The Array of Si Nanowires Covered with Ag Nanoparticles by ALD: Fabrication Process and Optical Properties

Abstract

:1. Introduction

2. Materials and Methods

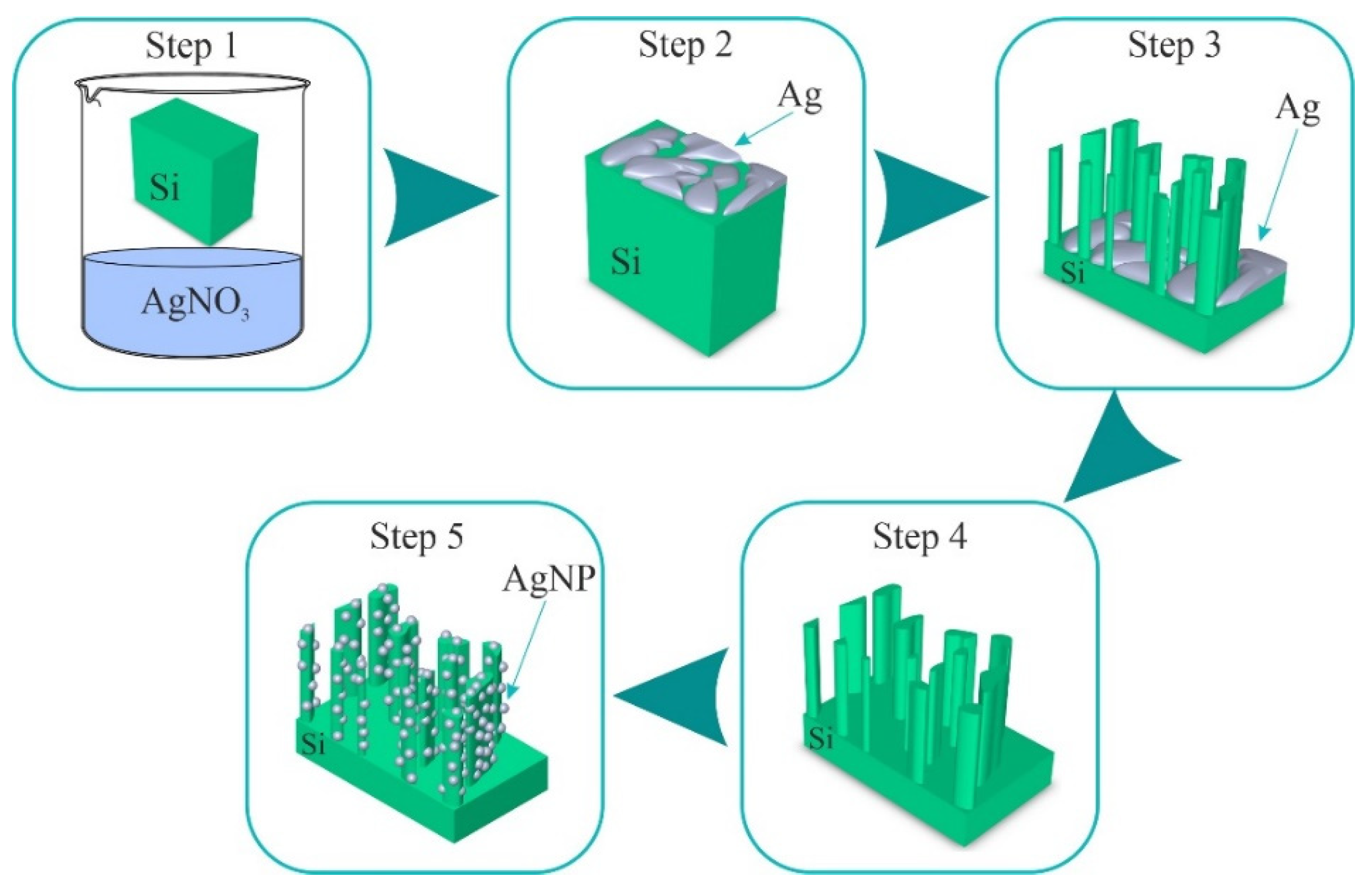

2.1. Fabrication of SiNWs

2.2. Precipitation of AgNPs by ALD Method

2.3. Scanning Electron Microscopy (SEM)

2.4. X-ray Photoelectron Spectroscopy (XPS)

2.5. Spectroscopic Ellipsometry

2.6. Simulation of Electromagnetic Field Enhancement in a Composite Structure

3. Results and Discussions

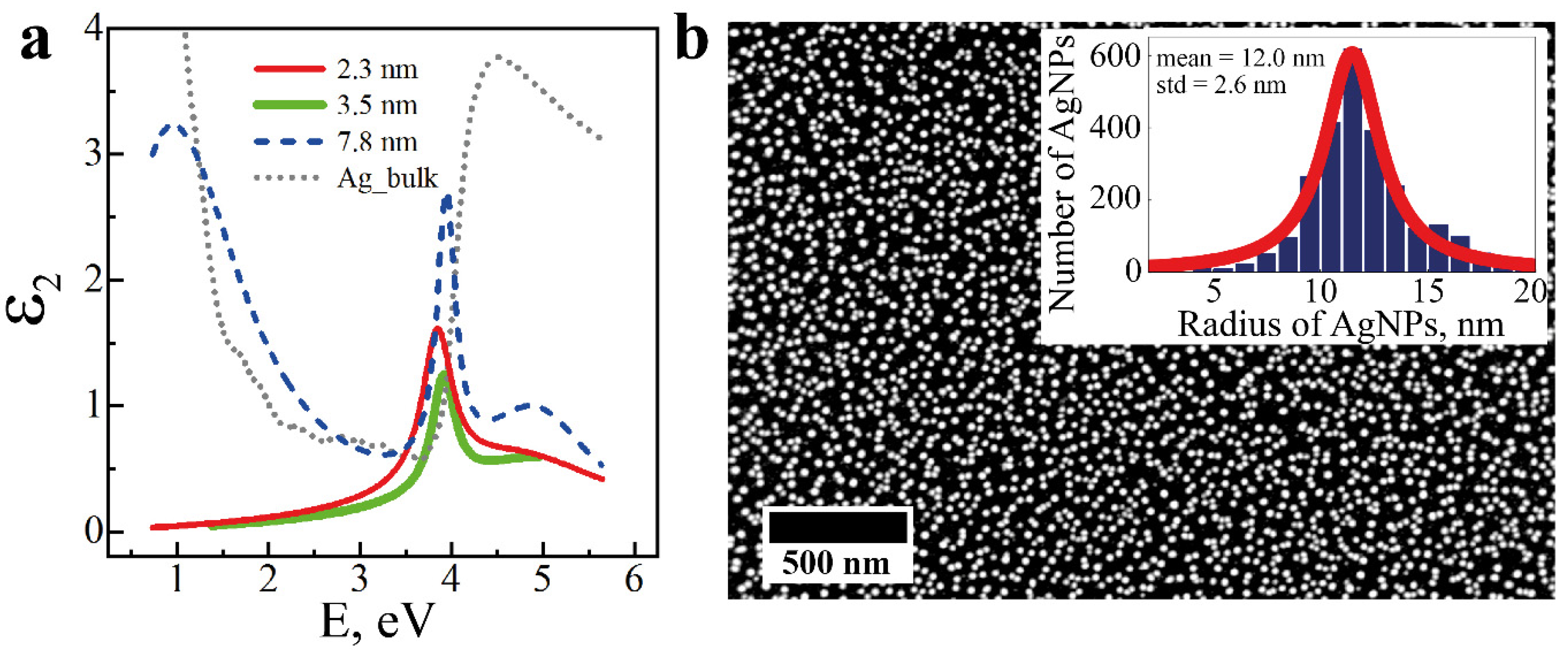

3.1. Fabrication Conditions of the AgNP Layers on the Si Wafer Surface Using ALD

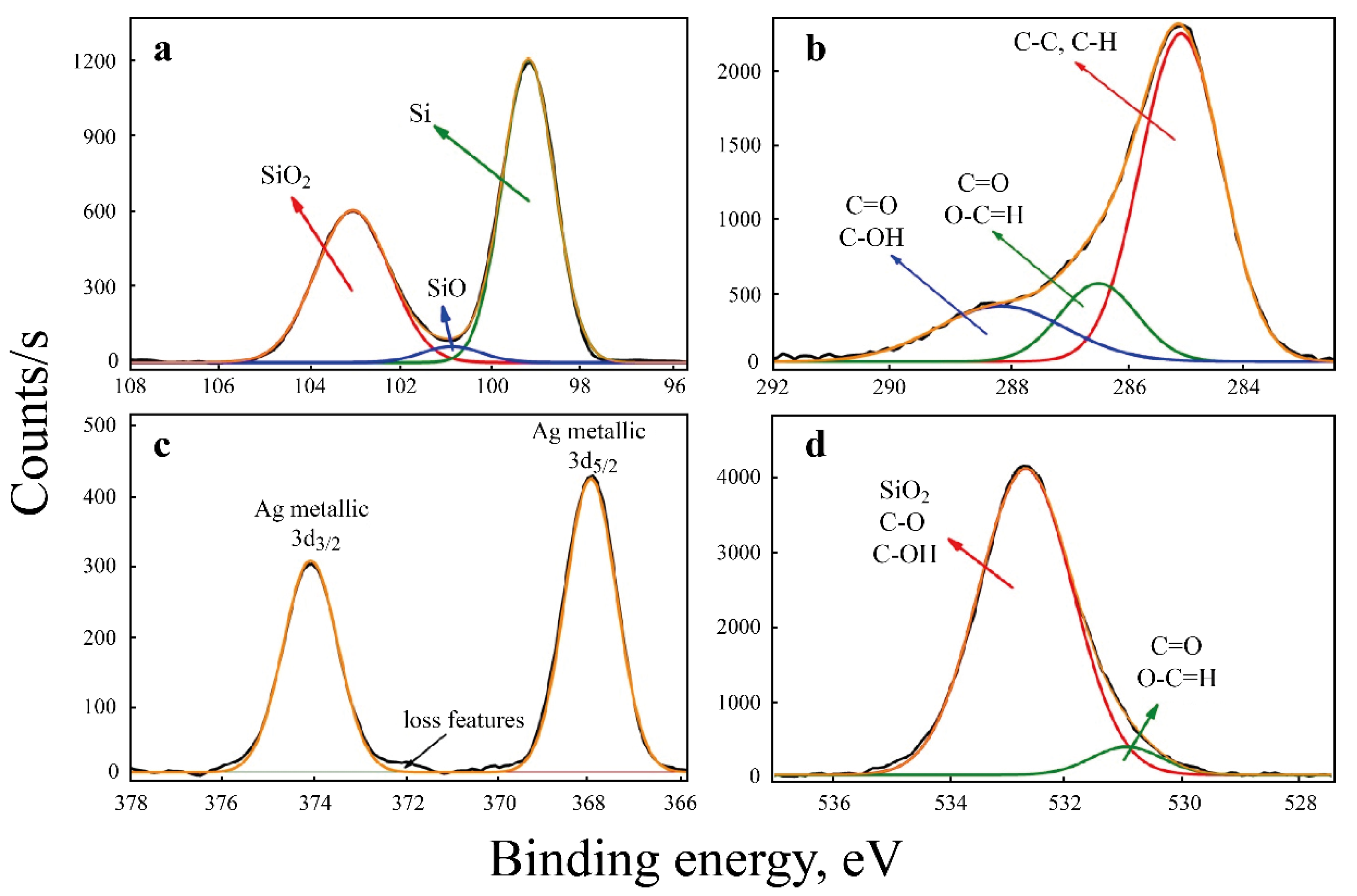

3.2. Study of the Chemical Composition of the AgNPs Layer Using XPS

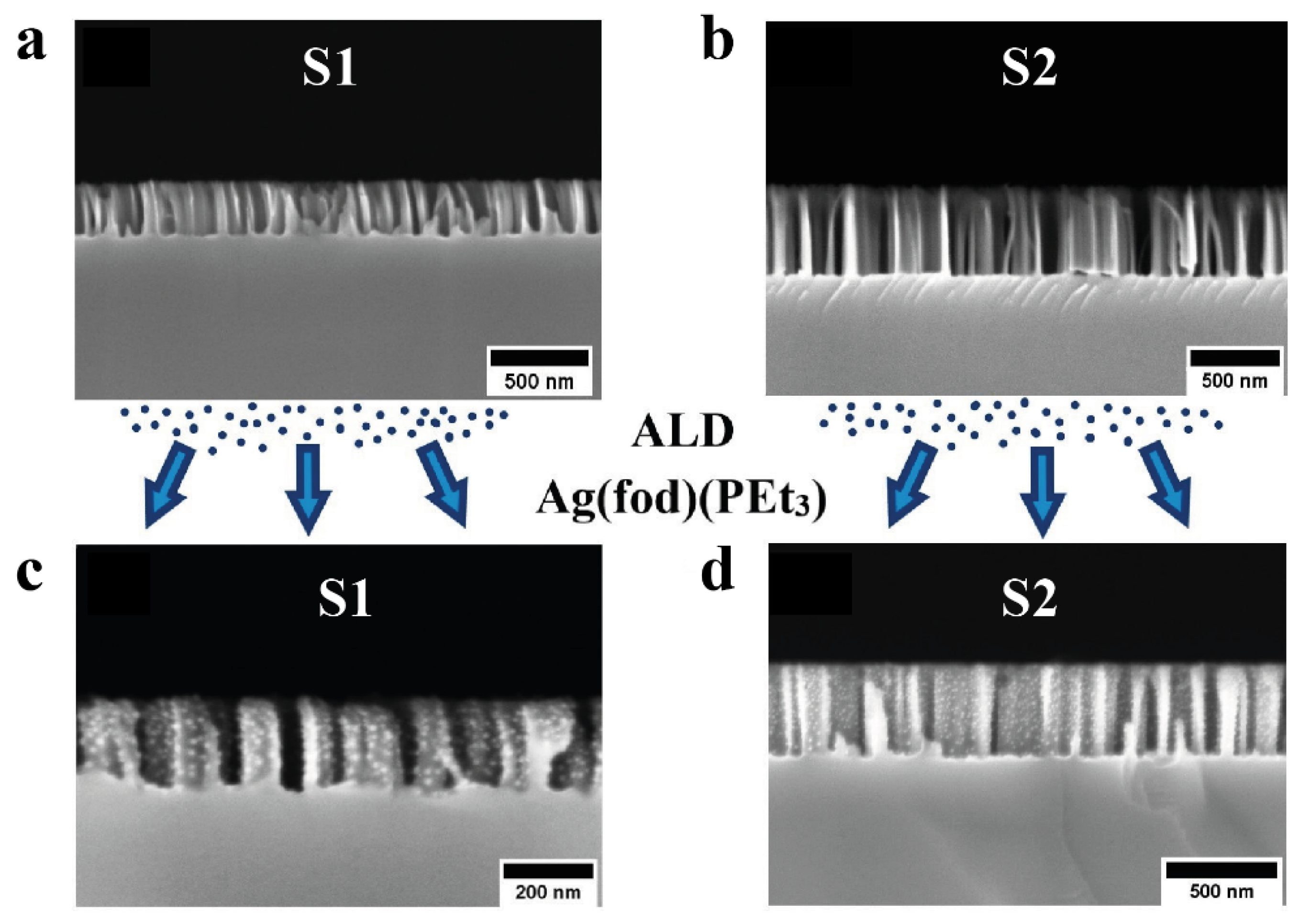

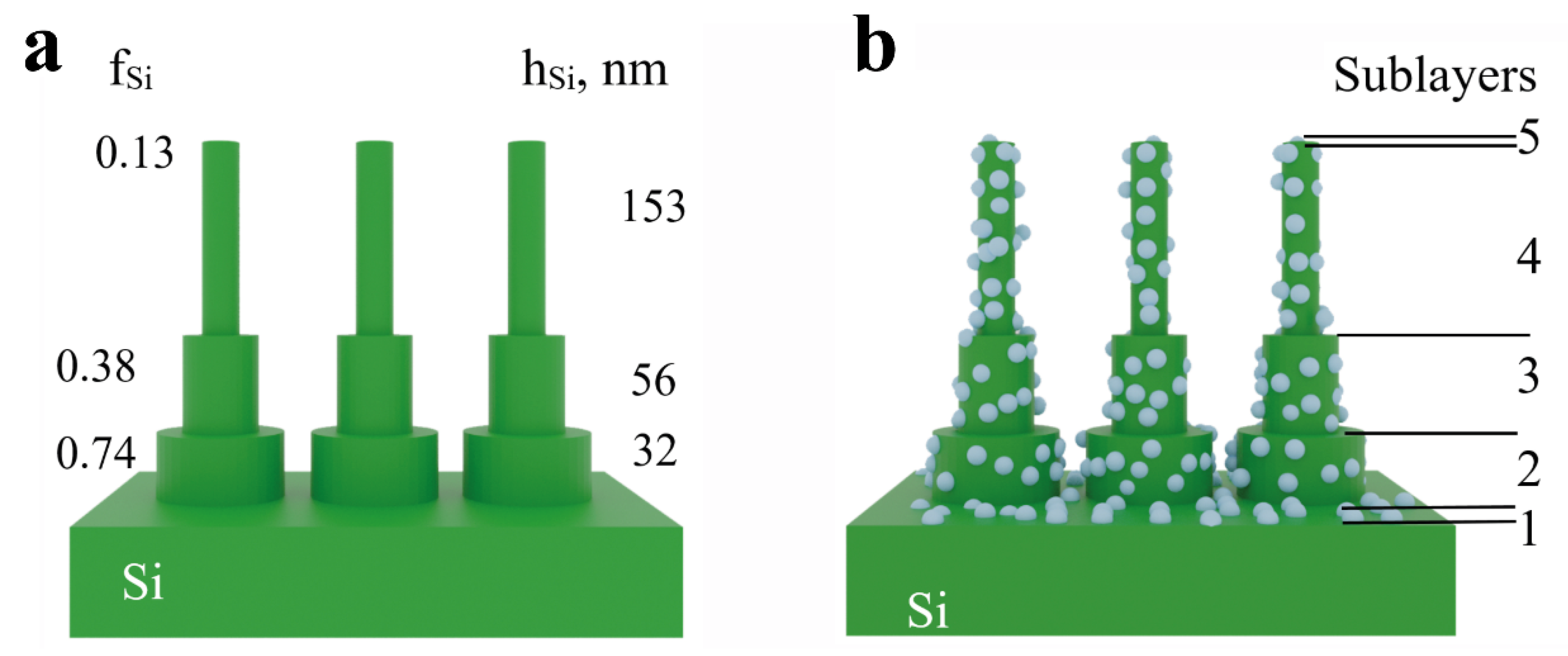

3.3. Morphology of SiNWs

3.4. Study of AgNPs Deposited on SiNWs

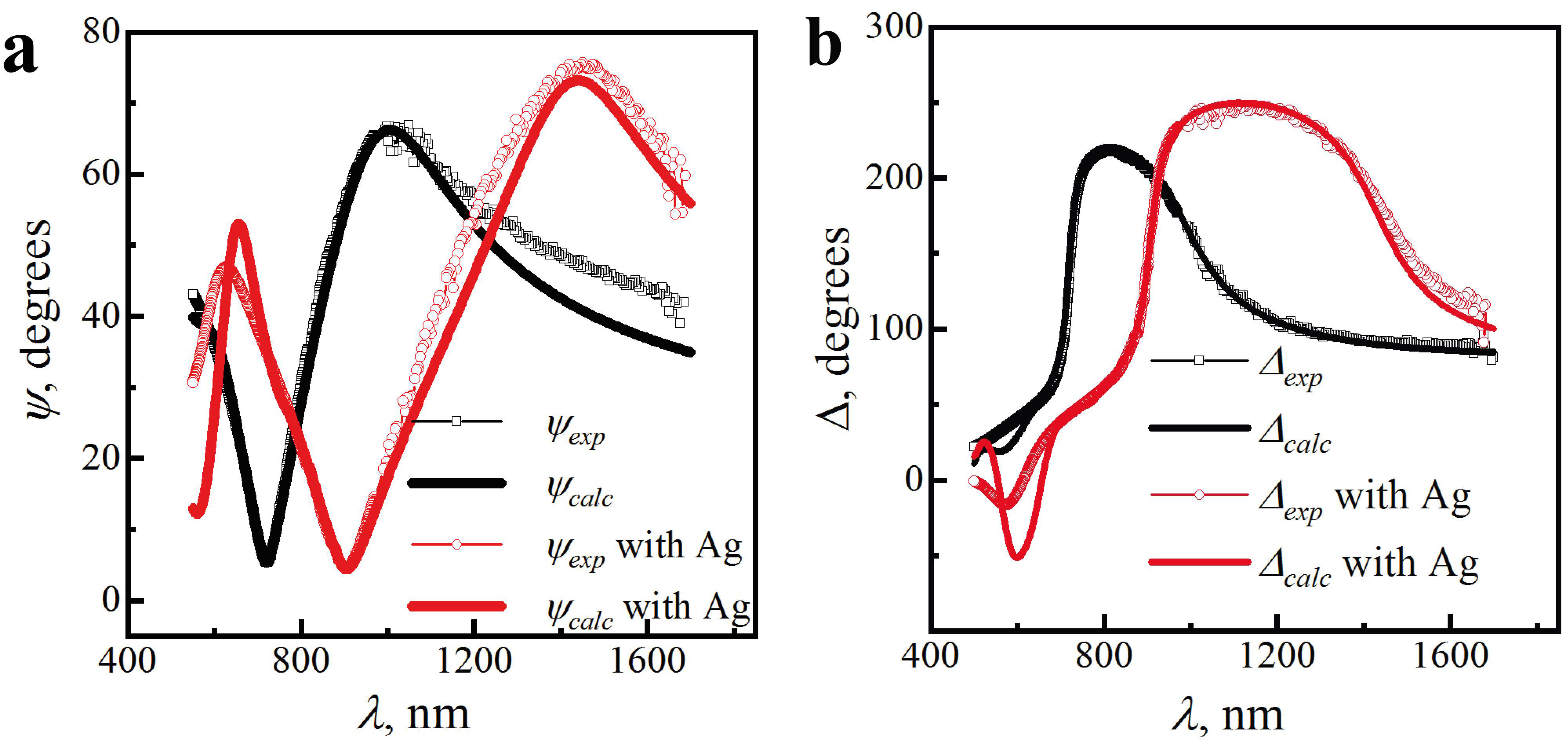

3.5. Ellipsometric Study of SiNW Arrays before and after the Deposition of AgNPs

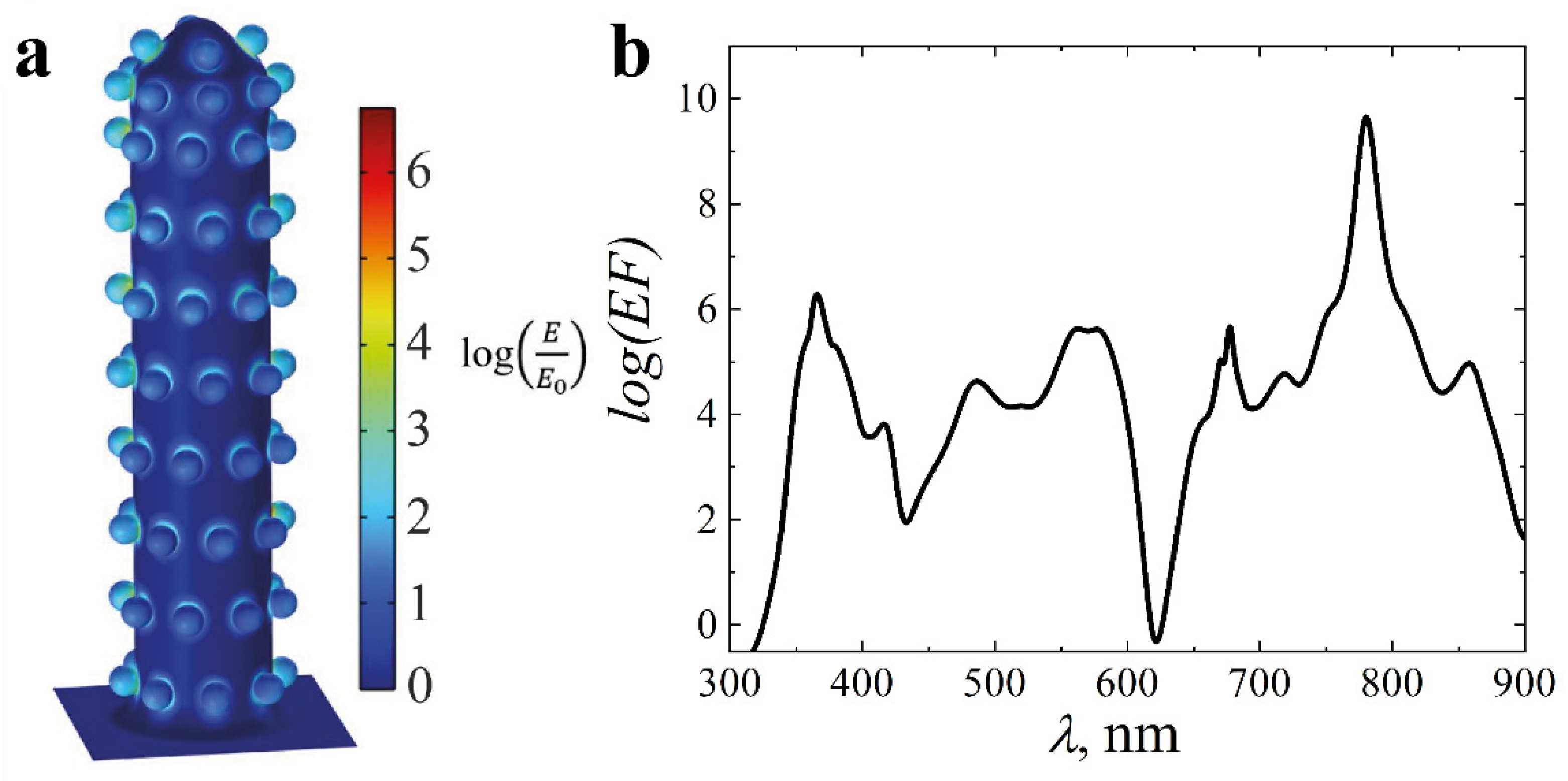

3.6. Modeling the Propagation of an Electromagnetic Field in a Composite Nanostructure Using COMSOL Multiphysics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Maier, S.A. Plasmonics: Fundamentals and Applications; Springer: New York, NY, USA, 2007. [Google Scholar]

- Schmidt, V.; Riel, H.; Senz, S.; Karg, S.; Riess, W.; Gösele, U. Realization of a Silicon Nanowire Vertical Surround-Gate Field-Effect Transistor. Small 2006, 2, 85–88. [Google Scholar] [CrossRef] [PubMed]

- Priolo, F.; Gregorkiewicz, T.; Galli, M.; Krauss, T.F. Silicon nanostructures for photonics and photovoltaics. Nat. Nanotechnol. 2014, 9, 19–32. [Google Scholar] [CrossRef]

- Canham, L. Handbook of Porous Silicon, 1st ed.; Springer: Cham, Switzerland, 2014. [Google Scholar]

- Tolmachev, V.; Astrova, E.; Pilyugina, J.; Perova, T.; Moore, R.; Vij, J. 1D photonic crystal fabricated by wet etching of silicon. Opt. Mater. 2005, 27, 831–835. [Google Scholar] [CrossRef]

- Hsu, S.-H.; Liu, E.-S.; Chang, Y.-C.; Hilfiker, J.N.; Kim, Y.D.; Kim, T.J.; Lin, C.-J.; Lin, G.-R. Characterization of Si nanorods by spectroscopic ellipsometry with efficient theoretical modeling. Phys. Status Solidi A 2008, 205, 876–879. [Google Scholar] [CrossRef]

- Fodor, B.; Defforge, T.; Agócs, E.; Fried, M.; Gautier, G.; Petrik, P. Spectroscopic ellipsometry of columnar porous Si thin films and Si nanowires. Appl. Surf. Sci. 2017, 421, 397–404. [Google Scholar] [CrossRef]

- Huang, Z.; Geyer, N.; Werner, P.; De Boor, J.; Gösele, U. Metal-Assisted Chemical Etching of Silicon: A Review. Adv. Mater. 2011, 23, 285–308. [Google Scholar] [CrossRef]

- Chiappini, C.; Liu, X.; Fakhoury, J.R.; Ferrari, M. Biodegradable Porous Silicon Barcode Nanowires with Defined Geometry. Adv. Funct. Mater. 2010, 20, 2231–2239. [Google Scholar] [CrossRef] [Green Version]

- Georgobiani, V.A.; Gonchar, K.A.; Zvereva, E.A.; Osminkina, L.A. Porous Silicon Nanowire Arrays for Reversible Optical Gas Sensing. Phys. Status Solidi A 2018, 215, 1700565. [Google Scholar] [CrossRef]

- Arshavsky-Graham, S.; Massad-Ivanir, N.; Segal, E.; Weiss, S.M. Porous Silicon-Based Photonic Biosensors: Current Status and Emerging Applications. Anal. Chem. 2019, 91, 441–467. [Google Scholar] [CrossRef]

- Žukovskaja, O.; Agafilushkina, S.; Sivakov, V.; Weber, K.; Cialla-May, D.; Osminkina, L.; Popp, J. Rapid detection of the bacterial biomarker pyocyanin in artificial sputum using a SERS-active silicon nanowire matrix covered by bimetallic noble metal nanoparticles. Talanta 2019, 202, 171–177. [Google Scholar] [CrossRef]

- Wang, X.; Shi, W.S.; She, G.W.; Mu, L.X.; Lee, S.T. High-performance surface-enhanced Raman scattering sensors based on Ag nanoparticles-coated Si nanowire arrays for quantitative detection of pesticides. Appl. Phys. Lett. 2010, 96, 053104. [Google Scholar] [CrossRef]

- Kartashova, A.D.; Gonchar, K.A.; Chermoshentsev, D.A.; Alekseeva, E.A.; Gongalsky, M.B.; Bozhev, I.V.; Eliseev, A.A.; Dyakov, S.A.; Samsonova, J.V.; Osminkina, L.A. Surface-Enhanced Raman Scattering-Active Gold-Decorated Silicon Nanowire Substrates for Label-Free Detection of Bilirubin. ACS Biomater. Sci. Eng. 2022, 8, 4175–4184. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.-A.; Zhao, Y.-Q.; Zhang, X.-J.; He, L.-F.; Wong, T.-L.; Chui, Y.-S.; Zhang, W.-J.; Lee, S.-T. Ordered Ag/Si Nanowires Array: Wide-Range Surface-Enhanced Raman Spectroscopy for Reproducible Biomolecule Detection. Nano Lett. 2013, 13, 5039–5045. [Google Scholar] [CrossRef] [PubMed]

- Wu, K.; Rindzevicius, T.; Schmidt, M.S.; Mogensen, K.B.; Hakonen, A.; Boisen, A. Wafer-Scale Leaning Silver Nanopillars for Molecular Detection at Ultra-Low Concentrations. J. Phys. Chem. C 2015, 119, 2053–2062. [Google Scholar] [CrossRef] [Green Version]

- Chattopadhyay, S.; Lo, H.-C.; Hsu, C.-H.; Chen, A.L.-C.; Chen, K.-H. Surface-Enhanced Raman Spectroscopy Using Self-Assembled Silver Nanoparticles on Silicon Nanotips. Chem. Mater. 2005, 17, 553–559. [Google Scholar] [CrossRef]

- Wu, R.; Jin, Q.; Storey, C.; Collins, J.; Gomard, G.; Lemmer, U.; Canham, L.; Kling, R.; Kaplan, A. Gold nanoplasmonic particles in tunable porous silicon 3D scaffolds for ultra-low concentration detection by SERS. Nanoscale Horizons 2021, 6, 781–790. [Google Scholar] [CrossRef]

- Wu, R.; Mathieu, T.; Storey, C.J.; Jin, Q.; Collins, J.; Canham, L.T.; Kaplan, A. Localized Plasmon Field Effect of Gold Clusters Embedded in Nanoporous Silicon. Adv. Opt. Mater. 2021, 9, 2002119. [Google Scholar] [CrossRef]

- Miikkulainen, V.; Leskela, M.; Ritala, M.; Puurunen, R.L. Crystallinity of inorganic films grown by atomic layer deposition: Overview and general trends. J. Appl. Phys. 2013, 113, 021301. [Google Scholar] [CrossRef]

- Zaera, F. The surface chemistry of thin film atomic layer deposition (ALD) processes for electronic device manufacturing. J. Mater. Chem. 2008, 18, 3521–3526. [Google Scholar] [CrossRef]

- Rolison, D.R.; Long, J.W.; Lytle, J.C.; Fischer, A.E.; Rhodes, C.P.; McEvoy, T.M.; Bourg, M.E.; Lubers, A.M. Multifunctional 3D nanoarchitectures for energy storage and conversion. Chem. Soc. Rev. 2009, 38, 226–252. [Google Scholar] [CrossRef]

- Marichy, C.; Bechelany, M.; Pinna, N. Atomic Layer Deposition of Nanostructured Materials for Energy and Environmental Applications. Adv. Mater. 2012, 24, 1017–1032. [Google Scholar] [CrossRef] [PubMed]

- O’Neill, B.J.; Jackson, D.H.K.; Lee, J.; Canlas, C.; Stair, P.C.; Marshall, C.L.; Elam, J.W.; Kuech, T.F.; Dumesic, J.A.; Huber, G.W. Catalyst Design with Atomic Layer Deposition. ACS Catal. 2015, 5, 1804–1825. [Google Scholar] [CrossRef] [Green Version]

- Palmstrom, A.F.; Santra, P.K.; Bent, S.F. Atomic layer deposition in nanostructured photovoltaics: Tuning optical, electronic and surface properties. Nanoscale 2015, 7, 12266–12283. [Google Scholar] [CrossRef] [PubMed]

- Asundi, A.S.; Raiford, J.A.; Bent, S.F. Opportunities for Atomic Layer Deposition in Emerging Energy Technologies. ACS Energy Lett. 2019, 4, 908–925. [Google Scholar] [CrossRef]

- Gupta, B.; Hossain, A.; Riaz, A.; Sharma, A.; Zhang, D.; Tan, H.H.; Jagadish, C.; Catchpole, K.; Hoex, B.; Karuturi, S. Recent Advances in Materials Design Using Atomic Layer Deposition for Energy Applications. Adv. Funct. Mater. 2021, 32, 2109105. [Google Scholar] [CrossRef]

- Masango, S.S.; Peng, L.; Marks, L.D.; Van Duyne, R.P.; Stair, P.C. Nucleation and Growth of Silver Nanoparticles by AB and ABC-Type Atomic Layer Deposition. J. Phys. Chem. C 2014, 118, 17655–17661. [Google Scholar] [CrossRef]

- Golrokhi, Z.; Chalker, S.; Sutcliffe, C.J.; Potter, R.J. Self-limiting atomic layer deposition of conformal nanostructured silver films. Appl. Surf. Sci. 2016, 364, 789–797. [Google Scholar] [CrossRef]

- Chalker, P.R.; Romani, S.; A Marshall, P.; Rosseinsky, M.J.; Rushworth, S.; A Williams, P. Liquid injection atomic layer deposition of silver nanoparticles. Nanotechnology 2010, 21, 405602. [Google Scholar] [CrossRef]

- Golrokhi, Z.; Marshall, P.A.; Romani, S.; Rushworth, S.; Chalker, P.R.; Potter, R.J. The influence of tertiary butyl hydrazine as a co-reactant on the atomic layer deposition of silver. Appl. Surf. Sci. 2017, 399, 123–131. [Google Scholar] [CrossRef]

- Wack, S.; Popa, P.L.; Adjeroud, N.; Guillot, J.; Pistillo, B.R.; Leturcq, R. Large-Scale Deposition and Growth Mechanism of Silver Nanoparticles by Plasma-Enhanced Atomic Layer Deposition. J. Phys. Chem. C 2019, 123, 27196–27206. [Google Scholar] [CrossRef]

- Ko, C.-T.; Yang, P.-S.; Han, Y.-Y.; Wang, W.-C.; Huang, J.-J.; Lee, Y.-H.; Tsai, Y.-J.; Shieh, J.; Chen, M.-J. Atomic-layer-deposited silver and dielectric nanostructures for plasmonic enhancement of Raman scattering from nanoscale ultrathin films. Nanotechnology 2015, 26, 265702. [Google Scholar] [CrossRef]

- Compton, R.; Prokes, S.M.; Glembocki, O.J.; Pala, I.R.; Gerardi, H.K.; Owrutsky, J.C. Observation of coherent oscillations in plasma-enhanced atomic layer deposition Ag films. Appl. Phys. Lett. 2014, 104, 073101. [Google Scholar] [CrossRef]

- Prokes, S.M.; Glembocki, O.J.; Cleveland, E. Novel optical properties of Ag films deposited by plasma enhanced atomic layer deposition (PEALD) In Nanoepitaxy: Materials and Devices IV; SPIE: Bellingham, WA, USA, 2012; Volume 8467, pp. 35–46. [Google Scholar] [CrossRef]

- Prokes, S.M.; Glembocki, O.J.; Cleveland, E.; Caldwell, J.D.; Foos, E.; Niinistö, J.; Ritala, M. Spoof-like plasmonic behavior of plasma enhanced atomic layer deposition grown Ag thin films. Appl. Phys. Lett. 2012, 100, 053106. [Google Scholar] [CrossRef] [Green Version]

- Prokes, S.M.; Glembocki, O.J. Self Assembled Metamaterials Formed via Plasma Enhanced ALD of Ag Thin Films. ECS Trans. 2014, 64, 279–289. [Google Scholar] [CrossRef]

- Kariniemi, M.; Niinistö, J.; Hatanpää, T.; Kemell, M.; Sajavaara, T.; Ritala, M.; Leskelä, M. Plasma-Enhanced Atomic Layer Deposition of Silver Thin Films. Chem. Mater. 2011, 23, 2901–2907. [Google Scholar] [CrossRef]

- Minjauw, M.M.; Solano, E.; Sree, S.P.; Asapu, R.; Van Daele, M.; Ramachandran, R.K.; Heremans, G.; Verbruggen, S.W.; Lenaerts, S.; Martens, J.A.; et al. Plasma-Enhanced Atomic Layer Deposition of Silver Using Ag(fod)(PEt3) and NH3-Plasma. Chem. Mater. 2017, 29, 7114–7121. [Google Scholar] [CrossRef]

- Mäkelä, M.; Hatanpää, T.; Mizohata, K.; Meinander, K.; Niinistö, J.; Räisänen, J.; Ritala, M.; Leskelä, M. Studies on Thermal Atomic Layer Deposition of Silver Thin Films. Chem. Mater. 2017, 29, 2040–2045. [Google Scholar] [CrossRef]

- Bruele, F.J.V.D.; Smets, M.; Illiberi, A.; Creyghton, Y.; Buskens, P.; Roozeboom, F.; Poodt, P. Atmospheric pressure plasma enhanced spatial ALD of silver. J. Vac. Sci. Technol. A Vac. Surfaces Films 2015, 33, 1. [Google Scholar] [CrossRef] [Green Version]

- Niskanen, A.; Hatanpää, T.; Arstila, K.; Leskelä, M.; Ritala, M. Radical-Enhanced Atomic Layer Deposition of Silver Thin Films Using Phosphine-Adducted Silver Carboxylates. Chem. Vap. Depos. 2007, 13, 408–413. [Google Scholar] [CrossRef]

- Sivakov, V.A.; Höflich, K.; Becker, M.; Berger, A.; Stelzner, T.; Elers, K.-E.; Pore, V.; Ritala, M.; Christiansen, S.H. Silver Coated Platinum Core-Shell Nanostructures on Etched Si Nanowires: Atomic Layer Deposition (ALD) Processing and Application in SERS. ChemPhysChem 2010, 11, 1995–2000. [Google Scholar] [CrossRef]

- Zharova, Y.; Ermina, A.; Pavlov, S.; Koshtyal, Y.; Tolmachev, V. Spectroscopic Characterization of Silicon Wire-Like and Porous Nanolayers in the Process of Metal-Assisted Chemical Etching of Single-Crystal Silicon. Phys. Status Solidi A 2019, 216, 1900318. [Google Scholar] [CrossRef]

- Nazarov, D.; Ezhov, I.; Yudintceva, N.; Shevtsov, M.; Rudakova, A.; Kalganov, V.; Tolmachev, V.; Zharova, Y.; Lutakov, O.; Kraeva, L.; et al. Antibacterial and Osteogenic Properties of Ag Nanoparticles and Ag/TiO2 Nanostructures Prepared by Atomic Layer Deposition. J. Funct. Biomater. 2022, 13, 62. [Google Scholar] [CrossRef] [PubMed]

- Azzam, R.M.A.; Bashara, N.M. Ellipsometry and Polarized Light, 1st ed.; North-Holland Publishing: Amsterdam, The Netherlands; New York, NY, USA; Oxford, UK, 1977. [Google Scholar]

- Oates, T.; Wormeester, H.; Arwin, H. Characterization of plasmonic effects in thin films and metamaterials using spectroscopic ellipsometry. Prog. Surf. Sci. 2011, 86, 328–376. [Google Scholar] [CrossRef]

- Bruggeman, D.A.G. Berechnung verschiedener physikalischer Konstanten von heterogenen Substanzen. I. Dielektrizitätskonstanten und Leitfähigkeiten der Mischkörper aus isotropen Substanzen. Ann. Phys. 1935, 416, 636–664. [Google Scholar] [CrossRef]

- Wang, Y.; Plummer, E.W.; Kempa, K. Foundations of Plasmonics. Adv. Phys. 2011, 60, 799–898. [Google Scholar] [CrossRef]

- Tolmachev, V.; Gushchina, E.; Nyapshaev, I.; Zharova, Y. Spectroscopic ellipsometry study of dielectric functions of Ag films and chemically deposited layers of Ag nanoparticles on silicon. Thin Solid Films 2022, 756, 139352. [Google Scholar] [CrossRef]

- Johnson, P.B.; Christy, R.W. Optical Constants of the Noble Metals. Phys. Rev. B 1972, 6, 4370. [Google Scholar] [CrossRef]

- Palik, E.D. Handbook of Optical Constants of Solids, 1st ed.; Academic Press: Orlando, FL, USA, 1985. [Google Scholar]

- Stamplecoskie, K.G.; Scaiano, J.C.; Tiwari, V.S.; Anis, H. Optimal Size of Silver Nanoparticles for Surface-Enhanced Raman Spectroscopy. J. Phys. Chem. C 2011, 115, 1403–1409. [Google Scholar] [CrossRef]

- Li, Z.-Y. Mesoscopic and Microscopic Strategies for Engineering Plasmon-Enhanced Raman Scattering. Adv. Opt. Mater. 2018, 6, 1701097. [Google Scholar] [CrossRef]

| Reagent Ag | Co-Reactant | T Source, °С | T Reactor, °С | Growth Per Cycle, nm | Ref. |

|---|---|---|---|---|---|

| (hfac)Ag(PMe3) | HCHO + H2O + CH3OH | 63–66 | 170–200 | 0.007 | [28] |

| TMA H2O | – | – | – | – | |

| 0.1 M solution of ((hfac) Ag (1.5-COD) in toluene | Propanol-1 | 130 | 125 (80–200) | 0.016 | [29] |

| Propanol | 50 | (110–150) | – | [30] | |

| Tertiary butyl hydrazine | 130 | 125 (80–200) | 0.018 | [31] | |

| Ag(fod)(PEt3) | Ar + H2 | 100 | 130 (120–160) | 0.017 | [32] |

| – | 120 | – | [33] | ||

| – | – | [34] | |||

| – | 125 | – | [35] | ||

| – | 125 | – | [36] | ||

| – | 125 | – | [37] | ||

| Ar + H2 140/20 sccm | 106 | 120 (120–150, 200) | 0.03–0.04 | [38] | |

| 106 | 120 | – | [39] | ||

| Ar + H2 (20%) | 95 | 130 | 0.04 | [40] | |

| BH3(NHMe2) | 95/32 | 110 (104–130) | 0.03–0.04 | [41] | |

| N2/H2 | – | 100, 120 | <0.018 | [42] | |

| NH3 | 95 | 130 | 0.24 | [40] | |

| Ag(Piv)(PEt3) | Ar + H2 | 125 | 140–160 | 0.12 | [43] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prigoda, K.; Ermina, A.; Bolshakov, V.; Nazarov, D.; Ezhov, I.; Lutakov, O.; Maximov, M.; Tolmachev, V.; Zharova, Y. The Array of Si Nanowires Covered with Ag Nanoparticles by ALD: Fabrication Process and Optical Properties. Coatings 2022, 12, 1748. https://doi.org/10.3390/coatings12111748

Prigoda K, Ermina A, Bolshakov V, Nazarov D, Ezhov I, Lutakov O, Maximov M, Tolmachev V, Zharova Y. The Array of Si Nanowires Covered with Ag Nanoparticles by ALD: Fabrication Process and Optical Properties. Coatings. 2022; 12(11):1748. https://doi.org/10.3390/coatings12111748

Chicago/Turabian StylePrigoda, Kristina, Anna Ermina, Vladimir Bolshakov, Denis Nazarov, Ilya Ezhov, Oleksiy Lutakov, Maxim Maximov, Vladimir Tolmachev, and Yuliya Zharova. 2022. "The Array of Si Nanowires Covered with Ag Nanoparticles by ALD: Fabrication Process and Optical Properties" Coatings 12, no. 11: 1748. https://doi.org/10.3390/coatings12111748

APA StylePrigoda, K., Ermina, A., Bolshakov, V., Nazarov, D., Ezhov, I., Lutakov, O., Maximov, M., Tolmachev, V., & Zharova, Y. (2022). The Array of Si Nanowires Covered with Ag Nanoparticles by ALD: Fabrication Process and Optical Properties. Coatings, 12(11), 1748. https://doi.org/10.3390/coatings12111748