Assessing Consumers’ Preference and Loyalty towards Biopolymer Films for Food Active Packaging

Abstract

:1. Introduction

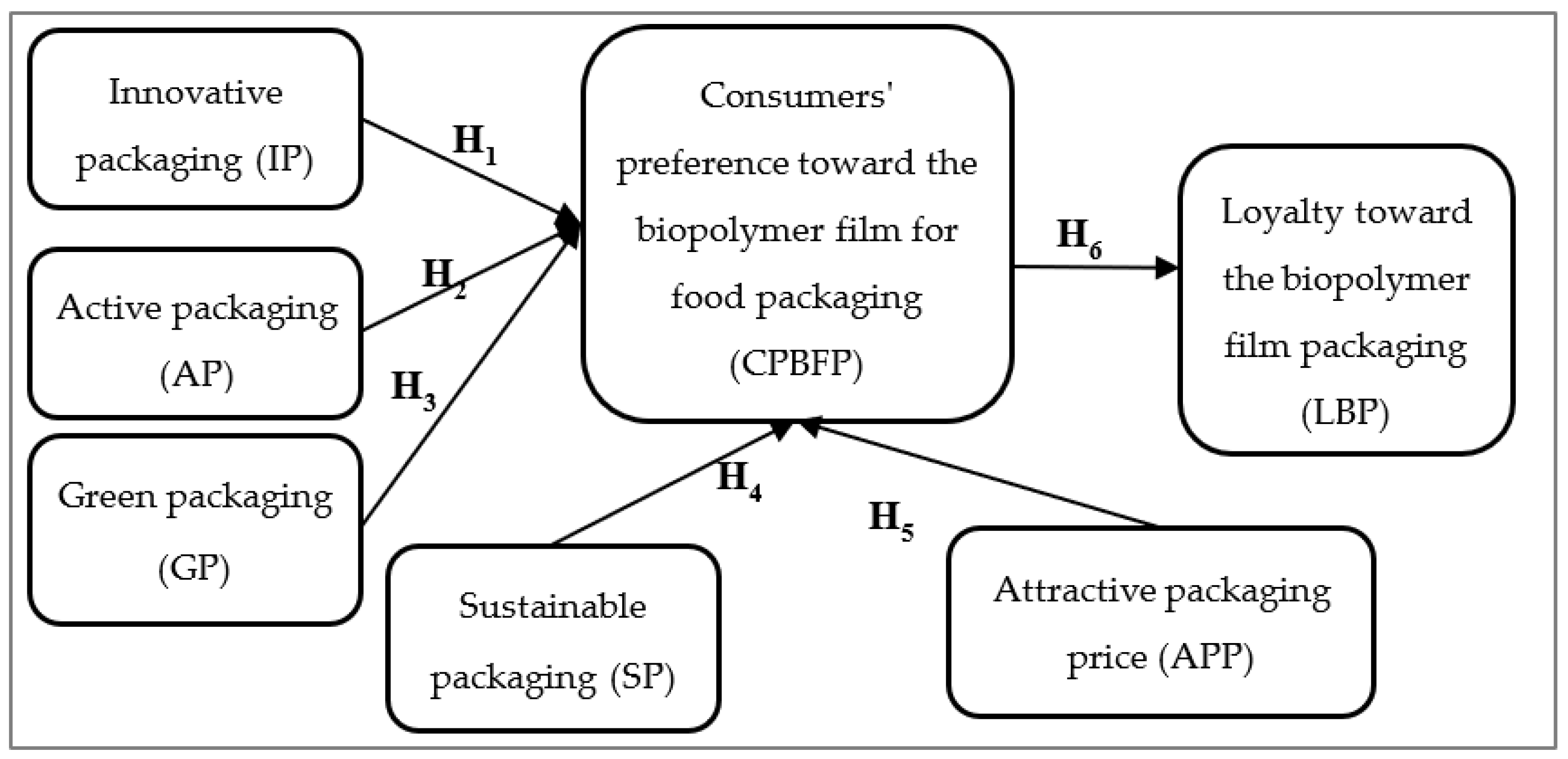

1.1. Literature Review: Hypothesis and Conceptual Model Development

1.1.1. The Stimulus–Organism–Response (SOR) Approach

1.1.2. From Traditional Food Packaging to Biopolymer-Film Packaging

2. Research Methodology

2.1. Research Design

2.2. Sampling and Data Collection

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Motelica, L.; Ficai, D.; Ficai, A.; Oprea, O.C.; Kaya, D.A.; Andronescu, E. Biodegradable antimicrobial food packaging: Trends and perspectives. Foods 2020, 9, 1438. [Google Scholar] [CrossRef] [PubMed]

- Lăzăroiu, G.; Valaskova, K.; Nica, E.; Durana, P.; Kral, P.; Bartoš, P.; Maroušková, A. Techno-economic assessment: Food emulsion waste management. Energies 2020, 13, 4922. [Google Scholar] [CrossRef]

- Rydell, L.; Suler, P. Underlying values that motivate behavioral intentions and purchase decisions: Lessons from the COVID-19 pandemic. Anal. Metaphys. 2021, 20, 116–129. [Google Scholar] [CrossRef]

- Alhamdi, F.M. Role of packaging in consumer buying behavior. Manag. Sci. Lett. 2020, 10, 1191–1196. [Google Scholar] [CrossRef]

- Saha, S.P. Impact of product packaging on consumer buying decision. J. Eng. Sci. Res. 2020, 4, 17–22. [Google Scholar] [CrossRef]

- Majid, I.; Nayik, G.A.; Dar, S.M.; Nanda, V. Novel food packaging technologies: Innovations and future prospective. J. Saudi Soc. Agric. Sci. 2018, 17, 454–462. [Google Scholar] [CrossRef] [Green Version]

- Mishra, P.; Jain, T.; Motiani, M. Have green, pay more: An empirical investigation of consumer’s attitude towards green packaging in an emerging economy. In Essays on Sustainability and Management; Sarkar, R., Shaw, A., Eds.; India Studies in Business and Economics; Springer: Singapore, 2017; pp. 125–150. [Google Scholar] [CrossRef]

- Pan, C.; Lei, Y.; Wu, J.; Wang, Y. The influence of green packaging on consumers’ green purchase intention in the context of online-to-offline commerce. J. Syst. Inf. Technol. 2021, 23, 133–153. [Google Scholar] [CrossRef]

- Diggle, A.; Walker, T.R. Implementation of harmonized Extended Producer Responsibility strategies to incentivize recovery of single-use plastic packaging waste in Canada. Waste Manag. 2020, 110, 20–23. [Google Scholar] [CrossRef]

- Wandosell, G.; Parra-Meroño, M.C.; Alcayde, A.; Baños, R. Green packaging from consumer and business perspectives. Sustainability 2021, 13, 1356. [Google Scholar] [CrossRef]

- Han, J.W.; Ruiz-Garcia, L.; Qian, J.-P.; Yang, X.-T. Food packaging: A comprehensive review and future trends. Compr. Rev. Food Sci. Food Saf. 2018, 17, 860–877. [Google Scholar] [CrossRef] [Green Version]

- Mruk-Tomczak, D.; Jerzyk, E.; Wawrzynkiewicz, N. Consumer engagement and the perception of packaging information. Olszt. Econ. J. 2019, 14, 195–207. [Google Scholar] [CrossRef]

- Young, E.; Mirosa, M.; Bremer, P. A systematic review of consumer perceptions of smart packaging technologies for food. Front. Sustain. Food Syst. 2020, 4, 63. [Google Scholar] [CrossRef]

- Pal, M.; Devrani, M.; Hadush, A. Recent developments in food packaging technologies. Beverage Food World 2019, 46, 21–25. [Google Scholar]

- Lăzăroiu, G.; Andronie, M.; Uţă, C.; Hurloiu, I. Trust management in organic agriculture: Sustainable consumption behavior, environmentally conscious purchase intention, and healthy food choices. Front. Public Health 2019, 7, 340. [Google Scholar] [CrossRef] [PubMed]

- Socaciu, M.-I.; Semeniuc, C.A.; Vodnar, D.C. Edible films and coatings for fresh fish packaging: Focus on quality changes and shelf-life extension. Coatings 2018, 8, 366. [Google Scholar] [CrossRef] [Green Version]

- Majerova, J.; Sroka, W.; Krizanova, A.; Gajanova, L.; Lăzăroiu, G.; Nadanyiova, M. Sustainable brand management of alimentary goods. Sustainability 2020, 12, 556. [Google Scholar] [CrossRef] [Green Version]

- Skvarciany, V.; Lapinskaite, I.; Volskyte, G. Circular economy as assistance for sustainable development in OECD countries. Oeconomia Copernic. 2021, 12, 11–34. [Google Scholar] [CrossRef]

- Mehrabian, A.; Russell, J.A. An Approach to Environmental Psychology; M.I.T. Press: Cambridge, MA, USA, 1974. [Google Scholar]

- Hopkins, E.; Potcovaru, A.-M. Consumer attitudes, values, needs, and expectations due to COVID-19. Anal. Metaphys. 2021, 20, 202–215. [Google Scholar] [CrossRef]

- Cichocka, I.; Krupa, J.; Mantaj, A. The consumer awareness and behaviour towards food packaging in Poland. Econ. Sociol. 2020, 13, 304–317. [Google Scholar] [CrossRef]

- Valaskova, K.; Durana, P.; Adamko, P. Changes in Consumers’ Purchase Patterns as a Consequence of the COVID-19 Pandemic. Mathematics 2021, 9, 1788. [Google Scholar] [CrossRef]

- Vilela, C.; Kurek, M.; Hayouka, Z.; Röcker, B.; Yildirim, S.; Antunes, M.D.C.; Nilsen-Nygaard, J.; Pettersen, M.K.; Freire, C.S.R. A concise guide to active agents for active food packaging. Trends Food Sci. Technol. 2018, 80, 212–222. [Google Scholar] [CrossRef]

- Robertson, G.L. History of food packaging. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Martins, V.G.; Romani, V.P.; Martins, P.C.; da Silva Filipini, G. Innovative packaging that saves food. In Saving Food: Production, Supply Chain, Food Waste and Food Consumption; Galanakis, C.M., Ed.; Academic Press: Amsterdam, The Netherlands, 2019; pp. 171–202. [Google Scholar] [CrossRef]

- Shendurse, A.M.; Gopikrishna, G.; Patel, A.C.; Pandya, A.J. Milk protein based edible films and coatings–preparation, properties and food applications. J. Nutr. Health Food Eng. 2018, 8, 219–226. [Google Scholar] [CrossRef] [Green Version]

- Socaciu, M.-I.; Fogarasi, M.; Semeniuc, C.A.; Socaci, S.A.; Rotar, M.A.; Mureşan, V.; Pop, O.L.; Vodnar, D.C. Formulation and characterization of antimicrobial edible films based on whey protein isolate and tarragon essential oil. Polymers 2020, 12, 1748. [Google Scholar] [CrossRef]

- Socaciu, M.-I.; Fogarasi, M.; Simon, E.L.; Semeniuc, C.A.; Socaci, S.A.; Podar, A.S.; Vodnar, D.C. Effects of whey protein isolate-based film incorporated with tarragon essential oil on the quality and shelf-life of refrigerated brook trout. Foods 2021, 10, 401. [Google Scholar] [CrossRef] [PubMed]

- Pires, C.; Ramos, C.; Teixeira, B.; Batista, I.; Nunes, M.L.; Marques, A. Hake proteins edible films incorporated with essential oils: Physical, mechanical, antioxidant and antibacterial properties. Food Hydrocoll. 2013, 30, 224–231. [Google Scholar] [CrossRef]

- Kavas, N.; Kavas, G. Physical-chemical and antimicrobial properties of egg white protein powder films incorporated with orange essential oil on Kashar cheese. Food Sci. Technol. Camp. 2016, 36, 672–678. [Google Scholar] [CrossRef] [Green Version]

- González, A.; Igarzabal, C.I.A. Soy protein—Poly (lactic acid) bilayer films as biodegradable material for active food packaging. Food Hydrocoll. 2013, 33, 289–296. [Google Scholar] [CrossRef]

- Luo, Q.; Hossen, M.A.; Zeng, Y.; Dai, J.; Li, S.; Qin, W.; Liu, Y. Gelatin-based composite films and their application in food packaging: A review. J. Food Eng. 2022, 313, 110762. [Google Scholar] [CrossRef]

- Jouki, M.; Yazdi, F.T.; Mortazavi, S.A.; Koocheki, A. Quince seed mucilage films incorporated with oregano essential oil: Physical, thermal, barrier, antioxidant and antibacterial properties. Food Hydrocoll. 2014, 36, 9–19. [Google Scholar] [CrossRef]

- Martins, J.T.; Cerqueira, M.A.; Vicente, A.A. Influence of α-tocopherol on physicochemical properties of chitosan-based films. Food Hydrocoll. 2012, 27, 220–227. [Google Scholar] [CrossRef] [Green Version]

- Bonilla, J.; Atarés, L.; Vargas, M.; Chiralt, A. Effect of essential oils and homogenization conditions on properties of chitosan-based films. Food Hydrocoll. 2012, 26, 9–16. [Google Scholar] [CrossRef]

- Leceta, I.; Guerrero, P.; Ibarburu, I.; Dueñas, M.T.; de la Caba, K. Characterization and antimicrobial analysis of chitosan-based films. J. Food Eng. 2013, 116, 889–899. [Google Scholar] [CrossRef]

- Tan, W.; Dong, F.; Zhang, J.; Zhao, X.; Li, Q.; Guo, Z. Physical and antioxidant properties of edible chitosan ascorbate films. J. Agric. Food Chem. 2019, 67, 2530–2539. [Google Scholar] [CrossRef]

- Gaba, A.B.M.; Hassan, M.A.; Abd EL-Tawab, A.A.; Abdelmonem, M.A.; Morsy, M.K. Protective impact of chitosan film loaded oregano and thyme essential oil on the microbial profile and quality attributes of beef meat. Antibiotics 2022, 11, 583. [Google Scholar] [CrossRef] [PubMed]

- Abreu, A.S.; Oliveira, M.; de Sá, A.; Rodrigues, R.M.; Cerqueira, M.A.; Vicente, A.A.; Machado, A.V. Antimicrobial nanostructured starch-based films for packaging. Carbohydr. Polym. 2015, 129, 127–134. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Luchese, C.L.; Benelli, P.; Spada, J.C.; Tessaro, I.C. Impact of the starch source on the physicochemical properties and biodegradability of different starch-based films. J. Appl. Polym. Sci. 2018, 135, 46564. [Google Scholar] [CrossRef]

- Júnior, L.M.; de Ávila Gonçalves, S.; da Silva, R.G.; Martins, J.T.; Vicente, A.A.; Alves, R.M.V.; Vieira, R.P. Effect of green propolis extract on functional properties of active pectin-based films. Food Hydrocoll. 2022, 131, 107746. [Google Scholar] [CrossRef]

- Guadarrama-Lezama, A.Y.; Castaño, J.; Velázquez, G.; Carrillo-Navas, H.; Alvarez-Ramírez, J. Effect of nopal mucilage addition on physical, barrier and mechanical properties of citric pectin-based films. J. Food Sci. Technol. 2018, 55, 3739–3748. [Google Scholar] [CrossRef]

- Galus, S.; Kadzińska, J. Food applications of emulsion-based edible films and coatings. Trends Food Sci. Technol. 2015, 45, 273–283. [Google Scholar] [CrossRef]

- Jiménez, A.; Fabra, M.J.; Talens, P.; Chiralt, A. Effect of re-crystallization on tensile, optical and water vapour barrier properties of corn starch films containing fatty acids. Food Hydrocoll. 2012, 26, 302–310. [Google Scholar] [CrossRef]

- Cerqueira, M.A.; Souza, B.W.S.; Teixeira, J.A.; Vicente, A.A. Effect of glycerol and corn oil on physicochemical properties of polysaccharide films—A comparative study. Food Hydrocoll. 2012, 27, 175–184. [Google Scholar] [CrossRef] [Green Version]

- Shit, S.C.; Shah, P.M. Edible polymers: Challenges and opportunities. J. Polym. 2014, 2014, 427259. [Google Scholar] [CrossRef] [Green Version]

- Cestari, L.A.; da Silva Scapim, M.R.; Madrona, G.S.; Yamashita, F.; Biondo, P.B.F.; Carvalho, V.M.; Bonin, E.; do Prado, I.N. Production, antioxidant characterization and application of active starch-based films containing essential oils for beef packaging. Res. Soc. Dev. 2021, 10, e4310816903. [Google Scholar] [CrossRef]

- Ganiari, S.; Choulitoudi, E.; Oreopoulou, V. Edible and active films and coatings as carriers of natural antioxidants for lipid food. Trends Food Sci. Technol. 2017, 68, 70–82. [Google Scholar] [CrossRef]

- Hashemi, S.M.B.; Jafarpour, D. The efficacy of edible film from Konjac glucomannan and saffron petal extract to improve shelf life of fresh-cut cucumber. Food Sci. Nutr. 2020, 8, 3128–3137. [Google Scholar] [CrossRef] [PubMed]

- Semeniuc, C.A.; Socaciu, M.-I.; Socaci, S.A.; Mureșan, V.; Fogarasi, M.; Rotar, A.M. Chemometric comparison and classification of some essential oils extracted from plants belonging to Apiaceae and Lamiaceae families based on their chemical composition and biological activities. Molecules 2018, 23, 2261. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Semeniuc, C.A.; Pop, C.R.; Rotar, A.M. Antibacterial activity and interactions of plant essential oil combinations against Gram-positive and Gram-negative bacteria. J. Food Drug Anal. 2017, 25, 403–408. [Google Scholar] [CrossRef] [Green Version]

- Nemes, S.A.; Szabo, K.; Vodnar, D.C. Applicability of agro-industrial by-products in intelligent food packaging. Coatings 2020, 10, 550. [Google Scholar] [CrossRef]

- Glogovețan, A.-I.; Dabija, D.-C.; Fiore, M.; Pocol, C.B. Consumer Perception and Understanding of European Union Quality Schemes: A Systematic Literature Review. Sustainability 2022, 14, 1667. [Google Scholar] [CrossRef]

- Chen, H. Functional properties and applications of edible films made of milk proteins. J. Dairy Sci. 1995, 78, 2563–2583. [Google Scholar] [CrossRef]

- Han, J.H. Edible films and coatings: A review. In Innovations in Food Packaging, 2nd ed.; Han, J.H., Ed.; Academic Press: Amsterdam, The Netherlands, 2014; pp. 213–255. [Google Scholar] [CrossRef]

- Piccirilli, G.N.; Soazo, M.; Pérez, L.M.; Delorenzi, N.J.; Verdini, R.A. Effect of storage conditions on the physicochemical characteristics of edible films based on whey protein concentrate and liquid smoke. Food Hydrocoll. 2018, 87, 221–228. [Google Scholar] [CrossRef]

- Taghinia, P.; Abdolshahi, A.; Sedaghati, S.; Shokrollahi, B. Smart edible films based on mucilage of lallemantia iberica seed incorporated with curcumin for freshness monitoring. Food Sci. Nutr. 2021, 9, 1222–1231. [Google Scholar] [CrossRef]

- Smith, A.; Machova, V. Consumer tastes, sentiments, attitudes, and behaviors related to COVID-19. Anal. Metaphys. 2021, 20, 145–158. [Google Scholar] [CrossRef]

- Zhao, Y.; McDaniel, M. Sensory quality of foods associated with edible film and coating systems and shelf-life extension. In Innovations in Food Packaging, 1st ed.; Han, J.H., Ed.; Academic Press: Amsterdam, The Netherlands, 2005; pp. 434–453. [Google Scholar] [CrossRef]

- Chen, S.; Brahma, S.; Mackay, J.; Cao, C.; Aliakbarian, B. The role of smart packaging system in food supply chain. J. Food Sci. 2020, 85, 517–525. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brody, A.L.; Bugusu, B.; Han, J.H.; Sand, C.K.; McHugh, T.H. Innovative food packaging solutions. J. Food Sci. 2008, 73, R107–R116. [Google Scholar] [CrossRef]

- Di Pierro, P.; Chico, B.; Villalonga, R.; Mariniello, L.; Damiao, A.E.; Masi, P.; Porta, R. Chitosan−whey protein edible films produced in the absence or presence of transglutaminase: Analysis of their mechanical and barrier properties. Biomacromolecules 2006, 7, 744–749. [Google Scholar] [CrossRef]

- Vidal, O.L.; Barros Santos, M.C.; Batista, A.P.; Andrigo, F.F.; Baréa, B.; Lecomte, J.; Figueroa-Espinoza, M.C.; Gontard, N.; Villeneuve, P.; Guillard, V.; et al. Active packaging films containing antioxidant extracts from green coffee oil by-products to prevent lipid oxidation. J. Food Eng. 2022, 312, 110744. [Google Scholar] [CrossRef]

- Moorthy, K.; Kamarudin, A.A.; Xin, L.; Hui, L.M.; Way, L.T.; Fang, P.S.; Carmen, W. Green packaging purchase behaviour: A study on Malaysian consumers. Environ. Dev. Sustain. 2021, 23, 15391–15412. [Google Scholar] [CrossRef]

- Herbes, C.; Beuthner, C.; Ramme, I. How green is your packaging—A comparative international study of cues consumers use to recognize environmentally friendly packaging. Int. J. Consum. Stud. 2020, 44, 258–271. [Google Scholar] [CrossRef] [Green Version]

- Singh, G.; Pandey, N. The determinants of green packaging that influence buyers’ willingness to pay a price premium. Australas. Mark. J. 2018, 26, 221–230. [Google Scholar] [CrossRef]

- Petrescu, D.C.; Bran, F.; Radulescu, C.V.; Petrescu-Mag, R.M. Green Procurement through Forest Stewardship Council (FSC) Certification in the Private Sector. Perceptions and Willingness to Buy of Private Companies from Romania. Amfiteatru Econ. 2020, 22, 42–56. [Google Scholar] [CrossRef]

- Lăzăroiu, G.; Neguriţă, O.; Grecu, I.; Grecu, G.; Mitran, P.C. Consumers’ decision-making process on social commerce platforms: Online trust, perceived risk, and purchase intentions. Front. Psychol. 2020, 11, 890. [Google Scholar] [CrossRef] [PubMed]

- Ketelsen, M.; Janssen, M.; Hamm, U. Consumers’ response to environmentally-friendly food packaging—A systematic review. J. Clean. Prod. 2020, 254, 120123. [Google Scholar] [CrossRef]

- Lăzăroiu, G.; Pera, A.; Ștefănescu-Mihăilă, R.O.; Mircică, N.; Neguriță, O. Can neuroscience assist us in constructing better patterns of economic decision-making? Front. Behav. Neurosci. 2017, 11, 188. [Google Scholar] [CrossRef] [PubMed]

- Siracusa, V.; Rosa, M.D. Sustainable packaging. In Sustainable Food Systems from Agriculture to Industry: Improving Production and Processing; Galanakis, C.M., Ed.; Academic Press: Amsterdam, The Netherlands, 2018; pp. 275–307. [Google Scholar] [CrossRef]

- Wu, F.; Misra, M.; Mohanty, A.K. Challenges and new opportunities on barrier performance of biodegradable polymers for sustainable packaging. Prog. Polym. Sci. 2021, 117, 101395. [Google Scholar] [CrossRef]

- Kozik, N. Sustainable packaging as a tool for global sustainable development. In Proceedings of the 19th International Scientific Conference Globalization and its Socio-Economic Consequences 2019—Sustainability in the Global-Knowledge Economy, Rajecke Teplice, Slovakia, 9–10 October 2019. [Google Scholar]

- Boz, Z.; Korhonen, V.; Koelsch Sand, C. Consumer considerations for the implementation of sustainable packaging: A review. Sustainability 2020, 12, 2192. [Google Scholar] [CrossRef] [Green Version]

- Tiekstra, S.; Dopico-Parada, A.; Koivula, H.; Lahti, J.; Buntinx, M. Holistic approach to a successful market implementation of active and intelligent food packaging. Foods 2021, 10, 465. [Google Scholar] [CrossRef]

- Orzan, G.; Cruceru, A.F.; Bălăceanu, C.T.; Chivu, R.-G. Consumers’ behavior concerning sustainable packaging: An exploratory study on Romanian consumers. Sustainability 2018, 10, 1787. [Google Scholar] [CrossRef]

- Kocetkovs, V.; Muizniece-Brasava, S.; Kirse-Ozolina, A. Consumer awareness and attitudes towards active and intelligent packaging systems in the Latvian market. In Proceedings of the 13th Baltic Conference on Food Science and Technology (FoodBalt 2019), Jelgava, Latvia, 2–3 May 2019. [Google Scholar]

- Drago, E.; Campardelli, R.; Pettinato, M.; Perego, P. Innovations in smart packaging concepts for food: An extensive review. Foods 2020, 9, 1628. [Google Scholar] [CrossRef] [PubMed]

- Popovic, I.; Bossink, B.A.G.; van der Sijde, P.C.; Fong, C.Y.M. Why are consumers willing to pay more for liquid foods in environmentally friendly packaging? A dual attitudes perspective. Sustainability 2020, 12, 2812. [Google Scholar] [CrossRef] [Green Version]

- Chersan, I.C.; Dumitru, V.F.; Gorgan, C.; Gorgan, V. Green Public Procurement in the Academic Literature. Amfiteatru Econ. 2020, 22, 82–101. [Google Scholar] [CrossRef]

- Kádeková, Z.; Savov, R.; Košičiarová, I.; Valaskova, K. CSR Activities and Their Impact on Brand Value in Food Enterprises in Slovakia Based on Foreign Participation. Sustainability 2020, 12, 4856. [Google Scholar] [CrossRef]

- Cammarelle, A.; Viscecchia, R.; Bimbo, F. Intention to purchase milk packaged in biodegradable packaging: Evidence from Italian consumers. Foods 2021, 10, 2068. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.P. Recent trends in packaging. In Edible Food Packaging; Poonia, A., Dhewa, T., Eds.; Springer: Singapore, 2022; pp. 449–460. [Google Scholar] [CrossRef]

- Watson, R.; Cug, J. The impact of the COVID-19 pandemic on consumer satisfaction judgments, behavior patterns, and purchase intentions. Anal. Metaphys. 2021, 20, 174–186. [Google Scholar] [CrossRef]

- Ratnapuri, C.I.; Kurnianingrum, D.; Yustian, O.R.; Alamsyah, D.P. Product packaging in support of consumer loyalty. In Proceedings of the Second Asia Pacific International Conference on Industrial Engineering and Operations Management, Surakarta, Indonesia, 14–16 September 2021. [Google Scholar]

- Kotler, P.; Keller, K.L. Marketing Management, Global Edition; Pearson Education: London, UK, 2016. [Google Scholar]

- Rundh, B. The multi-faceted dimension of packaging: Marketing logistic or marketing tool? Br. Food J. 2005, 107, 670–684. [Google Scholar] [CrossRef]

- Lydekaityte, J.; Tambo, T. Smart packaging: Definitions, models and packaging as an intermediator between digital and physical product management. Int. Rev. Retail Distrib. Consum. Res. 2020, 30, 377–410. [Google Scholar] [CrossRef]

- Ringle, C.M.; Wende, S.; Becker, J.M. SmartPLS 3; SmartPLS GmbH: Boenningstedt, Germany, 2015; Available online: https://www.smartpls.com (accessed on 15 September 2022).

- Hair, J.F.; Black, W.C.; Babin, B.J. Multivariate Data Analysis: A Global Perspective; Pearson Education: London, UK, 2010. [Google Scholar]

- Henseler, J.; Sarstedt, M. Goodness-of-fit indices for partial least squares path modeling. Comput. Stat. 2013, 28, 565–580. [Google Scholar] [CrossRef] [Green Version]

- Chin, W.W. The partial least squares approach for structural equation modeling. In Methodology for Business and Management; Marcoulides, G.A., Ed.; Lawrence Erlbaum Associates Publishers: Mahwah, NJ, USA, 1998; pp. 293–336. [Google Scholar]

- Mai, R.; Symmank, C.; Seeberg-Elverfeldt, B. Light and pale colors in food packaging: When does this package cue signal superior healthiness or inferior tastiness? J. Retail. 2016, 92, 426–4446. [Google Scholar] [CrossRef]

- Newman, C.L.; Howlett, E.; Burton, S. Effects of objective and evaluative front-of-package cues on food evaluation and choice: The moderating influence of comparative and noncomparative processing contexts. J. Consum. Res. 2016, 42, 749–766. [Google Scholar] [CrossRef]

- Sundar, A.; Noseworthy, T.J. Too exciting to fail, too sincere to succeed: The effects of brand personality on sensory disconfirmation. J. Consum. Res. 2016, 43, 44–67. [Google Scholar] [CrossRef] [Green Version]

- Binninger, A.-S. Perception of naturalness of food packaging and its role in consumer product evaluation. J. Food Prod. Mark. 2015, 23, 251–266. [Google Scholar] [CrossRef]

- Dabija, D.-C.; Băbuț, R. Enhancing apparel store patronage through retailers’ attributes and sustainability. A generational approach. Sustainability 2019, 11, 4532. [Google Scholar] [CrossRef] [Green Version]

- Nemat, B.; Razzaghi, M.; Bolton, K.; Rousta, K. The potential of food packaging attributes to influence consumers’ decisions to sort waste. Sustainability 2020, 12, 2234. [Google Scholar] [CrossRef] [Green Version]

- Dabija, D.-C.; Bejan, B.M.; Grant, D.B. The Impact of consumer green behaviour on green loyalty among retail formats: A Romanian case study. Morav. Geogr. Rep. 2018, 26, 173–185. [Google Scholar] [CrossRef]

- Dabija, D.C.; Câmpian, V.; Pop, A.-R.; Băbuț, R. Generating loyalty towards fast fashion stores: A cross-generational approach based on store attributes and socio-environmental responsibility. Oeconomia Copernic. 2022, 13, 891–934. [Google Scholar] [CrossRef]

- Wang, E.S.-T. Different effects of utilitarian and hedonic benefits of retail food packaging on perceived product quality and purchase intention. J. Food Prod. Mark. 2017, 23, 239–250. [Google Scholar] [CrossRef]

- Henseler, J.; Ringle, C.M.; Sarstedt, M. A new criterion for assessing discriminant validity in variance-based structural equation modeling. J. Acad. Mark. Sci. 2014, 43, 115–135. [Google Scholar] [CrossRef] [Green Version]

- Sarstedt, M.; Ringle, C.M.; Hair, J.F. Partial least squares structural equation modeling. In Handbook of Market Research; Homburg, C., Klarmann, M., Vomberg, A., Eds.; Springer: Cham, Switzerland, 2017; pp. 1–40. [Google Scholar] [CrossRef]

- Hao, Y.; Liu, H.; Chen, H.; Sha, Y.; Ji, H.; Fan, J. What affect consumers’ willingness to pay for green packaging? Evidence from China. Resour. Conserv. Recycl. 2019, 141, 21–29. [Google Scholar] [CrossRef]

- Bhat, S.A.; Rizwan, D.; Mir, S.A.; Wani, S.M.; Masoodi, F.A. Advances in apple packaging: A review. J. Food Sci. Technol. 2022. [Google Scholar] [CrossRef]

- Santos, V.; Gomes, S.; Nogueira, M. Sustainable packaging: Does eating organic really make a difference on product-packaging interaction? J. Clean. Prod. 2021, 304, 127066. [Google Scholar] [CrossRef]

- Otto, S.; Strenger, M.; Maier-Nöth, A.; Schmid, M. Food packaging and sustainability—Consumer perception vs. correlated scientific facts: A review. J. Clean. Prod. 2021, 298, 126733. [Google Scholar] [CrossRef]

- Kiss, A.; Pfeiffer, L.; Popp, J.; Oláh, J.; Lakner, Z. A Blind Man Leads a Blind Man? Personalised Nutrition-Related Attitudes, Knowledge and Behaviours of Fitness Trainers in Hungary. Nutrients 2020, 12, 663. [Google Scholar] [CrossRef] [Green Version]

- Salgado, P.R.; Di Giorgio, L.; Musso, Y.S.; Mauri, A.N. Recent developments in smart food packaging focused on biobased and biodegradable polymers. Front. Sustain. Food Syst. 2021, 5, 630393. [Google Scholar] [CrossRef]

- Sani, M.A.; Azizi-Lalabadi, M.; Tavassoli, M.; Mohammadi, K.; McClements, D.J. Recent advances in the development of smart and active biodegradable packaging materials. Nanomaterials 2021, 11, 1331. [Google Scholar] [CrossRef] [PubMed]

- Andronie, M.; Lăzăroiu, G.; Ștefănescu, R.; Ionescu, L.; Cocoșatu, M. Neuromanagement decision-making and cognitive algorithmic processes in the technological adoption of mobile commerce apps. Oeconomia Copernic. 2021, 12, 863–888. [Google Scholar] [CrossRef]

- Omerović, N.; Djisalov, M.; Živojević, K.; Mladenović, M.; Vunduk, J.; Milenković, I.; Knežević, N.Ž.; Gadjanski, I.; Vidić, J. Antimicrobial nanoparticles and biodegradable polymer composites for active food packaging applications. Compr. Rev. Food Sci. Food Saf. 2021, 20, 2428–2454. [Google Scholar] [CrossRef]

- Wei, S.; Ang, T.; Jancenelle, V.E. Willingness to pay more for green products: The interplay of consumer characteristics and customer participation. J. Retail. Consum. Serv. 2018, 45, 230–238. [Google Scholar] [CrossRef]

- Majeed, A.; Ahmed, I.; Rasheed, A. Investigating influencing factors on consumers’ choice behavior and their environmental concerns while purchasing green products in Pakistan. J. Environ. Plan. Manag. 2022, 65, 1110–1134. [Google Scholar] [CrossRef]

- Loučanová, E.; Parobek, J.; Nosáľová, M. The perception of intelligent packaging innovation: The latest process and technological progress. In Food Preservation and Packaging—Recent Process and Technological Advancements; Tumuluru, J.S., Ed.; IntechOpen: London, UK, 2022. [Google Scholar] [CrossRef]

- Yan, M.R.; Hsieh, S.; Ricacho, N. Innovative food packaging, food quality and safety, and consumer perspectives. Processes 2022, 10, 747. [Google Scholar] [CrossRef]

| Item | Measure | Loading | Cronbach’s α | AVE | CR |

|---|---|---|---|---|---|

| Innovative Packaging (IP), adapted from [93,94,95] | |||||

| IP1 | From a technical perspective, edible protein-based biopolymer-film packaging is innovative | 0.888 | 0.937 | 0.759 | 0.950 |

| IP2 | From a technical perspective, edible protein-based biopolymer-film packaging is intelligent | 0.890 | |||

| IP3 | From a technical perspective, edible protein-based biopolymer-film packaging is new | 0.877 | |||

| IP4 | From a technical perspective, edible protein-based biopolymer-film packaging is an extraordinary breakthrough | 0.856 | |||

| IP5 | From a technical perspective, edible protein-based biopolymer-film packaging is made thanks to technological progress | 0.872 | |||

| IP6 | From a technical perspective, edible protein-based biopolymer-film packaging is a cutting-edge product | 0.844 | |||

| Active Packaging (AP), adapted from [93,94] | |||||

| AP1 | Protects the food product against pathogenic agents | 0.920 | 0.899 | 0.832 | 0.937 |

| AP2 | AP helps me maintain my health | 0.903 | |||

| AP23 | AP inhibits microbial growth | 0.914 | |||

| Green Packaging (GP), adapted from [96] | |||||

| GP1 | GP contributes to the reduction of waste accumulation | 0.863 | 0.926 | 0.771 | 0.944 |

| GP2 | … is biodegradable | 0.903 | |||

| GP3 | … is compostable | 0.867 | |||

| GP4 | … is non-polluting | 0.884 | |||

| GP5 | … is made of natural ingredients | 0.873 | |||

| Attractive Packaging Price (APP), adapted from [97,98] | |||||

| APP1 | The price tag of the edible packaging is good for me | 0.889 | 0.911 | 0.738 | 0.934 |

| APP2 | … is fair | 0.886 | |||

| APP3 | … is scientifically supported | 0.827 | |||

| APP4 | … helps me save time | 0.857 | |||

| APP5 | … helps me save money, as it extends shelf-life | 0.833 | |||

| Sustainable Packaging (SP), adapted from [76,96] | |||||

| SP1 | … is green/bio/eco-friendly/organic | 0.805 | 0.900 | 0.665 | 0.923 |

| SP2 | … helps reduce food waste | 0.818 | |||

| SP3 | … helps me recycle | 0.794 | |||

| SP4 | … helps me sort waste | 0.793 | |||

| SP5 | … protects nature | 0.843 | |||

| SP6 | … decomposes quickly | 0.839 | |||

| Consumer Preference for Food Packaging (CPBFP), adapted from [96,99,100] | |||||

| CPBFP1 | I would prefer that the food products I buy have active and edible packaging, as it maintains the product quality | 0.892 | 0.934 | 0.791 | 0.950 |

| CPBFP2 | … ensures food safety | 0.880 | |||

| CPBFP3 | … stirs me positive emotions | 0.865 | |||

| CPBFP4 | … makes me want to buy the food product | 0.910 | |||

| CPBFP5 | … determines me to try the food product | 0.897 | |||

| Loyalty toward Biopolymer-film Packaging (LBP), adapted from [99,100,101] | |||||

| LBP1 | I will prefer only food products with edible packaging | 0.810 | 0.933 | 0.750 | 0.947 |

| LBP2 | I will prefer food products with edible packaging over conventional ones | 0.881 | |||

| LBP3 | I will buy food products with edible packaging | 0.889 | |||

| LBP4 | I will speak favorably to my friends and acquaintances about edible packaging | 0.890 | |||

| LBP5 | I will be willing to buy food products with edible packaging | 0.879 | |||

| LBP6 | I will buy food products with edible packaging, even if their price is 5 lei higher | 0.844 | |||

| Fornell–Larcker | Construct | Heterotrait–Monotrait (HTMT) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AP | CPBFP | APP | GP | IP | LBP | SP | AP | CPBFP | APP | GP | IP | LBP | SP | |

| 0.912 | AP | |||||||||||||

| 0.691 | 0.889 | CPBFP | 0.754 | |||||||||||

| 0.615 | 0.675 | 0.859 | APP | 0.678 | 0.728 | |||||||||

| 0.593 | 0.663 | 0.508 | 0.878 | GP | 0.647 | 0.710 | 0.546 | |||||||

| 0.728 | 0.665 | 0.546 | 0.699 | 0.871 | IP | 0.791 | 0.709 | 0.586 | 0.749 | |||||

| 0.617 | 0.677 | 0.800 | 0.532 | 0.564 | 0.866 | LBP | 0.674 | 0.722 | 0.869 | 0.566 | 0.595 | |||

| 0.687 | 0.696 | 0.616 | 0.810 | 0.666 | 0.620 | 0.816 | SP | 0.756 | 0.749 | 0.672 | 0.879 | 0.717 | 0.670 | |

| Paths | Path Coefficients | Standard Deviation | T-Value | Confidence Interval # | p-Value | Hypotheses |

|---|---|---|---|---|---|---|

| IP → CPBFP | 0.126 | 0.049 | 2.599 | 0.035~0.219 | 0.010 * | H1-Accepted |

| AP → CPBFP | 0.216 | 0.044 | 4.950 | 0.125~0.302 | 0.000 ** | H2-Accepted |

| GP → CPBFP | 0.198 | 0.052 | 3.793 | 0.089~0.301 | 0.000 ** | H3-Accepted |

| SP → CPBFP | 0.119 | 0.054 | 2.188 | 0.016~0.227 | 0.029 * | H4-Accepted |

| APP → CPBFP | 0.299 | 0.042 | 7.116 | 0.209~0.372 | 0.000 ** | H5-Accepted |

| CPBFP → LBP | 0.677 | 0.030 | 22.567 | 0.620~0.736 | 0.000 ** | H6-Accepted |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Socaciu, M.-I.; Câmpian, V.; Dabija, D.-C.; Fogarasi, M.; Semeniuc, C.A.; Podar, A.S.; Vodnar, D.C. Assessing Consumers’ Preference and Loyalty towards Biopolymer Films for Food Active Packaging. Coatings 2022, 12, 1770. https://doi.org/10.3390/coatings12111770

Socaciu M-I, Câmpian V, Dabija D-C, Fogarasi M, Semeniuc CA, Podar AS, Vodnar DC. Assessing Consumers’ Preference and Loyalty towards Biopolymer Films for Food Active Packaging. Coatings. 2022; 12(11):1770. https://doi.org/10.3390/coatings12111770

Chicago/Turabian StyleSocaciu, Maria-Ioana, Veronica Câmpian, Dan-Cristian Dabija, Melinda Fogarasi, Cristina Anamaria Semeniuc, Andersina Simina Podar, and Dan Cristian Vodnar. 2022. "Assessing Consumers’ Preference and Loyalty towards Biopolymer Films for Food Active Packaging" Coatings 12, no. 11: 1770. https://doi.org/10.3390/coatings12111770