Characterization of CdS/CdTe Ultrathin-Film Solar Cells with Different CdS Thin-Film Thicknesses Obtained by RF Sputtering

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

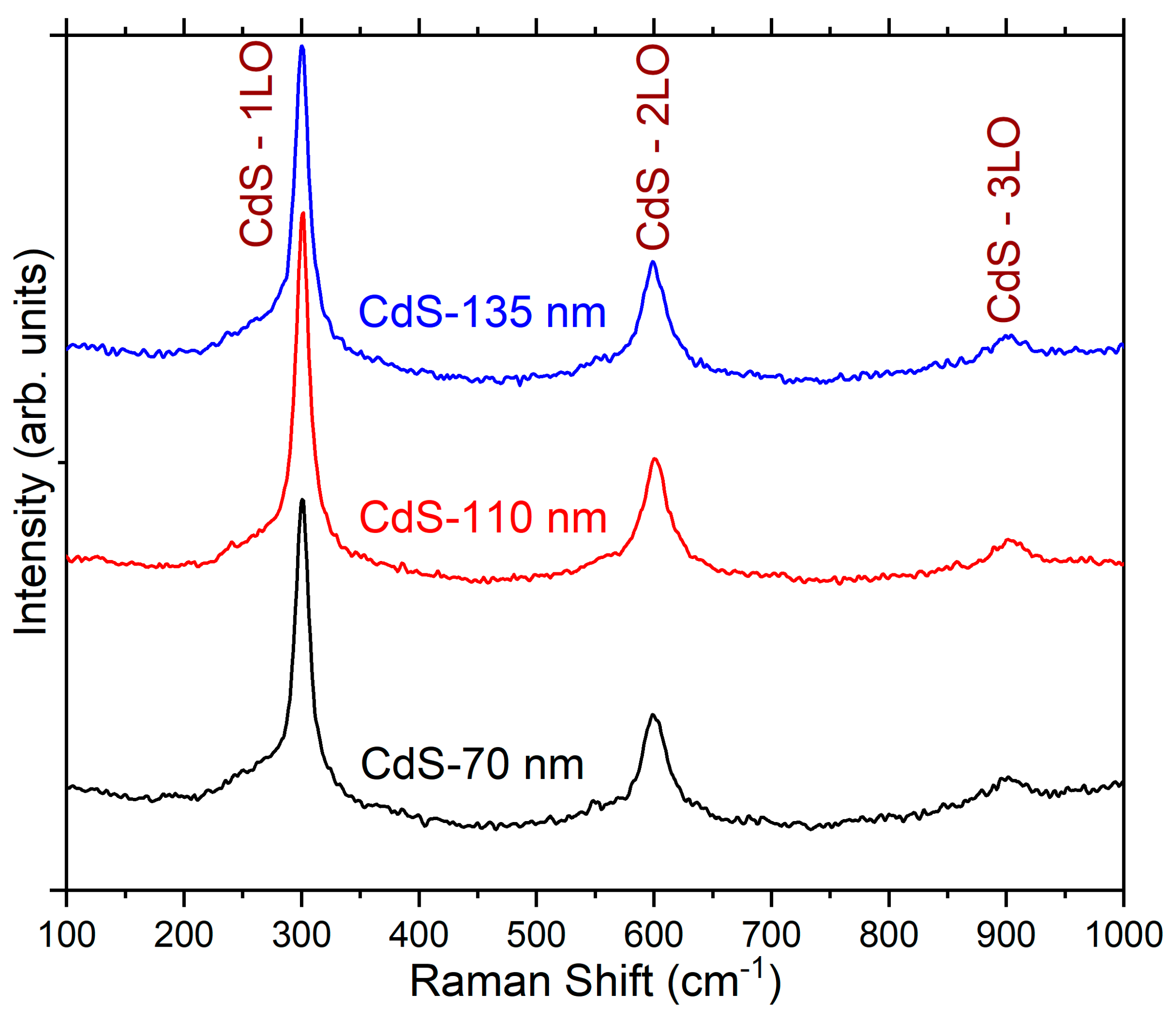

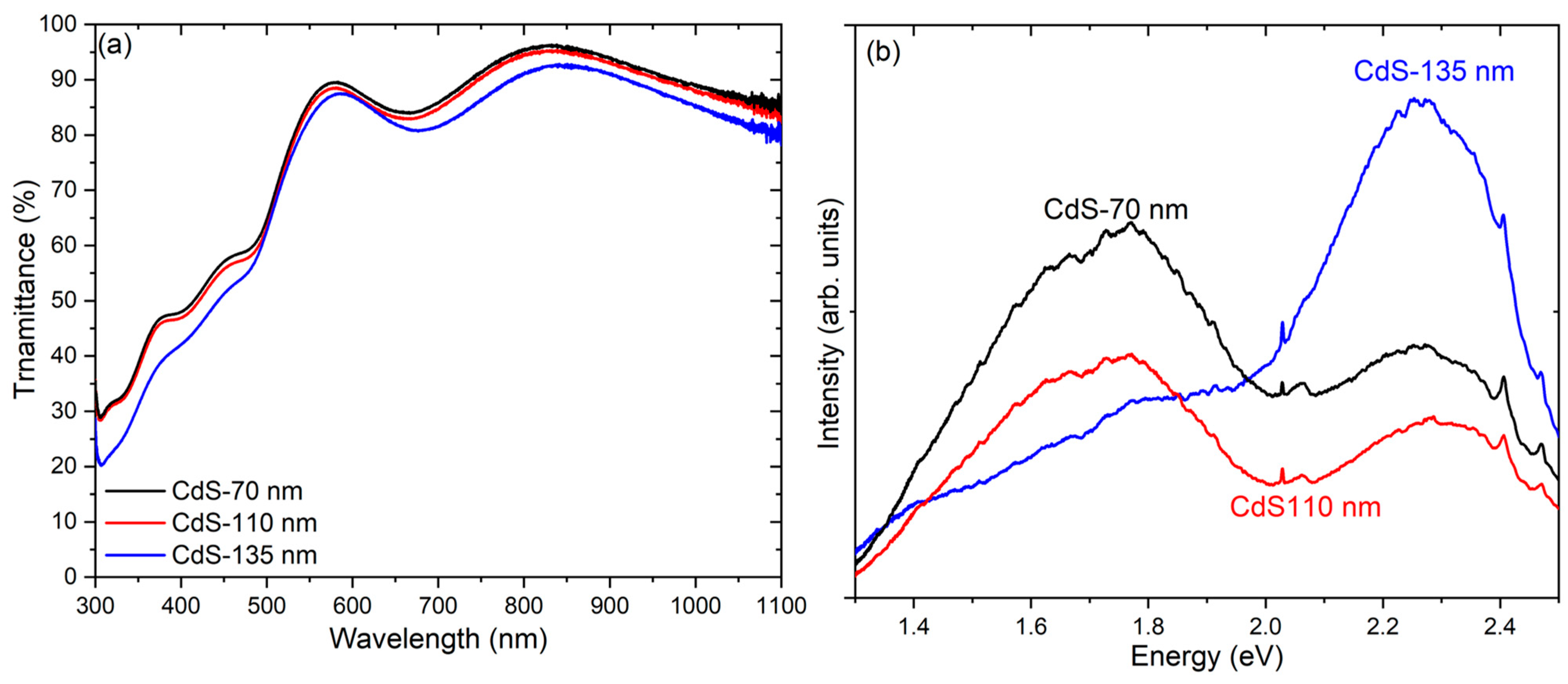

3.1. CdS Thin Films Deposited at Different Thicknesses

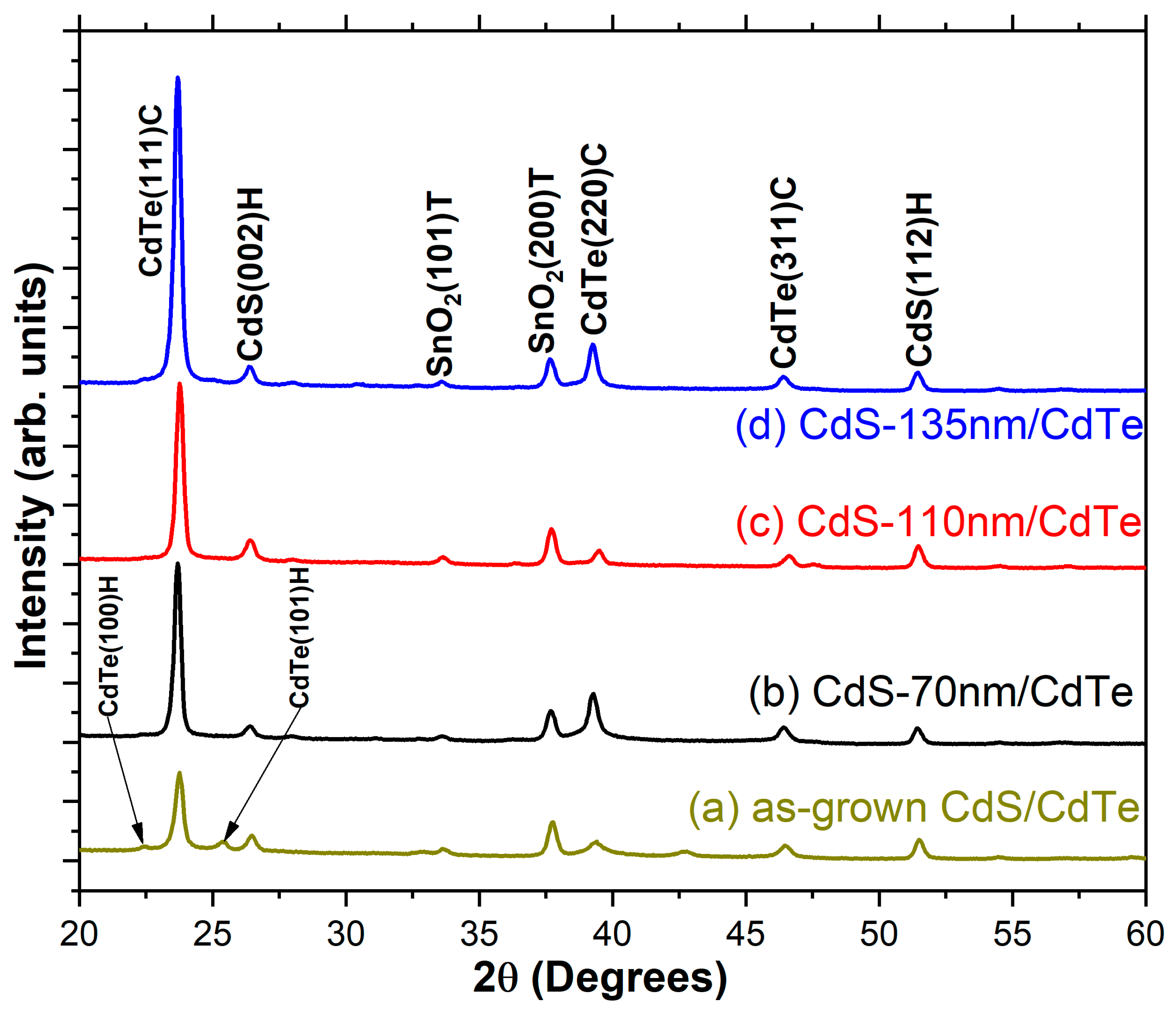

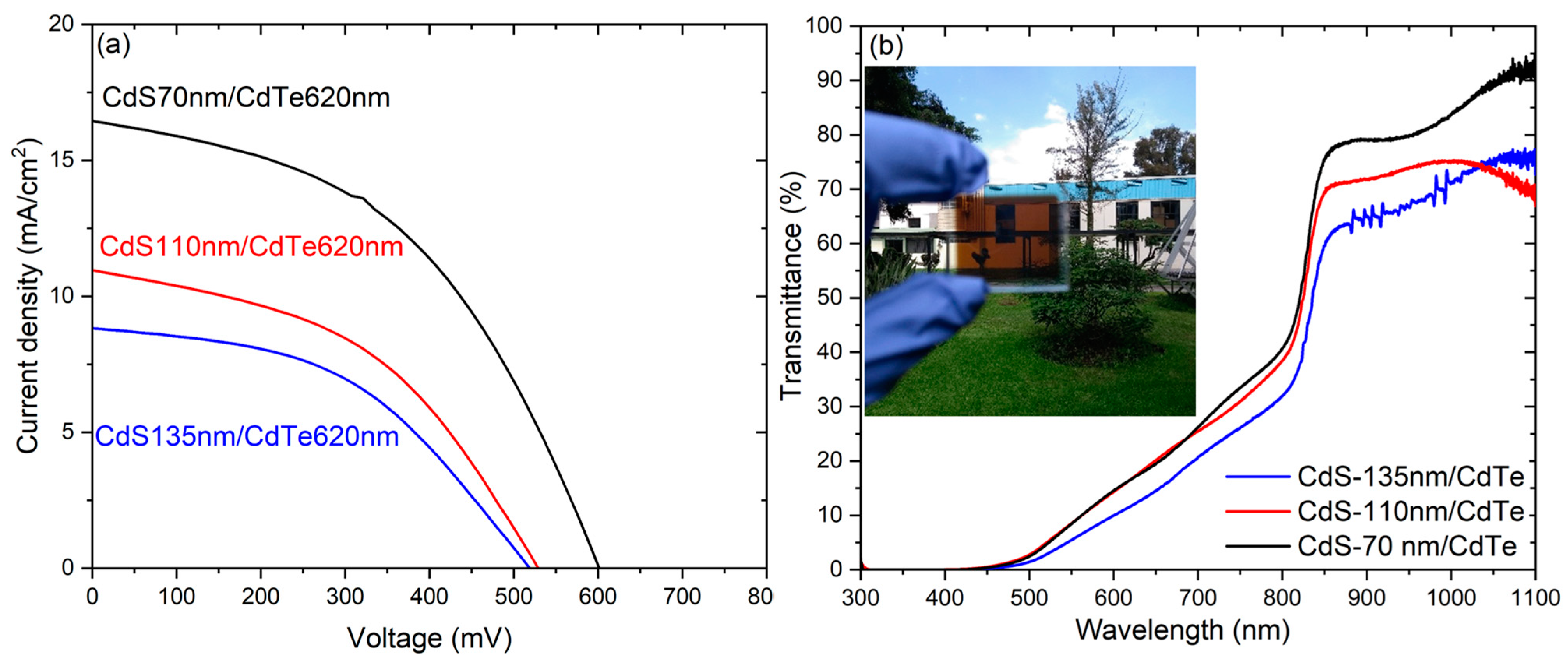

3.2. Characterization of SnO2:F/ZnO/CdS/CdTe Heterostructures with Different CdS Thicknesses

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mathur, A.S.; Singh, B.P. Study of effect of defects on CdS/CdTe heterojunction solar cell. Optik 2020, 212, 164717. [Google Scholar] [CrossRef]

- Green, M.A.; Dunlop, E.D.; Hohl-Ebinger, J.; Yoshita, M.; Kopidakis, N.; Ho-Baillie, A.W.Y. Solar Cell Efficiency Table Guide. Prog. Photovolt. Res. Appl. 2020, 28, 3–15. [Google Scholar] [CrossRef]

- Moon, M.M.A.; Rahman, M.F.; Kamruzzaman, M.; Hossain, J.; Ismail, A.B.M. Unveiling the prospect of a novel chemical route for synthesizing solution-processed CdS/CdTe thin-film solar cells. Energy Rep. 2021, 7, 1742–1756. [Google Scholar] [CrossRef]

- Li, H.; Liu, X. Improved performance of CdTe solar cells with CdS treatment. Sol. Energy 2015, 115, 603–612. [Google Scholar] [CrossRef]

- Nieto-Zepeda, K.E.; Guillén-Cervantes, A.; Rodríguez-Rosales, K.; Santos-Cruz, J.; Santos-Cruz, D.; de la Olvera, M.; Zelaya-Ángel, O.; Santoyo-Salazar, J.; Hernández-Hernández, L.A.; Contreras-Puente, G.; et al. Effect of the sulfur and fluorine concentration on physical properties of CdS films grown by chemical bath deposition. Results Phys. 2017, 7, 1971–1975. [Google Scholar] [CrossRef]

- Tinedert, I.E.; Pezzimenti, F.; Megherbi, M.L.; Saadoune, A. Design and simulation of a high efficiency CdS/CdTe solar cell. Optik 2020, 208, 164112. [Google Scholar] [CrossRef]

- Paudel, N.R.; Wieland, K.A.; Young, M.; Asher, S.; Compaan, A.D. Stability of sub-micron-thick CdTe solar cells. Prog. Photovolt. Res. Appl. 2014, 22, 107–114. [Google Scholar] [CrossRef]

- Plotnikov, V.; Liu, X.; Paudel, N.; Kwon, D.; Wieland, K.A.; Compaan, A.D. Thin-film CdTe cells: Reducing the CdTe. Thin Solid Film. 2011, 519, 7134–7137. [Google Scholar] [CrossRef]

- Li, J.; He, F.; Hao, X.; Lin, S.; Long, W.; Gan, T.; Wu, L.; Zhang, J.; Feng, L. Semitransparent CdTe solar cell with over 70% near-infrared transmittance. J. Mater. Sci. Mater. Electron. 2020, 31, 18198–18208. [Google Scholar] [CrossRef]

- Dang, H.; Ososanaya, E.; Zhang, N. Improving reliability of window-absorber solar cells through CdS nanowires. Opt. Mater. 2022, 132, 112721. [Google Scholar] [CrossRef]

- Kim, S.; Patel, M.; Youn, S.M.; Kim, Y.; Lee, K.; Kim, J. Color-tunable transparent photovoltaics for onsite power production under sunlight and indoor light. Mater. Today Energy 2023, 31, 101203. [Google Scholar] [CrossRef]

- Meng, W.; Jinqing, P.; Hongxing, Y.; Yimo, L. Performance evaluation of semi-transparent CdTe thin film PV window applying on commercial buildings in Hong Kong. Energy Procedia 2018, 152, 1091–1096. [Google Scholar] [CrossRef]

- He, F.; Li, J.; Lin, S.; Long, W.; Wu, L.; Hao, X.; Zhang, J.; Feng, L. Semitransparent CdTe solar cells with CdCl2 treated absorber towards the enhanced photovoltaic conversion efficiency. Sol. Energy 2021, 214, 196–204. [Google Scholar] [CrossRef]

- Gutierrez, Z.-B.K.; Zayas-Bazán, P.G.; De Melo, O.; De Moure-Flores, F.; Andraca-Adame, J.A.; Moreno-Ruiz, L.A.; Martínez-Gutiérrez, H.; Gallardo, S.; Sastré-Hernández, J.; Contreras-Puente, G. CdS/CdTe Heterostructures for Applications in Ultra-Thin Solar Cells. Materials 2018, 11, 1788. [Google Scholar] [CrossRef] [PubMed]

- Marasamy, L.; Aruna-Devi, R.; Robledo, O.I.D.; Carvayar, J.Á.C.; Barragán, N.E.V.; Santos-Cruz, J.; Mayén-Hernández, S.A.; Contreras-Puente, G.; de la Luz Olvera, M.; de Moure Flores, F. Probing the significance of RF magnetron sputtering conditions on the physical properties of CdS thin films for ultra-thin CdTe photovoltaic applications. Appl. Surf. Sci. 2022, 574, 151640. [Google Scholar] [CrossRef]

- Krishnakumar, V.; Han, J.; Klein, A.; Jaegermann, W. CdTe thin film solar cells with reduced CdS film thickness. Thin Solid Film. 2011, 519, 7138–7141. [Google Scholar] [CrossRef]

- García-Alvarado, G.I.; de Moure-Flores, F.; Mayén-Hernández, S.A.; Santos-Cruz, D.; Rivera-Muñoz, E.M.; Contreras-Puente, G.S.; Pal, M.; Santos-Cruz, J. CdTe/CdS solar cells with CdTe grown at low vacuum. Vacuum 2017, 142, 175–180. [Google Scholar] [CrossRef]

- Suchikova, Y.; Kovachov, S.; Bohdanov, I.; Popova, E.; Moskina, A.; Popov, A. Characterization of CdxTeyOz/CdS/ZnO Heterostructures Synthesized by the SILAR Method. Coatings 2023, 13, 639. [Google Scholar] [CrossRef]

- Doroody, C.; Rahman, K.S.; Rosly, H.N.; Harif, M.N.; Sopian, K.; Abdullah, S.F.; Amin, N. A comprehensive comparative study of CdTe thin films grown on ultra-thin glass substrates by close-spaced sublimation and RF magnetron sputtering. Mater. Lett. 2021, 293, 129655. [Google Scholar] [CrossRef]

- Parashar, D.; Krishna, V.S.G.; Moger, S.N.; Keshav, R.; Mahesha, M.G. Thickness Optimization of ZnO/CdS/CdTe Solar Cell by Numerical Simulation. Trans. Electr. Electron. Mater. 2020, 21, 587–593. [Google Scholar] [CrossRef]

- Montoya De Los Santos, I.; Pérez-Orozco, A.A.; Liña-Martínez, D.A.; Courel, M.; Meza-Avendaño, C.A.; Borrego-Pérez, J.A.; Pérez, L.M.; Laroze, D. Towards a CdTe Solar Cell Efficiency Promotion: The Role of ZnO:Al and CuSCN Nanolayers. Nanomaterials 2023, 13, 1335. [Google Scholar] [CrossRef] [PubMed]

- Nieto-Zepeda, K.E.; Quiñones-Galván, J.G.; Rodríguez Karen Guillén-Cervantes, A.; Santos Jose Zelaya-Angel, O.; de Moure-Flores, F. Optoelectronic properties of Cl and F doped CdS thin films grown by chemical bath deposition. Optik 2021, 226, 166004. [Google Scholar] [CrossRef]

- Islam, M.A.; Hatta, S.F.W.M.; Misran, H.; Akhtaruzzaman, M.; Amin, N. Influence of oxygen on structural and optoelectronic properties of CdS thin film deposited by magnetron sputtering technique. Chin. J. Phys. 2020, 67, 170–179. [Google Scholar] [CrossRef]

- Khan, A.D.; Rehman, Q.; Khan, A.D.; Subhan, F.E.; Noman, M.; Ahmed, S.; Khan, H.A. Broadband Solar Energy Absorption in Plasmonic Thin-Film Amorphous Silicon Solar Cell. Coatings 2019, 9, 638. [Google Scholar] [CrossRef]

- Liu, F.; Lai, Y.; Liu, J.; Wang, B.; Kuang, S.; Zhang, Z.; Li, J.; Liu, Y. Characterization of chemical bath deposited CdS thin films at different deposition temperature. J. Alloys Compd. 2010, 493, 305–308. [Google Scholar] [CrossRef]

- Doroody, C.; Rahman, K.S.; Rosly, H.N.; Harif, M.N.; Isah, M.; Kar, Y.B.; Tiong, S.K.; Amin, N. A comparative study of CdS thin films grown on ultra-thin glass substrates by RF magnetron sputtering and chemical bath deposition. Mater. Sci. Semicond. Process. 2021, 133, 105935. [Google Scholar] [CrossRef]

- Shaaban, E.R.; Osman, M.A.; Osman, A.A.; Sayed, M.M.; Aly, K.I. Influential role of CdS film thickness in improving CdS/CdTe junction performance for solar cells: Structural, optical, and electrical characterizations. J. Mater. Sci. Mater. Electron. 2022, 33, 4051–4063. [Google Scholar] [CrossRef]

- Mendoza-Pérez, R.; Aguilar-Hernández, J.; Sastre-Hernández, J.; Ximello-Quiebras, N.; Contreras-Puente, G.; Santana-Rodríguez, G.; Vigil-Galán, O.; Moreno-García, E.; Morales-Acevedo, A. Photoluminescence characteristics of CdS layers deposited in a chemical bath and their correlation to CdS/CdTe solar cell performance. Sol. Energy 2006, 80, 682–686. [Google Scholar] [CrossRef]

- Gemain, F.; Robin, I.C.; Renet, S.; Bernardi, S. Photoluminescence studies of CdS layers for solar cells. Phys. Status Solidi C Curr. Top. Solid State Phys. 2012, 9, 1740–1743. [Google Scholar] [CrossRef]

- Sivaraman, T.; Narasimman, V.; Nagarethinam, V.S.; Balu, A.R. Effect of chlorine doping on the structural, morphological, optical and electrical properties of spray deposited CdS thin films. Prog. Nat. Sci. Mater. Int. 2015, 25, 392–398. [Google Scholar] [CrossRef]

- Gutierrez, Z.-B.K.; Zayas-Bazán, P.G.; de Moure-Flores, F.; Jiménez-Olarte, D.; Sastré-Hernández, J.; Hernández-Gutiérrez, C.A.; Aguilar-Hernández, J.R.; Mejía-García, C.; Morales-Acevedo, A.; Contreras-Puente, G. Development of a CdCl2 thermal treatment process for improving CdS/CdTe ultrathin solar cells. J. Mater. Sci. Mater. Electron. 2019, 30, 16932–16938. [Google Scholar] [CrossRef]

- Paudel, N.R.; Wieland, K.A.; Compaan, A.D. Ultrathin CdS/CdTe solar cells by sputtering. Sol. Energy Mater. Sol. Cells 2012, 105, 109–112. [Google Scholar] [CrossRef]

- He, F.; Lin, S.; Wu, L.; Hao, X.; Zhao, D.; Zhang, J.; Feng, L. Plasma etching: A strategy to enhance the photovoltaic conversion efficiency of ultrathin CdTe solar cells. J. Phys. D Appl. Phys. 2021, 54, 374002. [Google Scholar] [CrossRef]

- Patel, M.; Song, J.; Kim, D.W.; Kim, J. Carrier transport and working mechanism of transparent photovoltaic cells. Appl. Mater. Today 2022, 26, 101344. [Google Scholar] [CrossRef]

- Patel, M.; Kim, S.; Nguyen, T.T.; Kim, J.; Wong, C.P. Transparent sustainable energy platform: Closed-loop energy chain of solar-electric-hydrogen by transparent photovoltaics, photo-electro-chemical cells and fuel system. Nano Energy 2021, 90, 106496. [Google Scholar] [CrossRef]

| Sample | Thickness [nm] | Atomic Composition | Cd:S | |

|---|---|---|---|---|

| Cd (%) | S (%) | |||

| CdS-70 | 70 ± 5 | 57.43 | 42.57 | 1.35 |

| CdS-110 | 110 ± 4 | 53.66 | 46.34 | 1.16 |

| CdS-135 | 135 ± 4 | 53.19 | 46.81 | 1.14 |

| Sample | Thickness CdS/CdTe (nm) | Voc (V) | Jsc (mA/cm2) | FF | PCE (%) |

|---|---|---|---|---|---|

| CdS-70 | 70/620 | 0.60 | 16.39 | 0.46 | 4.56 ± 0.11 |

| CdS-110 | 110/620 | 0.53 | 10.96 | 0.33 | 2.60 ± 0.10 |

| CdS-135 | 135/620 | 0.52 | 8.82 | 0.34 | 2.11 ± 0.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Melchor-Robles, J.A.; Nieto-Zepeda, K.E.; Vázquez-Barragán, N.E.; Arreguín-Campos, M.; Rodríguez-Rosales, K.; Cruz-Gómez, J.; Guillén-Cervantes, A.; Santos-Cruz, J.; Olvera, M.d.l.L.; Contreras-Puente, G.; et al. Characterization of CdS/CdTe Ultrathin-Film Solar Cells with Different CdS Thin-Film Thicknesses Obtained by RF Sputtering. Coatings 2024, 14, 452. https://doi.org/10.3390/coatings14040452

Melchor-Robles JA, Nieto-Zepeda KE, Vázquez-Barragán NE, Arreguín-Campos M, Rodríguez-Rosales K, Cruz-Gómez J, Guillén-Cervantes A, Santos-Cruz J, Olvera MdlL, Contreras-Puente G, et al. Characterization of CdS/CdTe Ultrathin-Film Solar Cells with Different CdS Thin-Film Thicknesses Obtained by RF Sputtering. Coatings. 2024; 14(4):452. https://doi.org/10.3390/coatings14040452

Chicago/Turabian StyleMelchor-Robles, J. A., K. E. Nieto-Zepeda, N. E. Vázquez-Barragán, M. Arreguín-Campos, K. Rodríguez-Rosales, J. Cruz-Gómez, A. Guillén-Cervantes, J. Santos-Cruz, M. de la L. Olvera, G. Contreras-Puente, and et al. 2024. "Characterization of CdS/CdTe Ultrathin-Film Solar Cells with Different CdS Thin-Film Thicknesses Obtained by RF Sputtering" Coatings 14, no. 4: 452. https://doi.org/10.3390/coatings14040452