Indoor Floor Heel Mark Removal Using Spark Discharges and Pressurized Airflow

Abstract

:1. Introduction

2. Experimental Section

2.1. Sample Preparation

2.2. Experimental Setup

2.3. Analysis

2.4. Electrical Measurements

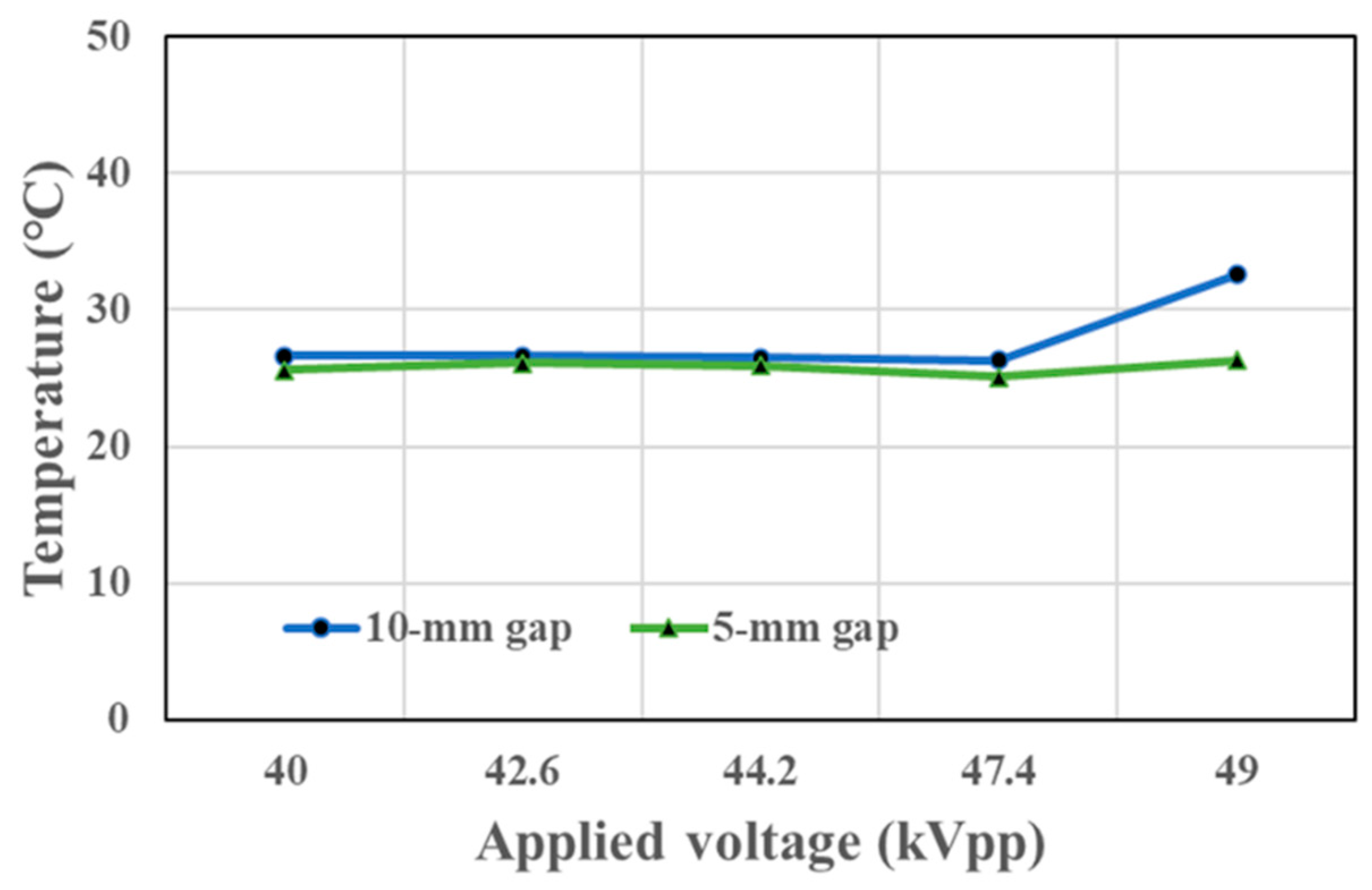

2.5. Temperature Measurements

3. Results

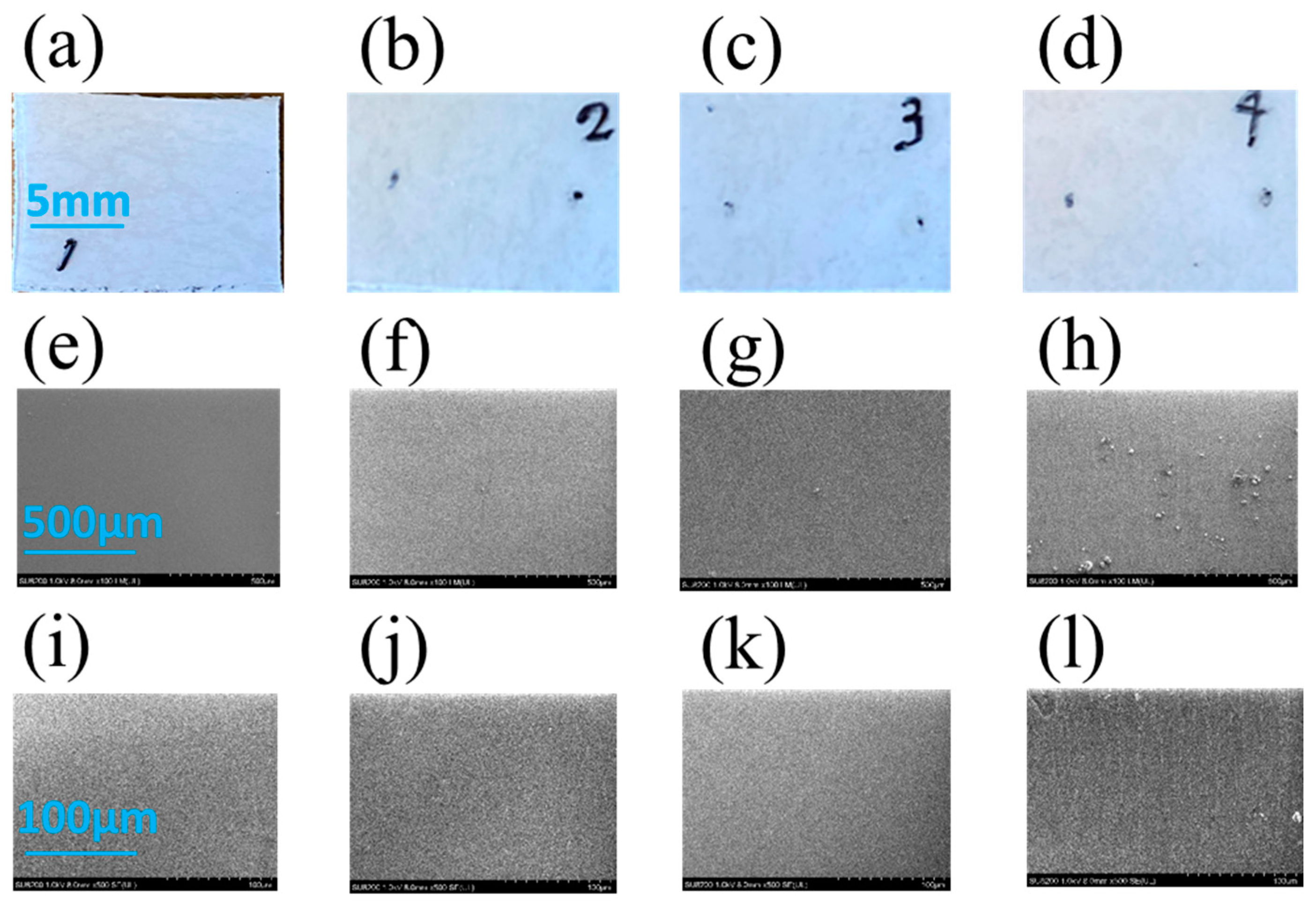

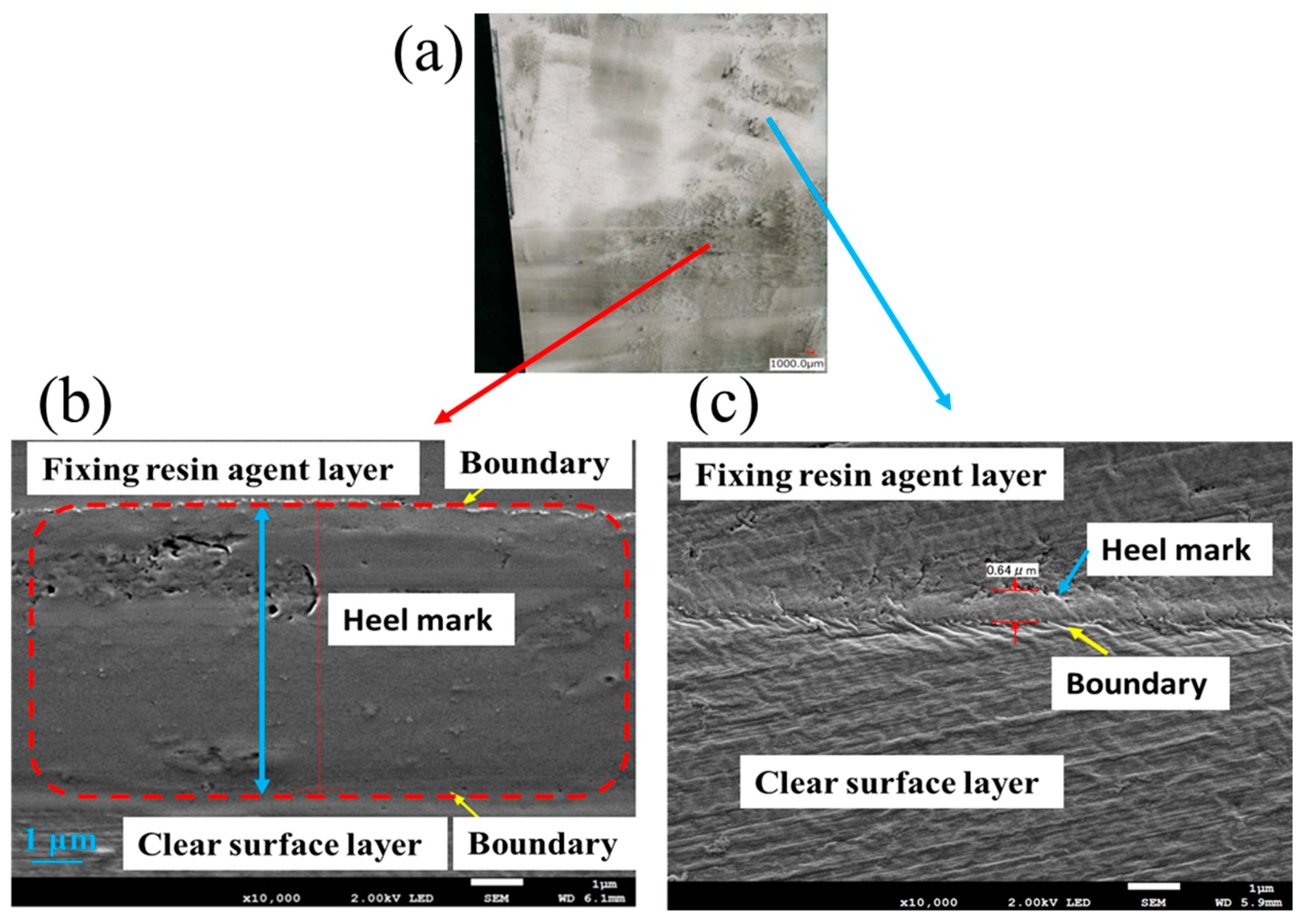

3.1. Stain Removal from Floor Samples

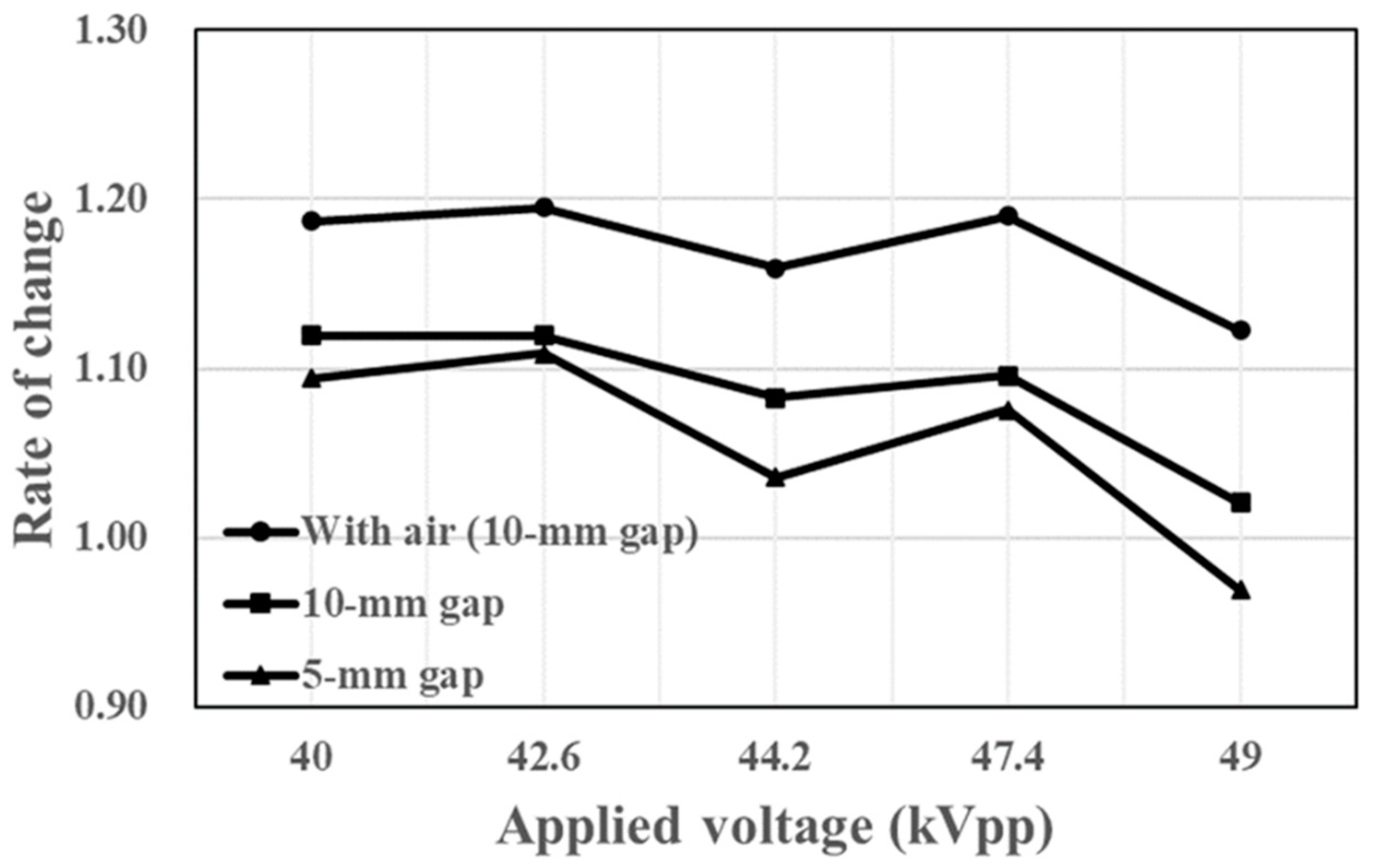

3.2. Improved Efficiency in Removing HM

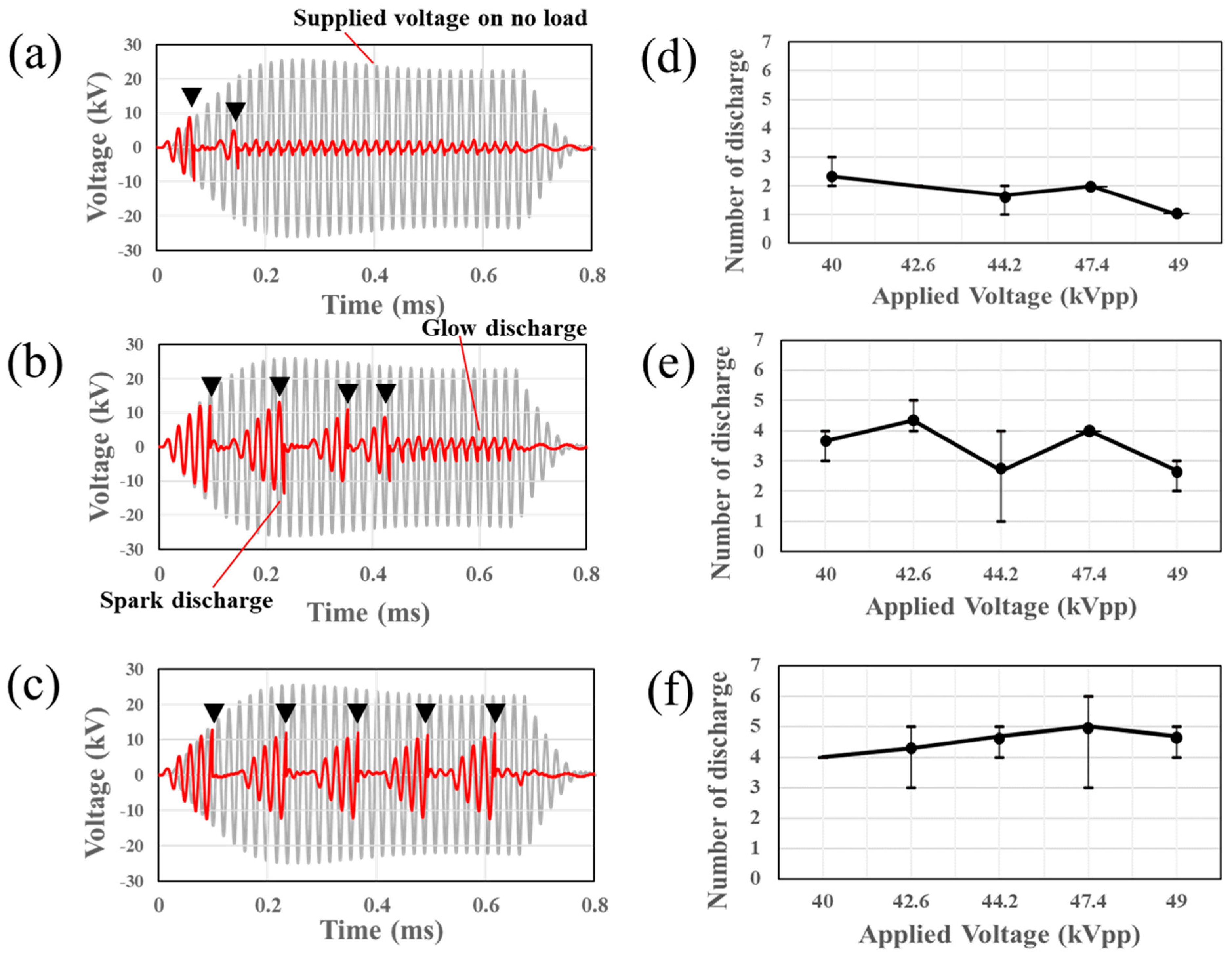

3.3. Electrical Waveforms

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Leadbitter, J. PVC and sustainability. Prog. Polym. Sci. 2002, 27, 2197–2226. [Google Scholar] [CrossRef]

- Cullen, P.J. Systems for Generation of Cold Plasma. In Applications of Cold Plasma in Food Safety; Springer: Berlin/Heidelberg, Germany, 2022; pp. 37–46. [Google Scholar]

- Kometani, R.; Ishikawa, K.; Takeda, K.; Kondo, H.; Sekine, M.; Hori, M. A High-Temperature Nitrogen Plasma Etching for Preserving Smooth and Stoichiometric GaN Surface. Appl. Phys. Express 2013, 6, 056201. [Google Scholar] [CrossRef]

- Shimoeda, H.; Kondo, H.; Ishikawa, K.; Hiramatsu, M.; Sekine, M.; Hori, M. Atomic Oxygen Etching from the Top Edges of Carbon Nanowalls. Appl. Phys. Express 2013, 6, 095201. [Google Scholar] [CrossRef]

- Miyawaki, Y.; Kondo, Y.; Sekine, M.; Ishikawa, K.; Hayashi, T.; Takeda, K.; Kondo, H.; Yamazaki, A.; Ito, A.; Matsumoto, H.; et al. Highly Selective Etching of SiO2 over Si3N4 and Si in Capacitively Coupled Plasma Employing C5HF7Gas. Jpn. J. Appl. Phys. 2013, 52, 016201. [Google Scholar] [CrossRef]

- Miyawaki, Y.; Shibata, E.; Kondo, Y.; Takeda, K.; Kondo, H.; Ishikawa, K.; Okamoto, H.; Sekine, M.; Hori, M. Etching Enhancement Followed by Nitridation on Low-kSiOCH Film in Ar/C5F10O Plasma. Jpn. J. Appl. Phys. 2013, 52, 020204. [Google Scholar] [CrossRef]

- Hayashi, T.; Ishikawa, K.; Sekine, M.; Hori, M. Dissociations of C5F8 and C5HF7 in Etching Plasma. Jpn. J. Appl. Phys. 2013, 52, 05EB02. [Google Scholar] [CrossRef]

- Itoh, H.; Kubota, Y.; Kashiwagi, Y.; Takeda, K.; Ishikawa, K.; Kondo, H.; Sekine, M.; Toyoda, H.; Hori, M. A Development of Atmospheric Pressure Plasma Equipment and Its Applications for Treatment of Ag Films Formed from Nano-Particle Ink. J. Phys. Conf. Ser. 2013, 441, 012019. [Google Scholar] [CrossRef] [Green Version]

- Suzuki, T.; Takeda, K.; Kondo, H.; Ishikawa, K.; Sekine, M.; Hori, M. Temporal changes in absolute atom densities in H2 and N2 mixture gas plasmas by surface modifications of reactor wall. Jpn. J. Appl. Phys. 2014, 53, 050301. [Google Scholar] [CrossRef]

- Donnelly, V.M.; Kornblit, A. Plasma etching: Yesterday, today, and tomorrow. J. Vac. Sci. Technol. A Vac. Surf. Film. 2013, 31, 050825. [Google Scholar] [CrossRef] [Green Version]

- Abe, Y.; Kawashima, S.; Fukushima, A.; Lu, Y.; Takeda, K.; Kondo, H.; Ishikawa, K.; Sekine, M.; Hori, M. Impact of hydrogen radical-injection plasma on fabrication of microcrystalline silicon thin film for solar cells. J. Appl. Phys. 2013, 113, 033304. [Google Scholar] [CrossRef]

- Sahu, B.B.; Yin, Y.; Han, J.G. Effect of plasma parameters on characteristics of silicon nitride film deposited by single and dual frequency plasma enhanced chemical vapor deposition. Phys. Plasmas 2016, 23, 033512. [Google Scholar] [CrossRef]

- Dong, X.; Koga, K.; Yamashita, D.; Seo, H.; Itagaki, N.; Shiratani, M.; Setsuhara, Y.; Sekine, M.; Hori, M. Effects of deposition rate and ion bombardment on properties of a-C:H films deposited by H-assisted plasma CVD method. Jpn. J. Appl. Phys. 2016, 55, 01AA11. [Google Scholar] [CrossRef]

- Oda, O.; Hori, M. Novel Epitaxy for Nitride Semiconductors Using Plasma Technology. Phys. Status Solidi (a) 2020, 218, 2000462. [Google Scholar] [CrossRef]

- Guo, H.; Liu, J.; Yang, B.; Chen, X.; Yang, C. Localized etching of polymer films using an atmospheric pressure air microplasma jet. J. Micromech. Microeng. 2015, 25, 015010. [Google Scholar] [CrossRef]

- Cools, P.; Morent, R.; De Geyter, N. Plasma Modified Textiles for Biomedical Applications. In Advances in Bioengineering; IntechOpen: London, UK, 2015. [Google Scholar]

- Sato, K.; Kogoma, M.; Tanaka, K. Development of Adhesive-Free Lamination of Liquid Crystal Polymer Using a Plasma Surface Treatment at Atmospheric Pressure. J. Photopolym. Sci. Technol. 2019, 32, 519–521. [Google Scholar] [CrossRef] [Green Version]

- Liston, E.M.; Martinu, L.; Wertheimer, M.R. Plasma surface modification of polymers for improved adhesion: A critical review. J. Adhes. Sci. Technol. 1993, 7, 1091–1127. [Google Scholar] [CrossRef]

- Zhang, Y.; Ishikawa, K.; Mozetič, M.; Tsutsumi, T.; Kondo, H.; Sekine, M.; Hori, M. Cover Picture: Plasma Process. Polym. 6/2019. Plasma Process. Polym. 2019, 16, 1970013. [Google Scholar] [CrossRef] [Green Version]

- Iwasaki, M.; Inui, H.; Matsudaira, Y.; Kano, H.; Yoshida, N.; Ito, M.; Hori, M. Nonequilibrium atmospheric pressure plasma with ultrahigh electron density and high performance for glass surface cleaning. Appl. Phys. Lett. 2008, 92, 081503. [Google Scholar] [CrossRef]

- Inui, H.; Takeda, K.; Kondo, H.; Ishikawa, K.; Sekine, M.; Kano, H.; Yoshida, N.; Hori, M. Measurement of Hydrogen Radical Density and Its Impact on Reduction of Copper Oxide in Atmospheric-Pressure Remote Plasma Using H2 and Ar Mixture Gases. Appl. Phys. Express 2010, 3, 126101. [Google Scholar] [CrossRef]

- Yamakawa, K.; Hori, M.; Goto, T.; Den, S.; Katagiri, T.; Kano, H. Ultrahigh-speed etching of SiO2 with ultrahigh selectivity over Si in microwave-excited non equilibrium atmospheric pressure plasma. Appl. Phys. Lett. 2004, 85, 549–551. [Google Scholar] [CrossRef]

- Yamakawa, K.; Hori, M.; Goto, T.; Den, S.; Katagiri, T.; Kano, H. Etching process of silicon dioxide with nonequilibrium atmospheric pressure plasma. J. Appl. Phys. 2005, 98, 013301. [Google Scholar] [CrossRef]

- Kawakami, R.; Aihara, M.; Izumi, T.; Shirai, A.; Mukai, T. Bactericidal effects of low-temperature atmospheric-pressure air plasma jets with no damage to plant nutrient solutions. Biochem. Eng. J. 2022, 187, 108661. [Google Scholar] [CrossRef]

- Katsigiannis, A.S.; Hojnik, N.; Modic, M.; Bayliss, D.L.; Kovač, J.; Walsh, J.L. Continuous in-line decontamination of food-processing surfaces using cold atmospheric pressure air plasma. Innov. Food Sci. Emerg. Technol. 2022, 81, 103150. [Google Scholar] [CrossRef]

- Bahrami, M.; Lavayen-Farfan, D.; Martínez, M.A.; Abenojar, J. Experimental and numerical studies of polyamide 11 and 12 surfaces modified by atmospheric pressure plasma treatment. Surf. Interfaces 2022, 32, 102154. [Google Scholar] [CrossRef]

- Devadevan, M.M.; Krishnanand, J.; Shilpa, K.B.; Kini, R.N. A Compact, Fast, and Efficient Plasma Cleaner. IEEE Trans. Plasma Sci. 2021, 49, 3576–3581. [Google Scholar] [CrossRef]

- Fanelli, F.; Fracassi, F. Atmospheric pressure non-equilibrium plasma jet technology: General features, specificities and applications in surface processing of materials. Surf. Coat. Technol. 2017, 322, 174–201. [Google Scholar] [CrossRef]

- Schutze, A.; Jeong, J.Y.; Babayan, S.E.; Jaeyoung, P.; Selwyn, G.S.; Hicks, R.F. The atmospheric-pressure plasma jet: A review and comparison to other plasma sources. IEEE Trans. Plasma Sci. 1998, 26, 1685–1694. [Google Scholar] [CrossRef] [Green Version]

- Hu, Z.-Y.; Zhang, Z.-H.; Cheng, X.-W.; Wang, F.-C.; Zhang, Y.-F.; Li, S.-L. A review of multi-physical fields induced phenomena and effects in spark plasma sintering: Fundamentals and applications. Mater. Des. 2020, 191, 108662. [Google Scholar] [CrossRef]

- Korzec, D.; Hoppenthaler, F.; Nettesheim, S. Piezoelectric Direct Discharge: Devices and Applications. Plasma 2020, 4, 1–41. [Google Scholar] [CrossRef]

- Penkov, O.V.; Khadem, M.; Lim, W.-S.; Kim, D.-E. A review of recent applications of atmospheric pressure plasma jets for materials processing. J. Coat. Technol. Res. 2015, 12, 225–235. [Google Scholar] [CrossRef]

- Douar, M.A.; Beroual, A.; Souche, X. Assessment of the resistance to tracking of polymers in clean and salt fogs due to flashover arcs and partial discharges degrading conditions on one insulator model. IET Gener. Transm. Distrib. 2016, 10, 986–994. [Google Scholar] [CrossRef]

- Yuan, M.; Zou, L.; Li, Z.; Pang, L.; Zhao, T.; Zhang, L.; Zhou, J.; Xiao, P.; Akram, S.; Wang, Z.; et al. A review on factors that affect surface charge accumulation and charge-induced surface flashover. Nanotechnology 2021, 32, 262001. [Google Scholar] [CrossRef] [PubMed]

- Pai, D.Z.; Lacoste, D.A.; Laux, C.O. Transitions between corona, glow, and spark regimes of nanosecond repetitively pulsed discharges in air at atmospheric pressure. J. Appl. Phys. 2010, 107, 093303. [Google Scholar] [CrossRef]

| Condition | Electrode Gap (mm) | Airflow (20 SLM) |

|---|---|---|

| A | 5 | no |

| B | 10 | no |

| C | 10 | yes |

| Component | Control | HM | Removed HM |

|---|---|---|---|

| C | 76 | 72 | 63 |

| O | 8 | 26 | 23 |

| Al | 10 | 2 | 1 |

| Cl | 6 | 0 | 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sakamoto, Y.; Tsutsumi, T.; Tanaka, H.; Ishikawa, K.; Hashizume, H.; Hori, M. Indoor Floor Heel Mark Removal Using Spark Discharges and Pressurized Airflow. Coatings 2022, 12, 1938. https://doi.org/10.3390/coatings12121938

Sakamoto Y, Tsutsumi T, Tanaka H, Ishikawa K, Hashizume H, Hori M. Indoor Floor Heel Mark Removal Using Spark Discharges and Pressurized Airflow. Coatings. 2022; 12(12):1938. https://doi.org/10.3390/coatings12121938

Chicago/Turabian StyleSakamoto, Yoshihiro, Takayoshi Tsutsumi, Hiromasa Tanaka, Kenji Ishikawa, Hiroshi Hashizume, and Masaru Hori. 2022. "Indoor Floor Heel Mark Removal Using Spark Discharges and Pressurized Airflow" Coatings 12, no. 12: 1938. https://doi.org/10.3390/coatings12121938

APA StyleSakamoto, Y., Tsutsumi, T., Tanaka, H., Ishikawa, K., Hashizume, H., & Hori, M. (2022). Indoor Floor Heel Mark Removal Using Spark Discharges and Pressurized Airflow. Coatings, 12(12), 1938. https://doi.org/10.3390/coatings12121938