Effects of Bias Voltage and Target Current on Microstructure and Load Measurement Performance of ZnO Piezoelectric Coatings Applied to Bolt in Transformer

Abstract

:1. Introduction

2. Experimental Details

2.1. Coating Preparation

2.2. Microstructure and Resistance Test

2.3. Performance Testing of the Bolt with Coating Deposited via Optimized Process

3. Results and Discussion

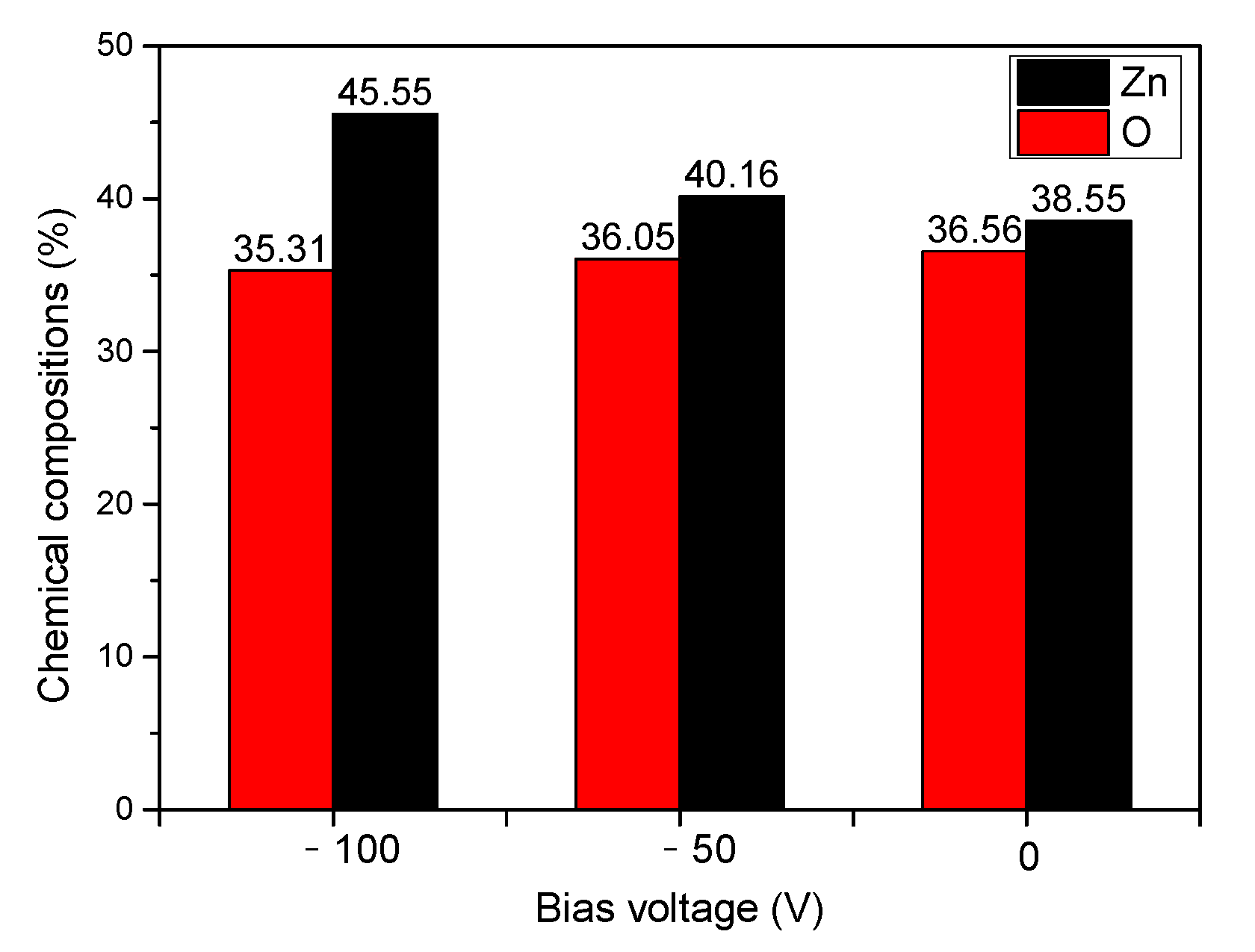

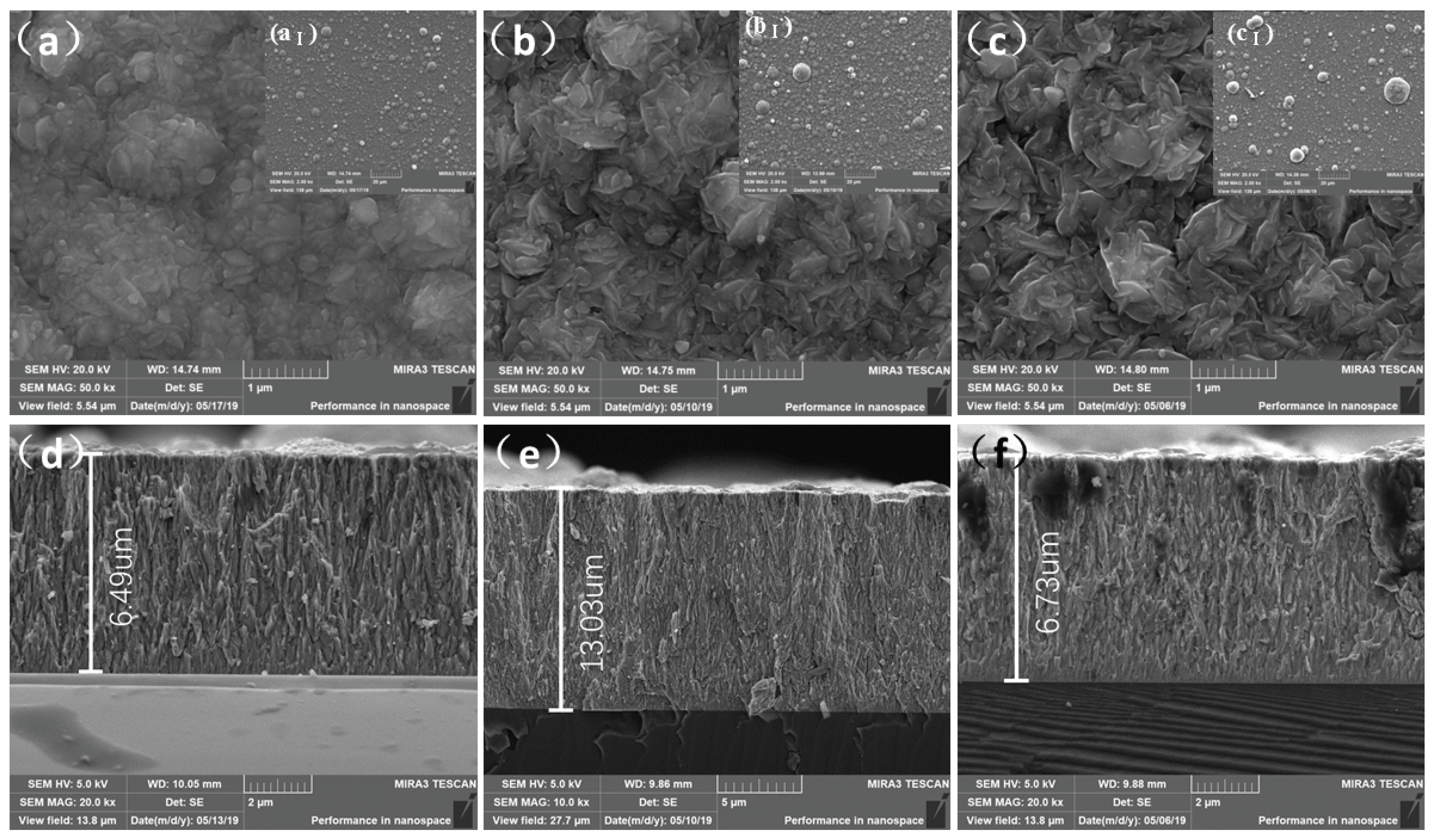

3.1. Effects of Bias Voltage on the Morphology and Growth Rate of ZnO Film

3.2. Effects of Bias Voltage on Crystal Characteristics and Resistance of Zno Coatings

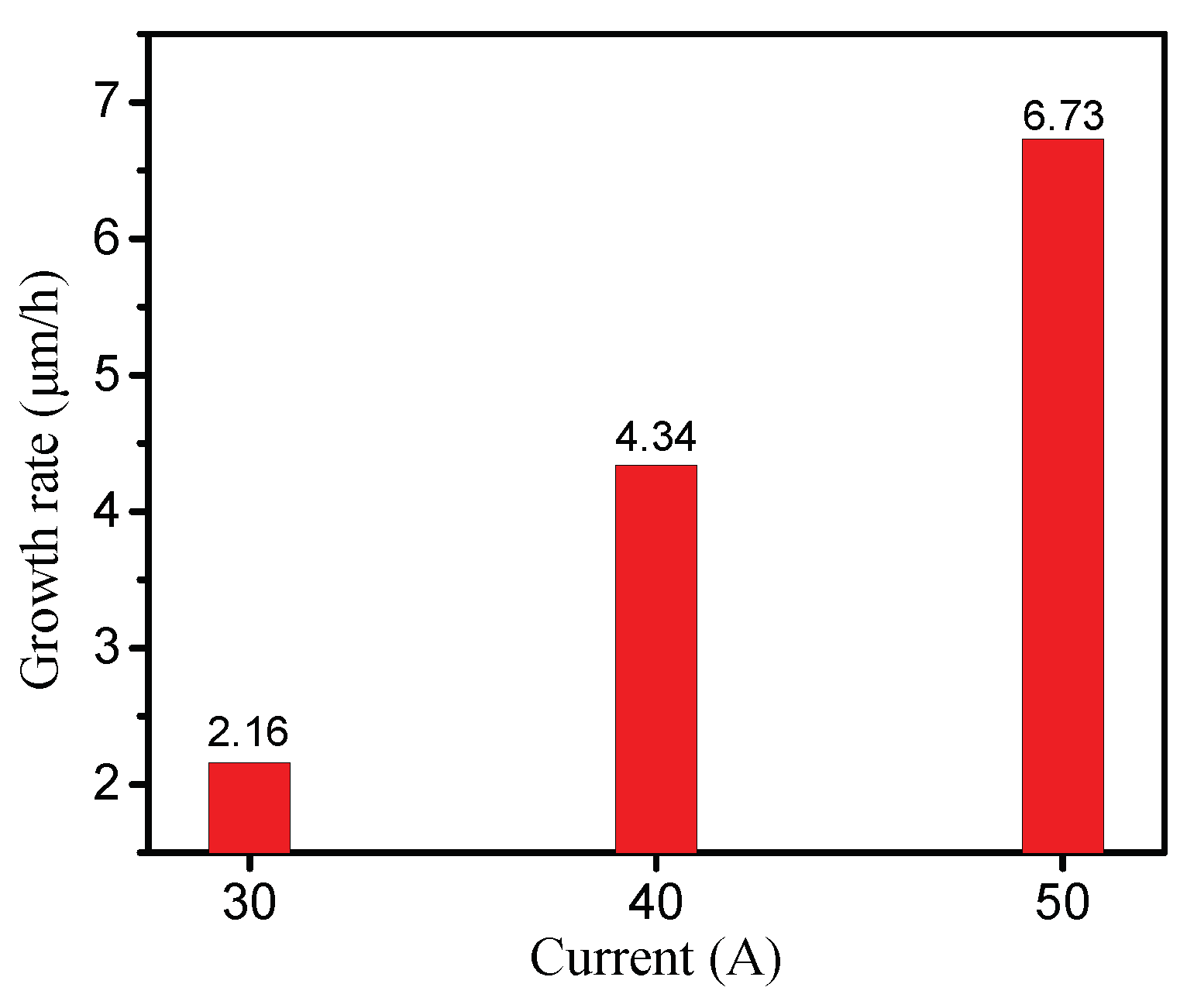

3.3. Effects of Target Current on the Morphology and Growth Rate of ZnO Film

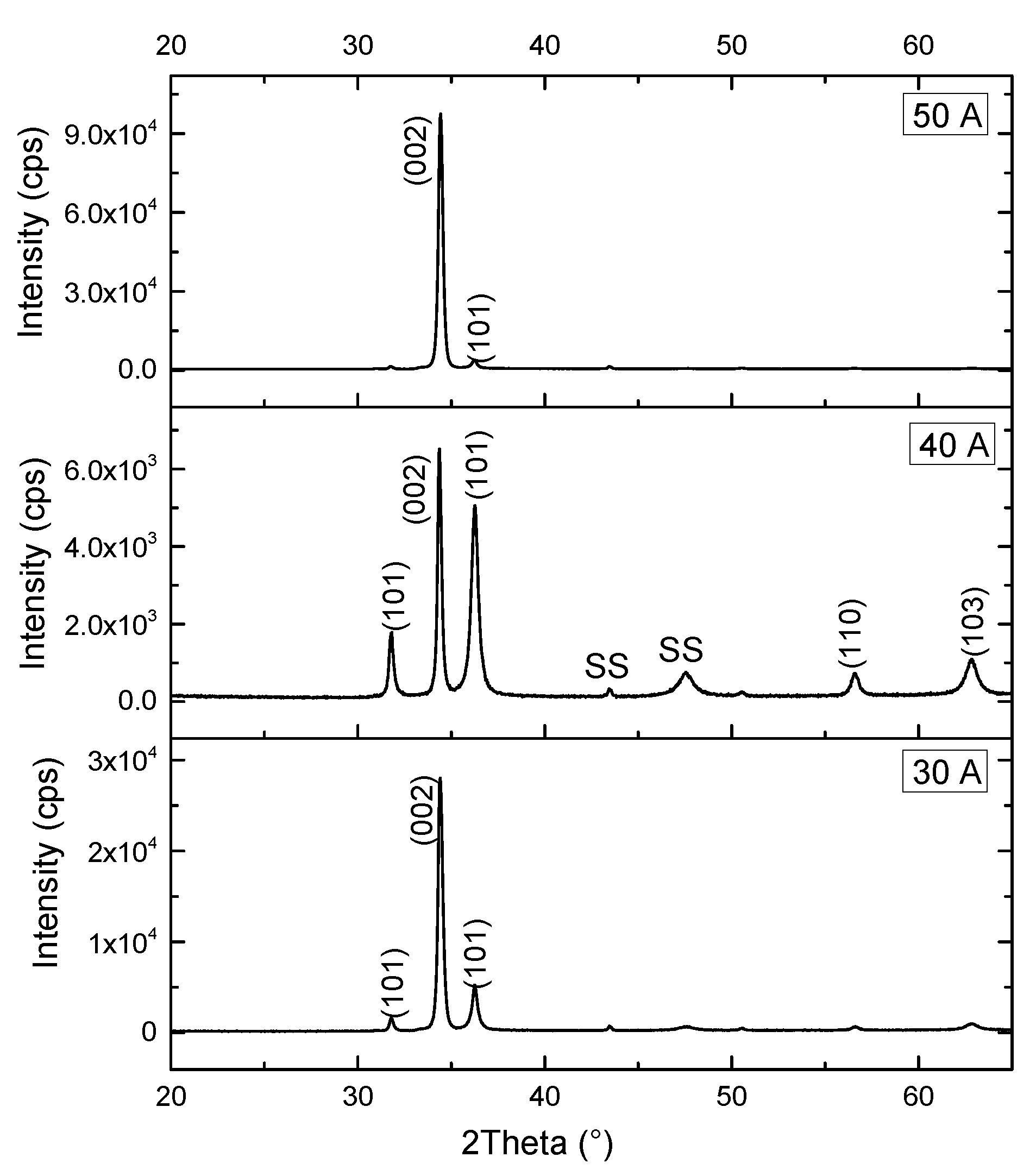

3.4. Effects of Target Currents on Crystal Characteristics and Resistance of ZnO Coatings

3.5. Performance of Bolt with ZnO Coating Deposited with Optimized Parameters

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Z. Characteristics of UHV AC Transmission System. In Ultra-High Voltage Ac/dc Grids; Academic Press: Cambridge, MA, USA, 2015; pp. 35–93. [Google Scholar]

- Hashemnia, N.; Abu-Siada, A.; Islam, S. Detection of power transformer bushing faults and oil degradation using frequency response analysis. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 222–229. [Google Scholar] [CrossRef]

- Sikorski, W.; Siodla, K.; Moranda, H.; Ziomek, W. Location of partial discharge sources in power transformers based on advanced auscultatory technique. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1948–1956. [Google Scholar] [CrossRef]

- Stone, G.C. Partial discharge diagnostics and electrical equipment insulation condition assessment. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 891–904. [Google Scholar] [CrossRef]

- Rosolem, J.B.; Tomiyama, E.K.; Dini, D.C.; Bassan, F.R.; Penze, R.S.; Leonardi, A.A.; Teixeira, R.M. A fiber optic powered sensor designed for partial discharges monitoring on high voltage bushings. In Proceedings of the 2015 SBMO/IEEE MTT-S International Microwave and Optoelectronics Conference (IMOC), Porto de Galinhas, Brazil, 3–6 November 2015; pp. 1–5. [Google Scholar]

- Senobari, R.K.; Sadeh, J.; Borsi, H. Frequency response analysis (FRA) of transformers as a tool for fault detection and location: A review. Electr. Power Syst. Res. 2018, 155, 172–183. [Google Scholar] [CrossRef]

- Cristaldi, L.; Faifer, M.; Laurano, C.; Ottoboni, R.; Toscani, S. Monitoring of power transformer bushings in high voltage substations. In Proceedings of the 2015 IEEE International Workshop on Applied Measurements for Power Systems (AMPS), Aachen, Germany, 23–25 September 2015; pp. 72–77. [Google Scholar]

- Jiang, J.; Ma, G.M.; Song, H.T.; Li, C.R.; Luo, Y.T. Dissolved Hydrogen Sensor in Power Transformer Oil Based on Side Polishing Fiber Bragg Grating. Trans. China Electrotech. Soc. 2017, 13, 264–270. [Google Scholar]

- Bodzenta, J.; Burak, B.; Gacek, Z.; Jakubik, W.P.; Kochowski, S.; Urbańczyk, M. Thin palladium film as a sensor of hydrogen gas dissolved in transformer oil. Sens. Actuators B Chem. 2002, 87, 82–87. [Google Scholar] [CrossRef]

- Zhang, M.; Shang, R.; Lu, Z.; Zhang, X.; Xie, K.; Zhang, B. Analysis of wind-induced response of down lead transmission line-connection fitting systems in ultrahigh-voltage substations. Eng. Struct. 2020, 206, 110144. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, Z.K.; Liu, L. Failure Mechanism Analysis and Preventive Measures of High Voltage Sleeve Head Seal of 500 kV Main Transformer. J. Anhui Electr. Eng. Prof. Tech. Coll. 2017, 22, 38–41. [Google Scholar]

- Chen, W.Q.; Shi, M.L.; Shen, Z.Y. Fault Analysis and Improvements on General Cap of Converter Transformer Bushing. Zhejiang Electr. Power 2020, 9, 42–47. [Google Scholar]

- Zhu, Z.Q.; Zhou, J.; Liu, G.Z. Research Progress on Growth Methods of ZnO Single Crystal. Chinese J. Rare Met. 2009, 33, 101–106. [Google Scholar]

- Jiao, M.Z.; Chen, X.Y.; Hu, K.X.; Qian, D.Y.; Zhao, X.H.; Ding, E.J. Recent developments of nanomaterials-based conductive type methane sensors. Rare Met. 2021, 40, 1515–1527. [Google Scholar] [CrossRef]

- Palshikar, A.J.A.Y.; Sharma, N. Review on Piezoelectric Materials as Thin Films with their Applications. Mater. Sci. Res. India 2015, 12, 79–84. [Google Scholar] [CrossRef]

- Wang, F. Progress in cathodic arc ion plating technology. Vac. Low Temp. 2020, 26, 87–95. [Google Scholar]

- Wang, Z.L.; Song, J. Piezoelectric Nanogenerators Based on Zinc Oxide Nanowire Arrays. Science 2006, 312, 242–246. [Google Scholar] [CrossRef] [PubMed]

- Ortiz, T.; Conde, C.; Khan, T.M.; Hussain, B. Thickness uniformity and optical/structural evaluation of RF sputtered ZnO thin films for solar cell and other device applications. Appl. Phys. A 2017, 123, 280. [Google Scholar] [CrossRef]

- Hussain, B.; Khan, T.M. Spatial Thickness Uniformity and Structural Evaluation of RF Sputtered ZnO Thin Films for Solar Cell. In Proceedings of the 2017 IEEE 44th Photovoltaic Specialist Conference (PVSC), Washington, DC, USA, 25–30 June 2017; pp. 451–454. [Google Scholar]

| Bias Voltage (V) | 0 | −50 | −100 |

|---|---|---|---|

| Intensity (cps) | 207,689 | 168,216 | 485 |

| FWHM | 0.3 | 0.36 | 0.91 |

| Resistance (KΩ) | 5.0 | 0.2 | 0.06 |

| Working Current (A) | 30 | 40 | 50 |

|---|---|---|---|

| Orientation coeffeicient | 0.47 | 0.8 | 1 |

| Intensity (cps.) | 6150 | 28,016 | 97,499 |

| FWHM | 0.28 | 0.268 | 0.203 |

| Resistance (KΩ) | 400 | 20,000 | 200 |

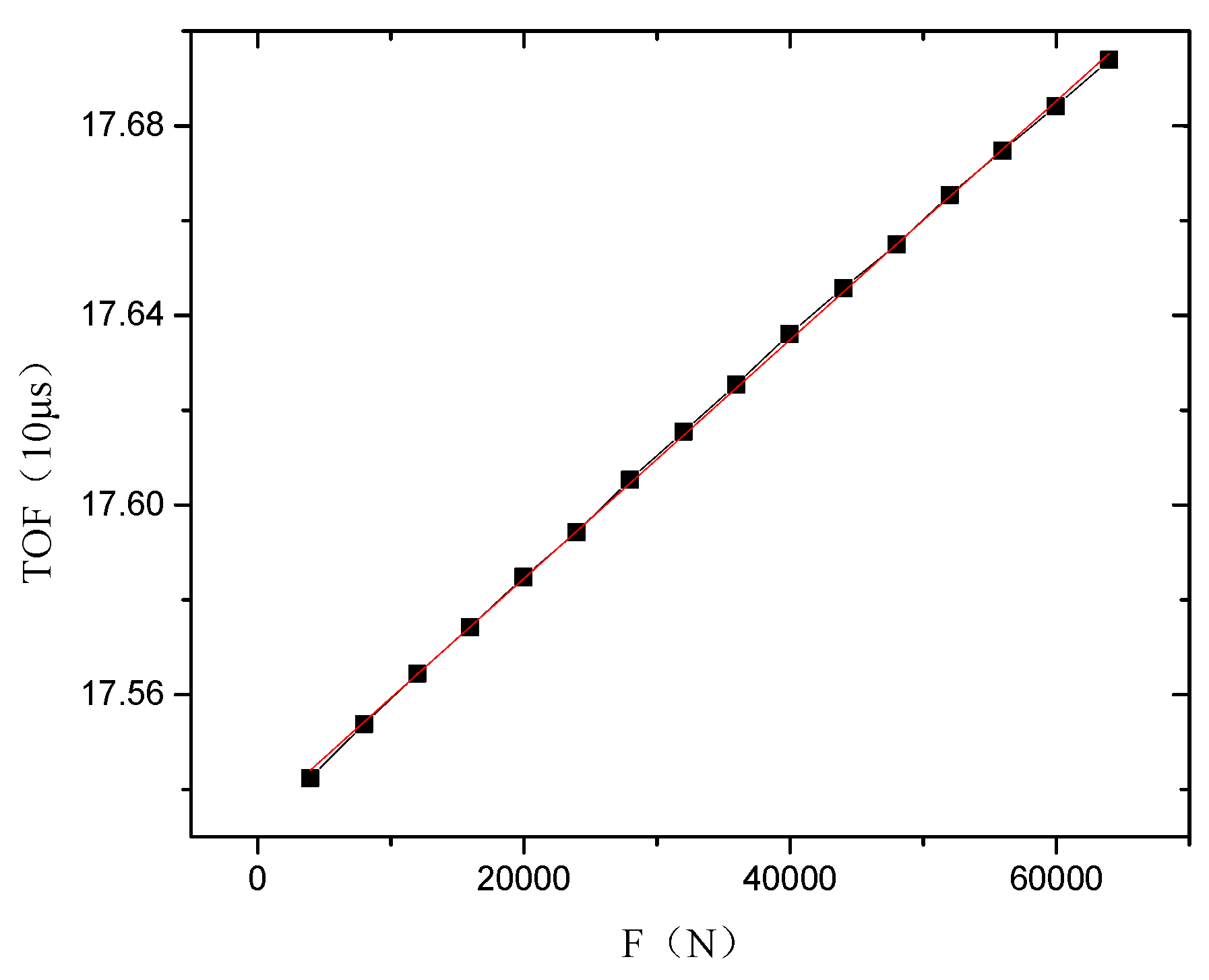

| Equation | y = a + b*x | ||

| Pearson’s r | 0.99985 | ||

| Adj. R-squared | 0.99967 | ||

| Value | Standard error | ||

| B | Intercept | 17.53412 | 4.54419 × 10−4 |

| Slope | 2.51855 × 10−6 | 1.17561 × 10−8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kou, H.; Wang, F.; Nie, D.; Ning, Z.; Li, Q.; Deng, J.; Lan, Z.; Xu, Z. Effects of Bias Voltage and Target Current on Microstructure and Load Measurement Performance of ZnO Piezoelectric Coatings Applied to Bolt in Transformer. Coatings 2023, 13, 1662. https://doi.org/10.3390/coatings13101662

Kou H, Wang F, Nie D, Ning Z, Li Q, Deng J, Lan Z, Xu Z. Effects of Bias Voltage and Target Current on Microstructure and Load Measurement Performance of ZnO Piezoelectric Coatings Applied to Bolt in Transformer. Coatings. 2023; 13(10):1662. https://doi.org/10.3390/coatings13101662

Chicago/Turabian StyleKou, Hanpeng, Fuyuan Wang, Dayu Nie, Zhaojun Ning, Qiaoqiao Li, Jiangang Deng, Zhenbo Lan, and Zhuolin Xu. 2023. "Effects of Bias Voltage and Target Current on Microstructure and Load Measurement Performance of ZnO Piezoelectric Coatings Applied to Bolt in Transformer" Coatings 13, no. 10: 1662. https://doi.org/10.3390/coatings13101662