Milk Protein-Based Edible Films: Influence on Mechanical, Hydrodynamic, Optical and Antioxidant Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

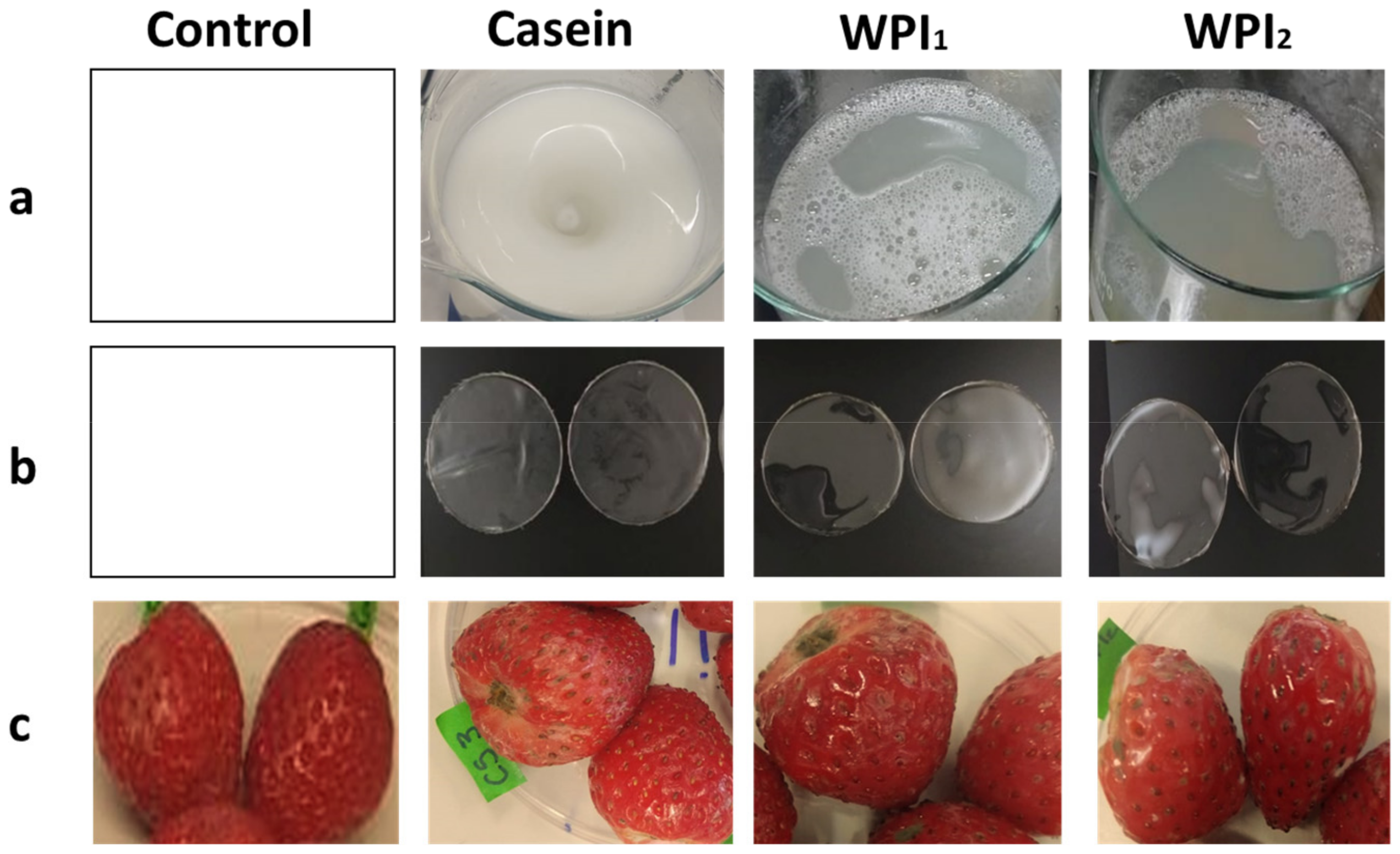

2.2. Preparation of Edible Films

2.3. Thickness

2.4. Tensile Test

2.5. Hydrodynamic Properties (Moisture Content, Water Solubility, Swelling Ratio and WPTR)

2.5.1. Moisture Content

2.5.2. Water Solubility

2.5.3. Swelling Ratio

2.5.4. Water Vapor Transmission Rate

2.6. Color and Optical Properties

2.7. Antioxidant Capacity

2.8. Statistical Analysis

3. Results and Discussion

3.1. Thickness

3.2. Tensile Test

3.3. Hydrodynamic Properties (Moisture Content, Water Solubility, Swelling Ratio and WPTR)

3.3.1. Moisture Content

3.3.2. Water Solubility

3.3.3. Swelling Ratio

3.3.4. Water Vapor Transmission Rate (WPTR)

3.4. Color and Optical Properties

3.5. Antioxidant Capacity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Avramescu, S.M.; Butean, C.; Popa, C.V.; Ortan, A.; Moraru, I.; Temocico, G. Edible and functionalized films/coatings—Performances and perspectives. Coatings 2020, 10, 687. [Google Scholar] [CrossRef]

- Roy, S.; Van Hai, L.; Kim, H.C.; Zhai, L.; Kim, J. Preparation and characterization of synthetic melanin-like nanoparticles reinforced chitosan nanocomposite films. Carbohydr. Polym. 2020, 231, 115729. [Google Scholar] [CrossRef] [PubMed]

- Brodhagen, M.; Peyron, M.; Miles, C.; Inglis, D.A. Biodegradable plastic agricultural mulches and key features of microbial degradation. Appl. Microbiol. Biotechnol. 2015, 99, 1039–1056. [Google Scholar] [CrossRef] [PubMed]

- Moghadam, M.; Salami, M.; Mohammadian, M.; Khodadadi, M.; Emam-Djomeh, Z. Development of antioxidant edible films based on mung bean protein enriched with pomegranate peel. Food Hydrocoll. 2020, 104, 105735. [Google Scholar] [CrossRef]

- Tulipano, G. Role of bioactive peptide sequences in the potential impact of dairy protein intake on metabolic health. Int. J. Mol. Sci. 2020, 21, 8881. [Google Scholar] [CrossRef]

- Pirsa, S.; Sharifi, K. A review of the applications of bioproteins in the preparation of biodegradable films and polymers. J. Chem. Lett. 2020, 1, 47–58. [Google Scholar] [CrossRef]

- López-Barreto, R.E.; Becerra-Jiménez, M.L.; Borrás-Sandoval, L.M. Caracterización físico-química y microbiológica del lactosuero del queso Paipa. Cienc. Agric. 2018, 15, 99–106. [Google Scholar] [CrossRef]

- Asdagh, A.; Sani, I.K.; Pirsa, S.; Amiri, S.; Shariatifar, N.; Eghbaljoo- Gharehgheshlaghi, H.; Shabahang, Z.; Taniyan, A. Production and characterization of nanocomposite film based on whey protein isolated/copper oxide nanoparticles containing coconut essential oil and paprika extract. J. Polym. Environ. 2020, 29, 335–349. [Google Scholar] [CrossRef]

- Yoshida, C.M.P.; Antunes, A.C.B.; Antunes, L.J.; Antunes, A.J. An analysis of water vapour diffusion in whey protein films. Int. J. Food Sci. Technol. 2003, 38, 595–601. [Google Scholar] [CrossRef]

- Schmid, M.; Merzbacher, S.; Müller, K. Time-dependent crosslinking of whey protein based films during storage. Mater. Lett. 2018, 215, 8–10. [Google Scholar] [CrossRef]

- Fernández-Pan, I.; Carrión-Granda, X.; Maté, J.I. Antimicrobial efficiency of edible coatings on the preservation of chicken breast fillets. Food Control 2014, 36, 69–75. [Google Scholar] [CrossRef]

- Catarino, M.D.; Alves-Silva, J.M.; Fernandes, R.P.; Gonçalves, M.J.; Salgueiro, L.R.; Henriques, M.F.; Cardoso, S.M. Development and performance of whey protein active coatings with Origanum virens essential oils in the quality and shelf life improvement of processed meat products. Food Control 2017, 80, 273–280. [Google Scholar] [CrossRef]

- Łopusiewicz, Ł.; Drozłowska, E.; Trocer, P.; Kostek, M.; Śliwiński, M.; Henriques, M.H.F.; Bartkowiak, A.; Sobolewski, P. Whey protein concentrate/isolate biofunctional films modified with melanin from watermelon (Citrullus lanatus) seeds. Materials 2020, 13, 3876. [Google Scholar] [CrossRef] [PubMed]

- Łopusiewicz, Ł.; Jędra, F.; Mizielińska, M. New poly (lactic acid) active packaging composite films incorporated with fungal melanin. Polymers 2018, 10, 386. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lafarga, T.; Rodríguez-Roque, M.J.; Bobo, G.; Villaró, S.; Aguiló-Aguayo, I. Effect of ultrasound processing on the bioaccessibility of phenolic compounds and antioxidant capacity of selected vegetables. Food Sci. Biotechnol. 2019, 28, 1713–1721. [Google Scholar] [CrossRef] [PubMed]

- Gasti, T.; Dixit, S.; D’souza, O.J.; Hiremani, V.D.; Vootla, S.K.; Masti, S.P.; Chougale, R.B.; Malabadi, R.B. Smart biodegradable films based on chitosan/methylcellulose containing Phyllanthus reticulatus anthocyanin for monitoring the freshness of fish fillet. Int. J. Biol. Macromol. 2021, 187, 451–461. [Google Scholar] [CrossRef]

- Doudiès, F.; Arsène, A.S.; Garnier-Lambrouin, F.; Famelart, M.H.; Bouchoux, A.; Pignon, F.; Gésan-Guiziou, G. Major Role of voluminosity in the compressibility and sol–gel transition of casein micelle dispersions concentrated at 7 °C and 20 °C. Foods 2019, 8, 652. [Google Scholar] [CrossRef] [Green Version]

- Ghiasi, F.; Golmakani, M.-T.; Eskandari, M.H.; Hosseini, S.M.H. A new approach in the hydrophobic modification of polysaccharide-based edible films using structured oil nanoparticles. Ind. Crop. Prod. 2020, 154, 112679. [Google Scholar] [CrossRef]

- Wagner, M.; Morel, M.H.; Bonicel, J.; Cuq, B. Mechanisms of heat-mediated aggregation of wheat gluten protein upon pasta processing. J. Agr. Food Chem. 2011, 59, 3146–3154. [Google Scholar] [CrossRef]

- Wang, B.; Sain, M. The effect of chemically coated nanofiber reinforcement on biopolymer based nanocomposites. Bioresources 2007, 2, 371–388. [Google Scholar]

- Sood, A.; Saini, C.S. Red pomelo peel pectin based edible composite films: Effect of pectin incorporation on mechanical, structural, morphological and thermal properties of composite films. Food Hydrocoll. 2022, 123, 107135. [Google Scholar] [CrossRef]

- Grad, S.; Kupcsik, L.; Gorna, K.; Gogolewski, S.; Alini, M. The use of biodegradable polyurethane scaffolds for cartilage tissue engineering: Potential and limitations. Biomaterials 2003, 24, 5163–5171. [Google Scholar] [CrossRef]

- Otoni, C.G.; Avena-Bustillos, R.J.; Azeredo, H.M.C.; Lorevice, M.V.; Moura, M.R.; Mattoso, L.H.C.; McHugh, T. Recent advances on edible films based on fruits and vegetables—A Review. Compr. Rev. Food Sci. Food Saf. 2017, 16, 1151–1169. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Farias, M.G.; Fakhouri, F.M.; de Carvalho, C.W.P.; Ascheri, J.L.R. Physicochemical characterization of edible starch films with barbados cherry (Malphigia emarginata D.C.). Quím. Nova 2012, 35, 546–552. [Google Scholar] [CrossRef] [Green Version]

- Liu, F.; Avena-Bustillos, R.J.; Chiou, B.S.; Li, Y.; Ma, Y.; Williams, T.G.; Wood, D.F.; McHugh, T.H.; Zhong, F. Controlled-release of tea polyphenol from gelatin films incorporated with different ratios of free/nanoencapsulated tea polyphenols into fatty food simulants. Food Hydrocoll. 2017, 62, 212–221. [Google Scholar] [CrossRef]

- Bertuzzi, M.A.; Castro Vidaurre, E.F.; Armada, M.; Gottifredi, J.C. Water vapor permeability of edible starch based films. J. Food Eng. 2007, 80, 972–978. [Google Scholar] [CrossRef]

- Schmid, M.; Zillinger, W.; Müller, K.; Sängerlaub, S. Permeation of water vapour, nitrogen, oxygen and carbon dioxide through whey protein isolate based films and coatings—Permselectivity and activation energy. Food Pack. Shelf Life 2015, 6, 21–29. [Google Scholar] [CrossRef]

- Velázquez, G.; Torres, J.A.; Martín-Polo, M.O. Temperature effect on the moisture sorption isotherms for methylcellulose and ethylcellulose films. J. Food Eng. 2001, 48, 91–94. [Google Scholar]

- Kamal, I. Edible films and coatings: Classification, preparation, functionality and applications—A review. Arch. Org. Inorg. Chem. Sci. 2019, 4, 501–510. [Google Scholar] [CrossRef]

- Yahia, E.M.; Gardea-Béjar, A.; Ornelas-Paz, J.J.; Maya-Meraz, I.O.; Rodríguez-Roque, M.J.; Rios-Velasco, C.; Ornelas-Paz, J.; Salas-Marina, M.A. Preharvest Factors Affecting Postharvest Quality. In Postharvest Technology of Perishable Horticultural Commodities, 1st ed.; Yahia, E.M., Ed.; Woodhead Publishing: Duxford, UK, 2019; Volume 1, pp. 99–128. ISBN 9780128132760. [Google Scholar]

- Schmid, M.; Pröls, S.; Kainz, D.M.; Hammann, F.; Grupa, U. Effect of thermally induced denaturation on molecular interaction-response relationships of whey protein isolate based films and coatings. Prog. Org. Coat. 2017, 104, 161–172. [Google Scholar] [CrossRef]

- Zhang, H.; Nakamura, S.; Kitts, D.D. Antioxidant properties of casein phosphopeptides (cpp) and maillard-type conjugated products. Antioxidants 2020, 9, 648. [Google Scholar] [CrossRef] [PubMed]

- Brandelli, A.; Daroit, D.J.; Corrêa, A.P.F. Whey as a source of peptides with remarkable biological activities. Food Res. Int. 2015, 73, 149–161. [Google Scholar] [CrossRef] [Green Version]

- Kerasioti, E.; Stagos, D.; Priftis, A.; Aivazidis, S.; Tsatsakis, A.M.; Hayes, A.W.; Kouretas, D. Antioxidant effects of whey protein on muscle C2C12 cells. Food Chem. 2014, 155, 271–278. [Google Scholar] [CrossRef] [PubMed]

| Films | Thickness (mm) | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|

| Casein | 0.19 ± 0.01a | 0.70 ± 0.06b | 49.67 ± 5.51a |

| WPI1 | 0.18 ± 0.01b | 2.32 ± 0.23a | 11.57 ± 0.67c |

| WPI2 | 0.17 ± 0.01b | 2.25 ± 0.13a | 28.17 ± 2.39b |

| Films | Moisture Content (%) | Water Solubility (%) | Swelling Ratio (%) | WVTR g/(m2·day) |

|---|---|---|---|---|

| Casein | 40.21 ± 1.91a | 34.71 ± 2.01b | 39.79 ± 3.08c | 15.28 ± 0.35c |

| WPI1 | 21.85 ± 1.63b | 36.46 ± 4.02ab | 109.08 ± 8.41a | 23.32 ± 1.80a |

| WPI2 | 24.75 ± 0.80c | 41.54 ± 1.23a | 82.71 ± 8.36b | 19.94 ± 0.50b |

| Film | L* | a* | b* | ΔE | WI | Opacity | Transparency |

|---|---|---|---|---|---|---|---|

| Casein | 95.76 ± 0.78a | −0.94 ± 0.06b | 2.36 ± 0.13a | 2.65 ± 0.27c | 95.04 ± 0.65a | 0.32 ± 0.03a | 3.35 ± 0.40c |

| WPI1 | 92.67 ± 0.80b | 0.36 ± 0.04a | 1.14 ± 0.07b | 7.36 ± 0.80b | 92.57 ± 0.79b | 0.16 ± 0.01b | 6.23 ± 0.51b |

| WPI2 | 89.34 ± 1.15c | 0.35 ± 0.04a | 0.92 ± 0.08c | 10.67 ± 1.15a | 89.29 ± 1.14c | 0.16 ± 0.02b | 4.90 ± 0.54a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fematt-Flores, G.E.; Aguiló-Aguayo, I.; Marcos, B.; Camargo-Olivas, B.A.; Sánchez-Vega, R.; Soto-Caballero, M.C.; Salas-Salazar, N.A.; Flores-Córdova, M.A.; Rodríguez-Roque, M.J. Milk Protein-Based Edible Films: Influence on Mechanical, Hydrodynamic, Optical and Antioxidant Properties. Coatings 2022, 12, 196. https://doi.org/10.3390/coatings12020196

Fematt-Flores GE, Aguiló-Aguayo I, Marcos B, Camargo-Olivas BA, Sánchez-Vega R, Soto-Caballero MC, Salas-Salazar NA, Flores-Córdova MA, Rodríguez-Roque MJ. Milk Protein-Based Edible Films: Influence on Mechanical, Hydrodynamic, Optical and Antioxidant Properties. Coatings. 2022; 12(2):196. https://doi.org/10.3390/coatings12020196

Chicago/Turabian StyleFematt-Flores, Gabriela Eugenia, Ingrid Aguiló-Aguayo, Begonya Marcos, Belén Arely Camargo-Olivas, Rogelio Sánchez-Vega, Mayra Cristina Soto-Caballero, Nora Aideé Salas-Salazar, María Antonia Flores-Córdova, and María Janeth Rodríguez-Roque. 2022. "Milk Protein-Based Edible Films: Influence on Mechanical, Hydrodynamic, Optical and Antioxidant Properties" Coatings 12, no. 2: 196. https://doi.org/10.3390/coatings12020196