A Highly Breathable and Machine-Washable ePTFE-Aided Down-Proof Cotton Fabric

Abstract

1. Introduction

2. Experimental Section

2.1. Materials and Reagents

2.2. Preparation of ePTFE-Aided Down-Proof Cotton Fabric

2.3. Characterization

2.3.1. Surface Morphology Observation

2.3.2. Contact Angle Test

2.3.3. Vertical Wicking Test

2.3.4. Pore Size Distribution of Fabrics

2.3.5. Anti-Drilling Performance Test

2.3.6. Laundering Test

2.3.7. Air Permeability Test

2.3.8. Water Vapor Permeability Test

2.3.9. Thermal Insulation Test

2.3.10. Tensile Test

3. Results and Discussion

3.1. Macro-Micro Structures of Down-Proof Fabric

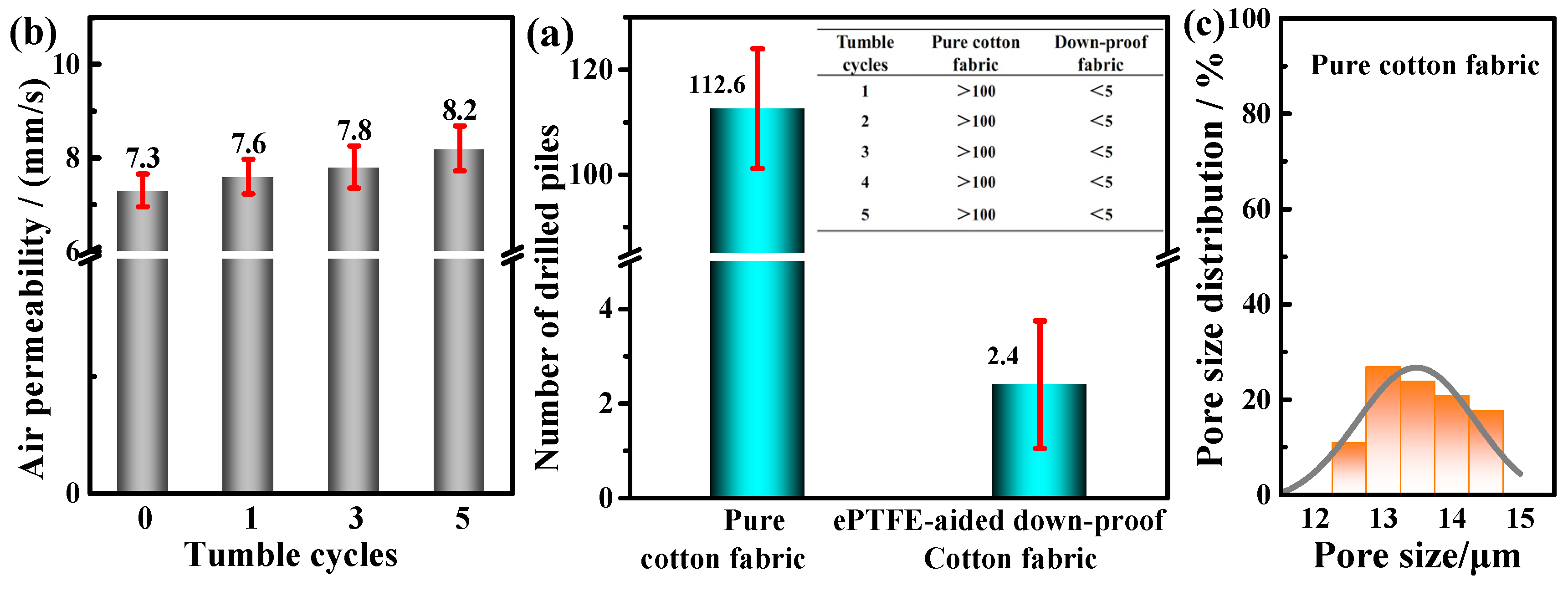

3.2. Effect of Tumble Cycles on Anti-Drilling Performance of Fabric

3.3. Effect of Washing Cycles on Anti-Drilling Performance of Fabric

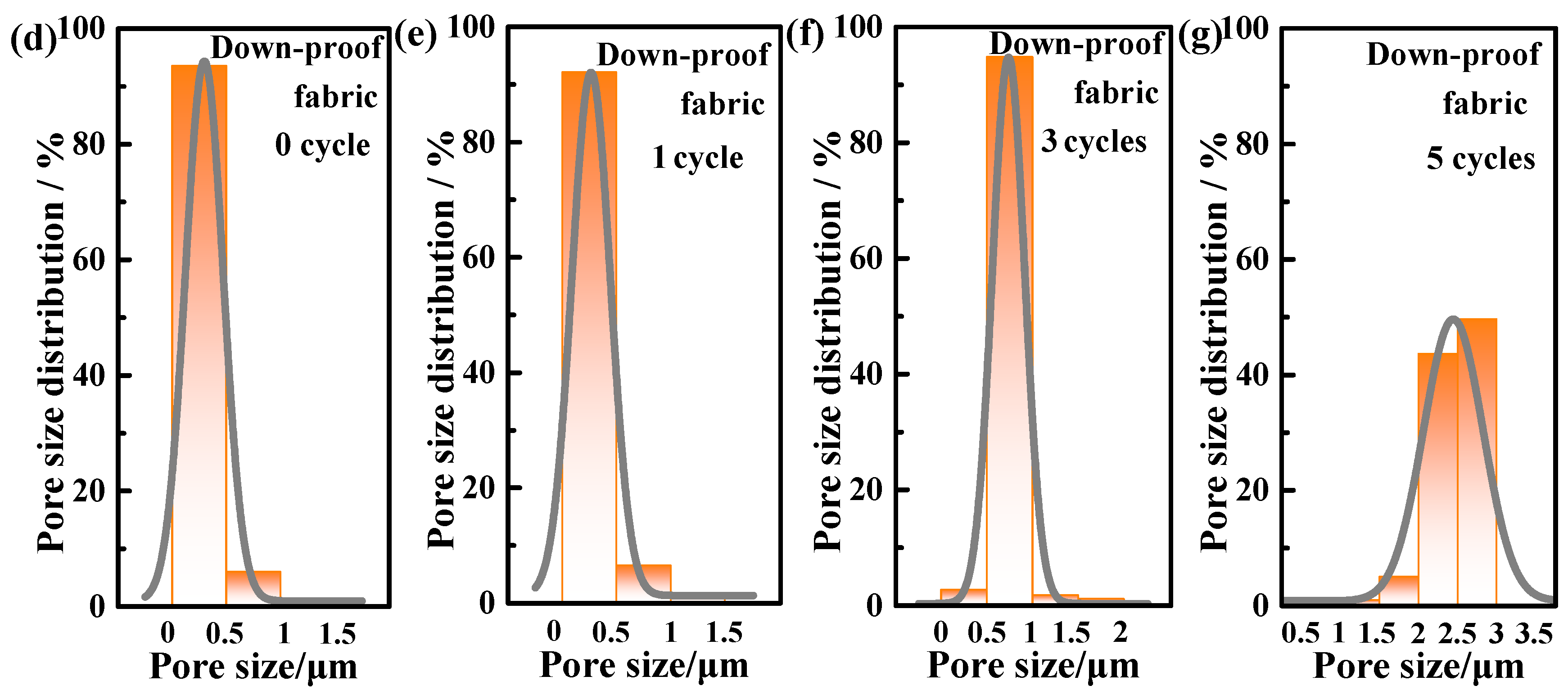

3.4. Machine Washable Behavior of Down-Proof Fabric

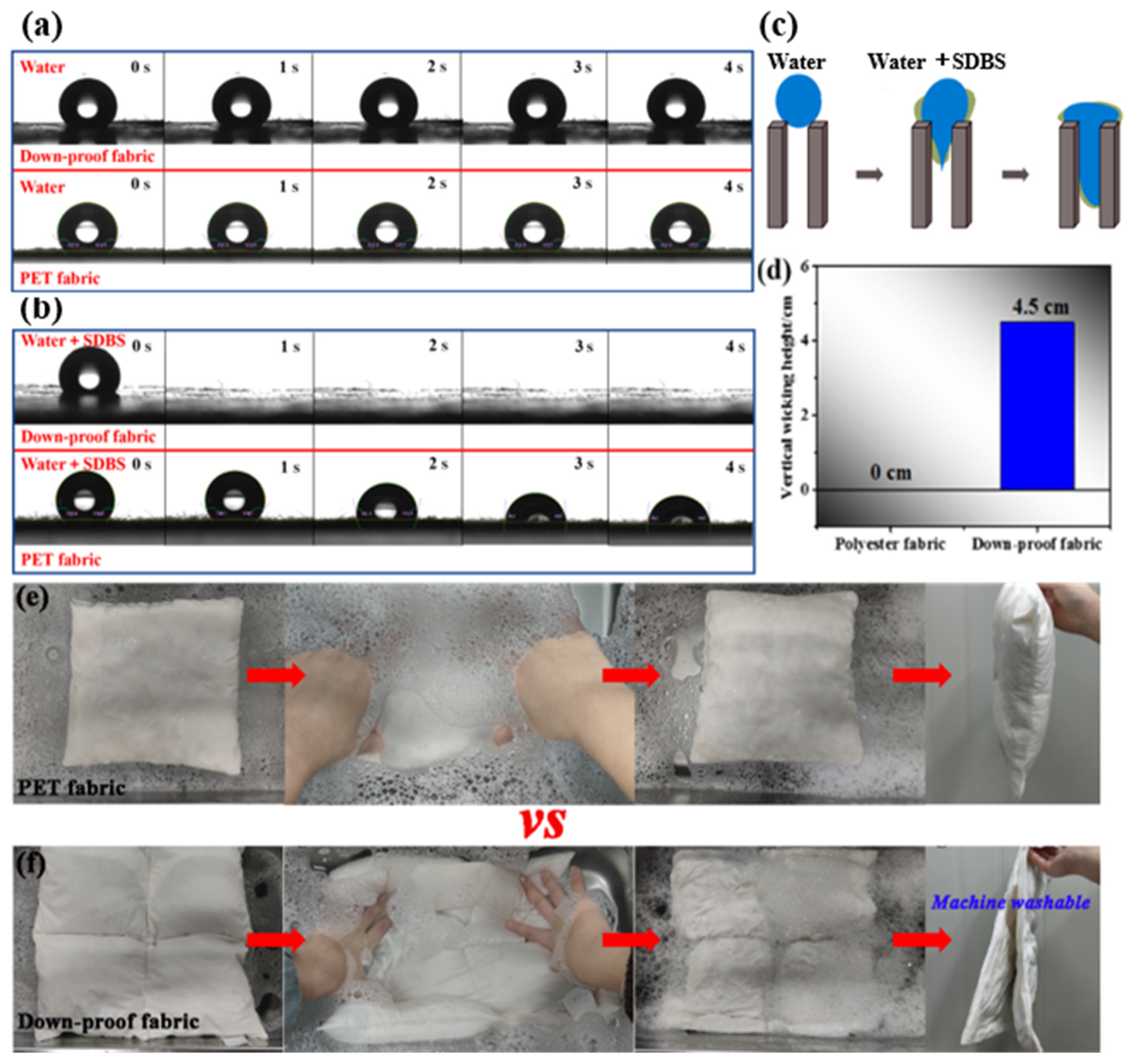

3.5. Water Vapor Permeability of Down-Proof Fabric

3.6. Thermal Insulation Behavior of Down-Proof Fabric

3.7. Tensile Behavior of Down-Proof Fabric

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zinatloo-Ajabshir, S.; Emsaki, M. Hosseinzadeh, G. Innovative construction of a novel lanthanide cerate nanostructured photocatalyst for efficient treatment of contaminated water under sunlight. J. Colloid Interf. Sci. 2022, 619, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Heidari-Asil, S.A.; Zinatloo-Ajabshir, S.; Alshamsi, H.A.; Al-Nayili, A.; Yousif, Q.A.; Salavati-Niasari, M. Magnetically recyclable ZnCo2O4/ Co3O4 nano-photocatalyst: Green combustion preparation, characterization and its application for enhanced degradation of contaminated water under sunlight. Int. J. Hydrogen Energy 2022, 47, 16852–16861. [Google Scholar] [CrossRef]

- Zinatloo-Ajabshir, S.; Morassaei, M.S.; Salavati-Niasari, M. Eco-friendly synthesis of Nd2Sn2O7-based nanostructure materials using grape juice as green fuel as photocatalyst for the degradation of erythrosine. Compos. Part B-Eng. 2019, 167, 643–653. [Google Scholar] [CrossRef]

- Dabrowska, A.K.; Bartkowiak, G.; Karcz, J.; Frydrych, I. Assessment of the non-woven, goose down and duck down as thermally insulating materials for the clothing protecting against cold. Int. J. Cloth. Sci. Technol. 2017, 29, 380–393. [Google Scholar] [CrossRef]

- Kim, S.; Kim, E.; Park, Y. Thermal insulation and morphology of natural and synthetic filled outdoor sportswear by repeated water washing and dry cleaning. Int. J. Cloth. Sci. Technol. 2018, 30, 428–443. [Google Scholar] [CrossRef]

- Morrissey, M.P.; Rossi, R.M. Recent developments in reflective cold protective clothing. Int. J. Cloth. Sci. Technol. 2015, 27, 17–22. [Google Scholar] [CrossRef]

- Kofler, P.; Nussbichler, M.; Veider, V.; Khanna, I.; Heinrich, D.; Bottoni, G.; Hasler, M.; Caven, B.; Bechtold, T.; Burtscher, M.; et al. Effects of two different battings (sheet wool versus polyester microfiber) in an outdoor jacket on the heat and moisture management and comfort sensation in the cold. Text. Res. J. 2016, 86, 191–201. [Google Scholar] [CrossRef]

- Tian, Y.; Sun, Y.; Du, Z.Q.; Zheng, D.M.; Zou, H.C.; Liu, Z.R.; Liu, G.; Pan, X.X. Tactile evaluation of down jacket fabric by the comprehensive handle evaluation system for fabrics and yarns. Text. Res. J. 2021, 91, 1227–1238. [Google Scholar] [CrossRef]

- Dong, T.; Wang, L.; Gao, W. Relations of pore size and distribution characteristics of down-proof fabric with breathability and anti-drilling property. J. Text. Res. 2020, 41, 49–53. [Google Scholar]

- Bin, S.; Kim, D.K.; Baek, Y.; Jin, S.; Bae, J.S. A study on high contraction conditions by the CPB process of the nylon fabric. Text. Coloration Finish. 2015, 27, 309–317. [Google Scholar] [CrossRef][Green Version]

- Han, H.; Zhang, Y.; Sun, D.; Qiao, L.; Zhang, M. Parameters of high-density soft breathable and anti-velvet fabric technology. Adv. Mat. Res. 2014, 941–944, 1336–1340. [Google Scholar] [CrossRef]

- Zheng, L.; Ma, Y.; Li, Y.; Ren, W. Once-forming production practice of seamless down-proof fabrics with square shapes. Tech. Text. 2019, 37, 9–13. [Google Scholar]

- Li, H.; Ye, L.; Xu, X.; Yang, Z. Current researches of down wear anti-drilling technology. Shandong Text. Sci. Technol. 2020, 61, 30–34. [Google Scholar]

- Chen, Y.; Wang, P.; Zhang, R. Study on the modified chitosan in textile anti-drilling. Text. Rep. 2018, 9, 29–33+53. [Google Scholar]

- Hosseinzadeh, G.; Zinatloo-Ajabshir, S.; Yousefi, A. Innovative synthesis of a novel ZnO/ZnBi2O4/graphene ternary heterojunction nanocomposite photocatalyst in the presence of tragacanth mucilage as natural surfactant. Ceram. Int. 2022, 48, 6078–6086. [Google Scholar] [CrossRef]

- Zinatloo-Ajabshir, S.; Heidari-Asil, S.A.; Salavati-Niasari, M. Rapid and green combustion synthesis of nanocomposites based on Zn-Co-O nanostructures as photocatalysts for enhanced degradation of acid brown 14 contaminant under sunlight. Sep. Purif. Technol. 2022, 280, 119841. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Wang, D.F.; Zhu, Z.; Li, W.; Xie, Y.X. Enhanced antistatic properties of polyethylene film/polypropylene-coated non-woven fabrics by compound of hot-melt adhesive and polymer antistatic agent. J. Ind. Text. 2021, 50, 921–938. [Google Scholar] [CrossRef]

- Karakaya, N.; Papila, M.; Özkoç, G. Effects of hot melt adhesives on the interfacial properties of overmolded hybrid structures of polyamide-6 on continuous carbon fiber/epoxy composites. Compos. Part A-Appl. S. 2020, 139, 106106. [Google Scholar] [CrossRef]

- Kucherov, F.A.; Gordeev, E.G.; Kashin, A.S.; Ananikov, V.P. Controlled natural biomass deoxygenation allows the design of reusable hot-melt adhesives acting in a multiple oxygen binding mode. ACS Appl. Mater. Inter. 2020, 12, 45394–45403. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, P.; Jin, X. Effect of wetting liquid on the testing of pore size characteristics of fiber filter materials by bubble point method. Tech. Text. 2011, 29, 40–43. [Google Scholar]

- Yanez, H.J.E.; Wang, Z.; Lege, S.; Obst, M.; Roehler, S.; Burkhardt, C.J.; Zwiener, C. Application and characterization of electroactive membrances based on carbon nanotubes and zerovalent iron nanoparticles. Water Res. 2017, 108, 78–85. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Zhao, J.; Andrew, E.B. Development of surfactants and builders in detergent formulations. Chin. J. Chem. Eng. 2008, 16, 517–527. [Google Scholar] [CrossRef]

- Pukale, D.D.; Bansode, A.S.; Pinjari, D.V.; Kulkarni, R.R.; Sayed, U. Application of silicone surfactant along with hydrocarbon surfactants to textile washing for the removal of different complex stains. J. Surfactants Deterg. 2017, 20, 287–295. [Google Scholar] [CrossRef]

- Adam, N.K. Detergent Action and its Relation to Wetting and Emulsification. J. Soc. Dyers Colour. 1937, 53, 121–129. [Google Scholar] [CrossRef]

- Wang, S.X.; Li, Y.; Tokura, H.; Hu, J.Y.; Han, Y.X.; Kwok, Y.L.; Au, R.W. Effect of moisture management on functional performance of cold protective clothing. Text. Res. J. 2007, 77, 968–980. [Google Scholar] [CrossRef]

- Cai, L.L.; Song, A.Y.; Wu, P.L.; Hsu, P.C.; Peng, Y.C.; Chen, J.; Liu, C.; Catrysse, P.B.; Liu, Y.Y.; Yang, A.K.; et al. Warming up human body by nanoporous metallized polyethylene textile. Nat. Commun. 2018, 81, 496. [Google Scholar] [CrossRef]

- Liu, C.; Liu, Z.; Zhang, Y. A multi-scale framework for modelling effective gas diffusivity in dry cement paste: Combined effects of surface, Knudsen and molecular diffusion. Cement Concrete Res. 2020, 131, 106035. [Google Scholar] [CrossRef]

- Spence, K.L.; Venditti, R.A.; Rojas, O.J.; Pawlak, J.J.; Hubbe, M.A. Water vapor barrier properties of coated and filled microfibrillated cellulose composite films. BioResources 2011, 6, 4370–4388. [Google Scholar] [CrossRef]

- Francis, L.; Ghaffour, N.; Alsaadi, A.A.; Amy, G.L. Material gap membrane distillation: A new design for water vapor flux enhancement. J. Membrane Sci. 2013, 448, 240–247. [Google Scholar] [CrossRef]

- Sadeghi, F.; Ajji, A.; Carreau, P.J. Analysis of microporous membranes obtained from polypropylene films by stretching. J. Membrane Sci. 2007, 292, 62–71. [Google Scholar] [CrossRef]

- Bui, N.; Meshot, E.R.; Kim, S.; Pena, J.; Gibson, P.W.; Wu, K.J.; Fornasiero, F. Ultrabreathable and protective membranes with sub-5 nm carbon nanotube pores. Adv. Mater. 2016, 28, 5871–5877. [Google Scholar] [CrossRef] [PubMed]

- Mondal, S.; Hu, J.L. Water vapor permeability of cotton fabrics coated with shape memory polyurethane. Carbohydr. Polym. 2007, 67, 282–287. [Google Scholar] [CrossRef]

- Huang, J.; Qian, X. Comparison of test methods for measuring water vapor permeability of fabrics. Text. Res. J. 2008, 78, 342–352. [Google Scholar] [CrossRef]

- Lee, S.; Obendorf, S.K. Statistical modeling of water vapor transport through woven fabrics. Text. Res. J. 2012, 82, 211–219. [Google Scholar] [CrossRef]

| Fabric Codes | Yarn Count (Tex) | Warp × Weft Density (Ends/cm × Picks/cm) | Thickness (mm) | Mass per Unit Area (g/m2) |

|---|---|---|---|---|

| Cotton fabric | 9.72 × 9.72 | 35.4 × 34.6 | 0.16 | 72.8 |

| Polyester fabric | 10.18 × 9.84 | 33.5 × 31.5 | 0.25 | 102 |

| ePTFE nanofiber membrane | / | / | 0.02 | 7.6 |

| ePTFE-aided down-proof cotton fabric | / | / | 0.18 | 82.4 |

| No. | Material | Tex | per/10 cm | Aperture Size/μm | Number of Drilled Piles | |||

|---|---|---|---|---|---|---|---|---|

| Warp | Weft | Warp | Weft | Warp | Weft | |||

| 1 | cotton | PET | 7.3 | 5.6 | 960 | 630 | 7.9 | 22 |

| 2 | cotton | PET | 7.3 | 5.6 | 953 | 768 | 5.1 | 15 |

| 3 | cotton | PET | 14.6 | 11.8 | 571 | 319 | 4.3 | 9 |

| 4 | cotton | PET | 14.6 | 5.6 | 571 | 610 | 11.0 | 35 |

| 5 | cotton | PET | 9.7 | 8.2 | 551 | 512 | 11.9 | 42 |

| 6 | cotton | cotton | 4.9 | 4.9 | 1035 | 933 | 5.2 | 10 |

| 7 | cotton | cotton | 5.8 | 8.1 | 906 | 709 | 10.2 | 23 |

| 8 | cotton | cotton | 5.8 | 8.1 | 906 | 728 | 8.5 | 21 |

| 9 | cotton | cotton | 5.8 | 8.1 | 906 | 748 | 5.4 | 11 |

| 10 | cotton | cotton | 9.7 | 8.1 | 551 | 271 | 12.3 | 50 |

| 11 | This work | 0.1–2 | <5 | |||||

| Tumble Cycles | Areal Weight (g/m2) | Thickness (mm) |

|---|---|---|

| 0 | 82.4 | 0.18 |

| 1 | 82.4 | 0.18 |

| 3 | 82.2 | 0.17 |

| 5 | 81.9 | 0.15 |

| Washing Cycles | Areal Weight (g/m2) | Thickness (mm) |

|---|---|---|

| 0 | 82.4 | 0.18 |

| 1 | 82.4 | 0.18 |

| 3 | 82.2 | 0.17 |

| 5 | 81.9 | 0.15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Ying, L.; Sun, R.; Li, C.; Ding, Z.; Wang, Z. A Highly Breathable and Machine-Washable ePTFE-Aided Down-Proof Cotton Fabric. Coatings 2022, 12, 826. https://doi.org/10.3390/coatings12060826

Wang Y, Ying L, Sun R, Li C, Ding Z, Wang Z. A Highly Breathable and Machine-Washable ePTFE-Aided Down-Proof Cotton Fabric. Coatings. 2022; 12(6):826. https://doi.org/10.3390/coatings12060826

Chicago/Turabian StyleWang, Yong, Lili Ying, Ruixia Sun, Changlong Li, Zhenhua Ding, and Zongqian Wang. 2022. "A Highly Breathable and Machine-Washable ePTFE-Aided Down-Proof Cotton Fabric" Coatings 12, no. 6: 826. https://doi.org/10.3390/coatings12060826

APA StyleWang, Y., Ying, L., Sun, R., Li, C., Ding, Z., & Wang, Z. (2022). A Highly Breathable and Machine-Washable ePTFE-Aided Down-Proof Cotton Fabric. Coatings, 12(6), 826. https://doi.org/10.3390/coatings12060826