Abstract

With the growth of the automobile, machinery, and aerospace industries, demand for high-performance surface coatings having multifunctional characteristics for use in mechanical parts is increasing. In this study, ternary/quaternary Mo–Cu–Cr–(N) nanocomposite coatings were deposited at different N2 gas flow rates using direct current magnetron sputtering from a multicomponent single-alloy target. The use of a single-alloy target simplifies the deposition process and improves the coating uniformity. The influence of the nitrogen content was investigated regarding the microstructural, mechanical, and tribological properties, and corrosion resistance of these coatings. The Mo–Cu–Cr–N coating containing 30.5 at.% nitrogen showed a nanocomposite structure comprising transition metal nitride phases (Mo–N/Cr–N) having high mechanical properties and corrosion resistance, while retaining the excellent tribological properties of ternary Mo–Cu–N coatings.

1. Introduction

Transition metal nitride coatings, such as Ti–N, Cr–N, and Mo–N, are deposited on the surface of base materials to improve the properties and durability of mechanical parts [1,2,3]. Among them, Mo–N-based coatings have useful characteristics, such as low friction coefficients, high hardness values, and excellent wear resistance. In addition, Mo–N exhibits good adhesion to steel substrates because of the solubility of molybdenum in iron-based materials [4,5,6,7]. To improve the properties of coatings and increase their applications, research has been conducted on ternary-phase coatings in which elements, such as Cu, Co, Cr, and Ni, are added to the Mo–N alloy [8,9]. Of these systems, the Mo–Cu–N system easily forms a nanocomposite because these elements are mutually insoluble, and phase separation into Mo–N and Cu particles in a nitrogen atmosphere is possible [10]. Nanocomposite coatings have complex structures at the nanoscale and can show various conventionally opposing properties simultaneously. For example, a Mo–Cu–N nanocomposite coating having multifunctional characteristics and showing relatively high hardness and excellent wear resistance has been reported, and these properties result from its nanocomposite structure and high nitrogen content [11,12,13]. However, to date, there has been no systematic research on quaternary thin-film systems, especially for Mo–Cu–X systems; ‘X’ means an undefined element. In the case of Mo–X–N-based ternary and quaternary coatings, the microstructure and physical properties of the coating vary greatly depending on the content of the second and third elements; therefore, a systematic study of the process variables is urgently required. Thus, we fabricated a quaternary Mo–Cu–Cr–N coating having an optimized composition to obtain a high-performance coating. Mo–Cu–Cr–N coatings are coatings deposited in a nitrogen atmosphere using a deposition source containing molybdenum, copper, and chromium elements. In this quaternary system, the Mo and Cr form nitride phases, and the chromium nitride coating layer has high elasticity, excellent adhesion strength, and excellent oxidation and abrasion resistance compared to chromium-plated layers [14,15]. In the case of Mo–X–N-based ternary and quaternary coatings reported so far, fabrication has been based on co-sputtering using multiple targets. In this study, a multi-component (Mo, Cu, and Cr) single-alloy target made of alloyed powder was used instead to improve the uniformity of the coating and simplify process control during sputtering, which we hope will make this an attractive process for industrial use. Because Mo and Cu are not co-soluble, even in the liquid phase [16], it is relatively easy to form a nanocomposite coating. Moreover, the use of an alloy target as the deposition source enables coating fabrication at relatively low temperatures, enabling the production of coatings on carburized steel substrate having improved mechanical properties compared to those produced by co-sputtering [17]. Further, in this study, to improve the adhesion of the coating, during the sputtering process, a Ti intermediate layer was added and a cathodic voltage was applied to the substrate. The characteristics of the deposited Mo–Cu–Cr–N coatings prepared at various nitrogen flow rates (0–18 standard cubic centimeters (sccm)) was compared and analyzed to determine the optimum nitrogen flow rate. In this study, the optimum N content of Mo–Cu–Cr–N coating was found to yield a fine microstructure, excellent mechanical properties, low friction coefficients, and excellent corrosion resistance.

2. Materials and Methods

2.1. Coating Deposition

Mo–Cu–Cr–(N) coatings were fabricated by direct current (DC) magnetron sputtering using a single-alloy Mo–Cu–Cr target having an atomic ratio of 80:10:10, respectively, at Ar: N2 gas ratios (sccm:sccm) of 36:0, 33:3, 30:6, 27:9, 24:12, 21:15, and 18:18. The multicomponent single-alloy target (Φ = 7.62 cm) had a Vickers hardness of 681.1 Hv and was fabricated via mechanical alloying and spark plasma sintering. The target was placed on the upper side of the chamber and connected to a DC power source. A Si (111) wafer (2 × 2 cm) and carburized 15Cr–4Mo steel alloy (ASTM B 25) circular specimen having a diameter of 12 mm and height of 4 mm were used as the substrate. The hardness of the carburized 15Cr–4Mo steel alloy with a surface roughness of approximately 0.01 μm was measured to be approximately 12 GPa. Before deposition, the substrates were cleaned in an ultrasonic cleaner using ethyl alcohol for 10 min and further cleaned by Ar ion bombardment at a bias voltage of −600 V for 10 min. The chamber was evacuated to a base pressure of 5 × 10−4 Pa using rotary and turbomolecular pumps and working pressures of 0.67 Pa were used. To improve the adhesion of the coating, a Ti buffer layer was deposited for 10 min under an Ar gas atmosphere from Ti target (Φ = 7.62 cm) by applying 300 W DC sputter power and a substrate bias voltage of −50 V.

2.2. Coating Characterization and Friction Tests

The microstructures and morphologies of the Mo–Cu–Cr-(N) coatings deposited at various nitrogen flow rates (0–18 sccm) were confirmed through scanning electron microscopy (SEM), electron probe microanalysis (EPMA), and X-ray diffractometry (XRD) analyses. The coating thickness and structure were obtained from cross-sectional FE-SEM images. The elemental composition of the coating surface was evaluated using EPMA (EPMA-1720 SHIMADZU, Gyeonggi-do, Korea). XRD measurements (X’Pert-Pro MPD PANalytical, Incheon, Korea) were carried out using Cu-Kα radiation to characterize the phase structure of the coatings. The angle of incidence was set to be 1°. The hardness values and elastic moduli of the coatings were evaluated using a nanoindentation tester (Fisherscope HM2000 LT Fischer, Gyeonggi-do, Korea) at an indentation load of 10 mN applied for 10 s loading/unloading times. Each measurement was repeated 10–12 times to ensure reliability; the indentation depth was approximately 0.1 to 0.15 μm. To characterize the friction behavior of the coatings, an STM-7 friction tester (referenced as a TE 77 high-frequency friction machine) was used. The uncoated substrate and Mo–Cu–Cr–N-coated samples were in contact with a gray iron-cast steel counterpart (JIS FC25, ASTM A48) and mounted on a reciprocating lever under a load of 100 N. The counterpart was a plate-shaped specimen having a length of 58 mm, a width of 20 mm, a height of 2.5 mm, hardness of 5.95 GPa, and average roughness (Ra) of 0.1 μm. The friction tests were conducted for 100 min at a reciprocating frequency of 10 Hz at a set temperature of 150 °C, with a sliding distance of 20 mm per cycle. Each value was obtained every 0.4 s during tribotesting. Polyalphaolefin (PAO 8) oil was used as the lubricant. PAO 8 is a biodegradable base oil without any environmentally toxic additives, such as sulfur, phosphorous, or chlorine [18,19]. PAO 8 is the most common major synthetic base oil used to protect engines and other mechanical systems operating under low friction and wear conditions, resulting in fuel savings and increased durability [20]. To evaluate the corrosion behavior of the substrate and coatings, potentiodynamic polarization measurements were performed in an aerated 3.5 wt.% NaCl solution at room temperature. The exposed surface areas of all specimens were fixed at 0.785 cm2. The test specimens were connected to the working electrode, and high-purity Pt and Ag/AgCl (in saturated KCl) strips were used as the counter and reference electrodes, respectively. Measurements were conducted at a scanning rate of 1 mV/s from −1000 to 800 mV.

3. Results and Discussion

3.1. Microstructure

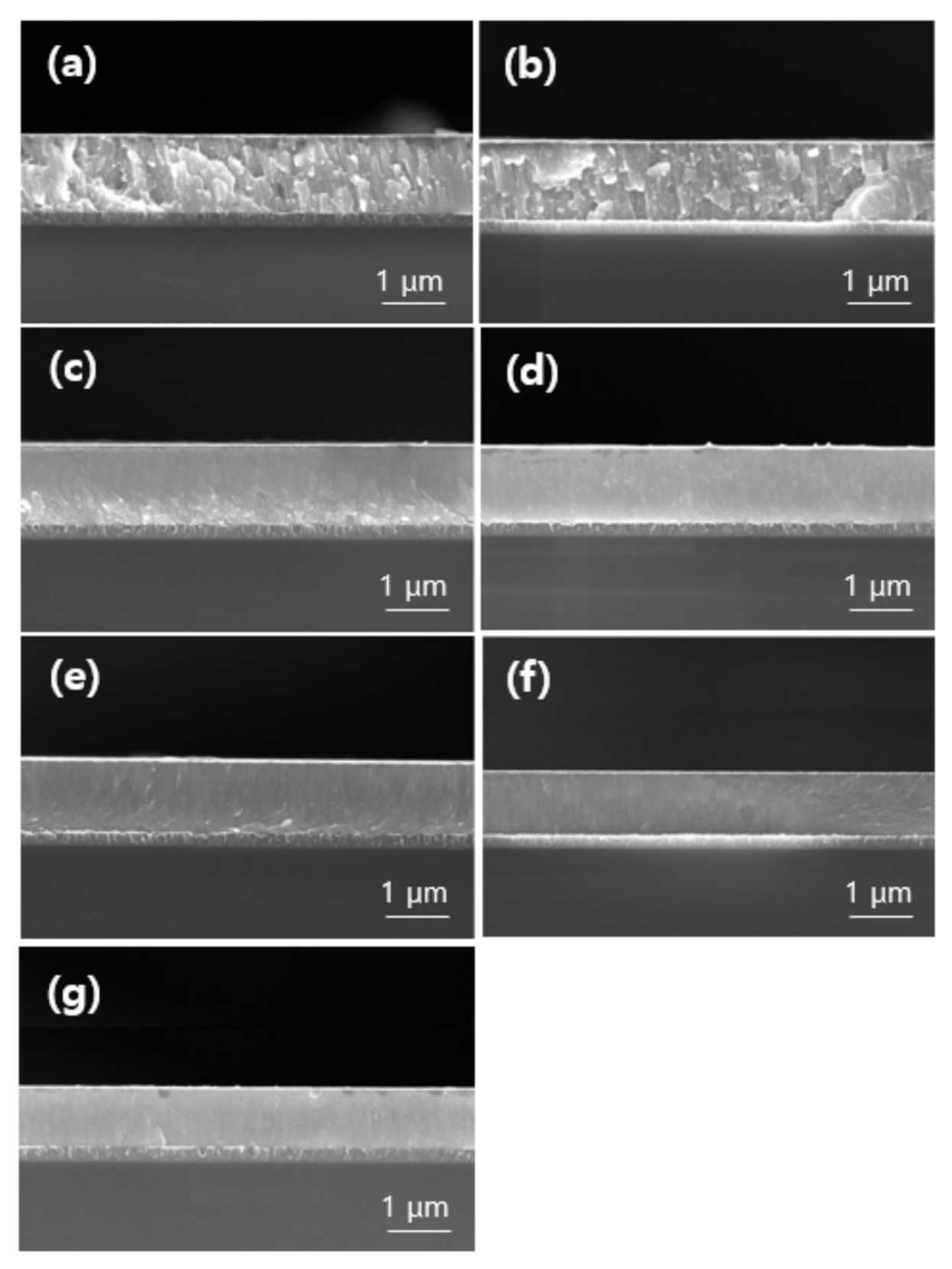

Figure 1 shows cross-sectional SEM images of the Mo–Cu–Cr–(N) coatings deposited at various nitrogen flow rates. As shown in each image, the Ti buffer layer has a columnar interlayer structure with a thickness of approximately 250 nm. Further, the Mo–Cu–Cr–(N) coatings prepared at nitrogen gas flow rates of 0 and 3 sccm have a columnar structure. On the other hand, the Mo–Cu–Cr–(N) coatings deposited with nitrogen gas flow rates of 6 sccm or more have dense, featureless structures. Typically, a columnar structure results in low hardness and poor corrosion resistance, unlike the dense, featureless nanocomposite structures [21]. The Mo–Cu–Cr coating prepared without nitrogen had a deposition rate of 34.6 nm/min, whereas, at nitrogen flow rates of 3, 6, 9, 12, 15, and 18 sccm, the deposition rates were 35.4, 35.8, 34.6, 33.5, 28.9, and 28.6 nm/min, respectively. Thus, at 15 sccm or more, the sputtering rate decreased. As shown in Figure S2, it was confirmed that the higher the nitrogen gas flow, the lower the current density becomes, and this result is almost proportional to the sputtering rate. It was confirmed that, as the nitrogen content increased, the current density was lower and the deposition rate was lower.

Figure 1.

Cross-sectional SEM images of the Mo–Cu–Cr–(N) coatings prepared at N2 gas flow rates of (a–g) 0, 3, 6, 9, 12, 15, and 18 sccm, respectively.

3.2. Crystal Structure

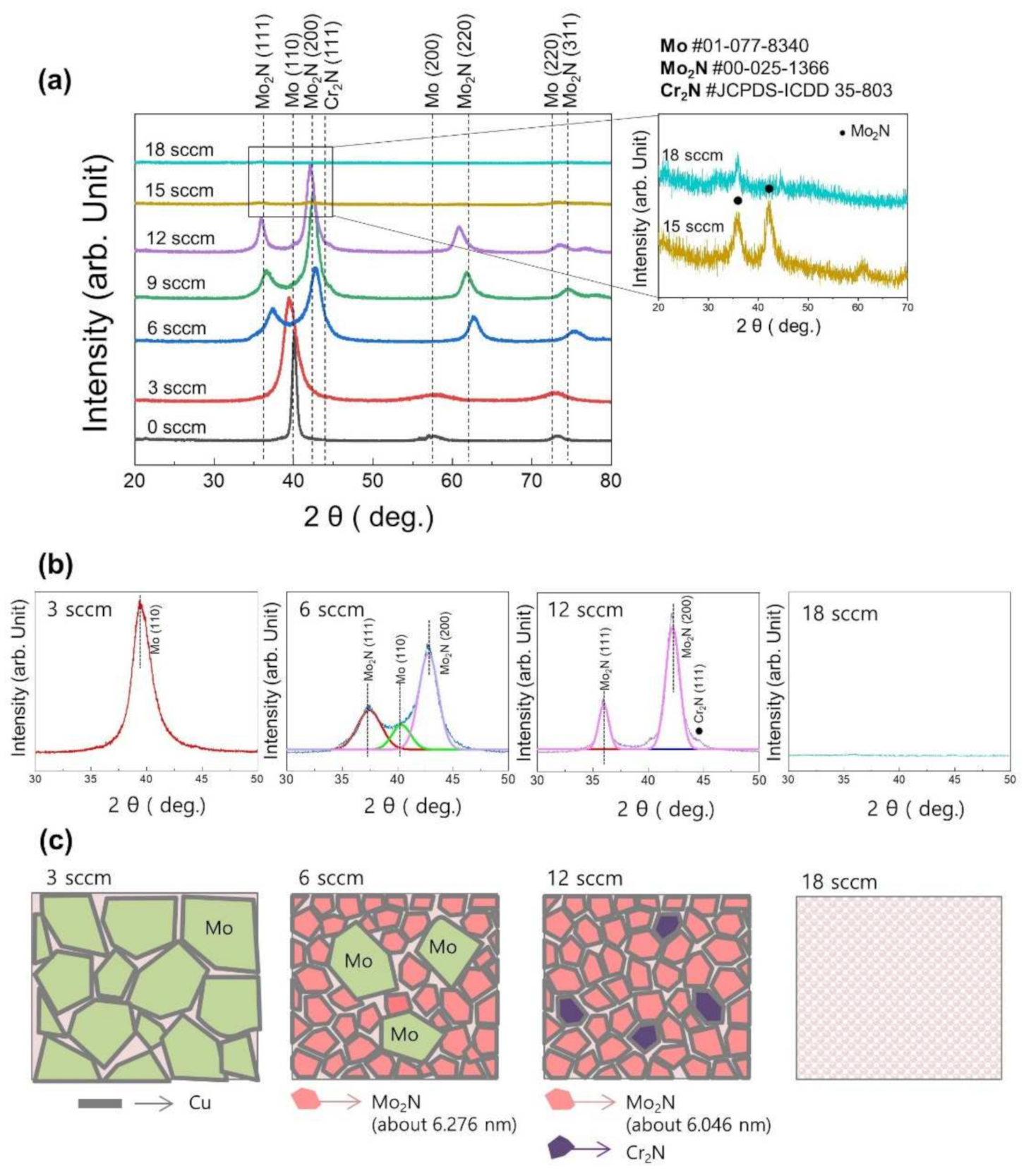

The crystal structures of the Mo–Cu–Cr–N coatings were studied using XRD measurements. Figure 2a shows the XRD patterns of the coatings deposited at various N2 gas flow rates. At 0 sccm, the nitride phase was not formed because the nitrogen flow rate was insufficient, and only a reflection corresponding to Mo (110) was observed at 2 θ ≈ 40° [22]. In contrast, at nitrogen gas flow rates of 6, 9, and 12 sccm, Mo–N nitride phases, such as Mo2N (111), Mo2N (200), were observed between 3 and 42° in common. Moreover, Mo2N (220) and Mo2N (311) were observed at a higher angle of 2 theta [23]. Specifically, Mo (110), Mo2N (111), Mo2N (200), Mo2N (220), and Mo2N (311) were observed in Mo–Cu–Cr–N coatings deposited in gas ratios of Ar:N2 = (30:6) and (27:9). Mo2N (111), Mo2N (200), Mo2N (220), and Mo2N (311) and Cr2N (111) were observed in Mo–Cu–Cr–N coatings deposited in a gas ratio of Ar:N2 = (24:12). From the result shown in Figure 2b, in the coating deposited with 6 sccm nitrogen gas flow, not all of the Mo elements form the transition metal nitride phase and partially remain as the Mo (110) phase due to insufficient nitrogen gas flow. In contrast, as shown in Figure 2b, at a sufficient flow rate, such as 12 sccm, peaks corresponding to Mo2N and Cr2N (111) nitride phases were observed. The substrate temperature becomes higher when nitrogen gas flow increases, and this applied as a driving force as fabrication of nitride phases. The grain size of the crystalline Mo2N phase was calculated to be approximately 6 nm using the Williamson–Hall formula from the XRD peaks [24]. The intensities of the peaks were very low in the XRD patterns of the coatings prepared at high nitrogen gas flow rates of 15 and 18 sccm. Specifically, a low-intensity Mo2N peak was observed in the XRD pattern of the sample prepared at 15 sccm, and a broad peak was observed in the XRD pattern of the sample prepared at 18 sccm. These trends are similar to the trends in coating structure observed by SEM (see Figure 1); specifically, the Mo–Cu–Cr–(N) coatings prepared at 0 sccm, which did not form nitrides, and 3 sccm, which hardly formed nitride phases, had a columnar structure. In contrast, the coatings prepared at 6 sccm or greater (i.e., those that formed molybdenum nitrides or whose XRD peaks indicate low crystallinity) had featureless structures. Figure 2c shows a schematic of the microstructure of the coatings based on the XRD patterns. Generally, Cu is present along grain boundaries because it does not dissolve easily in Mo–N phases [25]. Ti phase could not be confirmed on XRD. It is considered that the X-ray scan depth did not reach the Ti buffer layer (approx. 1 µm).

Figure 2.

(a) XRD patterns of Mo–Cu–Cr–(N) coatings prepared at various N2 gas flow rates and (b) fitted X-ray reflections for the samples prepared at 3, 6, 12, and 18 sccm. (c) Schematic of the microstructures of the coatings prepared at nitrogen gas flow rates of 3, 6, 12, and 18 sccm.

3.3. Composition

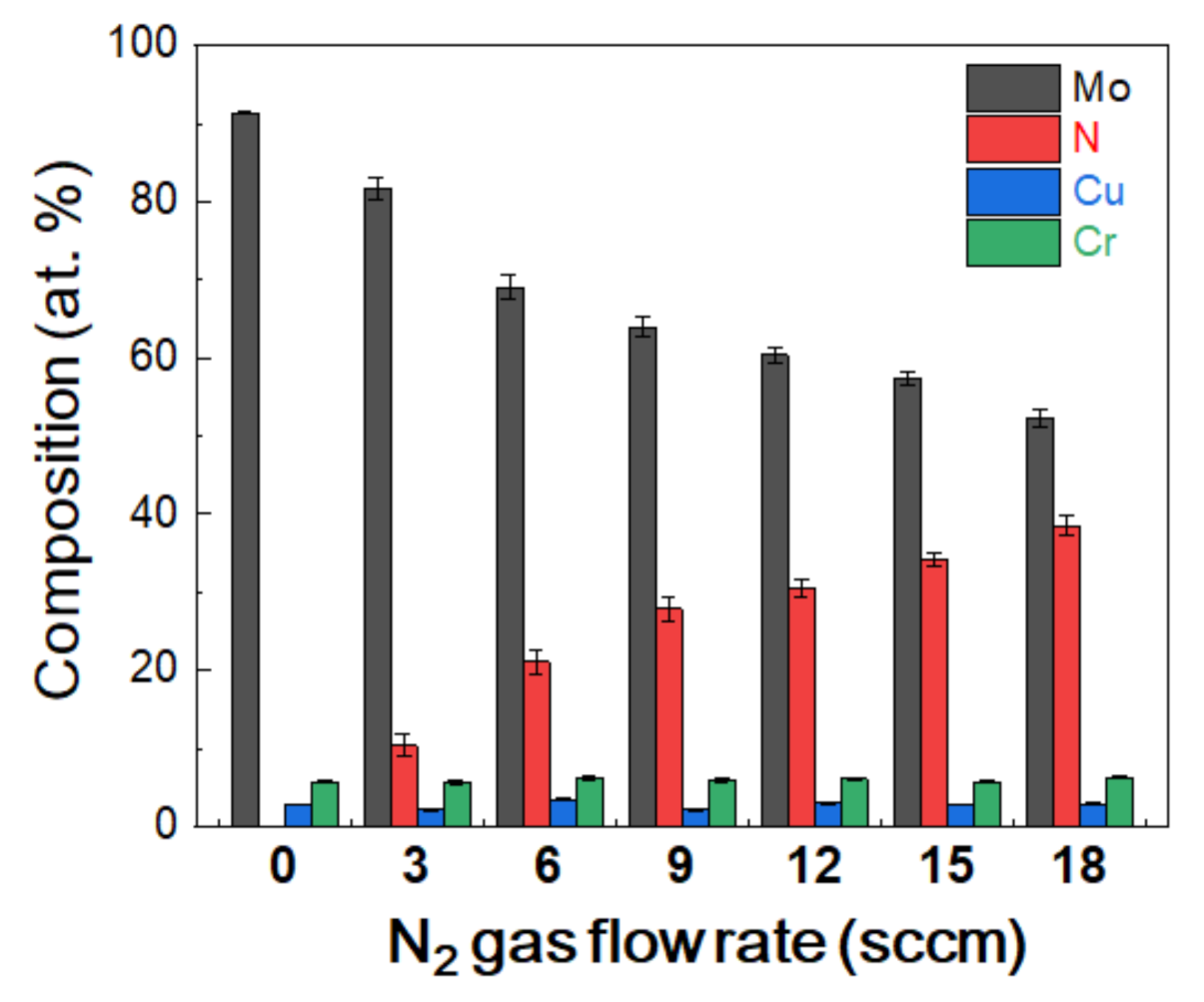

Quantitative EPMA measurements were performed to analyze the composition of each coating in Figure 3. Consistent with the content of the source material, the Mo content is the highest of the component elements. In the coating deposited with a nitrogen gas flow rate of 3 sccm that did not form a nitride phase (see Section 3.2), a low content of nitrogen was observed: 10 at.%. In contrast, in the samples prepared at 6 sccm or more, for which the XRD data indicate the formation of nitride phases, nitrogen contents of 20 at.% or more were determined. Therefore, the nitrogen content of approximately 20 at.% or more is required in the Mo–Cu–Cr–N coatings to form a nitride phase. The sample prepared using a nitrogen gas flow rate of 12 sccm had a nitrogen content of 30.5 at.%. The Mo–Cu–Cr–N (30.5 at.% N) coating contains grains of (Mo, Cr)2N phases of approximately 6 nm in diameter and has a dense and featureless fine nanocomposite microstructure. Also, in Figure S1, Scanning electron microscopy–energy dispersive X-ray spectroscopy (SEM-EDS) analysis (excluding N at.% content) was conducted to confirm that the components of the multicomponent single alloy target (Mo 80 at.%, Cu 10 at.%, and Cr 10 at.%) were transferred equally to the coating.

Figure 3.

Relative elemental composition of the Mo–Cu–Cr–N coatings deposited at various N2 gas flow rates.

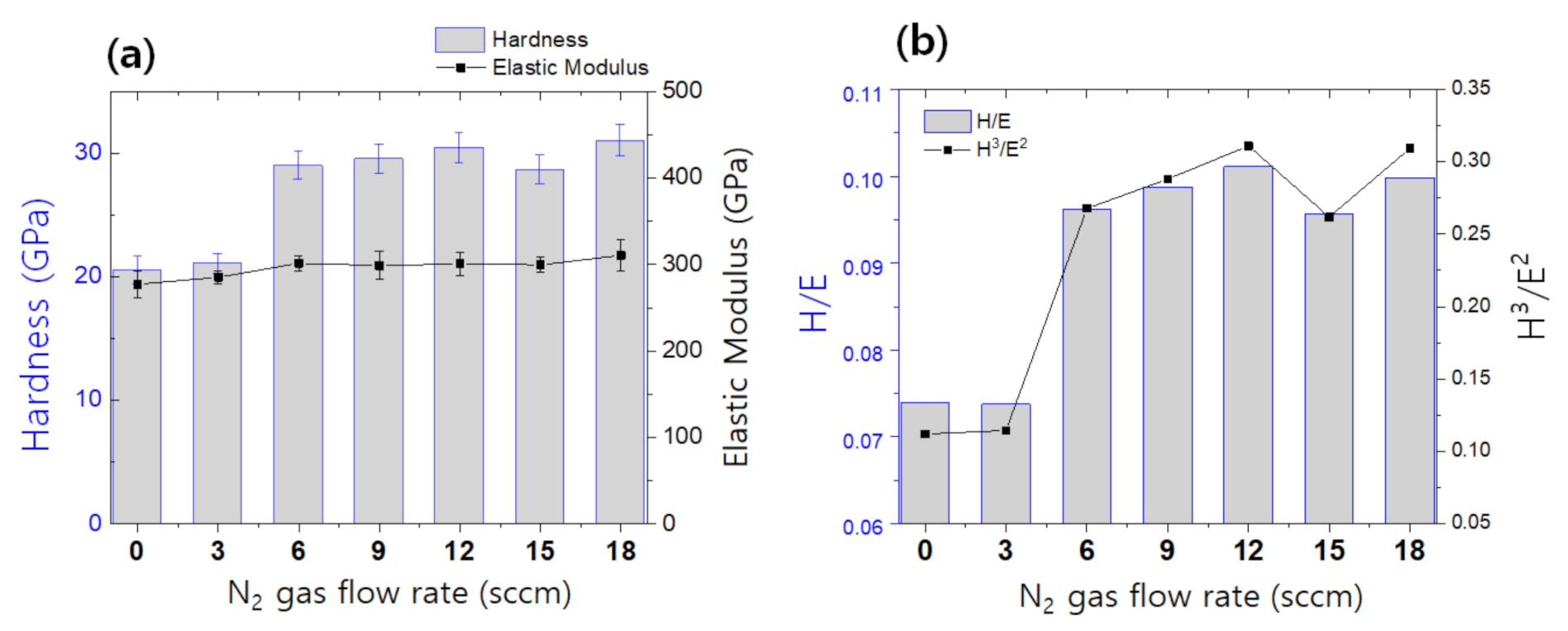

3.4. Mechanical Properties

Nanoindentation analysis was performed to compare and analyze the mechanical properties, including the microhardness and elastic modulus of the Mo–Cu–Cr–(N) quaternary coatings. In Figure 4, the microhardness and elastic modulus values were 20.5 ± 1.1 and 277.2 ± 15.6, and 21 ± 0.8 and 285.2 ± 7.5 GPa for the samples prepared at 0 and 3 sccm, respectively. In contrast, the microhardness, and elastic modulus values of the coatings prepared at 12 sccm were 30.4 ± 1.2 and 300.8 ± 13.8 GPa, respectively.

Figure 4.

(a) Hardness and elastic modulus of Mo–Cu–Cr–N coatings prepared with various N2 gas flow rates and (b) HIT/EIT and HIT3/EIT2 of the Mo–Cu–Cr–N coatings.

Between 6 and 12 sccm, Mo formed a Mo2N phase, and a Cr2N phase was also formed. As a result of the good mechanical properties of these phases, the mechanical properties of the coatings slightly increased. Specifically, the average microhardness and elastic modulus values for these samples are 29.6 and 300.4 GPa, respectively, with increases of 8.9 GPa (42.67%) and 19.1 GPa (6.8%), respectively, compared to those of the Mo–Cu–Cr–(N) coatings prepared at 0 sccm, which did not form transition metal nitrides, and 3 sccm, which hardly formed transition metal nitride phases. Therefore, the formation of crystalline transition-metal-nitride phases influences the mechanical properties of the thin films. The sample prepared at 18 sccm, which was almost amorphous according to the XRD pattern, showed high mechanical properties, having a microhardness and elastic modulus of 31 ± 1.3 and 310.6 ± 17.8 GPa, respectively. As a result, the mechanical property of the coating was increased. The indentation index (HIT)-to-indentation modulus (EIT) ratio was observed which has been reported as fracture toughness, and (HIT)3/(EIT)2 is related to the resistance to plastic deformation [26]. The HIT/EIT value was obtained for the samples prepared at 12 sccm, which formed crystalline transition-metal-nitride phases while having a dense and featureless nanocomposite microstructure.

3.5. Friction Behavior

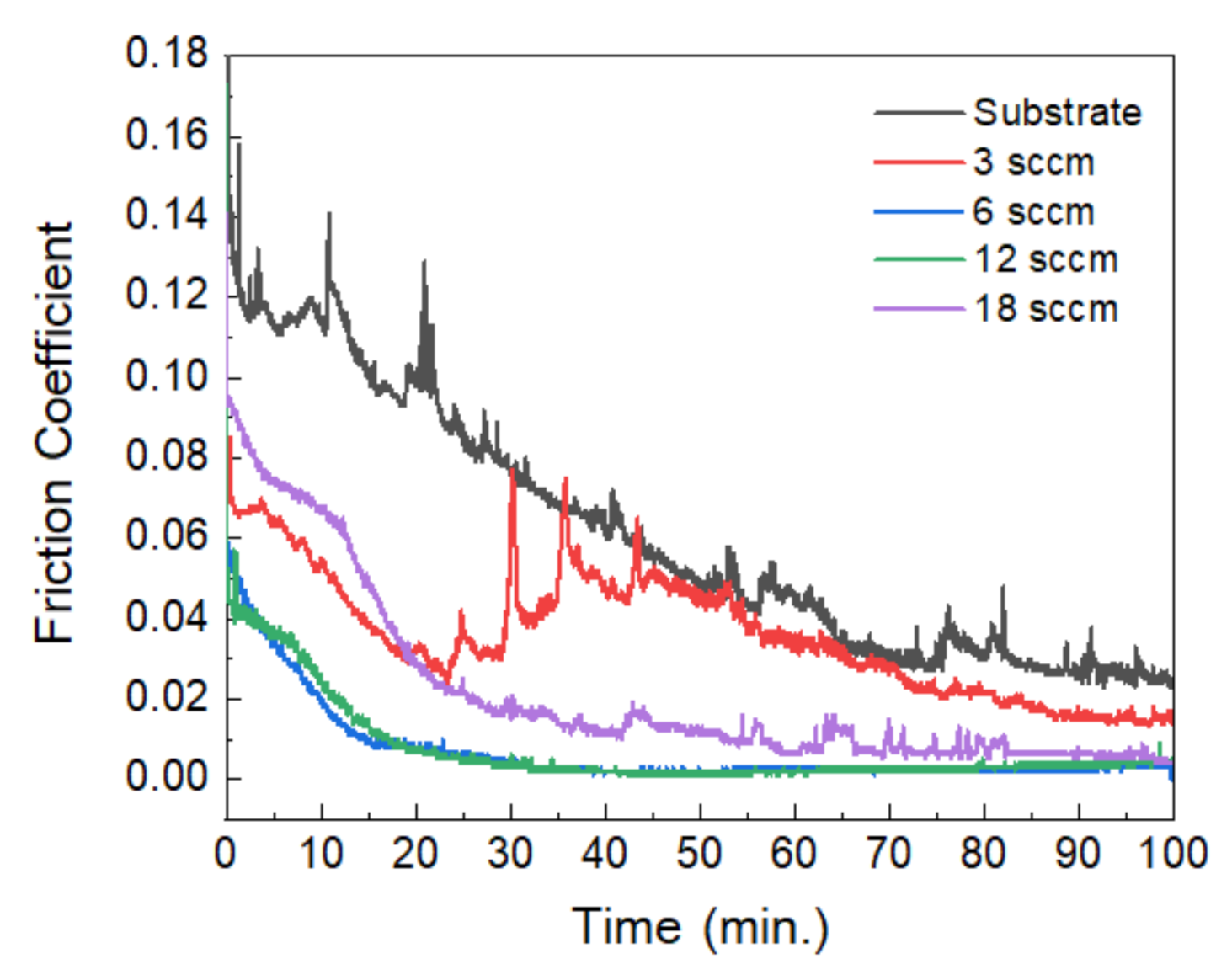

Tribology tests were performed using a face-contacting STM-7 high-frequency friction tester under harsh conditions. Figure 5 shows the friction curves of the substrate and Mo–Cu–Cr–N coatings prepared at various N2 gas flow rates in the presence of the PAO 8 base lubricant environment [27]. The initial coefficient of friction was calculated as the average value obtained over 0–20 min and the late coefficient of friction was calculated as the average value from 80 to 100 min from the friction curve. The initial coefficients of friction were 0.112 in the substrate (Cr–Mo steel alloy) and 0.05, 0.023, 0.024, and 0.061 in the coatings prepared with nitrogen gas flow rates of 3, 6, 12, and 18 sccm, respectively. The late (stabilized) coefficients of friction were 0.028 in the substrate and 0.017, 0.003, 0.003, and 0.006 in the coatings prepared with nitrogen gas flow rates of 3, 6, 12, and 18 sccm, respectively. Furthermore, the Mo–Cu–Cr–N coatings prepared with nitrogen gas flow rates of 6 and 12 sccm had the lowest initial friction coefficients and stabilized rapidly. The coefficient of friction of a reported Mo–Cu–N ternary coating was found to be approximately 0.003 under the same conditions [17]. Based on our results, the addition of Cr did not increase the friction coefficient of the Mo–Cu–N coatings in the PAO lubricant. However, the sample prepared at 3 sccm underwent delamination and had a friction coefficient similar to that of the substrate. In summary, using only PAO lubricating base oil without any additional chemical additives, very low coefficients of friction were obtained owing to the friction characteristics of the coatings prepared at 6 and 12 sccm. It has been reported that, in high-temperature, high-friction environments with lubrication, metal catalysts, such as Cu and Ni, interact with the olefin component of PAO to form a carbon-based tribofilm, thereby reducing the friction coefficient [27].

Figure 5.

Friction coefficients of the Mo–Cu–Cr–N coatings in the presence of the poly alpha olefin (PAO 8) base lubricant.

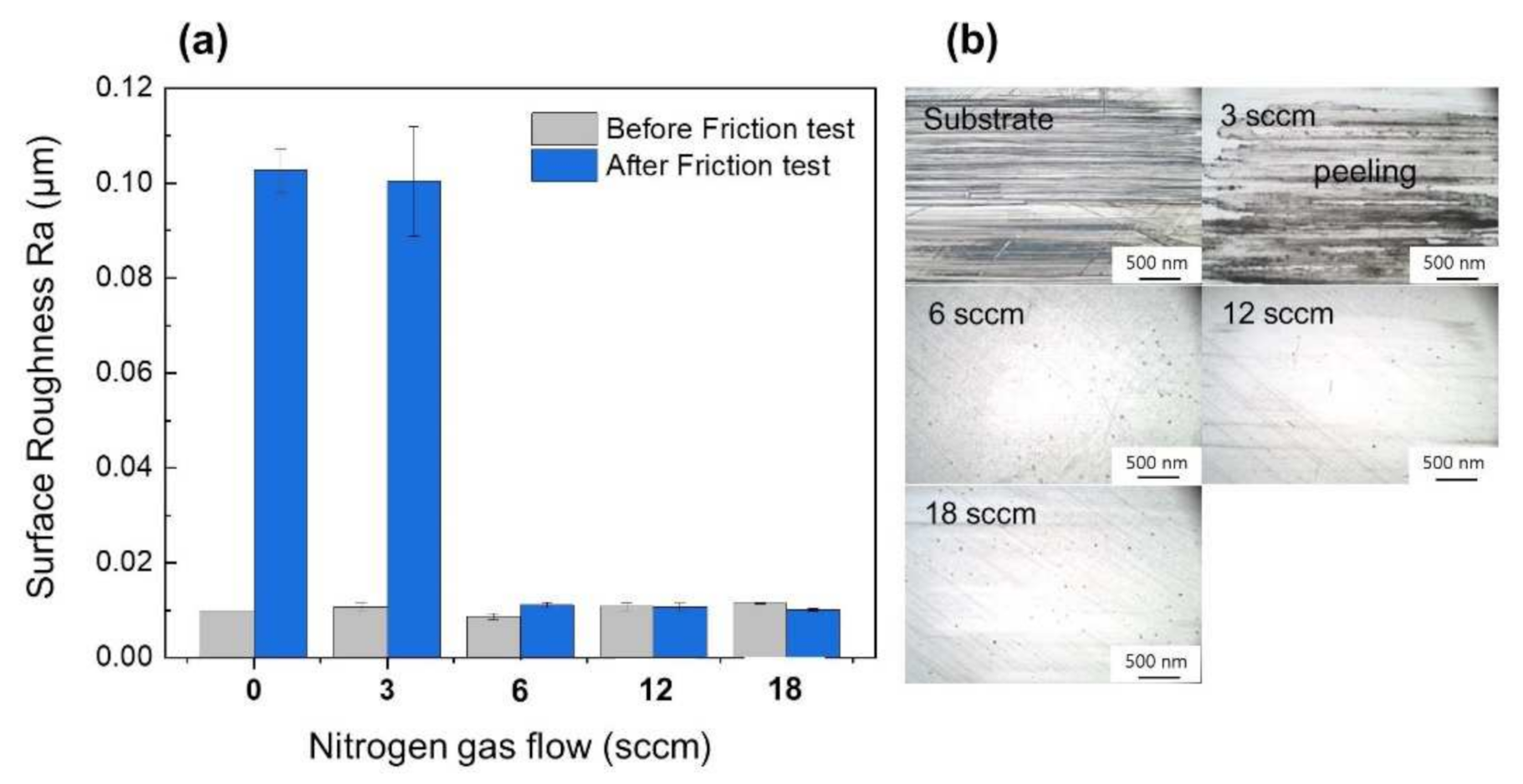

The average surface roughness values (Ra) were measured before and after friction tests to confirm the wear resistance of the coatings. Figure 6a shows the Ra values of the coating before and after the friction tests in the PAO base oil. The surface roughness of the uncoated base material was 0.01 µm, and the roughness values of the Mo–Cu–Cr–N thin films deposited at various nitrogen flow rates were approximately 0.011, 0.009, 0.01, and 0.011 µm for the coatings prepared at 3, 6, 12, and 18 sccm, respectively. Concerning the surface roughness values after the friction tests, the uncoated base material, which had the highest coefficient of friction, had the highest surface roughness (approximately 0.103 nm). This roughness is approximately 9.3 times higher than that before the friction test. The Mo–Cu–Cr–N coating prepared at 3 sccm and having a low HIT value and without any nitride phases showed delamination, and also had a high surface roughness value after the first test. On the other hand, the coatings prepared with nitrogen gas flow rates of 6, 12, and 18 sccm showed similar surface roughness values as before the friction test, thus demonstrating the excellent wear resistance of the Mo–Cu–Cr–N coatings. The excellent wear resistance can also be seen in the optical microscopy images of the surface after the friction tests, as shown in Figure 6b.

Figure 6.

(a) Surface roughness values before and after friction tests and (b) optical microscopy images of the surfaces after friction tests.

3.6. Corrosion

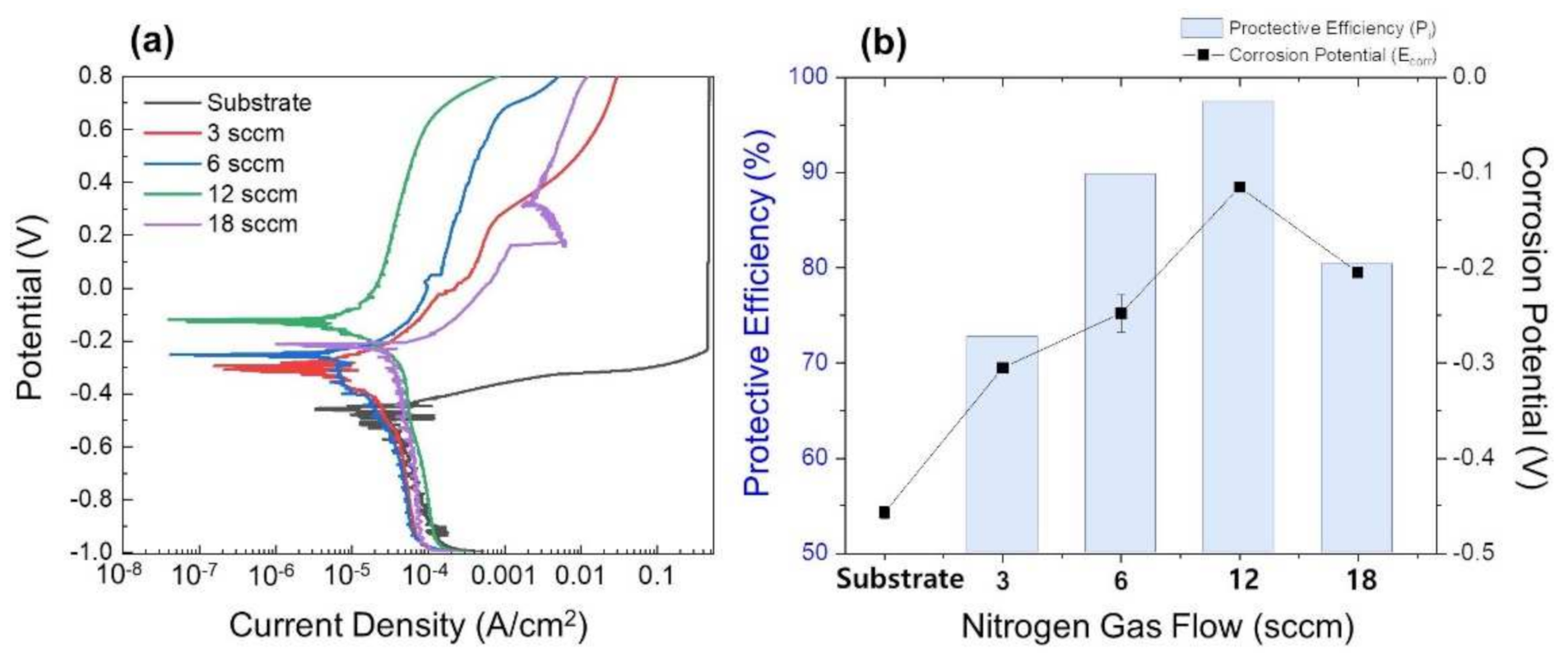

Potentiodynamic polarization measurements were performed to investigate the corrosion resistance of the Mo–Cu–Cr–N coatings concerning the nitrogen flow rate and coating structure. The corrosion resistance characteristics were compared and analyzed by determining the corrosion potential and protective efficiency from the polarization plots. The potentiodynamic polarization results for the substrate and coatings are shown in Figure 7. The corrosion current density and corrosion potential were obtained from the intersection of the extrapolated anodic and cathodic curves. A low current density indicates excellent corrosion resistance. As shown in Figure 7, the Cr–Mo steel alloy substrate had the lowest corrosion potential and corrosion current density, indicating the lowest corrosion rate, and the corrosion potential (Ecorr) for the uncoated substrate and those prepared at nitrogen gas flow rates of 3, 6, 12, and 18 sccm were −0.46, −0.3, −0.25, −0.12, and −0.2 V, respectively. The corrosion potential was highest for the coating prepared at 12 sccm, which formed highly crystalline Mo–N/Cr–N phases and showed a featureless coating structure. This corrosion potential is approximately 283.3% higher than that of the uncoated substrate. In addition, the coating prepared at a nitrogen gas flow rate of 3 sccm, which had a columnar structure, had the lowest corrosion potential. The calculated corrosion current densities (icorr) were 3.34 × 10−3 A/cm2 for the uncoated substrate and 9.12 × 10−5, 3.4 × 10−5, 8.64 × 10−6, and 6.57 × 10−5 A/cm2 for the samples prepared at 3, 6, 12, and 18 sccm, respectively. From the corrosion test results and using Equation (1), the protective efficiencies, Pi (%), of the coatings were determined; in Equation (1), icorr and i0corr indicate the corrosion current densities of the coating and substrate, respectively [28].

Figure 7.

(a) Potentiodynamic polarization curves and (b) corrosion potential and protective efficiency.

The Pi value was lowest for the coating containing column-like structures prepared at 3 sccm (72.7%), whereas the highest Pi was obtained for the sample prepared at 12 sccm (97.4%), which had a grain-like (6-nm grains) structure with a high nitride content. Crucially, a columnar structure results in low hardness and poor corrosion resistance, whereas a dense and featureless nanocomposite structure has the opposite effect [21], which is consistent with these results.

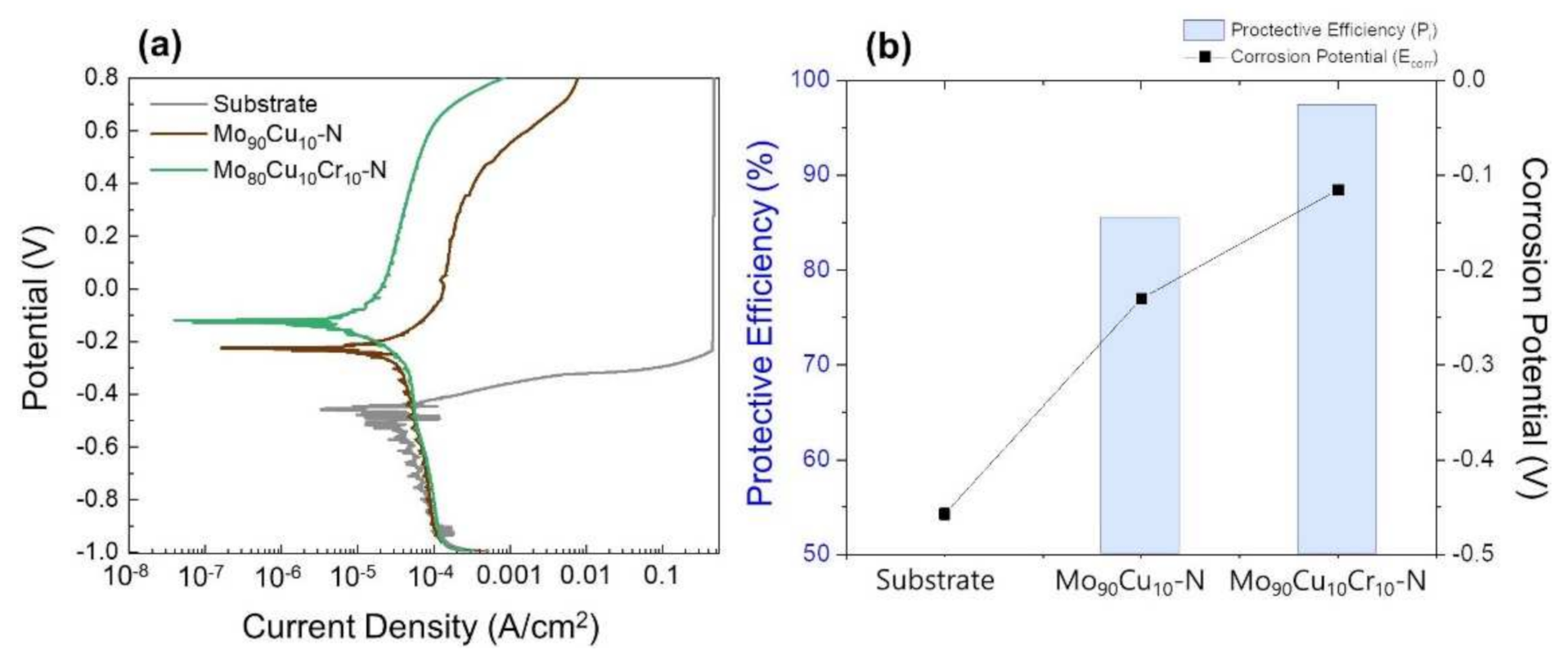

Next, we investigated the effect of the inclusion of Cr on the corrosion resistance properties. For this, the best-performing Mo–Cu–Cr–N coatings prepared at nitrogen flow rates of 12 sccm were used, and we also examined a coating prepared without Cr. Ternary Mo–Cu–N coatings deposited using Mo90Cu10 target were also tested. As shown in Figure 8a, the corrosion potentials (Ecorr) were −0.46 V for the substrate and −0.23 and −0.12 V for the Mo90Cu10–N and Mo80Cu10Cr10–N (12 sccm) coatings, and the corrosion current densities (icorr) were 4.84 × 10−5 and 8.64 × 10−6 A/cm2 for the Mo90Cu10–N and Mo80Cu10Cr10–N (12 sccm) coatings, respectively. The Pi values (Figure 8b) were 85.5% and 97.4% for the Mo90Cu10–N and Mo80Cu10Cr10–N (12 sccm) coatings, respectively. Thus, the Mo–Cu–Cr–N coating prepared at a nitrogen flow rate of 12 sccm, which contains highly crystalline nitride phases, had better corrosion resistance than the Mo–Cu–N ternary coating. This result indicates that the formation of the Cr2N phase resulting from the addition of Cr improves the corrosion resistance of the coating. The dense structure of fine equiaxed crystallites, which contained the Cr2N phase, prevents the entry of the corrosive medium, leading to improved corrosion resistance [29,30].

Figure 8.

(a) Potentiodynamic polarization curves and (b) corrosion potential and protective efficiency.

4. Conclusions

In this study, Mo–Cu–Cr–N coatings were fabricated through a sputtering process using multicomponent single-alloy targets at different nitrogen gas flow rates. The microstructure, mechanical properties, corrosion resistance, and friction behavior were characterized. The results can be summarized as follows:

- SEM and XRD analyses revealed that the coatings prepared at low nitrogen flow rates (0 and 3 sscm of N2 gas rate) had a columnar structure with no nitride phases. In contrast, the coatings prepared at nitrogen flow rates of 6–18 sccm had a featureless and dense coating structure.

- In the coating prepared at a gas ratio of Ar: N2 = (24:12), all the Mo and Cr formed nitride phases; thus, this flow rate was determined to be optimal. However, when nitrogen was added in excess at a flow rate of 18 sccm, broad peaks indicating an almost amorphous structure were observed in the XRD patterns.

- The Mo–Cu–Cr–N coating prepared at a gas ratio of Ar: N2 = (24:12) had a high hardness value (30.4 ± 1.2 GPa) and the highest fracture toughness value (>0.1) because of the formation of crystalline (Mo,Cr)2N phases.

- The stabilized coefficient of friction was approximately 0.003 for the samples prepared at a gas ratio of Ar: N2 = (24:12), confirming the low friction characteristics of the coatings in a lubricating PAO environment. The surface roughness values before and after the friction tests were mostly unchanged, confirming the excellent wear resistance.

- The lowest potential voltage and the highest corrosion current were obtained for the uncoated substrate and the coating prepared at a gas ratio of Ar: N2 = (33:3), which has a columnar coating structure and poor mechanical properties, revealing their low corrosion potentials and poor protective efficiency.

- The highest corrosion potential and protective efficiency were obtained for the sample with a prepared gas ratio of Ar: N2 = (24:12), due to containing a highly crystalline Mo2N phase with a grain size of approximately 6 nm, as well as a Cr2N phase, and a fine nanocomposite microstructure.

Therefore, in this study, novel nanocomposite Mo–Cu–Cr–N coatings (30.487 at.%N) having a fine microstructure, good mechanical properties, excellent corrosion properties, and maintained tribological properties were prepared by using a multicomponent single-alloy target. Further, the nitrogen flow rate can be used to control the nitride phases and, thus, the mechanical performance.

Supplementary Materials

The following are available online at https://www.mdpi.com/article/10.3390/coatings12030371/s1, Figure S1: SEM-EDS analysis of Mo–Cu–Cr–(N) coatings. (a) Coatings deposited without substrate bias and (b) coatings deposited with substrate bias (−50 V), Figure S2: VI Curve of Mo–Cu–Cr single alloy target in various N2 gas flow (a) 0 sccm, (b) 3 sccm, (c) 6 sccm, (d) 12 sccm, (e) 18 sccm. Reference [31] is cited in the supplementary materials.

Author Contributions

S.K.: Conceptualization, Analyzation of the experimental details, Writing—Original draft; K.W.A.: Analyzation of the experimental details, Writing—review and editing; H.W.Y. and H.J.P.: Conceptualization, Writing—review and editing; K.I.M. and C.S.L.: Supervision, Writing—review and editing; K.I.M. and C.S.L. contributed equally to this work as corresponding authors. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Industry Technology Innovation Program (20011767) and funded by the Ministry of Trade, industry, and Energy (MI, KOREA) & This study has been conducted with the support of the Korea Institute of Industrial Technology as “Development of intelligent root technology with add-on modules (KITECH EO-22-0005)”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Huang, J.-H.; Lau, K.-W.; Yu, G.-P. Effect of nitrogen flow rate on structure and properties of nanocrystalline TiN thin films produced by unbalanced magnetron sputtering. Surf. Coat. Technol. 2005, 191, 17–24. [Google Scholar] [CrossRef]

- Elangovan, T.; Kuppusami, P.; Thirumurugesan, R.; Ganesan, V.; Mohandas, E.; Mangalaraj, D. Nanostructured CrN thin films prepared by reactive pulsed DC magnetron sputtering. Mater. Sci. Eng. B 2010, 167, 17–25. [Google Scholar] [CrossRef]

- Shen, Y. Effect of deposition conditions on mechanical stresses and microstructure of sputter-deposited molybdenum and reactively sputter-deposited molybdenum nitride films. Mater. Sci. Eng. A 2003, 359, 158–167. [Google Scholar] [CrossRef]

- Heo, S.J.; Kim, K.H.; Kang, M.C.; Suh, J.H.; Park, C.-G. Syntheses and mechanical properties of Mo–Si–N coatings by a hybrid coating system. Surf. Coat. Technol. 2006, 201, 4180–4184. [Google Scholar] [CrossRef]

- Suszko, T.; Gulbiński, W.; Jagielski, J. The role of surface oxidation in friction processes on molybdenum nitride thin films. Surf. Coat. Technol. 2005, 194, 319–324. [Google Scholar] [CrossRef]

- Šůna, J.; Musil, J.; Dohnal, P. Control of macrostress σ in reactively sputtered Mo–Al–N films by total gas pressure. Vacuum 2006, 80, 588–592. [Google Scholar] [CrossRef]

- Beresnev, V.M.; Bondar, O.V.; Postolnyi, B.O.; Lisovenko, M.O.; Abadias, G.; Chartier, P.; Kolesnikov, D.A.; Borisyuk, V.N.; Mukushev, B.A.; Zhollybekov, B.R.; et al. Comparison of tribological characteristics of nanostructured TiN, MoN, and TiN/MoN Arc-PVD coatings. J. Frict. Wear 2014, 35, 374–382. [Google Scholar] [CrossRef]

- Pappacena, K.; Singh, D.; Ajayi, O.; Routbort, J.; Erilymaz, O.; Demas, N.; Chen, G. Residual stresses, interfacial adhesion and tribological properties of MoN/Cu composite coatings. Wear 2012, 278–279, 62–70. [Google Scholar] [CrossRef]

- Choi, E.Y.; Kang, M.C.; Kwon, D.H.; Shin, D.W.; Kim, K.H. Comparative studies on microstructure and mechanical properties of CrN, Cr–C–N and Cr–Mo–N coatings. J. Mater. Process. Technol. 2007, 187–188, 566–570. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. Design criteria for wear-resistant nanostructured and glassy-metal coatings. Surf. Coat. Technol. 2004, 177–178, 317–324. [Google Scholar] [CrossRef]

- Shin, J.H.; Wang, Q.M.; Kim, K.H. Microstructural evolution and tribological behavior of Mo–Cu–N coatings as a function of Cu content. Mater. Chem. Phys. 2011, 130, 870–879. [Google Scholar] [CrossRef]

- Öztürk, A.; Ezirmik, K.; Kazmanlı, K.; Ürgen, M.; Eryılmaz, O.; Erdemir, A. Comparative tribological behaviors of TiN, CrN and MoNCu nanocomposite coatings. Tribol. Int. 2008, 41, 49–59. [Google Scholar] [CrossRef]

- Kim, J.; Park, S.; Kim, T.; Lee, J. Structure and mechanical properties of Mo–N/Cu films produced by inductively coupled plasma reactive sputtering. Thin Solid Film. 2011, 519, 6876–6880. [Google Scholar] [CrossRef]

- Kim, K.H.; Choi, E.Y.; Hong, S.G.; Park, B.G.; Yoon, J.H.; Yong, J.H. Syntheses and mechanical properties of Cr–Mo–N coatings by a hybrid coating system. Surf. Coat. Technol. 2006, 201, 4068–4072. [Google Scholar] [CrossRef]

- Navinšek, B.; Panjan, P.; Milošev, I. Industrial applications of CrN (PVD) coatings, deposited at high and low temperatures. Surf. Coat. Technol. 1997, 97, 182–191. [Google Scholar] [CrossRef]

- Subramanlan, P.R.; Laughlln, D.E. The Cd-Cu (Cadmium-Copper) system. Bull. Alloy Phase Diagr. 1990, 11, 160–169. [Google Scholar] [CrossRef]

- Kim, S.; Yoon, H.W.; Moon, K.I.; Lee, C.S. Mechanical and friction behavior of sputtered Mo–Cu–(N) coatings under various N2 gas flow using a multicomponent single alloy target. Surf. Coat. Technol. 2021, 412, 127060. [Google Scholar] [CrossRef]

- Bartz, W.J. Lubricants and the environment. Tribol. Int. 1998, 31, 35–47. [Google Scholar] [CrossRef]

- Yue, W.; Liu, C.; Fu, Z.; Wang, C.; Huang, H.; Liu, J. Synergistic effects between sulfurized W-DLC coating and MoDTC lubricating additive for improvement of tribological performance. Tribol. Int. 2013, 62, 117–123. [Google Scholar] [CrossRef]

- She, D.; Gong, P.; Wang, Y.; Kang, J.; Zhu, L.; Ma, G.; Zhong, L.; Huang, H.; Wang, H.; Yue, W. Friction-reduction and anti-wear properties of polyalphaolefin oil with Mo-DTC additive enhanced by nano-carbon materials. Appl. Nanosci. 2020, 10, 3539–3551. [Google Scholar] [CrossRef]

- Musil, J.; Zeman, P.; Baroch, P. Hard Nanocomposite Coatings. Surf. Coat. Technol. 2014, 325–353. [Google Scholar] [CrossRef]

- Ravisubram, S.; Azad, A.; Sakthinath, G. Coating of Synthesized Molybdenum Nanopowder on Aluminium. Asian J. Sci. Res. 2013, 6, 603–608. [Google Scholar] [CrossRef][Green Version]

- Shirazi, M.; Ghasemloo, M.; Etaati, G.R.; Hosseinnejad, M.T.; Toroghinejad, M.R. Plasma focus method for growth of molybdenum nitride thin films: Synthesis and thin film characterization. J. Alloy Compd. 2017, 727, 978–985. [Google Scholar] [CrossRef]

- Solak, N.; Ustel, F.; Urgen, M.; Aydin, S.; Cakir, A.F. Oxidation behavior of molybdenum nitride coatings. Surf. Coat. Technol. 2003, 174–175, 713–719. [Google Scholar] [CrossRef]

- Baker, M.A.; Kench, P.J.; Tsotsos, C.; Gibson, P.N.; Leyland, A.; Matthews, A. Investigation of the nanostructure and wear properties of physical vapor deposited CrCuN nanocomposite coatings. J. Vac. Sci. Technol. A Vac. Surf. Film. 2005, 23, 423. [Google Scholar] [CrossRef]

- Chen, X.; Du, Y.; Chung, Y.-W. Commentary on using H/E and H/E as proxies for fracture toughness of hard coatings. Thin Solid Film. 2019, 688, 137265. [Google Scholar] [CrossRef]

- Erdemir, A.; Ramirez, G.; Eryilmaz, O.L.; Narayanan, B.; Liao, Y.; Kamath, G.; Sankaranarayanan, S.K.R.S. Carbon-based tribofilms from lubricating oils. Nature 2016, 536, 67–71. [Google Scholar] [CrossRef]

- Aramaki, K. Protection of iron corrosion by ultrathin two-dimensional polymer films of an alkanethiol monolayer modified with alkylethoxysilanes. Corros. Sci. 1999, 41, 1715–1730. [Google Scholar] [CrossRef]

- Liu, C.; Leyland, A.; Bi, Q.; Matthews, A. Corrosion resistance of multi-layered plasma-assisted physical vapour deposition TiN and CrN coatings. Surf. Coat. Technol. 2001, 141, 164–173. [Google Scholar] [CrossRef]

- Ou, Y.; Lin, J.; Tong, S.; Sproul, W.; Lei, M. Structure, adhesion and corrosion behavior of CrN/TiN superlattice coatings deposited by the combined deep oscillation magnetron sputtering and pulsed dc magnetron sputtering. Surf. Coat. Technol. 2016, 293, 21–27. [Google Scholar] [CrossRef]

- Anders, A.; Andersson, J. High power impulse magnetron sputtering: Current-voltage-time characteristics indicate the onset of sustained self-sputtering. J. Appl. Phys. 2007, 102, 113303. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).