The Effect of Deposition Temperature of TiN Thin Film Deposition Using Thermal Atomic Layer Deposition

Abstract

1. Introduction

2. Experiment and Discussion

2.1. Experimental Method

2.2. Experimental Results and Discussion

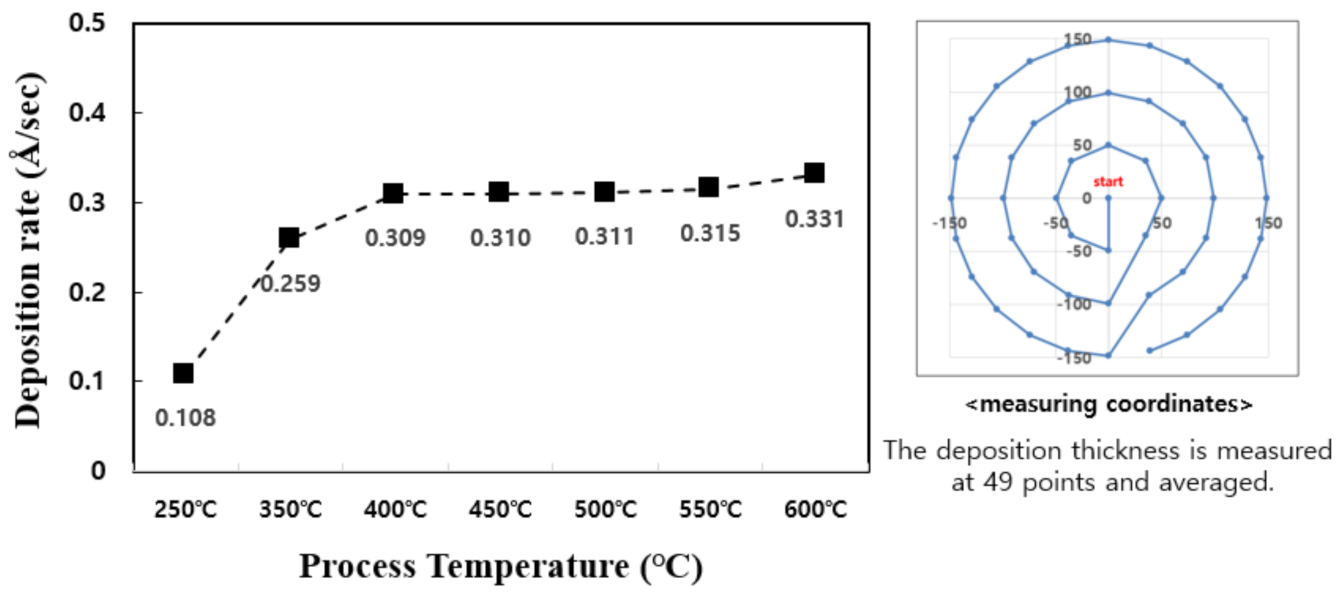

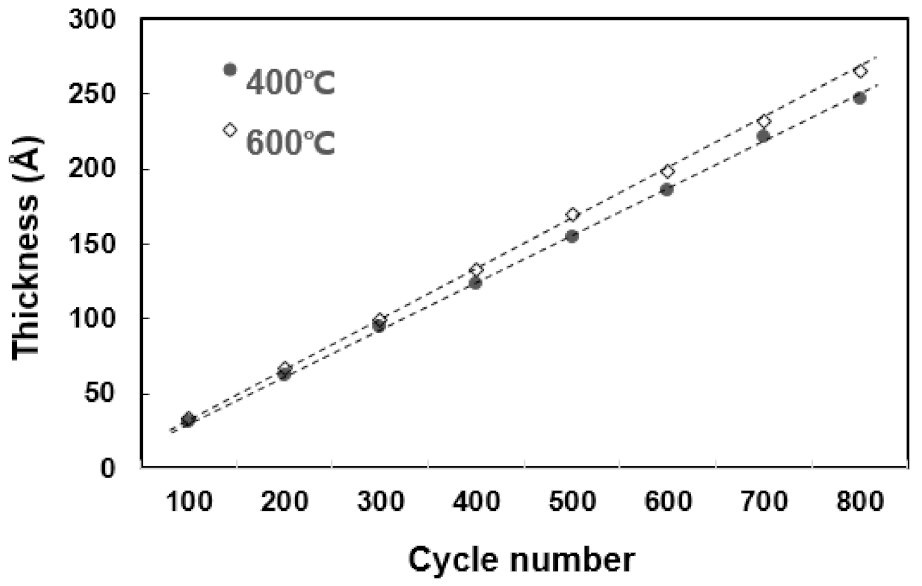

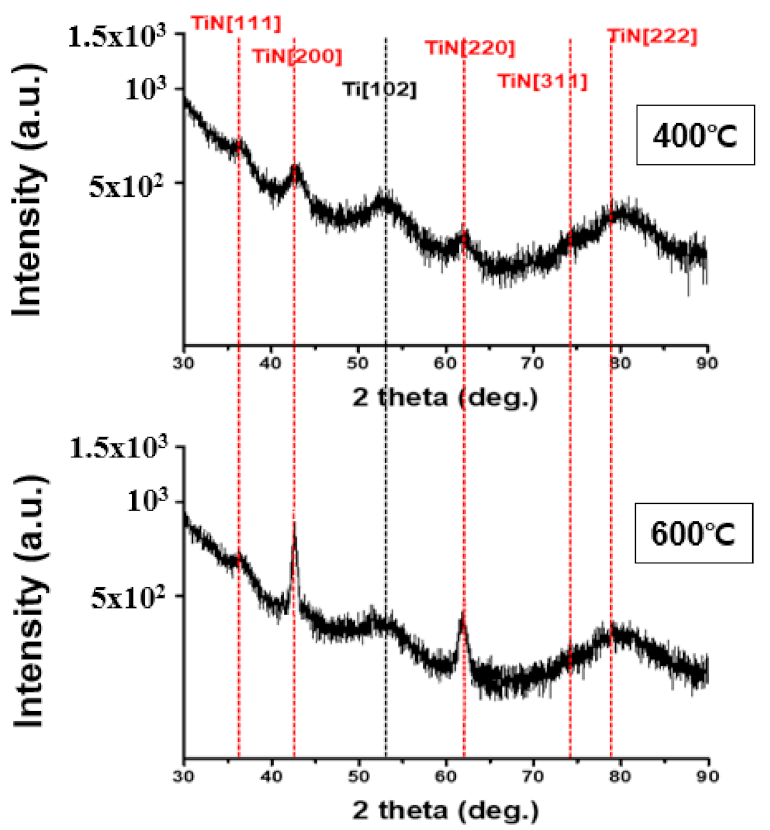

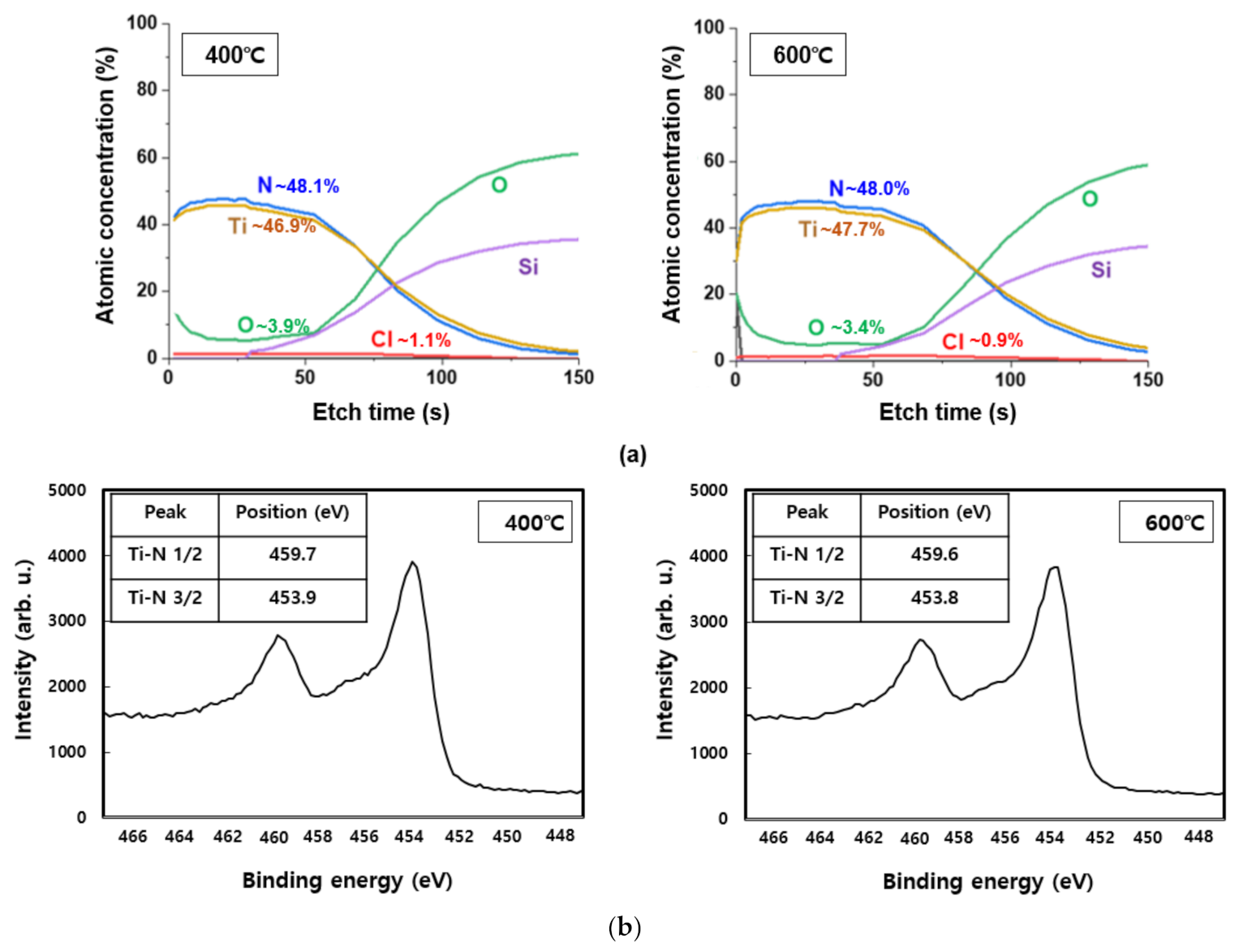

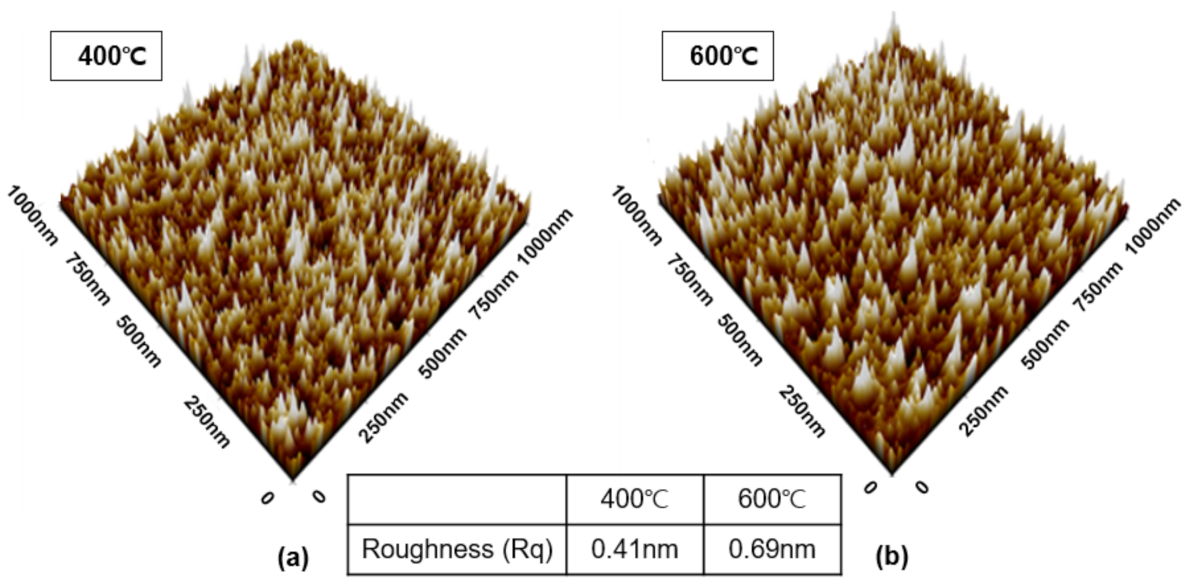

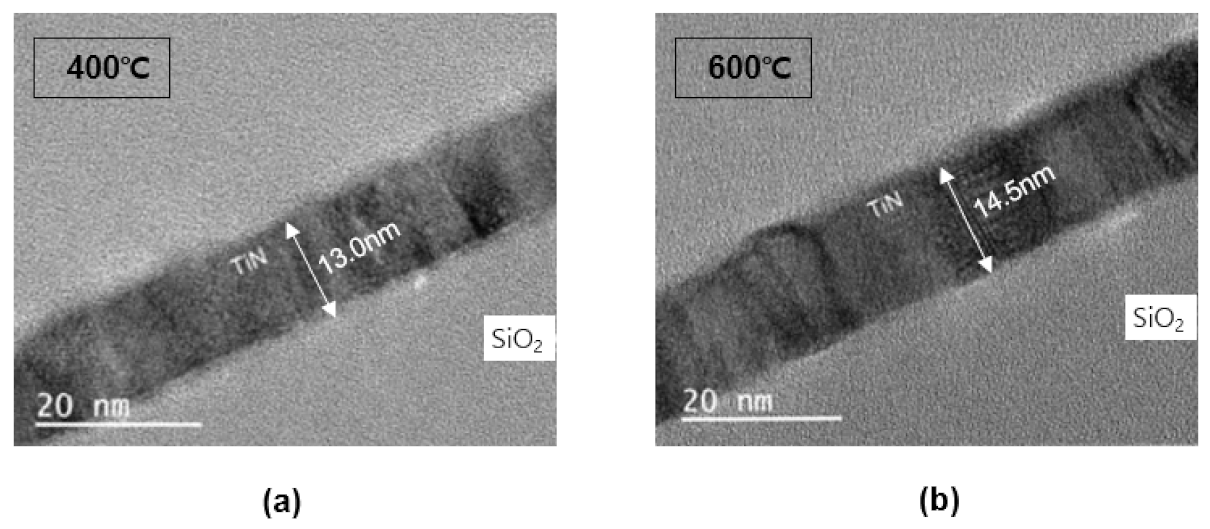

2.2.1. Flat Wafer Characteristic Evaluation

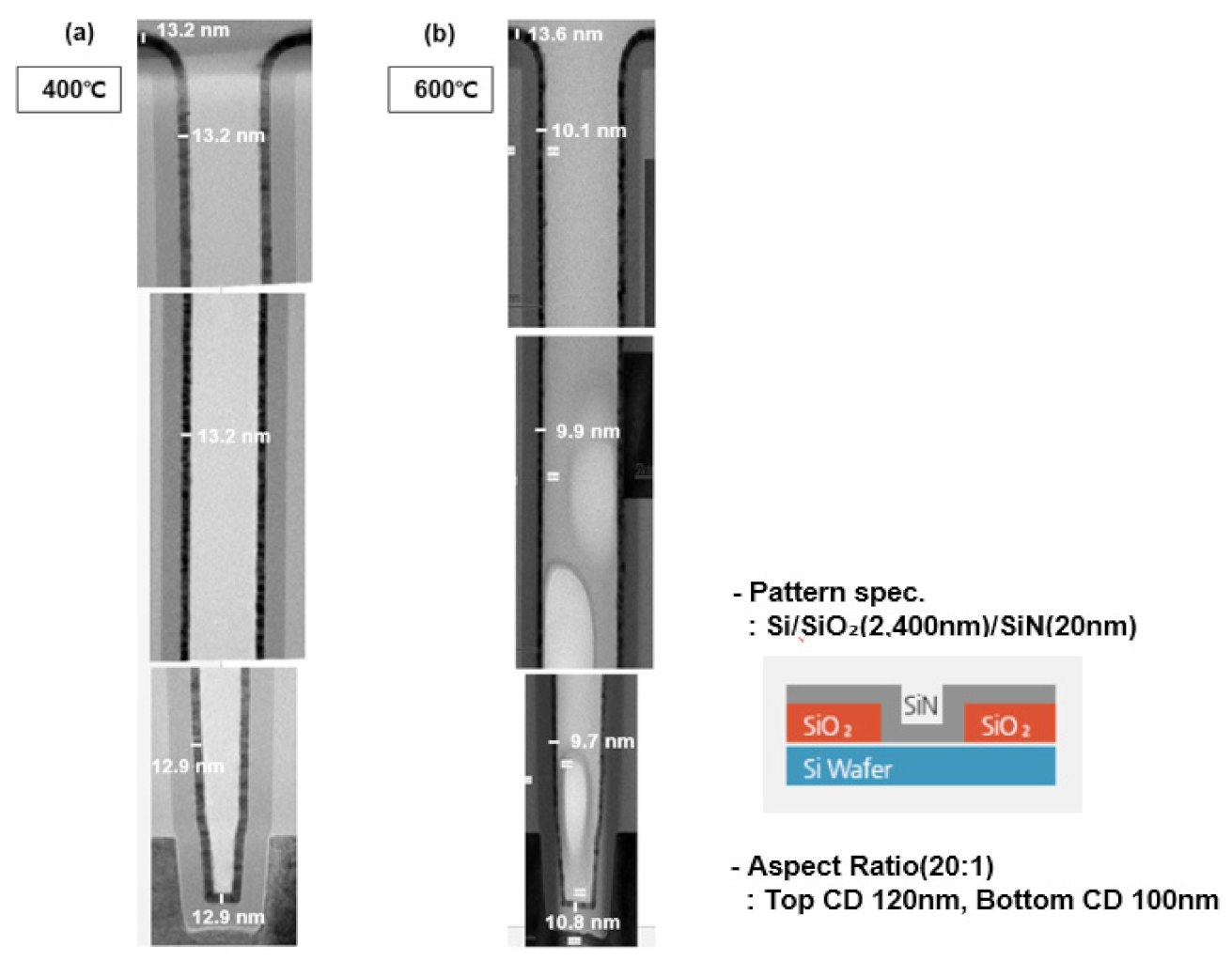

2.2.2. Pattern Wafer Characteristic Evaluation

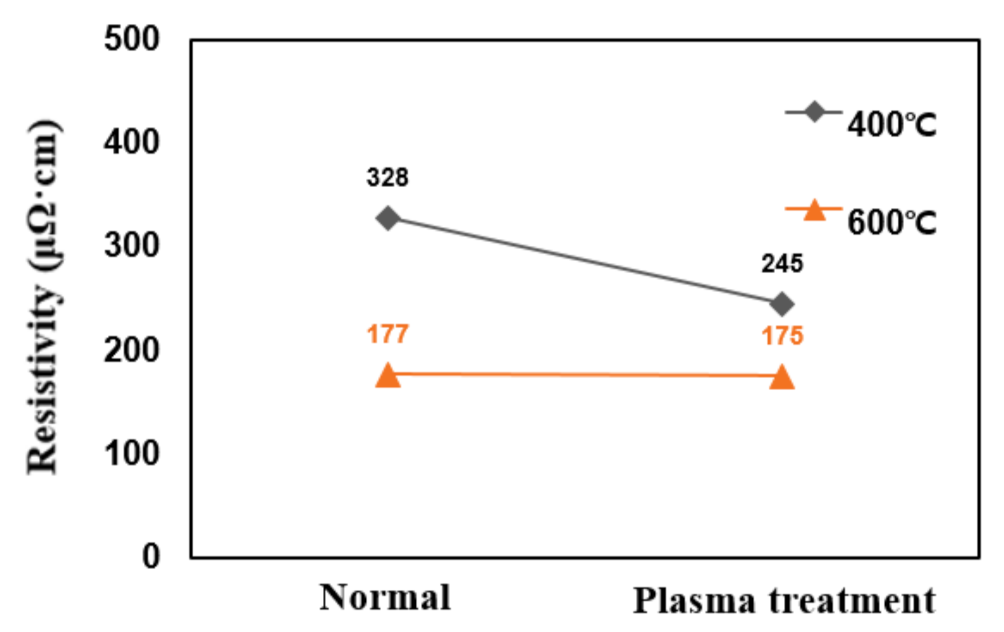

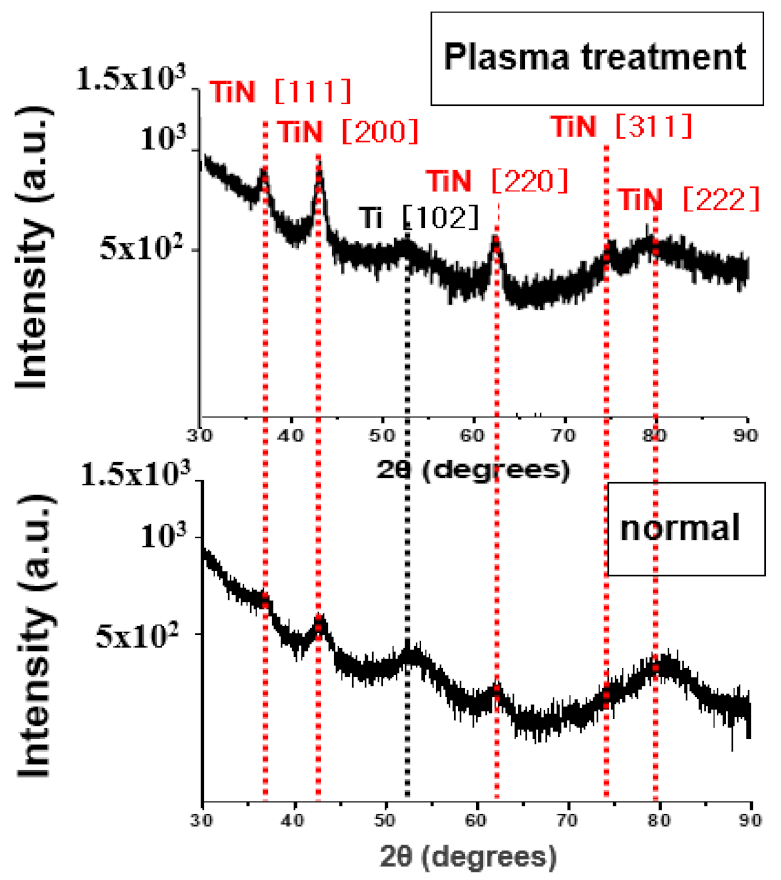

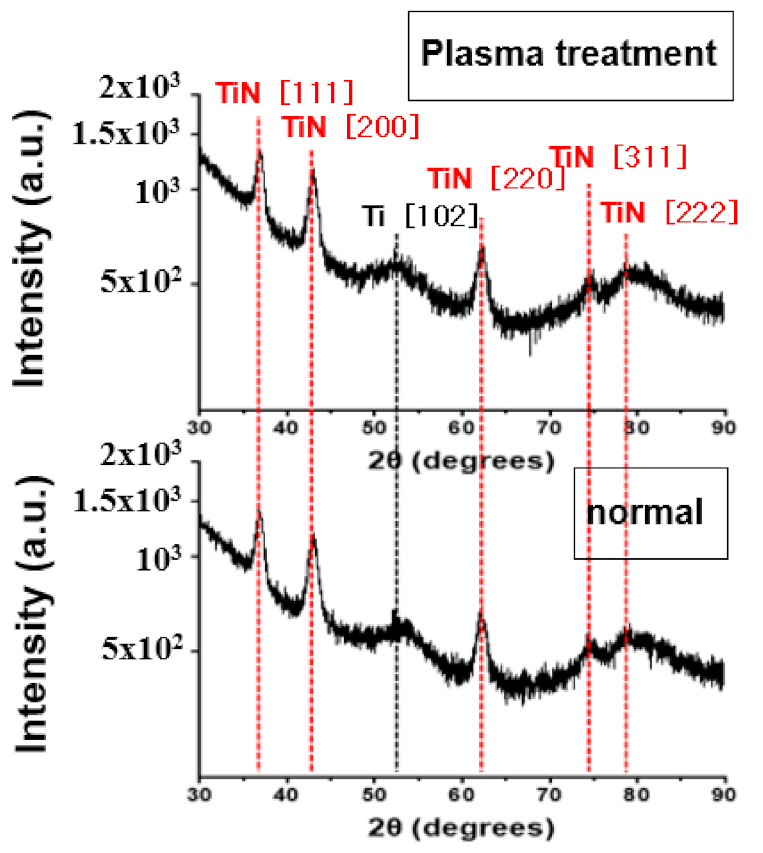

2.2.3. Characterization of Post-Plasma Treatment

3. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Elers, K.E.; Winkler, J.; Weeks, K.; Marcus, S. TiCl4 as a Precursor in the TiN Deposition by ALD and PEALD. J. Electrochem. Soc. 2005, 152, G589–G593. [Google Scholar] [CrossRef]

- Musschoot, J.; Xie, Q.; Deduytsche, D.; Berghe, S.V.D.; Van Meirhaeghe, R.; Detavernier, C. Atomic layer deposition of titanium nitride from TDMAT precursor. Microelectron. Eng. 2009, 86, 72–77. [Google Scholar] [CrossRef]

- De Baynast, H.; Bouteville, A.; Remy, J.-C. Optimization of Titanium Nitride Rapid Thermal CVD Process. Chem. Vap. Depos. 2000, 6, 115–119. [Google Scholar] [CrossRef]

- Ansari, M.Z.; Nandi, D.K.; Janicek, P.; Ansari, S.A.; Ramesh, R.; Cheon, T.; Shong, B.; Kim, S.-H. Low-Temperature Atomic Layer Deposition of Highly Conformal Tin Nitride Thin Films for Energy Storage Devices. ACS Appl. Mater. Interfaces 2019, 11, 43608–43621. [Google Scholar] [CrossRef]

- Ritala, M.; Leskelä, M.; Rauhala, E.; Haussalo, P. Atomic Layer Epitaxy Growth of TiN Thin Films. J. Electrochem. Soc. 1995, 142, 2731. [Google Scholar] [CrossRef]

- Bobb-Semple, D.; Nardi, K.L.; Draeger, N.; Hausmann, D.M.; Bent, S.F. Area-Selective Atomic Layer Deposition Assisted by Self-Assembled Monolayers: A Comparison of Cu, Co, W, and Ru. Chem. Mat. 2019, 31, 1635–1645. [Google Scholar] [CrossRef]

- Wojtecki, R.; Mettry, M.; Fine Nathel, N.F.; Friz, A.; De Silva, A.; Arellano, N.; Shobha, H. Fifteen Nanometer Resolved Pat-terns in Selective Area Atomic Layer Deposition-Defectivity Reduction by Monolayer Design. ACS Appl. Mater. Interfaces 2018, 10, 38630–38637. [Google Scholar]

- Fenouillet-Beranger, C.; Denorme, S.; Icard, B.; Boeuf, F.; Coignus, J.; Faynot, O.; Brevard, L.; Buj, C.; Soonekindt, C.; Todeschini, J.; et al. Fully-depleted SOI technology using high-k and single-metal gate for 32 nm node LSTP applications fea-turing 0.179 μm2 6T-SRAM bitcell. In Proceedings of the 2007 IEEE International Electron Devices Meeting, Washington, DC, USA, 10–12 December 2007; pp. 267–270. [Google Scholar]

- Bekiaris, N.; Wu, Z.; Ren, H.; Naik, M.; Park, J.H.; Lee, M.; Ha, T.H.; Hou, W.; Bakke, J.R.; Gage, M. Cobalt Fill for Advanced Interconnects. In Proceedings of the 2017 IEEE International Interconnect Technology Conference (IITC), Hsinchu, Taiwan, 16–18 May 2017; pp. 1–3. [Google Scholar]

- Choi, D.; Barmak, K. On the potential of tungsten as next-generation semiconductor interconnects. Electron. Mater. Lett. 2017, 13, 449–456. [Google Scholar] [CrossRef]

- Wen, L.G.; Roussel, P.; Pedreira, O.V.; Briggs, B.; Groven, B.; Dutta, S.; Popovici, M.I.; Heylen, N.; Ciofi, I.; Vanstreels, K.; et al. Atomic Layer Deposition of Ruthenium with TiN Interface for Sub-10 nm Advanced Interconnects beyond Copper. ACS Appl. Mater. Interfaces 2016, 8, 26119–26125. [Google Scholar] [CrossRef]

- Hashemi, F.S.M.; Prasittichai, C.; Bent, S.F. A New Resist for Area Selective Atomic and Molecular Layer Deposition on Met-al-Dielectric Patterns. J. Phys. Chem. C 2014, 118, 10957–10962. [Google Scholar] [CrossRef]

- Kerrigan, M.M.; Klesko, J.P.; Rupich, S.M.; Dezelah, C.L.; Kanjolia, R.K.; Chabal, Y.J.; Winter, C.H. Substrate selectivity in the low temperature atomic layer deposition of cobalt metal films from bis(1,4-di-tert-butyl-1,3-diazadienyl)cobalt and formic acid. J. Chem. Phys. 2017, 146, 052813. [Google Scholar] [CrossRef]

- Chockalingam, M.; Darwish, N.; Le Saux, G.; Gooding, J.J. Importance of the Indium Tin Oxide Substrate on the Quality of Self-Assembled Monolayers Formed from Organophosphonic Acids. Langmuir 2011, 27, 2545–2552. [Google Scholar] [CrossRef]

- Seo, S.; Yeo, B.C.; Han, S.S.; Yoon, C.M.; Yang, J.Y.; Yoon, J.; Yoo, C.; Kim, H.-J.; Lee, Y.-B.; Lee, S.J. Reaction Mechanism of Area-Selective Atomic Layer Deposition for Al2O3 Nanopatterns. ACS Appl. Mater. Interfaces 2017, 9, 41607–41617. [Google Scholar] [CrossRef]

- Lee, H.J.; Hwang, J.H.; Park, J.Y.; Lee, S.W. Alternative Surface Reaction Route in the Atomic Layer Deposition of Titanium Nitride Thin Films for Electrode Applications. ACS Appl. Electron. Mater. 2021, 3, 999–1005. [Google Scholar] [CrossRef]

- Burke, M.; Blake, A.; Povey, I.; Schmidt, M.; Petkov, N.; Carolan, P.; Quinn, A.J. Low sheet resistance titanium nitride films by low-temperature plasma-enhanced atomic layer deposition using design of experiments methodology. J. Vac. Sci. Technol. A Vac. Surf. Film. 2014, 32, 031506. [Google Scholar] [CrossRef]

- Snyder, M.Q.; McCool, B.A.; DiCarlo, J.; Tripp, C.P.; DeSisto, W.J. An infrared study of the surface chemistry of titanium nitride atomic layer deposition on silica from TiCl4 and NH3. Thin Solid Film. 2006, 514, 97–102. [Google Scholar] [CrossRef]

- Mochizuki, Y.; Okamoto, Y.; Ishitani, A.; Hirose, K.; Takada, T.T.T. On the Reaction Scheme for Ti/TiN Chemical Vapor Deposition (CVD) Process Using TiCl4. Jpn. J. Appl. Phys. 1995, 34, L326. [Google Scholar] [CrossRef]

- Zhao, C.; Xiang, J. Atomic Layer Deposition (ALD) of Metal Gates for CMOS. Appl. Sci. 2019, 9, 2388. [Google Scholar] [CrossRef]

- Krylov, I.; Qi, Y.; Korchnoy, V.; Weinfeld, K.; Eizenberg, M.; Yalon, E. Role of temperature on structure and electrical properties of titanium nitride films grown by low pressure plasma enhanced atomic layer deposition. J. Vac. Sci. Technol. A 2020, 38, 032403. [Google Scholar] [CrossRef]

- Kukli, K.; Ritala, M.; Leskelä, M. Atomic Layer Deposition and Chemical Vapor Deposition of Tantalum Oxide by Successive and Simultaneous Pulsing of Tantalum Ethoxide and Tantalum Chloride. Chem. Mater. 2000, 12, 1914–1920. [Google Scholar] [CrossRef]

- Kim, S.K.; Lee, S.W.; Han, J.H.; Lee, B.; Han, S.; Hwang, C.S. Capacitors with an Equivalent Oxide Thickness of <0.5 nm for Nanoelectronic Semiconductor Memory. ECS Meet. Abstr. 2010, MA2010-02, 1414. [Google Scholar] [CrossRef]

- Elam, J.W.; Routkevitch, D.; Mardilovich, P.P.; George, S.M. Conformal Coating on Ultrahigh-Aspect-Ratio Nanopores of Anodic Alumina by Atomic Layer Deposition. Chem. Mater. 2003, 15, 3507–3517. [Google Scholar] [CrossRef]

- Lee, S.W.; Han, J.H.; Han, S.; Lee, W.; Jang, J.H.; Seo, M.; Kim, S.K.; Dussarrat, C.; Gatineau, J.; Min, Y.-S.; et al. Atomic Layer Deposition of SrTiO3 Thin Films with Highly Enhanced Growth Rate for Ultrahigh Density Capacitors. Chem. Mater. 2011, 23, 2227–2236. [Google Scholar] [CrossRef]

- Park, Y.H.; Kim, M.H.; Bin Kim, S.; Jung, H.J.; Chae, K.; Ahn, Y.H.; Park, J.-Y.; Rotermund, F.; Lee, S.W. Enhanced Nucleation of High-k Dielectrics on Graphene by Atomic Layer Deposition. Chem. Mater. 2016, 28, 7268–7275. [Google Scholar] [CrossRef]

- Song, S.J.; Park, T.; Yoon, K.J.; Yoon, J.H.; Kwon, D.E.; Noh, W.; Lansalot-Matras, C.; Gatineau, S.; Lee, H.K.; Gautam, S.; et al. Comparison of the Atomic Layer Deposition of Tantalum Oxide Thin Films Using Ta(NtBu)(NEt2)3 and Ta(NtBu)(NEt2)2Cp and H2O. ACS Appl. Mater. Interfaces 2017, 9, 537. [Google Scholar] [CrossRef]

- Kim, S.H.; Lee, W.; An, C.H.; Kwon, D.S.; Kim, D.-G.; Cha, S.H.; Hwang, C.S. Effect of Growth Temperature During the Atomic Layer Deposition of the SrTiO3 Seed Layer on the Properties of RuO2/ SrTiO3/Ru Capacitors for Dynamic Random Access Memory Applications. ACS Appl. Mater. Interfaces 2018, 10, 41544. [Google Scholar] [CrossRef]

- Van Bui, H.; Groenland, A.W.; Aarnink, A.A.I.; Wolters, R.A.M.; Schmitz, J.; Kovalgin, A.Y. Growth Kinetics and Oxidation Mechanism of ALD TiN Thin Films Monitored by In Situ Spectroscopic Ellipsometry. J. Electrochem. Soc. 2011, 158, H214–H220. [Google Scholar] [CrossRef]

- Langereis, E.; Heil, S.B.S.; van Sanden, M.C.M.; Kessels, W.M.M. In situ spectroscopic ellipsometry study on the growth of ultrathin TiN films by plasma-assisted atomic layer deposition. J. Appl. Phys. 2006, 100, 023534. [Google Scholar] [CrossRef]

- Tiznado, H.; Zaera, F. Surface Chemistry in the Atomic Layer Deposition of TiN Films from TiCl4 and Ammonia. J. Phys. Chem. B 2006, 110, 13491–13498. [Google Scholar] [CrossRef]

- Cheng, H.-E.; Lee, W.-J. Properties of TiN films grown by atomic-layer chemical vapor deposition with a modified gaseous-pulse sequence. Mater. Chem. Phys. 2006, 97, 315–320. [Google Scholar] [CrossRef]

- Luoh, T.; Huang, Y.-K.; Hung, Y.-T.; Yang, L.-W.; Yang, T.-H.; Chen, K.-C. TiCl4 Barrier Process Engineering in Semiconductor Manufacturing. Coatings 2016, 6, 2. [Google Scholar] [CrossRef]

- Zhao, R.; Wang, X. Initial Growth and Agglomeration during Atomic Layer Deposition of Nickel Sulfide. Chem. Mater. 2019, 31, 445–453. [Google Scholar] [CrossRef]

- O’Conner, É.; Brennan, B.; Djara, V.; Cherkaoui, K.; Monaghan, S.; Newcomb, S.B.; Contreras, R.; Milojevic, M.; Hughes, G.; Pemble, M.E.; et al. A systematic study of (NH4)2S passivation (22%, 10%, 5%, or 1%) on the interface properties of the Al2O3/In0.53Ga0.47As/InP system for n-type and p-type In0.53Ga0.47As epitaxial layers. J. Appl. Phys. 2011, 109, 024101. [Google Scholar]

| Parameter | Condition |

|---|---|

| Precursor | TiCl4 |

| Reactant gas | NH3 |

| Purge gas | N2 |

| Pressure | 6–7 torr |

| Substrate | 12 inch Si(100)/oxide (1000 A) wafer |

| Process temperature | 350–600 °C |

| Parameter | Condition |

|---|---|

| Frequency | 13.56 MHz |

| RF power | 700 w (60 s) |

| Plasma discharge gas | N2 (3000 sccm)/He (2000 sccm) |

| Pressure | 1 torr |

| Temperature | 400 C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, B.-J.; Kim, Y.-S.; Seo, D.-W.; Choi, J.-W. The Effect of Deposition Temperature of TiN Thin Film Deposition Using Thermal Atomic Layer Deposition. Coatings 2023, 13, 104. https://doi.org/10.3390/coatings13010104

Lee B-J, Kim Y-S, Seo D-W, Choi J-W. The Effect of Deposition Temperature of TiN Thin Film Deposition Using Thermal Atomic Layer Deposition. Coatings. 2023; 13(1):104. https://doi.org/10.3390/coatings13010104

Chicago/Turabian StyleLee, Baek-Ju, Yoo-Seong Kim, Dong-Won Seo, and Jae-Wook Choi. 2023. "The Effect of Deposition Temperature of TiN Thin Film Deposition Using Thermal Atomic Layer Deposition" Coatings 13, no. 1: 104. https://doi.org/10.3390/coatings13010104

APA StyleLee, B.-J., Kim, Y.-S., Seo, D.-W., & Choi, J.-W. (2023). The Effect of Deposition Temperature of TiN Thin Film Deposition Using Thermal Atomic Layer Deposition. Coatings, 13(1), 104. https://doi.org/10.3390/coatings13010104