Effects of Niobium Carbide Additions on Ni-Based Superalloys: A Study on Microstructures and Cutting-Wear Characteristics through Plasma-Transferred-Arc-Assisted Deposition

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Evolution of Solidification Microstructures and Hardening Ability in NCR-7 with NbC Addition

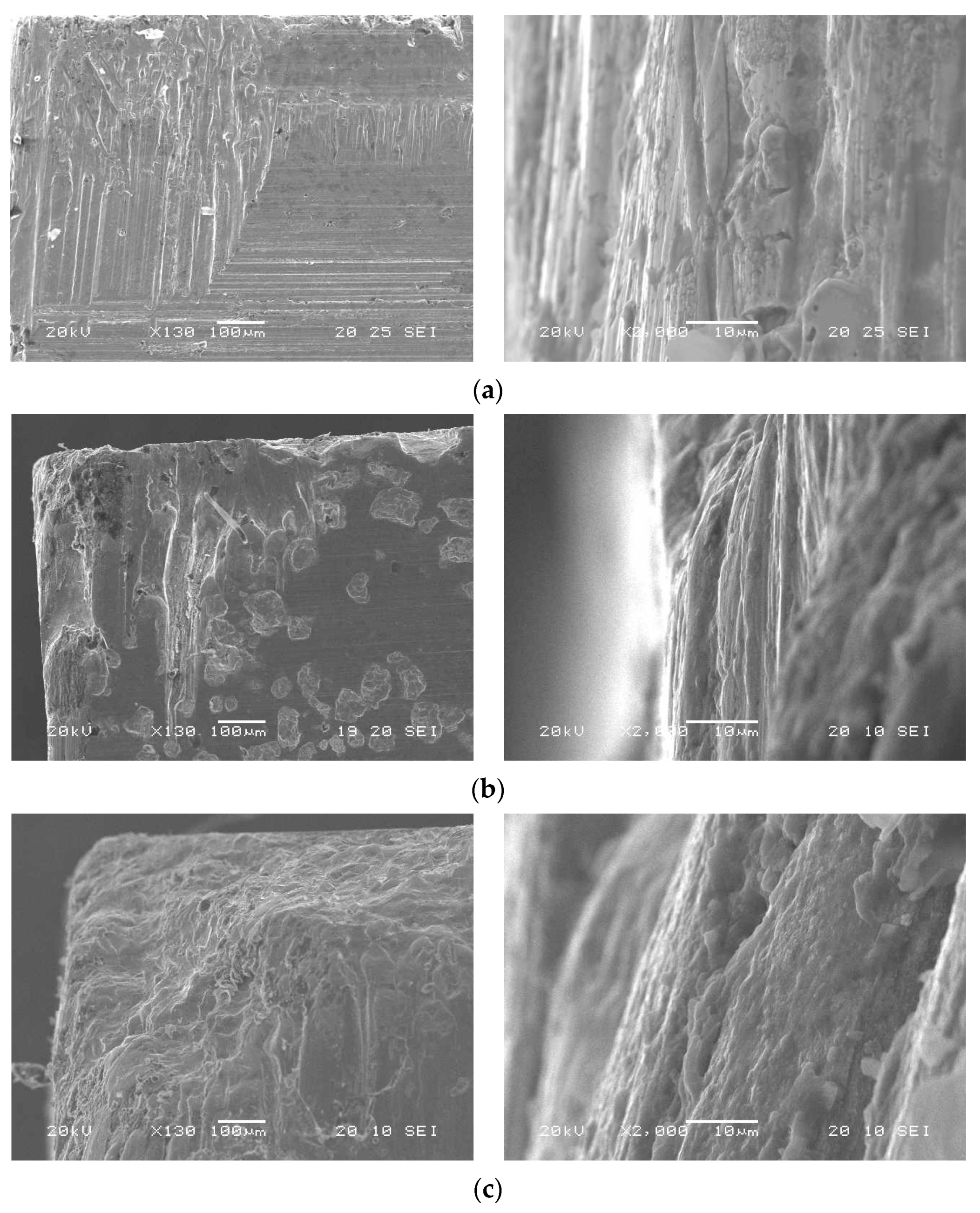

3.2. Effects of NbC Addition on Cutting-Wear Characteristics of Cladding Layer

4. Conclusions

- (1)

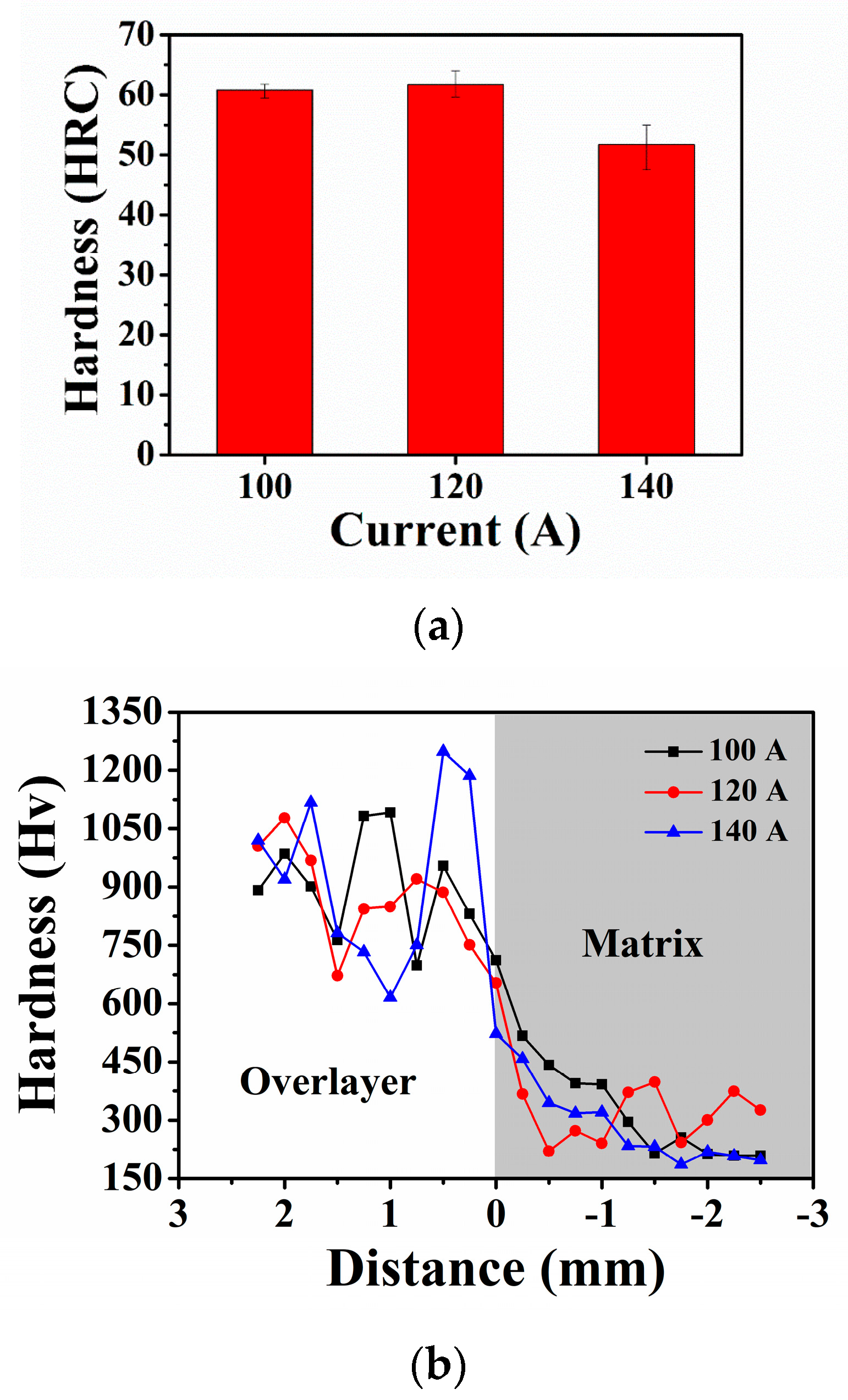

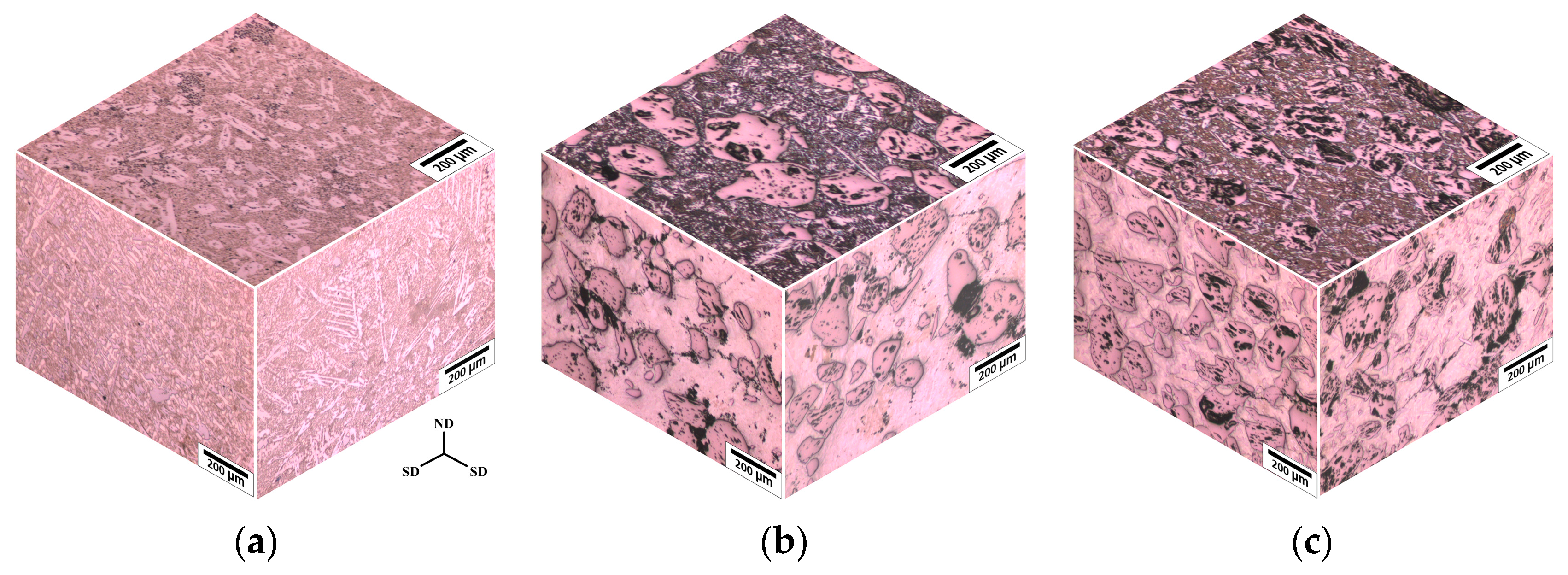

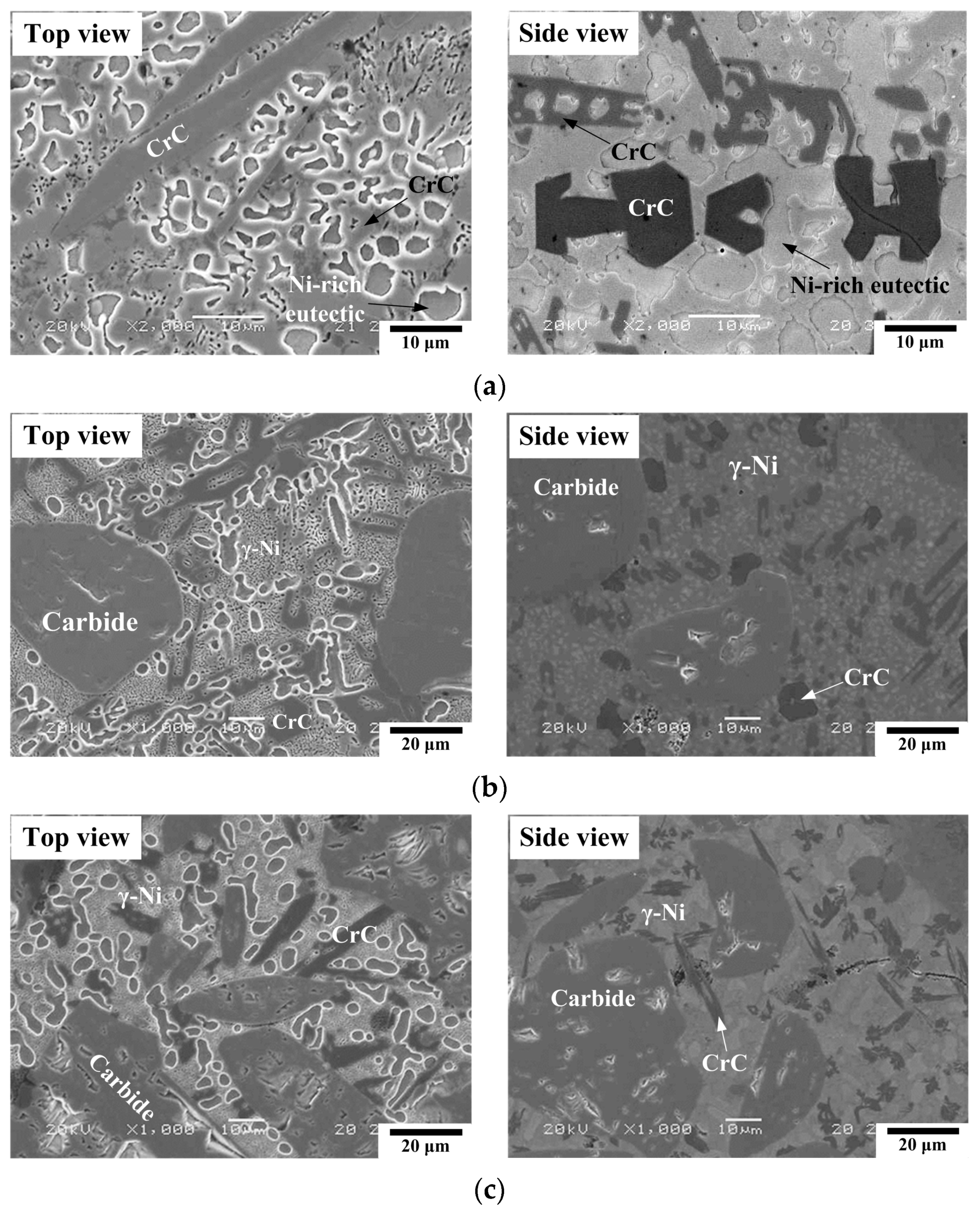

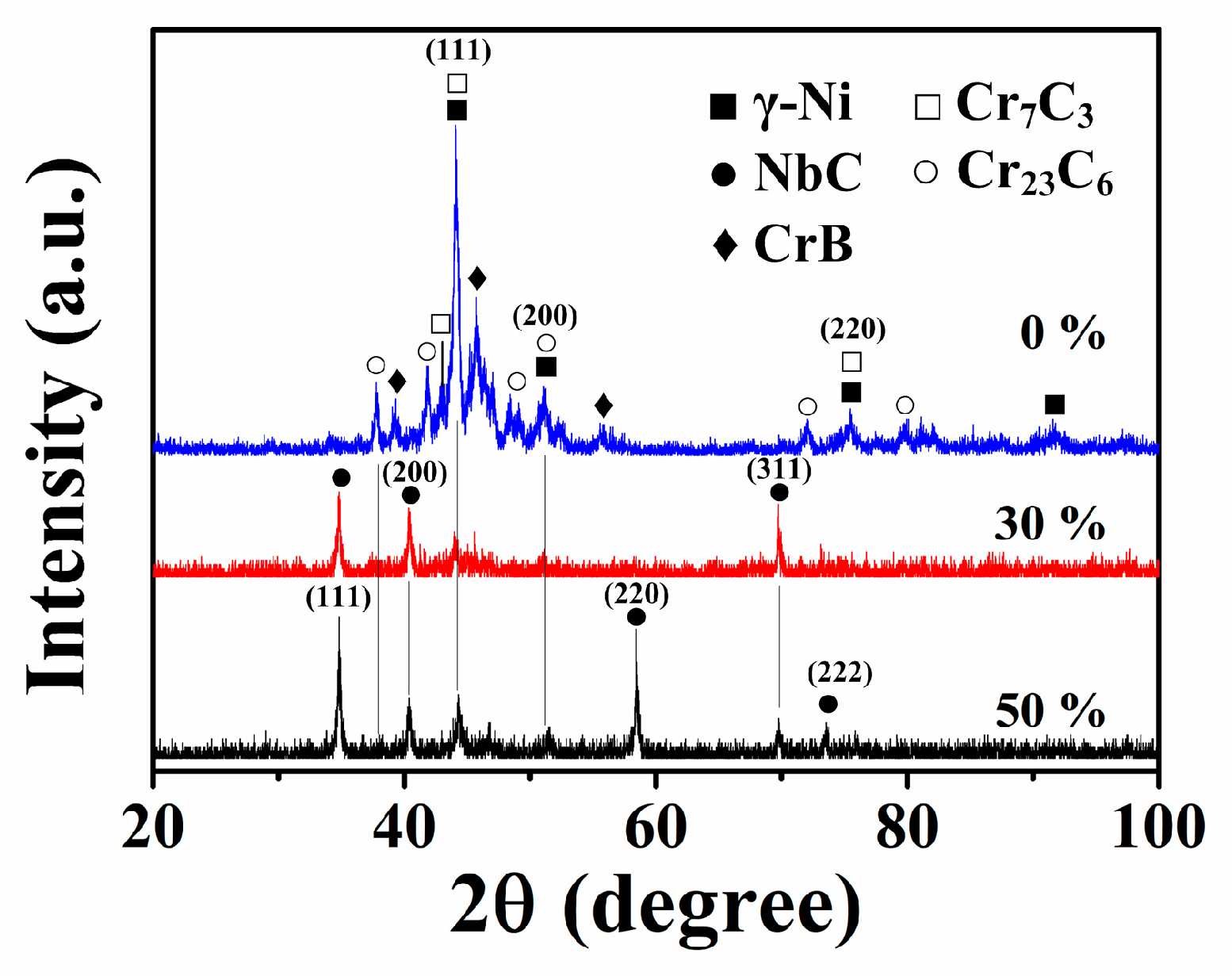

- The PTA-fabricated NCR-7 specimens exhibited uniform microstructures composed of dendrites and interdendritic eutectic mixtures. The NCR-7 microstructures were primarily composed of γ(Ni, Fe), Cr7C3, Cr23C6, and CrB phases, which contributed to the specimens’ considerable hardness, indicating that the specimens can be used in wear-resistant coating applications.

- (2)

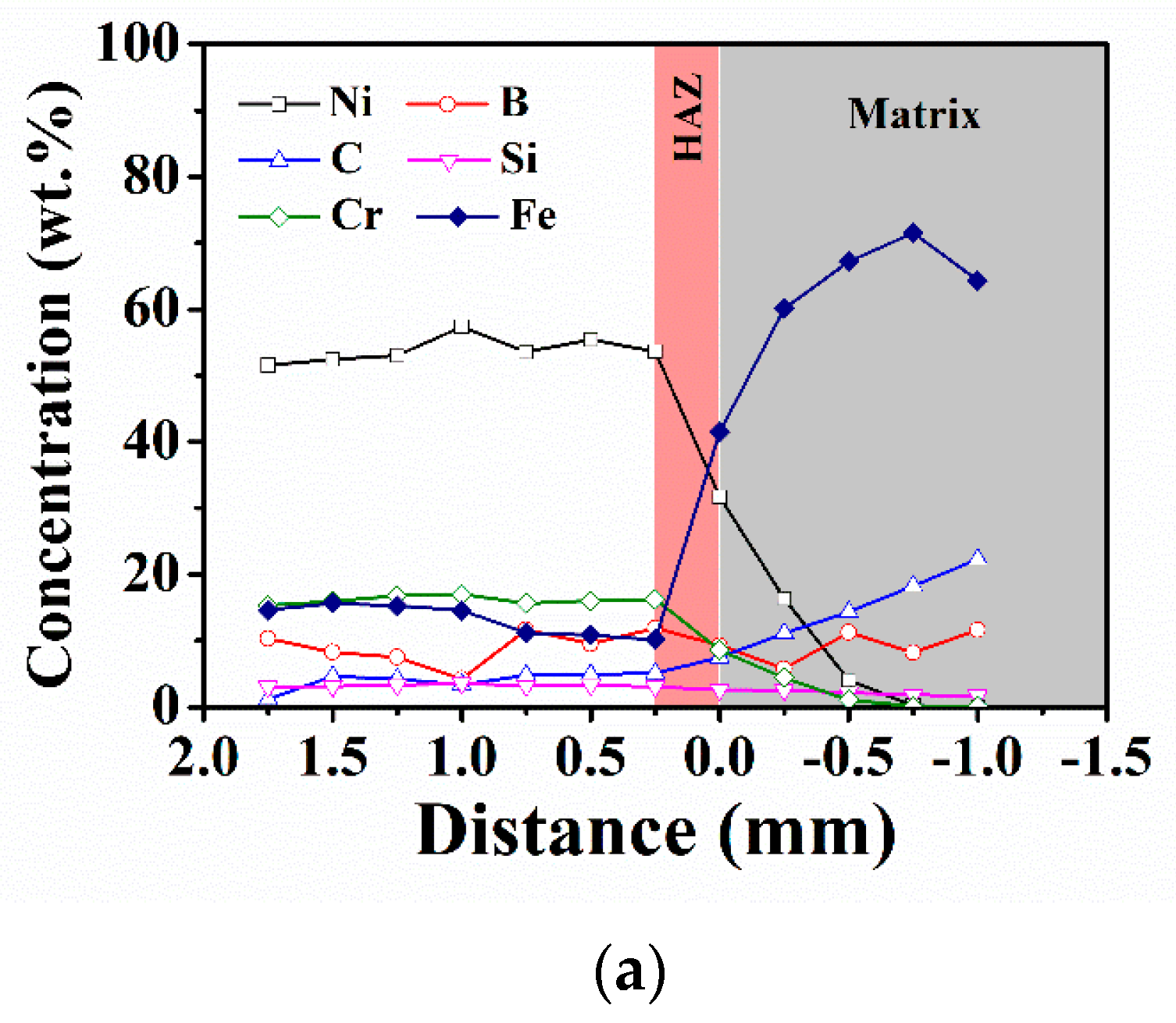

- Mixing NbC powder with NCR-7 powder introduced NbC hardening particles to the matrix of the PTA composite cladding. Compared with the NCR-7 specimen without NbC, the composite claddings with 30 and 50 wt.% NbC exhibited greater surface hardness due to dispersion strengthening. An analysis of interfacial elements revealed a substantial dilution effect caused by the thermal energy introduced in PTA welding. The composite claddings with NbC addition had considerable Nb content and a wider HAZ.

- (3)

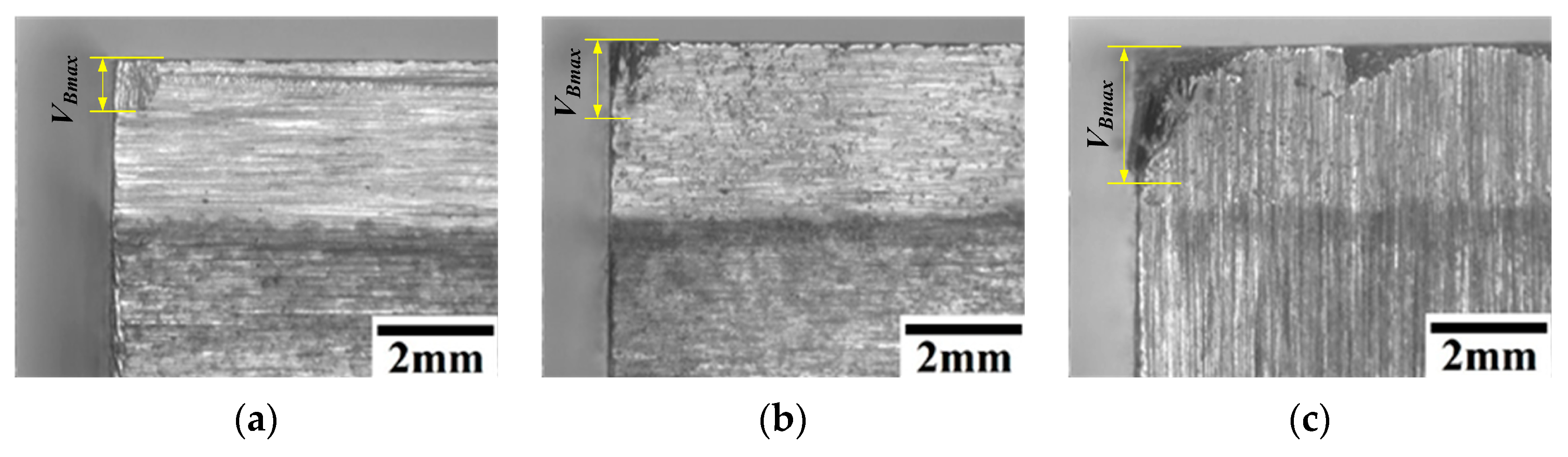

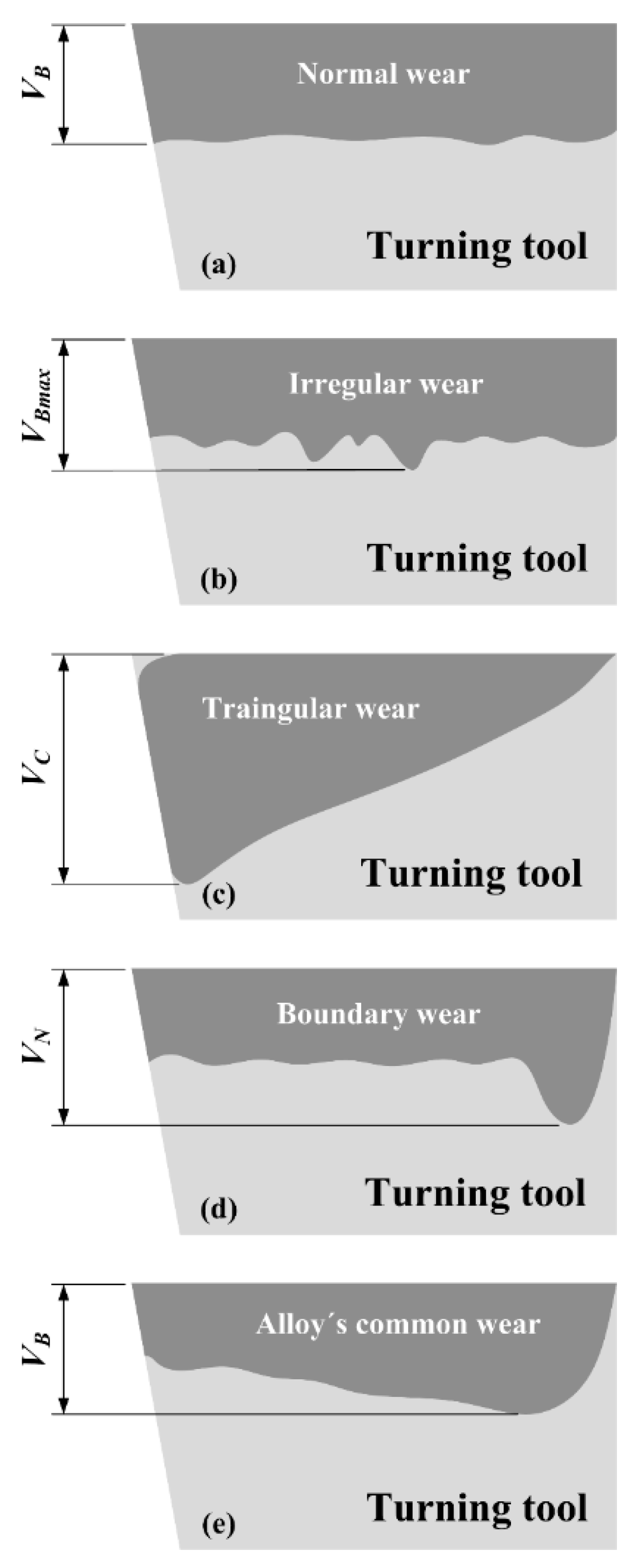

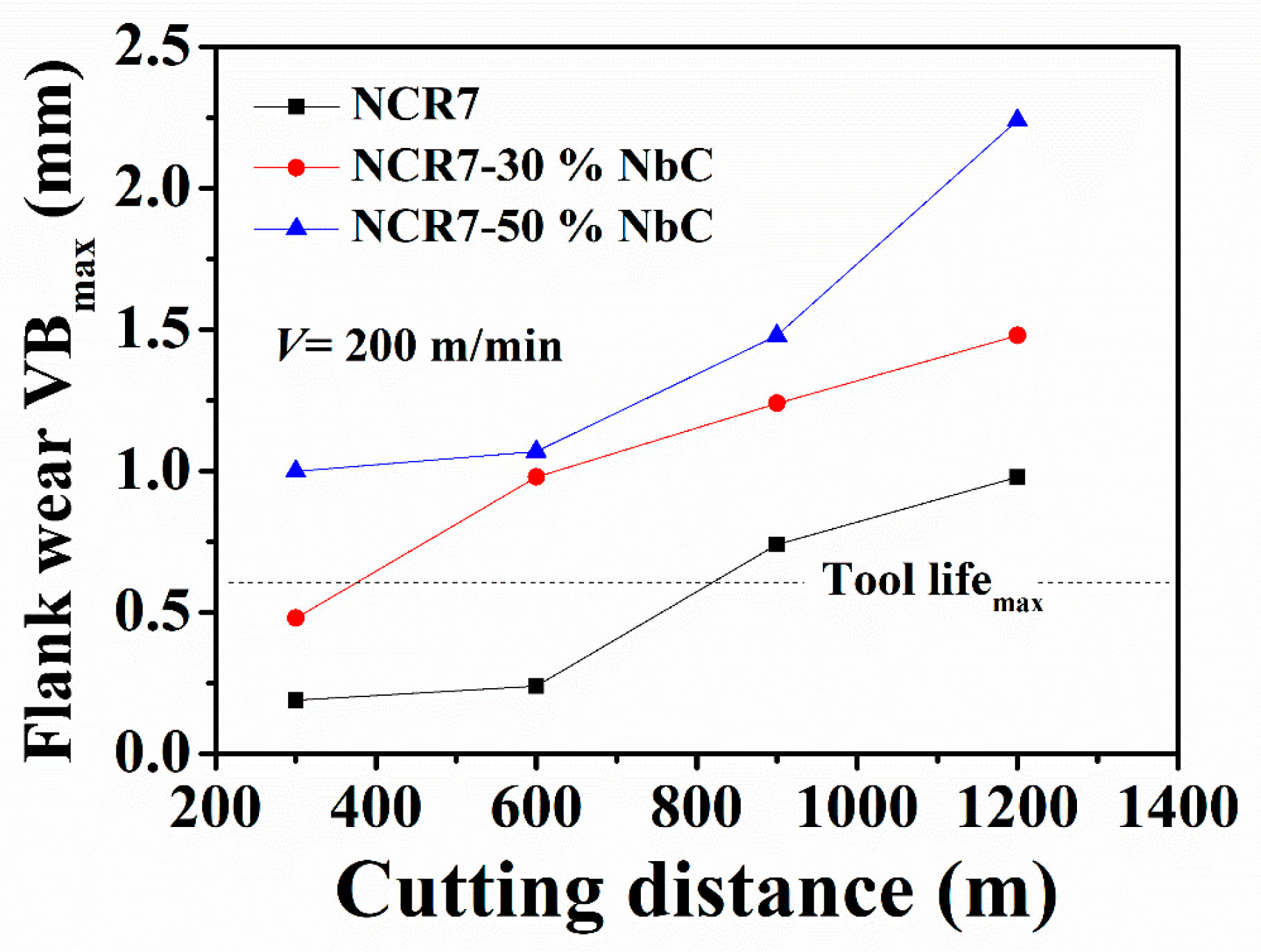

- Cutting tests revealed that the flank wear observed on the composite cladding tools exhibited a triangular wear morphology, which intensified as the NbC content was increased. The composite cladding tools with high NbC content exhibited failure at the beginning (300 m) of the cutting tests. The composite cladding tools composed of an excessive quantity of hardened NbC particles were prone to fracture due to stress concentration during the cutting tests. Thus, brittle fractures within the microstructures of the cladding tools directly shortened the lifespan of the tools. In addition, the study determined that material removal and fatigue wear during cutting contributed to the functional failure of the tools.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qu, X.Y.; Huang, H.; Wan, T.; Hu, L.; Yu, Z.L.; Liu, Y.J.; Dou, A.C.; Zhou, Y.; Su, M.R.; Peng, X.Q.; et al. An integrated surface coating strategy to enhance the electrochemical performance of nickel-rich layered cathodes. Nano Energy 2022, 91, 106665. [Google Scholar] [CrossRef]

- Hu, Y.J.; Wang, Z.X.; Pang, M. Effect of WC content on laser cladding Ni-based coating on the surface of stainless steel. Mater. Today Commun. 2022, 31, 103357. [Google Scholar] [CrossRef]

- Günen, A.; Soylu, B.; Karakaş, Ö. Titanium carbide coating to improve surface characteristics, wear and corrosion resistance of spheroidal graphite cast irons. Surf. Coat. Technol. 2022, 437, 128280. [Google Scholar] [CrossRef]

- Pham, T.H.N.; Nguyen, V.T. Microstructure and micro-hardness of Al2O3-TiO2 coating by plasma spraying on SKD61 steel. Mater. Trans. 2020, 61, 1829–1832. [Google Scholar] [CrossRef]

- Thompson, F.C.; Kustas, F.M.; Crawford, G.A. Oil-lubricated sliding wear performance of TiSiCN-coated ductile iron. Wear 2023, 514–515, 204567. [Google Scholar] [CrossRef]

- Karthick, M.; Pavithra, E.; Cep, R.; Elangovan, M. Machining of custom-450 grade stainless steel using TiAlSiN-coated tungsten carbide tool inserts. Processes 2023, 11, 1037. [Google Scholar] [CrossRef]

- Zhu, Y.X.; Keoleian, G.A.; Cooper, D.R. A parametric life cycle assessment model for ductile cast iron components. Resour. Conserv. Recycl. 2023, 189, 106729. [Google Scholar] [CrossRef]

- Wang, B.X.; Qiu, F.; Barber, G.C.; Pan, Y.M.; Cui, W.W.; Wang, R. Microstructure, wear behavior and surface hardening of austempered ductile iron. J. Mater. Res. Technol. 2020, 9, 9838–9855. [Google Scholar] [CrossRef]

- Guo, C.X.; Wang, X.; Xie, W.L.; Lai, S. Surface modification of aluminum alloy by wire electrical discharge machining with SiC nanofluid dielectric. Int. J. Adv. Manuf. Technol. 2023, 127, 3525–3536. [Google Scholar] [CrossRef]

- Grenadyorov, A.S.; Solovyev, A.A.; Yakovlev, E.V.; Glukhov, I.A.; Semin, V.O.; Popova, N.A.; Solovyov, A.V. Ti-based surface alloy formed on AISI 316L austenite steel surface using low-energy high-current electron beam. J. Alloys Comp. 2023, 955, 170243. [Google Scholar] [CrossRef]

- Chen, W.J.; Cai, Q.; Luo, Z.Y.; Wu, Y.B. Influence of heat treatment on strength and toughness of laser cladding iron-based coatings. Mater. Lett. 2023, 335, 133733. [Google Scholar] [CrossRef]

- Chen, K.J.; Hung, F.Y.; Lui, T.S.; Shih, Y.R. Wear inducing phase transformation of plasma transfer arc coated tools during friction stir welding with Al alloy. J. Eng. 2019, 2019, 6413608. [Google Scholar] [CrossRef]

- Xiao, B.T.; Yan, X.F.; Jiang, W.M.; Fan, Z.T.; Huang, Q.W.; Fang, J.; Xiang, J.H. Comparative study on the hardness and wear resistance of the remelted gradient layer on ductile iron fabricated by plasma transferred arc. Metals 2022, 12, 644. [Google Scholar] [CrossRef]

- Guo, X.H.; Zhang, P.; Li, H.; Wang, M.Y. Design and performance of nitrogen-alloyed iron-based coating for enhancing galling resistance by plasma transferred arc welding. Mater. Lett. 2023, 346, 134535. [Google Scholar] [CrossRef]

- Wang, R.D.; Ye, S.X.; Xie, Z.Y.; Zhang, Z.H.; Han, H.S.; Hong, J.G.; Zhang, Y.W.; Li, G.S.; Wu, W.H.; Lu, X.G. Effect of copper oxides on defect formation during PTA cladding of Stellite 6 on copper substrates. Surf. Coat. Techonl. 2023, 466, 129625. [Google Scholar] [CrossRef]

- Lopez, X.A.; Munoz-Arroyo, R.; Hernandez-Garcia, F.A.; Alvarez-Vera, M.; Mtz-Enriquez, A.I.; Diaz-Guillen, J.C.; Flores, I.G.; Betancourt-Cantera, J.A.; Hdz-Garcia, H.M. Processing of Co-base/C-nanotubes compound coating on D2 steel using plasma transferred by arc: Tribological and mechanical performance. Surf. Coat. Techonl. 2023, 461, 129458. [Google Scholar] [CrossRef]

- Wang, H.P.; Sun, R.X.; Zhang, M.Q.; Gou, B.; Mo, J.L. Impact-sliding behavior of Ni-based coating prepared on tunnel boring machine disc cutter material produced using a plasma transferred arc welding process. Surf. Coat. Technol. 2022, 442, 128186. [Google Scholar] [CrossRef]

- Witte, J.; Huebler, D.; Schroepfer, D.; Boerner, A.; Kannengiesser, T. Wear behavior of innovative niobium carbide cutting tools in ultrasonic-assisted finishing milling. Wear 2023, 522, 204722. [Google Scholar] [CrossRef]

- Gao, Q.; Zhang, L.Q.; Liu, J.Y.; Lin, J.P. Microstructure and mechanical properties of high nibium beta-gamma TiAl and IN718 alloy joints diffusion bonded by spark plasma sintering. Intermetallics 2022, 151, 107745. [Google Scholar] [CrossRef]

- Huang, Z.Y.; Hou, Q.Y.; Wang, P. Microstructure and properties of Cr3C2-modified nickel-based alloy coating deposited by plasma transferred arc process. Surf. Coat. Technol. 2008, 202, 2993–2999. [Google Scholar] [CrossRef]

- Haldar, V.; Pal, S. Influence of fusion zone metallurgy on the mechanical behavior of Ni-based superalloy and austenitic stainless steel dissimilar joint. J. Mater. Eng. Perform. 2023, 64. [Google Scholar] [CrossRef]

- Lemos, G.; Fredel, M.C.; Pyczak, F.; Tetzlaff, U. Creep resistance improvement of a polycrystalline Ni-based superalloy via TiC particles reinforcement. Mater. Sci. Eng. A 2022, 854, 143821. [Google Scholar] [CrossRef]

- Gang, D.; Biao, Y.; Qilin, D.; Ting, Y. Microstructure and wear resistance of in situ NbC particles reinforced Ni-based alloy composite coating by laser cladding. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2012, 27, 231–236. [Google Scholar] [CrossRef]

- Ficici, F.; Keser, M. Effect of casting modification materials on cutting forces of an Al12Si alloy used in aircraft technology. Mater. Test. 2023, 65, 616–628. [Google Scholar] [CrossRef]

- Fernandes, F.; Ramalho, A.; Loureiro, A.; Cavaleiro, A. Wear resistance of a nickel-based coating deposited by PTA on grey cast iron. Int. J. Surf. Sci. Eng. 2012, 6, 201–213. [Google Scholar] [CrossRef]

- Xu, H.M.; Huang, H.H.; Liu, Z.F. Influence of plasma transferred arc remelting on microstructure and properties of PTAW-deposited Ni-based overlay coating. J. Therm. Spray Technol. 2021, 4, 946–958. [Google Scholar] [CrossRef]

- Chan, W.S.; Lui, T.S.; Chen, L.H. Solidification structures in overlaying of cobalt-based superalloy on ferritic spheroidal graphite cast irons by plasma transferred arc process. Mater. Trans. 1996, 37, 50–55. [Google Scholar] [CrossRef]

- Cai, S.P.; Liu, Y.F.; Song, Z.K.; Lu, F.G.; Wu, Z.; Xie, M.Z. Design, preparation, microstructure and tribological properties of Cr7C3 and CrxSy reinforced composite coating. Wear 2023, 526–527, 204955. [Google Scholar] [CrossRef]

- Demirskyi, D.; Sakka, Y.; Vasylkiv, O. High-temperature reactive spark plasma consolidation of TiB2-NbC ceramic composites. Ceram. Int. 2015, 41, 10828–10834. [Google Scholar] [CrossRef]

- Wang, J.G.; Zhang, Q.K.; Shen, W.J.; Liang, Z.M.; Chang, C.Q.; Yang, L.Y.; Li, J.H.; Huang, F.S. Failure analysis of a chromium plating layer on a piston rod surface and the study of Ni-based composite coating with Nb addition by laser cladding. Metals 2022, 12, 1194. [Google Scholar] [CrossRef]

- Evangeline, A.; Sathiya, P. Dissimilar Cladding of Ni–Cr–Mo Superalloy over 316L Austenitic Stainless Steel: Morphologies and Mechanical Properties. Met. Mater. Int. 2021, 27, 1155–1172. [Google Scholar] [CrossRef]

- Pizzatto, A.; Teixeira, M.F.; Rabelo, A.; Falcade, T.; Scheid, A. Microstructure and wear behavior of NbC-reinforced Ni-based alloy composite coatings by laser cladding. Mater. Res. 2021, 23, e20200447. [Google Scholar] [CrossRef]

- Katea, S.N.; Tai, C.W.; Ström, P.; Larsson, P.O.; Vidarsson, H.; Westin, G. Niobium carbide—Nickel-niobium alloy composites from a nickel coated powder: Microstructural development during sintering. Open Ceram. 2021, 6, 100096. [Google Scholar] [CrossRef]

- Shi, B.M.; Hung, S.M.; Zhu, P.; Xu, C.G.; Zhang, T.F. Microstructure and wear behavior of in-situ NbC reinforced composite coatings. Materials 2020, 13, 3459. [Google Scholar] [CrossRef]

- Wang, H.; Song, X.; Wei, C.; Gao, Y.; Guo, G. Abrasion Resistance Enhancement of Ultrafine-structured WC-Co Coating Fabricated by using in situ Synthesized Composite Powder. J. Mater. Sci. Technol. 2013, 29, 1067–1073. [Google Scholar] [CrossRef]

- Wang, S.S.; Zhao, W.X.; Qiu, T.Y.; Liu, W.L.; Yan, P.; Jiao, L.; Wang, X.B. Effect of cutting fluid on milled surface quality and tool life of aluminum alloy. Materials 2023, 16, 2198. [Google Scholar] [CrossRef]

- Lin, H.M.; Liao, Y.S.; Wei, C.C. Wear behavior in turning high hardness alloy steel by CBN tool. Wear 2008, 264, 679–684. [Google Scholar] [CrossRef]

- Axinte, D.A.; Belluco, W.; Chiffre, L.D. Reliable tool life measurements in turning- an application to cutting fluid efficiency evaluation. Int. J. Mach. Tools Manuf. 2001, 41, 1003–1014. [Google Scholar] [CrossRef]

- Sun, S.; Fu, H.; Ping, X.; Lin, J.; Lei, Y.; Wu, W.; Zhou, J. Reinforcing behavior and microstructure evolution of NbC in laser cladding Ni45 coating. Appl. Surf. Sci. 2018, 455, 160–170. [Google Scholar] [CrossRef]

- Naskar, A.; Chattopadhyay, A.K. Investigation on flank wear mechanism of CVD and PVD gard coating in high speed dry turning of low and high carbon steel. Wear 2018, 396–397, 98–106. [Google Scholar] [CrossRef]

| Cr | C | Si | B | Ni | |

|---|---|---|---|---|---|

| NCR-7 | 19.0 | 0.95 | 4.7 | 3.5 | Bal. |

| C | Si | Mn | P | S | Cr | Cu | Mg | Fe |

|---|---|---|---|---|---|---|---|---|

| 3.50 | 2.78 | 0.32 | 0.01 | 0.015 | 0.21 | 0.60 | 0.03 | Bal. |

| PTA cladding | Powder flux | 2400 g/h |

| Plasma gas (Ar) | 4 L/min | |

| Powder delivery gas (Ar) | 3 L/min | |

| Shielding gas (Ar) | 24 L/min | |

| Overlay current | 100–140 A | |

| Overlay voltage | 32 V | |

| Travel speed | 80 mm/min | |

| Nozzle vibration | 70 times/min | |

| Cut testing | Cutting speed | 200 m/min |

| Feed rate | 0.01 mm/rev | |

| Cutting depth | 0.5 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, K.-J.; Lin, H.-M. Effects of Niobium Carbide Additions on Ni-Based Superalloys: A Study on Microstructures and Cutting-Wear Characteristics through Plasma-Transferred-Arc-Assisted Deposition. Coatings 2024, 14, 167. https://doi.org/10.3390/coatings14020167

Chen K-J, Lin H-M. Effects of Niobium Carbide Additions on Ni-Based Superalloys: A Study on Microstructures and Cutting-Wear Characteristics through Plasma-Transferred-Arc-Assisted Deposition. Coatings. 2024; 14(2):167. https://doi.org/10.3390/coatings14020167

Chicago/Turabian StyleChen, Kuan-Jen, and Hung-Mao Lin. 2024. "Effects of Niobium Carbide Additions on Ni-Based Superalloys: A Study on Microstructures and Cutting-Wear Characteristics through Plasma-Transferred-Arc-Assisted Deposition" Coatings 14, no. 2: 167. https://doi.org/10.3390/coatings14020167