Optimization of Milling Process Parameters for Fe45 Laser-Clad Molded Parts Based on the Nondominated Sorting Genetic Algorithm II

Abstract

:1. Introduction

2. Experiment

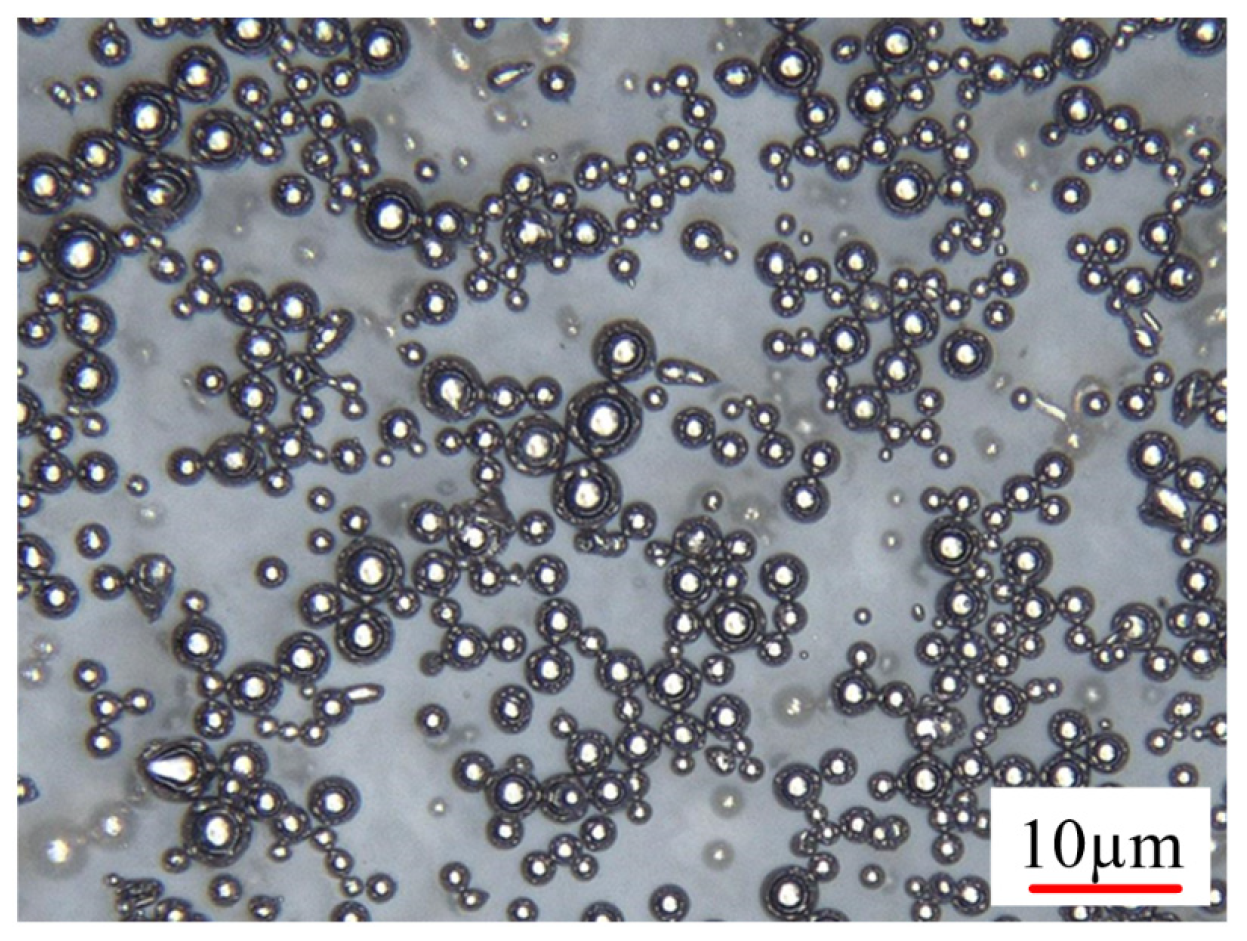

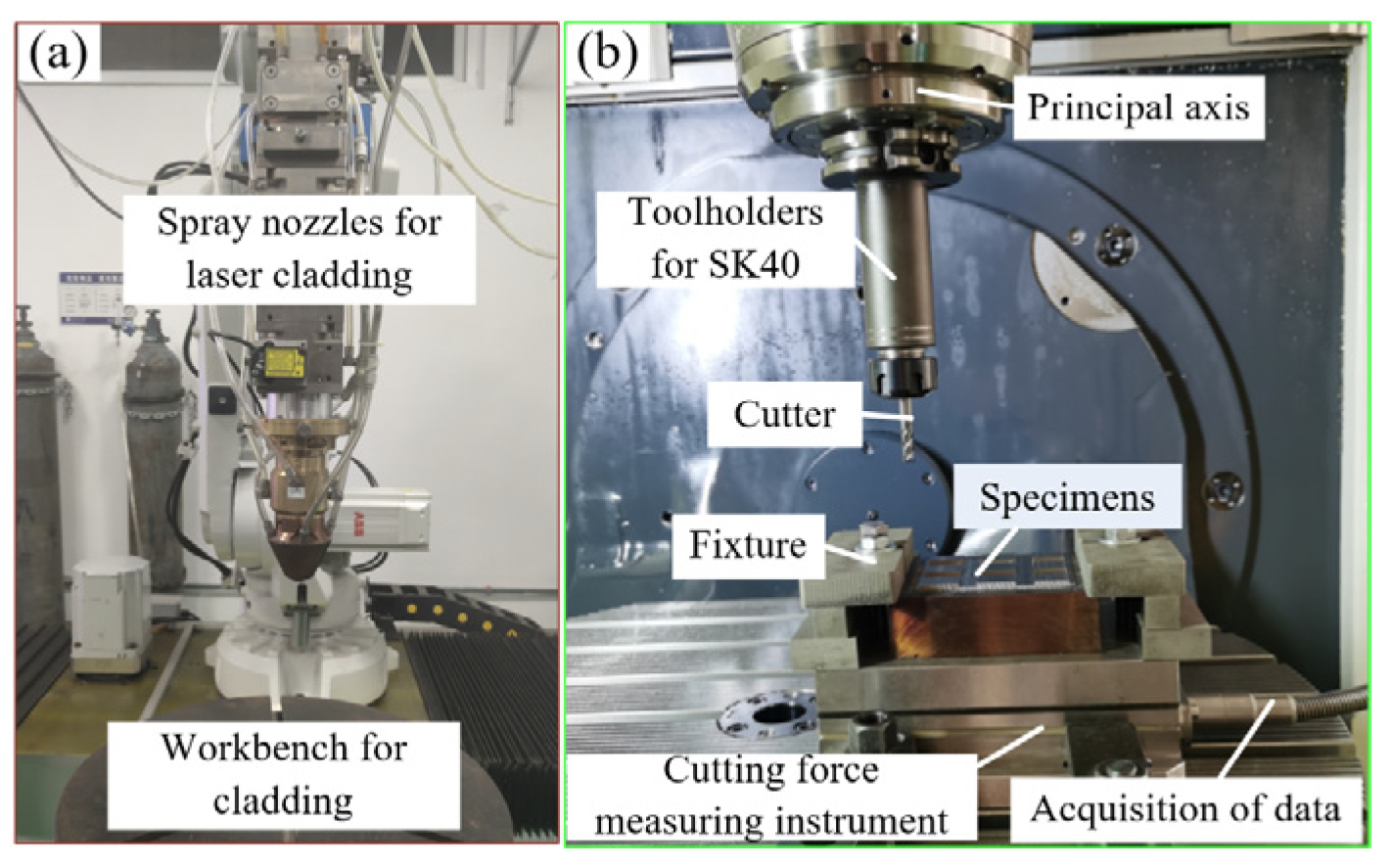

2.1. Materials and Equipment

2.2. Experimental Program

3. Analysis of Results

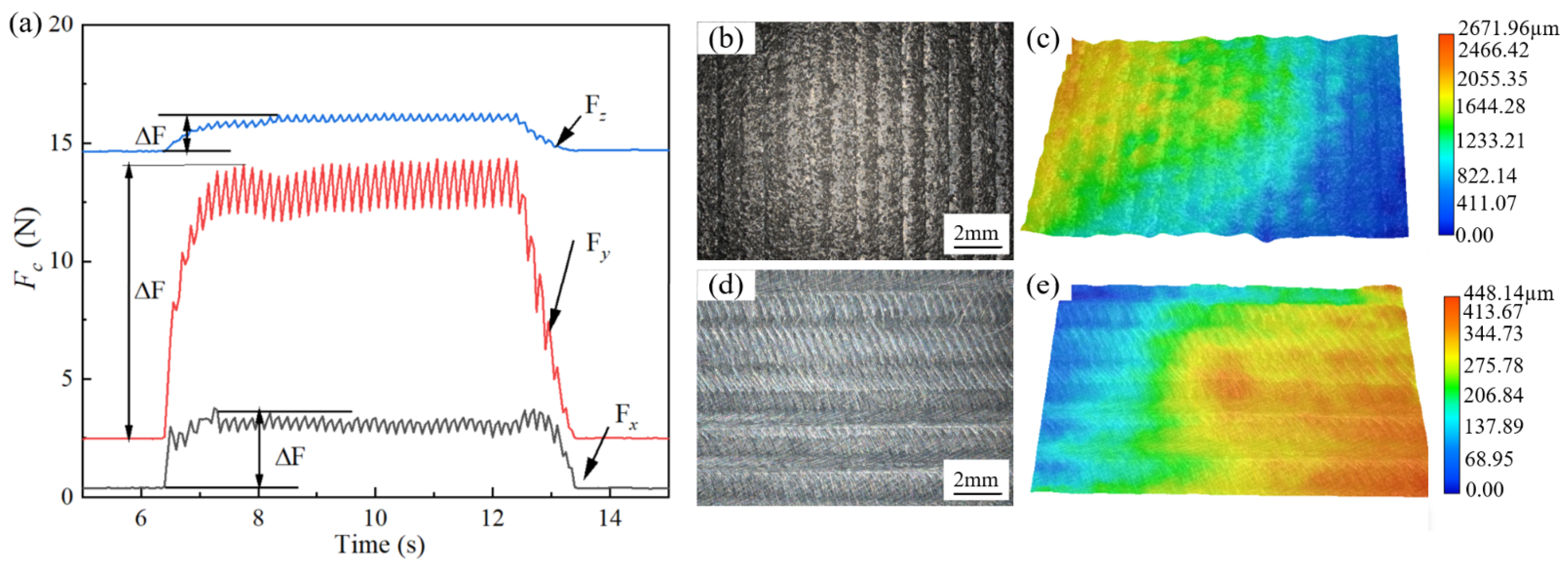

3.1. Experimental Results

3.2. Analysis of Process Significance Ranking

3.3. Model Construction Based on Experience

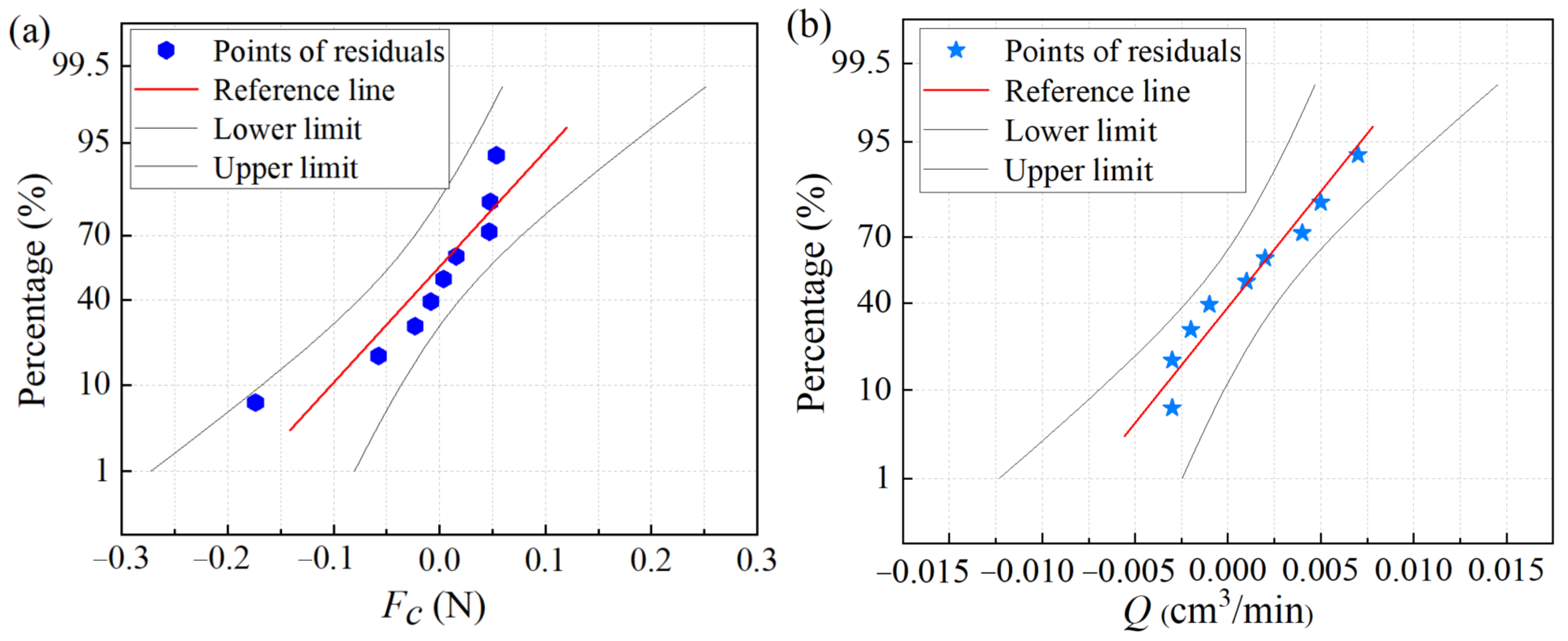

3.4. Significance Test of the Model

4. Optimization of Processes

4.1. Principle of the NSGA-II Algorithm

4.2. Model for Multi-Objective Optimization

- (1)

- Spindle speed:

- (2)

- Feed rate:

- (3)

- Cutting depth:

4.3. Results of the Optimization and Validation

5. Conclusions

- (1)

- The process effects of milling force were significantly ranked as cutting depth > spindle speed > feed rate. For the material removal rate, the significance was ranked as cutting depth > feed rate > spindle speed.

- (2)

- Reliable regression models for the spindle speed, feed rate, and cutting depth with the milling force and material removal rate were developed using empirical exponential models.

- (3)

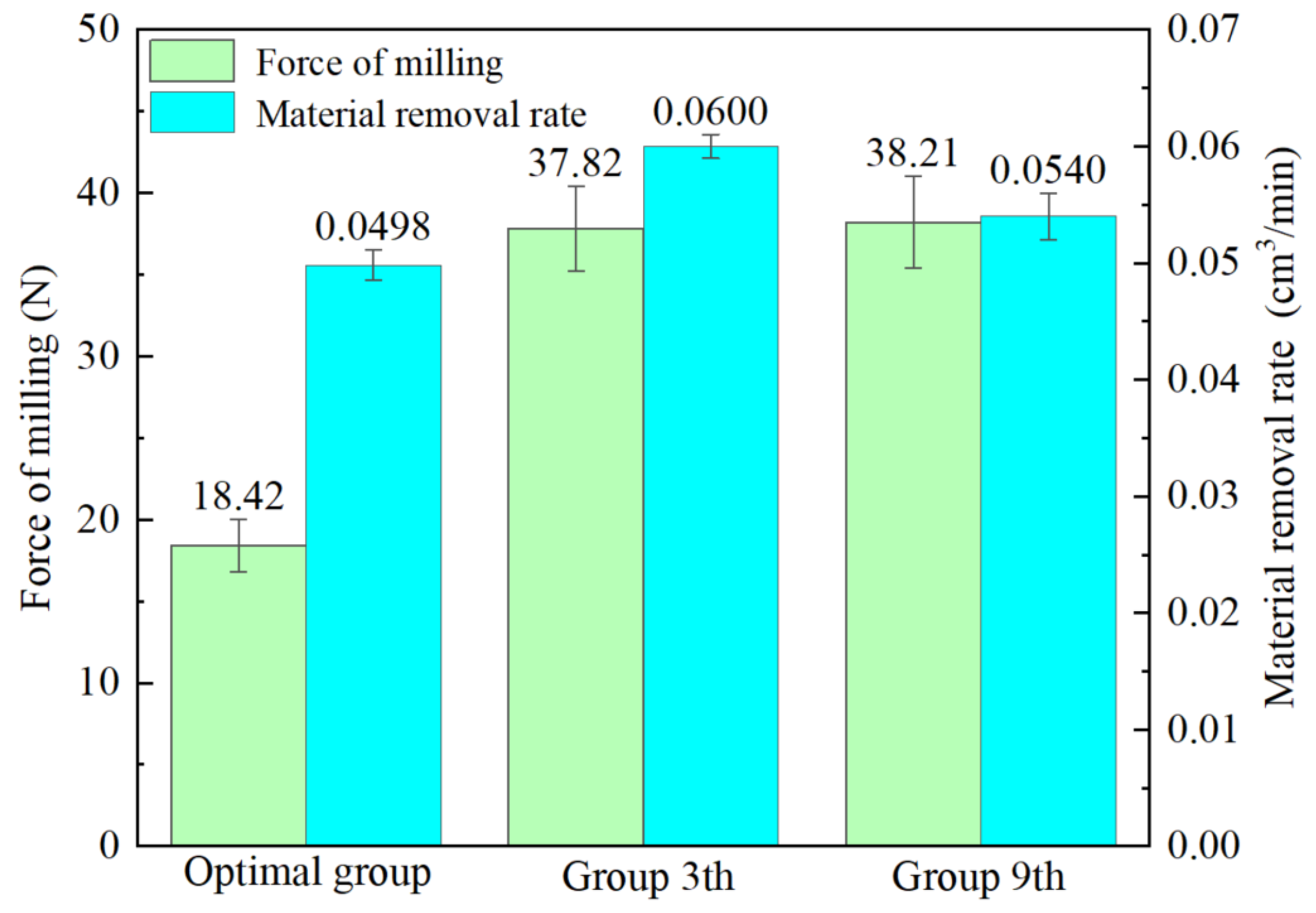

- The NSGA-II algorithm was used to optimize the milling parameters and the optimum process parameters were N = 2000 r/min, V = 120.0266 mm/min, and P = 0.45 mm. The results obtained with the algorithm were found to be better by comparing them with the two sets of results from the extreme variance analysis.

- (4)

- The results of this study can provide some technical support for the control and prediction of the milling process for laser-melted Fe45-forming coatings. Further research should continue to develop efficient hybrid intelligent optimization methods to improve the optimization accuracy in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, X.J.; Liu, M.H.; Li, Z.H.; Yao, B.B.; Wang, B.; Wang, N. Finite element simulation and experimental study of selective laser melted 40Cr steel forming process. Opt. Laser Technol. 2024, 169, 110080. [Google Scholar] [CrossRef]

- Wang, S.H.; Zheng, Z.Y.; Li, T.L.; Du, A.; Ma, R.N.; Fan, Y.Z.; Zhao, X.; Cao, X.M. Microstructure and properties of a YG18/40Cr joint vacuum–brazed by Cu–Sn–Ti filler metal. Vacuum 2023, 217, 112511. [Google Scholar] [CrossRef]

- Chen, B.; Li, X.M.; Tian, L.Y.; Jia, H.Y.; Li, H.; Li, Y. The CrFeNbTiMox refractory high-entropy alloy coatings prepared on the 40Cr by laser cladding. J. Alloys Compd. 2023, 966, 171630. [Google Scholar] [CrossRef]

- Gong, J.T.; Shu, L.S.; Zhang, C.M.; Qin, J.P.; He, W.; Li, A.J. Co-Optimization of the Preparation Process of Ni-Based Self-Lubricating Coatings by Magneto-Thermal-Assisted Laser Cladding. Coatings 2023, 13, 1749. [Google Scholar] [CrossRef]

- Lei, K.Y.; Qin, X.P.; Liu, H.M.; Ni, M. Analysis and modeling of melt pool morphology for high power diode laser cladding with a rectangle beam spot. Opt. Lasers Eng. 2018, 110, 89–99. [Google Scholar] [CrossRef]

- Cui, G.J.; Feng, X.G.; Han, W.P.; Liu, Y.P.; Kou, Z.M. Microstructure and high temperature wear behavior of in-situ synthesized carbides reinforced Mo-based coating by laser cladding. Surf. Coat. Technol. 2023, 467, 129713. [Google Scholar] [CrossRef]

- Weng, Z.K.; Wang, A.H.; Wang, Y.Y.; Xiong, D.H.; Tang, H.G. Diode laser cladding of Fe-based alloy on ductile cast iron and related interfacial behavior. Surf. Coat. Technol. 2016, 286, 64–71. [Google Scholar] [CrossRef]

- Lu, S.S.; Wang, L.Q.; Zhou, J.S.; Liang, J. Microstructure and tribological properties of laser-cladded Co-Ti3SiC2 coating with Ni-based interlayer on copper alloy. Tribol. Int. 2022, 171, 107549. [Google Scholar] [CrossRef]

- Wu, X.Q.; Zhou, G.H.; Sun, D.J.; Chen, L.Y.; He, J.Y.; Wang, S.Q.; Xie, F. Cultivating a comprehensive understanding of microstructural attributes and wear mechanisms in FeCrCoNiAlTix high-entropy alloy coatings on TC6 substrates through laser cladding fabrication. J. Alloys Compd. 2024, 984, 173865. [Google Scholar] [CrossRef]

- Ouyang, C.; Wang, R.; Zhao, C.; Wei, R.; Li, H.; Deng, R.; Bai, Q.; Liu, Y. Multi-layer laser cladding analysis and high-temperature oxidative wear behavior of cast iron with a low expansion coefficient. Surf. Coat. Technol. 2023, 474, 130079. [Google Scholar] [CrossRef]

- Zhu, L.; Xue, P.; Lan, Q.; Meng, G.; Ren, Y.; Yang, Z.; Xu, P.; Liu, Z. Recent research and development status of laser cladding: A review. Opt. Laser Technol. 2021, 138, 106915. [Google Scholar] [CrossRef]

- Wang, R.; Ouyang, C.Y.; Zhao, C.J.; Wei, R.Z.; Deng, R. Effect of high-temperature heat treatment on electrochemical corrosion behavior of laser cladding Fe-based alloy coating in H2SO4 solution. Mater. Lett. 2023, 346, 134560. [Google Scholar] [CrossRef]

- Wei, R.Z.; Ouyang, C.Y.; Wang, R.; Zhao, C.J.; Deng, R.; Li, H. Effect of chromic acid anodization on the corrosion resistance of Fe-based alloy coatings by high-speed laser cladding. Mater. Lett. 2023, 350, 134887. [Google Scholar] [CrossRef]

- Shu, L.S.; Cang, X.Y.; Zhou, J.; Heng, Z.; Wu, H.; He, W. Study on machinability and grain deformation of laser cladding manufactured and wrought IN718 alloys in dry milling process. Mater. Today Commun. 2023, 34, 105066. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, X.; Zhao, W.H. Research on the multi-physical coupling characteristics of the machine tool and milling process based on the systematically integrated model. J. Manuf. Process. 2023, 105, 46–69. [Google Scholar] [CrossRef]

- Wang, X.Q.; Wei, Z.C.; Wang, D.; Zhang, D.B.; Wang, X.Y.; Wang, M.J. A supplementary processing method of residual material in impeller plunge milling. J. Manuf. Process. 2023, 108, 1–11. [Google Scholar] [CrossRef]

- Liu, M.; Duan, C.; Li, G.; Cai, Y.; Wang, F. Friction property and milling machinability of Ni60 cladding layer in hybrid additive-subtractive manufacturing. J. Manuf. Process. 2023, 93, 162–172. [Google Scholar] [CrossRef]

- Wang, T.; Li, Y.; Liu, J.; Qin, L.; Wang, N.; Zhang, L.; Wang, H.; Li, Z. Milling Force and Surface Topography of Ti-6Al-4V Titanium Alloy Cladded by the Laser. Surf. Rev. Lett. 2018, 26, 1850185. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Sun, J.; Li, J.F. Effect of rare earth oxide on the properties of laser cladding layer and machining vibration suppressing in side milling. Appl. Surf. Sci. 2014, 321, 387–395. [Google Scholar] [CrossRef]

- Cang, X.Y.; Shu, L.S.; Hu, N.; Yu, H.L. Establishment and experimental verification of a three-dimensional finite element model for residual stress in surface processing of Inconel 718 alloy by laser cladding. Mater. Today Commun. 2023, 37, 107088. [Google Scholar] [CrossRef]

- Gong, H.H.; Ma, B.J.; Zhu, Y.P.; Yang, H. Enhancement of machinability and surface quality of Ti-6Al-4V by longitudinal ultrasonic vibration-assisted milling under dry conditions. Measurement 2022, 187, 110324. [Google Scholar] [CrossRef]

- Brehl, D.E.; Dow, T.A. Review of vibration-assisted machining. Precis. Eng. 2008, 32, 153–172. [Google Scholar] [CrossRef]

- Jiang, Z.G.; Zhou, F.; Zhang, H.; Wang, Y.; Sutherland, J.W. Optimization of machining parameters considering minimum cutting fluid consumption. J. Clean. Prod. 2015, 108, 183–191. [Google Scholar] [CrossRef]

- Adaan-Nyiak, M.A.; Alam, I.; Tiamiyu, A.A. Ball milling process variables optimization for high-entropy alloy development using design of experiment and genetic algorithm. Pow. Technol. 2023, 427, 118766. [Google Scholar] [CrossRef]

- Xu, Z.Y.; Yuan, J.F.; Wu, M.Y.; Arif, A.F.M.; Li, D.Y. Effect of laser cladding parameters on Inconel 718 coating performance and multi-parameter optimization. Opt. Laser. Technol. 2023, 158, 108850. [Google Scholar] [CrossRef]

- Wu, S.; Liu, Z.H.; Huang, X.F.; Wu, Y.F.; Gong, Y. Process parameter optimization and EBSD analysis of Ni60A-25% WC laser cladding. Int. J. Refract. Met. Hard Mater. 2021, 101, 105675. [Google Scholar] [CrossRef]

- Cao, H.J.; Liu, L.; Wu, B.; Gao, Y.; Qu, D. Process optimization of high-speed dry milling UD-CF/PEEK laminates using GA-BP neural network. Compos. Part B Eng. 2021, 221, 109034. [Google Scholar] [CrossRef]

- Huang, R.J.; Ma, Y.S.; Li, H.; Sun, C.Y.; Zhang, J.L.S.; Wang, H.Q.; Hao, B. Operation parameter multi-objective optimization method of large vertical mill based on CFD-DPM. Adv. Powder Technol. 2023, 34, 104014. [Google Scholar] [CrossRef]

- Peng, S.T.; Li, T.; Zhao, J.L.; Lv, S.P.; Tan, G.Z.; Dong, M.M.; Zhang, H.C. Towards energy and material efficient laser cladding process: Modeling and optimization using a hybrid TS-GEP algorithm and the NSGA-II. J. Clean. Prod. 2019, 227, 58–69. [Google Scholar] [CrossRef]

- Zhang, D.Y.; Liu, Z.S.; Song, K.W.; Zhai, Z.Y.; Zhang, Y.C.; Gao, Z.Q. Parameters optimization for laser-cladding CoCrFeNiMn high-entropy alloy layer based on GRNN and NSGA-II. Mater. Today Commun. 2024, 39, 108615. [Google Scholar] [CrossRef]

- Shu, L.S.; Heng, Z.; Li, P.Y.; Wu, H.; Li, J.; Feng, J. Effect of laser powers on the mechanical properties 27SiMn steel with Inconel 718 cladding coatings. Mater. Res. Express 2022, 9, 096511. [Google Scholar] [CrossRef]

- Chakradhar, B.; Singaravel, B.; Ugrasen, G.; Kumar, A.K. Prediction of cutting forces using MRA, GMDH and ANN techniques in micro end milling of titanium alloy. Mater. Today Proc. 2023, 72, 1943–1949. [Google Scholar] [CrossRef]

- Zheng, W.J.; Doerr, B. Mathematical runtime analysis for the non-dominated sorting genetic algorithm II (NSGA-II). Artif. Intell. 2023, 325, 104016. [Google Scholar] [CrossRef]

| Element | Cr | C | Si | Mn | Ni | W | Fe |

|---|---|---|---|---|---|---|---|

| 40Cr | 0.8 | 0.37 | 0.17 | 0.5 | - | - | - |

| Fe45 | 18.0 | 0.15 | 2.0 | 0.2 | 1.0 | 1.0 | Bal. |

| Level | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| N (r/min) | 2000 | 2600 | 3200 |

| V (mm/min) | 120 | 150 | 180 |

| P (mm) | 0.1 | 0.3 | 0.5 |

| Order | N (r/min) | V (mm/min) | P (mm) | Fx (N) | Fy (N) | Fz (N) | Fc (N) | Q (cm3/min) |

|---|---|---|---|---|---|---|---|---|

| 1 | 2000 | 120 | 0.1 | 1.385 | 2.2447 | 2.0664 | 3.3507 | 0.012 |

| 2 | 2000 | 150 | 0.3 | 2.7916 | 13.4316 | 2.286 | 13.9078 | 0.045 |

| 3 | 2000 | 180 | 0.5 | 4.8578 | 37.4857 | 1.1876 | 37.8178 | 0.06 |

| 4 | 2600 | 120 | 0.3 | 1.7881 | 13.6655 | 3.054 | 14.1163 | 0.036 |

| 5 | 2600 | 150 | 0.5 | 1.9372 | 47.4412 | 6.2078 | 47.8848 | 0.075 |

| 6 | 2600 | 180 | 0.1 | 1.5108 | 7.9717 | 7.6559 | 11.1554 | 0.018 |

| 7 | 3200 | 120 | 0.5 | 0.9848 | 44.6401 | 6.5052 | 45.1123 | 0.06 |

| 8 | 3200 | 150 | 0.1 | 1.0977 | 5.6013 | 6.193 | 8.4222 | 0.015 |

| 9 | 3200 | 180 | 0.3 | 1.0345 | 36.49 | 11.2882 | 38.2101 | 0.054 |

| Norm | Factor | K1 | K2 | K3 | R |

|---|---|---|---|---|---|

| Fc | N | 18.359 | 24.386 | 30.582 | 12.223 |

| V | 20.860 | 23.405 | 29.061 | 8.201 | |

| P | 7.643 | 22.078 | 43.605 | 35.962 | |

| Q | N | 0.049 | 0.043 | 0.043 | 0.006 |

| V | 0.036 | 0.045 | 0.054 | 0.018 | |

| P | 0.015 | 0.045 | 0.075 | 0.060 |

| Model | F | Fitting Degree | The Significance of Factors | ||||

|---|---|---|---|---|---|---|---|

| Fc | 0.860 | 58.521 | * | −4.649 | 4.940 | 13.557 | |

| Q | 0.979 | 7.312 | ** | 5.232 | 1.915 | 2.307 |

| Name of the Parameter | Setting Options |

|---|---|

| Types of populations | Double vector |

| Size of the group | 100 |

| Maximum number of iterations | 100 |

| Initial population | [2000, 120, 0.1] |

| Intersection function | Dual-node |

| Options for plotting | Pareto |

| Evaluation of the fitness function | Two-way traffic |

| Range of values | Min [2000, 120, 0.1] |

| Max [3200, 180, 0.5] |

| Number | N (r/min) | V (mm/min) | P mm | Fc (N) | Q (cm³/min) |

|---|---|---|---|---|---|

| 1 | 2000 | 120.0266 | 0.454815 | 17.43 | 0.0546 |

| 2 | 2000 | 120.0026 | 0.461203 | 17.71 | 0.0553 |

| 3 | 2000 | 120.1382 | 0.466846 | 17.97 | 0.0563 |

| 4 | 2000 | 120.0666 | 0.473983 | 18.25 | 0.0571 |

| 5 | 2000 | 120.2213 | 0.478866 | 18.56 | 0.0579 |

| 6 | 2000.001 | 120 | 0.486133 | 18.82 | 0.0585 |

| 7 | 2000 | 120.2292 | 0.491174 | 19.05 | 0.0591 |

| 8 | 2000 | 120 | 0.498324 | 19.38 | 0.0600 |

| 9 | 2000 | 120.9121 | 0.5 | 19.61 | 0.0606 |

| 10 | 2000 | 122.1445 | 0.5 | 19.95 | 0.0612 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Shu, L.; Li, A.; Hu, N.; Gong, J. Optimization of Milling Process Parameters for Fe45 Laser-Clad Molded Parts Based on the Nondominated Sorting Genetic Algorithm II. Coatings 2024, 14, 449. https://doi.org/10.3390/coatings14040449

Zhou J, Shu L, Li A, Hu N, Gong J. Optimization of Milling Process Parameters for Fe45 Laser-Clad Molded Parts Based on the Nondominated Sorting Genetic Algorithm II. Coatings. 2024; 14(4):449. https://doi.org/10.3390/coatings14040449

Chicago/Turabian StyleZhou, Jun, Linsen Shu, Anjun Li, Ning Hu, and Jiangtao Gong. 2024. "Optimization of Milling Process Parameters for Fe45 Laser-Clad Molded Parts Based on the Nondominated Sorting Genetic Algorithm II" Coatings 14, no. 4: 449. https://doi.org/10.3390/coatings14040449

APA StyleZhou, J., Shu, L., Li, A., Hu, N., & Gong, J. (2024). Optimization of Milling Process Parameters for Fe45 Laser-Clad Molded Parts Based on the Nondominated Sorting Genetic Algorithm II. Coatings, 14(4), 449. https://doi.org/10.3390/coatings14040449