Evaluation of Resistance Properties of Selected Surface Treatments on Medium Density Fibreboards

Abstract

:1. Introduction

2. Materials and Methods

2.1. Wooden Composites

- Raw MDF;

- Veneer-faced MDF—an MDF panel that consists of beech veneer with a thickness of 0.5 mm, which is joined to the MDF using urea–melamine–formaldehyde glue (LEP-PONAL FU 400 (Henkel CR, spol. s.r.o., Praha, Czech Republic). The spread rate was 150 g·m−2.

2.2. Coatings and Process of Coating of Wooden Composites

- Transparent waterborne polyurethane–acrylate (Aqua-Step Professional 30153 from ADLER-Werk Lackfabrik Johann Berghofer GmbH & Co. KG, Schwarz, Austria)—coating with a UV filter. A solution of aliphatic polyisocyanate is employed as a hardener. Three levels of application were used. The spread rate was 100 mL·m−2 per layer by spraying;

- Transparent solvent-borne polyurethane (PUR-Strong 26303 from ADLER-Werk Lackfabrik Johann Berghofer GmbH & Co. KG, Schwarz, Austria)—a two-component polyurethane coating that combines unique UV filters. Three levels of application were used. The spread rate was 150 mL·m−2 per layer by spraying;

- Transparent natural wax with oil (Naturnah Hartwachs 96050 from ADLER-Werk Lackfabrik Johann Berghofer GmbH & Co. KG, Schwarz, Austria)—hard wax made from natural oils and wax and free of solvents. Linseed oil, beeswax, carnauba wax, and cobalt–zircon siccative are all included in it. Three levels of application were used. The spread rate was 60 mL·m−2 per layer by hot spraying;

- Pigmented (white) coating systems with polyester (Polybian COV from SIRCA S.p.A., Sandono di Massanzago Padova, Italy) as a base coat and polyurethane (glossy LPP2530NC/RAL—NCS or matte OPP530NI/GTA RAL—NCS from SIRCA S.p.A., Sandono di Massanzago Padova, Italy) as a top coat. On the surface of the boards, the coating was applied by spraying at a spread rate of 100 mL·m−2 per layer of base coat and at a spread rate of 150 mL·m−2 per layer of top coat. The coating was created as a three-layer system (two base coats and one top coat) or as a four-layer system (two base coats and two top coats).

2.3. Furniture Foils and the Process of Lamination of Wooden Composites

- (a)

- Gloss/matte PVC foil with thickness of 0.4 mm (Konrad Hornschuch AG, Weißbach, Germany)—both gloss and matte PVC films were glued to the sanded MDF board (with the sandpaper with grain size number P150) using heat-activated one-component adhesives series based on polyurethane—Jowapur® (Jowat Swiss AG, Buchrainon, Switzerland) and vacuum pressed (Wemhöner Surface Technologies GmbH & Co. KG, Herford, Deutschland) at a temperature of about 120 °C and high pressure in company Niva Expo s.r.o. division Svet dvierok (Dobrá Niva, Slovakia).

- (b)

- High gloss PVC foil with a thickness of 0.5 mm (Renolit SE, Worms, Germany). To glue the foils to the MDF, the PUR adhesive Dorus Fd 150 Ls Plus and the hardener Dorus R 397 (3%–10%) (Henkel AG &Co. KGaA, Düsseldor, Germany) were used. It is a two-component dispersion adhesive for 3D lamination of foiled parts. The MDF panel was sanded with sandpaper with grain size number P150 prior to laminated finishing. The pressing process lasted 80 s at a temperature of 130 °C and a pressure of 0.38 MPa. The surface finish of MDF was performed in the company Sanas a.s. (Sabinov, Slovakia);

- (c)

- High gloss PET foil with a thickness of 0.5 mm (Renolit SE, Worms, Germany)—lamination process was the same as for the previous PVC foil (point b);

- (d)

- High gloss lacquered (acryl) film Senosan® AM1800TopX with a thickness of 0.7 mm (Senoplast Klepsch & Co. GmbH, Piesendorf, Österreich). A commercially prepared acryl (Senosan®) foil-faced MDF board was used in the experiment (from the trading company, Démos Trade, s.r.o., Žilina, Slovakia);

- (e)

- GFE (Ground foil) and subsequent applied pigment polyurethane-based coating system (specified in Section 2.2). A commercially prepared ground-faced MDF board was used in the experiment (from the trading company, Démos Trade, s.r.o., Žilina, Slovakia).

2.4. Determination of Thickness of Coating Film

2.5. Determination of Mechanical and Resistance Properties

2.5.1. Film Hardness by Pencil Test

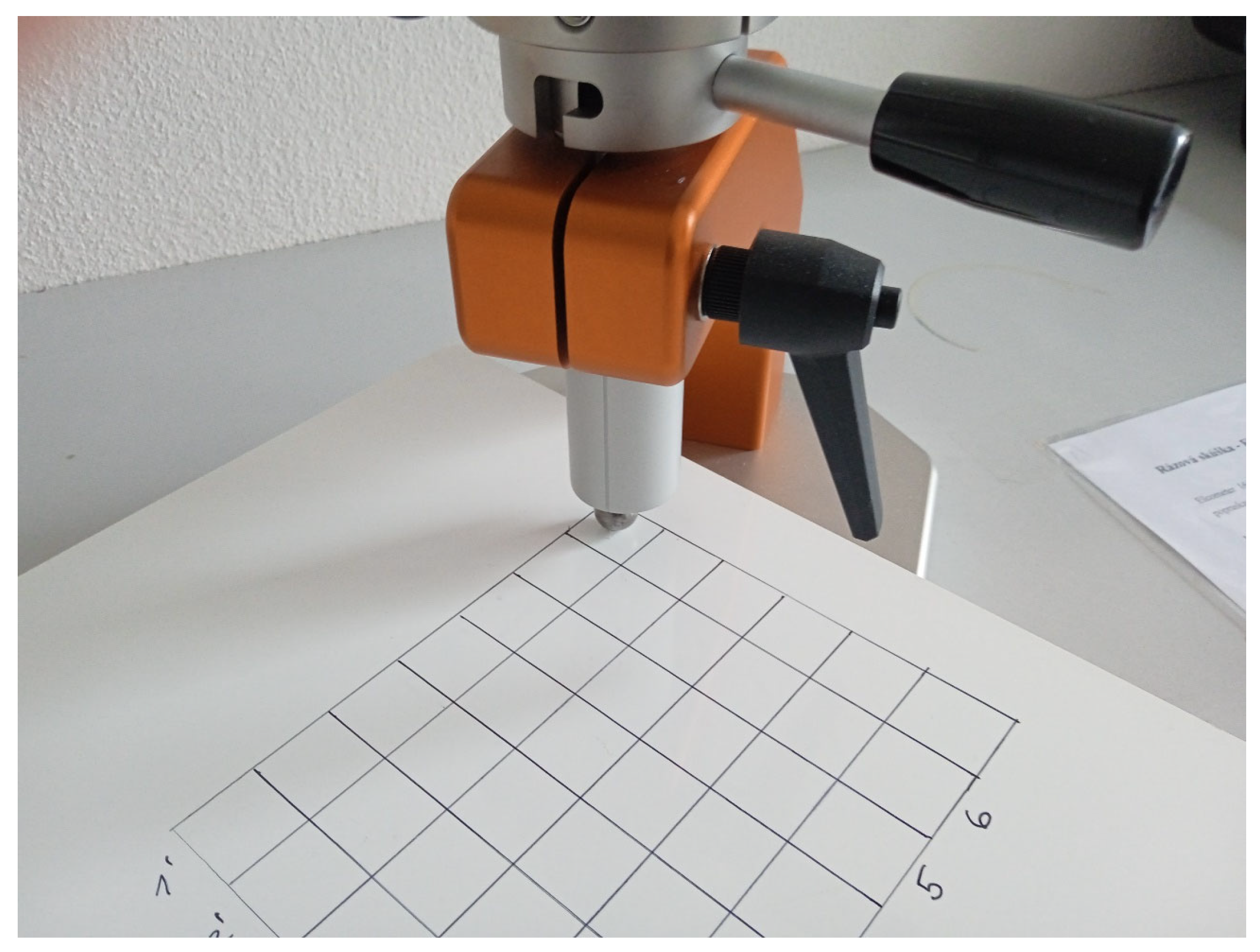

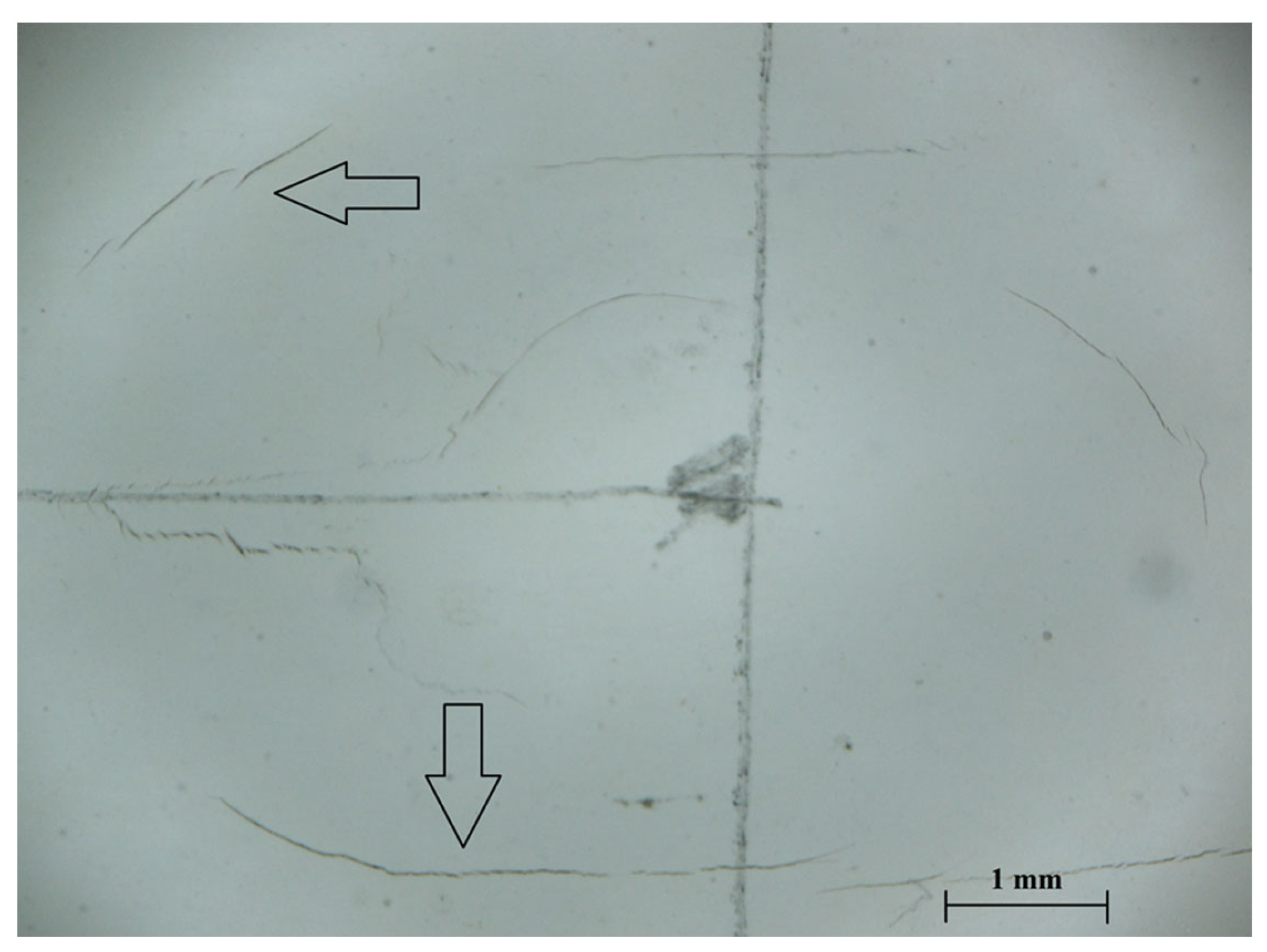

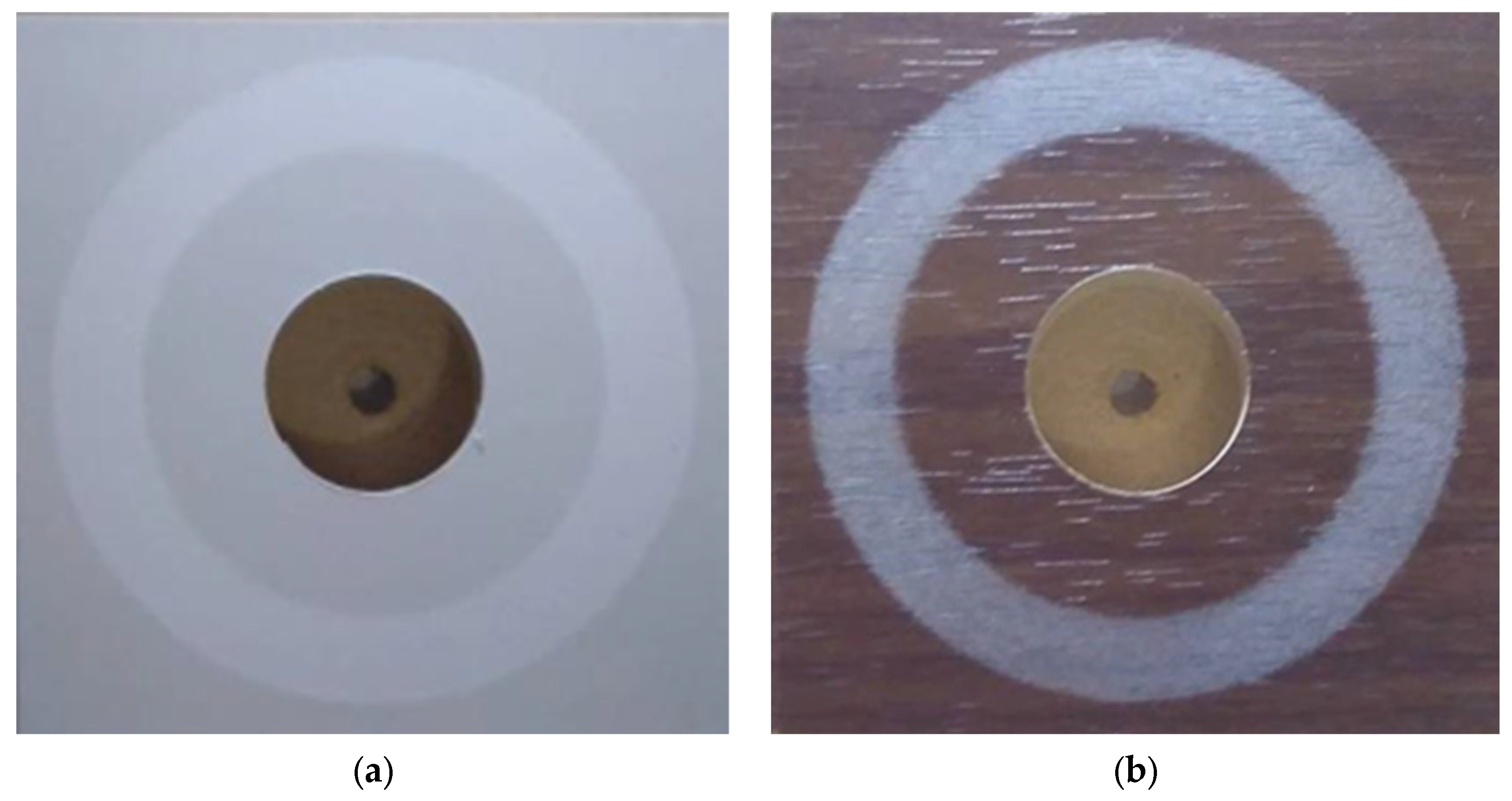

2.5.2. Falling-Weight Impact Resistance

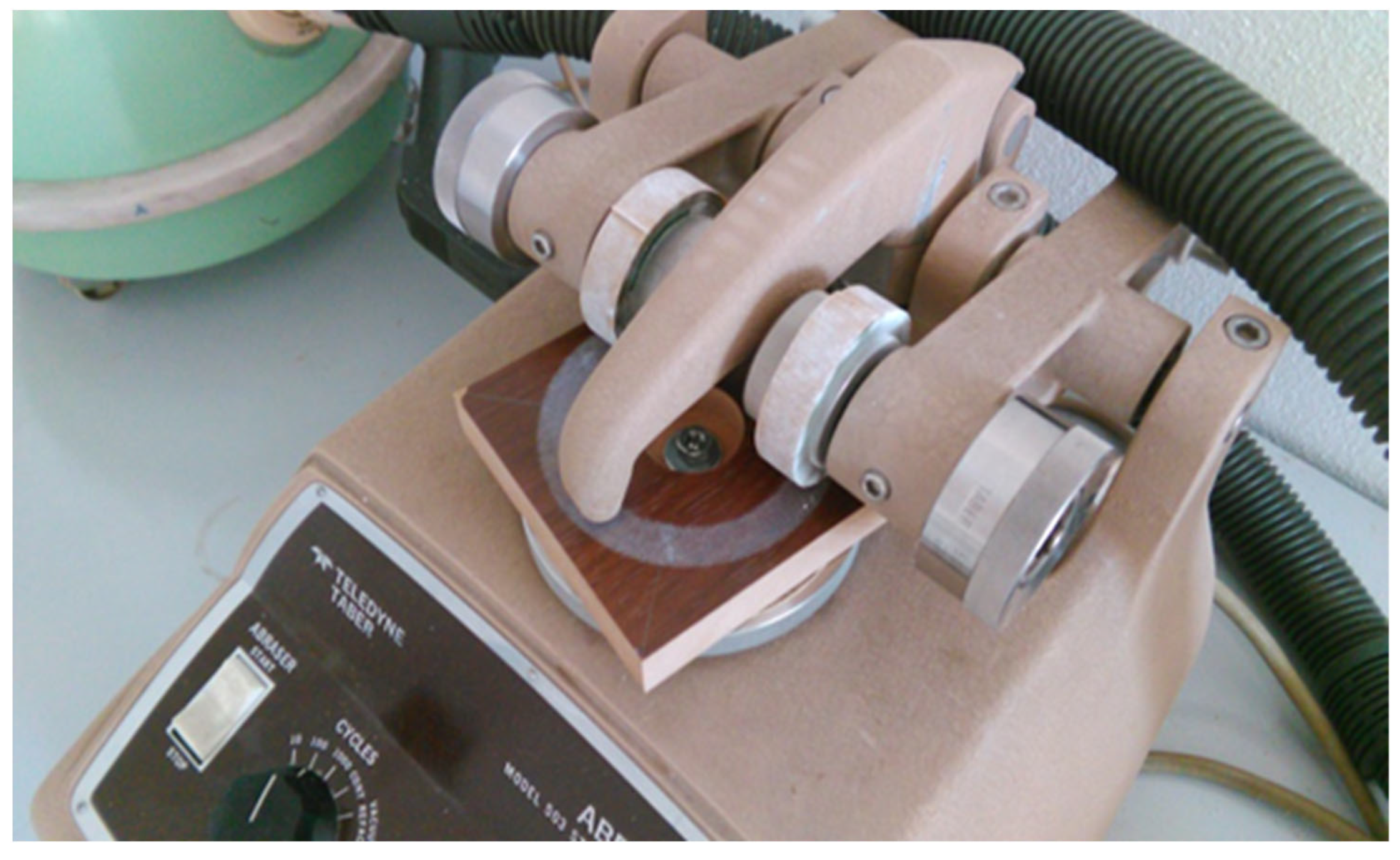

2.5.3. Abrasion Resistance

2.5.4. Resistance to Cold Liquids

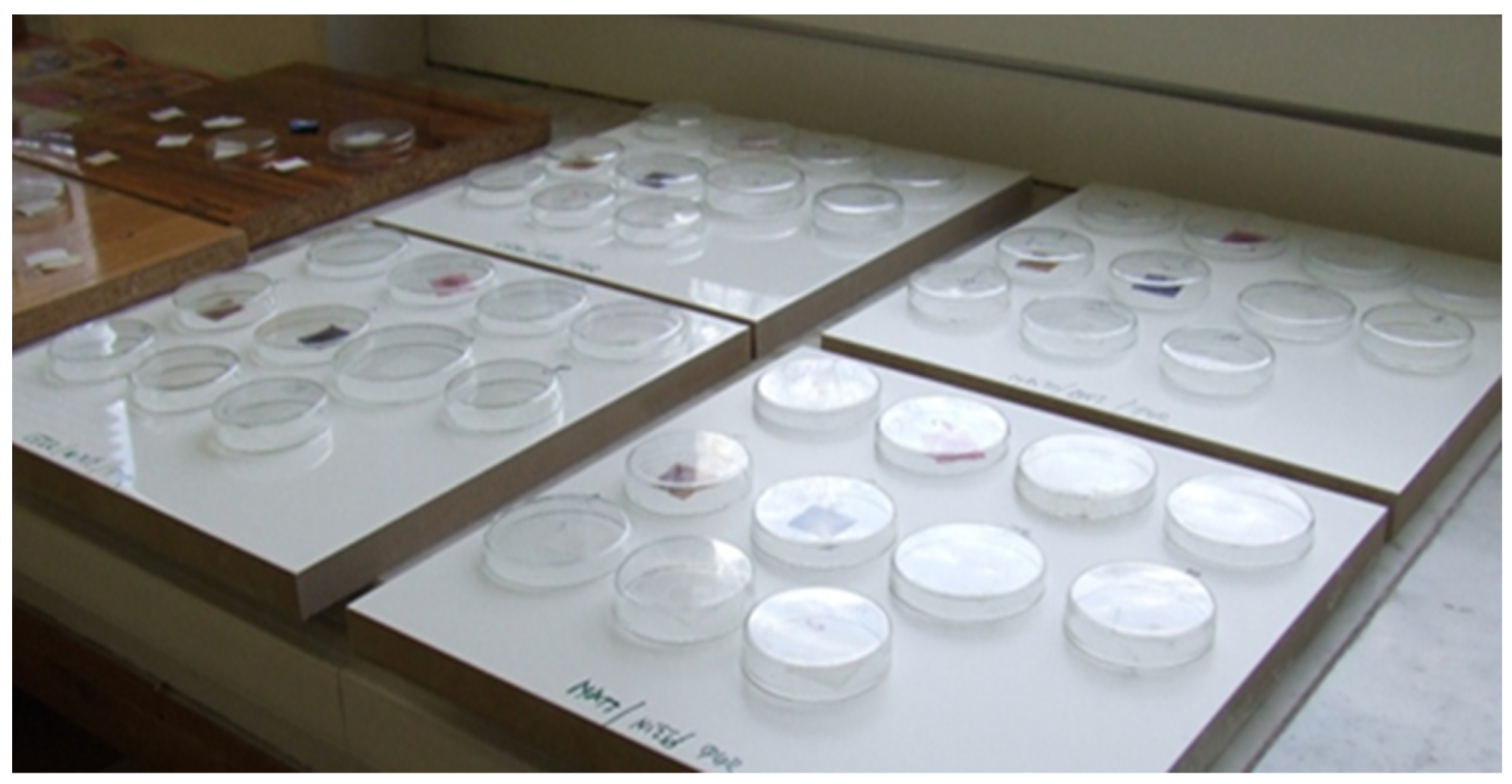

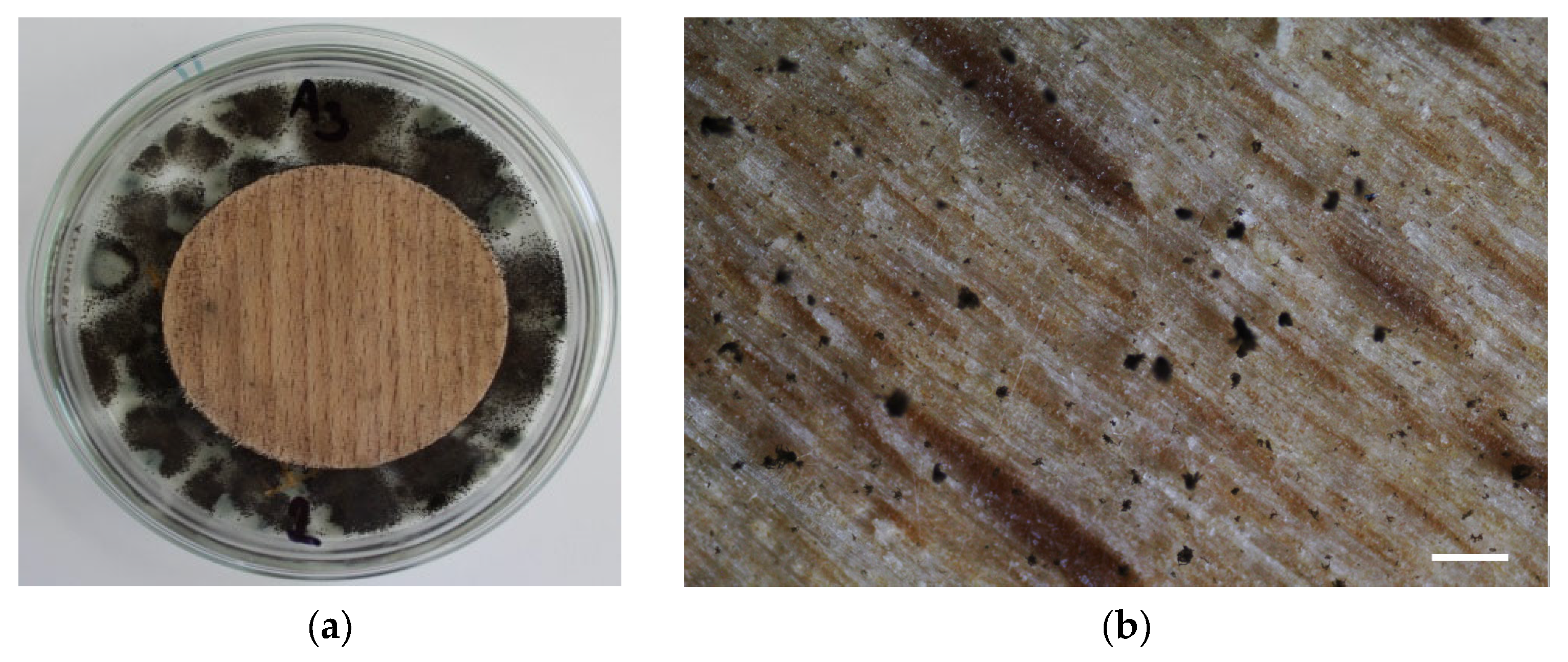

2.5.5. Resistance to Moulds

2.5.6. Statistical Evaluation

3. Results

3.1. Film Hardness by Pencil Test

3.2. Impact Resistance

3.3. Abrasion Resistance

3.4. Resistance to Cold Liquids

3.5. Resistance to Interior Moulds

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Krug, D.; Wagenführ, A.; Weber, A.; Wenderdel, C. Fiber-Based Materials. In Springer Handbook of Wood Science and Technology; Niemz, P., Teischinger, A., Sandberg, D., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 1491–1561. [Google Scholar] [CrossRef]

- Tobisch, S.; Dunky, M.; Hänsel, A.; Krug, D.; Wenderdel, C. Survey of Wood-Based Materials. In Springer Handbook of Wood Science and Technology; Niemz, P., Teischinger, A., Sandberg, D., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 1211–1282. [Google Scholar] [CrossRef]

- Norvydas, V.; Minelga, D. Strength and Stiffness Properties of Furniture Panels Covered with Different Coatings. Mater. Sci. 2006, 12, 328–332. Available online: https://matsc.ktu.lt/index.php/MatSc/article/view/26469 (accessed on 1 November 2023).

- Zdravković, V.; Palija, T.; Lovrić, A.; Obradović, A. Impact of Pressing Regime and Substrate Type on Bond Quality of Decorative Veneer. BioResources 2020, 15, 2668–2679. [Google Scholar] [CrossRef]

- Bekhta, P.; Kozak, R.; Sedliačik, J.; Gryc, V.; Sebera, V.; Bajzová, L.; Iždinský, J. Selected Properties of Veneered Lightweight Particleboards with Expanded Polystyrene. Materials 2022, 15, 6474. [Google Scholar] [CrossRef]

- Deppe, H.J.; Ernst, K. MDF–Mitteldichte Faserplatte; DRW-Verlag Weinbrenner GmbH & Co.: Leinfelder-Echterdingen, Germany, 1996; 200p. [Google Scholar]

- Nemli, G.; Usta, M. Influences of Some Manufacturing Factors on the Important Quality Properties of Melamine-impregnated Papers. Build. Environ. 2004, 39, 567–570. [Google Scholar] [CrossRef]

- Bardak, S.; Sarı, B.; Nemli, G.; Kırcı, H.; Baharoğlu, M. The Effect of Decor Paper Properties and Adhesive Type on Some Properties of Particleboard. Int. J. Adhes. Adhes. 2011, 31, 412–415. [Google Scholar] [CrossRef]

- Williams, R.S. Finishing of Wood. In Wood Handbook; USDA Forest Service: Madison, WI, USA, 2010; pp. 16–39. [Google Scholar]

- Badila, M.; Jocham, C.; Zhang, W.; Schmidt, T.; Wuzella, G.; Müller, U.; Kandelbauer, A. Powder Coating of Veneered Particle Board Surfaces by Hot Pressing. Prog. Org. Coat. 2014, 77, 1547–1553. [Google Scholar] [CrossRef]

- Henke, M.; Lis, B.; Krystofiak, T. Mechanical and Chemical Resistance of UV Coating Systems Prepared under Industrial Conditions. Materials 2023, 16, 4468. [Google Scholar] [CrossRef]

- Mahút, J.; Réh, R. Plywood and Decorative Veneers; Technical University: Zvolen, Slovakia, 2003; 240p. [Google Scholar]

- Bekhta, P.; Müller, M.; Hunko, I. Properties of Thermoplastic-Bonded Plywood: Effects of the Wood Species and Types of the Thermoplastic Films. Polymers 2020, 12, 2582. [Google Scholar] [CrossRef]

- Bekhta, P. Recent Developments in Eco-Friendly Wood-Based Composites II. Polymers 2023, 15, 1941. [Google Scholar] [CrossRef]

- Kılıç, M.; Burdurlu, E.; Aslan, S.; Altun, S.; Tümerdem, Ö. The Effect of Surface Roughness on Tensile Strength of the Medium Density Fiberboard (MDF) Overlaid with Polyvinyl Chloride (PVC). Mater. Des. 2009, 30, 4580–4583. [Google Scholar] [CrossRef]

- Kúdela, J. Surface Properties of a Medium Density Fibreboard Evaluated from the Viewpoint of its Surface Treatment. Acta Fac. Xylologiae Zvolen 2020, 62, 35–45. [Google Scholar] [CrossRef]

- Endo, T.; Reddy, L.; Nishikawa, H.; Kaneko, S.; Nakamura, Y.; Endo, K. Composite Engineering–direct Bonding of Plastic PET Films by Plasma Irradiation. Procedia Eng. 2017, 171, 88–103. [Google Scholar] [CrossRef]

- Erdene-Ochir, O.; Do, V.T.; Chun, D.M. Facile Fabrication of Durable and Flexible Superhydrophobic Surface with Polydimethylsiloxane and Silica Nanoparticle Coating on a Polyethylene Terephthalate Film by Hot-roll Lamination. Polymer 2022, 255, 125158. [Google Scholar] [CrossRef]

- Spear, M.J. Preservation, protection and modification of wood composites. In Wood Composites; Ansell, M.P., Ed.; Chapman & Hall: London, UK, 2015; pp. 253–310. [Google Scholar] [CrossRef]

- Bulian, F.; Graystone, J.A. Wood Coatings—Theory and Practice; Elsevier: Amsterdam, The Netherlands, 2009; p. 320. [Google Scholar]

- Jaic, M.; Zivanovic, R. The Influence of the Ratio of the Polyurethane Coating Components on the Quality of Finished Wood Surface. Eur. J. Wood Wood Prod. 1997, 55, 319–322. [Google Scholar] [CrossRef]

- Song, X.; Liu, G.; Feng, X.; Li, Z. Preparation and Properties of Agglomerated Cork Panels Bound with Chitosan Binder. Wood. Res. 2022, 67, 648–660. [Google Scholar] [CrossRef]

- Weththimuni, M.L.; Capsoni, D.; Malagodi, M.; Milanese, C.; Licchelli, M. Shellac/nanoparticles Dispersions as Protective Materials for Wood. Appl. Phys. A 2016, 122, 1058. [Google Scholar] [CrossRef]

- Iždinský, J.; Reinprecht, L.; Nosáľ, E.; Vidholdová, Z.; Krokošová, J. The Activity of Bacteria on Surfaces of Wooden Composites Painted with Acrylate Coating with Addition of Silver Nanoparticles. Book of Abstracts. 2017, pp. 130–131. Available online: https://iris.unibas.it/bitstream/11563/131255/1/2017_COST1407Conf_-_dig._proceedings_final.pdf#page=131 (accessed on 23 October 2023).

- Cataldi, A.; Corcione, C.E.; Frigione, M.; Pegoretti, A. Photocurable Resin/nanocellulose Composite Coatings for Wood Protection. Prog. Org. Coat. 2017, 106, 128–136. [Google Scholar] [CrossRef]

- Danková, M.; Kalendová, A.; Machotová, J. Waterborne Coatings Based on Acrylic Latex Containing Nanostructured ZnO as an Active Additive. J. Coat. Technol. Res. 2020, 17, 517–529. [Google Scholar] [CrossRef]

- Vidholdová, Z.; Slabejová, G.; Šmidriaková, M. Quality of Oil- and Wax-Based Surface Finishes on Thermally Modified Oak Wood. Coatings 2021, 11, 143. [Google Scholar] [CrossRef]

- Salca, E.A. Selected Coating Properties of Black Alder Wood as a Function of Surface Preparation, Varnish Type, Coating System and Exposure Conditions. In Recent Trends in Chemical and Material Sciences; Sutar, H., Ed.; B P International: London, UK, 2022; Chapter 7; Volume 5, pp. 69–90. [Google Scholar] [CrossRef]

- Šomšák, M.; Reinprecht, L.; Tiňo, R. Effect of Plasma and UV-absorbers in Transparent Acrylic Coatings on Photostability of Spruce Wood in Exterior). Acta Fac. Xylologiae Zvolen 2015, 57, 63–73. [Google Scholar]

- Gholamiyan, H.; Ashouri, J.; Ahmadi, P.; Hosseinpourpia, R. Surface Wettability and Coating Performance of Plasma-Treated Wood-Based Composite Panels. Coatings 2022, 12, 1894. [Google Scholar] [CrossRef]

- Goktas, O.; Bozkaya, Y.T.; Yeniocak, M. The Use of Herbal Extracts in Lacquer Paint Coloring and Determination of Some Mechanical Resistance Properties on Wood-based Surfaces. Maderas Cienc. Tecnol. 2023, 25, 1–10. [Google Scholar] [CrossRef]

- Jeżo, A.; Kowaluk, G. Carbon Capture and Storage through Upcycling of Suberinic Acid Residues in Wood Composites Finishing. C 2023, 9, 80. [Google Scholar] [CrossRef]

- STN EN ISO 15184; Paints and Varnishes-Determination of Film Hardness by Pencil Test. Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2021.

- STN 91 0102; Furniture. Surface Finishing of Wooden Furniture. Technical Requirements Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 1986.

- STN EN ISO 6272-2; Paints and Varnishes-Rapid-Deformation (Impact Resistance) Tests-Part 2: Falling-Weight Test, Small-Area Indenter. Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2012.

- STN EN ISO 7784-1; Paints and Varnishes-Determination of Resistance to Abrasion-Part 1: Method with Abrasive-Paper Covered Wheels and Rotating Test Specimen. Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2023.

- STN EN 12720+A1; Furniture-Assessment of Surface Resistance to Cold Liquids. Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2014.

- STN EN 15457; Paints and Varnishes-Laboratory Method for Testing the Efficacy of Film Preservatives in a Coating against Fungi. Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2022.

- Bekhta, P.; Proszyk, S.; Lis, B.; Krystofiak, T. Gloss of Thermally Densified Alder (Alnus glutinosa Goertn.), Beech (Fagus sylvatica L.), Birch (Betula verrucosa Ehrh.), and Pine (Pinus sylvestris L.) Wood Veneers. Eur. J. Wood Wood Prod. 2014, 72, 799–808. [Google Scholar] [CrossRef]

- Modrák, V.; Mandulák, J. Exploration of Impact of Technological Parameters on Surface Gloss of Plastic Parts. Procedia CIRP 2013, 12, 504–509. Available online: http://www.sciencedirect.com/science/article/pii/S2212827113007270 (accessed on 30 August 2023). [CrossRef]

- Vardi, J.; Golan, A.; Levy, D.; Gilead, I. Tracing Sickle Blade Levels of Wear and Discard Patterns: A New Sickle Gloss Quantification Method. J. Archaeol. Sci. 2010, 37, 1716–1724. [Google Scholar] [CrossRef]

- Cheumani Yona, A.M.; Žigon, J.; Dahle, S.; Petrič, M. Study of the Adhesion of Silicate-based Coating Formulations on a Wood Substrate. Coatings 2021, 11, 61. [Google Scholar] [CrossRef]

- Slabejová, G. Influence of Selected Factors on the Stability of Wood—Solid Coating Film. Acta Fac. Xylologiae Zvolen 2012, 54, 57–65. [Google Scholar]

- Slabejová, G.; Šmidriaková, M.; Pánis, D. Quality of Silicone Coating on the Veneer Surfaces. BioResources 2018, 13, 776–788. [Google Scholar] [CrossRef]

- Pavlič, M.; Žigon, J.; Petrič, M. Wood Surface Finishing of Selected Invasive Tree Species. Wood Ind. 2020, 71, 271–280. [Google Scholar] [CrossRef]

- Kalendová, A.; Kalenda, P. Technology of Paint Materials I. Binders, Solvents and Additives for the Production of Paint Materials; Univerzita of Pardubice: Pardubice, Czech Republic, 2004; 328p. [Google Scholar]

- Tesařová, D.; Chladil, J.; Čech, P.; Tobiášová, K. Ecological Finished Surfaces; Mendel University in Brno: Brno, Czech Republic, 2010; 126p. [Google Scholar]

- Pavlič, M.; Petrič, M.; Žigon, J. Interactions of Coating and Wood Flooring Surface System Properties. Coatings 2021, 11, 91. [Google Scholar] [CrossRef]

- Veigel, S.; Grüll, G.; Pinkl, S.; Obersriebnig, M.; Müller, U.; Gindl-Altmutter, W. Improving the Mechanical Resistance of Waterborne Wood Coatings by Adding Cellulose Nanofibres, Reactive and Functional. Polymers 2014, 85, 214–220. [Google Scholar] [CrossRef]

- Vidholdová, Z.; Iždinský, J.; Reinprecht, L.; Krokošová, J. Activity of Bacteria and Moulds on Surfaces of Commercial Wooden Composites. Mater. Sci. Forum 2015, 818, 190–193. [Google Scholar] [CrossRef]

- Nosáľ, E.; Reinprecht, L. Anti-bacterial and Anti-mold Efficiency of Silver Nanoparticles Present in Melamine-laminated Particleboard Surfaces. BioResources 2019, 14, 3914–3924. [Google Scholar] [CrossRef]

- Edge, M.; Allen, N.S.; Turner, D.; Robinson, J.; Seal, K. The enhanced performance of biocidal additives in paints and coatings. Prog. Org. Coat. 2001, 43, 10–17. [Google Scholar] [CrossRef]

- Lu, K.T.; Chang, J.P. Synthesis and Antimicrobial Activity of Metal-containing Linseed Oil-based Waterborne Urethane Oil Wood Coatings. Polymers 2020, 12, 663. [Google Scholar] [CrossRef]

| Pencil number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| Pencil hardness | 3B | 2B | B | HB | F | H | 3H | 4H | 5H | 6H | 7H | 8H | 9H |

| Degree | Visual Evaluation |

|---|---|

| 1 | No visible changes |

| 2 | No cracks on the surface, and the intrusion was only slightly visible |

| 3 | Visible light cracks on the surface, typically one to two circular cracks around the intrusion |

| 4 | Visible large cracks at the intrusion |

| 5 | Visible cracks were also off site of intrusion; peeling of the coating |

| Cold Liquid | Characteristic |

|---|---|

| Acetic acid | 10% (w/w) aqueous solution |

| Citric acid | 10% (w/w) aqueous solution |

| Ethanol (p.a.) | 96% (v/v) concentration |

| Coffee | Dissolved 4 g of instant coffee, medium roasted; freeze-dried in 100 mL boiling water |

| Wine | Black currant wine |

| Sanitizer | Chloramine T, 2.5% aqueous solution |

| Degree | Description |

|---|---|

| 5 | No visible changes (no damage) |

| 4 | Slight change in gloss—visible only in reflection of light source |

| 3 | Slight traces of damage (gloss)—visible from different directions |

| 2 | Strong traces of damage usually without changing the structure of varnish |

| 1 | Strong damage with change in varnish structure |

| Degree | Description |

|---|---|

| 0 | No mycelium on the top surface of the sample |

| 1 | Growth up to 10% on the top surface of the sample |

| 2 | Growth more than 10% up to 30% on the top surface of the sample |

| 3 | Growth more than 30% up to 50% on the top surface of the sample |

| 4 | More than 50% on the top surface of the sample |

| Surface Treatment | Thickness (m) | Film Hardness * | Impact Resistance ** (Using the Different Drop Height (mm)) | Abrasion Resistance *** Δm (g) | |||

|---|---|---|---|---|---|---|---|

| 50 | 100 | 200 | 400 | ||||

| I. MDF + coating | |||||||

| (a) Transparent waterborne polyurethane-acrylate | 87.6 (2.8) | 3H (7) | 0.0 (1) | 1.0 (1) | 1.3 (2) | 3.6 (2) | 0.061 (0.006) |

| (b) Transparent solvent-borne polyurethane | 93.8 (3.9) | 3H (7) | 0.0 (1) | 0.6 (1) | 2.0 (2) | 3.7 (2) | 0.095 (0.007) |

| (c) Transparent, wax | 77.3 (3.8) | 3H (7) | 0.0 (1) | 0.9 (1) | 2.2 (2) | 2.8 (2) | 0.052 (0.009) |

| II. MDF + coating system with polyester (base coat) and polyurethane (top coat) | |||||||

| (a) Pigment, gloss, 3 layers | 113.8 (3.9) | F (5) | 2.0 (2) | 3.2 (2) | 4.0 (3) | 5.0 (3) | 0.038 (0.006) |

| (b) Pigment, gloss, 4 layers | 133.8 (3.9) | F (5) | 2.0 (2) | 3.2 (2) | 5.0 (3) | 5.0 (3) | 0.039 (0.009) |

| (c) Pigment, matte, 3 layers | 117.3 (3.2) | 3H (7) | 2.0 (2) | 3.3 (2) | 4.0 (3) | 5.0 (3) | 0.050 (0.009) |

| (d) Pigment, matte, 4 layers | 123.8 (2.9) | 3H (7) | 2.1 (2) | 3.3 (2) | 5.1 (3) | 5.1 (3) | 0.047 (0.008) |

| III. Veneered MDF + coating system with polyester (base coat) and polyurethane (top coat) | |||||||

| (a) Pigment, gloss, 3 layers | 113.1 (3.1) | F (5) | 3.0 (4) | 4.3 (4) | 5.0 (4) | 6.0 (4) | 0.039 (0.007) |

| (b) Pigment, gloss, 4 layers | 123.8 (1.9) | F (5) | 3.1 (4) | 4.4 (4) | 4.1 (4) | 4.2 (4) | 0.041 (0.009) |

| (c) Pigment, matte, 3 layers | 111.7 (2.2) | 3H (7) | 3.0 (3) | 4.2 (3) | 5.0 (3) | 5.0 (3) | 0.049 (0.007) |

| (d) Pigment, matte, 4 layers | 133.8 (2.1) | 3H (7) | 3.0 (3) | 4.4 (3) | 4.9 (3) | 4.9 (5) | 0.048 (0.009) |

| IV. MDF + Foil | |||||||

| (a) PVC foil, gloss | 400 | 5H (9) | 2.0 (2) | 2.1 (2) | 2.1 (2) | 2.2 (2) | 0.001 (0.001) |

| (b) PVC foil, matte | 400 | >9H (>13) | 1.0 (1) | 1.4 (1) | 2.1 (2) | 2.2 (2) | 0.034 (0.002) |

| (c) high gloss PVC foil | 500 | 4H (8) | 3.0 (2) | 4.1 (3) | 4.4 (3) | 5.2 (3) | 0.077 (0.003) |

| (d) high gloss PET foil | 500 | 4H (8) | 1.9 (2) | 3.1 (2) | 3.3 (3) | 4.1 (3) | 0.006 (0.002) |

| (e) high gloss lacquered (acryl) film | 700 | 9H (13) | 2.0 (2) | 2.0 (2) | 2.1 (2) | 2.1 (2) | 0.015 (0.002) |

| (f) GFE + pigment polyurethane | 95.8 | 5H (9) | 2.0 (2) | 2.4 (2) | 3.1 (3) | 4.2 (4) | 0.077 (0.002) |

| Surface Treatment | Resistance to Cold Liquids | Resistance to Interior Moulds | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Acetic Acid | Citric Acid | Ethanol | Coffee | Wine | Sanitizer | 7th Day | 14th Day | 21st Day | |

| I. MDF + coating | |||||||||

| (a) Transparent waterborne polyurethane-acrylate | 5 | 5 | 4 | 5 | 5 | 4 | 1–2 | 2 | 3 |

| (b) Transparent solvent-borne polyurethane | 5 | 5 | 4 | 5 | 5 | 4 | 0 | 0 | 0 |

| (c) Transparent, wax | 5 | 4 | 4 | 3 | 3 | 1 | 3 | 4 | 4 |

| II. MDF + coating system with polyester (base coat) and polyurethane (top coat) | |||||||||

| (a) Pigment, gloss, 3 layers | 5 | 5 | 5 | 3 | 5 | 5 | 0 | 0 | 0 |

| (b) Pigment, gloss, 4 layers | 5 | 5 | 5 | 3 | 5 | 5 | 0 | 0 | 0 |

| (c) Pigment, matte, 3 layers | 3 | 5 | 3 | 3 | 4 | 4 | 0 | 0 | 0 |

| (d) Pigment, matte, 4 layers | 3 | 5 | 3 | 3 | 4 | 4 | 0 | 0 | 0 |

| III. Veneered MDF + coating system with polyester (base coat) and polyurethane (top coat) | |||||||||

| (a) Pigment, gloss, 3 layers | 5 | 5 | 5 | 3 | 5 | 5 | 0 | 0 | 0 |

| (b) Pigment, gloss, 4 layers | 5 | 5 | 5 | 3 | 5 | 5 | 0 | 0 | 0 |

| (c) Pigment, matte, 3 layers | 3 | 5 | 3 | 3 | 4 | 4 | 0 | 0 | 0 |

| (d) Pigment, matte, 4 layers | 3 | 5 | 3 | 3 | 4 | 4 | 0 | 0 | 0 |

| IV. MDF + Foil | |||||||||

| (a) PVC foil, gloss | 5 | 5 | 4 | 5 | 5 | 5 | 0 | 0 | 0 |

| (b) PVC foil, matte | 5 | 5 | 5 | 5 | 5 | 5 | 0 | 0 | 0 |

| (c) high gloss PVC foil | 5 | 5 | 4 | 5 | 4 | 4 | 0 | 0 | 0 |

| (d) high gloss PET foil | 5 | 5 | 4 | 5 | 5 | 5 | 0 | 0 | 0 |

| (e) high gloss lacquered (acryl) film | 5 | 5 | 5 | 5 | 5 | 5 | 0 | 0 | 0 |

| (f) GFE + pigment polyurethane | 5 | 5 | 5 | 5 | 5 | 5 | 0 | 0 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Slabejová, G.; Vidholdová, Z.; Iždinský, J. Evaluation of Resistance Properties of Selected Surface Treatments on Medium Density Fibreboards. Coatings 2023, 13, 1903. https://doi.org/10.3390/coatings13111903

Slabejová G, Vidholdová Z, Iždinský J. Evaluation of Resistance Properties of Selected Surface Treatments on Medium Density Fibreboards. Coatings. 2023; 13(11):1903. https://doi.org/10.3390/coatings13111903

Chicago/Turabian StyleSlabejová, Gabriela, Zuzana Vidholdová, and Ján Iždinský. 2023. "Evaluation of Resistance Properties of Selected Surface Treatments on Medium Density Fibreboards" Coatings 13, no. 11: 1903. https://doi.org/10.3390/coatings13111903

APA StyleSlabejová, G., Vidholdová, Z., & Iždinský, J. (2023). Evaluation of Resistance Properties of Selected Surface Treatments on Medium Density Fibreboards. Coatings, 13(11), 1903. https://doi.org/10.3390/coatings13111903