1. Introduction

Until the late 19th century, most traditional Western paintings had a transparent varnish coating as a surface finish. This outermost layer had a limited protective role, and its function was mainly aesthetic. In fact, the varnish improved the optical characteristics of the pictorial surface, making it more glossy and smooth, increasing the saturation of the colours [

1,

2,

3,

4,

5]. An ideal varnish should remain colourless, transparent, removable over time, and should have the correct mechanical properties of strength and flexibility to follow any movement of the underlying substrate without cracking. In addition, the varnish composition should be known and carefully evaluated towards its proper application as it should not alter the integrity of the paint film [

1,

4,

6]. Varnishes for paintings are generally organic-solvent-based, and the formulations are made by solubilising the resin in a low polarity solvent mixture with the highest dispersion factor (f

d), related to the percentage of dispersion forces as defined by the Teas solubility concept, to reduce any interactions with the binder or other pictorial materials [

7,

8,

9,

10,

11,

12,

13].

Varnish is the layer most exposed to degradation by external agents. Materials originally used as painting varnishes (typically natural resins) can alter at the molecular level mainly due to photo-oxidative degradation, resulting in loss of transparency, yellowing, and change of solubility. For this reason, varnishes are replaced over time during art restoration work, and over the years research has sought to find more stable products [

1,

4,

6]. In the 1920s, synthetic polymer resins, generally considered more stable than natural resins, were introduced to the market. However, varnishes obtained with synthetic polymers often give paints a different appearance from those produced with natural resins [

6,

9,

14]. Starting from the 1980s, studies conducted primarily by de la Rie to identify potential substitutes for natural resins [

8,

14,

15,

16] have shown that low molecular weight (LMW) synthetic resins can produce films with an appearance similar to those with natural resins and have better stability. Nowadays, LMW resins of the hydrogenated hydrocarbon type (e.g., Regalrez

® 1094) and the urea-aldehyde type (e.g., Laropal

® A81) are widely used in art restoration. These are, respectively, soluble in mixtures without or with a limited content of aromatic solvents [

1,

6,

8,

17]. Considering the adverse effects on paint films attributable to aromatic solvents (limiting swelling, solubilisation, and leaching) and the growing concern about the toxicity-related impacts on the environment and humans, the ability to use low polarity solvents potentially less damaging to conservators and paintings is a significant feature [

1,

8]. Solvent-based varnishes are not particularly resistant to physical degradation, but LMWs, such as Regalrez

® 1094 and Laropal

® A81, generally retain their characteristics even after ageing. Showing better behaviour than some natural and synthetic polymeric resins susceptible to cross linking processes and thus remaining soluble and easily removable, they are widely used as varnishes for paintings [

1,

6].

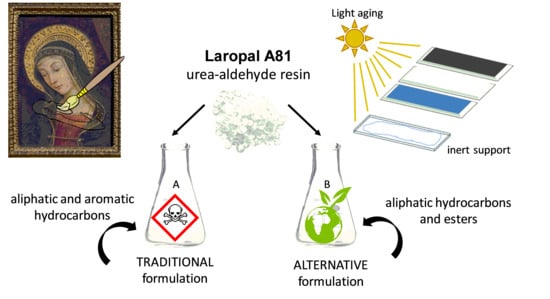

Laropal

® A81 was selected for the present study because it is considered one of the most stable resins currently used as a varnish for paintings [

16,

18]. Laropal

® A81 varnish is applied in liquid form by dissolving solid pellets in a suitable solvent mixture (with a certain degree of polarity), and the formation of the film occurs by evaporation of the solvent [

15,

19,

20,

21,

22,

23]. This resin typically forms transparent, colourless, and very stable varnish layers [

2,

6,

24,

25] when a solvent mixture with a high percentage of aromatic components is used. Laropal

® A81 typically requires 30–40% aromatic content in a hydrocarbon mixture for its solubilisation, whereas a solvent mixture completely devoid of aromatics would not give good results as varnish according to the recommendations [

1,

2,

6]. Manufacturers generally recommend these solvents to improve aesthetic aspects and protective efficacy. However, this indication leads to a critical issue regarding toxicity and sustainability. Indeed, it is well known that aromatic solvents are dangerous both for the environment, due to the processes associated with their disposal as hazardous air pollutants (HAPs), and for the health of the operators, as they are harmful and/or potentially carcinogenic. As such, the need for less impactful and hazardous solvents has paved the way for research on the application of alternative solvents or solvent mixtures [

17,

26]. The choice of the alternative solvent in the present research stems from previous studies by Eastman Chemical Company Corporate Headquarters [

27] on the formulation of protective varnish coatings in the industrial field and by Cremonesi [

17] on the use of surfactants and chelators for painting cleaning.

Eastman’s 2013 study focused on selecting effective substitutes for xylenes or other aromatic hydrocarbon mixtures used in traditional solvent-based varnish formulations. An aromatic hydrocarbon solvent, such as xylene, is widely used in varnish formulation, either as a primary solvent or as resin diluent. Due to its prominence in the paint industry, it is essential to find less-toxic alternatives to obtain solvent mixtures that have similar performance in terms of polarity (and thus solvent power) and evaporation rate to produce a film with the same characteristics [

17]. Eastman found three oxygenated solvents effective for substitution: a long-chain ketone, 2-heptanone or methyl n-amyl ketone (MAK); and two esters, n-butyl propionate (nBuOPr) and isobutyl iso-butyrate (IBIB). They are considered solvents with low-risk toxicity and are not hazardous air pollutants. Furthermore, they have an evaporation rate that can lead to the production of a film with characteristics comparable to those obtained from xylenes. It has also been shown that the oxygenated solvent can be mixed with an aliphatic hydrocarbon to reduce costs without affecting film appearance or performance [

27]. In this research, IBIB was chosen as an alternative solvent among the three proposed by Eastman based on its olfactory properties (the other two have an unpleasant odour) replacing the corresponding percentage of aromatic solvents consisting of a mixture of aromatic hydrocarbons containing xylenes and C9 (e.g., Shellsol

® A100, Shellsol

® A from Kremer Pigmente) commonly proposed in recipes from the literature [

1,

2,

6].

Cremonesi introduced the use of IBIB in art conservation as part of the research on surfactants and chelating agents for the treatment of paintings [

17]. He investigated the possible replacement of xylenes with alternative solvents of intermediate polarity, such as esters (including IBIB), to be added to a mixture of aliphatic hydrocarbon in the solvent phase of cleaning systems. Bearing in mind the issues of carcinogenicity and toxicity of various hydrocarbon solvents, his research considered the use of saturated aliphatic hydrocarbons or mixtures thereof with the lowest possible aromatic content and, in particular, the lowest possible residual benzene content, to be the least dangerous. Cremonesi’s goal was to conduct the solubilisation in a safer cleaning procedure for the operator’s health.

This research investigated a new varnish formulation for paintings based on Laropal® A81 using mixtures of aliphatic hydrocarbons and esters as alternative solvents to the classical aromatic hydrocarbon mixture. The traditional and alternative Laropal® A81 varnish formulations based on Shellsol® A and IBIB, respectively, were assessed in their short- and long-term behaviours. A multi-technique approach including spectroscopic methods was applied to evaluate the optical, colorimetric, and stability properties of the formulations on inert (laboratory glass slides) and paint (mock-ups) supports before and after natural and accelerated light ageing. Their comparison served to assess the suitability of the alternative formulation. Extraction tests on naturally aged unvarnished paint films were also carried out to investigate the effect of both traditional and alternative formulation in terms of leaching of the paint film by the Laropal® A81 varnishes.

3. Results and Discussion

3.1. Materials Characterisation

Prior to the preparation of the formulations and their application, all ingredients and pigments were analysed to check their composition and purity as claimed by the manufacturer by FT-IR,

1H-NMR, or UV-Vis-NIR spectroscopies as required by each specific component. The spectra recorded on commercial products agreed with what was reported in the technical data sheets and in the literature, as reported in

Table 3.

In addition, preliminary extraction tests were performed to verify the possibility of extraction of paint components by the solvent mixtures used for the two formulations. The tests were performed by soaking, for short (10 min) and long (24 h) time fragments of egg yolk film, egg tempera paint (yolk only) pigmented with ivory black, and linseed oil paint pigmented with rutile in the two different solvent mixtures, A and B, used to obtain the traditional and alternative formulations, respectively. For these preliminary extraction tests, available films with adequate natural ageing samples (containing ivory black with egg yolk and titanium rutile white for linseed oil) were used.

The extracted fractions, separated from the solid by filtration and evaporated to dryness, were weighed and analysed by means of

1H-NMR spectroscopy to investigate possible leaching phenomena caused by A and B solvent mixtures. The quantitative results were comparable for both solvent mixtures but changed for each type of sample extracted (egg film as is, egg with pigment, and oil film with pigment) (

Table 4). The extractions carried out on the egg yolk layers with ivory black and without pigment showed the signals attributable to egg oil (

Figure 2), which is soluble in chloroform, in a higher amount in the case of the yolk-only. In fact, the signals attributable to the saturated and oleic chains together with those attributable to the glyceric group, confirm the presence of soluble triglycerides in agreement with the non-drying properties of egg oils. Small variations in the relative intensity of the allylic signals found between samples of different compositions are attributable to the different effect of the pigment on the reactivity of these positions and not to the type of solvent used. On the other hand, the data obtained with the rutile pigment mixture with linseed oil could not be evaluated because the extractions were unable to highlight soluble components in accordance with the cross-linking of the binder and the reduced concentration of soluble components of the siccative oil. It is also necessary to consider that, for this pigment, the amount of binder used is extremely small and this factor also contributes to reducing the amount of soluble fraction (<1% as percentage relative to the dry weight (mg) of the extracted sample (mg)). In any case, no differences in behaviour between the two types of solvent mixtures, A and B, were noticed. The increase in the extraction time determines a slight increase in the quantities of fractions extracted in solution for the samples with egg binder while the values observed after 24 h for the samples with oil and rutile are substantially comparable and in agreement with the reduced presence of soluble components (<1%). The data obtained are in agreement with the composition and solubility of the samples such as the type of binder (egg or oil) and the amount of binder present in them with respect to the pigment (egg or egg with pigment).

Since both solvent mixtures showed identical leaching behaviour, the next step was dedicated to studying the varnish films obtained with formulations A and B by FT-IR and 1H-NMR. The spectra recorded on the varnish films obtained from the two formulations showed the characteristic signals of the Laropal® A81 resin. Spectra recorded after one year showed no variations in the signals present and in their relative intensity, highlighting the stability of both formulations in storage at room temperature.

3.2. Study of the Samples with Varnish

The varnish formulations were applied by brush. Consequently, the varnish films were not flat but wavy and without a uniform thickness, as evinced by UVL (

Figure 3).

The colorimetric data shown in

Table 5 are the average of three measurements, and the maximum error in all measurements for each colorimetric value is ≤0.04. L*, a*, and b* calculated before and after varnish application (T

0–T

i) on the slides and mock-ups of titanium white, showed non-significant differences. On the other hand, the two mock-ups of zinc white were characterised by a significant change in the b* coordinate; those of cerulean blue were also characterised by significant changes in the L* value, mainly for measurements in the SCE configuration, and partly in the a* coordinate for SCI measurements. Finally, it is interesting to note the result obtained for the A2 ivory black mock-up, where the colour difference T

0–T

i shows a substantial difference between SCI and SCE measurements. The variation in Chroma (C* = [(a*)

2 + (b*)

2]

½) after the application of the varnish cannot be very likely attributed to the varnish itself because a similar change in C* value would also have been detected on the slides (T

i = laboratory glass slides without varnish; T

0 = varnished laboratory glass slides).

There are a number of studies that have looked at appearance effects due to the application of varnish films on paint layers [

21,

22,

23,

24,

25,

33]. Among them, the study by Simonot and Elias concludes that firstly the varnish layer induces a levelling of the paint layer, which results in an increase in specular reflected light and gloss [

34,

35]. Added to this is a decrease in diffuse reflectance due to the weak absorption of the varnish layer. The result, the authors argue, is a darkening and desaturation of the final paint surface the lighter and more saturated the initial paint film (and the thicker the varnish layer).

Here, the considerations of Simonot and Elias are partly observed. Indeed, the colourimetric differences found for the zinc white and cerulean blue mock-ups can be explained by observing their reflectance spectra acquired after their preparation (T

i) and after the application of the thick layer of varnish (T

0) (

Figure 4a,b). From their spectra, it is clearly visible that the Ti spectra in the UV-blue region show different trends compared to those of the same samples acquired at T

0. These differences are largely due to the curing processes of the paint film and partly to the presence of the superficial varnish film, which was very thick. In the case of the varnished zinc white mock-ups, this fact resulted in a reduction of the yellow component manifested in both the SCI and SCE measurements. For cerulean blue mock-ups, instead, the effect of the varnish is more evident in the SCE configuration since, in addition to a marked variation in b* (it tends to increase the perception of blue), and there is a perceptible decrease in brightness L*. Differently from what is reported by Simonon and Elias, in this case C* tends to increase with the presence of the varnish film. The case of one of the two ivory black mock-ups (A2) deserves attention since a very different behaviour of L* was found between the two measurement configurations. In fact, once painted (T

0) the lightness value changes a lot (ΔL* = 12.05) compared to before (T

i) but only the value obtained with the SCE configuration. This fact can be explained by looking at the spectra (

Figure 4c) in which it is evident that the varnish has considerably reduced the reflectance (SCE) over the entire visible range (as reported by Simonot and Elias). This effect is more perceived by the measure in which the specular component (SCI) is present as the new paint film is extremely smooth with a strong gloss component that results in a more intense reflectance.

TR FT-IR spectra of varnished glass slides and paint samples showed all the characteristic absorption bands of the Laropal

® A81. No bands attributable to the underlying paint layer were detectable, probably because they are hidden by the varnish signals. As an example, the TR FT-IR spectra of the zinc white paint sample uncoated, with formulation A and with formulation B, are shown in

Figure 5.

No significant differences in colorimetric data were found between the application of type A and type B formulations, and the same spectral trends were obtained from the two formulations.

3.3. Study of the Samples after Natural Ageing

The natural aging of the specimens did not lead to changes that were observable visually nor by the spectroscopic techniques. The recorded colorimetric data (T

1) showed irrelevant differences compare to T

0, and the total colorimetric variations (ΔE

00) on all samples were considered imperceptible to the eye (

Table 5). The TR FT-IR spectra, repeated after one year of natural ageing, were found to be completely superimposable with those recorded at T

0.

3.4. Study of the Samples after Artificial Ageing

The glass slides appeared unchanged under microscope magnification, and no spectral changes (FT-IR and UV-Vis-NIR) were observed. Although a slight yellowing was detected (ΔE00 ≈ 1; Δb* ≈ 1), it remained below the limit perceptible by the naked eye. This result confirmed the stability of Laropal® A81 urea-aldehyde resin applied alone on an inert substrate.

Some artificially aged mock-ups showed visually and analytically detectable differences (imaging, FT-IR, UV-Vis-NIR, and

1H-NMR). Furthermore, these were most likely influenced by the substrate (i.e., the pigments) rather than the different formulations (A or B). Interestingly, the varnish films remained transparent in all cases with no or little perceptible yellowing (see T

2 in

Table 5), cracks, or lifting.

The zinc white mock-ups exhibited only a small reduction in the b* coordinate toward neutrality values, but the total colorimetric variation could also be considered almost imperceptible (ΔE00 ≈ 2). The TR FT-IR spectra were characterised by the fingerprint bands of Laropal® A81, and no bands attributable to structural changes in the oligomer or the presence of alteration products were detected.

A relatively good preservation of the varnish layer was also observed for the artificially aged titanium white paint samples. As with the zinc white mock-ups, a reduction in the yellow values (b*) towards the neutrality was detected with a non-perceptible colour variation (ΔE

00 < 2). Laropal

® A81 absorption bands were still clearly visible in the IR spectra, although, in some cases, they appeared to have a lower relative intensity because the characteristic bands of the titanium white pigment became more prominent (

Figure 6). These data could be related to a thinning of the varnish film, as reported in other papers for Laropal

® A81 on silicon wafers, quartz, and simple glass slides [

36,

37].

The cerulean blue and ivory black mock-ups showed the most noticeable changes following accelerated ageing, with significant colorimetric variations visible to the naked eye. The colorimetric parameters indicate that the blue mock-ups became lighter and less greenish after ageing, in particular for the SCE measurements (ΔE ≈ 3.5). The two ivory black mock-ups, also in this case, show a different behaviour. In fact, the A12 mock-up features ΔE00 ≈ 3.0 for both SCI and SCE. On the other hand, the A2 mock-up confirms what was previously shown (T0–Ti) given that the SCI component shows negligible ΔE00 values while the SCE component has ΔE00 ≈ 7, also in this case due to L*, bringing it back to have colorimetric values more similar to those of the unvarnished mock-up. This behaviour leads us to hypothesise that the artificial ageing caused a strong thinning of the varnish layer bringing the two mock-ups back to conditions similar to Ti.

The TR FT-IR and T FT-IR spectra collected from the blue and black mock-ups displayed no structural changes in the varnish or alteration products. However, they showed a less homogeneous distribution of both traditional and alternative varnishes after ageing, as the absorption bands of the resin show highly variable intensities depending on the areas analysed. This could be attributed to a decrease in its thickness in some areas caused by ageing in the climate chamber (

Figure 7).

To try to better understand the impact of the artificial ageing procedure (at T

2) on the ivory black mock-up, the one with varnish formulation A was analysed. To do so, the varnish residue from the surface was extracted using two cotton swabs, one soaked in ethyl acetate and one in acetone. The solutions obtained by counterwashing the two cotton swabs with the same solvents were taken to dryness, and the residue was analysed by

1H-NMR (

Figure 8a). Tinuvin

® 292 (

Figure 8b) is present in the varnish formulation in a small concentration as an additive, and before ageing (

Figure 8c) the signals from Tinuvin

® 292 (highlighted with *) were much less intense than those of the Laropal

® A81 resin which were well recognised. After ageing, signals from Tinuvin

® 292 were more intensely visible in spectrum

a than those characteristic of the Laropal

® A81 resin, which were weakly present. These results support the hypothesis of the varnish layer reduction, which cannot be attributed to a variation in the solubility of the resin after ageing. This is probably attributable to a reduction in the quantity of the varnish (particularly of the dried Laropal

® resin) as a result of depolymerisation processes, with the resin becoming proportionally less concentrated than Tinuvin

® 292. Spectrum

a also shows other not easily attributable signals that could be assigned to components extracted from the paint film; however, it is difficult to hypothesise a connection with transformation products of Tinuvin

® 292 or Laropal

® A81. In accordance with this interpretation, some TR FT-IR spectra acquired on areas with significant resin reduction showed only the spectral features of the pigments, whereas no absorption bands associated with Laropal

® A81 were detected. It is hypothesised that depolymerisation of the varnish occurred, which caused its loss through the formation of volatile products, in agreement with evidence in the literature [

36,

37].

Observing the UV-Vis spectral trends of the mock-ups (

Figure 9), one can infer that the film-forming materials applied to the glass slides transmitted the incident radiation without any absorption. As far as mock-ups are concerned, both white mock-ups absorbed the UV component while reflecting the visible one; those with cerulean blue absorbed the UV radiation and that in the 530–680 nm range; the black samples have absorbed all the incident radiation emitted by the SOLARBOX 3000e. It follows that the greater absorption of the incident radiation by the darker mock-ups could have induced a photochemical degradation and an increase in the temperature of the paint film surface that, in turn, would have increased the temperature of the varnish.

4. Conclusions

The most significant result obtained is that the study on the application properties of traditional and alternative Laropal® A81-based formulations, using chemical–physical techniques, showed no disadvantages between the application of type A and type B formulation. The aromatic percentage (Shellsol® A) traditionally used with an aliphatic hydrocarbon (Shellsol® D40) to adequately solubilise Laropal® A81 can thus be replaced with the alternative solvent (IBIB) without any particular criticism of the painting films and with considerable advantages for the health of the operators and environmental protection.

Moreover, based on the data obtained, it can reasonably be stated that the stability of Laropal® A81 resin is strongly influenced by the substrate present while it is not influenced by the formulation used.

After accelerated ageing, the results lead to the hypothesis of a depolymerisation of the Laropal

® A81 resin, with consequent loss of product due to the formation of volatile products. This phenomenon had already been detected by the studies of Farmakalidis et al. [

36,

37], in which a decrease in the thickness of Laropal

® A81-based varnish films was found, confirming the decrease in the molecular weight of the resin already reported in previous studies [

4,

9,

16,

38]. Information obtained from the studies by Farmakalidis et al. suggests that the emission of volatile products could be related to the breaking of the N–(C=O) bond with the subsequent formation of formaldehyde and urea. This would indicate a partial depolymerisation of the material and would explain the decrease in film thickness [

36,

37]. In the current project, this phenomenon was further explored with a clear distinction between the different colour backgrounds. The results shown that the layers of paint remained virtually unchanged on the glass slides and on the white backgrounds, while a loss of resin was found on the blue and black backgrounds. Moreover, it is very important to note that only in cases of artificial ageing (corresponds to approximately 87 years of ageing under museum conditions) this behaviour was observed on part of the painted areas, while this phenomenon was not observed for natural ageing (12 months). In addition to the difficulty of relating the effects of artificial ageing to natural ageing and their temporal correspondence, it is important to remember that the use of artificial ageing procedures significantly shortens exposure times to specific environmental parameters, and that in many cases they tend to produce conditions that are not perfectly comparable to those found in natural ageing. As far as the purpose of this study is concerned, it is of absolute importance to note that the results obtained do not appear to be influenced by the application of either the type A or type B formulation. In cases where the varnish persists, the recorded spectra reveal the characteristic signals of Laropal

® A81, which is therefore unaffected; no alteration or degradation products that could be harmful to paintings are detected in these areas. Furthermore, both A and B varnish films, even after accelerated ageing, remained transparent, with no perceptible yellowing and without cracking or lifting. In the future, it would be desirable to extend the studies on the stability of Laropal

® A81 following natural ageing for a longer time than that applied in this project, since studies on the oligomer are mainly found in the literature only following its accelerated ageing [

4,

15,

16,

18,

36,

37].

Additionally, as for the extraction tests carried out to assess possible leaching attributable to solvent mixtures A and B, it is important to observe that there were no differences in behaviour between the two formulations. However, the results will deserve further investigation, increasing the number of samples (pigments and binders) studied. In fact, the data obtained, on fragments of mock-ups aged naturally for about a year and a half, did reveal an unsatisfactory phenomenon with respect to egg-yolk-only and ivory black samples with yolk. Soluble components (egg oils) were indeed extracted from these fragments, which may have an influence on the plasticity of the film. On the other hand, no protein-binding extractions were observed. Certainly, the phenomenon deserves attention and further study to assess whether the loss of non-cross-linked egg oils is a phenomenon that is nonetheless present in aged egg films. Studies conducted to assess leaching against egg tempera paints are underrepresented in the literature [

39], while the phenomenon was mainly investigated on oil painting samples [

10,

32,

40,

41]. However, data from extraction tests conducted on paint samples prepared about 12 years ago using linseed oil and rutile do not show any appreciable results in terms of extraction, probably due to a very little amount of non-cross-linked materials present. With regard to the specific behaviour identified for the egg binder, it will be interesting in the future to compare the leaching of egg tempera samples containing different pigments and after different ageing conditions and times. Based on the preliminary results obtained,

1H-NMR spectroscopy is able to provide in detail the effects on the reactivity of the allylic position, and based on this it will be interesting to confirm the effect of the different metals contained in the pigments.

Further developments and research on this subject could involve the study of Laropal® A81 in interaction with other types of substrates, both paint layers and support, as the substrate present has been found to be an influential factor in the preservation of Laropal® A81 layers. In future research, it might be of interest to measure the surface temperature of the samples during accelerated ageing (comparable with the one carried out in the present study) in order to detect possible heating of the samples, and it might be relevant to combine this type of ageing with artificial thermal ageing.

The results obtained in this research are specific for the Laropal® A81 or for resins with similar solubility. However, the proposed study procedure is also applicable to formulations with different resins and different solvent mixtures with the aim of replacing solvents that are hazardous to the health of operators and to the environment. As far as the formulations studied in this research are concerned, further studies will be able to expand the knowledge relating to leaching on different binders and on the basis of this behaviour evaluating how to improve it, if possible, in the choice of new formulations that are safer for the environment and operators.