Effect of Low-Energy Implantation of In+ Ions on the Composition and Electronic Structure of Single-Crystal GaP(111)

Abstract

1. Introduction

2. Experimental Method

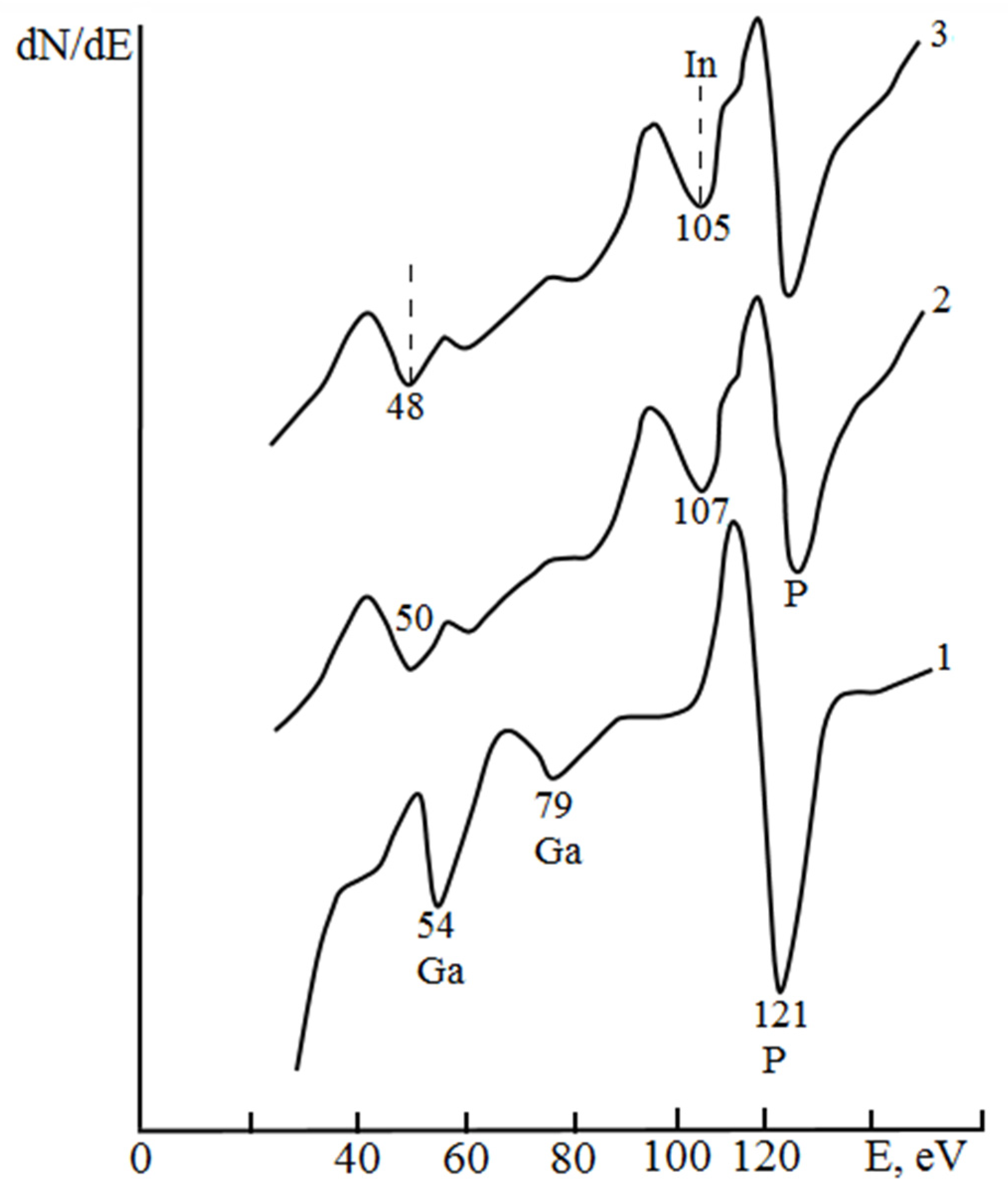

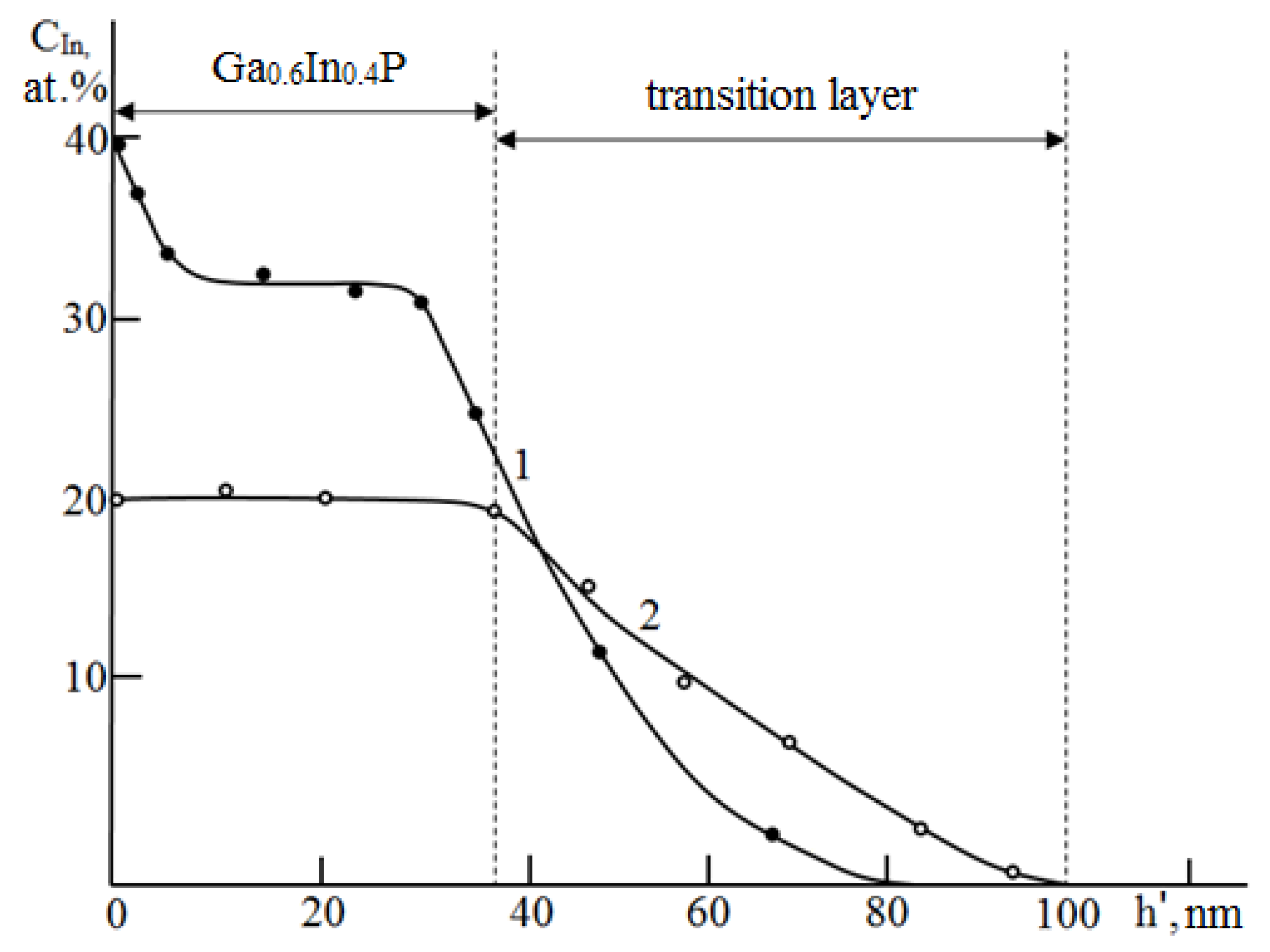

3. Experimental Results

| Studied Samples | h, nm | d, nm | Eg, eV | Ѳ, % |

|---|---|---|---|---|

| GaP(111) | Monocrystal sample | 2.36 | 0 | |

| Ga0.6In0.4P/GaP(111) | 3–3.5 | 15–20 | 2.3 | 40 |

| 3–3.5 | 25–30 | 2.0 | 70 | |

| 3–3.5 | continuous film | 1.85 | 100 | |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lazarenko, A.A.; Nikitina, E.V.; Pirogov, E.V.; Sobolev, M.S.; Egorov, A.Y. Molecular beam epitaxy of GaPN, GaPAsN, and InGaPN nitride solid solutions. Semiconductors 2014, 48, 392–396. [Google Scholar] [CrossRef]

- Abramkin, D.S.; Petrushkov, M.O.; Emelyanov, E.A.; Nenashev, A.V.; Yesin, M.Y.; Vasev, A.V.; Putyato, M.A.; Bogomolov, D.B.; Gutakovskiy, A.K.; Preobrazhenskiy, V.V. Formation of InAs/GaP Quantum-Well Heterostructures on Silicon Substrates by Molecular-Beam Epitaxy. Semiconductors 2021, 55, 139–146. [Google Scholar] [CrossRef]

- Sun, C.; Wade, M.T.; Lee, Y.; Orcutt, J.S.; Alloatti, L.; Georgas, M.S.; Waterman, A.S.; Shainline, J.M.; Avizienis, R.R.; Lin, S.; et al. Single-chip microprocessor that communicates directly using light. Nature 2015, 528, 534–538. [Google Scholar] [CrossRef] [PubMed]

- Uvarova, A.V.; Baranova, A.I.; Vyacheslavovaa, E.A.; Kalyuzhnyic, N.A.; Kudryashova, D.A.; Maksimovaa, A.A.; Morozova, I.A.; Mintairovc, S.A.; Saliic, R.A.; Gudovskikha, A.S. Formation of Heterostructures of GaP/Si Photoconverters by the Combined Method of MOVPE and PEALD. Tech. Phys. Lett. 2021, 47, 730–733. [Google Scholar] [CrossRef]

- Ladugin, M.A.; Andreev, A.Y.; Yarotskaya, I.V.; Ryaboshtan, Y.L.; Bagaev, T.A.; Padalitsa, A.A.; Marmalyuk, A.A.; Vasilev, M.G. Comparative Study of GaAs/GaInP and GaAs/AlGaAs Quantum Wells Grown by Metalorganic Vapor Phase Epitaxy. Inorg. Mater. 2019, 55, 315–319. [Google Scholar] [CrossRef]

- Razeghi, M. Technology of Quantum Devices; Springer: Boston, MA, USA, 2010; 560p. [Google Scholar]

- Gudovskikh, A.S.; Uvarov, A.V.; Morozov, I.A.; Bukatin, A.S.; Baranov, A.I.; Kudryashov, D.A.; Kalyuzhnyy, N.A.; Mintairov, S.A.; Zubkov, V.I. Study of GaP Nucleation Layers Grown on Si by Plasma-Enhanced Atomic Layer Deposition. Phys. Status Solidi A 2019, 217, 1900532. [Google Scholar] [CrossRef]

- Kunert, B.; Reinhard, S.; Koch, J.; Lampalzer, M.; Volz, K.; Stolz, W. First demonstration of electrical injection lasing in the novel dilute nitride Ga (NAsP)/GaP-material system. Phys. Status Solidi C 2006, 3, 614. [Google Scholar] [CrossRef]

- Sobolev, M.S.; Lazarenko, A.A.; Nikitina, E.V.; Pirogov, E.V.; Gudovskikh, A.S.; Egorov, A.Y. MBE Growth of GaP on a Si Substrate. Semiconductors 2015, 49, 559–562. [Google Scholar] [CrossRef]

- Gudovskikh, A.S.; Kalyuzhnyy, N.A.; Lantratov, V.M.; Mintairov, S.A.; Shvarts, M.Z.; Andreev, V.M. Properties of interfaces in GaInP solar cells. Semiconductors 2009, 43, 1363–1368. [Google Scholar] [CrossRef]

- Baranov, A.I.; Uvarov, A.V.; Maksimova, A.A.; Vyacheslavova, E.A.; Kalyuzhnyy, N.A.; Mintairov, S.A.; Salii, R.A.; Yakovlev, G.E.; Zubkov, V.I.; Gudovskikh, A.S. Study of InP/GaP quantum wells grown by vapor phase epitaxy. Tech. Phys. Lett. 2023, 49, 163–167. [Google Scholar]

- Dvoretckaia, L.N.; Bolshakov, A.D.; Mozharov, A.M.; Sobolev, M.S.; Kirilenko, D.A.; Baranov, A.I.; Mikhailovskii, V.Y.; Neplokh, V.V.; Morozov, I.A.; Fedorov, V.V.; et al. GaNP-based photovoltaic device integrated on Si substrate. Sol. Energy Mater. Sol. Cells 2019, 206, 110282. [Google Scholar] [CrossRef]

- Baranov, A.I.; Gudovskikh, A.S.; Egorov, A.Y.; LeGall, S.; Kudryashov, D.A.; Kleider, J.P. Defect properties of solar cells with layers of GaP based dilute nitrides grown by molecular beam epitaxy. J. Appl. Phys. 2020, 128, 023105. [Google Scholar] [CrossRef]

- Chang, L.L.; Ploog, K. (Eds.) Molecular Beam Epitaxy and Heterostructures; Springer: Dordrecht, The Netherlands, 2012; 728p. [Google Scholar]

- Fedorchenko, I.V.; Kushkov, A.R.; Gaev, D.S.; Rabinovich, O.I.; Marenkin, S.F.; Didenko, S.I.; Legotin, S.A.; Orlova, M.N.; Krasnov, A.A. Growth method for AIIIBV and AIVBVI heterostructures. J. Cryst. Growth 2018, 483, 245–250. [Google Scholar] [CrossRef]

- Mori, M.J. Lattice Mismatched Epitaxy of Heterostructures for Non-Nitride Green Light Emitting Devices. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, June, 2008. [Google Scholar]

- Uvarova, A.V.; Sharova, V.A.; Kudryashova, D.A.; Gudovskikha, A.S. Impact of Silicon Wafer Surface Treatment on the Morphology of GaP Layers Produced by Plasma Enhanced Atomic Layer Deposition. Semiconductors 2023, 57, 415–422. [Google Scholar] [CrossRef]

- Uvarov, A.V.; Gudovskikh, A.S.; Nevedomskiy, V.N.; Baranov, A.I.; Kudryashov, D.A.; Morozov, I.A. Low temperature epitaxial growth of GaP on Si by atomic-layer deposition with plasma activation. J. Phys. D Appl. Phys. 2020, 53, 345105. [Google Scholar] [CrossRef]

- Zhang, X.B.; Ryou, J.H.; Dupius, R.D.; Walter, G.; Holonyak, N. Metalorganic Chemical Vapor Deposition Growth and Characterization of GaInP/GaAs Superlattices. J. Electron. Mater. 2006, 35, 705–710. [Google Scholar] [CrossRef]

- Ushakov, V.V.; Dravin, V.A.; Melnik, N.N.; Zavaritskaya, T.V.; Loiko, N.N.; Karavanskii, V.A.; Timoshenko, V.Y. Ion implantation of porous gallium phosphide. Semiconductors 1998, 32, 886–890. [Google Scholar] [CrossRef]

- Bhattachar-Yaa, D.; Vinokurov, D.A.; Gusinskii, G.M.; Elyukhin, V.A.; Kovalenkov, O.V.; Kyutt, R.N.; Marsh, J.H.; Naidenov, V.O.; Portnoi, E.L. Low-temperature photoluminescence of heavy-ion-implanted InGaP solid solutions. Tech. Phys. Lett. 1998, 24, 690–691. [Google Scholar] [CrossRef]

- Evtushenko, N.G.; Stukalov, S.A. Defect formation in GaP during laser implantation of impurities of groups I and III. Bull. Odesnik State Univ. 2000, 5, 196–201. [Google Scholar]

- Donaev, S.B.; Djurabekova, F.; Tashmukhamedova, D.A.; Umirzakov, B.E. Formation of nanodimensional structures on surfaces of GaAs and Si by means of ion implantation. Phys. Status Solidi C 2015, 12, 89–93. [Google Scholar] [CrossRef]

- Ergashov, Y.S.; Tashmukhamedova, D.A.; Umirzakov, B.E. On the Synthesis of Nanoscale Phases of Metal Silicides in the Near-Surface Region of Silicon and the Study of Their Electronic Structures by Passing Light. J. Surf. Investig. X-ray Synchrotron Neutron Tech. 2017, 11, 480–484. [Google Scholar] [CrossRef]

- Donaev, S.B.; Umirzakov, B.E. Effect of the Implantation of Al+ Ions on the Composition, Electronic and Crystalline Structure of the GaP(111) Surface. Semiconductors 2020, 54, 860–862. [Google Scholar] [CrossRef]

- Karimov, M.K.; Kutliev, U.O.; Bobojonova, S.B.; Otabaeva, K.U. Investigation of Angular Spectrum of Scattered Inert Gas Ions from the InGaP (001) Surface. Phys. Chem. Solid State 2021, 22, 742–745. [Google Scholar] [CrossRef]

- Kutliev, U.; Karimov, M.; Sadullaeva, B.; Otaboev, M. Investigation of the ion scattering process from the A3B5 semiconductors by the computer simulation method. Compusoft 2018, 7, 2749–2751. [Google Scholar]

- Chanda, A.; Lenka, H.P.; Jacob, C. Study of high energy Mn+1 ion implantation in GaAs. Appl. Phys. A 2009, 94, 89–94. [Google Scholar] [CrossRef]

- Shirinov, G.M.; Donaev, S.B.; Umirzakov, B.Y.; Loboda, V.V. Emission, optical and electrical properties of GaInP/GaP nanofilms. St. Petersburg State Polytech. Univ. J. Phys. Math. 2023, 16, 89–97. [Google Scholar]

- Normurodov, M.T.; Rysbaev, A.S.; Bekpulatov, I.R.; Normurodov, D.A.; Tursunmetova, Z.A. Formation and electronic structure of barium-monosilicide and barium-disilicide films. J. Surf. Investig. 2021, 15, S211–S215. [Google Scholar] [CrossRef]

- Rysbaev, A.S.; Khuzhaniyazov, Z.B.; Normuradov, M.T.; Rakhimov, A.M.; Bekpulatov, I.R. Peculiarities of the electron structure of nanosized ion-implanted layers in silicon. Tech. Phys. 2014, 59, 1705–1710. [Google Scholar] [CrossRef]

- Donaev, S.B.; Karimova, V.N.; Azimov, A.T.; Boltaboyev, K.; Yakubova, M.M. Using of ion implantation for obtaining nanostructures with the wide band GaP based on GaP. IOP Conf. Ser. Earth Environ. Sci. 2020, 614, 012002. [Google Scholar] [CrossRef]

- Altukhov, A.A.; Zhirnov, V.V. Analysis of the morphology and stocsiometry of CoSi2/Si(100) films obtained by SPE and RE methods. In Proceedings of the II All-Union Conference, Moscow, Izhevsk, Russia, 23–25 October 1991; pp. 15–22. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Donaev, S.; Shirinov, G.; Umirzakov, B.; Donayev, B.; Wang, S. Effect of Low-Energy Implantation of In+ Ions on the Composition and Electronic Structure of Single-Crystal GaP(111). Coatings 2024, 14, 1231. https://doi.org/10.3390/coatings14101231

Donaev S, Shirinov G, Umirzakov B, Donayev B, Wang S. Effect of Low-Energy Implantation of In+ Ions on the Composition and Electronic Structure of Single-Crystal GaP(111). Coatings. 2024; 14(10):1231. https://doi.org/10.3390/coatings14101231

Chicago/Turabian StyleDonaev, Sardor, Ganjimurod Shirinov, Baltokhodja Umirzakov, Burkhan Donayev, and Shenghao Wang. 2024. "Effect of Low-Energy Implantation of In+ Ions on the Composition and Electronic Structure of Single-Crystal GaP(111)" Coatings 14, no. 10: 1231. https://doi.org/10.3390/coatings14101231

APA StyleDonaev, S., Shirinov, G., Umirzakov, B., Donayev, B., & Wang, S. (2024). Effect of Low-Energy Implantation of In+ Ions on the Composition and Electronic Structure of Single-Crystal GaP(111). Coatings, 14(10), 1231. https://doi.org/10.3390/coatings14101231