Structural and Mechanical Properties of DLC/TiN Coatings on Carbide for Wood-Cutting Applications

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

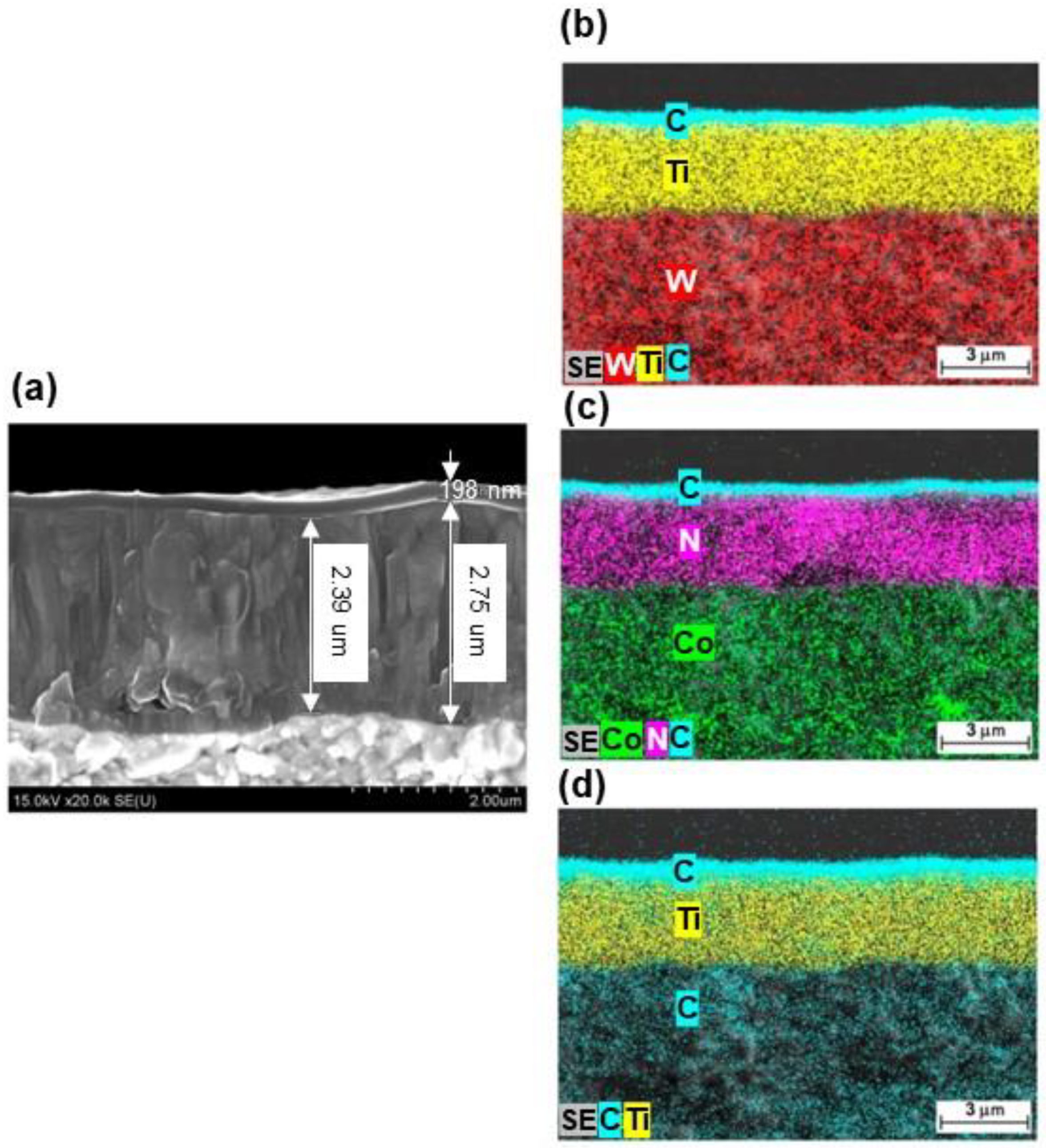

3.1. Microstructural Analysis

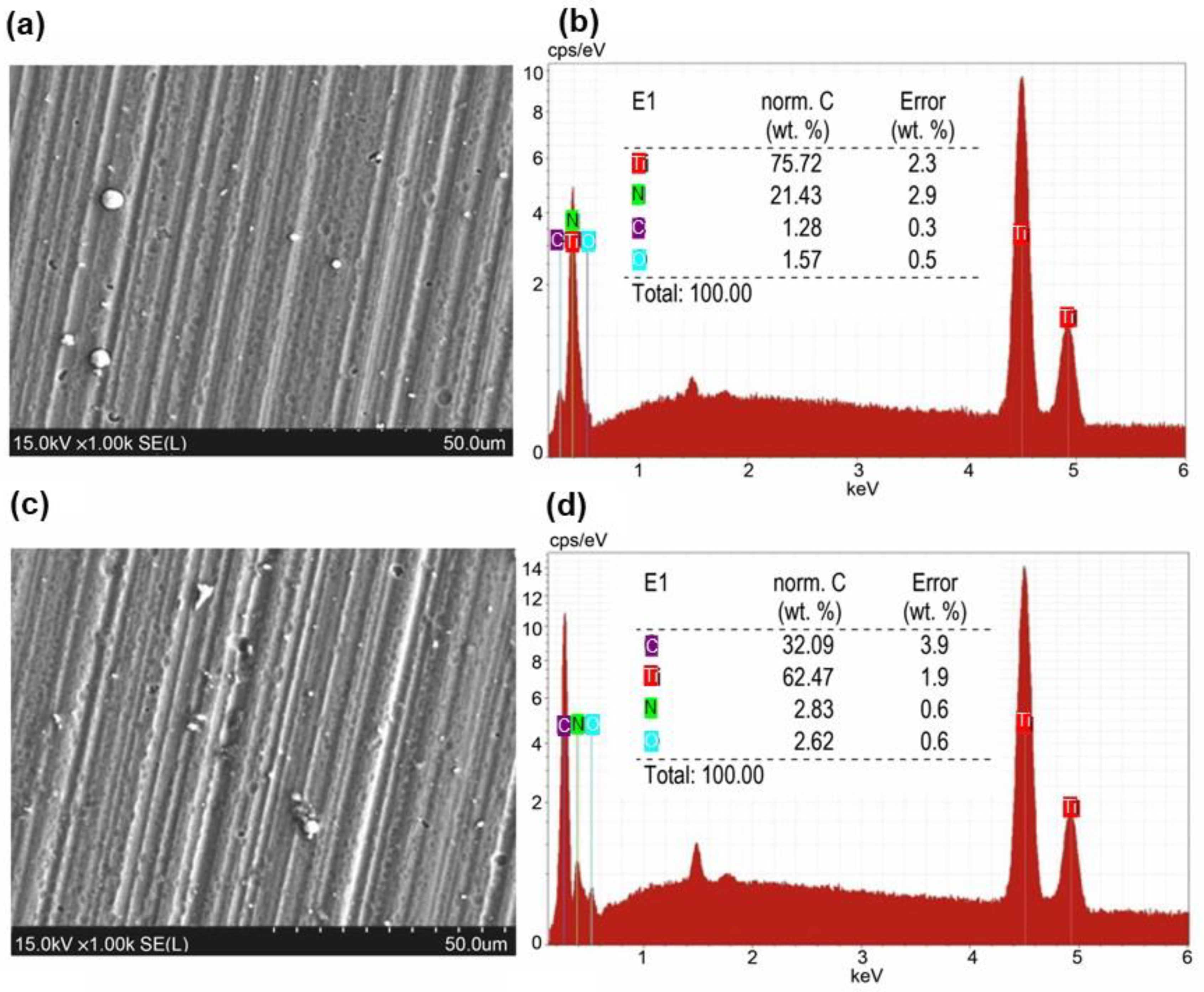

3.2. Surface Morphology

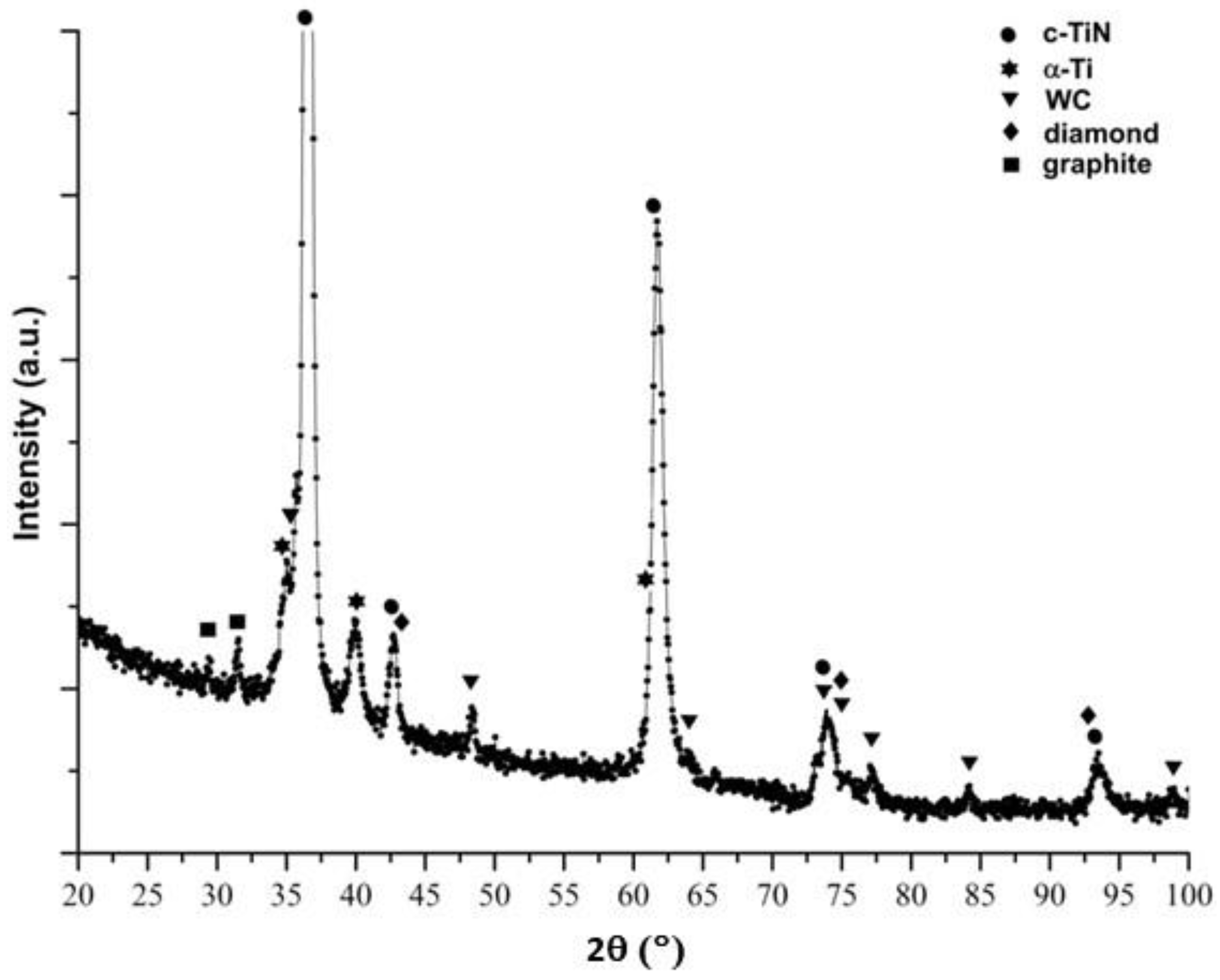

3.3. Phase Analysis

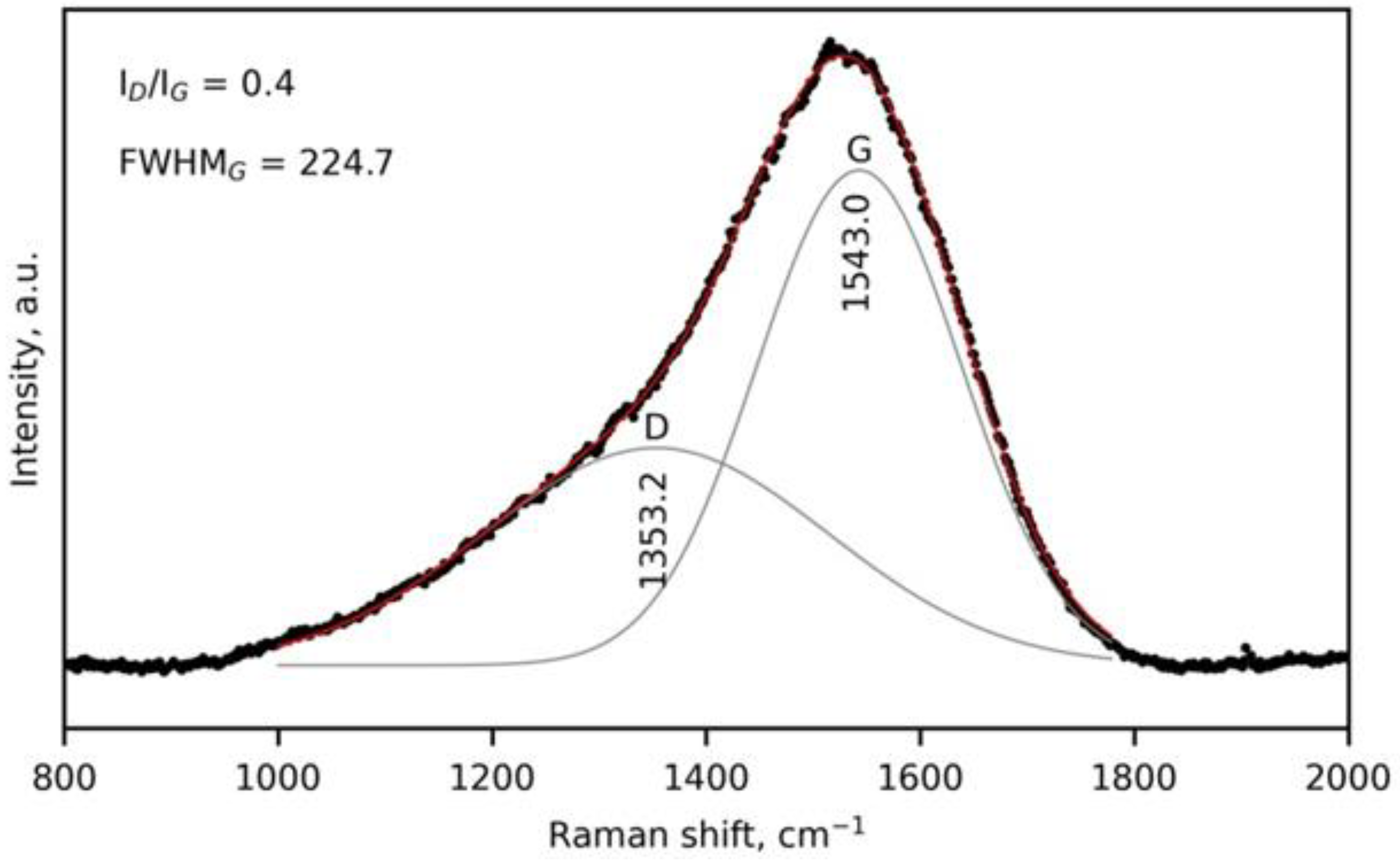

3.4. Raman Spectroscopy

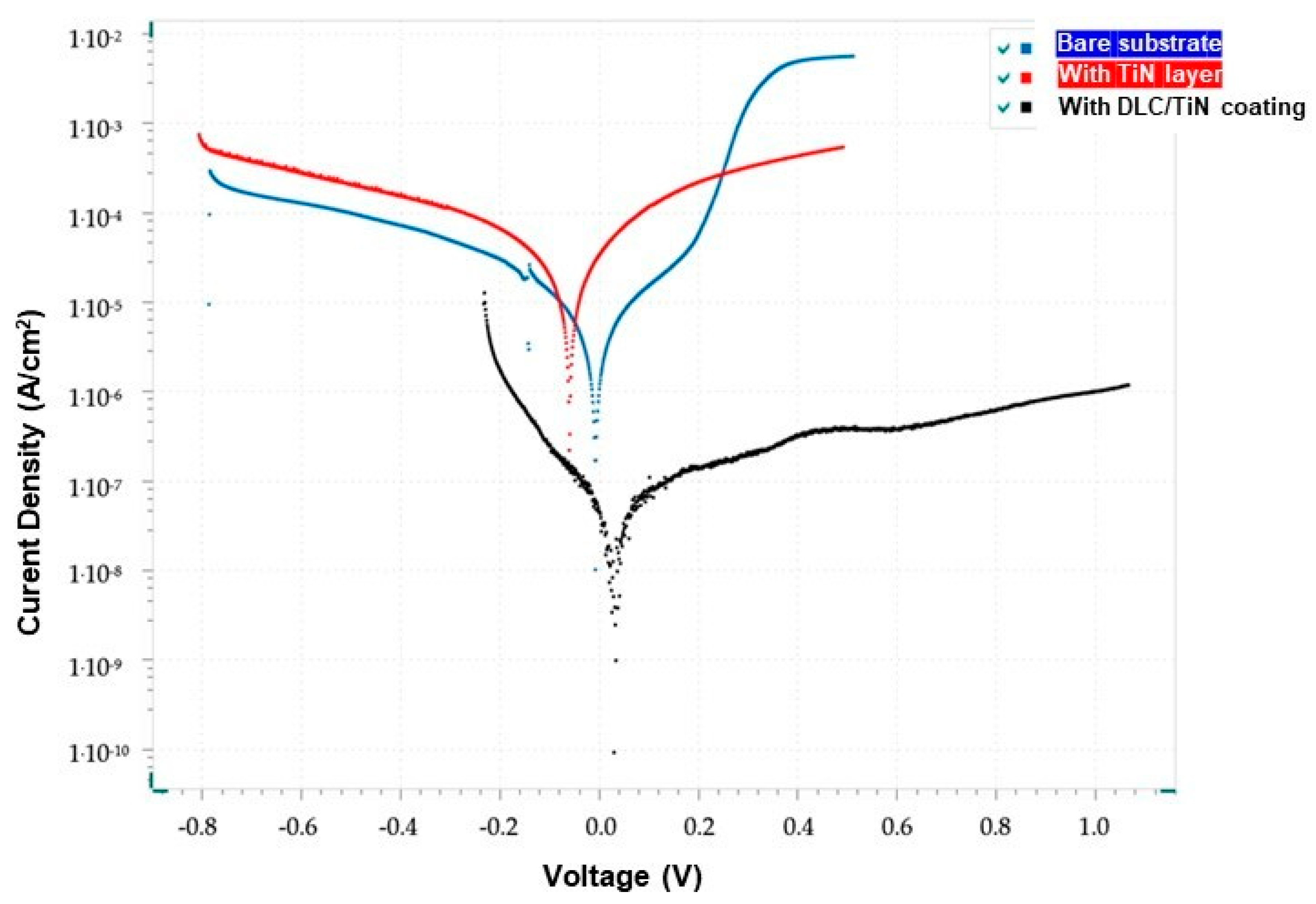

3.5. Corrosion Resistance

3.6. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guo, X.; Ekevad, M.; Grönlund, A.; Marklund, B.; Cao, P. Tool Wear and Machined Surface Roughness during Wood Flour/Polyethylene Composite Peripheral Up-milling using Cemented Tungsten Carbide Tools. Bioresources 2014, 9, 3779–3791. [Google Scholar] [CrossRef]

- Montenegro, P.; Gomes, J.; Rego, R.; Borille, A. Potential of niobium carbide application as the hard phase in cutting tool substrate. Int. J. Refract. Met. Hard Mater. 2018, 70, 116–123. [Google Scholar] [CrossRef]

- Strehler, C.; Ehrle, B.; Weinreich, A.; Kaiser, B.; Graule, T.; Aneziris, C.G.; Kuebler, J. Lifetime and Wear Behavior of Near Net Shaped Si3N4/SiC Wood Cutting Tools. Int. J. Appl. Ceram. Technol. 2012, 9, 280–290. [Google Scholar] [CrossRef]

- Sommer, F.; Kern, F.; Gadow, R. Injection molding of ceramic cutting tools for wood-based materials. J. Eur. Ceram. Soc. 2013, 33, 3115–3122. [Google Scholar] [CrossRef]

- Zhu, Z.; Guo, X.; Ekevad, M.; Cao, P.; Na, B.; Zhu, N. The effects of cutting parameters and tool geometry on cutting forces and tool wear in milling high-density fiberboard with ceramic cutting tools. Int. J. Adv. Manuf. Technol. 2017, 91, 4033–4041. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Vereschaka, A.A.; Fyodorov, S.V.; Sitnikov, N.N.; Batako, A.D. Comparative analysis of cutting properties and nature of wear of carbide cutting tools with multi-layered nano-structured and gradient coatings produced by using of various deposition methods. Int. J. Adv. Manuf. Technol. 2017, 90, 3421–3435. [Google Scholar] [CrossRef]

- Volkhonskii, A.O.; Vereshchaka, A.A.; Blinkov, I.V.; Vereshchaka, A.S.; Batako, A.D. Filtered cathodic vacuum Arc deposition of nano-layered composite coatings for machining hard-to-cut materials. Int. J. Adv. Manuf. Technol. 2016, 84, 1647–1660. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Vereschaka, A.S.; Bublikov, J.I.; Aksenenko, A.Y.; Sitnikov, N.N. Study of Properties of Nanostructured Multilayer Composite Coatings of Ti-TiN-(TiCrAl)N and Zr-ZrN-(ZrNbCrAl)N. J. Nano Res. 2016, 40, 90–98. [Google Scholar] [CrossRef]

- Moganapriya, C.; Rajasekar, R.; Ponappa, K.; Karthick, R.; Perundurai, R.V.; Kumar, P.S.; Pal, S.K. Tribomechanical behavior of TiCN/TiAlN/WC-C multilayer film on cutting tool inserts for machining. Mater. Test. 2017, 59, 703–707. [Google Scholar] [CrossRef]

- Park, I.-W.; Choi, S.R.; Lee, M.-H.; Kim, K.H. Effects of Si addition on the microstructural evolution and hardness of Ti–Al–Si–N films prepared by the hybrid system of arc ion plating and sputtering techniques. J. Vac. Sci. Technol. A 2003, 21, 895–899. [Google Scholar] [CrossRef]

- Kucharska, B.; Sobiecki, J.R.; Czarniak, P.; Szymanowski, K.; Cymerman, K.; Moszczyńska, D.; Panjan, P. Influence of Different Types of Cemented Carbide Blades and Coating Thickness on Structure and Properties of TiN/AlTiN and TiAlN/a-C:N Coatings Deposited by PVD Techniques for Machining of Wood-Based Materials. Materials 2021, 14, 2740. [Google Scholar] [CrossRef]

- Kuleshov, A.K.; Uglov, V.V.; Rusalsky, D.P.; Grishkevich, A.A.; Chayeuski, V.V.; Haranin, V.N. Effect of ZrN and Mo-N coatings and sulfacyanization on wear of wood-cutting knives. J. Frict. Wear 2014, 35, 201–209. [Google Scholar] [CrossRef]

- Chayeuski, V.; Zhylinski, V.; Grishkevich, A.; Rudak, P.; Barcik, S. Influence of High Energy Treatment on Wear of Edges Knives of Wood-Cutting Tool. MM Sci. J. 2016, 2016, 1519–1523. [Google Scholar] [CrossRef] [Green Version]

- Kubrak, P.B.; Drozdovich, V.B.; Zharski, I.M.; Chaevskiy, V.V. Electrodeposition of composite coatings containing car-bon-based nanomaterials and properties of coatings obtained. Electroplat. Surf. Treat. 2012, XX, 43–49. (In Russian) [Google Scholar]

- Tseluikin, V.N. Tribological properties of composite electrochemical nickel-based coatings. J. Frict. Wear 2010, 31, 356–358. [Google Scholar] [CrossRef]

- Dolmatov, V.Y.; Ozerin, A.N.; Kulakova, I.I.; Bochechka, O.O.; Lapchuk, N.M.; Myllymäki, V.; Vehanen, A. Detonation nanodiamonds: New aspects in the theory and practice of synthesis, properties and applications. Russ. Chem. Rev. 2020, 89, 1428–1462. [Google Scholar] [CrossRef]

- Burkat, G.K.; Dolmatov, V.Y. Application of ultrafine-dispersed diamonds in electroplating. Phys. Solid State 2004, 46, 703–710. [Google Scholar] [CrossRef]

- Polushin, N.I.; Kudinov, A.V.; Zhuravlev, V.V.; Stepareva, N.N.; Maslov, A.L. Dispersed strengthening of a diamond composite electrochemical coating with nanoparticles. Russ. J. Non-Ferr. Met. 2013, 54, 412–416. [Google Scholar] [CrossRef]

- Vityaz, P.A.; Zhornik, V.I.; Ilyushchenko, A.F.; Senyut, V.T.; Komarov, A.I.; Korzhenevskiy, A.P.; Ivakhnik, A.V. Nanodiamonds of Detonation Synthesis: Preparation and Application; Belaruskaya Navuka: Minsk, Belarus, 2013. (In Russian) [Google Scholar]

- Polini, R.; Barletta, M.; Rubino, G.; Vesco, S. Recent Advances in the Deposition of Diamond Coatings on Co-Cemented Tungsten Carbides. Adv. Mater. Sci. Eng. 2012, 2012, 151629. [Google Scholar] [CrossRef] [Green Version]

- Ma, L.; Yu, X.; Peng, Z.; Fu, Z.; Yue, W.; Wang, C.; Hua, M. Improvement of Film-to-Substrate Adhesion for Diamond and Related Films by Plasma-Based Technologies. IEEE Trans. Plasma Sci. 2011, 39, 3072–3079. [Google Scholar] [CrossRef]

- Wang, M.; Liu, Y.; Chen, H.; Wang, L.; Hu, D. First-Principles Calculations of Interfacial Structure and Properties between WC Substrate and TiN Coating Based on Density Functional Theory. Coatings 2022, 12, 1076. [Google Scholar] [CrossRef]

- Vereschaka, A.; Grigoriev, S.; Tabakov, V.; Migranov, M.; Sitnikov, N.; Milovich, F.; Andreev, N. Influence of the nanostructure of Ti-TiN-(Ti,Al,Cr)N multilayer composite coating on tribological properties and cutting tool life. Tribol. Int. 2020, 150, 106388. [Google Scholar] [CrossRef]

- Chim, Y.C.; Ding, X.Z.; Zeng, X.T.; Zhang, S. Oxidation resistance of TiN, CrN, TiAlN and CrAlN coatings deposited by lateral rotating cathode arc. Thin Solid Films 2009, 517, 4845–4849. [Google Scholar] [CrossRef]

- Gao, J.; Xu, F.; Ma, Z.; Shi, L.; Wang, X.; Zuo, D. Adherent diamond coating deposited on Ti by ultrasonic after carbonization pretreatment. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2019, 10, 095440541988478. [Google Scholar] [CrossRef]

- Han, C.X.; Zhi, J.Q.; Zeng, Z.; Wang, Y.S.; Zhou, B.; Gao, J.; Wu, Y.X.; He, Z.Y.; Wang, X.M.; Yu, S.W. Synthesis and characterization of nano-polycrystal diamonds on refractory high entropy alloys by chemical vapour deposition. Appl. Surf. Sci. 2023, 623, 157108. [Google Scholar] [CrossRef]

- Chayeuski, V.; Zhylinski, V.; Cernashejus, O.; Visniakov, N.; Mikalauskas, G. Structural and Mechanical Properties of the ZrC/Ni-Nanodiamond Coating Synthesized by the PVD and Electroplating Processes for the Cutting Knifes. J. Mater. Eng. Perform. 2019, 28, 1278–1285. [Google Scholar] [CrossRef]

- Chayeuski, V.; Taleb, A.; Zhylinski, V.; Kuleshov, A.; Shtempliuk, R. Preparation and Characterization of the Cr-Nanodiamonds/MoN Coatings with Performant Mechanical Properties. Coatings 2022, 12, 1012. [Google Scholar] [CrossRef]

- Dhandapani, V.S.; Subbiah, R.; Thangavel, E.; Arumugam, M.; Park, K.; Gasem, Z.M.; Veeraragavan, V.; Kim, D.-E. Tribological properties, corrosion resistance and biocompatibility of magnetron sputtered titanium-amorphous carbon coatings. Appl. Surf. Sci. 2016, 371, 262–274. [Google Scholar] [CrossRef]

- Santiago, J.A.; Fernández-Martínez, I.; Sánchez-López, J.C.; Rojas, T.C.; Wennberg, A.; Bellido-González, V.; Molina-Aldareguia, J.M.; Monclús, M.A.; González-Arrabal, R. Tribomechanical properties of hard Cr-doped DLC coatings deposited by low-frequency HiPIMS. Surf. Coatings Technol. 2019, 382, 124899. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Y.; Chen, H.; Wang, M. Modification Methods of Diamond like Carbon Coating and the Performance in Machining Applications: A Review. Coatings 2022, 12, 224. [Google Scholar] [CrossRef]

- Rajak, D.K.; Kumar, A.; Behera, A.; Menezes, P.L. Diamond-Like Carbon (DLC) Coatings: Classification, Properties, and Applications. Appl. Sci. 2021, 11, 4445. [Google Scholar] [CrossRef]

- Evaristo, M.; Fernandes, F.; Cavaleiro, A. Influence of the alloying elements on the tribological performance of DLC coatings in different sliding conditions. Wear 2023, 526-527, 204880. [Google Scholar] [CrossRef]

- Zou, C.W.; Wang, H.J.; Feng, L.; Xue, S.W. Effects of Cr concentrations on the microstructure, hardness, and temperature-dependent tribological properties of Cr-DLC coatings. Appl. Surf. Sci. 2013, 286, 137–141. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Vereschaka, A.A.; Sitnikov, N.N.; Milovich, F.; Bublikov, J.I.; Fyodorov, S.V.; Seleznev, A.E. Properties of (Cr,Al,Si)N-(DLC-Si) composite coatings deposited on a cutting ceramic substrate. Ceram. Int. 2020, 46, 18241–18255. [Google Scholar] [CrossRef]

- Grigoriev, S.; Volosova, M.; Fyodorov, S.; Lyakhovetskiy, M.; Seleznev, A. DLC-coating Application to Improve the Durability of Ceramic Tools. J. Mater. Eng. Perform. 2019, 28, 4415–4426. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Fedorov, S.V.; Okunkova, A.A.; Pivkin, P.M.; Peretyagin, P.Y.; Ershov, A. Development of DLC-Coated Solid SiAlON/TiN Ceramic End Mills for Nickel Alloy Machining: Problems and Prospects. Coatings 2021, 11, 532. [Google Scholar] [CrossRef]

- Wang, N.X.; Wang, Y.S.; Zheng, K.; Zhi, J.Q.; Zhou, B.; Wu, Y.X.; Xue, Y.P.; Ma, Y.; Cheng, F.; Gao, J.; et al. Achieving CVD diamond films on Mo0.5(TiZrTaW)0.5 highly concentrated alloy for ultrastrong corrosion resistance. Surf. Coatings Technol. 2023, 466, 129620. [Google Scholar] [CrossRef]

- Sun, H.; Yang, L.; Wu, H.; Zhao, L. Effects of Element Doping on the Structure and Properties of Diamond-like Carbon Films: A Review. Lubricants 2023, 11, 186. [Google Scholar] [CrossRef]

- Popov, A.N.; Kazachenko, V.P.; Popova, M.A.; Shil’ko, S.V.; Ryabchenko, T.V. Mechanical and Antifrictional Properties of Elastomeric Composites Based on a Rubber for Sealing Elements. Mech. Compos. Mater. 2017, 53, 505–514. [Google Scholar] [CrossRef]

- Kazachenko, V.; Dvorak, A.; Razanau, I.; Li, H. Structure, chemical composition, mechanical properties of fluorine-containing coatings based on diamond-like carbon. J. Phys. Conf. Ser. 2018, 1121, 012016. [Google Scholar] [CrossRef]

- Tao, H.; Zhylinski, V.; Vereschaka, A.; Chayeuski, V.; Yuanming, H.; Milovich, F.; Sotova, C.; Seleznev, A.; Salychits, O. Comparison of the Mechanical Properties and Corrosion Resistance of the Cr-CrN, Ti-TiN, Zr-ZrN, and Mo-MoN Coatings. Coatings 2023, 13, 750. [Google Scholar] [CrossRef]

- Poorqasemi, E.; Abootalebi, O.; Peikari, M.; Haqdar, F. Investigating accuracy of the Tafel extrapolation method in HCl solutions. Corros. Sci. 2009, 51, 1043–1054. [Google Scholar] [CrossRef]

- Sampath Kumar, T.; Balasivanandha Prabu, S.; Manivasagam, G. Metallurgical Characteristics of TiAlN/AlCrN Coating Synthesized by the PVD Process on a Cutting Insert. J. Mater. Eng. Perform. 2014, 23, 2877–2884. [Google Scholar] [CrossRef]

- Vereschaka, A.; Sitnikov, N.; Volosova, M.; Seleznev, A.; Sotova, C.; Bublikov, J. Investigation of Properties of the Zr,Hf-(Zr,Hf)N-(Zr,Hf,Me,Al)N Coatings, Where Me Means Cr, Ti, or Mo. Coatings 2021, 11, 1471. [Google Scholar] [CrossRef]

- Dhandapani, V.S.; Thangavel, E.; Arumugam, M.; Shin, K.S.; Veeraraghavan, V.; Yau, S.Y.; Kim, C.; Kim, D.-E. Effect of Ag content on the microstructure, tribological and corrosion properties of amorphous carbon coatings on 316L SS. Surf. Coatings Technol. 2014, 240, 128–136. [Google Scholar] [CrossRef]

- Dolmatov, V.Y.; Lapchuk, N.M.; Lapchuk, T.M.; Nguyen, B.T.T.; Myllymäki, V.; Vehanen, A.; Yakovlev, R.Y. A study of defects and impurities in doped detonation nanodiamonds by EPR, Raman scattering, and XRD methods. J. Superhard Mater. 2016, 38, 219–229. [Google Scholar] [CrossRef]

- Shen, X.; Wang, X.; Sun, F.; Ding, C. Sandblasting pretreatment for deposition of diamond films on WC-Co hard metal substrates. Diam. Relat. Mater. 2017, 73, 7–14. [Google Scholar] [CrossRef]

- Linnik, S.; Gaydaychuk, A. Processes and parameters of diamond films deposition in AC glow discharge. Diam. Relat. Mater. 2013, 32, 43–47. [Google Scholar] [CrossRef]

- Shishonok, E.M.; Luhin, V.G. XRD Evaluation of Relative Mechanical Strength and Irradiation Resistance of Synthetic Diamond. J. Mater. Sci. Chem. Eng. 2015, 3, 36–41. [Google Scholar] [CrossRef] [Green Version]

- Mykhaylyk, O.O.; Solonin, Y.M.; Batchelder, D.N.; Brydson, R. Transformation of nanodiamond into carbon onions: A comparative study by high-resolution transmission electron microscopy, electron energy-loss spectroscopy, x-ray diffraction, small-angle x-ray scattering, and ultraviolet Raman spectroscopy. J. Appl. Phys. 2005, 97, 074302. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. R Rep. 2002, 37, 129–281. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Peng, Z.; Fu, Z.; Wu, S.; Yue, W.; Wang, C. Microstructural, mechanical and tribological properties of tungsten-gradually doped diamond-like carbon films with functionally graded interlayers. Surf. Coat. Technol. 2011, 205, 3631–3638. [Google Scholar] [CrossRef]

- Jun, Z.; Hui, Z.; Zhi-Hua, W.; Rui-Peng, S. Structure and mechanical properties of tungsten-containing hydrogenated diamond like carbon coatings for space applications. Phys. Procedia 2011, 18, 245–250. [Google Scholar] [CrossRef] [Green Version]

- Gershman, I.; Mironov, A.; Mezrin, A.; Torskaya, E.; Kuznetsova, T.; Lapitskaya, V.; Rogachev, A. Effect of sp3–sp2 Transformation on the Wear Rate of the DLC Coating. Lubricants 2022, 10, 85. [Google Scholar] [CrossRef]

- Jiang, Y.; Yang, J.; Liu, R.; Wang, X.; Fang, Q. Oxidation and corrosion resistance of WC coated tungsten fabricated by SPS carburization. J. Nucl. Mater. 2013, 450, 75–80. [Google Scholar] [CrossRef]

- Nave, M.I.; Kornev, K.G. Complexity of Products of Tungsten Corrosion: Comparison of the 3D Pourbaix Diagrams with the Experimental Data. Met. Mater. Trans. A 2016, 48, 1414–1424. [Google Scholar] [CrossRef]

- Li, R.; Wang, S.; Zhou, D.; Pu, J.; Yu, M.; Guo, W. A new insight into the NaCl-induced hot corrosion mechanism of TiN coatings at 500 °C. Corros. Sci. 2020, 174, 108794. [Google Scholar] [CrossRef]

- Vega, J.; Scheerer, H.; Andersohn, G.; Oechsner, M. Experimental studies of the effect of Ti interlayers on the corrosion resistance of TiN PVD coatings by using electrochemical methods. Corros. Sci. 2018, 133, 240–250. [Google Scholar] [CrossRef]

- Zhou, D.; Peng, H.; Zhu, L.; Guo, H.; Gong, S. Microstructure, hardness and corrosion behaviour of Ti/TiN multilayer coatings produced by plasma activated EB-PVD. Surf. Coat. Technol. 2014, 258, 102–107. [Google Scholar] [CrossRef]

- Shukla, K.; Rane, R.; Alphonsa, J.; Maity, P.; Mukherjee, S. Structural, mechanical and corrosion resistance properties of Ti/TiN bilayers deposited by magnetron sputtering on AISI 316L. Surf. Coat. Technol. 2017, 324, 167–174. [Google Scholar] [CrossRef]

- Zhang, M.; Niu, Y.; Xin, L.; Su, J.; Li, Y.; Wu, T.; Zhao, H.; Zhang, Y.; Xie, W.; Zhu, S.; et al. Studies on corrosion resistance of thick Ti/TiN multilayer coatings under solid NaCl–H2O–O2 at 450 °C. Ceram. Int. 2020, 46, 19274–19284. [Google Scholar] [CrossRef]

- Freire, F.; Mariotto, G.; Brusa, R.; Zecca, A.; Achete, C. Structural characterization of amorphous hydrogenated carbon and carbon nitride films deposited by plasma-enhanced CVD. Diam. Relat. Mater. 1995, 4, 499–502. [Google Scholar] [CrossRef]

- Sui, J.; Zhang, Z.; Cai, W. Surface characteristics and electrochemical corrosion behavior of fluorinated diamond-like carbon (F-DLC) films on the NiTi alloys. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2009, 267, 2475–2479. [Google Scholar] [CrossRef]

- Moolsradoo, N.; Watanabe, S. Influence of Elements on the Corrosion Resistance of DLC Films. Adv. Mater. Sci. Eng. 2017, 2017, 3571454. [Google Scholar] [CrossRef] [Green Version]

- Li, B.; Xu, Y.; Rao, G.; Wang, Q.; Zheng, J.; Zhu, R.; Chen, Y. Tribological Properties and Cutting Performance of AlTiN Coatings with Various Geometric Structures. Coatings 2023, 13, 402. [Google Scholar] [CrossRef]

- Tkadletz, M.; Schalk, N.; Daniel, R.; Keckes, J.; Czettl, C.; Mitterer, C. Advanced characterization methods for wear resistant hard coatings: A review on recent progress. Surf. Coat. Technol. 2016, 285, 31–46. [Google Scholar] [CrossRef]

- Khamseh, S.; Alibakhshi, E.; Ramezanzadeh, B.; Sari, M.G. A tailored pulsed substrate bias voltage deposited (a-C: Nb) thin-film coating on GTD-450 stainless steel: Enhancing mechanical and corrosion protection characteristics. Chem. Eng. J. 2020, 404, 126490. [Google Scholar] [CrossRef]

- Kucharska, B.; Czarniak, P.; Kulikowski, K.; Krawczyńska, A.; Rożniatowski, K.; Kubacki, J.; Szymanowski, K.; Panjan, P.; Sobiecki, J.R. Comparison Study of PVD Coatings: TiN/AlTiN, TiN and TiAlSiN Used in Wood Machining. Materials 2022, 15, 7159. [Google Scholar] [CrossRef]

| Number of Samples | Coating | Corrosion Potential E (V) | Corrosion Current Density icorr (μA/cm2) | Corrosion Penetration D, μm/year | Polarization Resistance R0 (kOhm) |

|---|---|---|---|---|---|

| 1 | uncoated | −0.006 | 3.612 | 21.10 | 7.20 |

| 2 | TiN | −0.058 | 13.375 | 91.52 | 1.95 |

| 3 | TiN/DLC | +0.042 | 0.046 | 0.31 | 564.46 |

| Number of Samples | Coating | Microhardness at a Load of 200 g (GPa) | Microhardness at a Load of 300 g (GPa) |

|---|---|---|---|

| 1 | uncoated | 25.4 | 23.5 |

| 2 | TiN | 35.6 | 27.1 |

| 3 | DLC/TiN | 40.4 | 38.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chayeuski, V.; Zhylinski, V.; Kazachenko, V.; Tarasevich, A.; Taleb, A. Structural and Mechanical Properties of DLC/TiN Coatings on Carbide for Wood-Cutting Applications. Coatings 2023, 13, 1192. https://doi.org/10.3390/coatings13071192

Chayeuski V, Zhylinski V, Kazachenko V, Tarasevich A, Taleb A. Structural and Mechanical Properties of DLC/TiN Coatings on Carbide for Wood-Cutting Applications. Coatings. 2023; 13(7):1192. https://doi.org/10.3390/coatings13071192

Chicago/Turabian StyleChayeuski, Vadzim, Valery Zhylinski, Victor Kazachenko, Aleksandr Tarasevich, and Abdelhafed Taleb. 2023. "Structural and Mechanical Properties of DLC/TiN Coatings on Carbide for Wood-Cutting Applications" Coatings 13, no. 7: 1192. https://doi.org/10.3390/coatings13071192

APA StyleChayeuski, V., Zhylinski, V., Kazachenko, V., Tarasevich, A., & Taleb, A. (2023). Structural and Mechanical Properties of DLC/TiN Coatings on Carbide for Wood-Cutting Applications. Coatings, 13(7), 1192. https://doi.org/10.3390/coatings13071192