Post-Wear Surface Morphology Assessment of Selective Laser Melting (SLM) AlSi10Mg Specimens after Heat Exposure to Different Gas Flames

Abstract

:1. Introduction

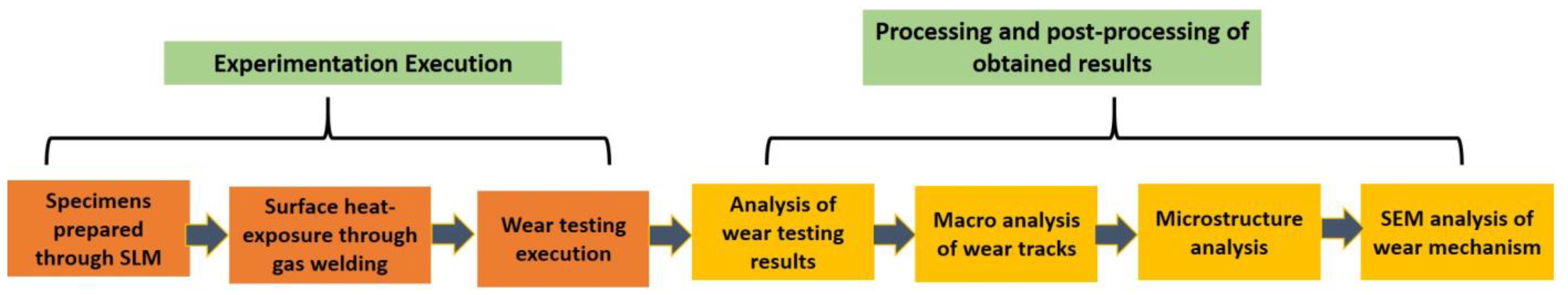

2. Experimental and Methodology

2.1. Fabrication of AlSi10Mg Specimens through SLM

2.2. Execution of Surface Heat Exposure from Gas Flames

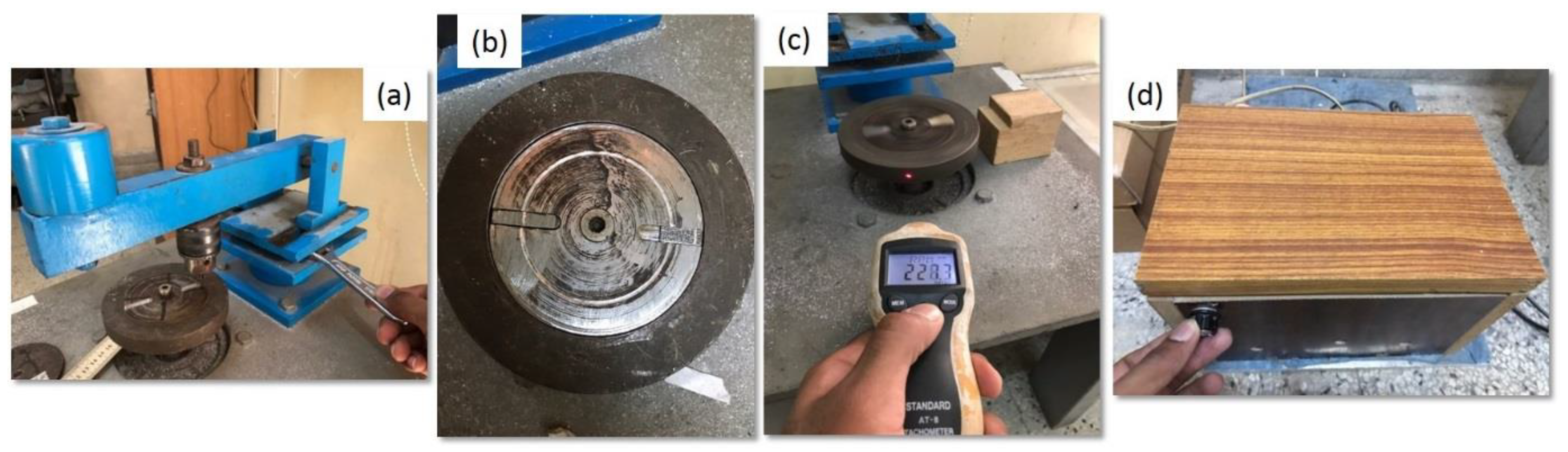

2.3. Wear Testing Execution

3. Results and Discussion

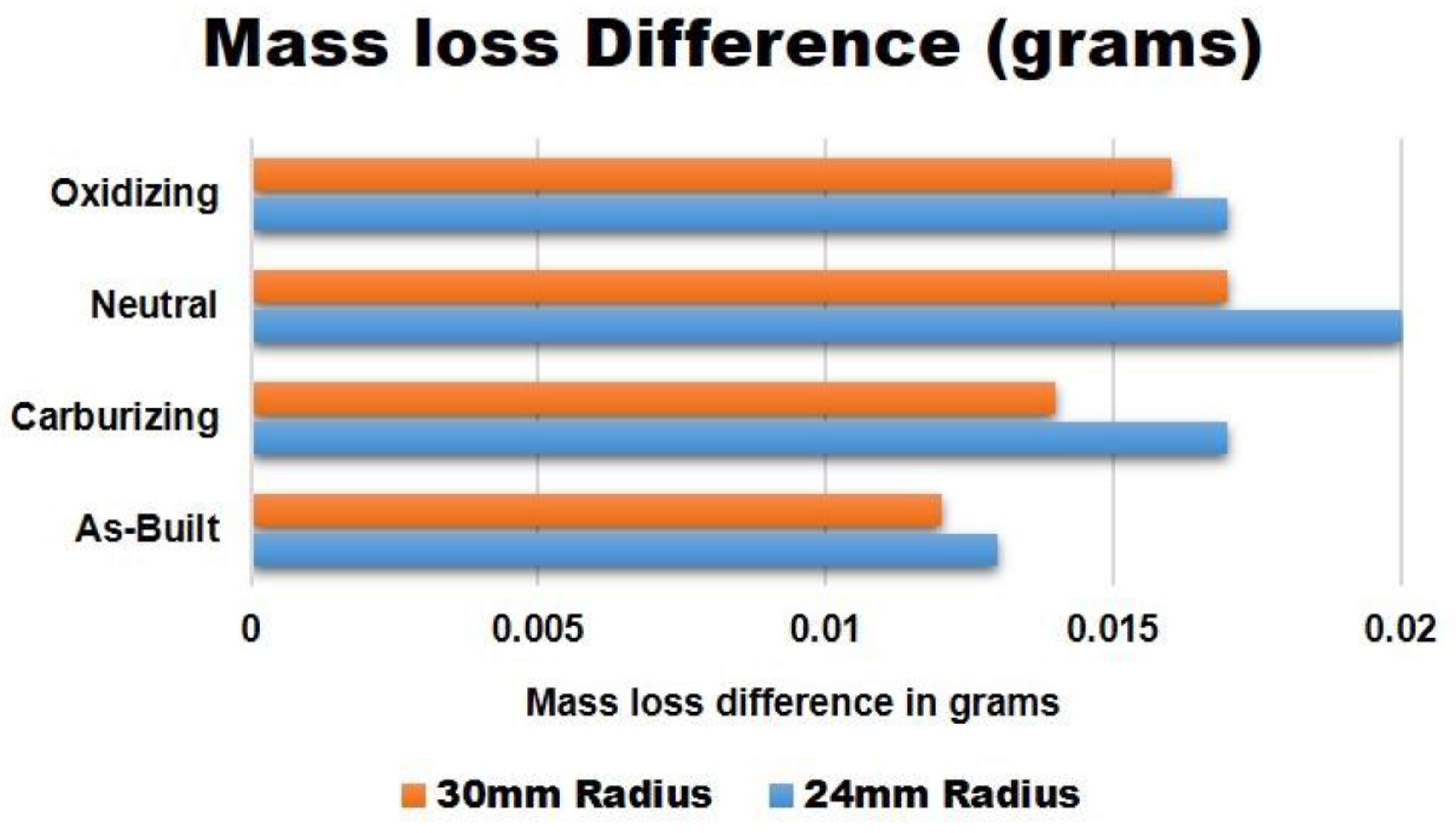

3.1. Mass Loss Analysis after Wear Testing

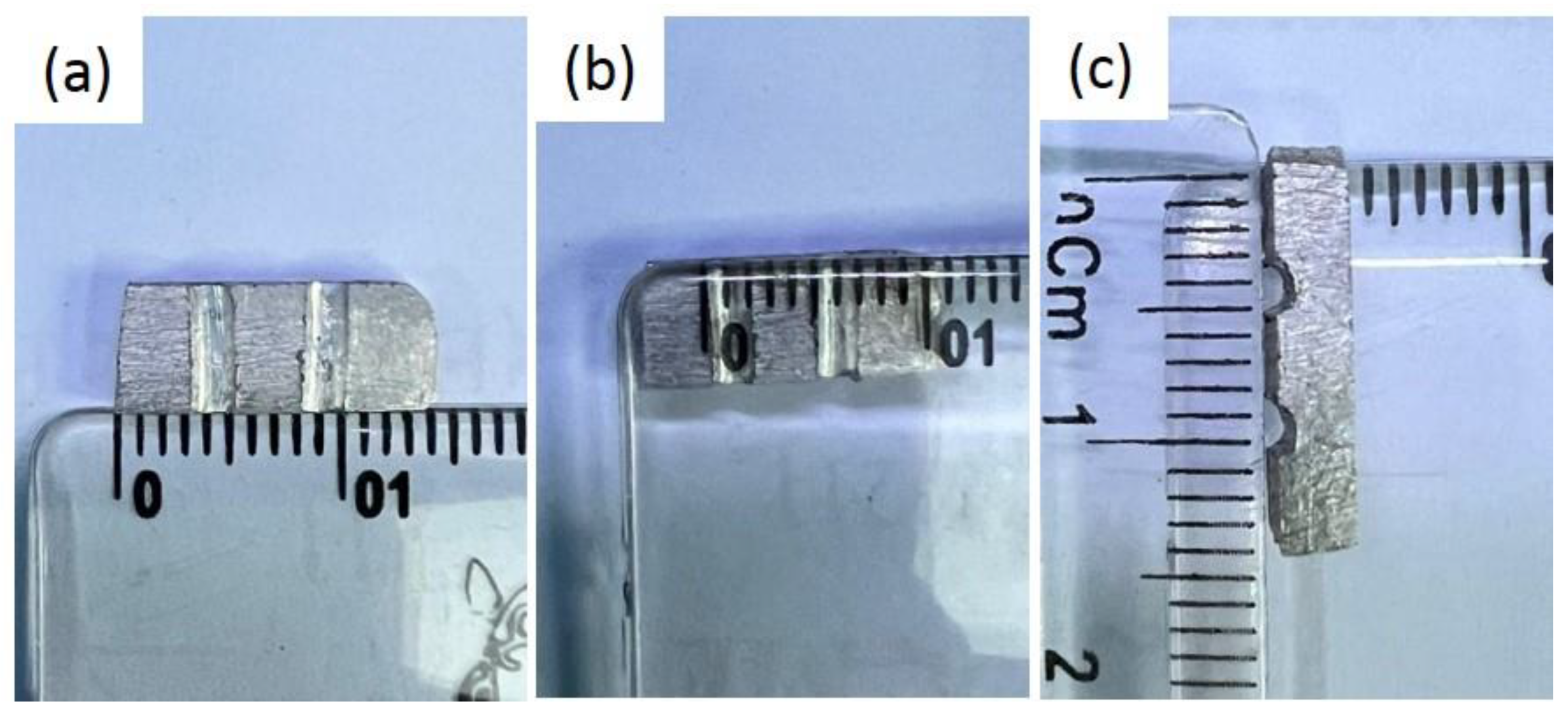

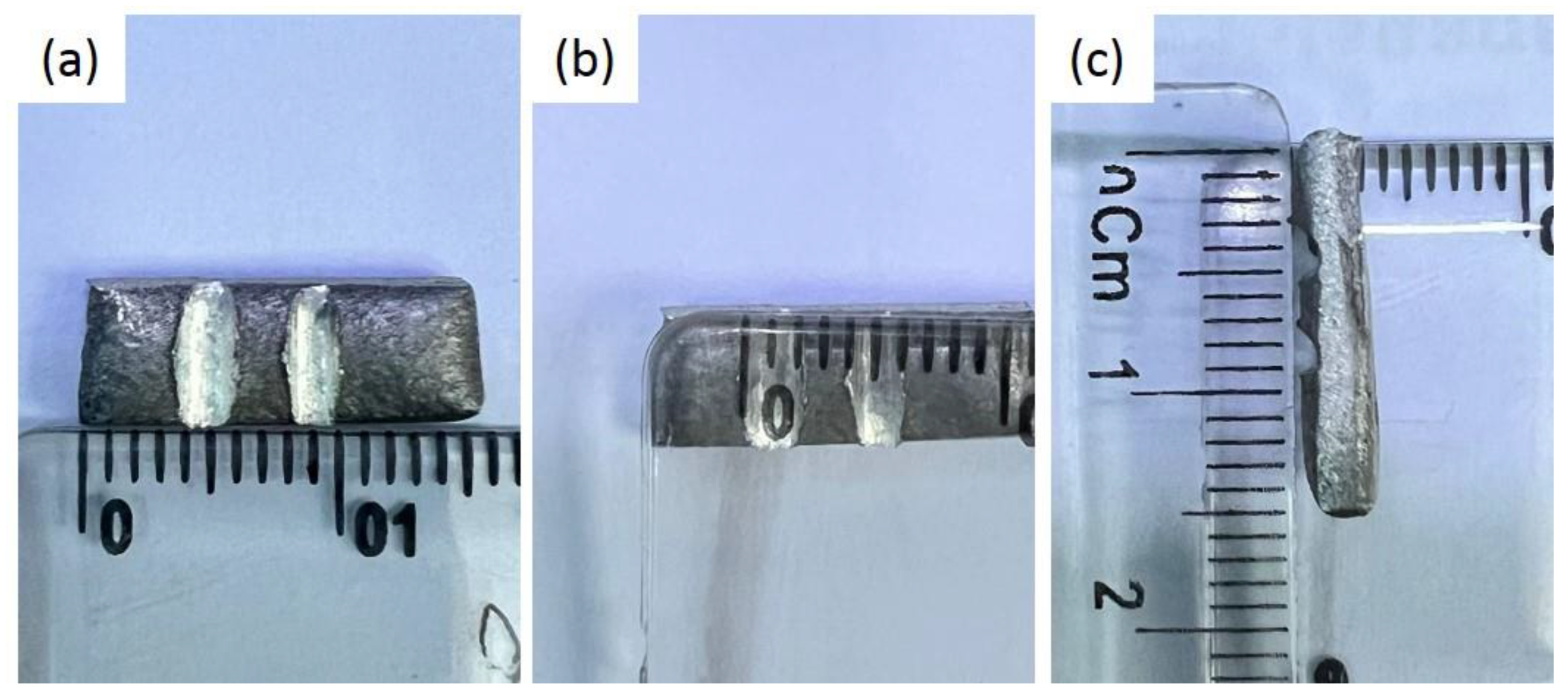

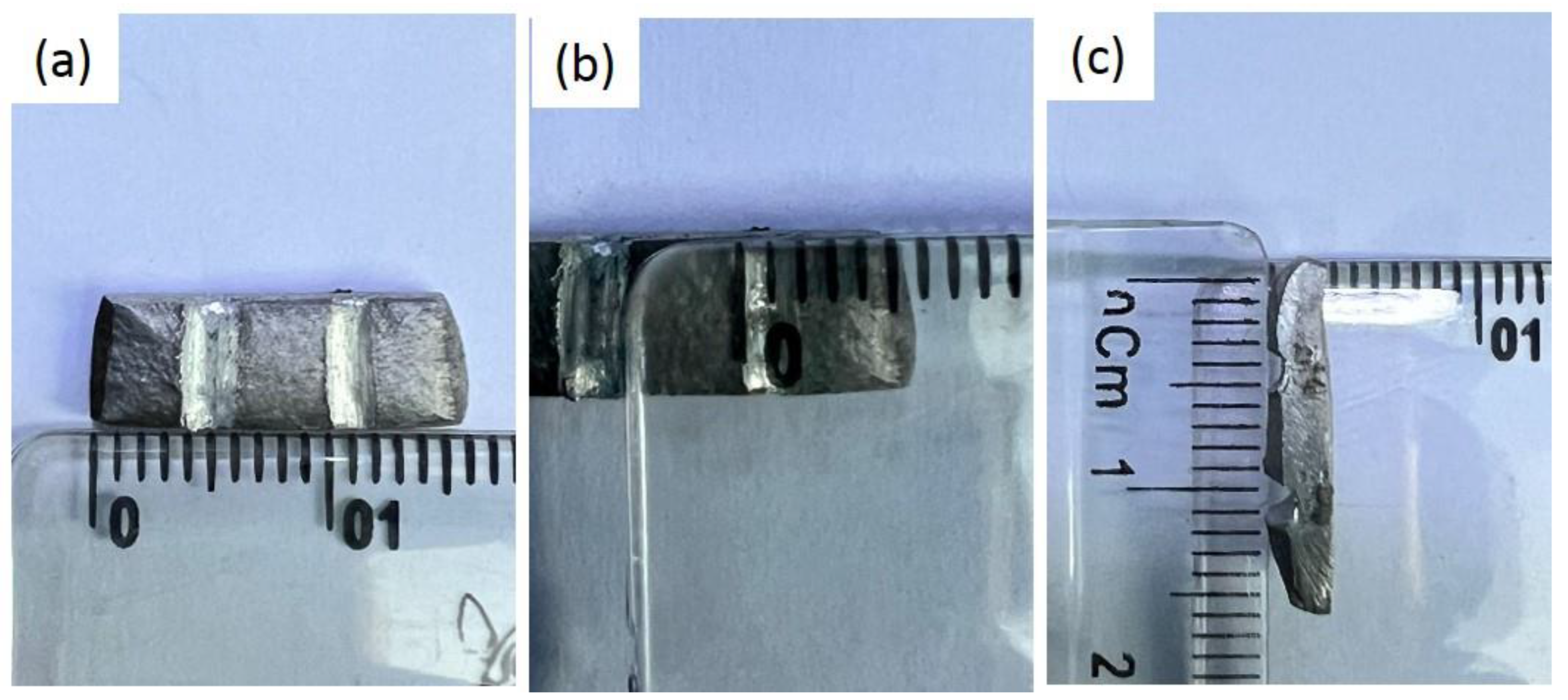

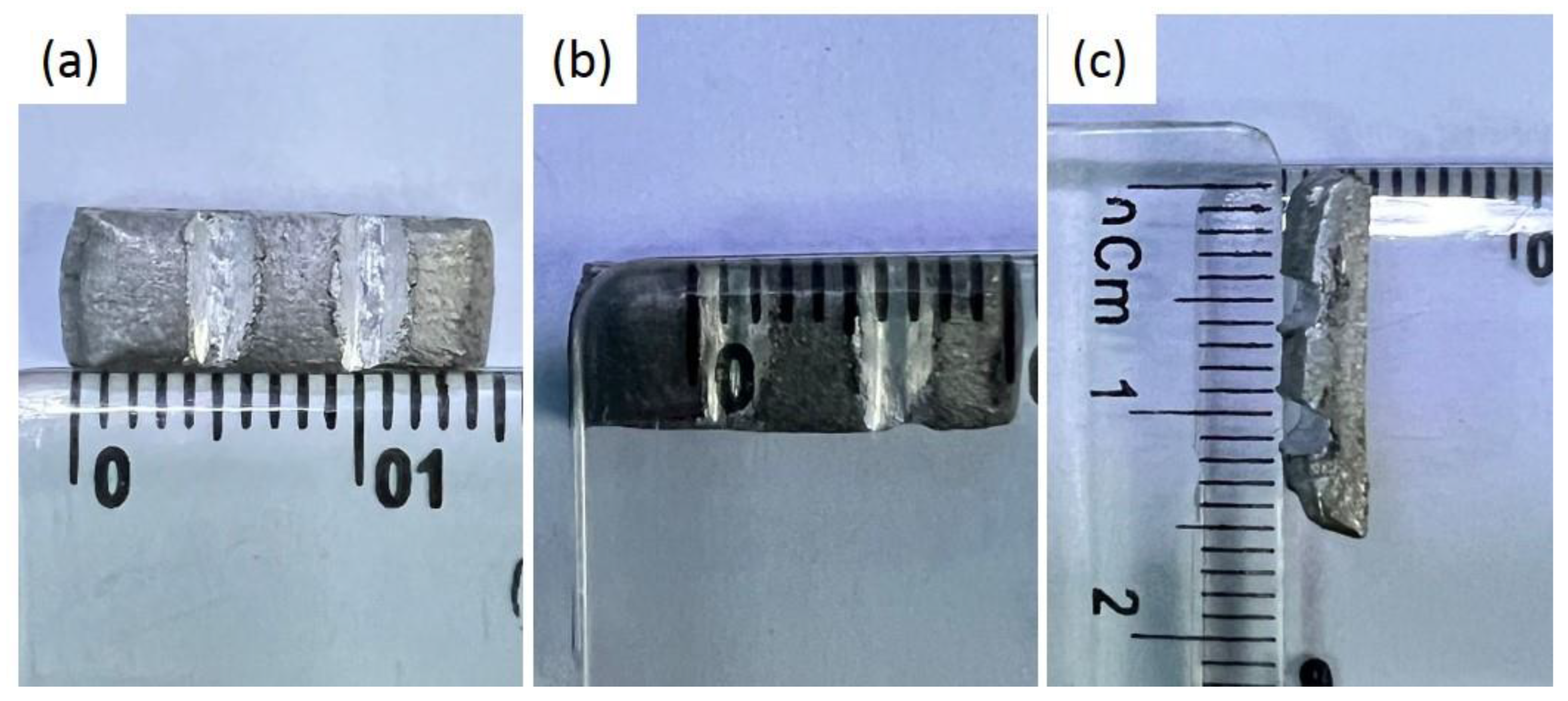

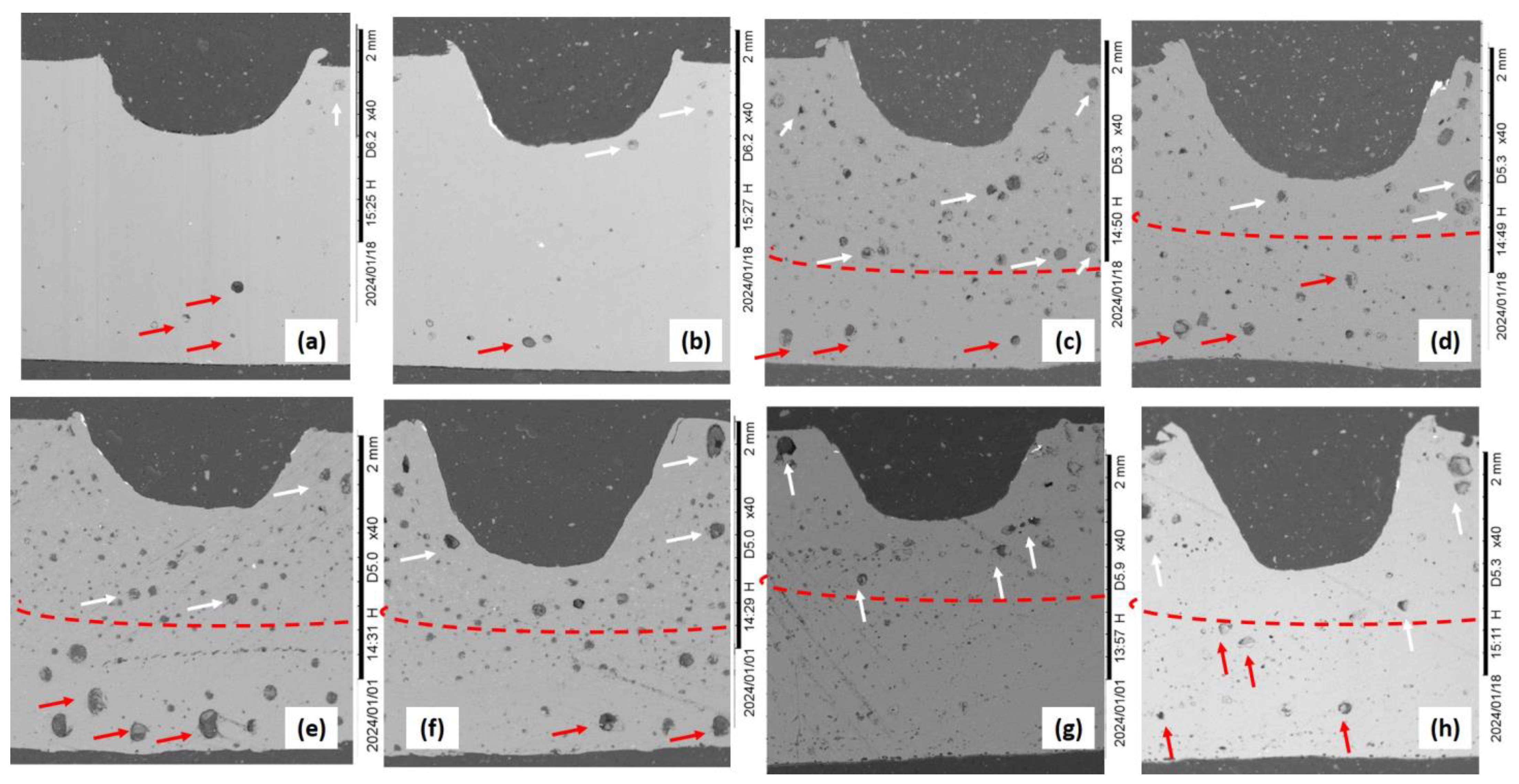

3.2. Macro Analysis of Wear-Track Images and Cross-Sections

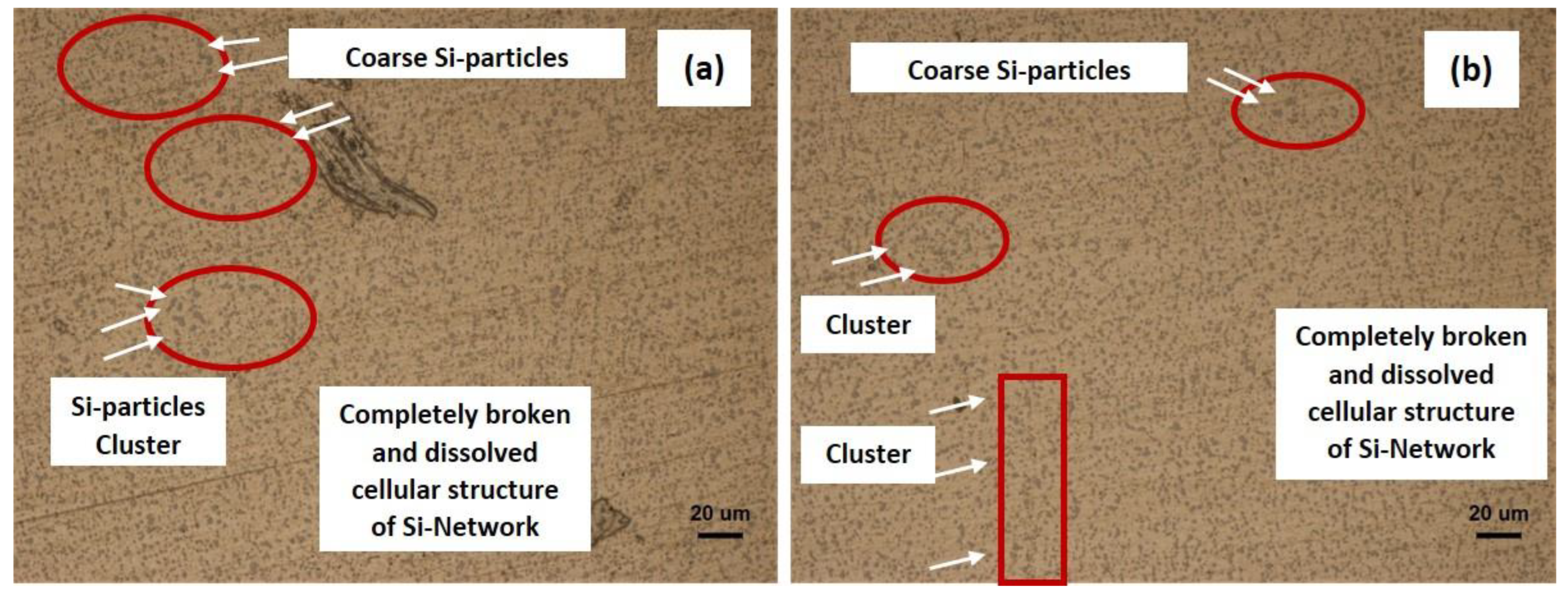

3.3. Microstructure and EDX Analysis of Heat-Exposure Specimens

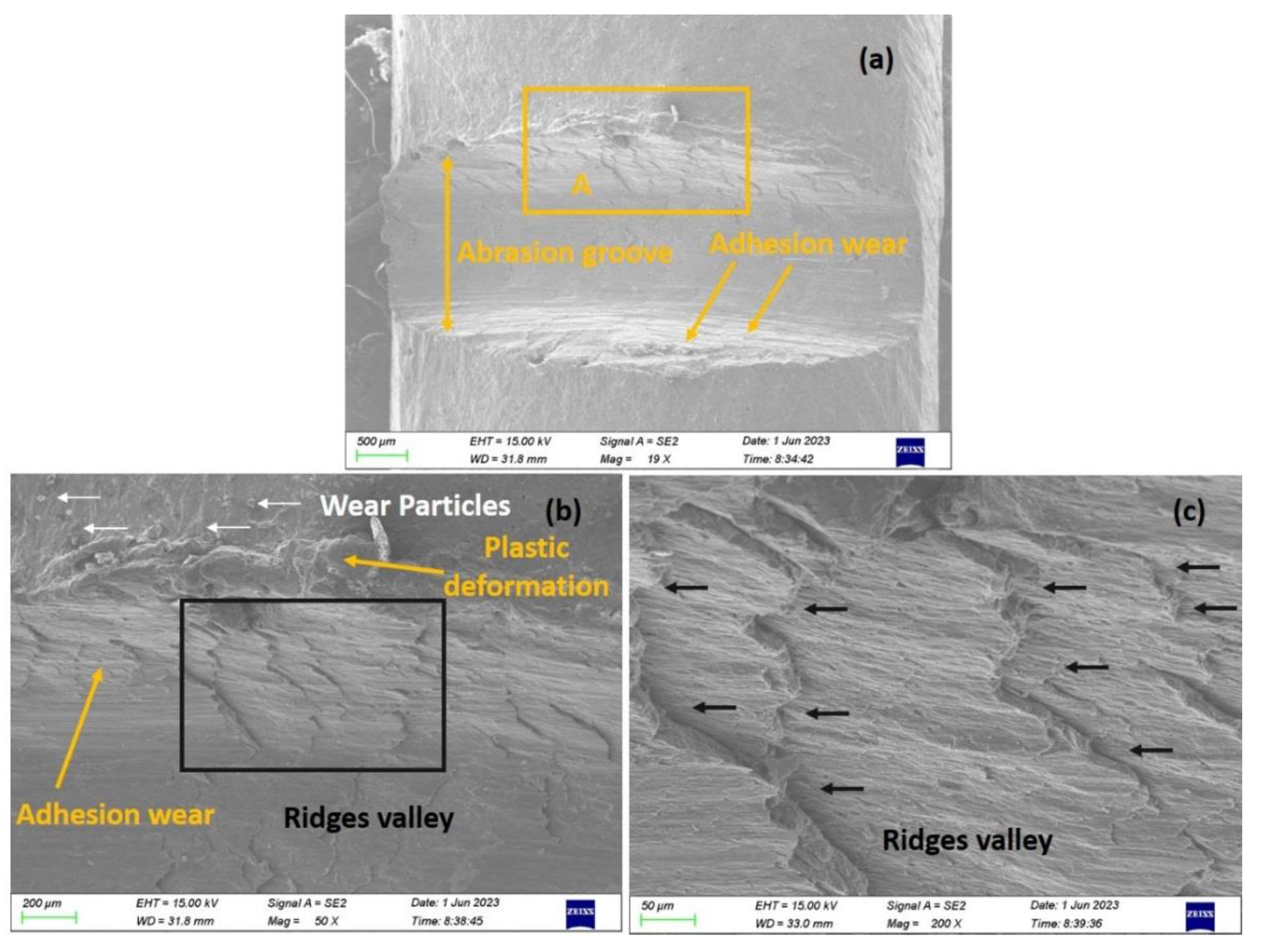

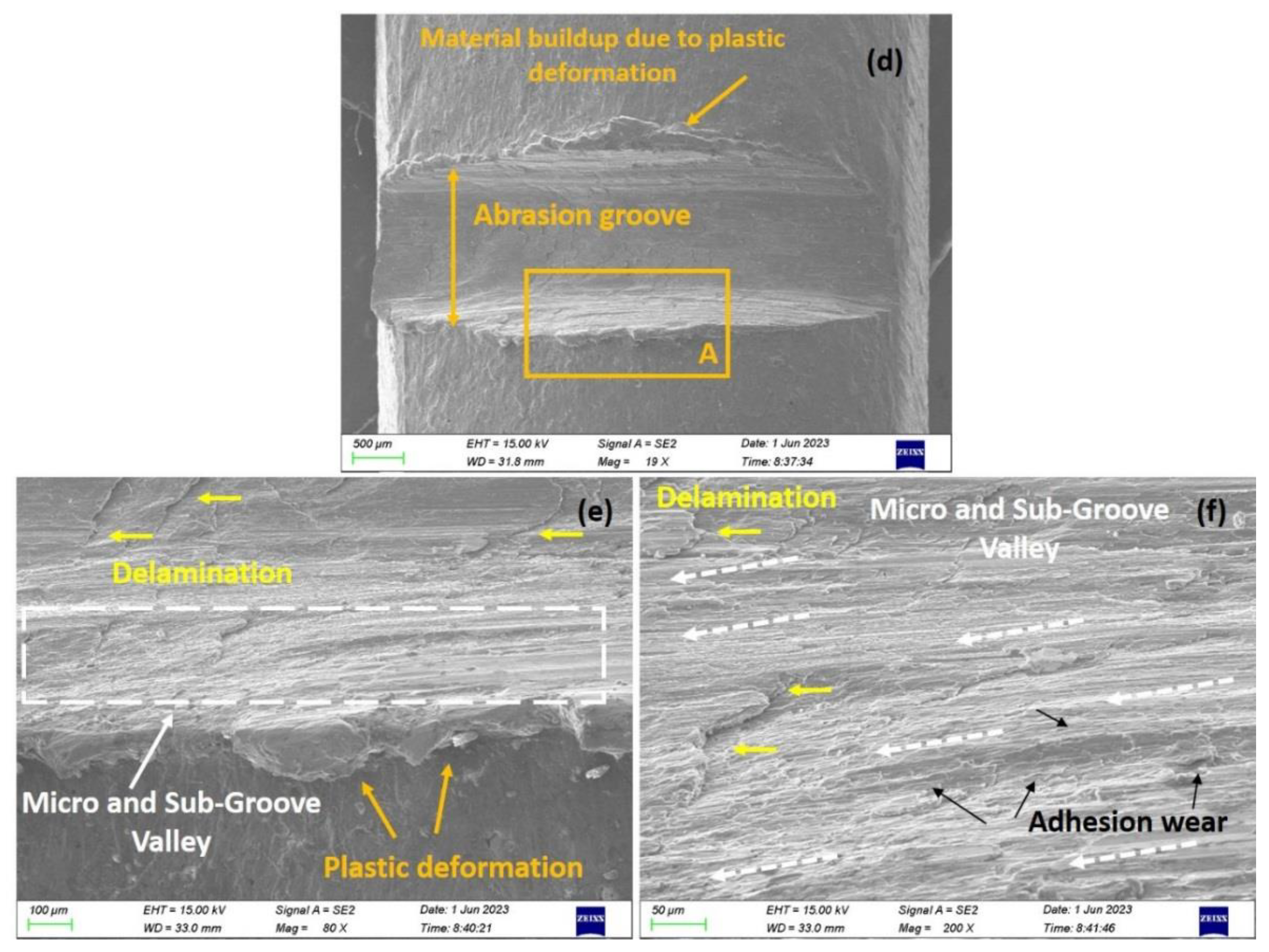

3.4. SEM Analysis of the Worn Surfaces after Heat-Exposure

4. Conclusions

- The wear testing of the as-built SLM specimen exhibits the lowest mass loss of all of the surface exposure specimens through different flames. Moreover, the smallest block of mass loss also belongs to the as-built SLM condition with almost identical values at 24 mm and 30 mm radii, respectively.

- The wear behavior of SLM AlSi10Mg specimens exhibits nuanced responses to distinct heat exposures. Notably, the neutral flame produces the highest mass losses at both the 24 mm and 30 mm radii. However, carburizing and oxidizing flames yield lower mass losses in contrast to the neutral flame but higher values than the as-built condition specimens. These findings underscore the influence of heat exposure on wear characteristics, offering insights for tailored applications.

- By comparing the macro morphology of the developed wear tracks; the width of the built-in SLM specimens is sharp and consistent throughout the length though an elliptical impression; which is more widened at the center for the cases of heat exposure specimens. Even, the signs of extreme deformation with a bit more deeper and larger in width tracks for all of the flames, including carburizing, neutral, and oxidizing, are available along with badly affected dimensional stability.

- The observed wear pattern for all types of flames indicated that adhesive wear is the prevalent wear mechanism for both the wear tracks. A large amount of adhered amount exhibited on both sideways due to plastic deformation along with the ridges valley and micro-groove valley at 24 mm and 30 mm radii for carburizing flame are the highlighted features. However, severe ploughing, macro ridges, ploughing of grains, and delamination are the wear mechanism features of the neutral flame. SEM analysis revealed extended sideways carrying rough patches of macro linear groove in the direction of sliding for the oxidizing flame.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Duran, M.M.; Moro, G.; Zhang, Y.; Islam, A. 3D printing of silicone and polyurethane elastomers for medical device application: A review. Adv. Ind. Manuf. Eng. 2023, 7, 100125. [Google Scholar] [CrossRef]

- Pramanik, J.; Brahma, B.; Pradhan, S.; Senapati, M.R.; Samal, A.K.; Pani, S.K. 3D printing application in biomedical—A review. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Ajibola, O.O.; Adebayo, A.O.; Borisade, S.G.; Owa, A.F.; Ige, O.O. Characterisation and tribological behaviour of zinc-aluminium (Zn-Al) alloy under dry sliding reciprocating ball on disk tribometer. Mater. Today Proc. 2021, 38, 1140–1146. [Google Scholar] [CrossRef]

- Haque, M.S.; Rokon, S.N.; Kaiser, M.S. Strengthening and softening behavior of non-heat-treatable aluminum alloys subject to deformation and annealing treatment. Mater. Today Proc. 2023, 82, 151–157. [Google Scholar] [CrossRef]

- Wang, L.F.; Sun, J.; Yu, X.L.; Shi, Y.; Zhu, X.G.; Cheng, L.Y.; Liang, H.H.; Yan, B.; Guo, L.J. Enhancement in mechanical properties of selectively laser-melted AlSi10Mg aluminum alloys by T6-like heat treatment. Mater. Sci. Eng. A 2018, 734, 299–310. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, R.; Liu, Y.; Zhang, L. Understanding melt pool characteristics in laser powder bed fusion: An overview of single-and multi-track melt pools for process optimization. Adv. Powder Mater. 2023, 2, 100137. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Attallah, M.M. Selective laser melting of AlSi10Mg alloy: Process optimisation and mechanical properties development. Mater. Des. (1980–2015) 2015, 65, 417–424. [Google Scholar]

- Dinaharan, I.; Gladston, J.A.K.; Selvam, J.D.R.; Jen, T.C. Influence of particle content and temperature on dry sliding wear behavior of rice husk ash reinforced AA6061 slurry cast aluminum matrix composites. Tribol. Int. 2023, 183, 108406. [Google Scholar] [CrossRef]

- Akram, S.; Babutskyi, A.; Chrysanthou, A.; Montalvão, D.; Whiting, M.J.; Pizurova, N. Improvement of the wear resistance of nickel-aluminium bronze and 2014-T6 aluminium alloy by application of alternating magnetic field treatment. Wear 2021, 480, 203940. [Google Scholar] [CrossRef]

- Bukhari, S.M.A.; Husnain, N.; Siddiqui, F.A.; Anwar, M.T.; Khosa, A.A.; Imran, M.; Qureshi, T.H.; Ahmad, R. Effect of laser surface remelting on Microstructure, mechanical properties and tribological properties of metals and alloys: A review. Opt. Laser Technol. 2023, 165, 109588. [Google Scholar] [CrossRef]

- Li, F.; Zhang, T.; Chen, C.; Liu, X.; Zhou, K. Constructing an ultrahard layer on the surface of Ti3AlC2 ceramics via electron beam surface remelting. Mater. Lett. 2021, 301, 130315. [Google Scholar] [CrossRef]

- Ciubotariu, C.R.; Frunzăverde, D.; Mărginean, G.; Șerban, V.A.; Bîrdeanu, A.V. Optimization of the laser remelting process for HVOF-sprayed Stellite 6 wear resistant coatings. Opt. Laser Technol. 2016, 77, 98–103. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, W.; Li, X.; Yan, M.; Li, Y. Microstructure and mechanical properties of Ti-6Al-4V prepared by nickel preplating and electron beam surface remelting. J. Mater. Process. Technol. 2019, 271, 420–428. [Google Scholar] [CrossRef]

- Li, Y.; Song, P.; Wang, W.; Lei, M.; Li, X. Microstructure and wear resistance of a Ni-WC composite coating on titanium grade 2 obtained by electroplating and electron beam remelting. Mater. Charact. 2020, 170, 110674. [Google Scholar] [CrossRef]

- Chari, V.S.; Jhavar, S. Surface properties modification of SS316L using plasma beam remelting (PBR) and its applications in additive manufacturing. Trans. Indian Natl. Acad. Eng. 2021, 6, 1017–1025. [Google Scholar] [CrossRef]

- Pan, W.X.; Meng, X.; Li, G.; Fei, Q.X.; Wu, C.K. Feasibility of laminar plasma-jet hardening of cast iron surface. Surf. Coat. Technol. 2005, 197, 345–350. [Google Scholar] [CrossRef]

- Clark, D.A.; Johnson, W.S. Temperature effects on fatigue performance of cold expanded holes in 7050-T7451 aluminum alloy. Int. J. Fatigue 2003, 25, 159–165. [Google Scholar] [CrossRef]

- Lacarac, V.D.; Smith, D.J.; Pavier, M.J. The effect of cold expansion on fatigue crack growth from open holes at room and high temperature. Int. J. Fatigue 2001, 23, 161–170. [Google Scholar] [CrossRef]

- Jabra, J.; Romios, M.; Lai, J.; Lee, E.; Setiawan, M.; Ogren, J.R.; Clark, R.; Oppenheim, T.; Es-Said, O.S.; Lee, E.W.; et al. The effect of thermal exposure on the mechanical properties of 2099-T6 die forgings, 2099-T83 extrusions, 7075-T7651 plate, 7085-T7452 die forgings, 7085-T7651 plate, and 2397-T87 plate aluminum alloys. J. Mater. Eng. Perform. 2006, 15, 601–607. [Google Scholar] [CrossRef]

- Ceschini, L.; Morri, A.; Morri, A.; Rotundo, F.; Toschi, S. Heat treatment response and influence of overaging on mechanical properties of C355 cast aluminum alloy. Metall. Ital. 2014, 5, 11–17. [Google Scholar]

- Zhou, L.; Mehta, A.; Schulz, E.; McWilliams, B.; Cho, K.; Sohn, Y. Microstructure, precipitates and hardness of selective-ly laser melted AlSi10Mg alloy before and after heat treatment. Mater. Charact. 2018, 143, 5–17. [Google Scholar] [CrossRef]

- Alghamdi, F.; Song, X.; Hadadzadeh, A.; Shalchi-Amirkhiz, B.; Mohammadi, M.; Haghshenas, M. Post heat treatment of additive manufactured AlSi10Mg: On silicon morphology, texture and small-scale properties. Mater. Sci. Eng. A 2020, 783, 139296. [Google Scholar] [CrossRef]

- Tonolini, P.; Montesano, L.; Tocci, M.; Pola, A.; Gelfi, M. Wear behavior of AlSi10Mg alloy produced by laser-based powder bed fusion and gravity casting. Adv. Eng. Mater. 2021, 23, 2100147. [Google Scholar] [CrossRef]

- Park, T.H.; Baek, M.S.; Sohn, Y.; Lee, K.A. Effect of post-heat treatment on the wear properties of AlSi10Mg alloy manufactured by selective laser melting. Arch. Metall. Mater. 2020, 65, 1073–1080. [Google Scholar] [CrossRef]

- Zhang, Y.; Majeed, A.; Muzamil, M.; Lv, J.; Peng, T.; Patel, V. Investigation for macro mechanical behavior explicitly for thin-walled parts of AlSi10Mg alloy using selective laser melting technique. J. Manuf. Process. 2021, 66, 269–280. [Google Scholar] [CrossRef]

- Majeed, A.; Muzamil, M.; Lv, J.; Liu, B.; Ahmad, F. Heat treatment influences densification and porosity of AlSi10Mg alloy thin-walled parts manufactured by selective laser melting technique. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 267. [Google Scholar] [CrossRef]

- Majeed, A.; Muzamil, M.; Khan, M.A.; Malik, E.H.; Huzaifa, M.; Lv, J.; Dar, N.U. Comprehensive Mechanical Behavior of Thin-Walled Additively-Manufactured Parts of AlSi10Mg by SLM in As-Built, Post-Solution, and Aging Treatment Conditions. JOM 2023, 75, 3067–3082. [Google Scholar] [CrossRef]

- ASTM G99-05; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2006; Volume 5, pp. 1–6.

- Hammond, V.; Schuch, M.; Bleckmann, M. The influence of a process interruption on tensile properties of AlSi10Mg samples produced by selective laser melting. Rapid Prototyp. J. 2019, 25, 1442–1452. [Google Scholar] [CrossRef]

- Maconachie, T.; Leary, M.; Zhang, J.; Medvedev, A.; Sarker, A.; Ruan, D.; Lu, G.; Faruque, O.; Brandt, M. Effect of build orientation on the quasi-static and dynamic response of SLM AlSi10Mg. Mater. Sci. Eng. A 2020, 788, 139445. [Google Scholar] [CrossRef]

- Galy, C.; Le Guen, E.; Lacoste, E.; Arvieu, C. Main defects observed in aluminum alloy parts produced by SLM: From causes to consequences. Addit. Manuf. 2018, 22, 165–175. [Google Scholar] [CrossRef]

- Tabatabaei, N.; Zarei-Hanzaki, A.; Moshiri, A.; Abedi, H.R. The effect of heat treatment on the room and high temperature mechanical properties of AlSi10Mg alloy fabricated by selective laser melting. J. Mater. Res. Technol. 2023, 23, 6039–6053. [Google Scholar] [CrossRef]

- Strauß, L.; Lübbecke, S.; Löwisch, G. Optimizing the Solution Annealing of Additively Manufactured AlSi10Mg. HTM J. Heat Treat. Mater. 2023, 78, 300–316. [Google Scholar] [CrossRef]

- Li, W.; Li, S.; Liu, J.; Zhang, A.; Zhou, Y.; Wei, Q.; Yan, C.; Shi, Y. Effect of heat treatment on AlSi10Mg alloy fabricated by selective laser melting: Microstructure evolution, mechanical properties and fracture mechanism. Mater. Sci. Eng. A 2016, 663, 116–125. [Google Scholar] [CrossRef]

- Wei, P.; Wei, Z.Y.; Chen, Z.; Du, J.; He, Y.Y.; Li, J.F.; Zhou, Y.T. The AlSi10Mg samples produced by selective laser melting: Single track, densification, microstructure and mechanical behavior. Appl. Surf. Sci. 2017, 408, 38–50. [Google Scholar] [CrossRef]

- Fousová, M.; Dvorský, D.; Michalcová, A.; Vojtěch, D. Changes in the microstructure and mechanical properties of additively manufactured AlSi10Mg alloy after exposure to elevated temperatures. Mater. Charact. 2018, 137, 119–126. [Google Scholar] [CrossRef]

- Wei, P.; Chen, Z.; Zhang, S.; Fang, X.; Lu, B.; Zhang, L.; Wei, Z. Effect of T6 heat treatment on the surface tribological and corrosion properties of AlSi10Mg samples produced by selective laser melting. Mater. Charact. 2021, 171, 110769. [Google Scholar] [CrossRef]

- Kempf, A.; Hilgenberg, K. Influence of heat treatments on AlSi10Mg specimens manufactured with different laser powder bed fusion machines. Mater. Sci. Eng. A 2021, 818, 141371. [Google Scholar] [CrossRef]

- McConnell, J.E.; Segall, A.E.; Eden, T.J. The Dry Sliding Behavior of Al2O3 Transformed, Hypereutectic, 2xxx, and 7xxx, Aluminum Alloys Under Simulated Wire–Rope Induced Wear. Tribol. Trans. 2006, 49, 563–573. [Google Scholar] [CrossRef]

- D’Amato, C.; Buhagiar, J.; Betts, J.C. Tribological characteristics of an A356 aluminium alloy laser surface alloyed with nickel and Ni–Ti–C. Appl. Surf. Sci. 2014, 313, 720–729. [Google Scholar] [CrossRef]

- Rajamure, R.S.; Vora, H.D.; Gupta, N.; Karewar, S.; Srinivasan, S.G.; Dahotre, N.B. Laser surface alloying of molybdenum on aluminum for enhanced wear resistance. Surf. Coat. Technol. 2014, 258, 337–342. [Google Scholar] [CrossRef]

- Zhang, Y.; Lei, G.; Luo, K.; Chen, P.; Kong, C.; Yu, H. Tribological behavior of high-entropy alloy particle reinforced aluminum matrix composites and their key impacting factors. Tribol. Int. 2022, 175, 107868. [Google Scholar] [CrossRef]

| Technical/Processing Parameters | Values/Description |

|---|---|

| Laser power (kW) | 0.32 |

| Scan Speed (m/s) | 0.90 |

| Hatch distance (mm) | 0.08 |

| Slice thickness (mm) | 0.03 |

| Beam focus diameter (mm) | 0.08 |

| Scanning strategy | 67° with checkerboard |

| Building direction | Vertical |

| Building substrate plate | 280.0 mm × 280.0 mm × 70.0 mm (L × W × H) |

| Wear Testing Radius | Specimen | Mass before Wear Testing (g) | Mass after Wear Testing (g) | Mass Difference (g) | Percentage of Mass Loss (%) |

|---|---|---|---|---|---|

| Wear Testing at R = 24 mm | As-Built | 0.498 | 0.485 | 0.013 | 2.610 |

| Carburizing | 0.470 | 0.453 | 0.017 | 3.617 | |

| Neutral | 0.470 | 0.450 | 0.020 | 4.255 | |

| Oxidizing | 0.474 | 0.457 | 0.017 | 3.586 | |

| Wear Testing at R = 30 mm | As-Built | 0.485 | 0.473 | 0.012 | 2.474 |

| Carburizing | 0.453 | 0.439 | 0.014 | 3.090 | |

| Neutral | 0.453 | 0.436 | 0.017 | 3.752 | |

| Oxidizing | 0.457 | 0.441 | 0.016 | 3.501 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akhtar, M.; Muzamil, M.; Samiuddin, M.; Alsaleh, N.; Khan, R.; Khan, M.A.; Djuansjah, J.; Siddiqui, A.K.; Majeed, A. Post-Wear Surface Morphology Assessment of Selective Laser Melting (SLM) AlSi10Mg Specimens after Heat Exposure to Different Gas Flames. Coatings 2024, 14, 252. https://doi.org/10.3390/coatings14030252

Akhtar M, Muzamil M, Samiuddin M, Alsaleh N, Khan R, Khan MA, Djuansjah J, Siddiqui AK, Majeed A. Post-Wear Surface Morphology Assessment of Selective Laser Melting (SLM) AlSi10Mg Specimens after Heat Exposure to Different Gas Flames. Coatings. 2024; 14(3):252. https://doi.org/10.3390/coatings14030252

Chicago/Turabian StyleAkhtar, Maaz, Muhammad Muzamil, Muhammad Samiuddin, Naser Alsaleh, Rashid Khan, Mahad Ali Khan, Joy Djuansjah, Ali Khursheed Siddiqui, and Arfan Majeed. 2024. "Post-Wear Surface Morphology Assessment of Selective Laser Melting (SLM) AlSi10Mg Specimens after Heat Exposure to Different Gas Flames" Coatings 14, no. 3: 252. https://doi.org/10.3390/coatings14030252

APA StyleAkhtar, M., Muzamil, M., Samiuddin, M., Alsaleh, N., Khan, R., Khan, M. A., Djuansjah, J., Siddiqui, A. K., & Majeed, A. (2024). Post-Wear Surface Morphology Assessment of Selective Laser Melting (SLM) AlSi10Mg Specimens after Heat Exposure to Different Gas Flames. Coatings, 14(3), 252. https://doi.org/10.3390/coatings14030252