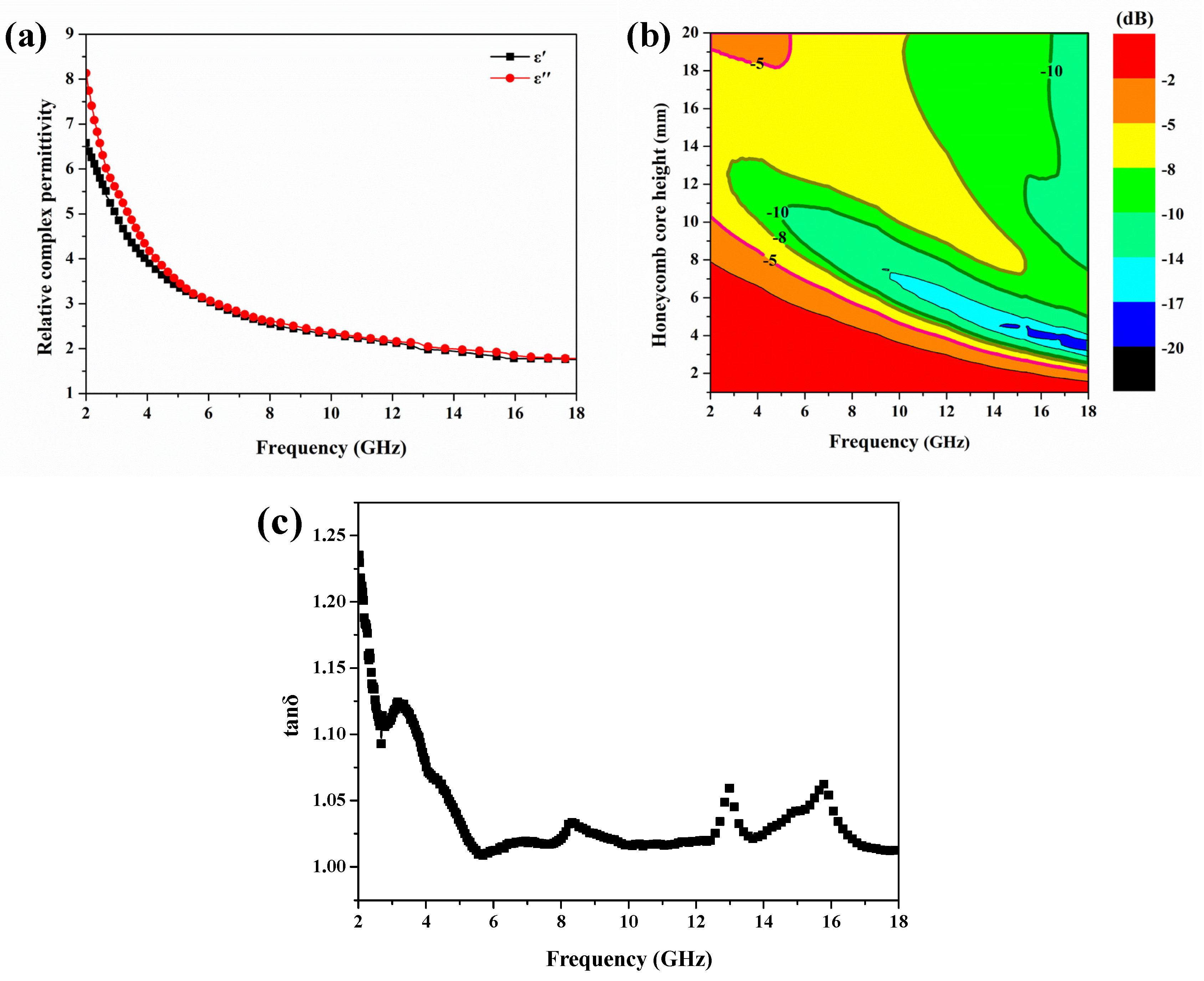

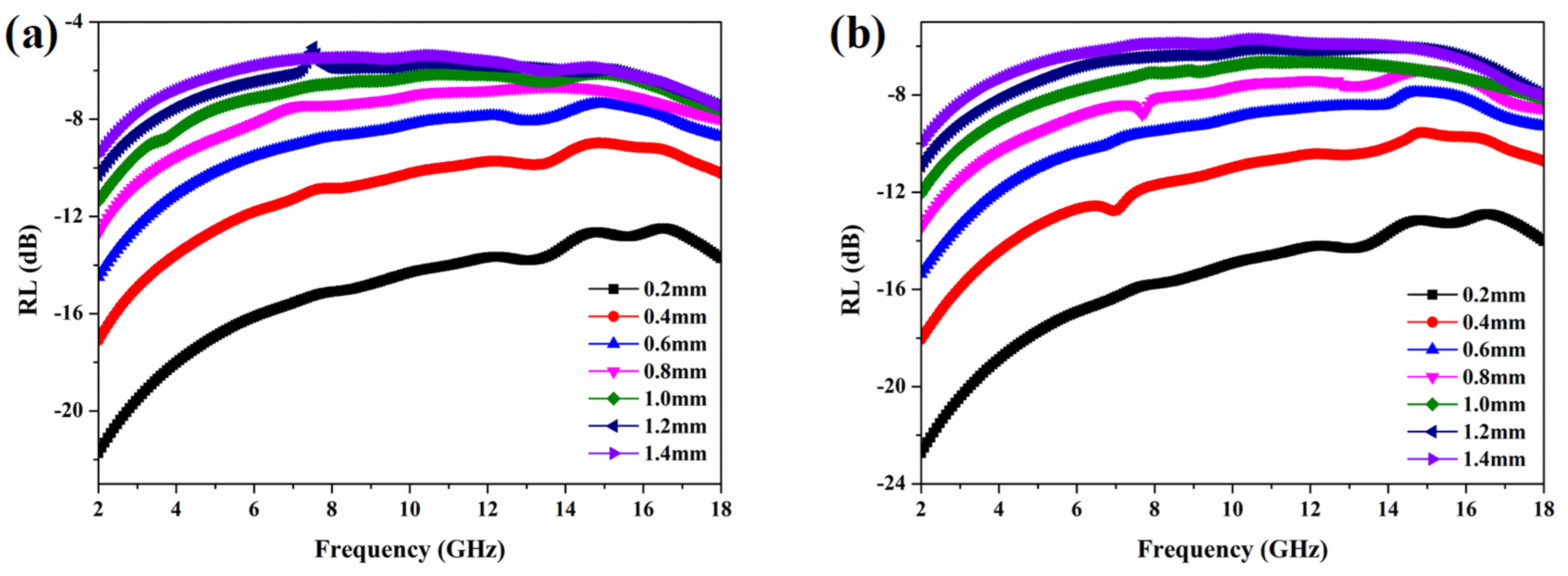

3.1. Microwave Absorption Efficiency of Honeycomb with Carbon Black/ER Coating

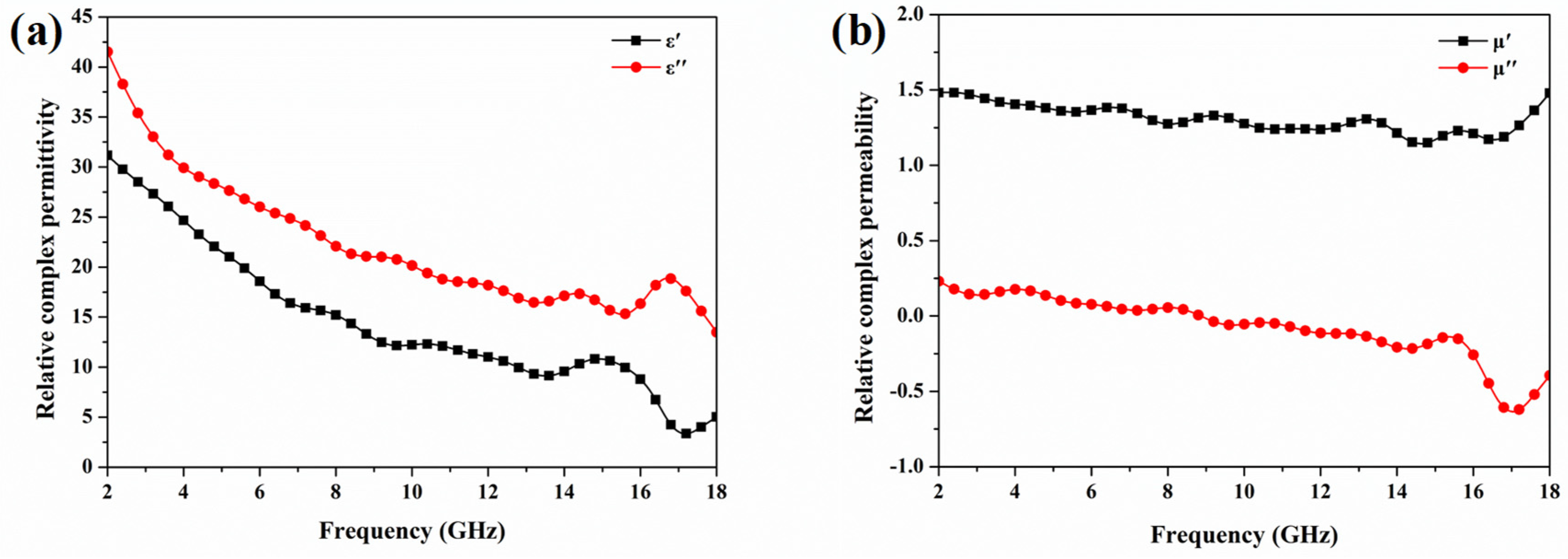

3.2. Microwave Absorption Efficiency of Honeycomb with Bottom Panel Layer

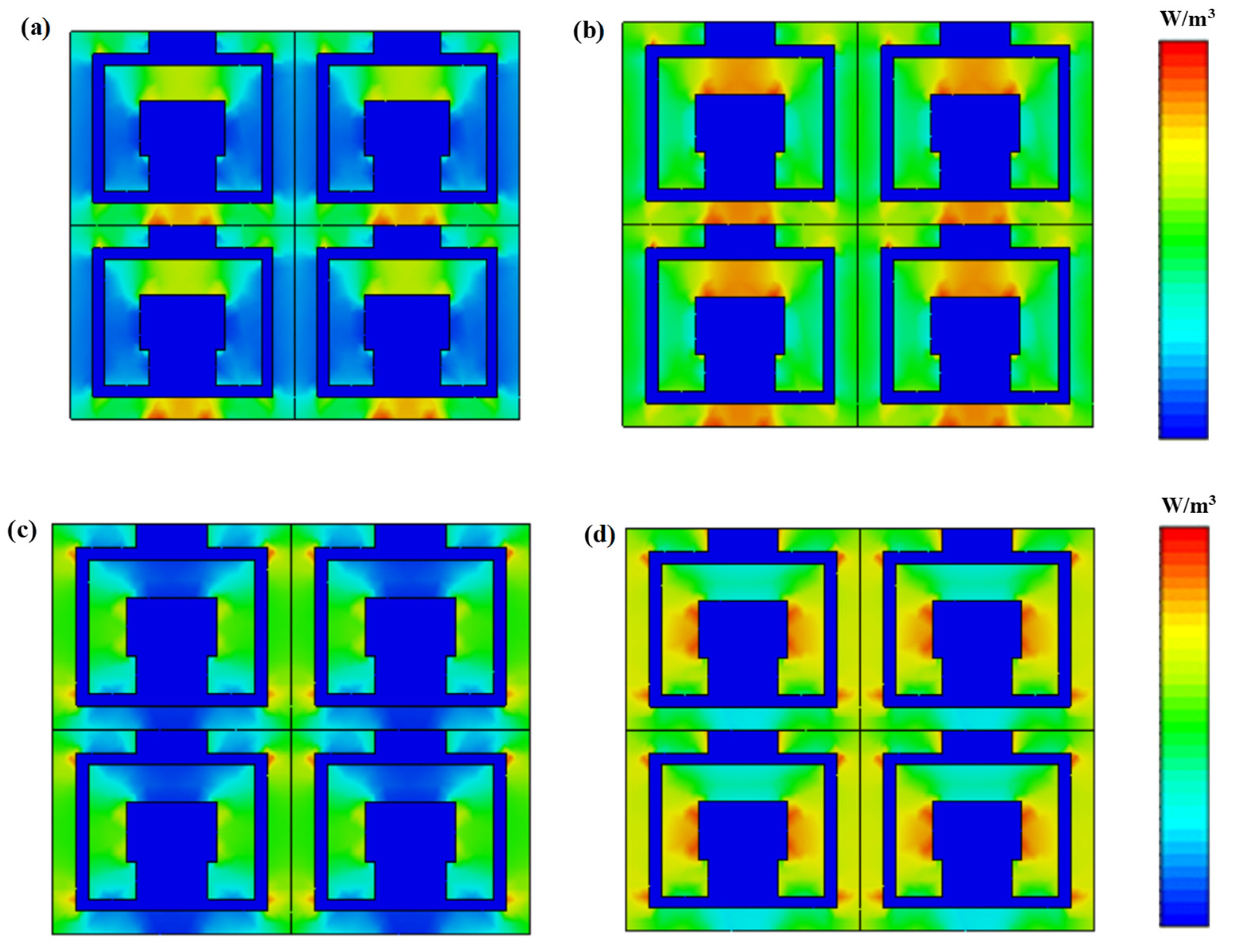

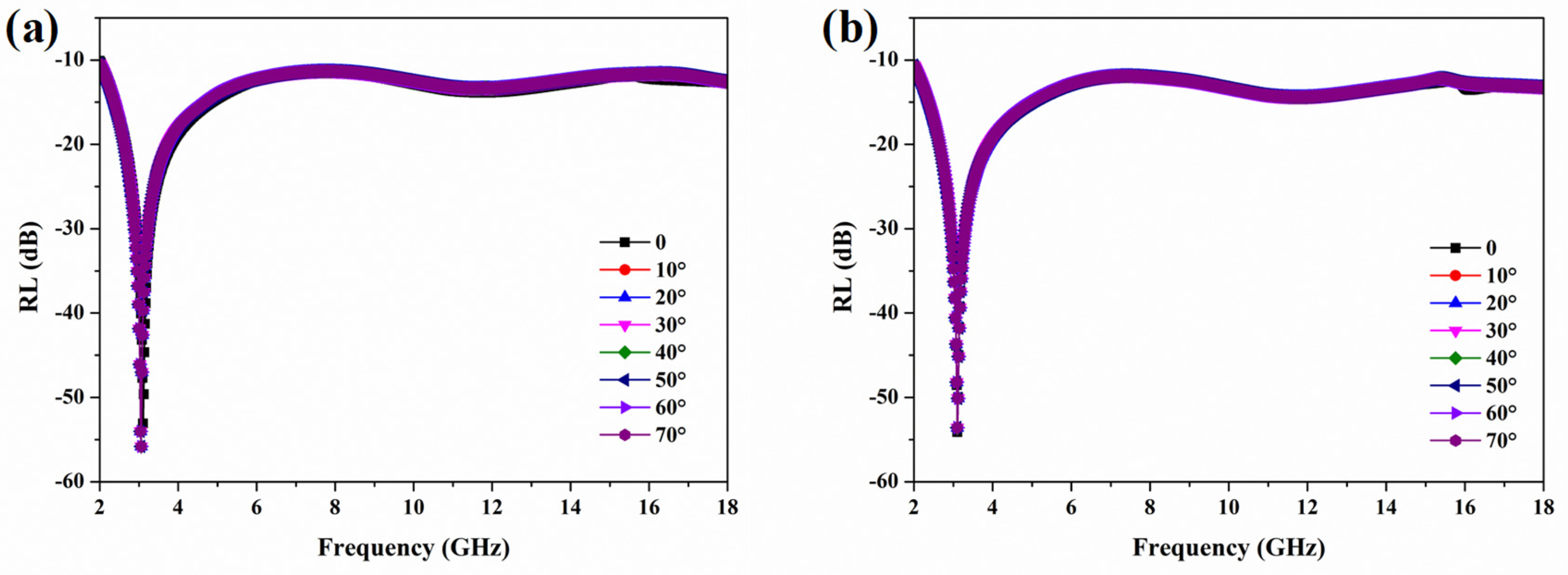

3.3. Microwave Absorption of Split-Ring Resonator-Loaded Honeycomb Sandwich Structure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, Y.; Shan, Y.; Ji, G.; Sun, Y.; Shi, W.; Li, M. Enhanced Microwave-Absorbing Property of Honeycomb Sandwich Structure with a Significant Interface Effect. Materials 2022, 15, 5741. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Wu, D.; Chen, M.; Zhang, K.; Fang, D. Evolutionary Optimization Design of Honeycomb Metastructure with Effective Mechanical Resistance and Broadband Microwave Absorption. Carbon 2021, 177, 79–89. [Google Scholar] [CrossRef]

- Micheli, D.; Vricella, A.; Pastore, R.; Marchetti, M. Synthesis and Electromagnetic Characterization of Frequency Selective Radar Absorbing Materials Using Carbon Nanopowders. Carbon 2014, 77, 756–774. [Google Scholar] [CrossRef]

- Sheffield, R.G. Official F-19 Stealth Fighter Handbook; Compute: New York, NY, USA, 1989. [Google Scholar]

- Zhou, Q.; Xue, B.; Sg, A.; Gu, S.; Ye, F.; Fan, X. Ultra Broadband Electromagnetic Wave Absorbing and Scattering Properties of Flexible Sandwich Cylindrical Water-based Metamaterials. Res. Phys. 2022, 38, 105587. [Google Scholar] [CrossRef]

- Zainud-Deen, S.H.; Malhat, H.A.; Shabayek, N.A. Reconfigurable RCS Reduction from Curved Structures Using Plasma Based FSS. Plasmonics 2020, 15, 341–350. [Google Scholar] [CrossRef]

- Yin, X.; Kong, L.; Zhang, L.; Cheng, L. Electromagnetic Properties of Si-C-N Based Ceramics and Composites. Int. Mater. 2014, 59, 326–355. [Google Scholar] [CrossRef]

- Chen, X.; Wu, Y.; Gu, W.; Zhou, M.; Tang, S. Research Progress on Nanostructure Design and Composition Regulation of Carbon Spheres for the Microwave Absorption. Carbon 2022, 189, 617–633. [Google Scholar] [CrossRef]

- Liu, Q.; Zeng, M.; Liu, J. Fe-based Material@N-doped Carbon Composites as Environment-Friendly Microwave Absorbers. Carbon 2021, 171, 646–657. [Google Scholar] [CrossRef]

- Zhang, B.; Mahariq, B.; Tran, N. Enhanced Electromagnetic Wave Dissipation Features of Magnetic Ni Microspheres by Developing Core-Double Shells Structure. Ceram. Int. 2022, 48, 446–454. [Google Scholar] [CrossRef]

- Min, Y.L.; Choi, Y.L.; Woo, H.J.; Sang, W.K. Microwave Absorption Properties of Ni0.6Zn0.4Fe2O4 Composites with Nonmagnetic Nanoferrite Percentages. Ceram. Int. 2022, 48, 20187–20193. [Google Scholar]

- Zeng, M.; Cao, Q.; Liu, J.; Guo, B.; Hao, X.; Liu, Q. Hierarchical Cobalt Selenides as Highly Efficient Microwave Absorbers with Tunable Frequency Response. ACS Appl. Mater. Interfaces 2020, 12, 1222–1231. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, Q.; Sun, Y. A Frequency Selective Surface Loaded Two-Layer Composite for Tunable Microwave Absorption. Mater. Res. Express 2022, 9, 066301. [Google Scholar] [CrossRef]

- Yadav, R.; Panwar, R. Effective Medium Approximation Fused Optimization Strategy Derived New Kind of Honeycomb Microwave Absorbing Structure. IEEE Trans. Magn. 2022, 58, 2501311. [Google Scholar] [CrossRef]

- Baek, S.M.; Lee, W.J.; Kim, S.Y.; Kim, S.S. A Study on the Microwave Absorbing Honeycomb Core Embedded with Conductive Periodic Patterned Surfaces for the Effective Dielectric Constant. Compos. Struct. 2022, 289, 115471. [Google Scholar] [CrossRef]

- Pang, H.; Duan, Y.; Dai, Y. The Electromagnetic Response of Composition-Regulated Honeycomb Structural Materials used for Broadband Microwave Absorption. J. Mater. Sci. Technol. 2021, 88, 203–214. [Google Scholar] [CrossRef]

- He, F.; Si, K.; Zha, D.; Li, R.; Jiang, J. Broadband Microwave Absorption Properties of a Frequency-Selective Surface Embedded in a Patterned Honeycomb Absorber. IEEE Trans. Electromagn. Compat. 2021, 63, 1290–1294. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, J.; Xu, J. Electromagnetic and Microwave Absorption Properties of Ti3SiC2/AgNWs/ Acrylic Acid Resin Composite Coatings with FSS Incorporation. J. Alloys Compd. 2022, 899, 163327. [Google Scholar] [CrossRef]

- Miles, P.A.; Westphal, W.B.; Von Hippel, A. Dielectric Spectroscopy of Ferromagnetic Semiconductors. Rev. Mod. Phys. 1957, 29, 279–307. [Google Scholar] [CrossRef]

- Naito, Y.; Suetake, K. Application of Ferrite to Electromagnetic Wave Absorber and its Characteristics. IEEE Trans. Microw. Theory Tech. 1971, 19, 65–71. [Google Scholar] [CrossRef]

- Smith, D.R.; Schultz, S.; Markos, P. Determination of Effective Permittivity and Permeability of Metamaterials from Reflection and Transmission Coefficients. Phys. Rev. B 2001, 65, 195104. [Google Scholar] [CrossRef]

- Koschny, T.; Markos, P.; Smith, D.R. Resonant and Antiresonant Frequency Dependence of the Effective Parameters of Metamaterials. Phys. Rev. E 2003, 68, 065602. [Google Scholar] [CrossRef] [PubMed]

- Linden, S.; Enkrich, C.; Wegener, M. Magnetic Response of Metamaterials at 100 Terahertz. Science 2004, 306, 1351–1353. [Google Scholar] [CrossRef] [PubMed]

- Katsarakis, N.; Koschny, T.; Kafesaki, M.; Economou, N.E. Electric Coupling to the Magnetic Resonance of Split Ring Resonators. Appl. Phys. Lett. 2004, 84, 2943–2945. [Google Scholar] [CrossRef]

| Frequency Ranges (GHz) | Dimensions of Samples (mm) |

|---|---|

| 1.72–2.61 | 54.46 × 108.92 × (8.0–12.0) |

| 2.60–3.95 | 33.89 × 71.84 × (8.0–12.0) |

| 3.94–5.99 | 22.0 × 47.25 × (8.0–12.0) |

| 5.38–8.2 | 15.75 × 34.70 × (2.0–6.0) |

| 8.2–12.4 | 22.9 × 10.2 × (2.0–6.0) |

| 12.4–18 | 15.9 × 8.03 × (2.0–4.0) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Liu, Q.; Xu, Z.; Ji, G.; Mo, R. A Split-Ring Resonator-Loaded Honeycomb Sandwich Structure for Broadband Microwave Absorption. Coatings 2022, 12, 1706. https://doi.org/10.3390/coatings12111706

Zhao Y, Liu Q, Xu Z, Ji G, Mo R. A Split-Ring Resonator-Loaded Honeycomb Sandwich Structure for Broadband Microwave Absorption. Coatings. 2022; 12(11):1706. https://doi.org/10.3390/coatings12111706

Chicago/Turabian StyleZhao, Yiming, Qingwei Liu, Zhonghao Xu, Guoliang Ji, and Ran Mo. 2022. "A Split-Ring Resonator-Loaded Honeycomb Sandwich Structure for Broadband Microwave Absorption" Coatings 12, no. 11: 1706. https://doi.org/10.3390/coatings12111706

APA StyleZhao, Y., Liu, Q., Xu, Z., Ji, G., & Mo, R. (2022). A Split-Ring Resonator-Loaded Honeycomb Sandwich Structure for Broadband Microwave Absorption. Coatings, 12(11), 1706. https://doi.org/10.3390/coatings12111706