1. Introduction

The blending of fibers is extensively used in textiles. The properties of materials, such as functionality, end-use, and physical properties, are enhanced by fiber blending. Even though linen and silk fibers are of natural origin, it is still of crucial importance to possess the data on their behavior during the process of finishing when they are bound to be mixed. Linen fiber is processed in an alkaline medium, whereas silk is commonly processed in an acidic medium and dyed with acidic substances. However, silk may also be dyed and processed in an alkaline medium [

1].

The dye type (natural, reactive, pigment, direct, sulfur, etc.) has a significant influence on fastness relative to the different impacts of textile fabrics woven by different raw materials (cotton, silk, lyocell, viscose, polyester, wool, etc.) and using different auxiliaries (mordants, softeners, etc.) [

2,

3,

4,

5,

6,

7,

8,

9,

10,

11,

12,

13]. It can be stated that different kinds of dyes and auxiliaries affect color fastness differently. For example, cellulose fibers dyed in reactive dyes are characterized by exceptional color fastness. Protein origin fibers dyed in acidic and reactive dyes are also well known for excellent color fastness [

14,

15].

If color fastness is unsatisfactory, it is immediately evident that dyeing or rinsing was performed improperly, and the employed regimes of fabric finishing should be reviewed by a technological point of view [

14].

The results of color fastness established with non-expert and expert methods were compared in one study [

16]. There were some differences in the assessments between experts and the non-experts and also among the experts. These results indicate that it is difficult to assess color changes in multi-colored fabrics.

Washing is the most common process in the care of textiles. A complex combination of thermal, mechanical, and physical factors influences the fabrics during the washing process. It is known that textile garments change their dimensions during washing [

17]. For example, the behavioral changes in cotton and viscose were different in terms of shrinkage properties [

18].

Fabric weave also affects its shrinkage—as the length of the floats increases, the width shrinkage also increases. This shrinkage also contributes to the increased area density of the product due to the higher yarn setting per unit area [

19,

20]. It has also been found that as the weft setting decreases, the shrinkage in the weft direction also decreases [

21,

22].

The capacity of fabric shrinking during washing also depends on specific washing conditions, such as water solidity, the choice of washing powder, temperature, and the mechanical effect [

23,

24]. One study [

25] analyzed the shrinkage behaviors of untreated wool fabric and chlorine–Hercosett-treated wool fabric with different moisture contents. Cellulose yarn showed low shrinkage and no pilling in comparison to cotton, viscose, and polyester yarn [

26].

In all cases, the dimensional change is the most prominent one after the first washing because of relaxation shrinkage, and the degree of change decreases with repeated washing [

20].

The application of cross-linking resin is an effective method for improving and controlling dimensional stability, such as the shrinkage of viscose single jersey knits [

27].

Having reviewed previous research, it is evident that the finishing, the selected regimes of finishing, the materials used, and many other factors of finishing impact the fastness of dyeing. Additionally, the major significance of the physical properties of textiles is attributed to the composition of their fibers. In the case of the presently explored fibers, the key issue is the different origins of the fibers in use, which may have a detrimental effect on the quality of the applied finishing. The weave and weft settings of the fabrics were chosen in such a manner that the influence of fabric structure also can be studied, but the main purpose of investigation is to evaluate the influence of the finishing type of the fabrics analyzed. However, the main reason of the research was that quality of the fabric dyeing and printing could be evaluated according to performed color fastness and pH tests; in addition, the final dimensions of the dyed or printed fabric can be predicted according to its shrinkage in the directions of warp and weft. Moreover, the possibility of improving of the finishing processes can be established according to the given investigation results. The objective of the present research is to investigate color fastness and the shrinkage of dyed and digitally printed linen/silk woven fabrics in terms of the quality of finishing.

This research is prevalent because the quality of finishing can be established according to the results of color fastness relative to different impacts and pH value. Thus, the decision about the next course of finishing can be made according to these results. The investigation of shrinkage is also very important, because in many textile companies, products are sewn larger than necessary at first, and then they are dyed right after sewing. In that case, fabric shrinkage in the finished fabric is very prevalent. Thus, the investigation performed is very important for contemporary textile companies and also for textile science.

2. Materials and Methods

2.1. Materials

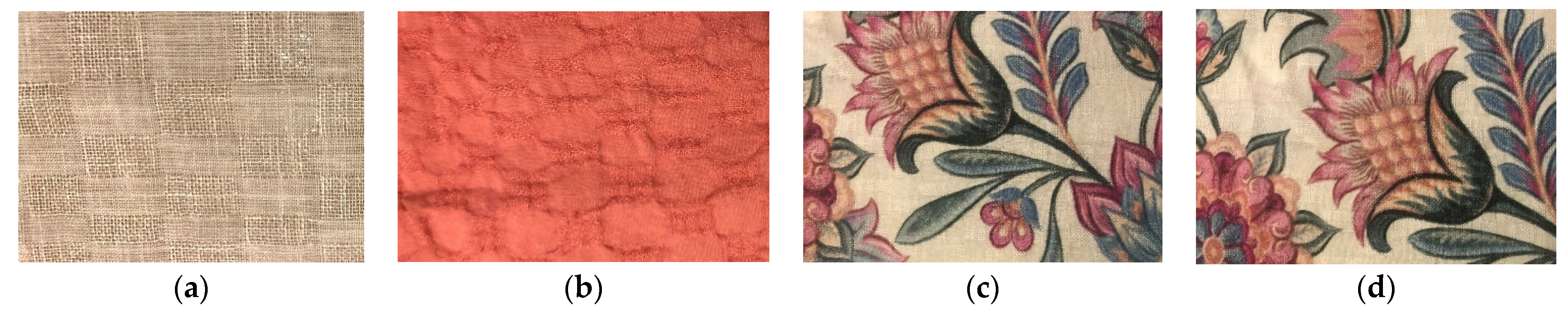

The warp and the weft of the researched fabric were single-blended 70% linen/30% silk yarn with a linear density of 26 tex (Linificio E Canapificio Nazionale (S.P.A.), Bergamo, Italy). The warp density was 220 threads/10 cm, and the weft density was 223 threads/10 cm. The fabric was woven in combined one-layered and two-layered plain weave with an alteration of the layers. The area density of the loom-state fabric was 116.4 g/m

2; the area density of the washed fabric was 186.1 g/m

2. The thickness of the loom-state fabric was 0.83 mm; the thickness of the washed fabric was 1.60 mm. The images of grey and dyed fabrics are shown in

Figure 1.

Such a complicated fabric weave was chosen, because the influence of different yarn settings and other structure parameters in different locations of the repeated pattern can be predicted in different locations of the fabric. The weave in each small fabric place is plain: it is comprised one-layer (dense) or two-layer (rare) weaves.

The fabric was woven with the weaving loom Itema 9500 at textile enterprise Klasikinė tekstilė (Kaunas, Lithuania).

The blended linen/silk yarn was chosen, because silk improves properties of linen fabric, i.e., the fabric becomes more elastic, more flexible, softer, has less wrinkle, etc. In addition, the fabric’s appearance also changes—it becomes more shiny and is not so rough compared to pure linen fabric.

2.2. Finishing Methods

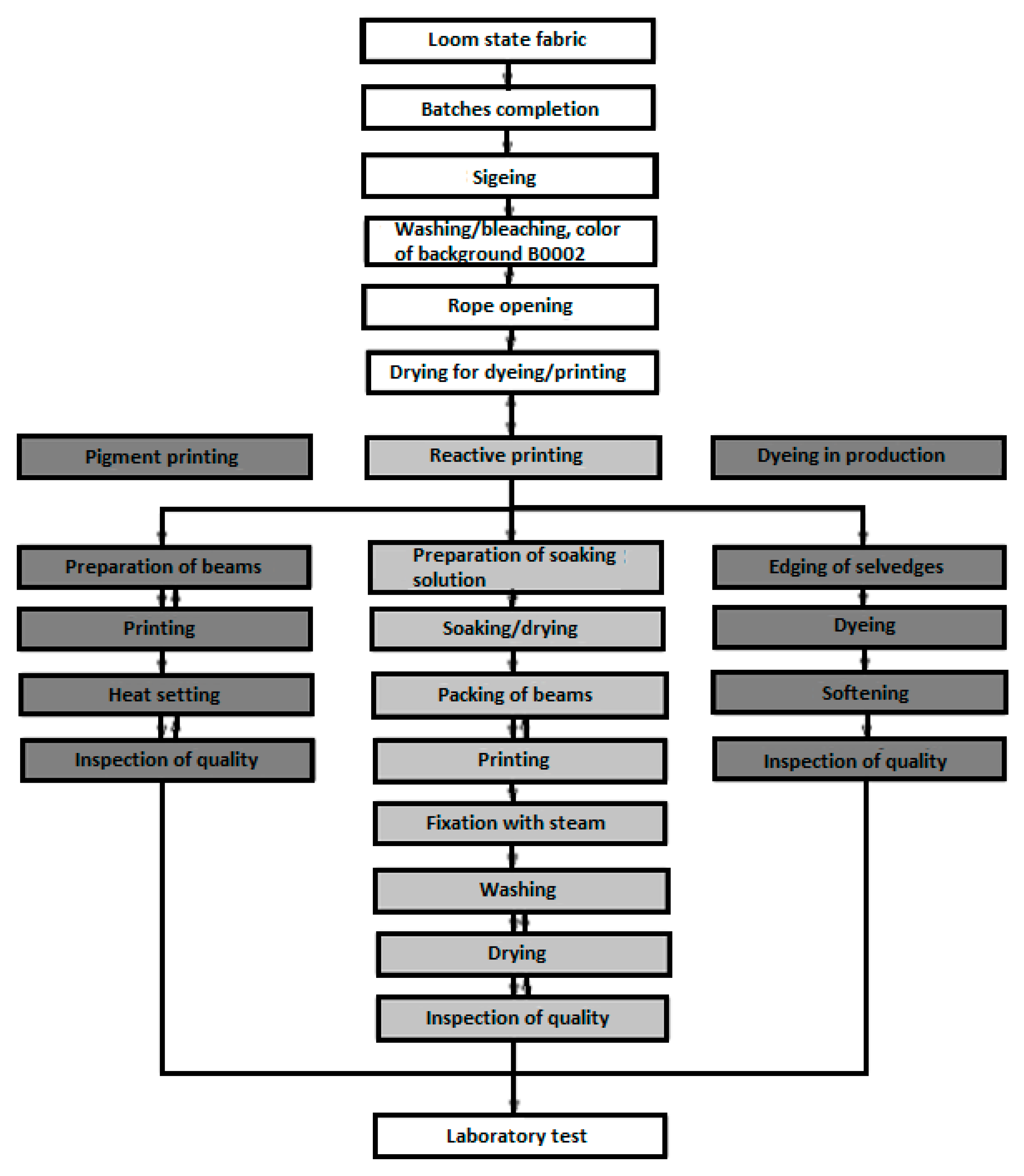

The established finishing procedures for the researched fabrics are outlined in

Figure 2. As the scheme shows, the technological courses do differ between fabrics that are dyed and those that are softened at the products department and fabrics that are printed in reactive and pigment dyes. The most extensive and complex course is the technological pass of active printing. The construction of printing equipment is different as well.

All finishing procedures (washing, dyeing, rinsing, softening, and drying) were performed in BRONGO 100 (Brongo srl, Florence, Italy). The fabrics were washed for 10–15 min at a temperature of 65 °C and dyed for 75–120 min at a temperature of 60 °C. Reactive dyestuff Everzol (Everlight Chemical, Taipei, Taiwan) was used. The color of the dyed fabric was blended by combining dyestuffs of three colors—Everzol Supra Red 3BS h/c, Everzol Yellow 3RS h/c, and Everzol Blue ED-G. The fabrics were rinsed twice in cold water and twice in hot water after dyeing. One session of rinsing took 5 min. Softening was performed in an acid environment; softener Perustol CCF (Rudolph Group, Gerestried, Germany) was used.

Both pigment and reactive digital printing were performed with a piezoelectric DOD ink head. The piezoelectric material was placed in an ink-filled chamber behind each nozzle. In this mechanism, when demand (impulse) is applied, this special material changes the shape, which generates pressure pulse. This effect makes the ink fluid come out from the nozzle. This means that any kind of ink can be used for printing with the same print head. Pigment printing was performed in this work using a printing machine, Mimaki (Mimaki Engineering Co., Ltd., Tomi, Japan), and reactive printing was conducted with the printing machine Mtex500 (Techno Fashion World, Milano, Italy).

For the experiment, we used both pigment dyestuff and reactive dyestuff. Pigment and reactive dyestuffs were manufactured by Mimaki (Mimaki Engineering Co., Ltd., Tomi, Japan). The difference between the two inks is fundamental. Pigment dyestuff contains a binder in the dyestuff; thus, the fabric does not need any special preparation before starting printing. Reactive dyestuff inks do not possess this feature. Fabrics need to be specially prepared for printing, and they are soaked in a combination of chemicals to control color intensity, background color, and line sharpness. All ingredients are fundamentally important, but urea plays a key role in the soaking process. Urea is responsible for the color intensity, and it must fulfill highly set requirements for the drying process. The other major difference is the fixation process. Printed fabrics with pigments need completely dry fixation and do not require washing afterwards; otherwise, when using reactive dyestuff, a steaming process is required, and washing afterwards is a necessary step.

2.3. Environmental Conditions

The samples of fabrics were conditioned under standard environmental conditions according to Standard EN ISO 139: 2005/A1: 2011—“Textiles. Standard atmospheres for conditioning and testing”. The temperature was 20 ± 2 °C, and relative humidity was 65% ± 4%.

2.4. Fastness to Washing and Perspiration

Fastness to washing and perspiration was investigated with fastness research equipment developed by Washtec Roaches (Roaches International, Birstall, UK).

Fastness to washing was established by Standard EN ISO 105–C06. The materials used in this work were standard soap, 706–749 (without optical brightener); distilled water; natrium perborate tetrahydrate, 1 g/L; and non-dyed blended fiber cloth, 702–421.

The liquid-to-fabric weight ratio was 1:50. From the solution of distilled water and standard soap, the working solution was prepared (5 g of standard soap 706–749 and 95 g of distilled water). The researched sample was doubled with the non-dyed blended fiber fabric and processed in a special container (volume of the container = 550 mL) with a washing solution containing 1 g/L of sodium perborate tetrahydrate under specified conditions of temperature, duration, and pH. The container was placed into the Washtech Roaches (Roaches International, Birstall, UK) fastness measurement equipment; a temperature of 40 °C was maintained for 30 min.

We assessed the alteration of color by employing a grayscale. The degree of the coloring of the researched sample and the non-dyed blended fiber fabric was assessed in grades according to the grayscale (

Figure 3). The grayscale shows the difference between the etalon (high picture) and the picture of the non-dyed blended fiber fabric after the test. The score is obtained according this difference of colors, as it is shown in

Figure 3. This score evaluation method was applied to all tests for the determination of color fastness.

Fastness to perspiration was established by Standard EN ISO 105–E04. The materials used in this work were acid perspiration solution, pH 5.5; 1-histidine monohydrochloride monohydrate, 0.5 g/L; sodium chloride, 2.0 g/L; and disodium hydrophosphate dihydrate NaH2PO4·2H2O, 2.2 g/L.

The investigated fabric and the blended fabric were well permeated in the perspiration solution in order to establish the pH value. The investigated dyed sample was doubled with the non-dyed blended fiber sample and processed in a special 550 mL container. The temperature of the solution was 40 °C. The color change was assessed by employing the grayscale. The extent of coloration of both samples was assigned a grade according to the grayscale, and the obtained values are recorded here.

2.5. Color Fastness to Dry and Wet Friction

The test was conducted according to Standard EN ISO 105-X12:2016. Textile samples were rubbed with a wet rubbing fabric and a dry rubbing fabric. Rubbing was conducted with a Roaches crockmeter (Roaches International, Birstall, UK). The crockmeter was automatic; therefore, it was sufficient to set the number of rubbing movements and press the start button after releasing the pressing head. The sample was rubbed with a press value of 9 ± 0.2 kN. Ten forward and ten backward movements were performed. The color grade of the rubbed sample was assessed according to the grayscale under appropriate lighting.

2.6. Area Density

The fabric samples of 100 cm2 were cut and weighed by an EW 150-3M electronic balance (Kern & Sohn GmbH, Albstadt, Germany).

2.7. Fabric Shrinkage in the Directions of Warp and Weft after Household Washing

The samples were stored under standard climatic conditions. Before applying the appropriate methods of washing and drying, they were marked and evaluated according to ISO 3759. After drying and storing under standard climatic conditions and repeated measurements, measurement alterations were calculated.

Fabric swatches were marked in warp and weft directions with an indelible pen. All edges were overlocked with polyester threads [

12].

After the swatches had been marked, they were washed. After the shrinkage dots were detected, their locations were used to calculate dimensional changes in the fabric swatches from before to after washing. Shrinkage was measured both vertically and horizontally. The vertical measurement is the percentage in Euclidean distance between the top shrinkage dot and the bottom shrinkage dot from before washing to after washing. The horizontal measurement is analogous to the vertical measurement [

21].

The average measurement value alterations in the directions of longitude and width were determined according to ISO 3759.

The alteration in the measurement values was marked with the minus (−) sign if the measured value decreased (i.e., the sample shrank), and the plus (+) sign was used if the value increased (i.e., the sample became elongated).

2.8. Fabric Shrinkage in the Direction of Warp and Weft after Washing, Softening, and Dyeing at the Garment Department

The measurement of fabric shrinkage, softening, or dyeing in consumer products is conducted in the same way as after household washing; the only difference is that the samples are adapted to real-life manufacturing and undergo the same processing procedure as the items that go on sale. Dried samples were stored in the conditioned environment for 30 min; then, measurements according to Standard ISO 3759 were conducted.

2.9. Fabric pH Value Measurement by Applying the Extraction Method

To determine the pH value of the fabric, a 2 g sample had to be produced and pulverized in order to maximize the contact surface of distilled water and the sample. The sample was placed in a 150 mL vessel, and 100 mL of distilled water was poured in. The solution was mixed for one hour. After an hour, the solution was removed from the pieces of the fabric, and the value of the obtained solution was measured with a pH meter.

3. Results and Discussion

The conducted finishing yielded different types of results for the same type of fabric. However, in principle, the desired result was achieved—after finishing, the fabrics became suitable for end-use as they became pleasant to touch, and rigidity, which is common for loom-state fabrics, was also eliminated. In the course of dyeing and printing, the external view of the fabric was altered as it became denser, and no more open pores (previously visible in unfinished items) remained (

Figure 4). The fabric became more elastic, and the weave became more prominent [

2,

3,

9]. However, different types of finishing yielded alterations of relief, which was conditioned by the type of weave. Due to shrinkage, the width of fabrics was also altered [

17,

18,

19].

The scanning electron microscopy (SEM) images were performed for the fabrics with different finishing (

Table 1). It can be observed that the main differences of the fabric structure are observed in the images of low magnitude (100×). The image of loom state fabric is the smoothest and clearest. The structure of dyed fabric is the most uneven and hairiest, because it suffers the largest mechanical and chemical effects during mechanical softening and dyeing. The changes in microstructure with higher magnification are less observed.

Both for dyed and printed fabrics, the issue of the properties of color fastness against various impacts is of high relevance (see

Table 2). The measurement was conducted by employing the grayscale. Both measurement methods, by grayscale and by spectrophotometer, are used for the evaluation of color fastness [

16], but the first method predominates in the analyzed scientific literature. Therefore, this method was chosen for our research. All scores except for wet friction were assigned high grades, i.e., all samples were given grade 5. The results show that the quality of finishing, especially dyeing and scouring, is high, because different impacts do not influence the color fastness of the investigated fabrics. Thus, it can be explained by good dyestuff fixation during dyeing, printing, and scouring. These results are positive because poor fastness relative to water, perspiration, and friction causes dye migration, which results in irritation and another negative impact on human skin [

2]. The research data correspond to the data in references [

11,

12,

13], which state that different forms of textile cleaning and softening methods do not worsen color fastness. The results also correspond to the references [

11,

20], which established that excellent color fastness is characteristic of both cellulose and protein fibers. The only difference was found for wet friction, which was assigned grade 3 for dyed and softened fabric, whereas fabrics printed with pigment and reactive dyes received grade 4. Color fastness also shows the quality of finishing, especially for dyeing and rinsing, because by choosing the correct dyeing process parameters, we can achieve low dye migration and rapid wear [

8].

Color fastness relative to the wet friction of linen fabrics, especially darker ones, is a highly relevant problem. Some producers of dyes indicate in their recommendation outlines that the highest possible grade of color fastness against wet friction is merely grade 2 or grade 3. In the present case, digitally printed fabrics scored grade 4, whereas the garment department-dyed sample received grade 3. These scores demonstrate that the parameters of finishing should be improved for printed fabrics. These results correspond to the results of references [

11,

20], which state that the grade of color fastness relative to wet friction is lower than these results relative to other impacts.

All remaining linen/silk fabric samples printed in pigment and reactive dyes demonstrated dyeing fastness relative to various impacts (dry friction, perspiration, and washing) and could be assigned maximum points, e.g., 5 points. These results prove the stainless quality of the implementation of finishing [

11,

15,

16,

20]. This means that dye migration was very low in this case because dyeing, printing, and scouring were performed at high quality levels.

In order to determine the quality of the performed finishing, pH value tests were also conducted. The obtained values were close to the neutral pH value, which suggests that the selected technological sequence and neutralization after finishing were performed correctly. The obtained results adhered to the requirements, and the manufactured product may be delivered to the end consumer. If the pH value is not neutral, then it means that rinsing was not performed precisely and that the fabric must be rinsed again [

1,

2].

It does not make sense to perform the quantitative evaluation of color fastness relative to different finished fabrics using spectrophotometers or similar laboratory equipment, because there is only dyed fabric to which it can be applied. Customizing the quantitative evaluation of color fastness relative to printed fabrics is not possible, because they do not have constant color on their surfaces. We should choose exactly the same location of the printed pattern for fabrics printed with different methods, and this is not entirely possible.

The images of fabrics before and after testing are presented in

Table 3. It can be observed that the color of almost all fabrics remains the same after finishing, except in the case of color fastness relative to wet friction. In this case, the color of the fabric sample changed a little, i.e., the color faded. The results in

Table 1 also prove this phenomenon, i.e., the results of color fastness to wet friction show the change of color samples after the test.

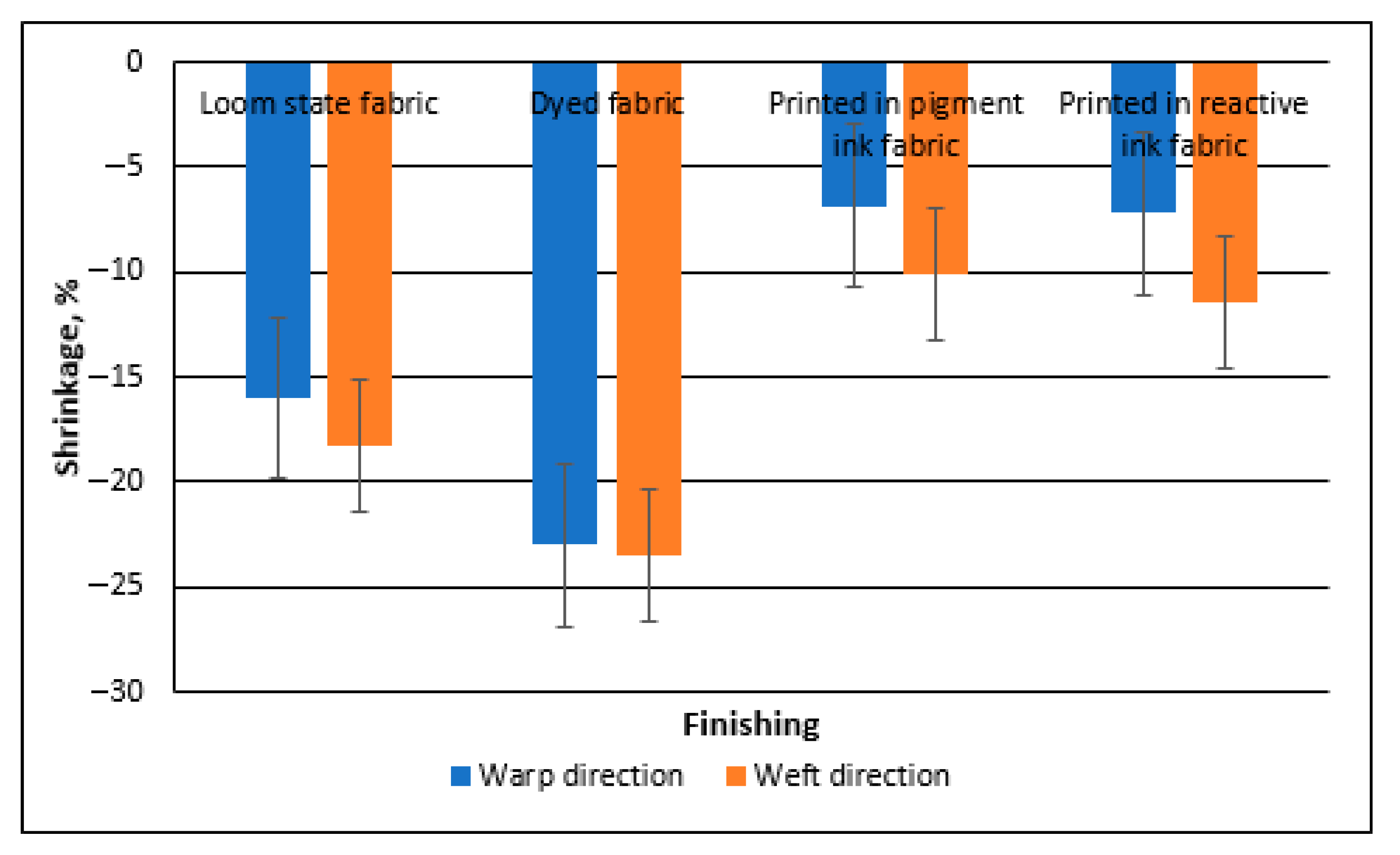

By producing and using fabrics and their products, it is fundamentally important to estimate their shrinkage after finishing and washing. The impact of the linen/silk fabric on fabric shrinking in the directions of warp and weft is outlined in

Table 4. The table shows that the most prominent shrinkage in either direction was observed for the linen/silk fabric dyed in the manufacturing department. Slightly less prominent shrinkage was determined for the washed and softened loom-state fabric. Meanwhile, fabrics printed in reactive and pigment methods commonly exhibited three-times lower shrinkage after finishing. These results can be explained by the softeners that were added to the solution of dyeing as well as when dyeing was performed in rope, while digital printing was performed on the plane-straightened fabric. Because of these reasons, the shrinkage of loose dyed fabric was significantly higher than that of the straightened and printed fabric. Slightly (about 5 percent) lower scores were received for the shrinking of pigment printed fabrics in the directions of both warp and weft. The same trends were observed regarding the alterations of the width of the fabric. Upon the shrinkage of fabrics after finishing, their area density also changed; the alterations ranged from 20% in the case of reactive printing to 40% in the case of washed and softened raw fabric. Such results can be explained by the fact that fabric shrinks during finishing. The width of the fabric becomes lower, and area density becomes higher because the shrunken fabric becomes denser. References [

17,

18,

19,

20] agree that thermal, mechanical, and physical factors influence fabric shrinkage. The shrinkage of textile dimensions was the highest after the first washing, and the degree of changes decreased with repeated washing [

19,

20]. Softening also influences the increase in fabric shrinkage, as is stated in references [

23,

24].

Figure 5 contains a diagram of the shrinkage of samples in the directions of warp and weft for loom-state samples, samples dyed in the garment department, and samples printed with pigment and reactive dyes. The diagram shows that the most prominent shrinkage in both directions was observed for the fabric that was dyed and softened at the garment department. The shrinkage of loom state and washed fabric was 22% lower in comparison to dyed fabric. The lowest shrinkage values were exhibited for fabrics printed by employing both methods; the values reached 57% in comparison to the dyed fabric value. This could be because the type of finishing, such as the dyed sample, becomes squat due being dyed in rope and being softened, while the printed samples were finished in the straightened shape. Because of this, the shrinkage of dyed fabric was significantly higher than that of the printed fabric. Moreover, the diagram demonstrates that, in the direction of warp, fabrics shrunk 2%–39% less than in the direction of weft. This is caused by the fact that the warp yarn when weaving is more stretched, and its crimp is lower in comparison to that of the weft. The results correspond to those in references [

18,

22,

24], which state that with the increase in weft setting, the warp shrinkage also increases, in addition to the interlacing of warp. The fabric weave also has influence on shrinkage—shrinkage is higher for fabrics with longer floats than for those with shorter floats [

23,

26].

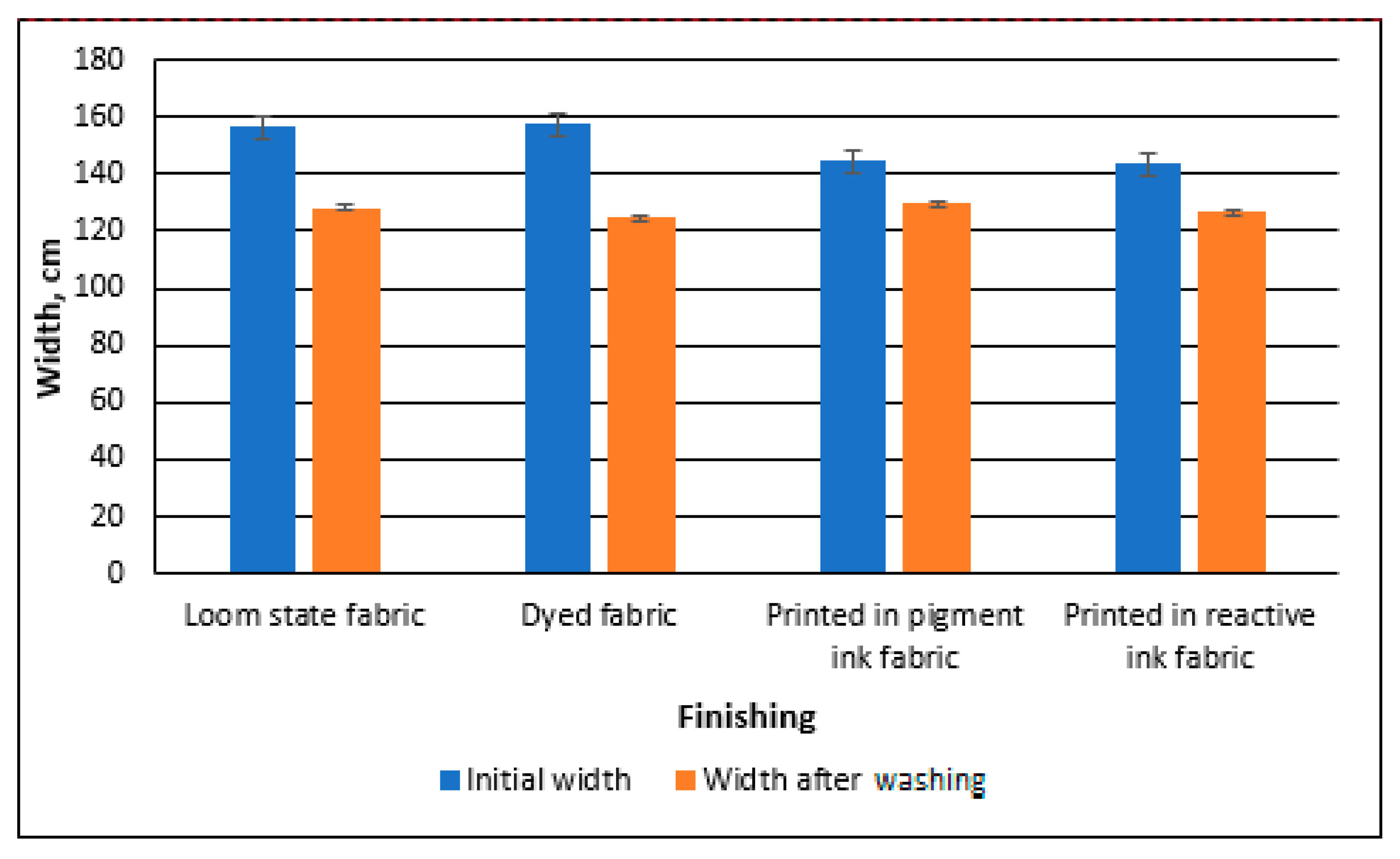

Due to the shrinkage of the weft after finishing, the width of the fabric changes as well.

Figure 6 presents a diagram highlighting fabric width alteration changes by comparing the values before and after washing different types of finishing. The changes in the width of raw and dyed fabrics were more prominent. After finishing, loom-state and dyed fabrics shrank about 22%, whereas for both methods of printing, the fabrics shrank about 13%. Due to the more prominent shrinkage of the weft, loom-state and dyed fabrics also produced higher shrinkage values. The shrinkage in the directions of weft is the reason for reducing the fabric’s width. The width of dyed fabric is higher than that of printed fabrics, because the printed fabrics are flatter and their shrinkage in the direction of weft is lower. References [

20,

25,

26] analyzed fabric shrinkage in terms of fabric width and established the same tendencies. Different auxiliaries (mordants, brighteners, and softeners) also improved fabric shrinkage, as mentioned in references [

22,

24,

27].

Figure 7 highlights the alterations of the area density of fabrics with different types of finishing before and after washing. More prominent changes were observed for loom-state and dyed fabrics; the value of 37% was observed. The area density of both types of investigated printed fabrics increased by about 19%. This was caused by, as shown in

Figure 5 and

Figure 6, the alteration of other structural factors of loom-state and dyed fabrics, such as the settings of the loom-state warp and weft as well as the width of the fabric. The figure demonstrates that the area density of all fabrics increased as the fabrics shrank, and the threads loosened after the impact was experienced in the course of weaving. Therefore, the settings of both warp and weft increased, and area density increased as well. The authors of [

19] stated that greater shrinkage influences increased area density due to high yarn setting per unit area. Fabric weave and weft settings also affect area density, as is mentioned in references [

19,

22]. These results explain the given results in this article. The higher quantity of auxiliaries influences the decrease in fabric width and increase in area density [

19,

20,

21].

It can be observed from

Table 4 and

Figure 6 and

Figure 7 that the dimensions and area density of the fabrics investigated changed after finishing. However, these changes were lower for printed fabrics with pigment and reactive inks, i.e., 19.5% for area density of printed with pigment inks fabric, 20% for area density of printed with reactive inks fabric, 10% for width of printed with pigment inks fabric, and 12% for width of printed with reactive inks fabric. While the width of loom state and dyed fabrics changed in a similar range (18% for loom state fabric and 21% for dyed fabric), area density changes more, i.e., 37.5% for loom state fabric and 37% for dyed fabrics. This fact can be explained by the use of softening procedures during the finishing processes of loom-state and dyed fabrics. They were affected by higher mechanical and chemical effects, which cause higher changes in fabric dimensions. Unfortunately, these changes cannot be observed from the pictures before and after washing.

In conclusion, the structural parameters of fabrics with different finishing (shrinkage in the direction of warp and weft, width, and area density) experience alterations after washing. More prominent parameter changes were observed for loom state and dyed fabrics.