Critical Review of Nanoindentation-Based Numerical Methods for Evaluating Elastoplastic Material Properties

Abstract

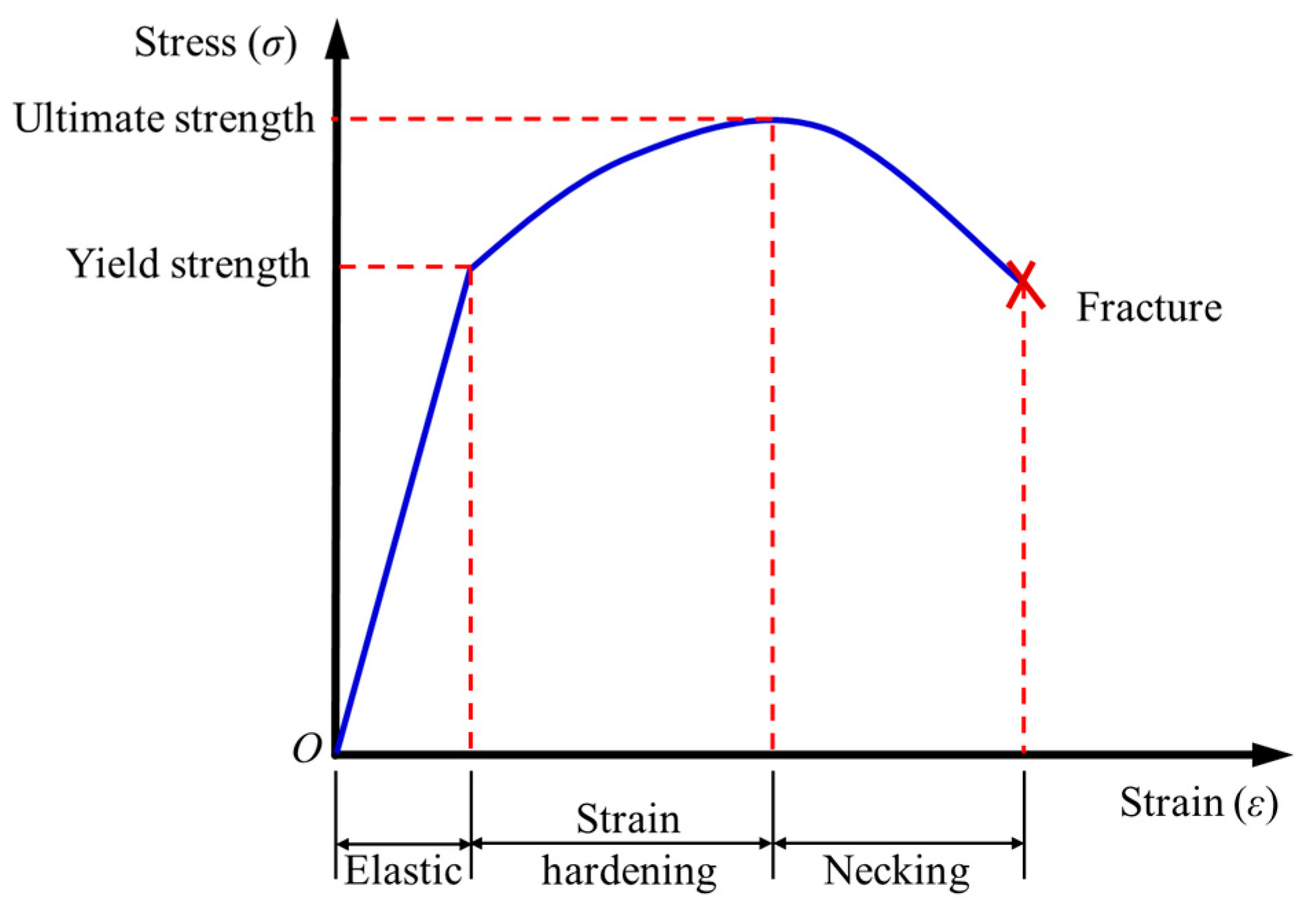

1. Introduction

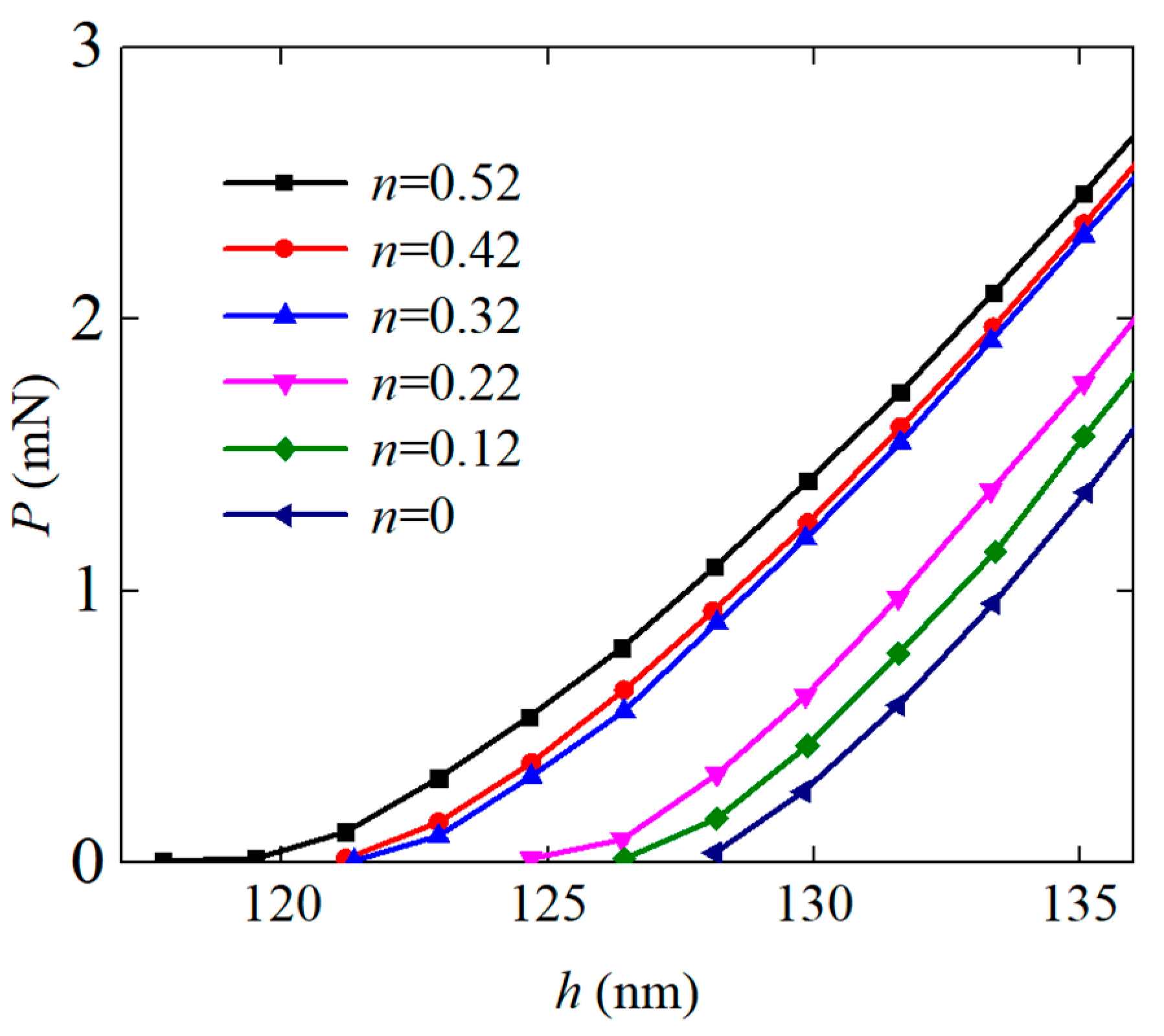

2. Load-Displacement Curve

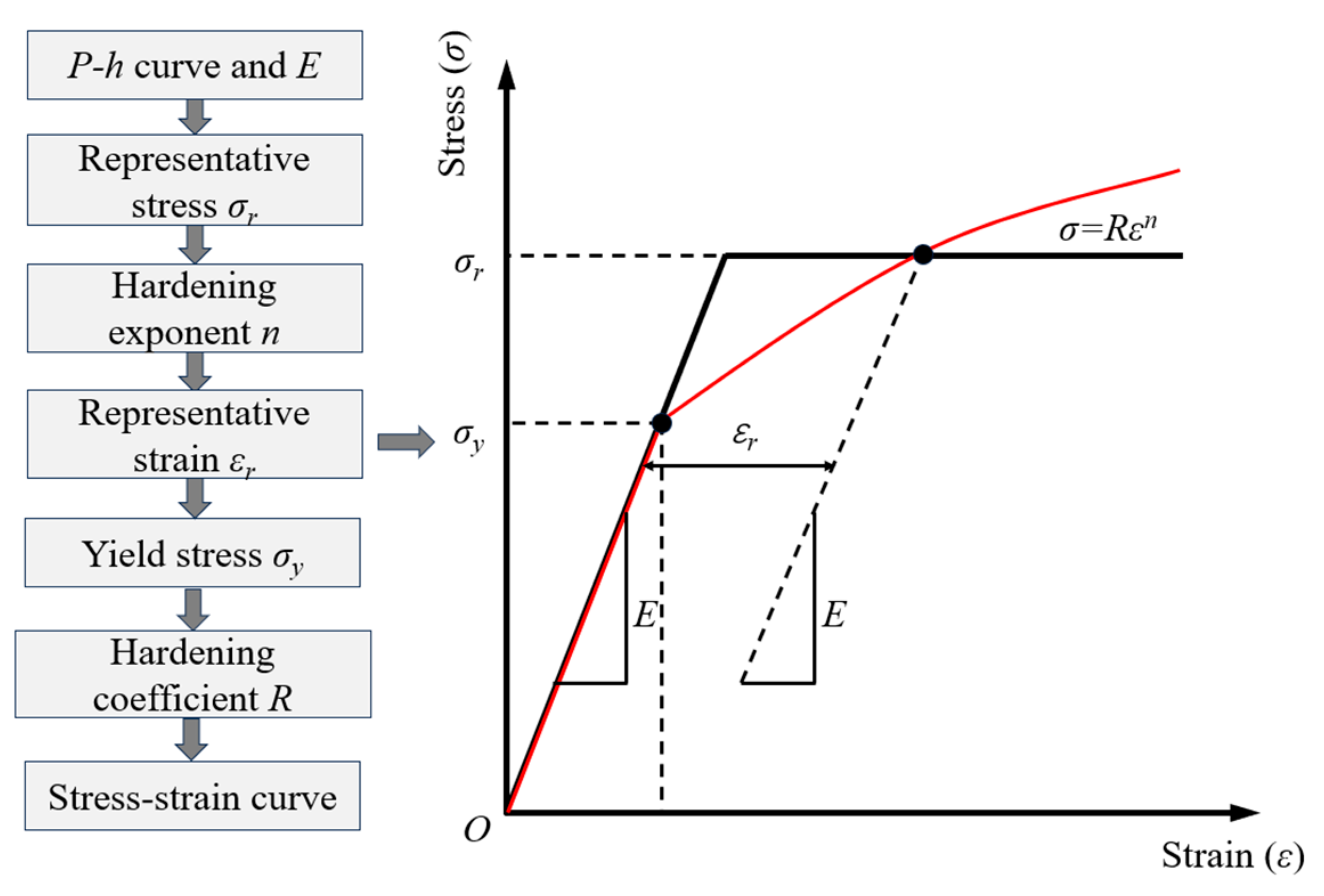

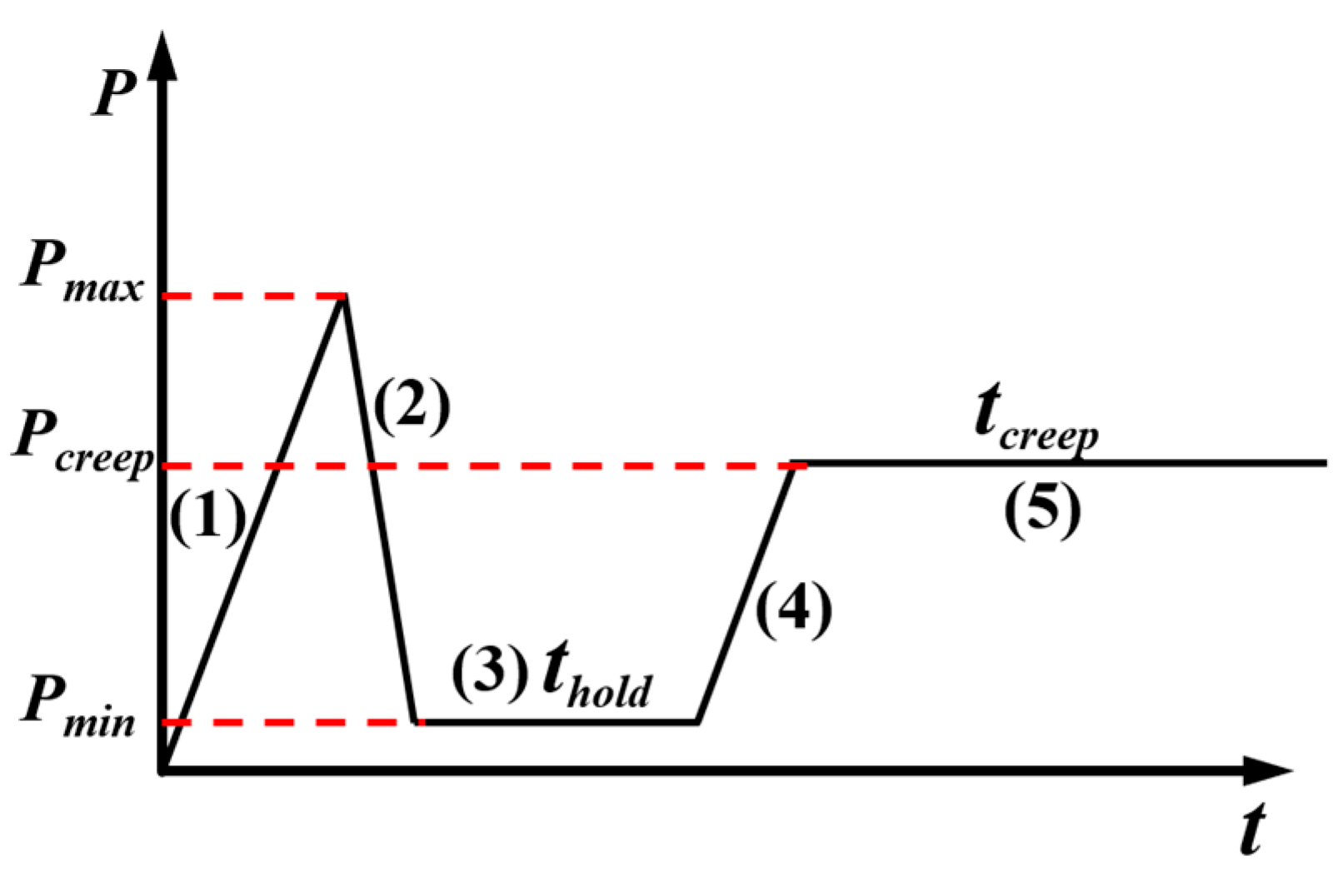

2.1. Dimensionless Method

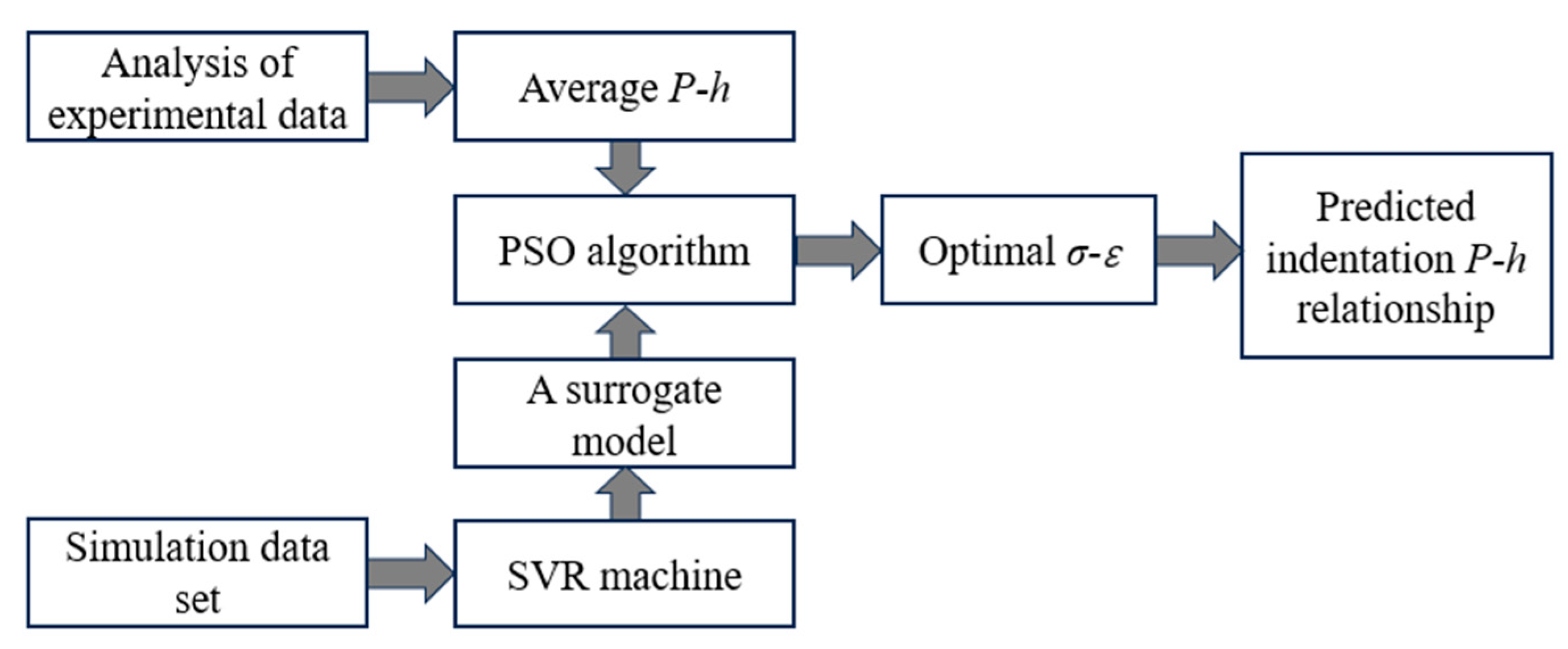

2.2. Machine Learning

2.3. FEMU Method

3. Contact Stiffness

4. Density Functional Theory

5. Molecular Dynamics

6. Other Methods

7. Current and Emerging Applications

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, E.H. Some comments on elastic-plastic analysis. Int. J. Solids Struct. 1981, 17, 859–872. [Google Scholar]

- Long, X.; Wang, S.; He, X.; Yao, Y. Annealing optimization for tin–lead eutectic solder by constitutive experiment and simulation. J. Mater. Res. 2017, 32, 3089–3099. [Google Scholar]

- Peng, L.; Liu, F.; Ni, J.; Lai, X. Size effects in thin sheet metal forming and its elastic–plastic constitutive model. Mater. Des. 2007, 28, 1731–1736. [Google Scholar]

- Wong, S.L.; Dawson, P.R. Influence of directional strength-to-stiffness on the elastic–plastic transition of fcc polycrystals under uniaxial tensile loading. Acta Mater. 2010, 58, 1658–1678. [Google Scholar]

- Shergold, O.A.; Fleck, N.A.; Radford, D. The uniaxial stress versus strain response of pig skin and silicone rubber at low and high strain rates. Int. J. Impact Eng. 2006, 32, 1384–1402. [Google Scholar]

- Ghaednia, H.; Wang, X.; Saha, S.; Xu, Y.; Sharma, A.; Jackson, R.L. A Review of Elastic–Plastic Contact Mechanics. Appl. Mech. Rev. 2017, 69, 060804. [Google Scholar]

- Bucaille, J.-L.; Stauss, S.; Schwaller, P.; Michler, J. A new technique to determine the elastoplastic properties of thin metallic films using sharp indenters. Thin Solid Film. 2004, 447, 239–245. [Google Scholar]

- Golovin, Y.I. Nanoindentation and mechanical properties of solids in submicrovolumes, thin near-surface layers, and films: A Review. Phys. Solid State 2008, 50, 2205–2236. [Google Scholar]

- Long, X.; Du, C.; Li, Z.; Guo, H.; Yao, Y.; Lu, X.; Hu, X.; Ye, L.; Liu, J. Finite Element Analysis to the Constitutive Behavior of Sintered Silver Nanoparticles under Nanoindentation. Int. J. Appl. Mech. 2019, 10, 1850110. [Google Scholar]

- Long, X.; Wang, S.; Feng, Y.; Yao, Y.; Keer, L.M. Annealing effect on residual stress of Sn-3.0Ag-0.5Cu solder measured by nanoindentation and constitutive experiments. Mater. Sci. Eng. A 2017, 696, 90–95. [Google Scholar]

- Long, X.; Zhang, X.; Tang, W.; Wang, S.; Feng, Y.; Chang, C. Calibration of a Constitutive Model from Tension and Nanoindentation for Lead-Free Solder. Micromachines 2018, 9, 608. [Google Scholar] [PubMed]

- Long, X.; Jia, Q.; Shen, Z.; Liu, M.; Guan, C. Strain rate shift for constitutive behaviour of sintered silver nanoparticles under nanoindentation. Mech. Mater. 2021, 158, 103881. [Google Scholar]

- Long, X.; Hu, B.; Feng, Y.; Chang, C.; Li, M. Correlation of microstructure and constitutive behaviour of sintered silver particles via nanoindentation. Int. J. Mech. Sci. 2019, 161, 105020. [Google Scholar]

- Doerner, M.F.; Nix, W.D. A method for interpreting the data from depth-sensing indentation instruments. J. Mater. Res. 1986, 1, 601–609. [Google Scholar]

- Venkataraman, S.; Kohlstedt, D.L.; Gerberich, W.W. Microscratch analysis of the work of adhesion for Pt thin films on NiO. J. Mater. Res. 1992, 7, 1126–1132. [Google Scholar]

- Bolshakov, A.; Oliver, W.C.; Pharr, G.M. Influences of stress on the measurement of mechanical properties using nanoindentation: Part II. Finite element simulations. J. Mater. Res. 1996, 11, 760–768. [Google Scholar]

- Liu, K.; Ostadhassan, M.; Bubach, B. Applications of nano-indentation methods to estimate nanoscale mechanical properties of shale reservoir rocks. J. Nat. Gas Sci. Eng. 2016, 35, 1310–1319. [Google Scholar]

- Kontomaris, S.-V. The Hertz Model in AFM Nanoindentation Experiments: Applications in Biological Samples and Biomaterials. Micro Nanosyst. 2018, 10, 11–22. [Google Scholar]

- Van Helvert, S.; Friedl, P. Strain Stiffening of Fibrillar Collagen during Individual and Collective Cell Migration Identified by AFM Nanoindentation. ACS Appl. Mater. Interfaces 2016, 8, 21946–21955. [Google Scholar] [PubMed]

- Kozlovskiy, A.L.; Zdorovets, M.V. Synthesis, structural, strength and corrosion properties of thin films of the type CuX (X = Bi, Mg, Ni). J. Mater. Sci. Mater. Electron. 2019, 30, 11819–11832. [Google Scholar]

- Kotelnikova, A.; Zubar, T.; Vershinina, T.; Panasyuk, M.; Kanafyev, O.; Fedkin, V.; Kubasov, I.; Turutin, A.; Trukhanov, S.; Tishkevich, D.; et al. The influence of saccharin adsorption on NiFe alloy film growth mechanisms during electrodeposition. RSC Adv. 2022, 12, 35722–35729. [Google Scholar] [PubMed]

- Lee, J.; Lee, C.; Kim, B. Reverse analysis of nano-indentation using different representative strains and residual indentation profiles. Mater. Des. 2009, 30, 3395–3404. [Google Scholar]

- Clifford, C.A.; Seah, M.P. Quantification issues in the identification of nanoscale regions of homopolymers using modulus measurement via AFM nanoindentation. Appl. Surf. Sci. 2005, 252, 1915–1933. [Google Scholar]

- Arrayago, I.; Real, E.; Gardner, L. Description of stress–strain curves for stainless steel alloys. Mater. Des. 2015, 87, 540–552. [Google Scholar]

- Pharr, G.M.; Cook, R.R. Instrumentation of a conventional hardness tester for load-displacement measurement during indentation. Mater. Res. Soc. 1989, 5, 847–851. [Google Scholar]

- Mohan, S.; Millan-Espitia, N.; Yao, M.; Steenberge, N.V.; Kalidindi, S.R. Critical Evaluation of Spherical Indentation Stress-Strain Protocols for the Estimation of the Yield Strengths of Steels. Exp. Mech. 2021, 61, 641–652. [Google Scholar]

- Rakheja, S.; Chen, Z.; Chen, C.-T. Guest Editorial: Dimensional Scaling of Material Functional Properties to Meet Back-End-of-Line (BEOL) Challenges. Appl. Phys. Lett. 2023, 123, 030401. [Google Scholar]

- Li, H.; Chen, J.; Chen, Q.; Liu, M. Determining the constitutive behavior of nonlinear visco-elastic-plastic PMMA thin films using nanoindentation and finite element simulation. Mater. Des. 2021, 197, 109239. [Google Scholar]

- Long, X.; Shen, Z.; Jia, Q.; Li, J.; Dong, R.; Su, Y.; Yang, X.; Zhou, K. Determine the unique constitutive properties of elastoplastic materials from their plastic zone evolution under nanoindentation. Mech. Mater. 2022, 175, 104485. [Google Scholar]

- Xu, Z.; Peng, L.; Bao, E. Size effect affected springback in micro/meso scale bending process: Experiments and numerical modeling. J. Mater. Process. Technol. 2018, 252, 407–420. [Google Scholar]

- Yuan, Z.; Li, F.; Zhang, P.; Chen, B.; Xue, F. Mechanical properties study of particles reinforced aluminum matrix composites by micro-indentation experiments. Chin. J. Aeronaut. 2014, 27, 397–406. [Google Scholar]

- Zhang, Z.-N.; Li, Y.-L.; Wu, W.-P. Effects of loading rate and peak load on nanoindentation creep behavior of DD407Ni-base single crystal superalloy. Trans. Nonferrous Met. Soc. China 2022, 32, 206–216. [Google Scholar]

- Wang, J.S.; Zheng, X.J.; Zheng, H.; Song, S.T.; Zhu, Z. Identification of elastic parameters of transversely isotropic thin films by combining nanoindentation and FEM analysis. Comput. Mater. Sci. 2010, 49, 378–385. [Google Scholar]

- Shi, X.; Zhao, Y.-P. Comparison of various adhesion contact theories and the influence of dimensionless load parameter. J. Adhes. Sci. Technol. 2004, 18, 55–68. [Google Scholar]

- Dao, M.; Chollacoop, N.V.; Van Vliet, K.J.; Venkatesh, T.A.; Suresh, S. Computational modeling of the forward andreverse problems in instrumented sharpindentation. Acta Mater. 2001, 20, 3899–3918. [Google Scholar] [CrossRef]

- Jiang, L.-M.; Zhou, Y.-C.; Huang, Y.-L. Elastic-plastic properties of thin film on elastic-plastic substrates characterized by nanoindentation test. Trans. Nonferrous Met. Soc. China 2010, 20, 2345–2349. [Google Scholar]

- Hong, R.Y.; Cheng, H.C.; Hu, H.C.; Chen, W.H. Characterization of Elastic-Plastic Properties of Intermetallic Compounds. In Proceedings of the 2016 International Conference on Electronics Packaging (ICEP), Hokkaido, Japan, 20–22 April 2016; Volume 4, pp. 282–285. [Google Scholar]

- Long, X.; Shen, Z.; Lu, C.; Jia, Q.; Guan, C.; Chen, C.; Wang, H.; Li, Y. Reverse Analysis of Surface Strain in Elasto-Plastic Materials by Nanoindentation. Int. J. Appl. Mech. 2021, 13, 2150106. [Google Scholar]

- Bazzaz, E.; Darvizeh, A.; Alitavoli, M.; Yarmohammad Tooski, M. Comparing AM200® with Titanium-Based Coatings Elastic–Plastic Properties by Nanoindentation, Modified Dimensional Analysis and Minimum Resultant Error Method. Iran. J. Sci. Technol. Trans. Mech. Eng. 2020, 45, 197–213. [Google Scholar]

- Wang, K.; Ma, Q.; Xu, J.; Liao, T.; Wang, P.; Chen, R.; Kan, Q.; Cui, G.; Li, L. Determining the elastic–plastic properties of materials with residual stress included using nanoindentation experiments and dimensionless functions. Eng. Fract. Mech. 2023, 282, 109175. [Google Scholar] [CrossRef]

- Long, X.; Jia, Q.P.; Li, Z.; Wen, S.X. Reverse analysis of constitutive properties of sintered silver particles from nanoindentations. Int. J. Solids Struct. 2020, 191, 351–362. [Google Scholar] [CrossRef]

- Long, X.; Li, J.; Shen, Z.; Su, Y. Dimensionless Analysis to Determine Elastoplastic Properties of Thin Films by Indentation. Coatings 2022, 12, 1768. [Google Scholar] [CrossRef]

- Sanchez-Camargo, C.-M.; Hor, A.; Mabru, C. A robust inverse analysis method for elastoplastic behavior identification using the true geometry modeling of Berkovich indenter. Int. J. Mech. Sci. 2020, 171, 105370. [Google Scholar] [CrossRef]

- Xing, X.; Wang, Y.; Xiao, G.; Shu, X.; Yu, S.; Wu, Y. Identifying the elastoplastic properties of ductile film on hard substrate by nanoindentation. Vacuum 2021, 189, 110252. [Google Scholar] [CrossRef]

- Weng, J.; Lindvall, R.; Zhuang, K.; Ståhl, J.-E.; Ding, H.; Zhou, J. A machine learning based approach for determining the stress-strain relation of grey cast iron from nanoindentation. Mech. Mater. 2020, 148, 103522. [Google Scholar] [CrossRef]

- Laxmikant Vajire, S.; Prashant Singh, A.; Kumar Saini, D.; Kumar Mukhopadhyay, A.; Singh, K.; Mishra, D. Novel machine learning-based prediction approach for nanoindentation load-deformation in a thin film: Applications to electronic industries. Comput. Ind. Eng. 2022, 174, 108824. [Google Scholar] [CrossRef]

- Alipour, M.; Esatyana, E.; Sakhaee-Pour, A.; Sadooni, F.N.; Al-Kuwari, H.A. Characterizing fracture toughness using machine learning. J. Pet. Sci. Eng. 2021, 200, 108202. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, G.; Liu, T.; Wang, W. Determination of Elastoplastic Properties of 2024 Aluminum Alloy Using Deep Learning and Instrumented Nanoindentation Experiment. Acta Mech. Solida Sin. 2023, 36, 327–339. [Google Scholar] [CrossRef]

- Long, X.; Ding, X.; Li, J.; Dong, R.; Su, Y.; Chang, C. Indentation Reverse Algorithm of Mechanical Response for Elastoplastic Coatings Based on LSTM Deep Learning. Materials 2023, 16, 2617. [Google Scholar] [CrossRef]

- Long, X.; Lu, C.; Shen, Z.; Su, Y. Identification of Mechanical Properties of Thin-Film Elastoplastic Materials by Machine Learning. Acta Mech. Solida Sin. 2022, 36, 13–21. [Google Scholar] [CrossRef]

- Fauvel, V.; Gaillard, Y.; Guillemet, R.; Garabédian, P.; Richard, F. Simultaneous extraction of the elastic-plastic properties of a thin film and its substrate from an identifiability-based design of depth-sensing nanoindentation testing. J. Mech. Phys. Solids 2022, 163, 104860. [Google Scholar] [CrossRef]

- Barick, M.C.; Gaillard, Y.; Lejeune, A.; Amiot, F.; Richard, F. On the uniqueness of intrinsic viscoelastic properties of materials extracted from nanoindentation using FEMU. Int. J. Solids Struct. 2020, 202, 929–946. [Google Scholar] [CrossRef]

- Renner, E.; Bourceret, A.; Gaillard, Y.; Amiot, F.; Delobelle, P.; Richard, F. Identifiability of single crystal plasticity parameters from residual topographies in Berkovich nanoindentation on FCC nickel. J. Mech. Phys. Solids 2020, 138, 103916. [Google Scholar] [CrossRef]

- Fauvel, V.; Gaillard, Y.; Guillemet, R.; Garabédian, P.; Richard, F. Numerical and experimental crossed analysis of coated nanostructures through nanoindentation. Int. J. Mech. Sci. 2023, 245, 108091. [Google Scholar] [CrossRef]

- Shi, X.; Jiang, S.; Wang, Z.; Bai, B.; Xiao, D.; Tang, M. Application of nanoindentation technology for characterizing the mechanical properties of shale before and after supercritical CO2 fluid treatment. J. CO2 Util. 2020, 37, 158–172. [Google Scholar] [CrossRef]

- Li, X.; Bhushan, B. A review of nanoindentation continuous stiffness measurement technique and its applications. Mater. Charact. 2002, 26, 11–36. [Google Scholar] [CrossRef]

- Voyiadjis, G.Z.; Malekmotiei, L. Variation of the strain rate during CSM nanoindentation of glassy polymers and its implication on indentation size effect. J. Polym. Sci. Part B Polym. Phys. 2016, 54, 2179–2187. [Google Scholar] [CrossRef]

- Ogasawara, N.; Chiba, N.; Chen, X. Measuring the plastic properties of bulk materials by single indentation test. Scr. Mater. 2006, 54, 65–70. [Google Scholar] [CrossRef]

- Zhao, M.; Chen, X.; Yan, J.; Karlsson, A. Determination of uniaxial residual stress and mechanical properties by instrumented indentation. Acta Mater. 2006, 54, 2823–2832. [Google Scholar] [CrossRef]

- Rodríguez, M.; Molina-Aldareguía, J.M.; González, C.; Llorca, J. Determination of the mechanical properties of amorphous materials through instrumented nanoindentation. Acta Mater. 2012, 60, 3953–3964. [Google Scholar] [CrossRef]

- Long, X.; Feng, Y.; Yao, Y. Cooling and Annealing Effect on Indentation Response of Lead-Free Solder. Int. J. Appl. Mech. 2017, 9, 1750057. [Google Scholar] [CrossRef]

- Long, X.; Tang, W.; Feng, Y.; Chang, C.; Keer, L.M.; Yao, Y. Strain rate sensitivity of sintered silver nanoparticles using rate-jump indentation. Int. J. Mech. Sci. 2018, 140, 60–67. [Google Scholar] [CrossRef]

- Phani, P.S.; Oliver, W.C.; Pharr, G.M. Understanding and modeling plasticity error during nanoindentation with continuous stiffness measurement. Mater. Des. 2020, 194, 108923. [Google Scholar] [CrossRef]

- Long, X.; Li, Z.; Lu, X.; Guo, H.; Chang, C.; Zhang, Q.; Zehri, A.; Ke, W.; Yao, Y.; Ye, L.; et al. Mechanical behaviour of sintered silver nanoparticles reinforced by SiC microparticles. Mater. Sci. Eng. A 2019, 744, 406–414. [Google Scholar] [CrossRef]

- Shenoy, V.B.; Johari, P.; Qi, Y. Elastic softening of amorphous and crystalline Li–Si Phases with increasing Li concentration: A first-principles study. J. Power Sources 2010, 195, 6825–6830. [Google Scholar] [CrossRef]

- Lamuta, C.; Campi, D.; Cupolillo, A.; Aliev, Z.S.; Babanly, M.B.; Chulkov, E.V.; Politano, A.; Pagnotta, L. Mechanical properties of Bi2Te3 topological insulator investigated by density functional theory and nanoindentation. Scr. Mater. 2016, 121, 50–55. [Google Scholar] [CrossRef]

- Zhou, X.; Lu, Z.; Zhang, Q.; Chen, D.; Li, H.; Nie, F.; Zhang, C. Mechanical Anisotropy of the Energetic Crystal of 1,1-Diamino-2,2-dinitroethylene (FOX-7): A Study by Nanoindentation Experiments and Density Functional Theory Calculations. J. Phys. Chem. C 2016, 120, 13434–13442. [Google Scholar] [CrossRef]

- Hayes, R.L.; Ho, G.; Ortiz, M.; Carter, E.A. Prediction of dislocation nucleation during nanoindentation of Al3Mg by the orbital-free density functional theory local quasicontinuum method. Philos. Mag. 2006, 86, 2343–2358. [Google Scholar] [CrossRef]

- Hayes, R.L.; Fago, M.; Ortiz, M.; Carter, E.A. Prediction of Dislocation Nucleation During Nanoindentation by the Orbital-Free Density Functional Theory Local Quasi-continuum Method. Multiscale Model. Simul. 2005, 4, 359–389. [Google Scholar] [CrossRef]

- Fang, T.-H.; Weng, C.-I.; Chang, J.-G. Molecular dynamics analysis of temperature effects on nanoindentation measurement. Mater. Sci. Eng. A 2003, 357, 7–12. [Google Scholar] [CrossRef]

- Li, Y.; Goyal, A.; Chernatynskiy, A.; Jayashankar, J.S.; Kautzky, M.C.; Sinnott, S.B.; Phillpot, S.R. Nanoindentation of gold and gold alloys by molecular dynamics simulation. Mater. Sci. Eng. A 2016, 651, 346–357. [Google Scholar]

- Verkhovtsev, A.V.; Yakubovich, A.V.; Sushko, G.B.; Hanauske, M.; Solov’yov, A.V. Molecular dynamics simulations of the nanoindentation process of titanium crystal. Comput. Mater. Sci. 2013, 76, 20–26. [Google Scholar] [CrossRef]

- Fang, T.-H.; Wu, J.-H. Molecular dynamics simulations on nanoindentation mechanisms of multilayered films. Comput. Mater. Sci. 2008, 43, 785–790. [Google Scholar] [CrossRef]

- Qiu, C.; Zhu, P.; Fang, F.; Yuan, D.; Shen, X. Study of nanoindentation behavior of amorphous alloy using molecular dynamics. Appl. Surf. Sci. 2014, 305, 101–110. [Google Scholar] [CrossRef]

- Trukhanov, A.V.; Panina, L.V.; Trukhanov, S.V.; Kostishyn, V.G.; Turchenko, V.A.; Vinnik, D.A.; Zubar, T.I.; Yakovenko, E.S.; Macuy, L.Y.; Trukhanova, E.L. Critical influence of different diamagnetic ions on electromagnetic properties of BaFe12O19. Ceram. Int. 2018, 44, 13520–13529. [Google Scholar] [CrossRef]

- Shlimas, D.I.; Kozlovskiy, A.L.; Zdorovets, M.V. Study of the formation effect of the cubic phase of LiTiO2 on the structural, optical, and mechanical properties of Li2±xTi1±xO3 ceramics with different contents of the X component. J. Mater. Sci. Mater. Electron. 2021, 32, 7410–7422. [Google Scholar] [CrossRef]

- Puchi-Cabrera, E.S.; Rossi, E.; Sansonetti, G.; Sebastiani, M.; Bemporad, E. Machine learning aided nanoindentation: A review of the current state and future perspectives. Curr. Opin. Solid State Mater. Sci. 2023, 27, 101091. [Google Scholar] [CrossRef]

- Dhal, A.; Sankar Haridas, R.; Agrawal, P.; Gupta, S.; Mishra, R.S. Mapping hierarchical and heterogeneous micromechanics of a transformative high entropy alloy by nanoindentation and machine learning augmented clustering. Mater. Des. 2023, 230, 111957. [Google Scholar] [CrossRef]

- Jacq, C.; Lormand, G.; Ne´Lias, D.; Girodin, D.; Vincent, A. Materials Science and Engineering A—On the influence of residual stresses in determining the micro-yield stress profile in a nitrided steel by nano-indentation. Mater. Sci. Eng. 2003, 9, 311–319. [Google Scholar] [CrossRef]

- Ureña, A.; Rams, J.; Escalera, M.D.; Sánchez, M. Characterization of interfacial mechanical properties in carbon fiber/aluminium matrix composites by the nanoindentation technique. Compos. Sci. Technol. 2005, 65, 2025–2038. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Zhang, Y.W.; Zeng, K.Y.; Shen, L. Nanoindentation of Polymers with a Sharp Indenter. J. Mater. Res. 2005, 20, 1597–1605. [Google Scholar] [CrossRef]

- Sakai, M. Elastic recovery in the unloading process of pyramidal microindentation. J. Mater. Res. 2003, 18, 1631–1640. [Google Scholar] [CrossRef]

- Pharr, G.M.; Bolshakov, A. Understanding nanoindentation unloading curves. J. Mater. Res. 2002, 17, 2660–2671. [Google Scholar] [CrossRef]

- Saraswati, T.; Sritharan, T.; Mhaisalkar, S.; Breach, C.D.; Wulff, F. Cyclic loading as an extended nanoindentation technique. Mater. Sci. Eng. A 2006, 423, 14–18. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, Y.; Yu, H.-F.; Zhang, X.-Y.; Shu, X.-F.; Tang, B. Plastic characterization of metals by combining nanoindentation test and finite element simulation. Trans. Nonferrous Met. Soc. China 2013, 23, 2368–2373. [Google Scholar] [CrossRef]

- Weaver, J.S.; Priddy, M.W.; Mcdowell, D.L.; Kalidindi, S.R. On capturing the grain-scale elastic and plastic anisotropy of alpha-Ti with spherical nanoindentation and electron back-scattered diffraction. Acta Mater. 2016, 117, 23–34. [Google Scholar] [CrossRef]

- Roa, S.; Sirena, M. A finite element analysis of conical indentation in elastic-plastic materials: On strain energy based strategies for an area-independent determination of solids mechanical properties. Int. J. Mech. Sci. 2021, 207, 106651. [Google Scholar] [CrossRef]

- Zeng, Z.; Flyagina, I.S.; Tan, J.C. Nanomechanical behavior and interfacial deformation beyond the elastic limit in 2D metal-organic framework nanosheets. Nanoscale Adv. 2020, 2, 5181–5191. [Google Scholar] [CrossRef]

- Griepentrog, M.; Krämer, G.; Cappella, B. Comparison of nanoindentation and AFM methods for the determination of mechanical properties of polymers. Polym. Test. 2013, 32, 455–460. [Google Scholar] [CrossRef]

- Guo, W.C.; Xu, H.; Gao, X.Q.; Hou, X.L.; Li, Y. A Modified Method for Hardness Determination from Nanoindentation Experiments with Imperfect Indenters. Adv. Mater. Sci. Eng. 2016, 2016, 9213841. [Google Scholar] [CrossRef]

- Lee, H.; Huen, W.Y.; Vimonsatit, V.; Mendis, P. An Investigation of Nanomechanical Properties of Materials using Nanoindentation and Artificial Neural Network. Sci. Rep. 2019, 9, 13189. [Google Scholar] [CrossRef]

- Tran, H.S.; Bouffioux, C.; Dedry, O.; Rojas-Ulloa, C.; Duchêne, L.; Mertens, A.; Habraken, A.M. Identification of a soft matrix-hard inclusion material by indentation. Int. J. Mech. Sci. 2022, 235, 107723. [Google Scholar] [CrossRef]

- Chen, X.; Shaw, C.; Gelman, L.; Grattan, K.T.V. Advances in test and measurement of the interface adhesion and bond strengths in coating-substrate systems, emphasising blister and bulk techniques. Measurement 2019, 139, 387–402. [Google Scholar] [CrossRef]

- Koumoulos, E.P.; Tofail, S.a.M.; Silien, C.; De Felicis, D.; Moscatelli, R.; Dragatogiannis, D.A.; Bemporad, E.; Sebastiani, M.; Charitidis, C.A. Metrology and nano-mechanical tests for nano-manufacturing and nano-bio interface: Challenges & future perspectives. Mater. Des. 2018, 137, 446–462. [Google Scholar]

- Kurland, N.E.; Drira, Z.; Yadavalli, V.K. Measurement of nanomechanical properties of biomolecules using atomic force microscopy. Micron 2012, 43, 116–128. [Google Scholar] [CrossRef]

- Trukhanov, S.V.; Trukhanov, A.V.; Vasiliev, A.N.; Balagurov, A.M.; Szymczak, H. Magnetic state of the structural separated anion-deficient La0.70Sr0.30MnO2.85 manganite. J. Exp. Theor. Phys. 2011, 113, 819–825. [Google Scholar] [CrossRef]

- Kozlovskiy, A.; Egizbek, K.; Zdorovets, M.V.; Ibragimova, M.; Shumskaya, A.; Rogachev, A.A.; Ignatovich, Z.V.; Kadyrzhanov, K. Evaluation of the Efficiency of Detection and Capture of Manganese in Aqueous Solutions of FeCeOx Nanocomposites Doped with Nb2O5. Sensors 2020, 20, 4851. [Google Scholar] [CrossRef]

- Ramamurty, U.; Jang, J.-I. Nanoindentation for probing the mechanical behavior of molecular crystals—A review of the technique and how to use it. CrystEngComm 2014, 16, 12–23. [Google Scholar] [CrossRef]

- Varughese, S.; Kiran, M.S.R.N.; Solanko, K.A.; Bond, A.D.; Ramamurty, U.; Desiraju, G.R. Interaction anisotropy and shear instability of aspirin polymorphs established by nanoindentation. Chem. Sci. 2011, 2, 2236–2242. [Google Scholar] [CrossRef]

- Shi, X.; Jiang, S.; Lu, S.; He, Z.; Li, D.; Wang, Z.; Xiao, D. Investigation of mechanical properties of bedded shale by nanoindentation tests: A case study on Lower Silurian Longmaxi Formation of Youyang area in southeast Chongqing, China. Pet. Explor. Dev. 2019, 46, 163–172. [Google Scholar] [CrossRef]

- Liu, K.; Ostadhassan, M.; Bubach, B.; Dietrich, R.; Rasouli, V. Nano-dynamic mechanical analysis (nano-DMA) of creep behavior of shales: Bakken case study. J. Mater. Sci. 2017, 53, 4417–4432. [Google Scholar] [CrossRef]

- Maier, V.; Merle, B.; Göken, M.; Durst, K. An improved long-term nanoindentation creep testing approach for studying the local deformation processes in nanocrystalline metals at room and elevated temperatures. J. Mater. Res. 2013, 28, 1177–1188. [Google Scholar] [CrossRef]

- Managuli, V.; Bothra, Y.S.; Kumar, S.; Gaur, P.; Chandracharya, P.L. Overview of Mechanical Characterization of Bone using Nanoindentation Technique and Its Applications. Eng. Sci. 2023, 22, 820. [Google Scholar] [CrossRef]

- Kasyap, S.S.; Senetakis, K. Application of Nanoindentation in the Characterization of a Porous Material with a Clastic Texture. Materials 2021, 14, 4579. [Google Scholar] [CrossRef]

- Nyman, J.S.; Granke, M.; Singleton, R.C.; Pharr, G.M. Tissue-Level Mechanical Properties of Bone Contributing to Fracture Risk. Curr. Osteoporos. Rep. 2016, 14, 138–150. [Google Scholar] [CrossRef] [PubMed]

- Pelled, G.; Tai, K.; Sheyn, D.; Zilberman, Y.; Kumbar, S.; Nair, L.S.; Laurencin, C.T.; Gazit, D.; Ortiz, C. Structural and nanoindentation studies of stem cell-based tissue-engineered bone. J. Biomech. 2007, 40, 399–411. [Google Scholar] [CrossRef]

- Kawamura, M.; Masaki, C.; Shibata, Y.; Kondo, Y.; Mukaibo, T.; Miyazaki, T.; Hosokawa, R. Pentosidine correlates with nanomechanical properties of human jaw bone. J. Mech. Behav. Biomed. Mater. 2019, 98, 20–25. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Long, X.; Dong, R.; Su, Y.; Chang, C. Critical Review of Nanoindentation-Based Numerical Methods for Evaluating Elastoplastic Material Properties. Coatings 2023, 13, 1334. https://doi.org/10.3390/coatings13081334

Long X, Dong R, Su Y, Chang C. Critical Review of Nanoindentation-Based Numerical Methods for Evaluating Elastoplastic Material Properties. Coatings. 2023; 13(8):1334. https://doi.org/10.3390/coatings13081334

Chicago/Turabian StyleLong, Xu, Ruipeng Dong, Yutai Su, and Chao Chang. 2023. "Critical Review of Nanoindentation-Based Numerical Methods for Evaluating Elastoplastic Material Properties" Coatings 13, no. 8: 1334. https://doi.org/10.3390/coatings13081334

APA StyleLong, X., Dong, R., Su, Y., & Chang, C. (2023). Critical Review of Nanoindentation-Based Numerical Methods for Evaluating Elastoplastic Material Properties. Coatings, 13(8), 1334. https://doi.org/10.3390/coatings13081334